Optimization of Mesa Etch for a Quasi-Vertical GaN Schottky Barrier Diode (SBD) by Inductively Coupled Plasma (ICP) and Device Characteristics

Abstract

1. Introduction

2. Materials and Methods

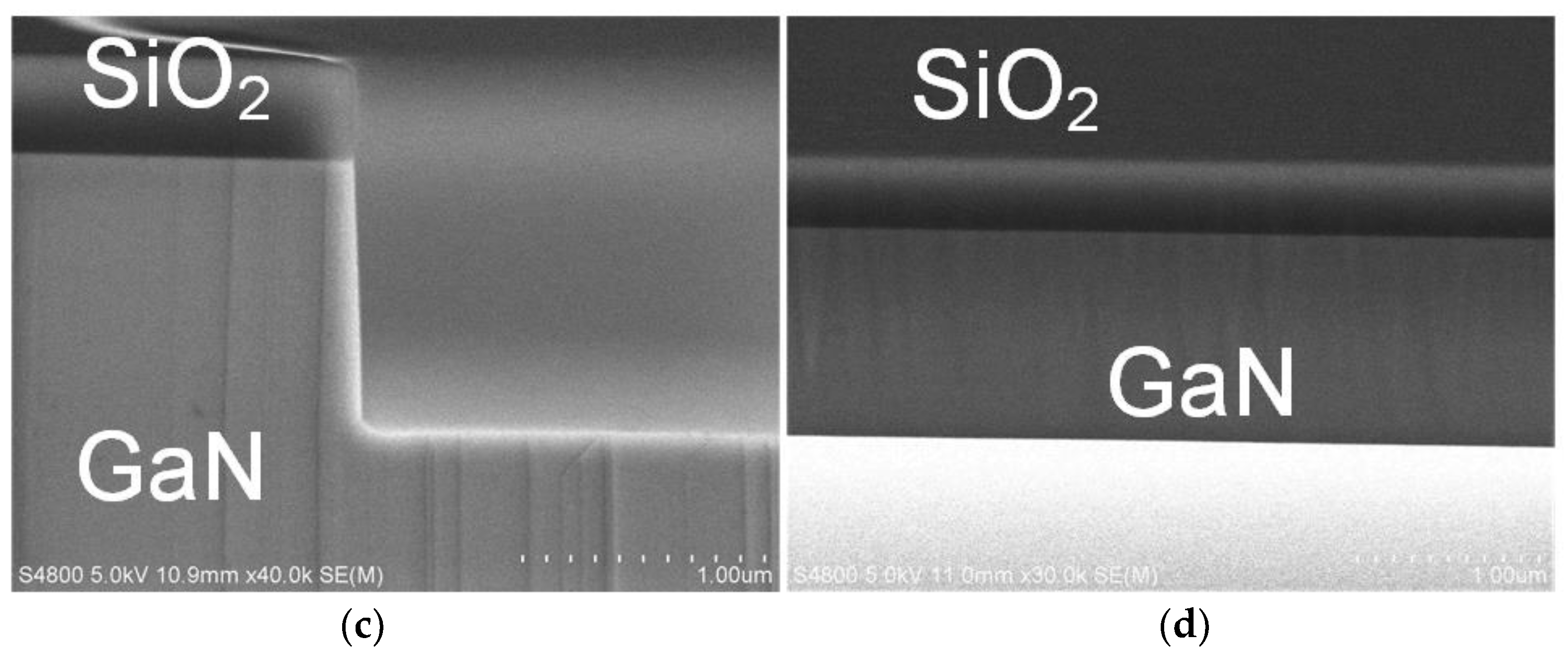

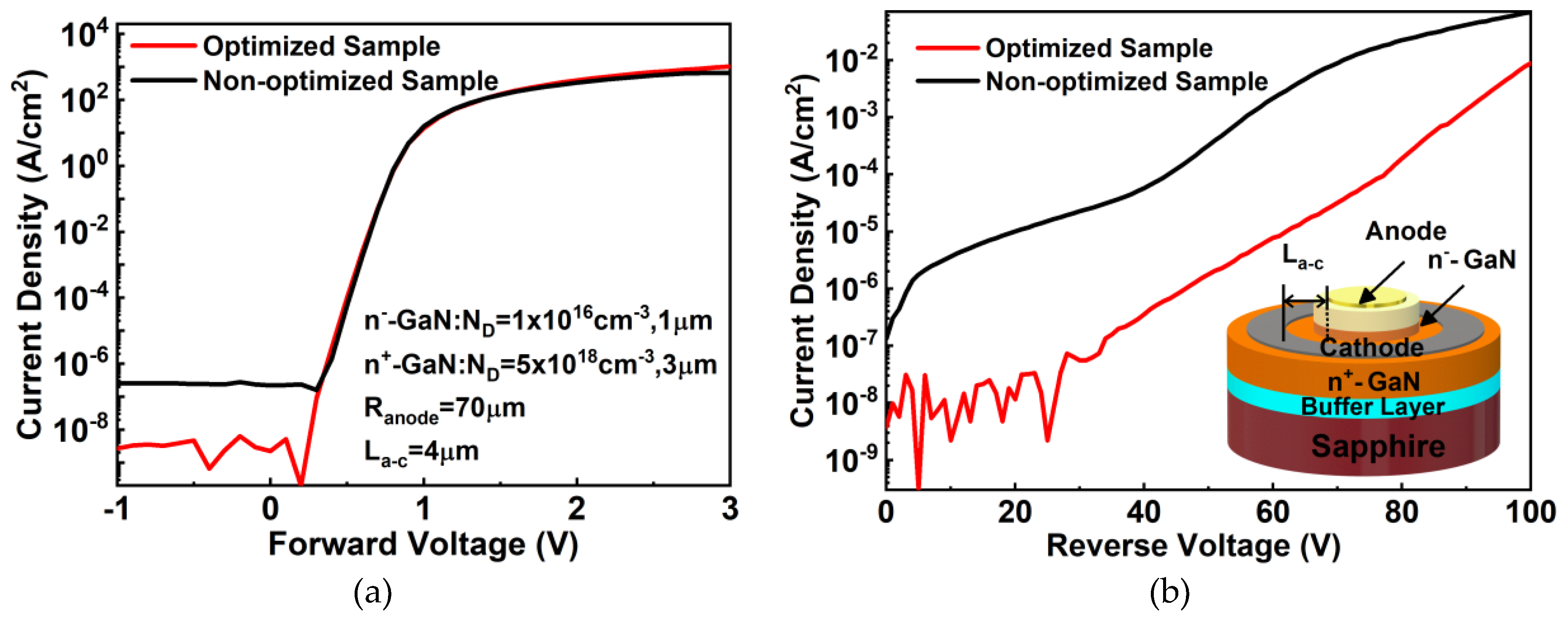

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baliga, B.J. Gallium nitride devices for power electronic applications. Semicond. Sci. Technol. 2013, 28, 074011. [Google Scholar] [CrossRef]

- Yuhao, Z.; Min, S.; Piedra, D.; Hennig, J.; Dadgar, A.; Palacios, T. Reduction of on-resistance and current crowding in quasi-vertical GaN power diodes. Appl. Phys. Lett. 2017, 111, 163506. [Google Scholar]

- Oka, T. Recent development of vertical GaN power devices. Jpn. J. Appl. Phys. 2019, 58, SB0805. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, X.; Zheng, Y.; Lu, J.; Tian, X.; Wei, K.; Wu, H.; Wang, W.; Liu, X.; Zhang, G. Review of the Recent Progress on GaN-Based Vertical Power Schottky Barrier Diodes (SBDs). Electronics 2019, 8, 575. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, M.; Wong, H.; Lin, Y.; Srivastava, P.; Hatem, C.; Azize, M.; Piedra, D.; Yu, L.; Sumitomo, T.; et al. Origin and Control of OFF-State Leakage Current in GaN-on-Si Vertical Diodes. IEEE Trans. Electron Devices 2015, 62, 2155–2161. [Google Scholar] [CrossRef]

- Han, C.; Zhang, Y.; Song, Q.; Zhang, Y.; Tang, X.; Yang, F.; Niu, Y. An Improved ICP Etching for Mesa-Terminated 4H-SiC p-i-n Diodes. IEEE Trans. Electron Devices 2015, 62, 1223–1229. [Google Scholar] [CrossRef]

- Rawal, D.S.; Arora, H.; Agarwal, V.R.; Vinayak, S.; Kapoor, A.; Sehgal, B.K.; Muralidharan, R.; Saha, D.; Malik, H.K. GaN etch rate and surface roughness evolution in Cl2/Ar based inductively coupled plasma etching. Thin Solid Film. 2012, 520, 7212–7218. [Google Scholar] [CrossRef]

- Yang, G.F.; Chen, P.; Wu, Z.L.; Yu, Z.G.; Zhao, H.; Liu, B.; Hua, X.M.; Xie, Z.L.; Xiu, X.Q.; Han, P.; et al. Characteristics of GaN thin films by inductively coupled plasma etching with Cl2/BCl3 and Cl2/Ar. J. Mater. Sci. Mater. Electron. 2012, 23, 1224–1228. [Google Scholar] [CrossRef]

- Rawal, D.S.; Sehgal, B.K.; Muralidharan, R.; Malik, H.K.; Dasgupta, A. Effect of BCl3 concentration and process pressure on the GaN mesa sidewalls in BCl3/Cl2 based inductively coupled plasma etching. Vacuum 2012, 86, 1844–1849. [Google Scholar] [CrossRef]

- Sheu, J.K.; Su, Y.K.; Chi, G.C.; Jou, M.J.; Liu, C.C.; Chang, C.M.; Hung, W.C. Inductively coupled plasma etching of GaN using Cl2/Ar and Cl2/N2 gases. J. Appl. Phys. 1999, 85, 1970–1974. [Google Scholar] [CrossRef]

- Li, X.L.; Ma, P.; Ji, X.L.; Wei, T.B.; Tan, X.Y.; Wang, J.X.; Li, J.M. Implementation of slow and smooth etching of GaN by inductively coupled plasma. J. Semicond. 2018, 39, 6. [Google Scholar] [CrossRef]

- Chang, L.B.; Liu, S.S.; Jeng, M.J. Etching selectivity and surface profile of GaN in the Ni, SiO2 and photoresist masks using an inductively coupled plasma. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2001, 40, 1242–1243. [Google Scholar] [CrossRef]

- Hahn, H.; Gruis, J.B.; Ketteniss, N.; Urbain, F.; Kalisch, H.; Vescan, A. Influence of mask material and process parameters on etch angle in a chlorine-based GaN dry etch. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 051302. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Hu, W.; Wei, Z.; Li, J.D.; Yang, S.; Huang, Z.L.; Jian, Z.; An, D.S. Controllable process of nanostructured GaN by maskless inductively coupled plasma (ICP) etching. J. Micromech. Microeng. 2017, 27, 7. [Google Scholar] [CrossRef]

- Efremov, A.; Min, N.-K.; Choi, B.-G.; Baek, K.-H.; Kwon, K.-H. Model-Based Analysis of Plasma Parameters and Active Species Kinetics in Cl2/X (X = Ar, He, N2) Inductively Coupled Plasmas. J. Electrochem. Soc. 2008, 155, D777–D782. [Google Scholar] [CrossRef]

- Rawal, D.S.; Arora, H.; Sehgal, B.K.; Muralidharan, R. Comparative study of GaN mesa etch characteristics in Cl2 based inductively coupled plasma with Ar and BCl3 as additive gases. J. Vac. Sci. Technol. A 2014, 32, 10. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.J.; Xia, X.X.; Yang, H.F.; Li, J.J.; Gu, C.Z. Fabrication of GaN hexagonal cones by inductively coupled plasma reactive ion etching. J. Vac. Sci. Technol. B 2016, 34, 4. [Google Scholar] [CrossRef]

- Pearton, S.J.; Zolper, J.C.; Shul, R.J.; Ren, F. GaN: Processing, defects, and devices. J. Appl. Phys. 1999, 86, 1–78. [Google Scholar] [CrossRef]

- Reflow of Photoresist. Available online: https://www.microchemicals.com/technical_information/reflow_photoresist.pdf (accessed on 24 February 2020).

- Liu, H.; Herrnsdorf, J.; Gu, E.; Dawson, M.D. Control of edge bulge evolution during photoresist reflow and its application to diamond microlens fabrication. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2016, 34, 021602. [Google Scholar] [CrossRef]

- O’neill, F.T.; Sheridan, J.T. Photoresist reflow method of microlens production Part I: Background and experiments. Optik 2002, 113, 391–404. [Google Scholar] [CrossRef]

- Cui, Z. Basics of Photoresists. In Nanofabrication, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2017; Volume 17. [Google Scholar]

- Rubico Jay, T.; Stern, M. Preshaping photoresist for refractive microlens fabrication. Opt. Eng. 1994, 33, 3552–3556. [Google Scholar]

- Mahorowala, A.P. Feature Profile Evolution during the High-Density Plasma Etching of Polysilicon. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 20 August 1998. [Google Scholar]

- Watanabe, M.; Shaw, D.M.; Collins, G.J. Reduction of microtrenching and island formation in oxide plasma etching by employing electron beam charge neutralization. Appl. Phys. Lett. 2001, 79, 2698–2700. [Google Scholar] [CrossRef]

- Smith, S.A.; Wolden, C.A.; Bremser, M.D.; Hanser, A.D.; Davis, R.F.; Lampert, W.V. High rate and selective etching of GaN, AlGaN, and AlN using an inductively coupled plasma. Appl. Phys. Lett. 1997, 71, 3631–3633. [Google Scholar] [CrossRef]

- Zhou, S.; Cao, B.; Liu, S. Optimized ICP etching process for fabrication of oblique GaN sidewall and its application in LED. Appl. Phys. A Mater. Sci. Process. 2011, 105, 369–377. [Google Scholar] [CrossRef]

- Turner, M.M.; Lieberman, M.A. Hysteresis and the E-to-H transition in radiofrequency inductive discharges. Plasma Sources Sci. Technol. 1999, 8, 313–324. [Google Scholar] [CrossRef]

- Kempkes, P.; Singh, S.V.; Pargmann, C.; Soltwisch, H. Temporal behaviour of the e to H mode transition in an inductively coupled argon discharge. Plasma Sources Sci. Technol. 2006, 15, 378–383. [Google Scholar] [CrossRef]

- Cooke, M.J.; Hassall, G. Low-pressure plasma sources for etching and deposition. Plasma Sources Sci. Technol. 2002, 11, A74–A79. [Google Scholar] [CrossRef]

- Qiu, R.F.; Lu, H.; Chen, D.J.; Zhang, R.; Zheng, Y.D. Optimization of inductively coupled plasma deep etching of GaN and etching damage analysis. Appl. Surf. Sci. 2011, 257, 2700–2706. [Google Scholar] [CrossRef]

- Kim, B.; Bae, J.; Teak Lee, B. Microtrench depth and width of SiON plasma etching. Vacuum 2006, 81, 338–343. [Google Scholar] [CrossRef]

- Kim, H.S.; Yeom, G.Y.; Lee, J.W.; Kim, T.I. Characteristics of inductively coupled Cl2/BCl3 plasmas during GaN etching. J. Vac. Sci. Technol. A 1999, 17, 2214–2219. [Google Scholar] [CrossRef]

- Wang, T.B.; Hsu, W.C.; Che, Y.W.; Chen, Y.J. Inductively coupled plasma mesa etched InGaN/GaN light emitting diodes using Cl2/BCl3/Ar plasma. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Brief Commun. Rev. Pap. 2006, 45, 6800–6802. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kim, H.S.; Yeom, G.Y.; Lee, J.W.; Yoo, M.C.; Kim, T.I. Etch characteristics of GaN using inductively coupled Cl2/Ar and Cl2/BCl3 plasmas. J. Vac. Sci. Technol. Vac. Surf. Film. 1998, 16, 1478–1482. [Google Scholar] [CrossRef]

- Zhou, S.J.; Cao, B.; Liu, S. Dry etching characteristics of GaN using Cl-2/BCl3 inductively coupled plasmas. Appl. Surf. Sci. 2010, 257, 905–910. [Google Scholar] [CrossRef]

- Lee, Y.H.; Sung, Y.J.; Yeom, G.Y.; Lee, J.W.; Kim, T.I. Magnetized inductively coupled plasma etching of GaN in Cl2/BCl3 plasmas. J. Vac. Sci. Technol. A Vac. Surf. Film. 2000, 18, 1390–1394. [Google Scholar] [CrossRef]

- Kim, B.; Kim, J.; Lee, S.; Park, J.; Lee, B. Plasma etching of silicon oxynitride in a low-pressure C 2 F 6 plasma. J. Korean Phys. Soc. 2005, 47, 712–715. [Google Scholar]

- Abdollahi-Alibeik, S.; Mcvittie, J.P.; Saraswat, K.C.; Sukharev, V.; Schoenborn, P. Analytical modeling of silicon etch process in high density plasma. J. Vac. Sci. Technol. A Vac. Surf. Film. 1999, 17, 2485–2491. [Google Scholar] [CrossRef]

- Sarangan, A. Wet Chemical and Plasma Etching. In Nanofabrication: Principles to Laboratory Practice, 1st ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2016; pp. 235–237. [Google Scholar]

- Ladroue, J.; Meritan, A.; Boufnichel, M.; Lefaucheux, P.; Ranson, P.; Dussart, R. Deep GaN etching by inductively coupled plasma and induced surface defects. J. Vac. Sci. Technol. A 2010, 28, 1226–1233. [Google Scholar] [CrossRef]

- Wang, P.; Cao, B.; Gan, Z.Y.; Liu, S. A Study of GaN-Based LED Structure Etching Using Inductively Coupled Plasma. In 3rd International Photonics and Optoelectronics Meetings; Ye, C., Wang, Z.L., Zhou, B., Eds.; IOP Publishing Ltd.: Bristol, UK, 2011. [Google Scholar]

- Awan, K.M.; Muhammad, M.M.; Sivan, M.; Bonca, S.; Roqan, I.S.; Dolgaleva, K. Fabrication and optical characterization of GaN waveguides on (−201)-oriented β-Ga2O3. Opt. Mater. Express 2017, 8, 88–96. [Google Scholar] [CrossRef]

- He, J.; Feng, M.; Zhong, Y.; Wang, J.; Zhou, R.; Gao, H.; Zhou, Y.; Sun, Q.; Liu, J.; Huang, Y.; et al. On-wafer fabrication of cavity mirrors for InGaN-based laser diode grown on Si. Sci. Rep. 2018, 8, 7922. [Google Scholar] [CrossRef]

- Wan, H.; Tang, B.; Li, N.; Zhou, S.; Gui, C.; Liu, S. Revealing the Role of Sidewall Orientation in Wet Chemical Etching of GaN-Based Ultraviolet Light-Emitting Diodes. Nanomaterials 2019, 9, 365. [Google Scholar] [CrossRef]

- Chen, J.; Bian, Z.; Liu, Z.; Ning, J.; Duan, X.; Zhao, S.; Wang, H.; Tang, Q.; Wu, Y.; Song, Y.; et al. High-performance quasi-vertical GaN Schottky barrier diode with anode selective fluorine treatment. Semicond. Sci. Technol. 2019, 34, 115019. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; Yin, R.; Zhang, J.; Tao, M.; Xie, B.; Hao, Y.; Yang, X.; Wen, C.P.; Shen, B. Quasi-Vertical GaN Schottky Barrier Diode on Silicon Substrate with 1010 High On/Off Current Ratio and Low Specific On-Resistance. IEEE Electron Device Lett. 2020, 41, 329–332. [Google Scholar] [CrossRef]

- Hashimoto, S.; Yoshizumi, Y.; Tanabe, T.; Kiyama, M. High-purity GaN epitaxial layers for power devices on low-dislocation-density GaN substrates. J. Cryst. Growth 2007, 298, 871–874. [Google Scholar] [CrossRef]

- Cao, Y.; Chu, R.; Li, R.; Chen, M.; Williams, A.J. Improved performance in vertical GaN Schottky diode assisted by AlGaN tunneling barrier. Appl. Phys. Lett. 2016, 108, 112101. [Google Scholar] [CrossRef]

- Kang, X.; Wang, X.; Huang, S.; Zhang, J.; Liu, X. Recess-free AlGaN/GaN lateral Schottky barrier controlled Schottky rectifier with low turn-on voltage and high reverse blocking. In Proceedings of the 2018 IEEE 30th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Chicago, IL, USA, 13–17 May 2018. [Google Scholar]

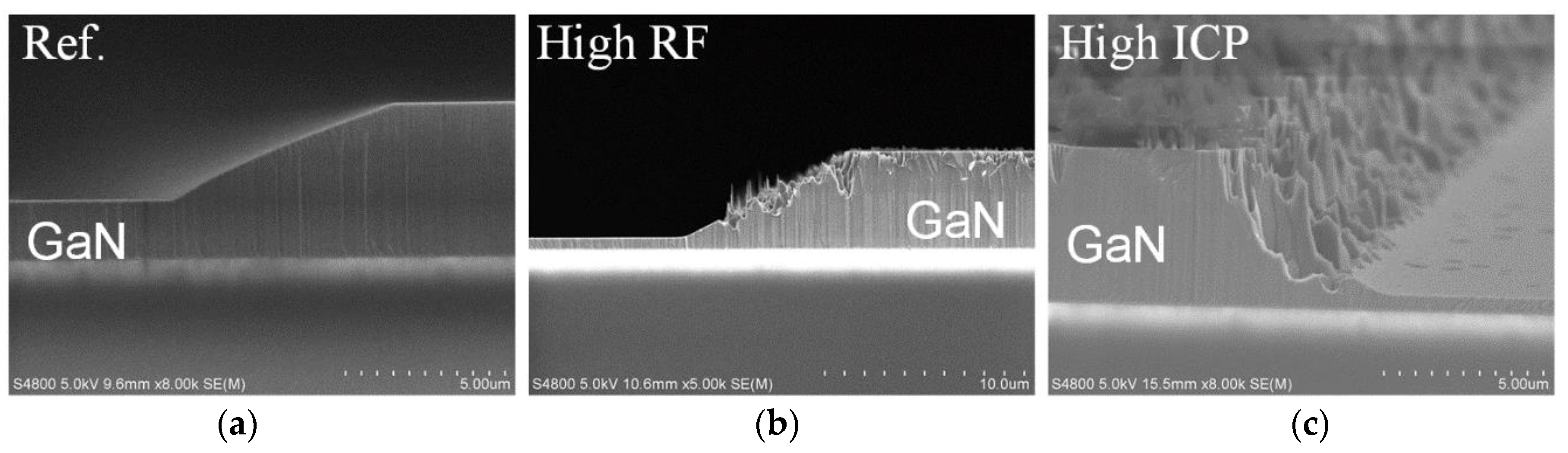

| Sample | ICP Power (W) | RF Power (W) | Pressure (Pa) | Cl2 (sccm) | GaN Etching Rate (nm/min) | θGaN |

|---|---|---|---|---|---|---|

| Reference | 360 | 63 | 1.5 | 130 | 120 | 25.0° |

| High RF | 360 | 210 | 1.5 | 130 | 537 | - |

| High ICP | 540 | 63 | 1.5 | 130 | 550 | - |

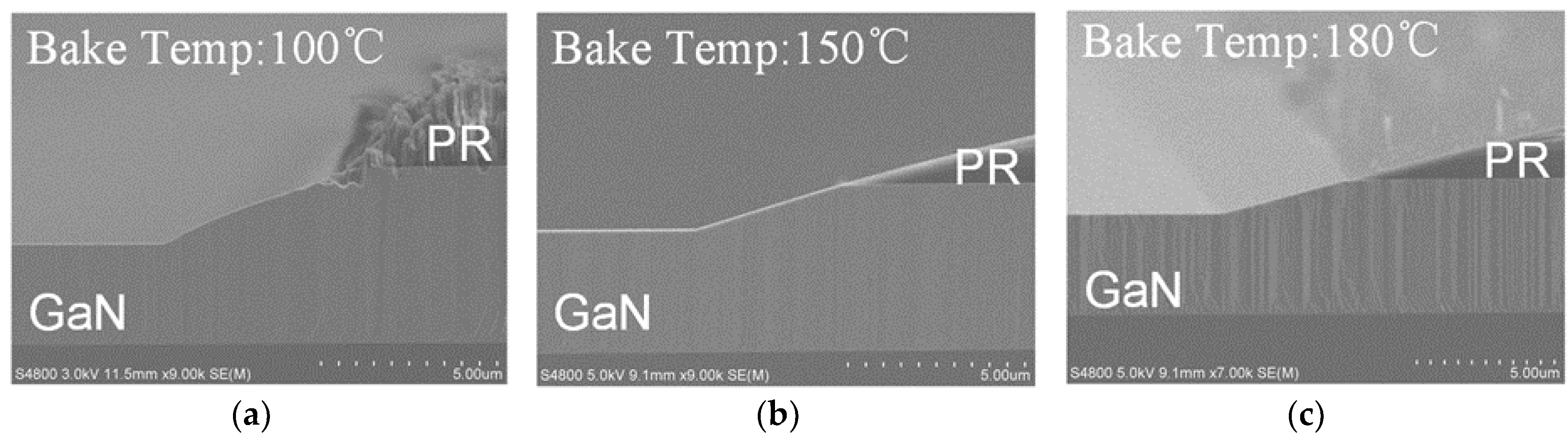

| Sample | ICP Power (W) | RF Power (W) | Pressure (Pa) | Cl2 (sccm) | GaN Etching Rate (nm/min) | θGaN | T (℃) |

|---|---|---|---|---|---|---|---|

| 1 | 360 | 63 | 1.5 | 130 | 135 | 23.0° | 100 |

| 2 | 360 | 63 | 1.5 | 130 | 123 | 17.0° | 150 |

| 3 | 360 | 63 | 1.5 | 130 | 117 | 15.0° | 180 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Kang, X.; Zheng, Y.; Wei, K.; Li, P.; Wang, W.; Liu, X.; Zhang, G. Optimization of Mesa Etch for a Quasi-Vertical GaN Schottky Barrier Diode (SBD) by Inductively Coupled Plasma (ICP) and Device Characteristics. Nanomaterials 2020, 10, 657. https://doi.org/10.3390/nano10040657

Sun Y, Kang X, Zheng Y, Wei K, Li P, Wang W, Liu X, Zhang G. Optimization of Mesa Etch for a Quasi-Vertical GaN Schottky Barrier Diode (SBD) by Inductively Coupled Plasma (ICP) and Device Characteristics. Nanomaterials. 2020; 10(4):657. https://doi.org/10.3390/nano10040657

Chicago/Turabian StyleSun, Yue, Xuanwu Kang, Yingkui Zheng, Ke Wei, Pengfei Li, Wenbo Wang, Xinyu Liu, and Guoqi Zhang. 2020. "Optimization of Mesa Etch for a Quasi-Vertical GaN Schottky Barrier Diode (SBD) by Inductively Coupled Plasma (ICP) and Device Characteristics" Nanomaterials 10, no. 4: 657. https://doi.org/10.3390/nano10040657

APA StyleSun, Y., Kang, X., Zheng, Y., Wei, K., Li, P., Wang, W., Liu, X., & Zhang, G. (2020). Optimization of Mesa Etch for a Quasi-Vertical GaN Schottky Barrier Diode (SBD) by Inductively Coupled Plasma (ICP) and Device Characteristics. Nanomaterials, 10(4), 657. https://doi.org/10.3390/nano10040657