Multi-Functional Properties of MWCNT/PVA Buckypapers Fabricated by Vacuum Filtration Combined with Hot Press: Thermal, Electrical and Electromagnetic Shielding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

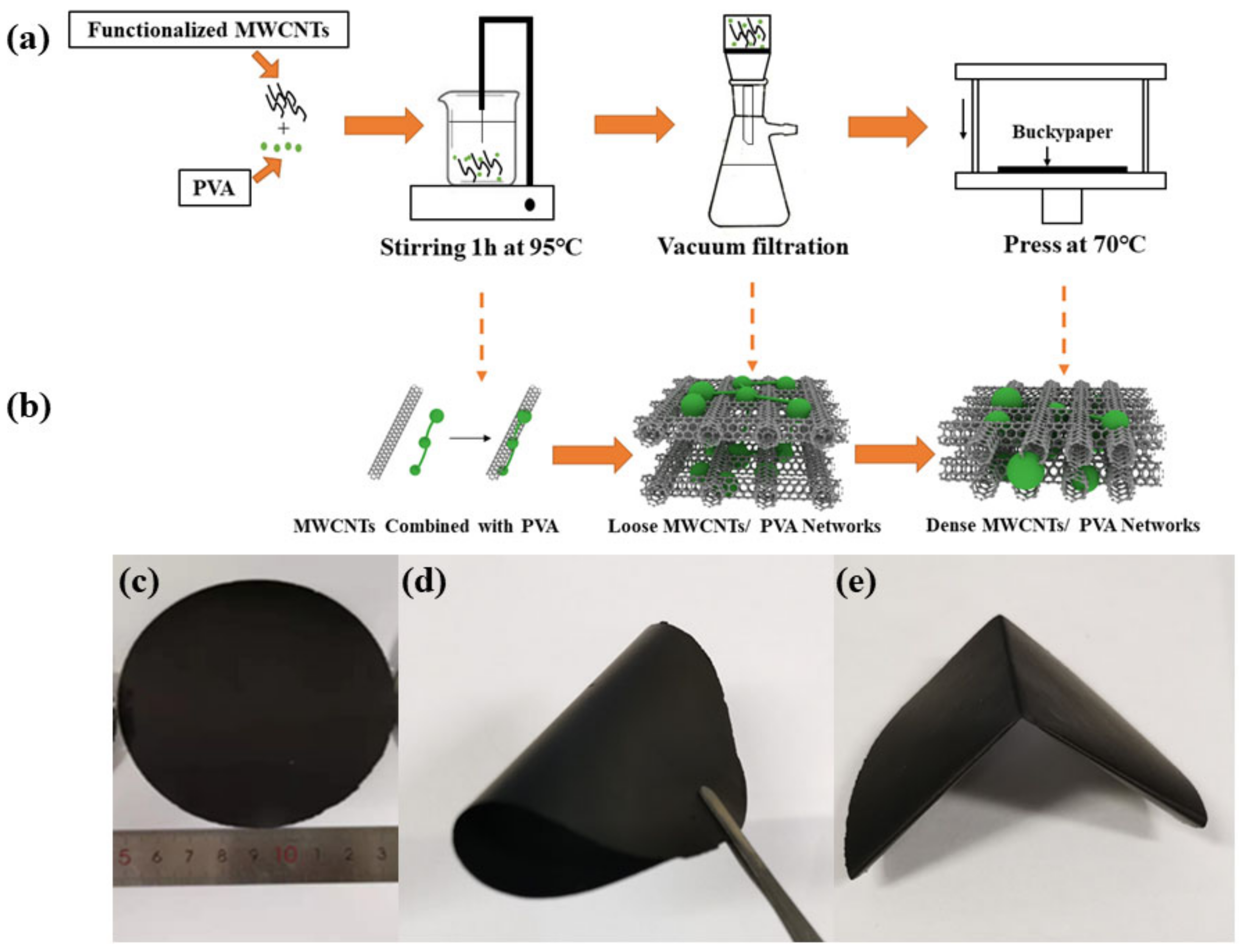

2.2. Preparation of MWCNT/PVA Buckypaper

2.3. Characterization

3. Results

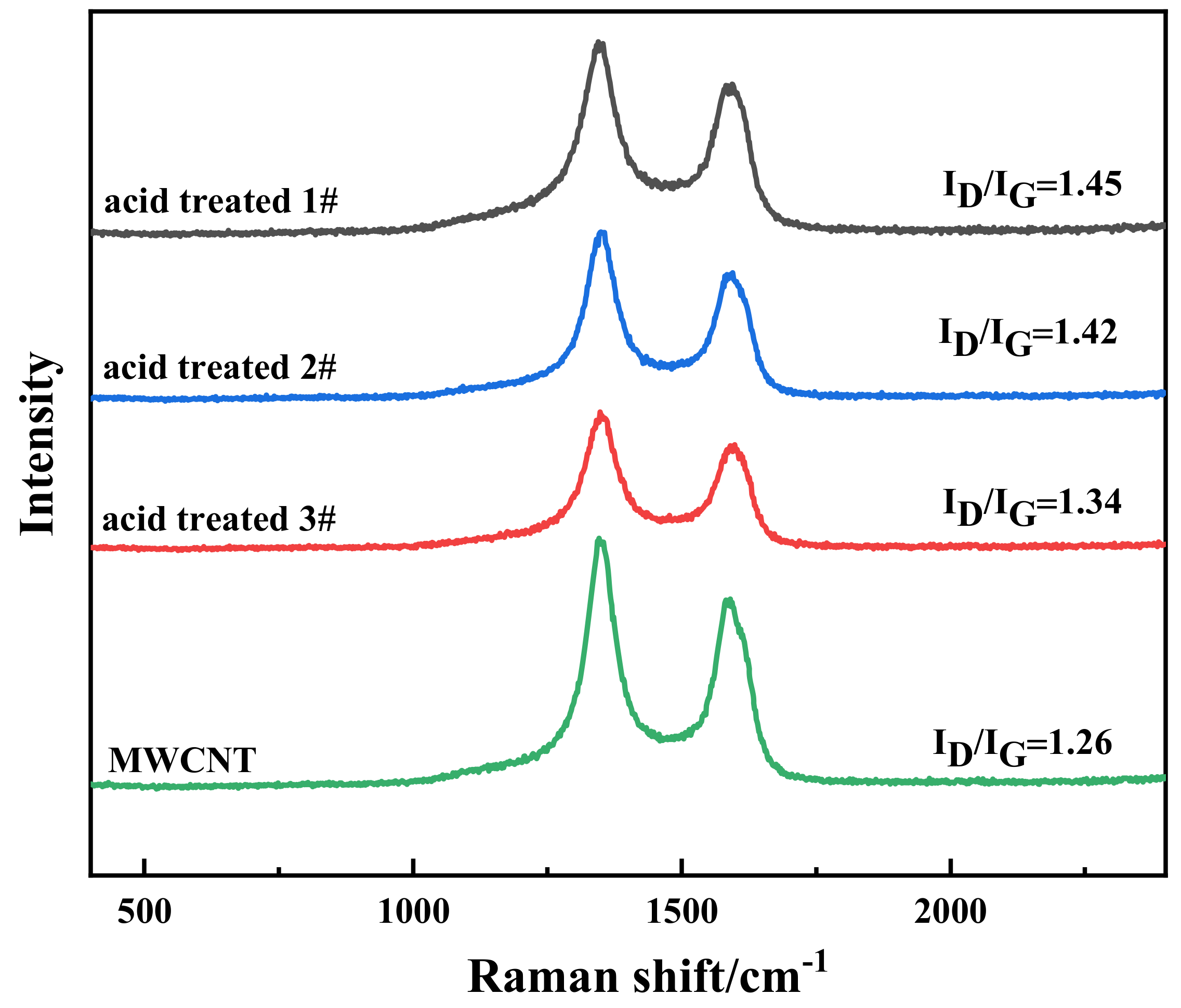

3.1. Raman Spectrum of Buckypapers

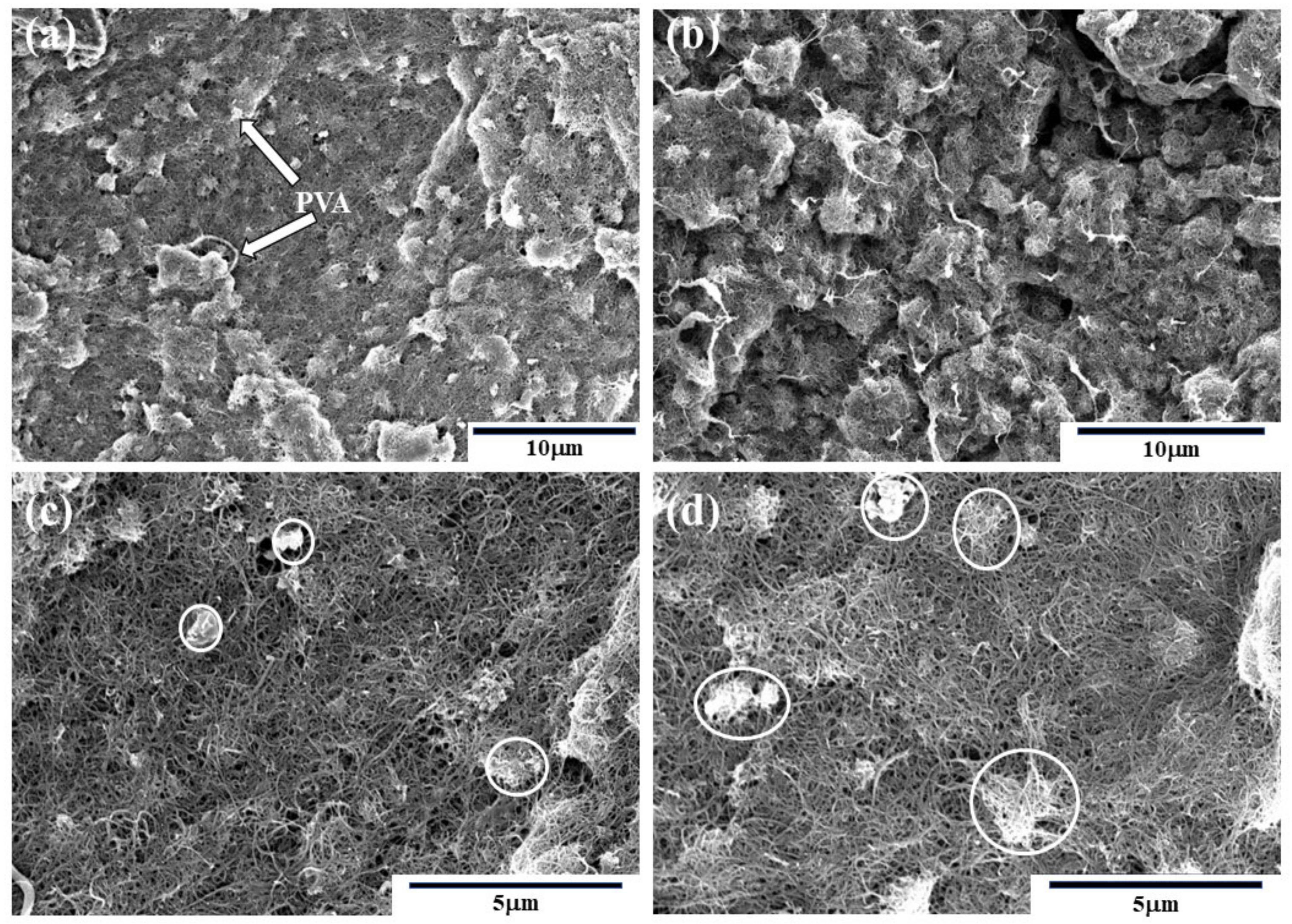

3.2. Microstructure of MWCNT/PVA Buckypapers

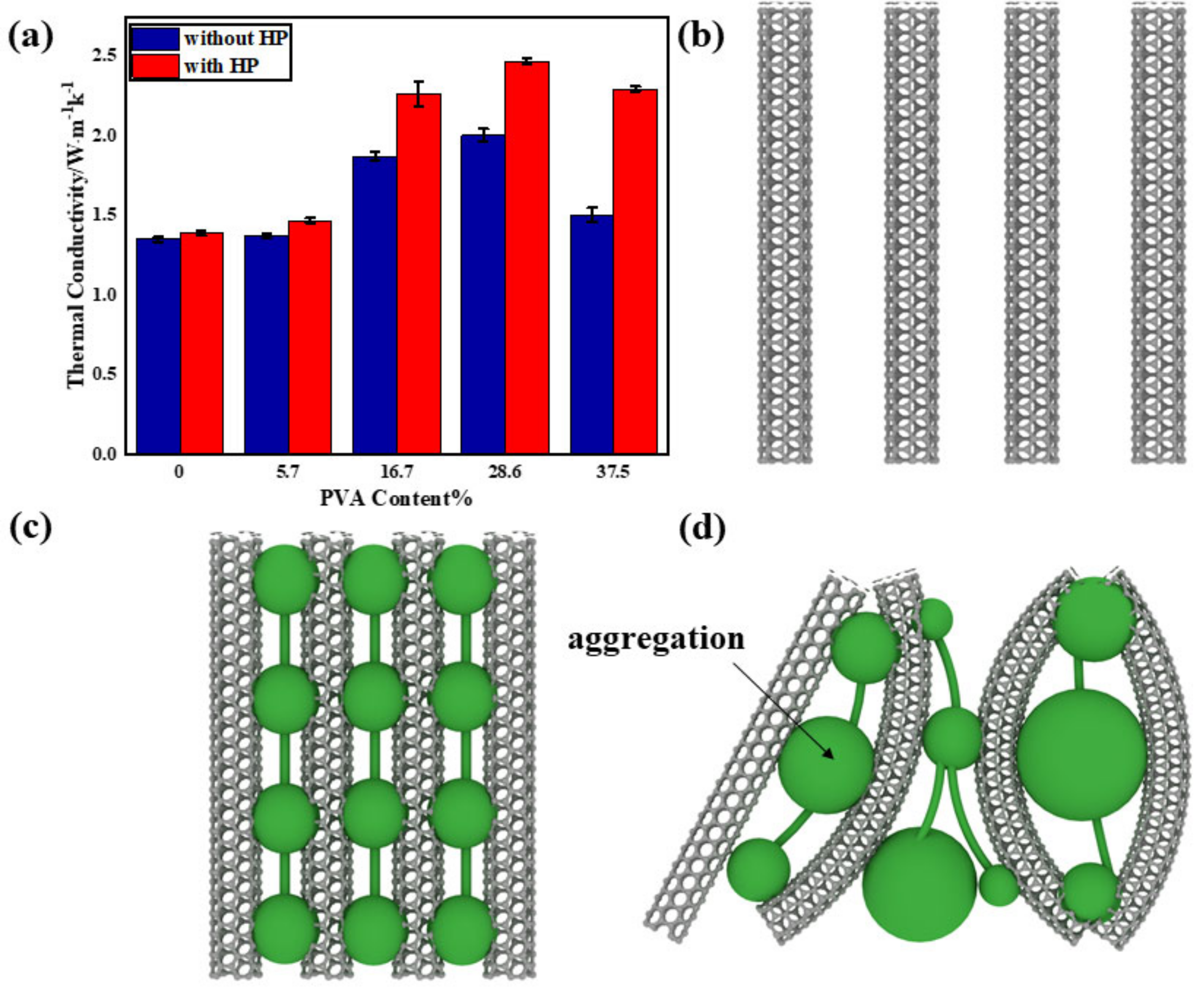

3.3. Thermal Conductivity and Finite Element Analysis

3.3.1. Thermal Conductivity

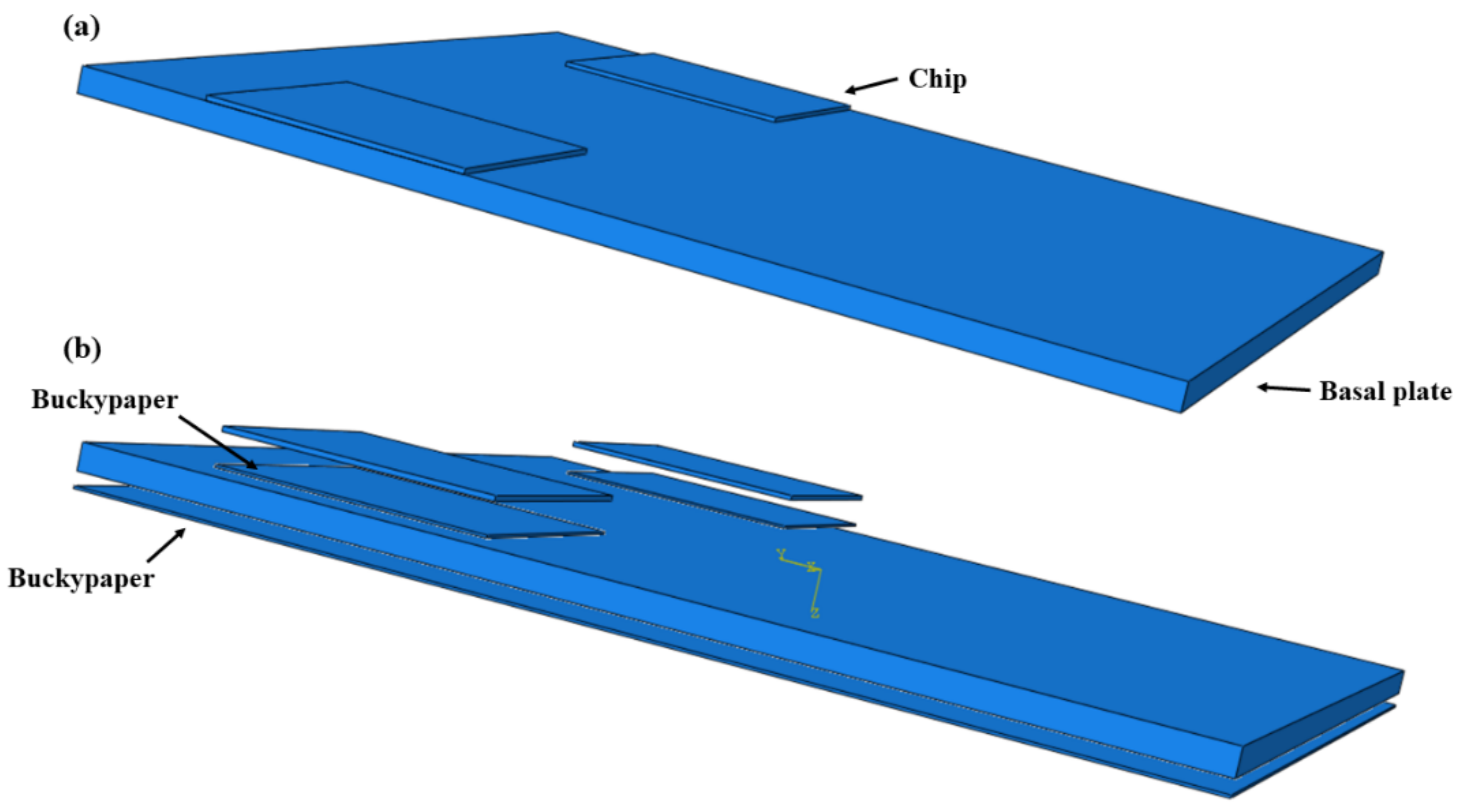

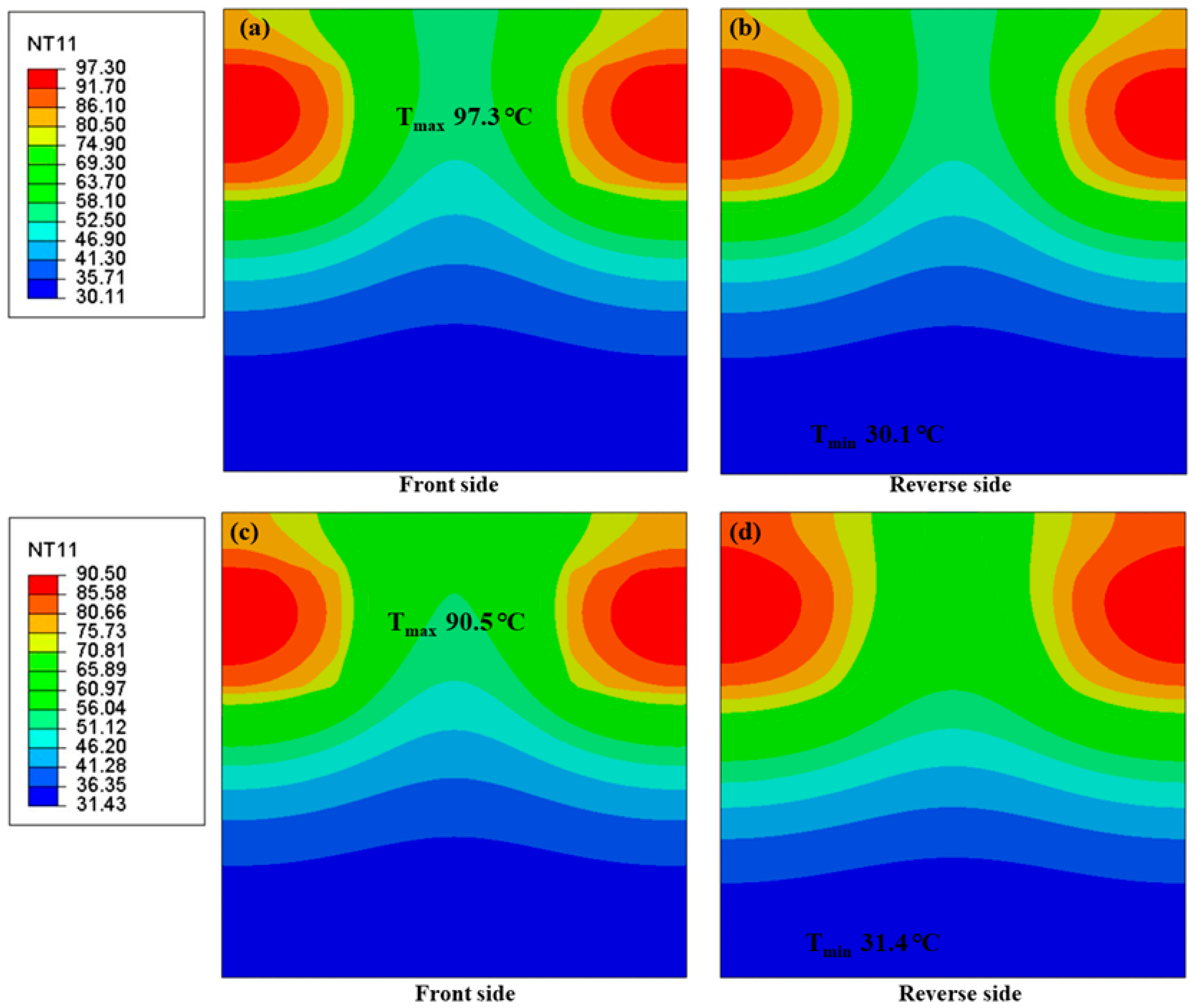

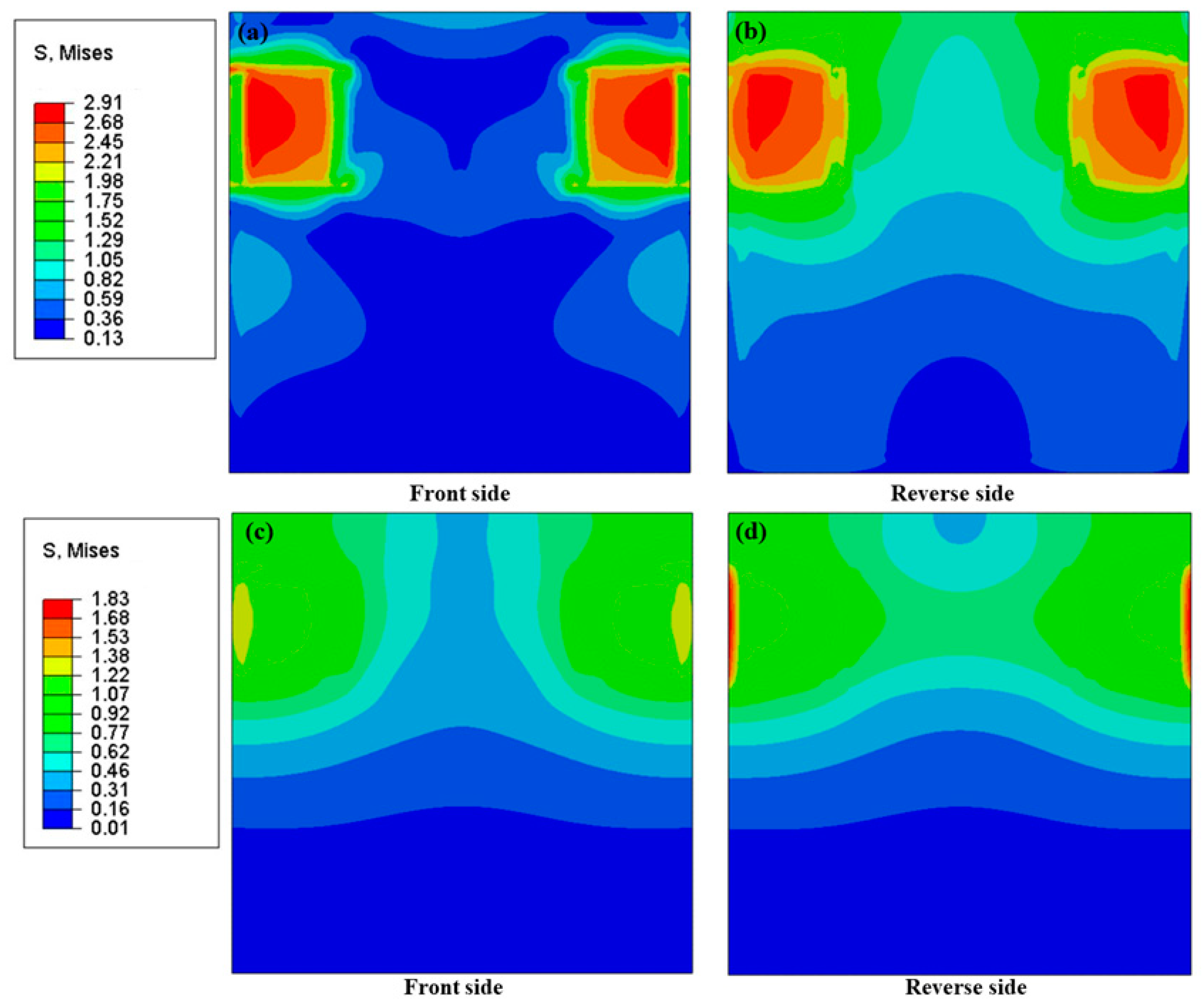

3.3.2. Finite Element Analysis

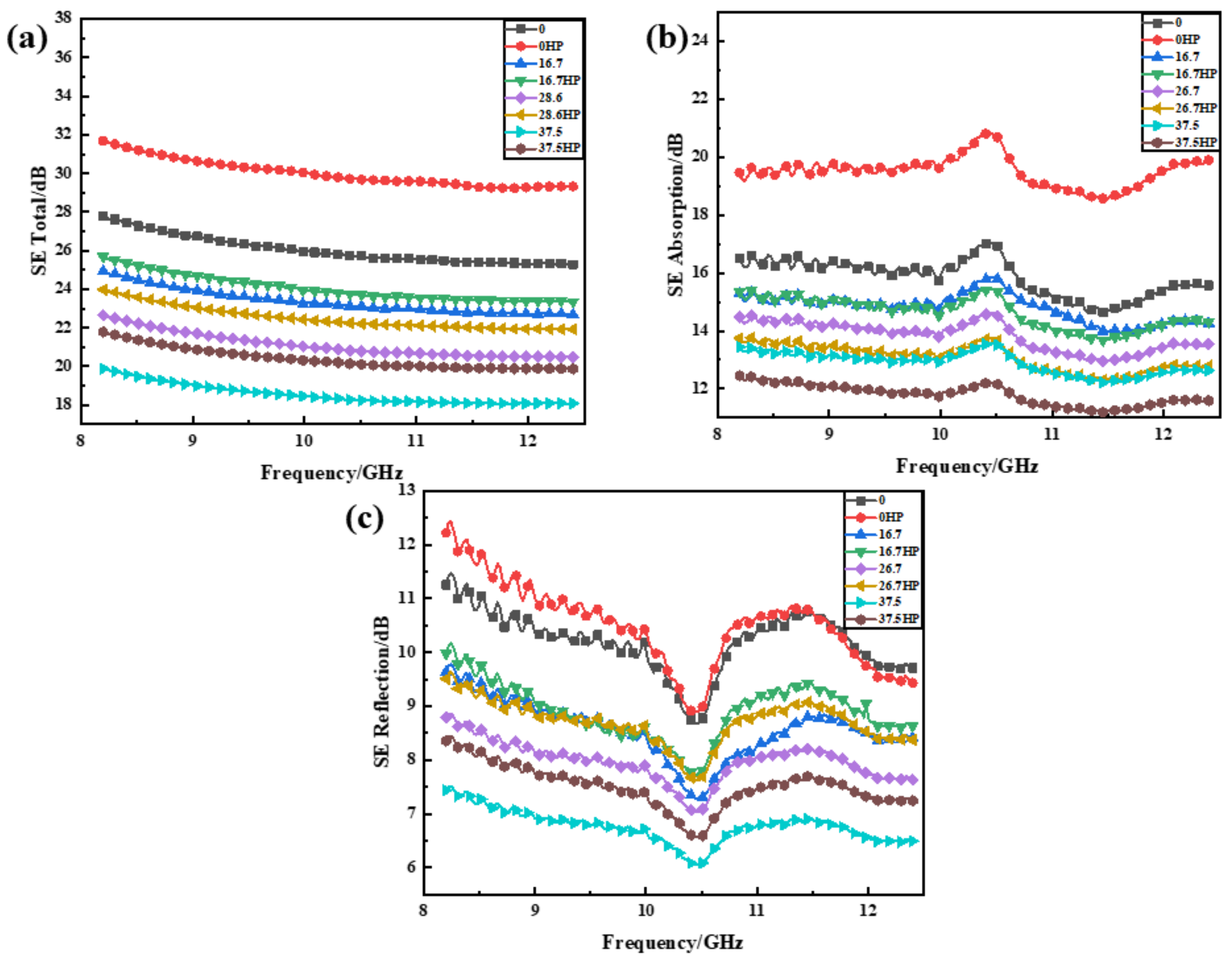

3.4. Electrical Conductivity and Electromagnetic Interference Shielding Properties

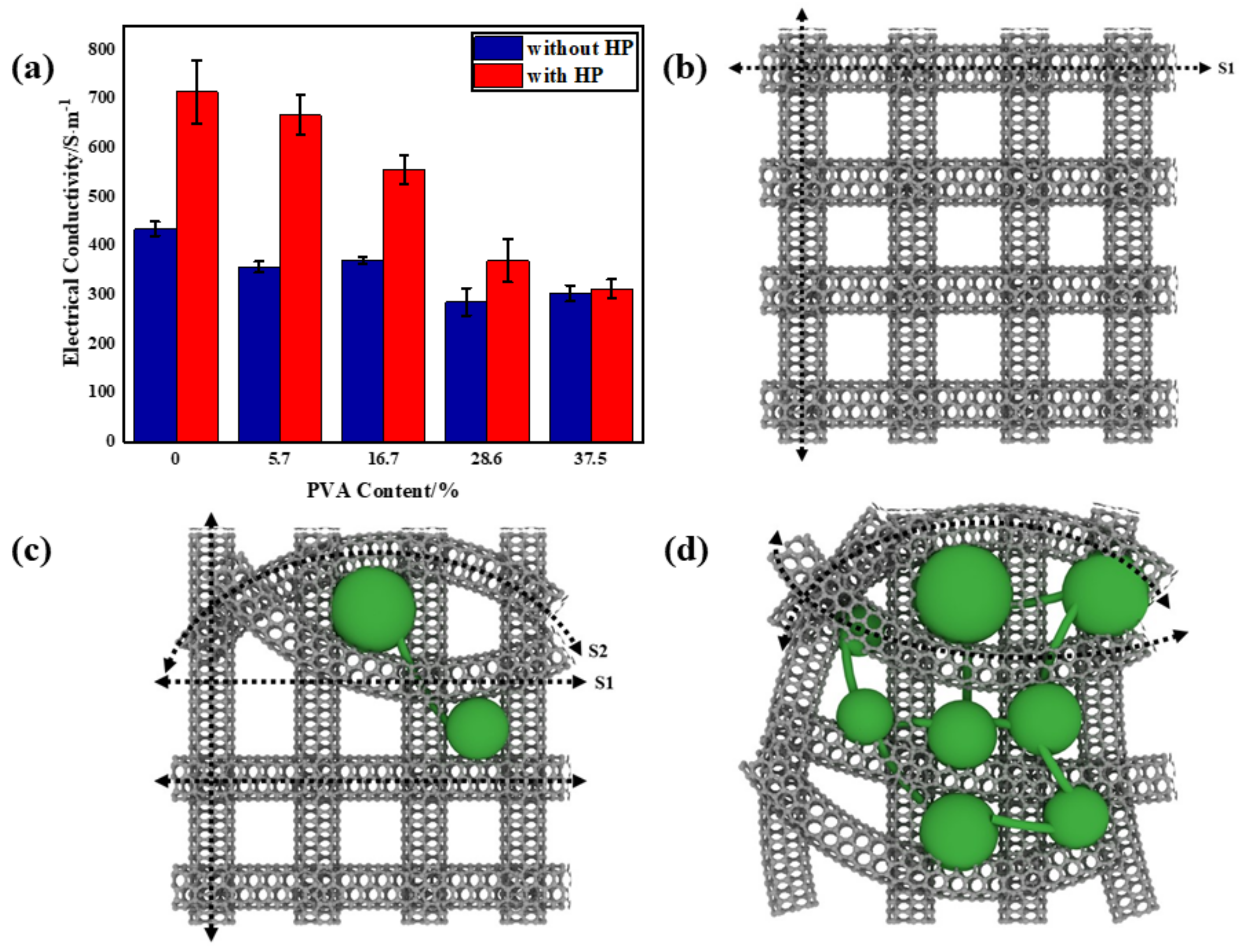

3.4.1. Electrical Conductivity

3.4.2. Electromagnetic Interference Shielding Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, L.; Zhang, G.; Liu, C.; Fan, S. High-density carbon nanotube buckypapers with superior transport and mechanical properties. Nano Lett. 2012, 12, 4848–4852. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, A.P.; Kumari, S.; Srivastava, A.K.; Bathula, S.; Dhawan, S.K.; Dutta, P.K.; Dhar, A. EM shielding effectiveness of Pd-CNT-Cu nanocomposite buckypaper. J. Mater. Chem. A 2015, 3, 13986–13993. [Google Scholar] [CrossRef] [Green Version]

- Chaudhary, A.; Kumari, S.; Kumar, R.; Teotia, S.; Singh, B.P.; Singh, A.P.; Dhawan, S.K.; Dhakate, S.R. Lightweight and Easily Foldable MCMB-MWCNTs Composite Paper with Exceptional Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2016, 8, 10600–10608. [Google Scholar] [CrossRef]

- Gargama, H.; Thakur, A.K.; Chaturvedi, S.K. Polyvinylidene fluoride/nanocrystalline iron composite materials for EMI shielding and absorption applications. J. Alloys Compd. 2016, 654, 209–215. [Google Scholar] [CrossRef]

- Lu, S.; Shao, J.; Ma, K.; Chen, D.; Wang, X.; Zhang, L.; Meng, Q.; Ma, J. Flexible, mechanically resilient carbon nanotube composite films for high-efficiency electromagnetic interference shielding. Carbon 2018, 136, 387–394. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Katsnelson, M.I.; Grigorieva, I.V.; Dubonos, S.V.; Firsov, A.A. Two-dimensional gas of massless Dirac fermions in graphene. Nature 2005, 438, 197–200. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [Green Version]

- Cho, S.Y.; Yu, H.; Choi, J.; Kang, H.; Park, S.; Jang, J.S.; Hong, H.J.; Kim, I.D.; Lee, S.K.; Jeong, H.S.; et al. Continuous Meter-Scale Synthesis of Weavable Tunicate Cellulose/Carbon Nanotube Fibers for High-Performance Wearable Sensors. ACS Nano 2019, 13, 9332–9341. [Google Scholar] [CrossRef]

- Endo, M.; Muramatsu, H.; Hayashi, T.; Kim, Y.A.; Terrones, M.; Dresselhaus, N.S. ‘Buckypaper’ from coaxial nanotubes. Nature 2005, 433, 476. [Google Scholar] [CrossRef]

- Meng, C.Z.; Liu, C.H.; Fan, S.S. Flexible carbon nanotube/polyaniline paper-like films and their enhanced electrochemical properties. Electrochem. Commun. 2009, 11, 186–189. [Google Scholar] [CrossRef]

- Yu, M.F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552–5555. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gojny, F.H.; Wichmann, M.H.G.; Fiedler, B.; Kinloch, I.A.; Bauhofer, W.; Windle, A.H.; Schulte, K. Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 2006, 47, 2036–2045. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Zheng, J.P.; Liang, R.; Zhang, C.; Wang, B.; Hendrickson, M.; Plichta, E.J. Lithium-Air Batteries Using SWNT/CNF Buckypapers as Air Electrodes. J. Electrochem. Soc. 2010, 157, A953–A956. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, T.-W.; Lee, S.-E.; Lim, J.; Jeong, Y.G. Silver nanowire/carbon nanotube/cellulose hybrid papers for electrically conductive and electromagnetic interference shielding elements. Compos. Sci. Technol. 2017, 150, 45–53. [Google Scholar] [CrossRef]

- Bradford, P.D.; Wang, X.; Zhao, H.; Maria, J.-P.; Jia, Q.; Zhu, Y.T. A novel approach to fabricate high volume fraction nanocomposites with long aligned carbon nanotubes. Compos. Sci. Technol 2010, 70, 1980–1985. [Google Scholar] [CrossRef]

- Trakakis, G.; Tasis, D.; Aggelopoulos, C.; Parthenios, J.; Galiotis, C.; Papagelis, K. Open structured in comparison with dense multi-walled carbon nanotube buckypapers and their composites. Compos. Sci. Technol. 2013, 77, 52–59. [Google Scholar] [CrossRef]

- Trakakis, G.; Anagnostopoulos, G.; Sygellou, L.; Bakolas, A.; Parthenios, J.; Tasis, D.; Galiotis, C.; Papagelis, K. Epoxidized multi-walled carbon nanotube buckypapers: A scaffold for polymer nanocomposites with enhanced mechanical properties. Chem. Eng. J. 2015, 281, 793–803. [Google Scholar] [CrossRef]

- Geng, H.Z.; Kim, K.K.; So, K.P.; Lee, Y.S.; Chang, Y.; Lee, Y.H. Effect of acid treatment on carbon nanotube-based flexible transparent conducting films. J. Am. Chem. Soc. 2007, 129, 7758–7759. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, X.; Shimoyama, I.; Sun, X.; Seo, W.S.; Dai, H. Langmuir-blodgett assembly of densely aligned single-walled carbon nanotubes from bulk materials. J. Am. Chem. Soc. 2007, 129, 4890–4891. [Google Scholar] [CrossRef] [Green Version]

- Nasibulin, A.G.; Kaskela, A.; Mustonen, K.; Anisimov, A.S.; Ruiz, V.; Kivisto, S.; Rackauskas, S.; Timmermans, M.Y.; Pudas, M.; Aitchison, B.; et al. Multifunctional free-standing single-walled carbon nanotube films. ACS Nano 2011, 5, 3214–3221. [Google Scholar] [CrossRef]

- Reynaud, O.; Nasibulin, A.G.; Anisimov, A.S.; Anoshkin, I.V.; Jiang, H.; Kauppinen, E.I. Aerosol feeding of catalyst precursor for CNT synthesis and highly conductive and transparent film fabrication. Chem. Eng. J. 2014, 255, 134–140. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D.; Peng, H.-X.; Qin, F. Enhanced mechanical and electrical properties of carbon nanotube buckypaper by in situ cross-linking. Carbon 2013, 63, 125–132. [Google Scholar] [CrossRef]

- Yuan, C.; Duan, B.; Li, L.; Xie, B.; Huang, M.; Luo, X. Thermal Conductivity of Polymer-Based Composites with Magnetic Aligned Hexagonal Boron Nitride Platelets. ACS Appl Mater Interfaces 2015, 7, 13000–13006. [Google Scholar] [CrossRef]

- Brown, B.; Swain, B.; Hiltwine, J.; Brooks, D.B.; Zhou, Z.G. Carbon nanosheet buckypaper: A graphene-carbon nanotube hybrid material for enhanced supercapacitor performance. J. Power Sour. 2014, 272, 979–986. [Google Scholar] [CrossRef]

- Khan, D.M.; Kausar, A.; Salman, S.M. Buckypapers of polyvinyl chloride/poly(styrene-co-maleic anhydride) blend intercalated graphene oxide-carbon nanotube nanobifiller: Physical property exploration. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 202–212. [Google Scholar] [CrossRef]

- Im, T.H.; Park, D.Y.; Lee, H.K.; Park, J.H.; Jeong, C.K.; Joe, D.J.; Lee, K.J. Xenon Flash Lamp-Induced Ultrafast Multilayer Graphene Growth. Part. Part. Syst. Charact. 2017, 34, 1600429. [Google Scholar] [CrossRef] [Green Version]

- Reddy, A.L.M.; Ramaprabhu, S. Nanocrystalline metal oxides dispersed multiwalled carbon nanotubes as supercapacitor electrodes. J. Phys. Chem. C 2007, 111, 7727–7734. [Google Scholar] [CrossRef]

- Kim, Y.H.; Park, S.J. Roles of nanosized Fe3O4 on supercapacitive properties of carbon nanotubes. Curr. Appl. Phys. 2011, 11, 462–466. [Google Scholar] [CrossRef]

- Hao, W.T.; Zhang, J.L. Microstructure and dielectric property of hot-pressed high density CaCu3Ti4O12 ceramics. J. Alloys Compd. 2013, 559, 16–19. [Google Scholar] [CrossRef]

- Lu, S.; Ma, K.; Wang, X.; Xiong, X.; Xu, W.; Jia, C. Fabrication and characterization of polymer composites surface coated Fe3O4/MWCNTs hybrid buckypaper as a novel microwave-absorbing structure. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Hu, C.; Li, F.; Qu, D.; Wang, Q.; Xie, R.; Zhang, H.; Peng, S.; Bao, Y.; Zhou, Y. Developments in Hot Pressing (HP) and Hot Isostatic Pressing (HIP) of Ceramic Matrix Composites; Woodhead Publ Ltd.: Cambridge, MA, USA, 2014; pp. 164–189. [Google Scholar]

- Xu, X.H.; Wang, X.Q.; Liu, W.P.; Zhang, X.; Li, Z.Z.; Du, S.Y. Microwave curing of carbon fiber/bismaleimide composite laminates: Material characterization and hot pressing pretreatment. Mater. Des. 2016, 97, 316–323. [Google Scholar] [CrossRef]

- Long, F.C.; Kamsom, R.A.; Nurfaizey, A.H.; Isa, M.H.M.; Masripan, N.A.B. The Influence of Electrospinning Distances on Fibre Diameter of Poly(Vinyl Alcohol) Electrospun Nanofibres; Centre Advanced Research Energy-Care: Durian Tunggal, Malaysia, 2017. [Google Scholar]

- Ranjbar, N.; Kashefi, A.; Maheri, M.R. Hot-pressed geopolymer: Dual effects of heat and curing time. Cem. Concr. Compos. 2018, 86, 1–8. [Google Scholar] [CrossRef]

- Patole, S.P.; Arif, M.F.; Kumar, S. Polyvinyl alcohol incorporated buckypaper composites for improved multifunctional performance. Compos. Sci. Technol. 2018, 168, 429–436. [Google Scholar] [CrossRef]

- Yi, G.; Fan, X.F.; Quan, X.; Chen, S.; Yu, H.T. Comparison of CNT-PVA membrane and commercial polymeric membranes in treatment of emulsified oily wastewater. Front. Environ. Sci. Eng. 2019, 13, 9. [Google Scholar] [CrossRef]

- Chen, S.C.; Luo, J.L.; Wang, X.L.; Li, Q.Y.; Zhou, L.C.; Liu, C.; Feng, C. Fabrication and Piezoresistive/Piezoelectric Sensing Characteristics of Carbon Nanotube/PVA/Nano-ZnO Flexible Composite. Sci. Rep. 2020, 10, 12. [Google Scholar] [CrossRef]

- Yuan, Y.G.; Zhang, X.X.; Ding, J.J.; Ruan, J. Measurement of WC grain size in ultrafine grained WC-Co cemented carbides. In Advances in Mechatronics and Control Engineering, Pts 1–3; Kim, Y.H., Yarlagadda, P., Eds.; Trans Tech Publications Ltd.: Zurich, Switzerland, 2013; Volume 278-280, pp. 460–463. [Google Scholar]

- Santos, R.F.D.; Gomes-Junior, F.G.; Marcos-Filho, J. Morphological and physiological changes during maturation of okra seeds evaluated through image analysis. Sci. Agric. 2020, 77. [Google Scholar] [CrossRef]

- Wang, J.; Cao, L.; Liu, Y.; Zhang, Y.; Fang, H.; Chen, J. Fabrication of improved flexural strength C/SiC composites via LA-CVI method using optimized spacing of mass transfer channels. J. Eur. Ceram. Soc. 2020, 40, 2828–2833. [Google Scholar] [CrossRef]

- Wepasnick, K.A.; Smith, B.A.; Schrote, K.E.; Wilson, H.K.; Diegelmann, S.R.; Fairbrother, D.H. Surface and structural characterization of multi-walled carbon nanotubes following different oxidative treatments. Carbon 2011, 49, 24–36. [Google Scholar] [CrossRef]

- Saito, T.; Matsushige, K.; Tanaka, K. Chemical treatment and modification of multi-walled carbon nanotubes. Phys. B Condens. Matter 2002, 323, 280–283. [Google Scholar] [CrossRef]

- Chelmecka, E.; Pasterny, K.; Kupka, T.; Stobinski, L. DFT studies of COOH tip-functionalized zigzag and armchair single wall carbon nanotubes. J. Mol. Model. 2012, 18, 2241–2246. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Zhang, X.; He, Y.; Guo, Z.-S.; Zhang, J.; Song, Y. Combined effect of relative humidity and temperature on dynamic viscoelastic properties and glass transition of poly(vinyl alcohol). J. Appl. Polym. Sci. 2013, 130, 3161–3167. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, W.; Luo, X.G.; Wang, J.N. High performance carbon nanotube based composite film from layer-by-layer deposition. Carbon 2015, 90, 215–221. [Google Scholar] [CrossRef]

- Trakakis, G.; Tomara, G.; Datsyuk, V.; Sygellou, L.; Bakolas, A.; Tasis, D.; Parthenios, J.; Krontiras, C.; Georga, S.; Galiotis, C.; et al. Mechanical, Electrical, and Thermal Properties of Carbon Nanotube Buckypapers/Epoxy Nanocomposites Produced by Oxidized and Epoxidized Nanotubes. Materials 2020, 13, 4308. [Google Scholar] [CrossRef]

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Musallam, M.; Johnson, C.M.; Yin, C.Y.; Lu, H.; Bailey, C. In Service Life Consumption Estimation in Power Modules. In In Proceedings of the 2008 13th International Power Electronics and Motion Control Conference, IEEE, Poznan, Poland, 1–3 September 2008. [Google Scholar]

- Senturk, O.S.; Helle, L.; Munk-Nielsen, S.; Rodriguez, P.; Teodorescu, R. Electro-thermal Modeling for Junction Temperature Cycling-Based Lifetime Prediction of a Press-Pack IGBT 3L-NPC-VSC Applied to Large Wind Turbines. In In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 16–21 September 2011. [Google Scholar]

- Ohki, Y. Development of Epoxy Resin Composites With High Thermal Conductivity. IEEE Electr. Insul. Mag. 2010, 26, 48–49. [Google Scholar] [CrossRef]

- Gillot, C.; Schaeffer, C.; Massit, C.; Meysenc, L. Double-sided cooling for high power IGBT modules using flip chip technology. IEEE Trans. Compon. Packag. Technol. 2001, 24, 698–704. [Google Scholar] [CrossRef]

- Park, J.G.; Louis, J.; Cheng, Q.; Bao, J.; Smithyman, J.; Liang, R.; Wang, B.; Zhang, C.; Brooks, J.S.; Kramer, L.; et al. Electromagnetic interference shielding properties of carbon nanotube buckypaper composites. Nanotechnology 2009, 20, 415702. [Google Scholar] [CrossRef] [Green Version]

- Xia, Q.; Zhang, Z.; Chu, H.; Liu, Y.; Leng, J. Research on high electromagnetic interference shielding effectiveness of a foldable buckypaper/polyacrylonitrile composite film via interface reinforcing. Compos. Part A Appl. Sci. Manuf. 2018, 113, 132–140. [Google Scholar] [CrossRef]

- Biel, B.; Blase, X.; Triozon, F.; Roche, S. Anomalous Doping Effects on Charge Transport in Graphene Nanoribbons. Phys. Rev. Lett. 2009, 102, 4. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Xue, X.; Zhang, Z. Microstructure Design of Lightweight, Flexible, and High Electromagnetic Shielding Porous Multiwalled Carbon Nanotube/Polymer Composites. Small 2017, 13, 1701388. [Google Scholar] [CrossRef]

- Wang, G.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.; Li, H.; Zhao, G.; Park, C.B. Ultralow-Threshold and Lightweight Biodegradable Porous PLA/MWCNT with Segregated Conductive Networks for High-Performance Thermal Insulation and Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2018, 10, 1195–1203. [Google Scholar] [CrossRef] [PubMed]

| Sample | Pore Diameter/nm | Pore Area/nm2 | Thickness/mm | Density/g·cm−3 | ||||

|---|---|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | Before | After | |

| BP 0# | 25.80 | 23.56 | 546.95 | 512.01 | 0.28 | 0.12 | 0.20 | 0.46 |

| BP 5.7# | 22.38 | 20.49 | 504.03 | 488.36 | 0.25 | 0.11 | 0.22 | 0.50 |

| BP 16.7# | 22.12 | 19.22 | 454.24 | 402.80 | 0.25 | 0.08 | 0.22 | 0.69 |

| BP 28.6# | 20.15 | 19.36 | 413.19 | 394.45 | 0.24 | 0.12 | 0.23 | 0.46 |

| BP 37.5# | 18.96 | 17.02 | 395.02 | 383.66 | 0.26 | 0.10 | 0.21 | 0.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Liu, Y.; Wang, J.; Pan, Y.; Zhang, Y.; Wang, N.; Chen, J. Multi-Functional Properties of MWCNT/PVA Buckypapers Fabricated by Vacuum Filtration Combined with Hot Press: Thermal, Electrical and Electromagnetic Shielding. Nanomaterials 2020, 10, 2503. https://doi.org/10.3390/nano10122503

Cao L, Liu Y, Wang J, Pan Y, Zhang Y, Wang N, Chen J. Multi-Functional Properties of MWCNT/PVA Buckypapers Fabricated by Vacuum Filtration Combined with Hot Press: Thermal, Electrical and Electromagnetic Shielding. Nanomaterials. 2020; 10(12):2503. https://doi.org/10.3390/nano10122503

Chicago/Turabian StyleCao, Liyang, Yongsheng Liu, Jing Wang, Yu Pan, Yunhai Zhang, Ning Wang, and Jie Chen. 2020. "Multi-Functional Properties of MWCNT/PVA Buckypapers Fabricated by Vacuum Filtration Combined with Hot Press: Thermal, Electrical and Electromagnetic Shielding" Nanomaterials 10, no. 12: 2503. https://doi.org/10.3390/nano10122503

APA StyleCao, L., Liu, Y., Wang, J., Pan, Y., Zhang, Y., Wang, N., & Chen, J. (2020). Multi-Functional Properties of MWCNT/PVA Buckypapers Fabricated by Vacuum Filtration Combined with Hot Press: Thermal, Electrical and Electromagnetic Shielding. Nanomaterials, 10(12), 2503. https://doi.org/10.3390/nano10122503