Spatially Resolved Optoelectronic Properties of Al-Doped Zinc Oxide Thin Films Deposited by Radio-Frequency Magnetron Plasma Sputtering Without Substrate Heating

Abstract

1. Introduction

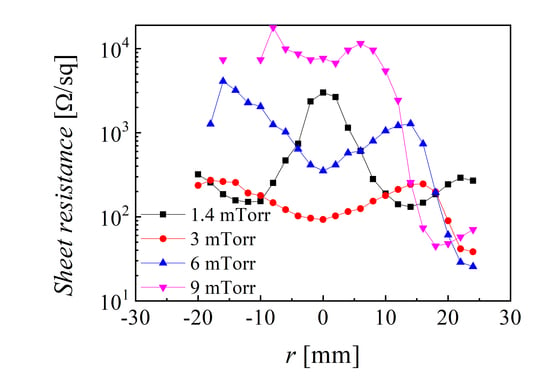

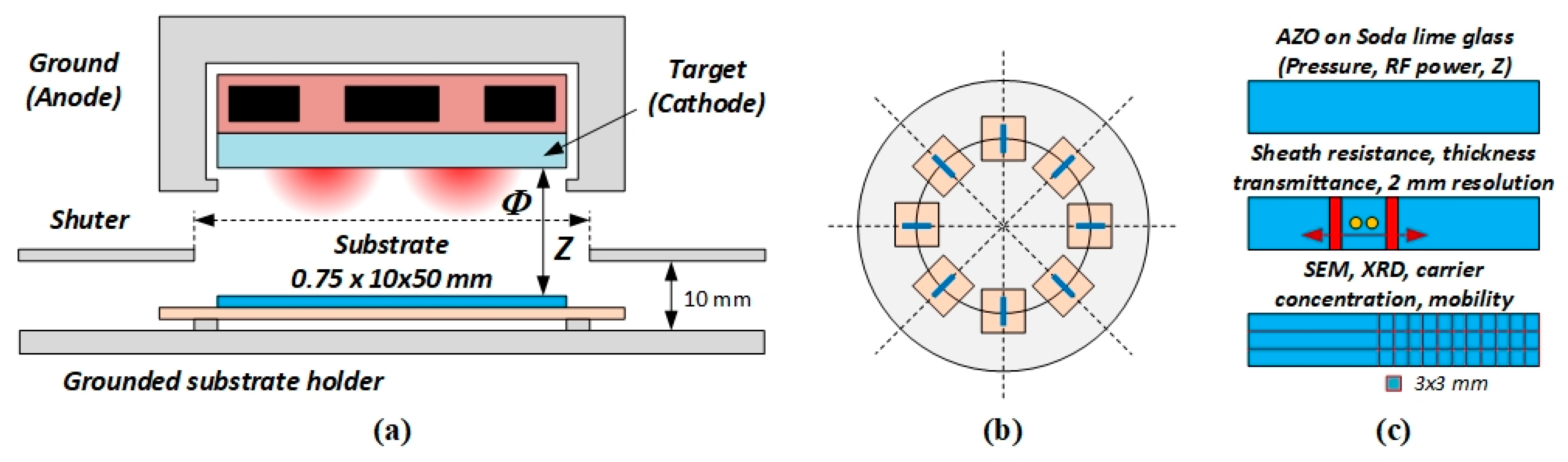

2. Materials and Methods

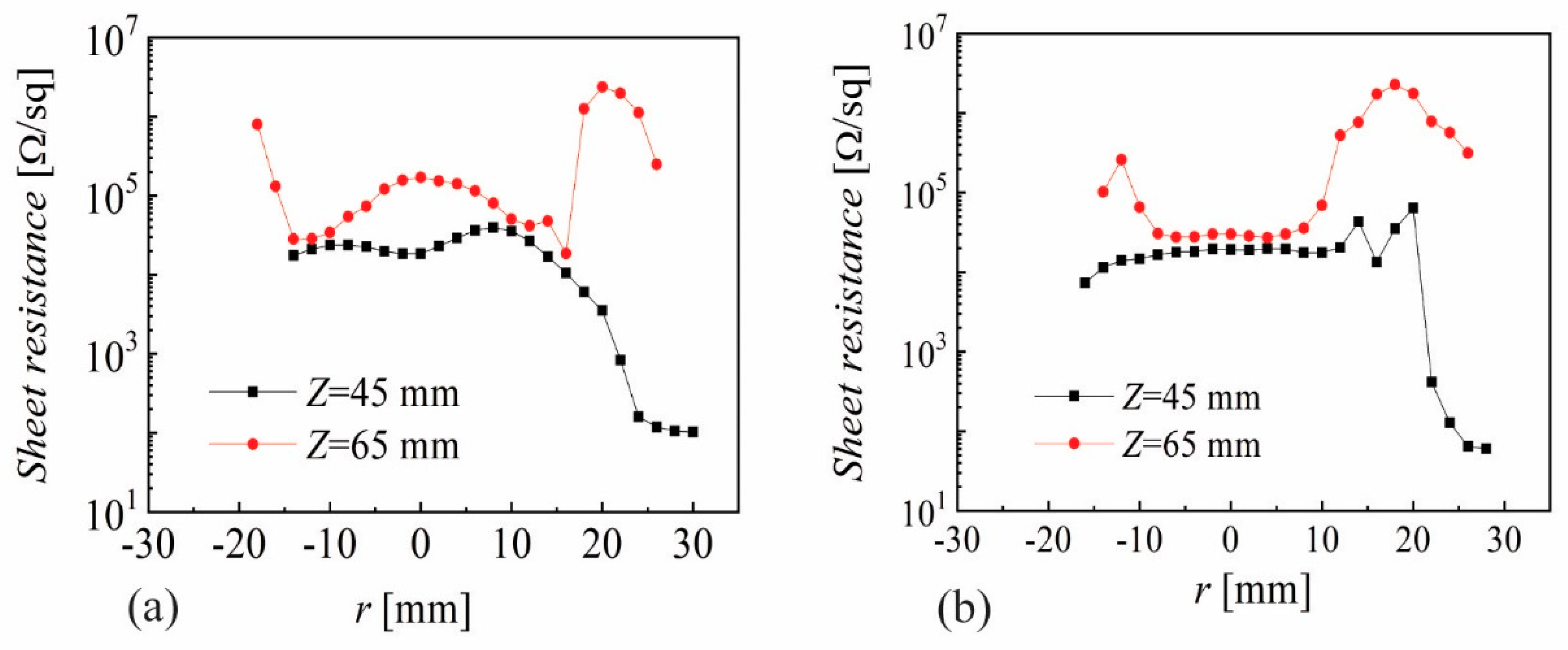

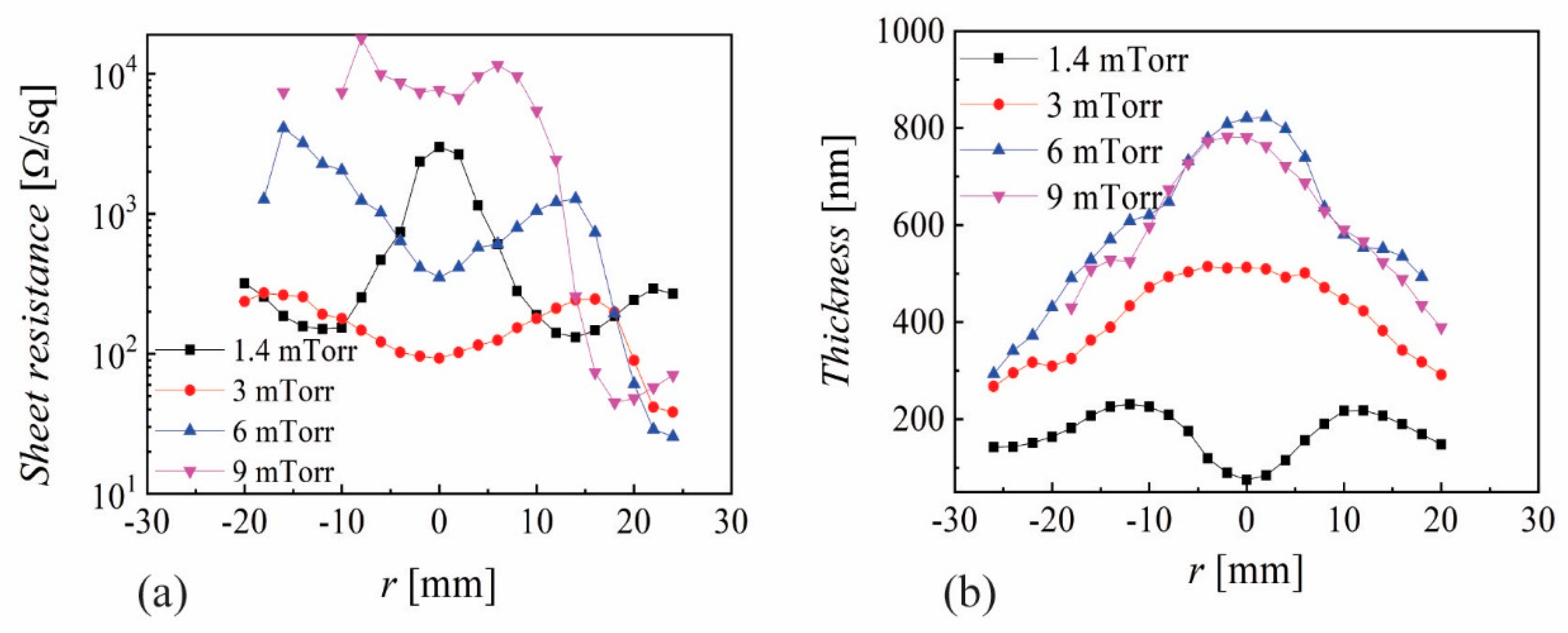

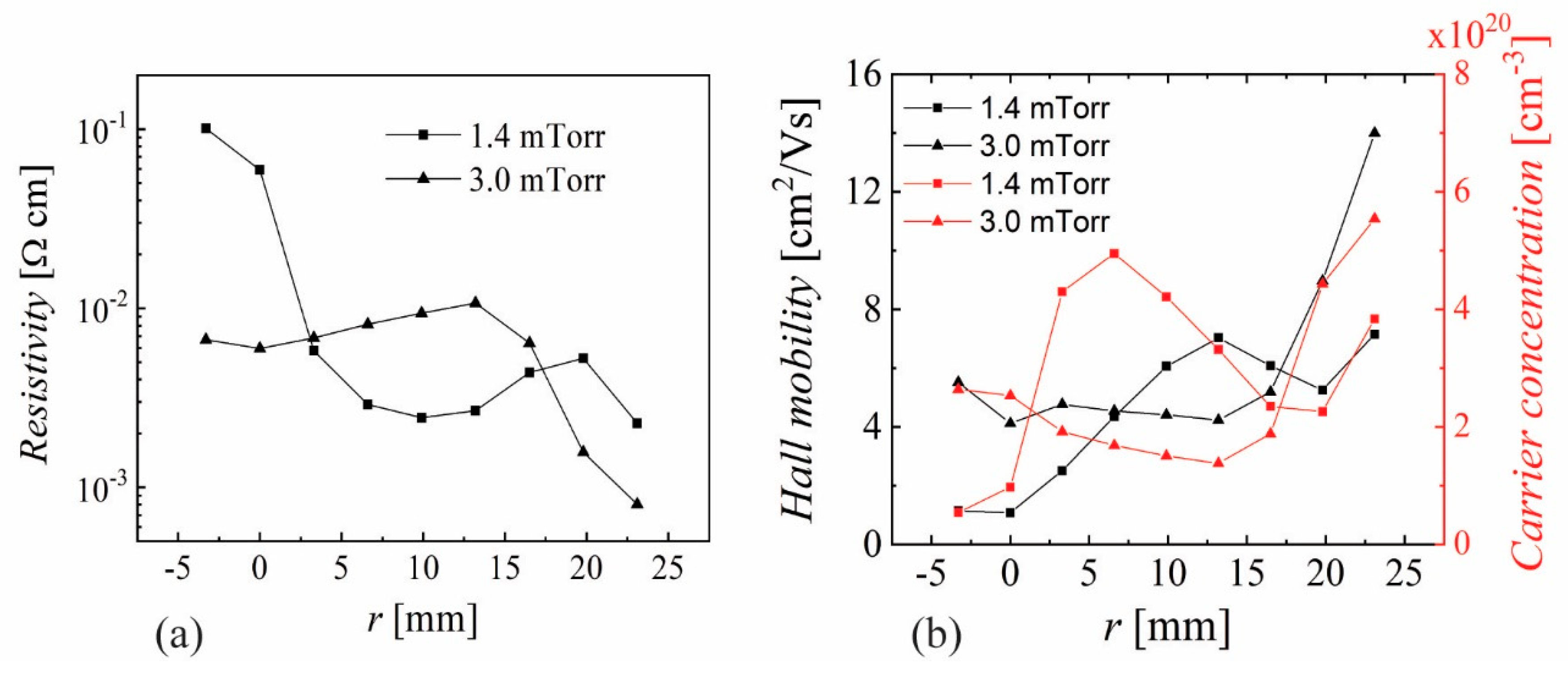

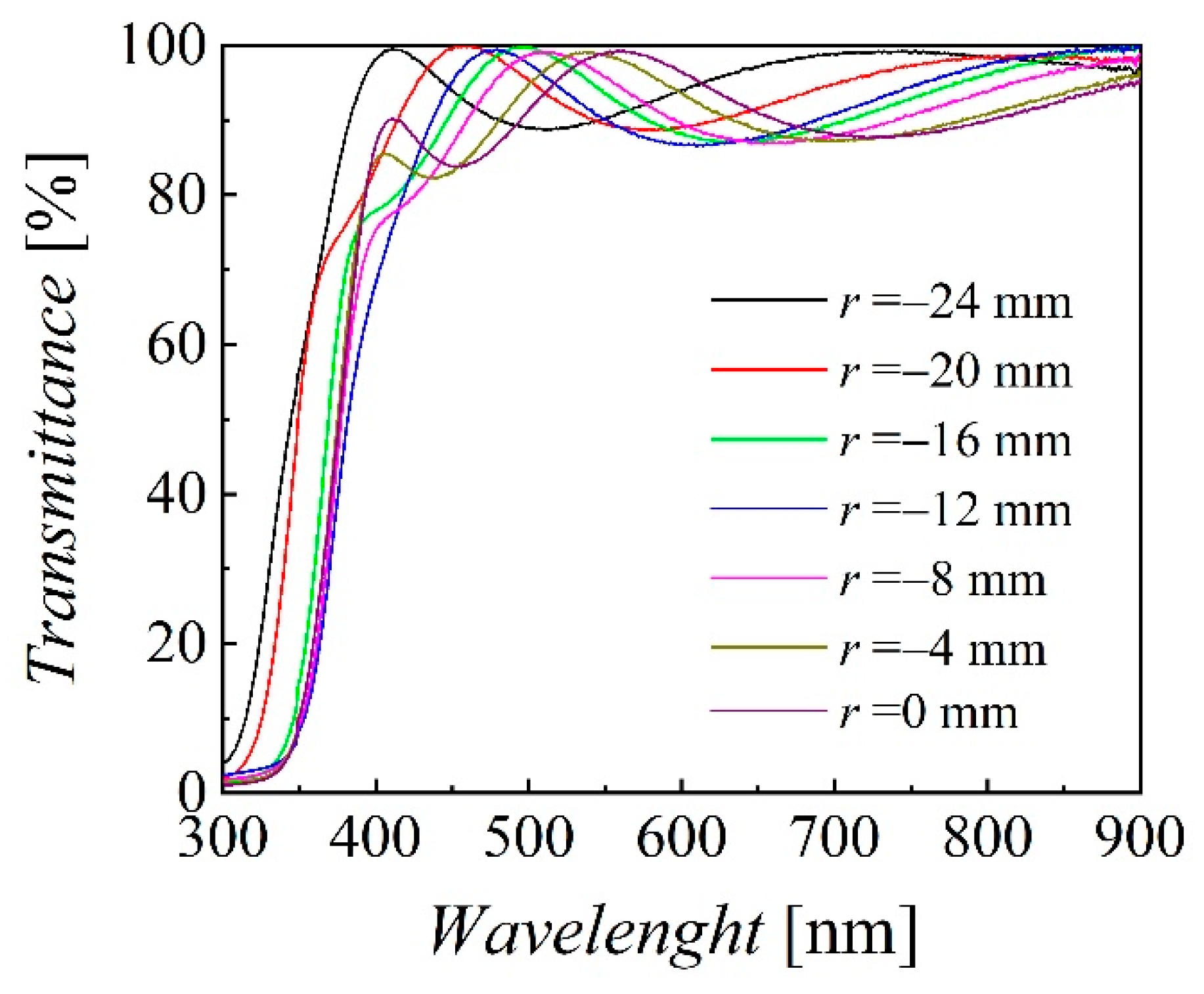

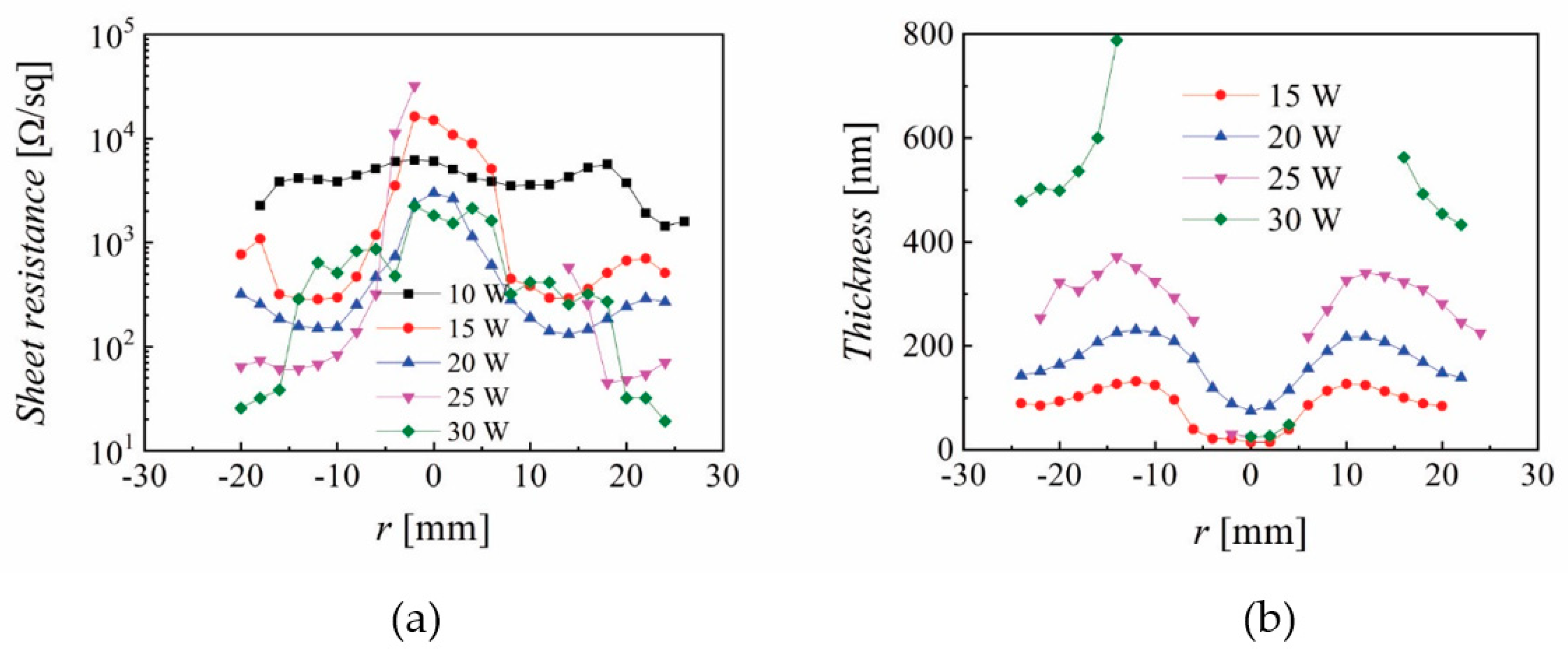

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ginley, D.S.; Perkins, J.D. Transparent Conductors. In Handbook of Transparent Conductors; Ginley, D.S., Hosono, H., Paine, D.C., Eds.; Springer: New York, NY, USA, 2011; pp. 1–27. [Google Scholar]

- Ellmer, K. Transparent conductive zinc oxide and its derivatives. In Handbook of Transparent Conductors; Ginley, D.S., Hosono, H., Paine, D.C., Eds.; Springer: New York, NY, USA, 2011; pp. 193–264. [Google Scholar]

- Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photonics 2012, 6, 809–817. [Google Scholar] [CrossRef]

- Granqvist, C.G. Transparent conductors as solar energy materials: A panoramic review. Sol. Energy Mater. Sol. Cells 2012, 91, 1529–1598. [Google Scholar] [CrossRef]

- Minami, T. Transparent conducting oxide semiconductors for transparent electrodes. Semicond. Sci. Technol. 2005, 20, S35–S44. [Google Scholar] [CrossRef]

- Reinhard, P.; Chirila, A.; Blösch, P.; Pinezzi, F.; Nishiwaki, S.; Buecheler, S.; Tiwari, A.N. Review of progress toward 20% efficiency flexible CIGS solar cells and manufacturing issues of solar modules. IEEE J. Photovolt. 2013, 3, 572–580. [Google Scholar] [CrossRef]

- Hajijafarassar, A.; Martinho, F.; Stulen, F.; Grini, S.; Lopez-Marrino, S.; Espindola-Rodriguez, M.; Dobeli, M.; Canulescu, S.; Stamate, E.; Gansukh, M.; et al. Monolitic thin-film chalcogenide-silicon tandem solar cells enabled by a diffusion barrier. Sol. Energy Mater. Sol. Cells 2019, in press. [Google Scholar]

- Agashe, C.; Kluth, O.; Schöpe, G.; Siekmann, H.; Hüpkes, J.; Rech, B. Optimization of the electrical properties of magnetron sputtered aluminum-doped zinc oxide films for opto-electronic applications. Thin Solid Film. 2003, 442, 167–172. [Google Scholar] [CrossRef]

- Evcimen Duygulu, N.; Kodolbas, A.O.; Ekerim, A. Effects of argon pressure and r.f. power on magnetron sputtered aluminum doped ZnO thin films. J. Cryst. Growth 2014, 394, 116–125. [Google Scholar] [CrossRef]

- Ghorannevis, Z.; Akbarnejad, E.; Salar Elahi, A.; Ghoranneviss, M. Application of RF magnetron sputtering for growth of AZO on glass substrate. J. Cryst. Growth 2016, 447, 62–66. [Google Scholar] [CrossRef]

- Kim, D.K.; Kim, H.B. Room temperature deposition of Al-doped ZnO thin films on glass by RF magnetron sputtering under different Ar gas pressure. J. Alloy. Comp. 2011, 509, 421–425. [Google Scholar] [CrossRef]

- Miao, D.; Jiang, S.; Zhao, H.; Shang, S.; Chen, Z. Characterization of AZO and Ag based films prepared by RF magnetron sputtering. J. Alloy. Comp. 2014, 616, 26–31. [Google Scholar] [CrossRef]

- Patel, K.H.; Rawal, S.K. Influence of poFwer and temperature on properties of sputtered AZO films. Thin Solid Film. 2016, 620, 182–187. [Google Scholar] [CrossRef]

- Prabhakar, T.; Dai, L.; Zhang, L.; Yang, R.; Li, L.; Guo, T.; Yan, Y. Effects of growth process on the optical and electrical properties in Al-doped ZnO thin films. J. Appl. Phys. 2014, 115, 083702. [Google Scholar] [CrossRef]

- Shantheyanda, B.P.; Todi, V.O.; Sundaram, K.B.; Vijayakumar, A.; Oladeji, I. Compositional study of vacuum annealed Al doped ZnO thin films obtained by RF magnetron sputtering. J. Vac. Sci. Technol. A 2011, 29, 051514. [Google Scholar] [CrossRef]

- Shih, N.F.; Chen, J.Z.; Jiang, Y.L. Properties and analysis of transparency conducting AZO films by using DC power and RF power simultaneous magnetron sputtering. Adv. Mater. Sci. Eng. 2013, 2013, 1–7. [Google Scholar] [CrossRef]

- Sreedhar, A.; Kwon, J.H.; Yi, J.; Gwag, J.S. Improved physical properties of Al-doped ZnO thin films deposited by unbalanced RF magnetron sputtering. Ceram. Int. 2016, 42, 14456–14462. [Google Scholar] [CrossRef]

- Sytchkova, A.; Luisa Grilli, M.; Rinaldi, A.; Vedraine, S.; Torchio, P.; Piegari, A.; Flory, F. Radio frequency sputtered Al:ZnO-Ag transparent conductor: A plasmonic nanostructure with enhanced optical and electrical properties. J. Appl. Phys. 2013, 114, 094509. [Google Scholar] [CrossRef]

- Zubizarreta, C.; G.-Berasategui, E.; Ciarsolo, I.; Barriga, J.; Gaspar, D.; Martins, R.; Fortunato, E. The influence of target erosion grade in the optoelectronic properties of AZO coatings growth by magnetron sputtering. Appl. Surf. Sci. 2016, 380, 218–222. [Google Scholar] [CrossRef]

- Crovetto, A.; Ottsen, T.S.; Stamate, E.; Kjær, D.; Schou, J.; Hansen, O. On performance limitations and property correlations of Al-doped ZnO deposited by radio-frequency sputtering. J. Phys. D Appl. Phys. 2016, 49, 295101. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, W.; He, Q.; Zhang, Y.; Yu, T.; Sun, Y. Influence of negative ion resputtering on Al-doped ZnO thin films prepared by mid-frequency magnetron sputtering. Appl. Surf. Sci. 2010, 256, 1694–1697. [Google Scholar] [CrossRef]

- Guillén, C.; Herrero, J. High conductivity and transparent ZnO: Al films prepared at low temperature by DC and MF magnetron sputtering. Thin Solid Film. 2006, 515, 640–643. [Google Scholar] [CrossRef]

- Hong, R.J.; Jiang, X.; Szyszka, B.; Sittinger, V.; Pflug, A. Studies on ZnO:Al thin films deposited by in-line reactive mid-frequency magnetron sputtering. Appl. Surf. Sci. 2003, 207, 341–350. [Google Scholar] [CrossRef]

- Hong, R.; Xu, S. ZnO: Al films prepared by reactive mid-frequency magnetron sputtering with rotating cathode. J. Mater. Sci. Technol. 2010, 26, 872–877. [Google Scholar] [CrossRef]

- Posadowski, W.M.; Wiatrowski, A.; Dora, J.; Radzimski, Z.J. Magnetron sputtering process control by medium-frequency power supply parameter. Thin Solid Film. 2008, 516, 4478–4482. [Google Scholar] [CrossRef]

- Zhao, B.; Tang, L.D.; Wang, B.; Liu, B.W.; Feng, J.H. Optical and electrical characterization of gradient AZO thin film by magnetron sputtering. J. Mater. Sci. Mater. Electron. 2016, 27, 10320–10324. [Google Scholar] [CrossRef]

- Chung, Y.M.; Moon, C.S.; Jung, M.J.; Han, J.G. The low temperature synthesis of Al doped ZnO films on glass and polymer using magnetron co-sputtering: Working pressure effect. Surf. Coat. Technol. 2005, 200, 936–939. [Google Scholar] [CrossRef]

- Kumar, M.; Wen, L.; Sahu, B.B.; Han, J.G. Simultaneous enhancement of carrier mobility and concentration via tailoring of Al-chemical states in Al-ZnO thin films. Appl. Phys. Lett. 2015, 106, 241903. [Google Scholar] [CrossRef]

- Linss, V. Comparison of the large-area reactive sputter processes of ZnO: Al and ITO using industrial size rotatable targets. Surf. Coat. Technol. 2016, 290, 43–57. [Google Scholar] [CrossRef]

- Linss, V. Challenges in the industrial deposition of transparent conductive oxide materials by reactive magnetron sputtering from rotatable targets. Thin Solid Film. 2017, 634, 149–154. [Google Scholar] [CrossRef]

- Nguyen, H.C.; Trinh, T.T.; Le, T.; Tran, C.V.; Tran, T.; Park, H.; Yi, J. The mechanisms of negative oxygen ion formation from Al-doped ZnO target and the improvements in electrical and optical properties of thin films using off-axis dc magnetron sputtering at low temperature. Semicond. Sci. Technol. 2011, 26, 105022. [Google Scholar] [CrossRef]

- Oda, J.-I.; Nomoto, J.-I.; Miyata, T.; Minami, T. Improvements of spatial resistivity distribution in transparent conducting Al-doped ZnO thin films deposited by DC magnetron sputtering. Thin Solid Film. 2010, 518, 2984–2987. [Google Scholar] [CrossRef]

- Rayerfrancis, A.; Bhargav, P.B.; Ahmed, N.; Bhattacharya, S.; Chandra, B.; Dhara, S. Sputtered AZO Thin Films for TCO and Back Reflector Applications in Improving the Efficiency of Thin Film a-Si:H Solar Cells. Silicon 2017, 9, 31–38. [Google Scholar] [CrossRef]

- Sahu, B.B.; Han, J.G.; Hori, M.; Takeda, K. Langmuir probe and optical emission spectroscopy studies in magnetron sputtering plasmas for Al-doped ZnO film deposition. J. Appl. Phys. 2015, 117, 023301. [Google Scholar] [CrossRef]

- Sato, Y.; Ishihara, K.; Oka, N.; Shigesato, Y. Spatial distribution of electrical properties for Al-doped ZnO films deposited by dc magnetron sputtering using various inert gases. J. Vac. Sci. Technol. A 2010, 28, 895–900. [Google Scholar] [CrossRef]

- Wen, L.; Sahu, B.B.; Kim, H.R.; Han, J.G. Study on the electrical, optical, structural, and morphological properties of highly transparent and conductive AZO thin films prepared near room temperature. Appl. Surf. Sci. 2019, 473, 649–656. [Google Scholar] [CrossRef]

- Xia, Y.; Wang, P.; Shi, S.; Zhang, M.; He, G.; Lv, J.; Sun, Z. Deposition and characterization of AZO thin films on flexible glass substrates using DC magnetron sputtering technique. Ceram. Int. 2017, 43, 4536–4544. [Google Scholar] [CrossRef]

- Fumagalli, F.; Martí-Rujas, J.; Di Fonzo, F. Room temperature deposition of high figure of merit Al-doped zinc oxide by pulsed-direct current magnetron sputtering: Influence of energetic negative ion bombardment on film’s optoelectronic properties. Thin Solid Film. 2014, 569, 44–51. [Google Scholar] [CrossRef]

- Tiron, V.; Sirghi, L.; Popa, G. Control of aluminum doping of ZnO:Al thin films obtained by high-power impulse magnetron sputtering. Thin Solid Film. 2012, 520, 4305–4309. [Google Scholar] [CrossRef]

- Mickan, M.; Helmersson, U.; Rinnert, H.; Ghanbaja, J.; Muller, D.; Horwat, D. Room temperature deposition of homogeneous, highly transparent and conductive Al-doped ZnO films by reactive high power impulse magnetron sputtering. Sol. Energy Mater. Sol. Cells 2016, 157, 742–749. [Google Scholar] [CrossRef]

- Fu, S.W.; Chen, H.J.; Wu, H.T.; Hung, K.T.; Shih, C.F. Electrical and optical properties of Al:ZnO films prepared by ion-beam assisted sputtering. Ceram. Int. 2016, 42, 2626–2633. [Google Scholar] [CrossRef]

- Pokorný, P.; Mišina, M.; Bulíř, J.; Lančok, J.; Fitl, P.; Musil, J.; Novotný, M. Investigation of the negative ions in Ar/O2 plasma of magnetron sputtering discharge with Al:Zn target by ion mass spectrometry. Plasma Process. Polym. 2011, 8, 459–464. [Google Scholar] [CrossRef]

- Bikowski, A.; Welzel, T.; Ellmer, K. The correlation between the radial distribution of high-energetic ions and the structural as well as electrical properties of magnetron sputtered ZnO: Al films. J. Appl. Phys. 2013, 114, 223716. [Google Scholar] [CrossRef]

- Bikowski, A.; Welzel, T.; Ellmer, K. The impact of negative oxygen ion bombardment on electronic and structural properties of magnetron sputtered ZnO: Al films. Appl. Phys. Lett. 2013, 102, 242106. [Google Scholar] [CrossRef]

- Ellmer, K. Magnetron sputtering of transparent conductive zinc oxide: Relation between the sputtering parameters and the electronic properties. J. Phys. D Appl. Phys. 2000, 4, R17–R32. [Google Scholar] [CrossRef]

- Agura, H.; Suzuki, A.; Matsushita, T.; Aoki, T.; Okuda, M. Low resistivity transparent conducting Al-doped ZnO films prepared by pulsed laser deposition. Thin Solid Film. 2003, 445, 263–267. [Google Scholar] [CrossRef]

- Stamate, E. Method for Improving Optoelectronic Properties of Transparent Conductive Oxide Thin Films. Denmark Patent Application No. 70572, 18 September 2019. [Google Scholar]

- Stamate, E.; Ohe, K. Influence of surface condition in Langmuir probe measurements. J. Vac. Sci. Technol. A 2002, 20, 661–666. [Google Scholar] [CrossRef]

- Stamate, E. Status and challenges in electrical diagnostics of processing plasmas. Surf. Coat. Technol. 2014, 260, 401–410. [Google Scholar] [CrossRef]

- Gao, J.; Nafarizal, N.; Sasaki, K. Measurement of Cu atom density in a magnetron plasma source using YBaCuO target by laser-induced fluorescence imaging spectroscopy. J. Vac. Sci. Technol. A 2006, 24, 2100–2104. [Google Scholar] [CrossRef]

| RF Power [W] | Sheet Resistance/sq | Hall Mobility [cm2/Vs] | Carrier Concentration [cm−3] | Resistivity [cm] | Averaged Transmittance [%] |

|---|---|---|---|---|---|

| 10 | 2320 | 2.62 | 5.07 × 1019 | 4.69 × 10−2 | 92.2 |

| 15 | 311 | 6.93 | 3.05 × 1020 | 2.95 × 10−3 | 89.6 |

| 20 | 175 | 7.15 | 3.84 × 1020 | 2.27 × 10−3 | 86.2 |

| 25 | 67.2 | 9.33 | 4.33 × 1020 | 1.54 × 10−3 | 87.7 |

| 30 | 13.6 | 17.3 | 6.63 × 1020 | 5.45 × 10−4 | 88.5 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stamate, E. Spatially Resolved Optoelectronic Properties of Al-Doped Zinc Oxide Thin Films Deposited by Radio-Frequency Magnetron Plasma Sputtering Without Substrate Heating. Nanomaterials 2020, 10, 14. https://doi.org/10.3390/nano10010014

Stamate E. Spatially Resolved Optoelectronic Properties of Al-Doped Zinc Oxide Thin Films Deposited by Radio-Frequency Magnetron Plasma Sputtering Without Substrate Heating. Nanomaterials. 2020; 10(1):14. https://doi.org/10.3390/nano10010014

Chicago/Turabian StyleStamate, Eugen. 2020. "Spatially Resolved Optoelectronic Properties of Al-Doped Zinc Oxide Thin Films Deposited by Radio-Frequency Magnetron Plasma Sputtering Without Substrate Heating" Nanomaterials 10, no. 1: 14. https://doi.org/10.3390/nano10010014

APA StyleStamate, E. (2020). Spatially Resolved Optoelectronic Properties of Al-Doped Zinc Oxide Thin Films Deposited by Radio-Frequency Magnetron Plasma Sputtering Without Substrate Heating. Nanomaterials, 10(1), 14. https://doi.org/10.3390/nano10010014