1. Introduction

Around the world, marine infrastructure such as ports, bridges, seawalls, and offshore wind farms is a key for global logistics and energy and marine industries. However, these structures are directly exposed to harsh environmental conditions–such as seawater, repeated tidal actions, and climatic variations–over extended periods of time, resulting in material degradation and structural defects. Reinforced concrete structures cause corrosion, cracking, and peeling due to chloride penetration, reducing structural strength and durability and increasing long-term maintenance costs [

1,

2]. Such damage is initially difficult to identify with the naked eye, increasing the need for early diagnosis and systematic monitoring [

3].

To date, marine concrete structure inspections have been mainly approached by divers or maintenance personnel, relying on visual inspections or intermittent coring. However, this approach is less reliable due to subjectivity and environmental constraints, and precise inspection of large-scale structures or underwater and near-surface members is nearly impossible [

4]. It is also time-consuming and expensive and comes with safety issues. As a result, Non-Destructive Testing (NDT) has emerged as a key tool in the maintenance and safety diagnosis of marine infrastructure [

5].

NDT can detect internal and surface defects without damaging structures, which has contributed to reduced maintenance costs and extended structural life. Ultrasound, Acoustic Emission (AE), Ground-Penetrating Radar (GPR), Infrared Thermal imaging (IRT), and optical imaging techniques are applied not only to terrestrial structures but also to marine structures. However, ocean turbidity, waves, water temperature, salinity changes, bio-attachment, etc., cause attenuation and scattering of NDT sensor signals, degrading the accuracy of data interpretation [

4,

5]. For example, ultrasound technology is advantageous for deep concrete detection, but defect identification is difficult because of scattering caused by seawater, whereas GPR is effective for surface defects, but the high conductivity of seawater constrains deep detection [

6,

7]. As such, existing NDT technology has limitations in early diagnosis and real-time monitoring due to lack of measurement reliability and precision under extreme conditions of marine structures.

Recently, to overcome these limitations, research on the incorporation of Artificial Intelligence (AI) into NDT data analysis has been active. AI learns large-scale image and signal data to suppress noise, automatically identify defect-specific patterns, and correct data deviations between sensors and equipment [

8,

9]. Furthermore, time-series analysis of long-term monitoring data has been applied to estimate damage progress and residual life, enabling the transition from conventional reactive maintenance to predictive maintenance [

10,

11,

12,

13]. This approach is particularly effective for subjects with complex conditions and long inspection cycles, such as marine structures. AI improves data interpretation accuracy and optimizes sensor placement and inspection routes, increasing efficiency and reducing dependence on skilled operators through high-resolution imaging and automated classification [

4,

14,

15].

This paper provides a comprehensive and critical review of recent developments in AI-based non-destructive testing for marine concrete structures. It aims to synthesize state-of-the-art knowledge, evaluate the performance of AI-based non-destructive testing in real marine environments, and understand the effects and limitations of current approaches.

2. Current NDT Techniques for Marine Applications

Marine concrete structures such as port inner walls, breakwaters, maritime bridges, and offshore wind power foundations are exposed to continuous waves, currents, and tidal waves. In this exposed environment, chloride slowly penetrates and corrodes the rebar, and the tensile stress caused by corrosion expansion causes microcracks, leading to surface scaling and spalling [

16,

17]. Accordingly, NDT, which detects and monitors internal defects without damaging the structure to extend the life of the structure, becomes the core of maintenance [

18,

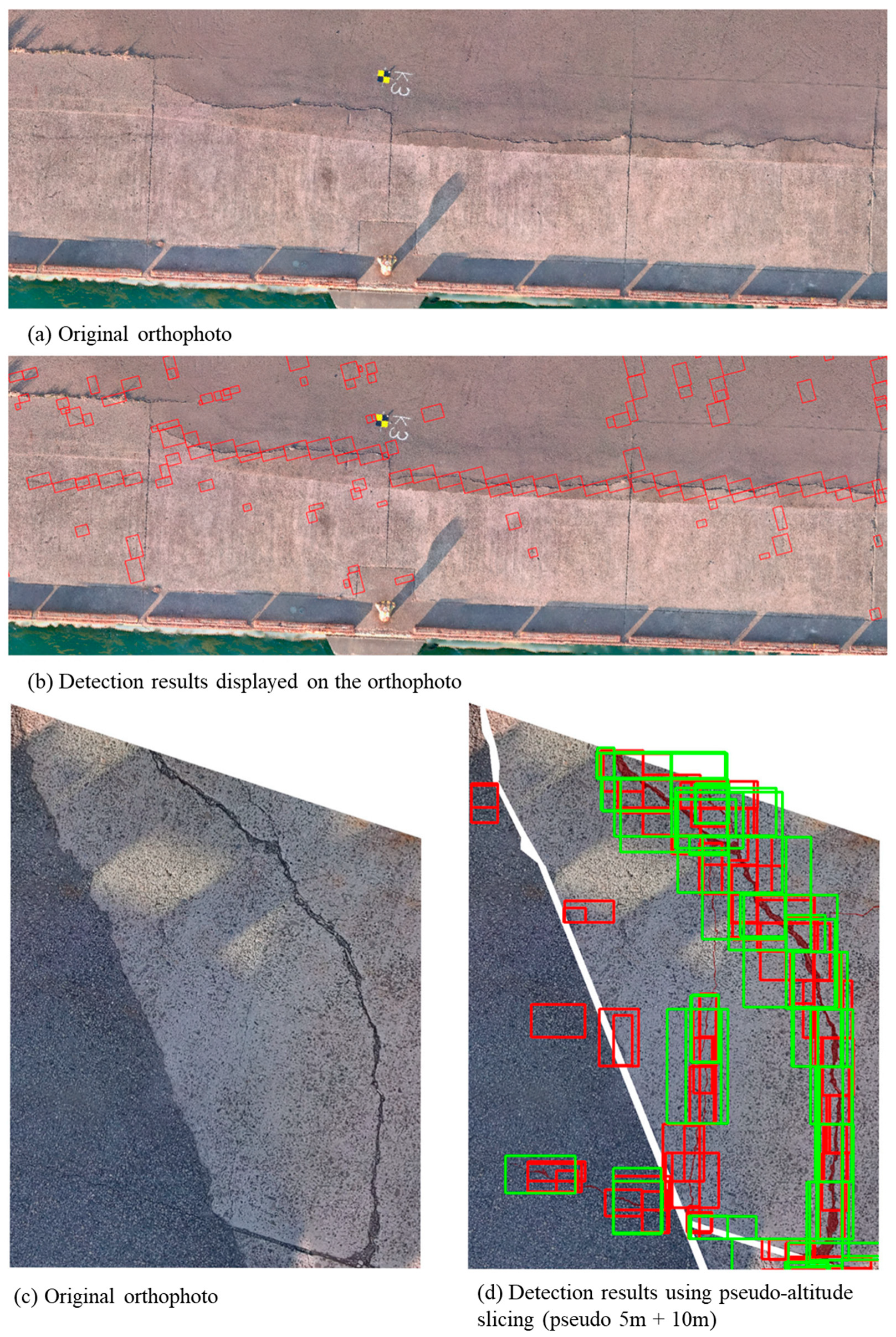

19]. Currently, several types of NDT are applied to marine structures for marine structure inspection. There are various types of tests present in NDT. Among them, the technique of collecting images using the optical principle of a measuring instrument and conducting inspection with the collected images is called optical image-based inspection, as shown in

Figure 1.

Figure 1 shows the interconnected flow of optical NDT, in which various types of observation devices use optical principles and analyze the observed data through IRT, visual observation, etc. Optical image-based examination is the most intuitive method among NDT techniques and is a method of diagnosing surface degradation based on visual information. Traditionally, it was conducted through visual inspection, but recently, it has been digitized, enabling inspections in a manner suitable for the underwater environment and tidal table using Unmanned Aerial Vehicles (UAVs), Remotely Operated Vehicles (ROVs), and diver cameras. UAVs can photograph the outer walls and upper structures of the water surface with high-resolution RGB and thermal images to identify cracks, spalling, and rebar exposure. ROVs photograph the outer walls, foundation, and caisson joints of the water and ae equipped with auxiliary light sources to reduce the effects of turbidity or algae [

4,

14].

IRT is effective in quickly detecting cracks in thermal images in areas where internal bonding defects or spalling are suspected by measuring the temperature distribution of the surface [

20,

21]. Through thermal images of a concrete bridge deck specimen and a bridge in Ontario, Canada, the spalling of a bridge deck and port block in Lavrio, Greece, was detected, and research is being conducted to accurately determine the crack size and apply it to the actual operating infrastructure by combining optical image-based inspection with Impact Echo (IE) or ultrasonic inspection, which are types of signal NDT [

14,

20,

22]. In addition to optical image NDT, a signal-type system between the instrument and the data logger can be implemented as a technique that collects data using an instrument for NDT and analyzes the collected data through a data logger [

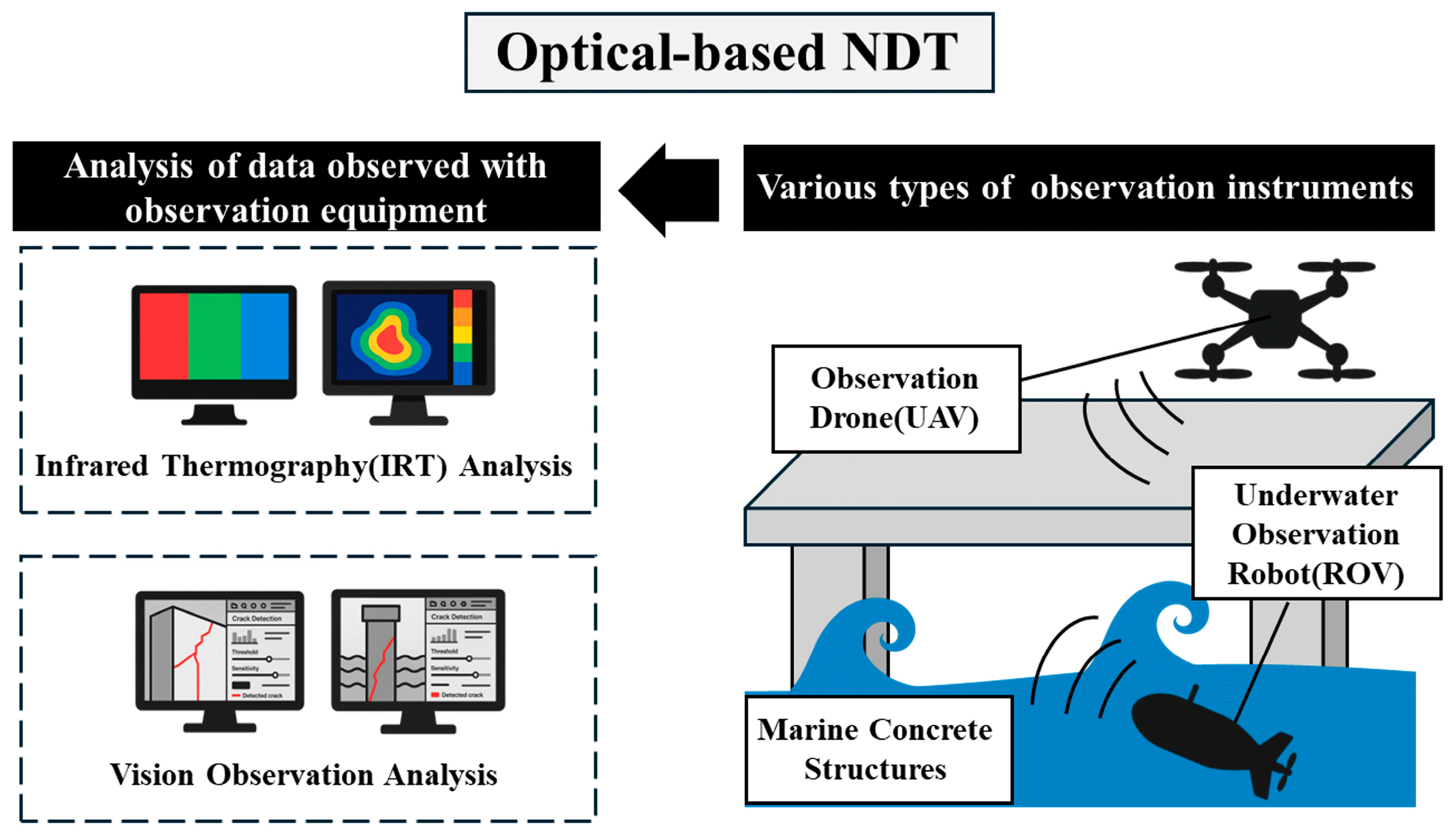

23]. These signal-type systems are transmitted and received based on waves, and the technique varies depending on the wave transmitted and received, which is shown in

Figure 2.

Wave-based NDT is a method of measuring sound waves and ultrasonic waves, with the method divided according to wave activity and passivity in wave measurement. There are Ultrasonic Tests (UTs) that measure transmitted waves by injecting signals in a way that actively transmits waves, in addition to Impact Echo (IE) and Acoustic Emission (AE), which passively detect natural acoustic waves that crack or emit inside the structure [

24]. UT measures the Ultrasonic Pulse Velocity (UPV) by injecting ultrasonic waves into concrete structures to determine internal defects in marine structures. The measured UPV is analyzed and judged by quantifying the homogeneity and crack degree of concrete. In addition, Phased Array UT (PAUT) is an internal tomography image in which sound waves from various directions are arranged in a pattern using a phased array transducer, and IE estimates the spalling depth or thickness using reflection frequency components [

24,

25]. These active techniques are effective in determining internal conditions by injecting signals from the outside and measuring reflection and scattering. AE manually detects natural acoustic waves inside the structure, placing multiple sensors to capture the signal and analyze the time difference to estimate the location of the damage. AE is effective in checking the condition of structures after typhoons, earthquakes, and ship collisions because it can monitor the crack activity of structures in real time [

24,

26]. A radiation test transmits X-rays or gamma rays to image internal pore, discontinuity, and weld defects [

24,

26]. Due to radiation handling regulations, safety concerns, and shielding requirements, its application is extremely limited in marine structure sites. Some steel welds have been limitedly used, but they do not apply to large concrete structures [

27]. Therefore, the use of RTs is evaluated as a technique that is theoretically possible for marine structures but has low practical utility. Eddy current tests, GPR, etc., can be used in such a way as to detect cracks in structures by measuring transmitted or reflected electromagnetic waves by irradiating electromagnetic waves. GPR diagnoses spalling and cracking by emitting high-frequency electromagnetic waves into the structure to analyze the reflected signal. In addition, the dielectric constant change of the signal is analyzed to evaluate the relative moisture distribution and salt penetration tendency [

28]. However, marine concrete has high moisture and salt contents, so electromagnetic attenuation is severe, and the depth of detection is limited due to the large change in dielectric constant of the surface salt membrane. Therefore, GPR has strength in evaluating rebar position and cladding thickness, but there is a limit to long-term moisture and salinity tracking [

29].

Reinforced corrosion is one of the most important mechanisms of marine structure degradation. Various electrochemical techniques have been introduced to evaluate this. The Half-Cell Potential (HCP) electrically connects the reinforcement and measures the potential through the external reference electrode to measure the corrosion position of the reinforcement in a simple way. It is easy to investigate potential in places such as large bridge decks and sidewalls [

30]. Electrical Resistance (ER) measures corrosion risk through ion mobility and measures electrical resistivity through the two electrode methods—namely, the Wenner probe method (WPM) and the electrode disk test method, which is effective in evaluating chloride-induced deterioration conditions [

31].

Auxiliary techniques include sonar series, Fiber Optic Sensors/Distributed Fiber Optics Sensors (FOSs/DFOSs), and Wireless Sensor Networks (WSNs). To prevent collapse caused by the foundation erosion of Irish viaducts, the type of Sona (multibeam or side-scan) evaluates changes in cave, erosion, and protrusion by generating the outer shape of the structure as a point group when visibility is not secured underwater [

32]. WSNs represent a method of monitoring by detecting physical variables and transmitting data through multiple sensors. Through this monitoring, water temperature, pressure, wind direction, salinity, pH, etc., can be measured and diagnosed [

33]. Compared to monitoring that needs to be carried out by attaching many sensors, FOSs, which have relatively small and low power loss, are attached to marine infrastructure facilities and large structures and are used for real-time structural health monitoring. However, FOSs, which can monitor salt and crack growth by tracking strain, temperature, and humidity over a long period of time, are subject to many disturbances in deep sea environments, so continuous development of fiber optic technology is required [

34].

3. Limitations of Conventional NDT and the Need for AI Integration

Unlike inland structures, marine concrete structures are continuously exposed to tidal zones and salt-saturated environments, and complex and quantifiable damage mechanisms exist not only on the surface but also within the concrete [

35]. A study on concrete columns exposed to tidal environments showed that the chloride-dominated convection layer was 22–24 mm in the presence of cracks and 6–7 mm in the absence of cracks, confirming that corrosion progression tended to be concentrated in the surface layer [

16]. Furthermore, in the early stages of cladding delamination, crack opening (COD) occurs along with deformation that causes the cladding to gradually lift off due to internal reinforcement corrosion. This cladding lift and COD have been measured through accelerated corrosion experiments [

1]. Because such damage is not clearly visible externally, detection is limited to visual inspection or a single NDT. This confirms the limitations of existing nondestructive testing techniques for exposed marine structures.

In a study on structural delamination detection using infrared thermal imaging (IRT), the detection accuracy under field conditions was reported to be 68–79%, with an average of approximately 69%, indicating that heat distribution-based methods, which are sensitive to changes in wind, moisture, and solar radiation, face the risk of data loss and false positives detections in marine environments [

20,

21,

22,

36]. In the case of the ultrasonic wave (UPV) method, a study showed that the P-wave velocity decreased by approximately 2–4% when the temperature increased from 20 to 40 °C, which is far higher than the typical sensor/contact error (0.1–0.5%). Therefore, systematic bias may occur in intensity conversion in environments such as marine structures where water temperature, contact conditions, and saturation fluctuate [

37]. In addition, in GPR exploration experiments on wet concrete, signal penetration was significantly reduced as moisture and salinity increased, which may reduce the reliability of delamination identification [

6].

These inaccurate non-destructive testing results not only limit technical applications but also cause direct economic losses. During the maintenance phase of marine infrastructure, the rate of unnecessary repairs and reinforcements due to misdiagnosis is approximately 17–23% of the total maintenance. If repeated repairs occur due to underestimation of defects, the total maintenance cost increases by 1.6–2.2 times over the life cycle [

5,

38]. Life cycle cost (LCC) analyses of port and bridge structures have also shown that shortening the maintenance cycle due to inaccurate diagnosis increases the overall LCC by approximately 10–20% of the initial construction cost and by up to 24% in some aging marine structures [

5,

38]. Furthermore, misdiagnoses from inaccurate non-destructive testing result in indirect losses due to port operations interrupted for maintenance, amounting to USD 1200–4800 per hour and USD 3000–5000 per hour for bridges and large port facilities [

38,

39]. NDT, which has low reliability for application in marine environments, is a major cause of economic inefficiency that goes beyond simple diagnostic errors and leads to increased maintenance costs and operational downtime losses.

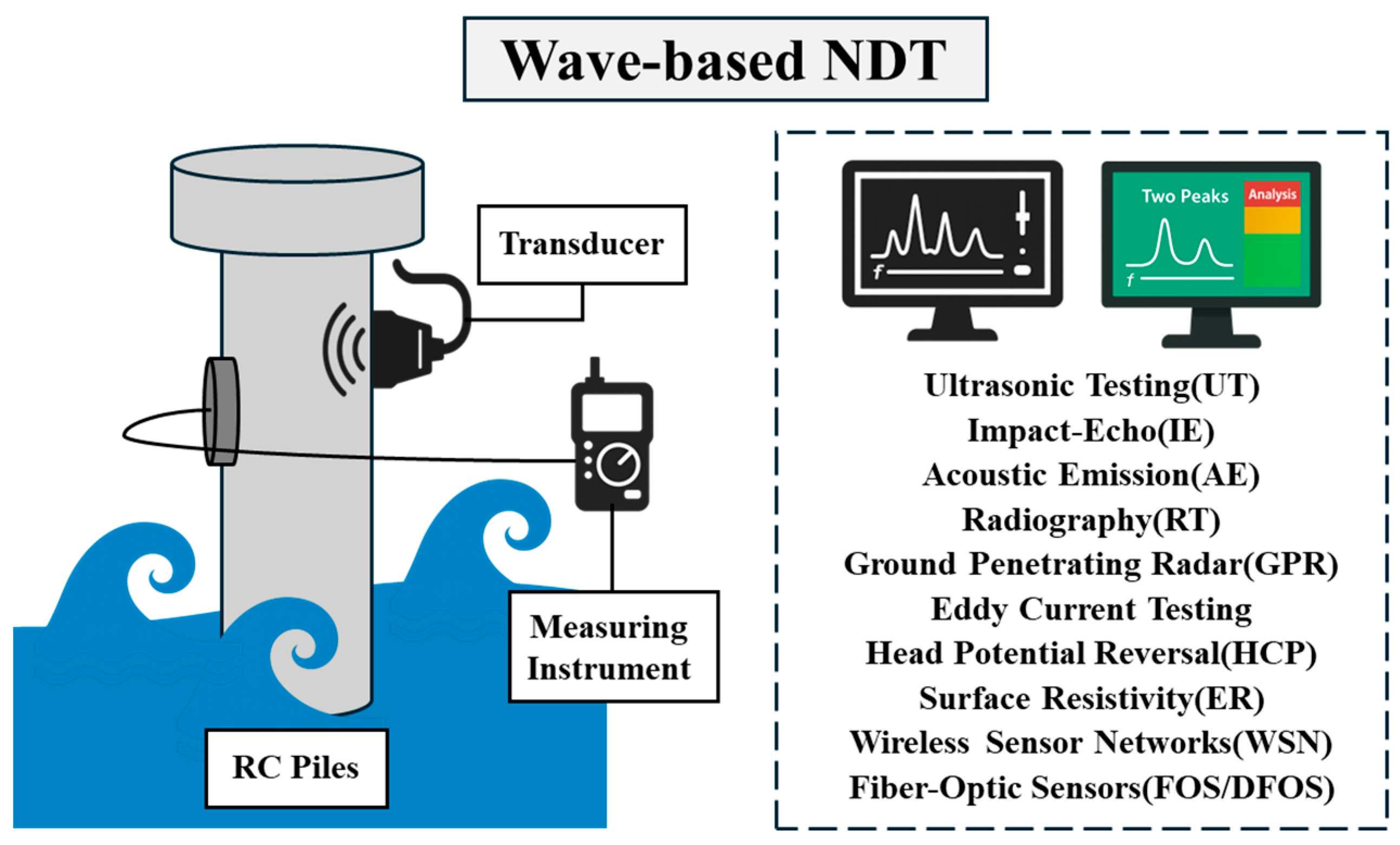

Ultimately, when applying NDT to marine environments, errors occur in each NDT type due to marine vulnerabilities, and these errors accumulate uncertainty during data processing and monitoring. This process is schematically illustrated in

Figure 3. By introducing AI that can learn data patterns and correct uncertainty at the point of error occurrence, as classified in

Figure 3, we aim to enhance the reliability of NDT applications in marine environments. Therefore, we want to increase the reliability of NDT applications in marine environments by introducing AI that can learn data patterns and correct uncertainties in the error occurrence stage. For example, as shown in

Table 1, AE signals are vulnerable to wave and vibration noise, but LSTM and CNNs can effectively distinguish between noise and defect signals and estimate the location of crack propagation.

Even in IRT, CNNs and Transformers automatically detect fine damage and predict deterioration progress. In addition, in the case of GPR, reflective wave distortion depending on environmental conditions can be corrected with DNNs and GAN-based learning, and drone image-based exploration has already shown the ability of AI to improve reliability at each NDT stage, such as YOLO identifying cracks and corrosion in real time. Therefore, as shown in

Figure 3, to effectively compensate for errors occurring in marine vulnerability, data processing, and monitoring, a strategy that selectively introduces AI techniques suitable for the characteristics of each stage is needed. Chapter 3 discusses the necessity and specific role of applying AI in each of these error stages in more depth.

3.1. Marine Vulnerabilities and AI Enhancement of Visually Based NDT

Optically based imaging and thermal imaging tests have been used as a method of directly identifying and diagnosing surface damage. Cracks, spalling, and rebar exposure can be observed relatively easily with camera images or thermal images. However, in marine structures, the results of optical imaging are different from those on land. In the underwater environment, the absorption and scattering of light drastically lowers the image contrast; in particular, red light is quickly lost, distorting the color information. On the surface of the water, the image is blurred or geometric distortion occurs due to the shaking of the wave and the measuring instrument, and illuminance changes and water surface reflection produce different images depending on the time and conditions, even for the same object [

40,

41,

42]. Moreover, marine life and floaters cover surfaces or block vision, making defect detection more difficult. Diagnosis and prediction results based on these images lead to errors, which degrade the reliability of NDT. To solve existing problems simply by using high-resolution cameras or enhancing lighting, the specificity of marine structures should be considered further [

43].

AI complements the optical limitations in these underwater environments. Although the measuring instrument is the same, the use of GANs, YOLOv9-OREPA, or Transformer-based image restoration models in the preprocessing stage of data can correct color distortion and contrast degradation of underwater photographed images to minimize optical distortion [

40,

42,

44,

45]. Furthermore, defects such as cracks and spalling are learned to be more exposed during the calibration process, and deep learning models such as CNNs, U-Net, and SegNet can automatically analyze thousands of images to detect defects and quantify their size and area [

40,

41,

42,

43,

44,

45,

46]. Unlike conventional methods that rely on qualitative judgment, this process provides objective and repeatable results.

Table 1.

Results of applying AI to NDT (AE, IRT, GPR, UAVs, ROVs, and UT).

Table 1.

Results of applying AI to NDT (AE, IRT, GPR, UAVs, ROVs, and UT).

| NDT Type | AI Type | Expected Effect | Ref. |

|---|

| AE | LSTM

CNN | Effectively distinguish between noise and defective signals

Estimate crack propagation trends and locations

Automatic recognition of unique damage patterns | [10] |

| IRT | CNN

Transformer | Automatic detection of micro-damage areas

Precisely predict damage progression trends | [40,41,42,43,44,45,46] |

| GPR | CNN

DNN

GAN | Automatic detection of internal voids or rebar placement

Generate virtual reflected wave data to provide reinforcement material for learning | [37,47,48] |

Drone(UAV) and

Robot-based video

inspection | CNN

YOLO

SegNet | Detect cracks, delamination, and corrosion

Detect cracks in real time

Quantify the area of damage | [49,50,51] |

| UT | YOLO

Random Forest | Predict compressive strength

Reliable fault detection, even in noisy signals | [52] |

3.2. Marine Vulnerability and AI Enhancement of Signal-Based NDT

NDT, which utilizes signal-based techniques such as frequency-modulated continuous wave, acoustic emission, and eddy current techniques, can observe linear defects up to 0.5 mm deep and 5 mm long and detect discontinuous internal concrete defects of 1 to 5 mm in size [

53]. These non-contact, signal-based NDTs detect various defects through various sensors. However, signal distortion and noise problems are serious in the marine environment. Ultrasound waves have a different propagation speed due to changes in moisture saturation and salt concentration, and the results vary greatly depending on the time point and conditions, even in the same structure [

24,

25,

26]. In the impact echo, reflective waves are abnormally scattered due to microcracks and surface wetting, and in the AE technique, noise caused by external factors such as waves, mechanical vibration, and ship noise is difficult to distinguish from noise caused by defects [

24,

26]. GPR is limited to a depth of penetration within a few tens of centimeters due to its seawater conductivity, and clutter occurs significantly when reinforcement arrangements and voids overlap [

28,

29]. In addition, signal-based NDTs are often measured by attaching sensors, and in marine structures, the combination of sensors and surfaces is a problem. It is difficult to inspect NDT in marine structures due to problems such as surface roughness and bio-attachment, and water film destabilizes the bond and disturbance of the signal as a result of turbulence and pressure changes [

54].

However, AI can correct and minimize factors that affect signal-type techniques in the marine environment. The use of ultrasound data enhances the reliability of strength estimation by integrating measurements of wave velocity, density, and moisture content, and combining information from multivariate models such as ANNs and random forests, which are subsequently cross-validated with the original data [

8]. CNN-based approaches analyze ultrasound signals by converting them into spectrograms to capture missing fault patterns in simple domain interpretation [

9]. AE data show that CNNs classify noise and defect signals, while LSTM learns time-series patterns to predict the trend of cracks [

10]. On offshore wind blades, the AE-LSTM fusion model succeeded in optimizing maintenance strategies by capturing microcrack growth patterns early [

55]. GPR utilizes CNNs and DNNs to automatically detect rebars and voids and complements the data scarcity problem with synthetic data generation using GANs [

47,

48]. Recently, research on the quantification of the reliability of prediction results by combining uncertainty estimates has also been active [

37].

Reinforced corrosion is one of the biggest factors shortening the lifespan of marine structures. HCP, Electrical Resistance (ER), Electrochemical Impedance Spectroscopy (EIS), etc., are used to evaluate this. However, these techniques are difficult to apply to marine environments. However, the measurement method involves measuring the value by touching an electrode to a surface or structure, and electrode contact is unstable underwater, making it difficult to collect data, and the water temperature and salt concentration cause considerable fluctuations in the potential and resistance values. In long-term monitoring, electrode polarization accumulates, resulting in poor reliability of measurements. EIS requires the fitting of complex impedance curves into equivalent circuits, a process that is inefficient for large-scale structure evaluation [

11,

12,

13,

18,

56,

57,

58].

Data stabilization is maximized by fusing AI with electrochemical NDT techniques with these limitations. Machine learning regression models learn potential resistance data, along with environmental variables, enabling much more precise corrosion likelihood assessments than simple thresholds [

59]. XGBoost or autoencoders transform the impedance spectrum into a feature space, which automatically extracts equivalent circuit parameters and interprets large-scale data in real time [

60,

61,

62]. This AI-integrated electrochemical NDT technique accumulates learning data based on environmental variables rather than calculating real-time analysis and simple measurement values to minimize the data loss of electrochemical techniques.

3.3. AI Enhancement in Data Processing and Monitoring

Marine structures have different locations, designs, construction methods, and environmental conditions, and even in the same marine structure, the expression of images and signals varies depending on the angle and illuminance of the measuring instrument; even cracks in the same structure have different water temperatures and salinity depending on the location of the cracks [

40,

41,

42]. Therefore, if the data reference model of the measuring instrument is overfit to a specific condition, a problem arises such that the performance of a new structure or other locations in the same structure rapidly deteriorates. In particular, the data collected by NDT using UAVs and ROVs is inconsistent [

49,

50]. To solve this problem, AI intermediate transfer learning and domain adaptation are utilized. Transfer learning maintains performance by rapidly calibrating large pre learning models with small amounts of field data and calibrating measurements in real time [

50]. Domain adaptation learns invariant features by reducing differences in data distribution between different environments and increases the reliability of continuous measurements based on these values [

51]. The AI virtually corrects the difference in photographing conditions, thereby enhancing the adaptability of NDT in the marine environment [

63]. Furthermore, by quantifying uncertainty and using Bayesian neural networks or ensemble models to provide confidence intervals to predictions, maintenance managers are being studied to make decisions considering the reliability of AI results [

37,

64]. This is the development of AI from a simple analysis tool to an auxiliary means of an actual management system [

65].

Traditional NDT is a method of identifying short-term defects through periodic inspections. However, in marine structures, it is difficult to properly grasp the deterioration process without long-term monitoring because the damage is continuously caused by accumulated blue algae and repetitive loads [

39]. Optical fiber sensors, long-term AE devices, strain meters, vibration sensors, etc., can provide real-time data, but the vast amount of data and complex patterns result in time-consuming processes and economic loss associated with the data interpretation [

36,

65].

AI processes such monitoring data in real time to create a pre-emptive management system. LSTM and Transformer models learn long-term time-series data to distinguish normal fluctuations from abnormal patterns and detect signs of damage early amid microscopic changes. This contributes to the establishment of maintenance strategies by quantifying the crack growth rate, deterioration trend, and remaining life span [

66,

67,

68]. With multi-sensor fusion, the combination of AE and fiber optic sensors can track crack position and stress distribution simultaneously, and the combination of ROV images and electrochemical data can evaluate both surface defects and internal corrosion [

69,

70]. In real-world cases, multimodal AI models integrated with drone images, AE, and GPR data have shown significantly higher accuracy and reliability compared to single techniques [

68,

69,

70]. As such, AI-based monitoring can go beyond simple diagnosis and lead to a long-term maintenance system that considers the life cycle of the structure [

71]. By converting AI, it is possible to shift the paradigm from post response-oriented management to pre-emptive prevention-oriented management and secure the safety and economic feasibility of the structure.

4. Performance Evaluation of AI-Integrated NDT for Marine Concrete Structures

As discussed in

Section 3 above, it was confirmed that AI must be introduced to increase the reliability of NDT in the marine environment and that AI can play an important role in the design process, especially in areas with a high probability of error and reinforcement points.

Section 4 examines how this need is being implemented in the actual field. It is divided into a visually based NDT technique and a signal-type NDT technique to examine how each technique has been combined with AI in the inspection and monitoring of marine concrete structures and what performance improvements have been achieved compared to the existing method through the use of examples. Across all reviewed case studies, AI integration improved detection accuracy by an average of 17–25% compared to conventional NDT methods. The mean increase in mAP for vision-based NDT was 4.0%, and the average rise in signal-based NDT accuracy (GPR, AE, and UT) was 15–20%. These quantitative improvements demonstrate the clear benefit of AI convergence in enhancing reliability and precision under marine environmental variability [

15,

63,

72,

73].

4.1. Visualy Based NDT

4.1.1. Port Application of Gouqi Island in the East China Sea

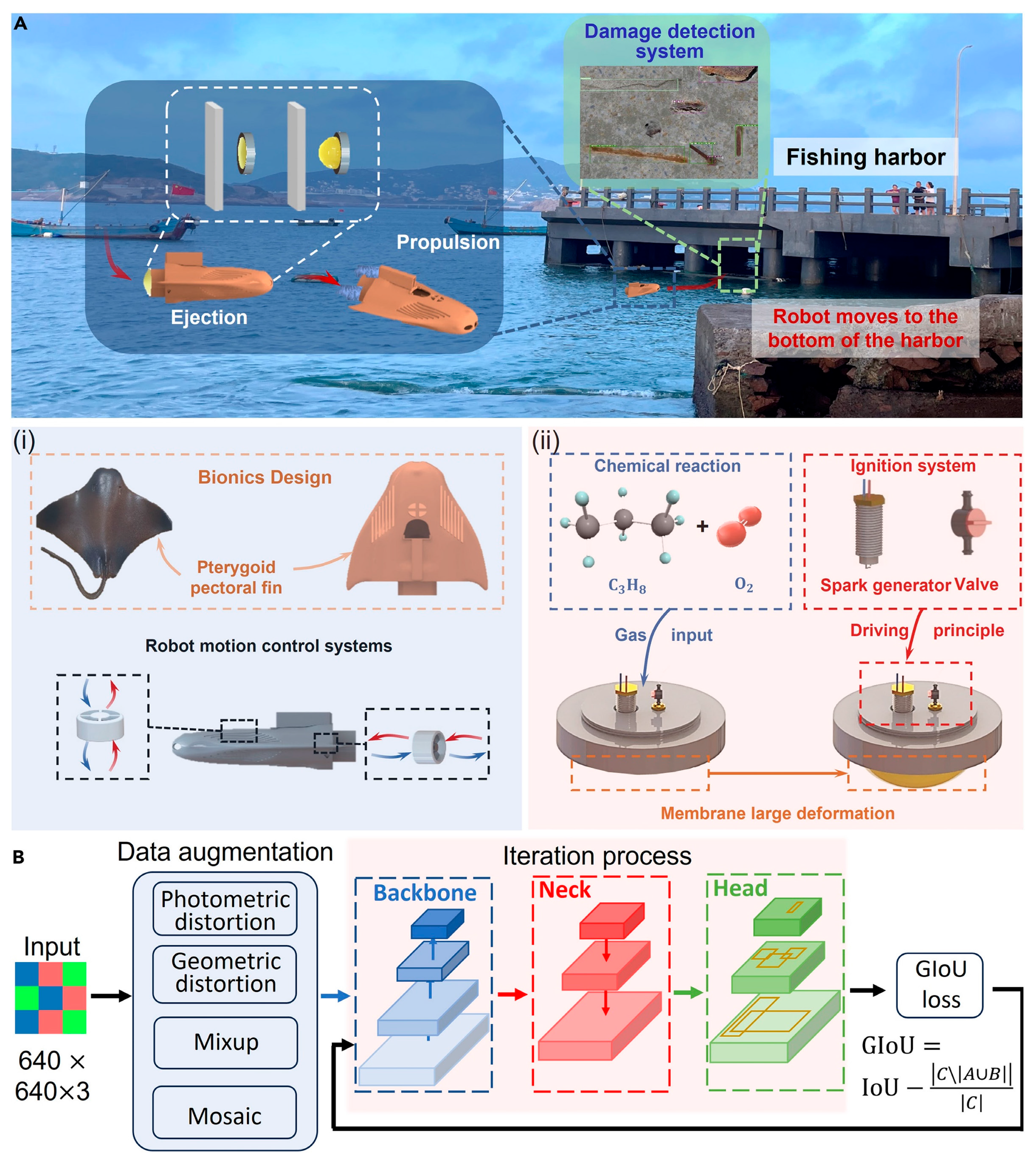

Concrete at the port located on Gouqi Island, East China Sea, is in underwater conditions, and it is difficult to detect cracks and determine internal defects due to continuous waves. As a method of monitoring structural damage to these underwater structures, we used an optically based NDT that photographs port concrete using an underwater robot from the Mantaray model and monitors structural damage [

73]. However, in this process, underwater visibility conditions are affected by depth and turbidity, resulting in poor quality in data processing due to distorted color and illuminance-induced image data [

4,

14]. Therefore, the YOLOX-DG algorithm was integrated with a robot to construct data on concrete targets, and the damage was diagnosed by dividing the data into cracks, spalling, exposed rebar, and corrosion with a multi attribute determination algorithm. In this process, photometric distortion, geometric distortion, and mixed mosaic techniques are utilized for data augmentation; IoU loss is changed to GIoU loss; and performance is improved from mAP 0.5 to 2.6% and mAP 0.5:0.95 to 4.5%, an algorithmic performance indicator of detection performance for cracks [

73].

In addition, image processing-based NDT determines the reliability of the data based on the angle and accuracy of the image, and in the case of underwater environments, operation control is poor, resulting in a problem of poor image reliability. However, with the Transient Driving Method (TDM), the underwater robot can be teleoperated within 0.1 s, allowing for fast obstacle avoidance and quick response start [

73]. For this reason, structural damage monitoring using ROVs for marine concrete structures can be applied as an optically based NDT method.

Figure 4 visually shows the robot-based damage detection technique and the application process of the YOLOX-DG algorithm. In (i) and (ii) of

Figure 4A, the driving principle of the Mantaray model robot is shown, and in (B), the learning procedure of the detection algorithm using light intensity, geometric distortion correction, mixed mosaic-based data augmentation, and GioU loss can be clearly identified.

4.1.2. Example of Underwater Image Correction for Visually Based Autonomous Underwater Vehicle (AUV) Photography

Autonomous Underwater Vehicles (AUVs) are equipment capable of applying optically based NDT, like ROVs and UAVs, and are widely used for the monitoring of damage such as cracking, spalling, and corrosion of concrete structures in underwater environments [

74]. However, in the underwater photographed image, serious color distortion and contrast deterioration occur due to suspended particles, light scattering, and absorption. It is difficult to accurately grasp the state of the original structure due to the rapid attenuation of red light in the long-wavelength region; furthermore, the image is skewed to cyan, and noise and blurring phenomena are added [

75].

To solve this problem, a physical model-based color correction technique was initially applied, but there was a limit to the correction performance because it did not reflect various underwater conditions. Recently, CNN-based AI models have been used to perform noise suppression and image contrast improvement through large-scale data learning. However, CNN methods require vast amounts of test data and suffer from poor generalization performance for new environments. To compensate for this, the convergence of conditional Generative Adversarial Networks (cGANs) enables learning optimized for a specific domain with only a limited number of test data [

72].

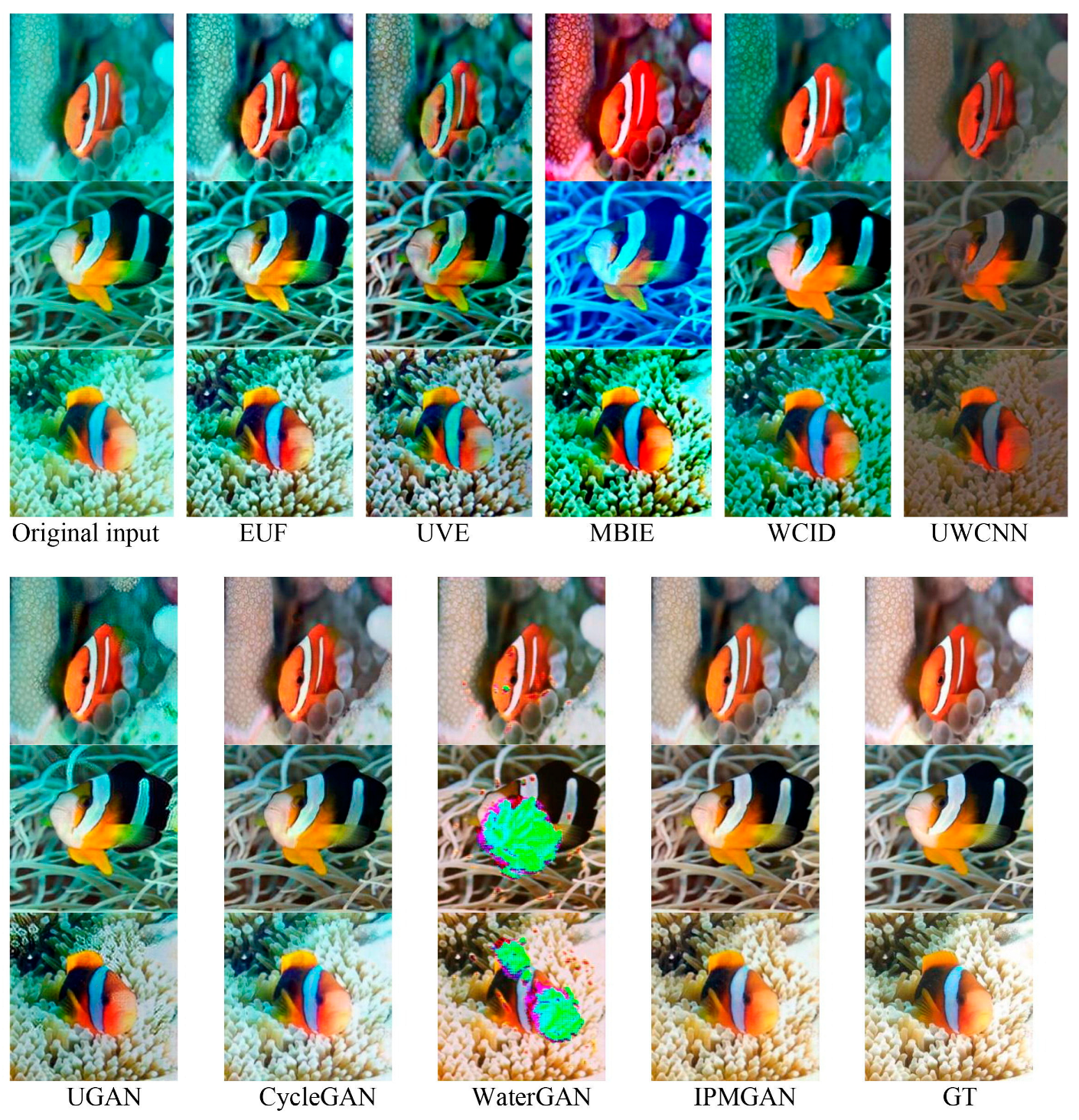

Figure 5 presents the results of various correction techniques, comparing these problems with the results of the original image and physically based models (EUF, UVE, MBIE, WCID), CNN-based models (UWCNN) and GAN-based models (UGAN, CycleGAN, WaterGAN, and IPMGAN) models. Physical models and single CNN-based techniques still suffer from cyan color distortion, contrast degradation, and detailed texture loss, while IPMGAN integrates physical model information into the network, showing the best results in terms of color restoration, contrast enhancement, and noise suppression. This represents the qualitative quality closest to the Ground Truth (GT).

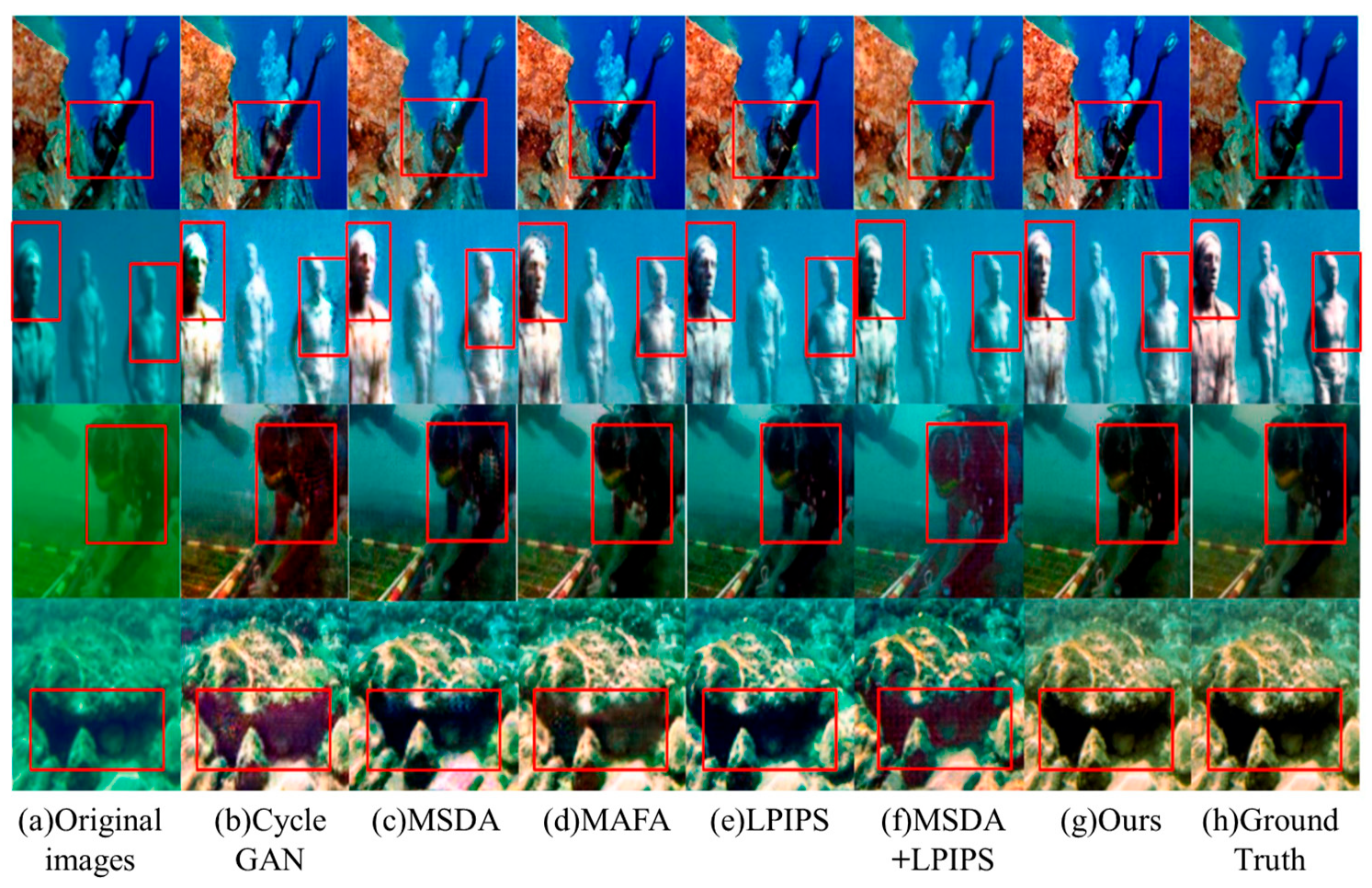

Figure 6 also compares the results of underwater image correction according to different AI techniques, presented side by side: (a) original images; (b) Cycle GAN; (c) MSDA; (d) MAFA; (e) LPIPS; (f) MSDA+LPIPS; (g) ours; (h) ground truth are [

63]. Comparison shows that CycleGAN and single feature-based techniques still exhibit color distortion, contrast degradation, and detailed structure loss, while the proposed technique combining Multi-Scale Adaptive Fusion (MSAF) and Learned Perceptual Image Patch Similarity (LPIPS) achieves natural color restoration and sharp boundary preservation, representing the closest visual quality to GT. This hybrid approach has contributed to improved image processing speed, color balance, and sharpness, even under complex underwater conditions, increasing the visual reliability required for real-world structural damage detection [

63,

72].

Therefore, this case shows that AUV-based underwater imaging, when combined with AI, can achieve significantly higher precision and efficiency than conventional simple correction techniques, representing important applicability for long-term monitoring and early damage detection for marine infrastructure.

4.1.3. Case of Application of the Interior Wall of Osaka Port in Japan

The inner wall of Osaka Port in Japan is continuously exposed to seawater, and precise inspection is difficult due to altitude changes, slopes, and the absence of scaffolding. Small general-purpose drones have been used because they are difficult for humans to access directly in such an environment. However, small drones have low resolution because they are equipped with low-cost cameras, making it difficult to detect microscopic cracks in the millimeter range [

15]. According to Japan’s Ministry of Land, Infrastructure, and Transport’s existing system for port facility inspection and diagnosis, the inspection threshold of crack width could be evaluated based on 3 mm, but early maintenance requires the ability to identify cracks at the 1 mm level [

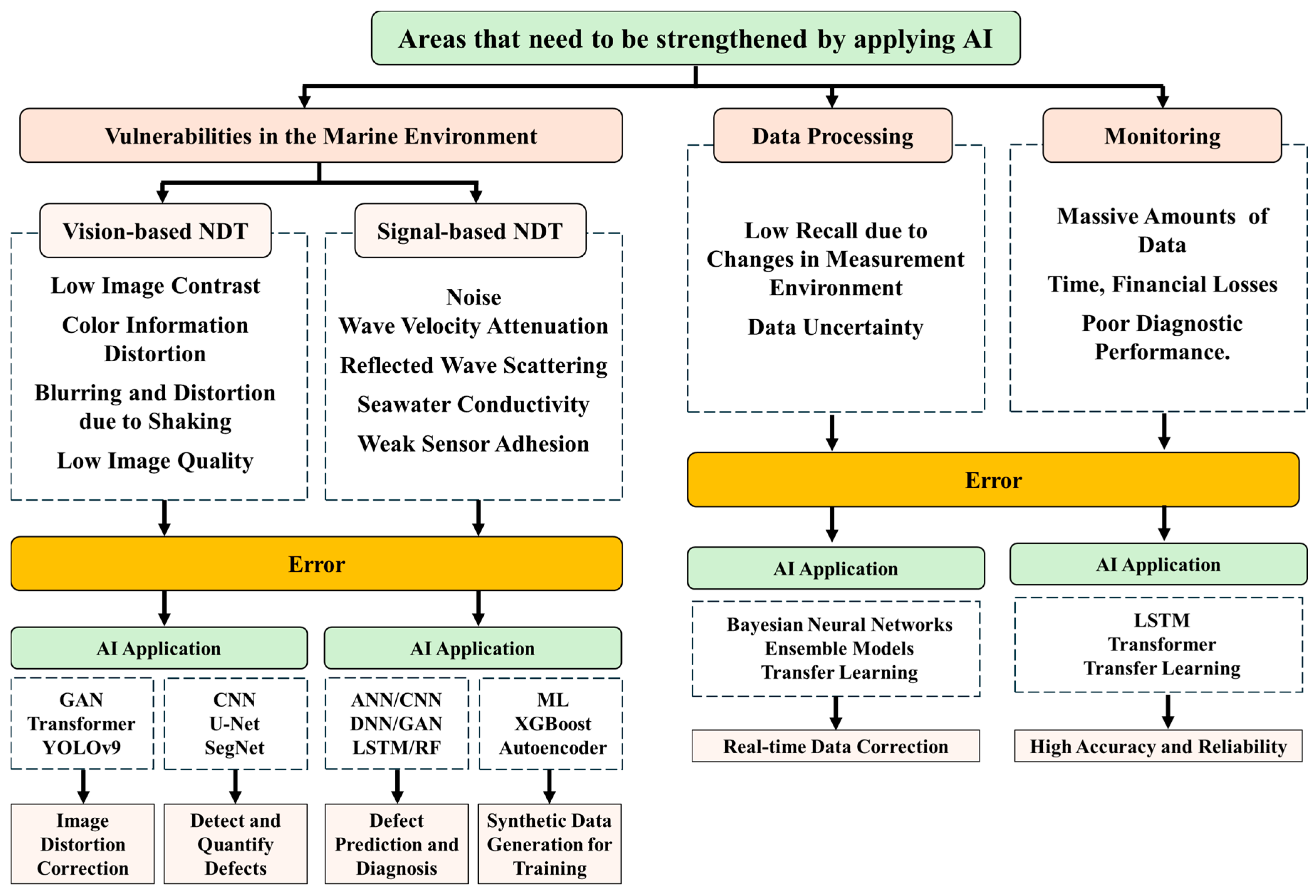

76]. To solve this problem, superimposed image tiling and pseudo level slicing techniques were applied in the image preprocessing process. Overlapping tiling reduced missed detections at the image boundary, and pseudo degree slicing improved the generalization performance of the detection model by virtually adjusting the drone’s shooting altitude to reproduce the crack size at various scales. Through the data preprocessing process, the reproduction rate improved by 24% due to the high efficiency of the YOLOR object detection algorithm. This enables early detection of deterioration and preventive maintenance by enabling stable identification of microcracks that were difficult to detect only with existing small drones.

Furthermore, the detected crack information was mapped with geographic coordinates on orthogonal photographs, allowing for the quantitative tracking of damage changes over time [

15]. The Osaka Port case is a prime example of how AI and NDT convergence technologies can significantly improve cost efficiency while securing performance equivalent to that of commercial systems in actual marine infrastructure maintenance scenario.

Figure 7 visually shows the NDT application case of the Osaka Port inner wall presented in this study. (a) and (c) present the original orthogonal photo, (b) shows an image of the crack detection result applied with the YOLOR object detection algorithm on the orthogonal photo, and (d) presents the result of supplementing crack detection with the application of pseudo altitude slicing (5 m + 10 m) [

15]. This figure shows the process of improving crack detection performance through preprocessing and slicing procedures on the original image acquired by the drone and visually demonstrates the practical effectiveness of the proposed technique.

4.2. Signal-Based NDT

4.2.1. RC Slabs at Ferry Terminal (HKM) in Macao, Hong Kong and RC Pillars at Vehicle Quay (NP) in North Point

The RC slab of Macau Perry Terminal in Hong Kong and the RC pillar of the North Point vehicle pier are structures located in the ocean, and it can be confirmed that rebar corrosion occurred due to spalling through GPR. Surface cracks occurred, along with spalling in the RC pillar of the NP, identifying 15 coring locations by GPR for each spalling [

77]. Using this value as a verification value, the experimental design of the field conditions and the time-course method were the same, and the concrete slab and concrete column were evaluated equally by GPR. As a result, there are differences between the experimental and verification values. Defects in the actual marine environment are peeled off, the rebar in the concrete corrodes, and the induced scattering increases, increasing the amplitude, and the presence of rust and cracks on the surface increases the amplitude. This can be confirmed through

Figure 8, which shows how the amplitude of the RC column of NP is formed. Relatively low amplitudes (−45 to −35 dB) are observed near the lower center, starting from the red point (the observation point), while relatively high amplitudes (−30 to −20 dB) are observed in some areas near the edges and in upper regions. These amplitude differences reflect the effects of the location, density, and internal concrete defects of the rebar and show that reflection and attenuation occur in the structural discontinuities as the NP signal propagates along the column [

77].

Figure 7.

NDT Case Study: Application of the YOLOR object detection algorithm to the quay walls of Osaka Port, Japan: (

a,

c) original orthophoto; (

b) detection results displayed on the orthophoto; (

d) detection results using pseudo altitude slicing (pseudo 5 m + 10 m) [

15].

Figure 7.

NDT Case Study: Application of the YOLOR object detection algorithm to the quay walls of Osaka Port, Japan: (

a,

c) original orthophoto; (

b) detection results displayed on the orthophoto; (

d) detection results using pseudo altitude slicing (pseudo 5 m + 10 m) [

15].

Figure 8.

NDT Case Study: RC columns at North Point Vehicle Terminal (NP), Hong Kong [

77].

Figure 8.

NDT Case Study: RC columns at North Point Vehicle Terminal (NP), Hong Kong [

77].

Experimental values also tend to be similar, but they do not have the same results, so this gap must be corrected for application to actual marine environments. As a method of correcting marine environment exposure data collected by GPR, not only must the absolute value of the reinforcement reflection intensity be considered; the verification value and the experimental value can be matched similarly through deep learning and machine learning algorithms after preprocessing the data with Short-Time Fourier Transform (STFT), including time- and time–frequency-domain analysis [

78]. The accuracy of rebar detection in concrete was 0.94, and the reproduction rate was 0.93, while the accuracy of corrosion detection due to corrosion was 0.84, securing a high accuracy and reproduction rate of GPR based on deep learning and machine learning [

78]. By combining AI in this way, it is possible to increase the consistency of GPR, thereby increasing its applicability to marine concrete structures.

4.2.2. Case of RC Pile Application in Simulated Marine Environment

The performance of columns or RC stakes in elevated docks exposed to the marine environment for a long period of time may deteriorate due to corrosion and rebar damage [

79]. Therefore, the corrosion evaluation of RC structures is essential.

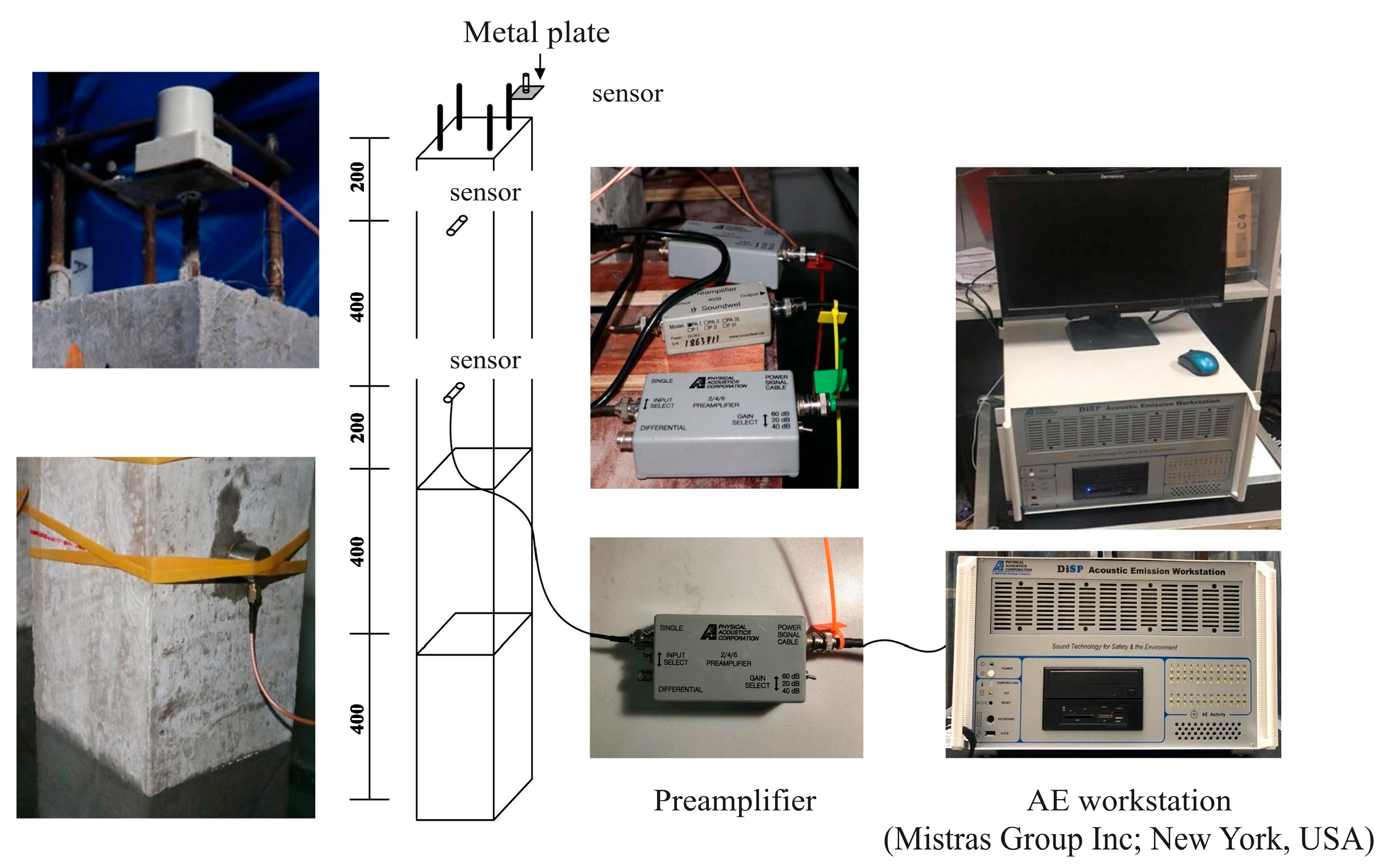

Figure 9 shows the monitoring process using the AE technique during NDT to determine whether corrosion damage has progressed, involving a pillar test that simulates an elevated pier pillar exposed to the marine environment for a long time. However, quantitative data on AE monitoring in marine environments are limited [

80]. The AE technique measures acoustic waves generated by cracks in structures; however, it is difficult to apply in marine environment because noise and signal attenuation occur during the measurement process [

81].

Therefore, a multi-layered perceptron-based intelligent model that connects AE measurements with crack detection was applied to the AE technique to quantify damage to RC piles in the simulated marine environment and diagnose the degree of corrosion. Together with the AE signal, the geometric Fractal Dimension (FD) parameter is analyzed to determine the coupling in a complex manner, and the AE measurement value pretreated with an Amplitude Duration Peak Frequency (ADPF) filter is predicted and monitored by machine learning [

80]. This method is a reinforcement method using AI that increases the applicability of AE in marine environments.

4.2.3. Case Study on the Top of the NASA Causeway Bridge

Since the signal-type NDT using ultrasonic waves measures ultrasonic waves, even thick concrete structures can be measured with minimal measuring instruments [

7]. This simple measurement method is advantageous for measuring of large-scale concrete structures or for use under harsh conditions [

82,

83]. However, there is a limit to the scattering effect and complex defect detection in the marine environment, so 2D and 3D tomography are introduced to determine the spatial location and severity of defects, although it is difficult to remove noise and discriminate defects in the process, so AI application in this area is necessary [

52].

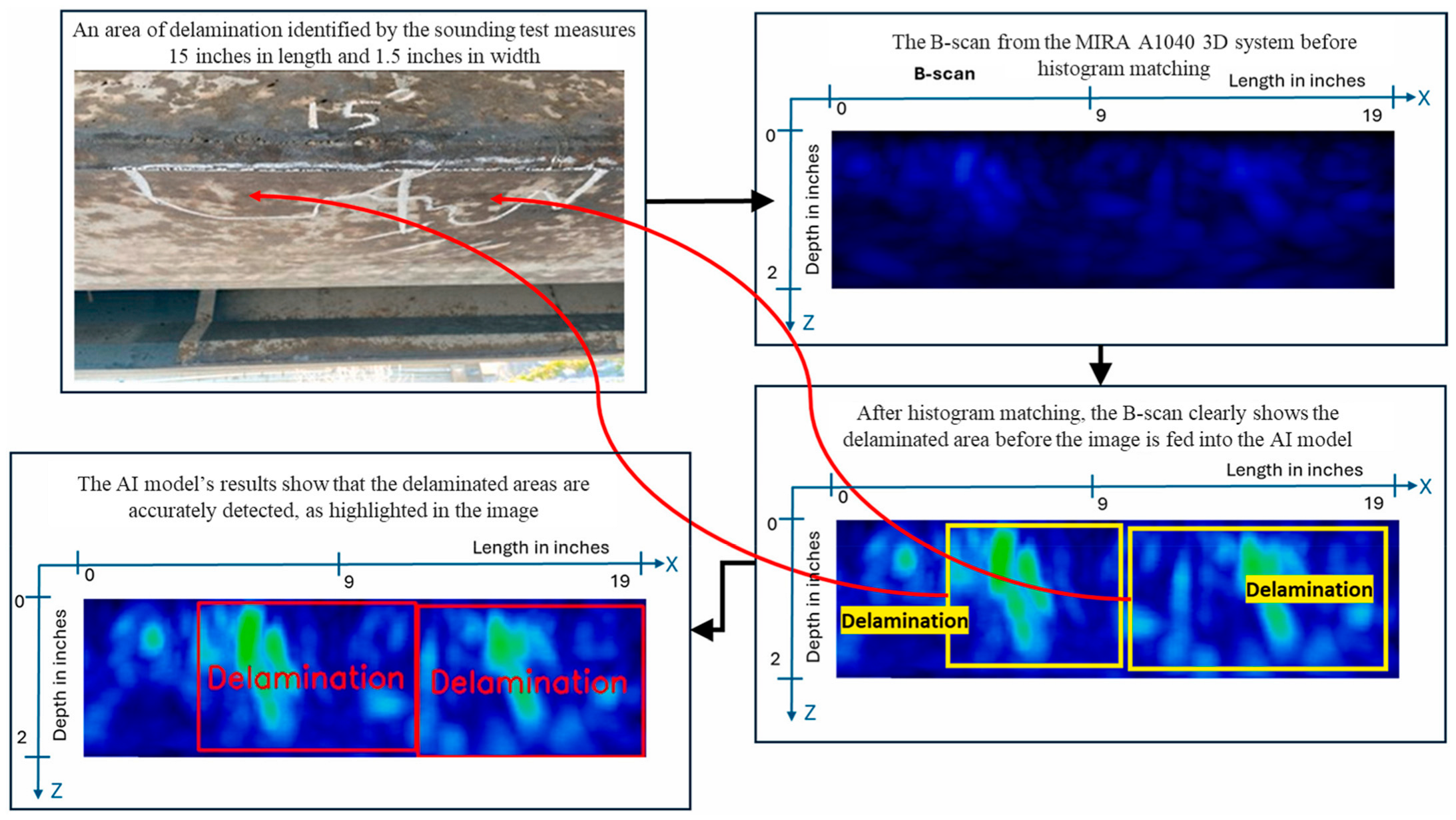

Based on the data collected by ultrasonic tomography of the top of the NASA Causeway bridge through deep learning, the analysis error that occurs because the color scale varies between instruments was first corrected. The YOLOv8n algorithm was then applied to learn to automatically identify various defects such as peeling, voids, and buried rebar and ducts. By converting the data from the training set to a consistent color scale, the noise was learned less sensitively, thereby improving the accuracy.

Figure 10 is a visual representation of this ultrasonically based AI detection process, and the color-scale correction of the data, defect identification through the use of the YOLOv8n model, and major detection performance indicators are presented together to facilitate understanding of the procedure and the performance of ultrasonic image analysis at a glance. As a result, mAP@0.5 = 0.73, mAP@0.5–0.95 = 0.62, and average IoU = 0.80, confirming that the ultrasonic techniques applied with AI are effective. Through this verification, the practical applicability of the investigated method in real marine environments was demonstrated [

52].

5. Limitations of AI-Integrated NDT Techniques and Future Works

The convergence of AI and NDT is effective in early diagnosis of cracks, spalling, and corrosion of marine concrete structures and increasing maintenance efficiency [

15,

39]. Performance was evaluated through practical application cases in

Section 4. However, there are still several limitations that prevent these technologies from achieving stability and long-term applicability in real field conditions. These include issues related to data quality and standardization, difficulties in operating under extreme conditions such as marine environments, challenges concerning economic performance and operating costs, and problems with regulatory frameworks.

The biggest limitations are the lack of data quality and standardization. In the marine environment, various variables are encountered, such as water temperature, salt, turbidity, and bio-attachment, so the signals collected by sensors vary considerably in time and space [

6,

39]. For this reason, there are many cases where AI models developed in one area do not perform the same in another area or under different conditions. In addition, integrated analysis is not easy because monitoring data accumulated over a long time are insufficient and the data format and preprocessing method differ depending on the sensor. To improve this, it is necessary to standardize data acquisition and processing methods for large-scale data accumulation reflecting various marine conditions [

24,

39,

64].

The specificity of the marine environment also makes it difficult to apply in the field. Tidal fluctuations, high waves, floats, and bio-attachment hinder the stable operation of sensors and robot platforms and reduce data quality and collection frequency. Drones and autonomous underwater vehicles have been used, but measurements are limited, and data non-uniformity occurs due to rough weather conditions and currents. Even if AI is fused and corrected in the data acquisition process, the marine environment makes it difficult to apply in the field for measurement. To solve this problem, it is necessary to develop a hardware platform that integrates AI technologies [

4,

14,

69].

For example, deep learning-based object and defect recognition models such as YOLO, CNNs, and U-Net require tens of thousands of annotated images for training. However, in the case of marine structures, external conditions such as currents, turbidity, lighting, and viewing angles vary significantly, resulting in significant differences in image characteristics, even for the same defect. This makes dataset generalization difficult and necessitates model retraining or the construction of separate datasets for each environment. In fact, in image-based defect detection research, approximately 60–70% of the total development time is spent on data labeling and preprocessing, which reduces the efficiency of AI-NDT systems and delays real-time analysis and deployment in the field. To overcome these limitations, additional research is needed, including research on transfer learning, small-scale data learning, and synthetic data generation [

44,

50].

Economic feasibility and operational cost issues are also important challenges in the practical application of AI-based NDT. AI models require large-scale training data and considerable computational resources, and model construction and periodic relearning take a considerable amount of time. These long processing times and high computational costs lead to operational burdens when real-time defect detection and monitoring are implemented in large sensor networks. Therefore, to spread AI-based NDT practically, efforts to shorten computation time and secure economic feasibility through the use of a lightweight model with improved data processing efficiency, a high-speed learning algorithm, and a distributed processing system using cloud and edge computing are required [

10,

70].

International standards are required for NDT technology combined with AI to be used in earnest for the maintenance and diagnosis of marine structures. Currently, it is difficult to objectively evaluate the performance and safety of the technology because specific regulations and standards for the use of AI for NDT are insufficient. In addition, to standardize AI’s application through the use of data learning, it is necessary to repeatedly verify its performance under various marine conditions and standardize data formats, processing methods, and evaluation indicators accordingly to ensure a reliable recall rate [

26,

39,

56,

76].

Future research needs to overcome these limitations and move beyond the fragmentary use of single NDT technologies to an AI-based NDT framework that connects data collection to tracking in one flow. In the field, various AI-based NDT technologies effectively collect surface and internal-defect signals and secure data, even in hard-to-reach areas using drones or underwater robots. By automatically preprocessing the vast amounts of signals and video data collected in this way, noise is removed, and different signals are integrated for each sensor, allowing the AI model to quantitatively determine the location, shape, and severity of the defect. The identified data is accumulated in a digital-twin model reflecting the actual state of the structure and utilized to predict damage and residual life over time to form a single circulation system. Furthermore, unlike conventional methods centered on single-shot or follow-up inspections, it is necessary to move toward a systematic AI-based framework centered on prediction and prevention [

39,

65,

66,

70]. This integrated AI framework can greatly increase the long-term safety and management efficiency of structures, even in extreme marine environments.

6. Discussion

This study critically reviewed the development and practical application cases of NDT technology fused with AI for maintenance and damage diagnosis of marine concrete structures. The marine environment distorts NDT signals and reduces the reliability of data due to complex factors such as the presence of algae and bio-attachment, so there is limit to early defect detection and predictive maintenance with existing techniques alone. The introduction of AI in response to this limitation greatly improved detection accuracy and reproducibility by removing noise from image and signal data, automatically identifying defect-specific patterns, and integrating and analyzing data collected from various sensors and instruments.

A comparison of vision-based NDT and signal-based NDT revealed that the effectiveness of AI varied depending on the data type. In vision-based NDT, deep learning models such as YOLO, Cycle GAN, and MSDA were applied to resolve color distortion and contrast degradation in underwater images, enabling quantitative tracking of cracks and delamination areas. On the other hand, signal-based NDT was used to analyze abnormal signals in ultrasonic, AE, and GPR data using LSTM, CNN, and Random Forest models to suppress noise and distinguish defect signals, thereby improving prediction accuracy. The AE-LSTM fusion model learned crack propagation trends in real time, securing detection accuracy approximately 20–30% higher than conventional models.

These results imply that AI goes beyond simply automating data interpretation and plays a role in compensating for the physical uncertainties inherent in the marine environment. While changes in illumination, humidity, and salinity directly lead to signal distortion in conventional NDT, AI can independently derive correction factors by learning these environmental variables. This is considered a key factor in enhancing the reliability of periodic monitoring and digital twin-based lifespan prediction models.

Case studies show these effects in detail. In visually based NDT, the problem of color distortion and contrast deterioration in the underwater environment was solved by AI-based correction techniques and object detection models, enabling quantitative tracking of microcracks and surface damage. In signal-based NDT, the analytical accuracy and predictive power were improved by incorporating AI into ultrasound, GPR, and AE data processing. This integration enables the early detection of fine defects, improves overall detection performance compared to conventional methods, and facilitates preemptive maintenance responses.

In this way, AI has demonstrated the potential to quantitatively compensate for the attenuation, noise, and environmental dependency issues inherent in conventional NDT. However, poor data quality, insufficient standardization, high costs, and considerable computational requirements remain obstacles to practical application. The diversity of marine environments makes data generalization difficult, and differences in data formats and preprocessing methods across equipment create inefficiencies in integrated analysis. Furthermore, AI model training requires large-scale labeled data and high-performance GPUs, making cost-effectiveness and real-time performance critical challenges.

In the future, it will be important to develop these technologies into an integrated framework that connects data acquisition, preprocessing, analysis, monitoring, prediction, and post response, not just individual defect diagnosis. It is necessary to establish a predictive maintenance system that supports the entire life cycle of marine infrastructure by linking sensors such as drones, ROVs, FOSs, and AE and GPR instruments and by combining digital twins and simulation-based virtual data generation to predict long-term deterioration processes.

In addition, along with technological advances, progress in standardization, reliability and cost-effectiveness is required. At present, the absence of internationally unified evaluation criteria for AI-NDT applications in the marine environment–along with high costs, substantial computational requirements, the need for high-performance equipment, and frequent model retraining–continue to hinder practical application. These problems can be solved by empirical tests and data sharing under various marine conditions, as well as by preparing standardized performance indicators and operating guidelines.

AI convergence NDT technology has the potential to break through the limitations of existing inspection methods and to innovatively improve the long-term safety and maintenance efficiency of marine concrete structures. Sustainable management of marine infrastructure will be possible if the data processing process, algorithms, and hardware are continuously improved, in addition to establishing an institutional foundation.

7. Conclusions

This study comprehensively examined the effectiveness and applicability of AI-integrated non-destructive testing (NDT) in improving the maintenance efficiency of marine concrete structures. The introduction of AI quantitatively compensates for signal distortions unique to the marine environment, such as salinity, waves, currents, and biological fouling. It also overcomes the limitations of conventional NDT by removing noise and recognizing patterns in image and signal data.

Vision-based NDT enables color distortion correction and quantitative detection of microcracks, while signal-based NDT improves data analysis accuracy and predictive power in ultrasound, ground-based photo recognition (GPR), and AE applications. These achievements demonstrate that AI is evolving beyond simple data processing technology to become a core infrastructure for intelligent structural diagnosis and maintenance systems.

Going beyond the application of fragmented techniques, it is crucial to establish an integrated AI-NDT framework that seamlessly integrates data acquisition, preprocessing, analysis, monitoring, prediction, and post-event response. Furthermore, with the advancement of standardized performance indicators, international datasets, and cloud- and edge-based real-time processing technologies, AI-NDT will become a key technology for realizing a predictive and sustainable management paradigm for marine infrastructure.

In summary, AI-integrated NDT is establishing itself as a key technology that overcomes the limitations of existing inspection methods and enhances the long-term safety and durability of marine concrete structures. This study suggests that this technology could be a real turning point for sustainable marine infrastructure management.