Marine Hydrogen Pressure Reducing Valves: A Review on Multi-Physics Coupling, Flow Dynamics, and Structural Optimization for Ship-Borne Storage Systems

Abstract

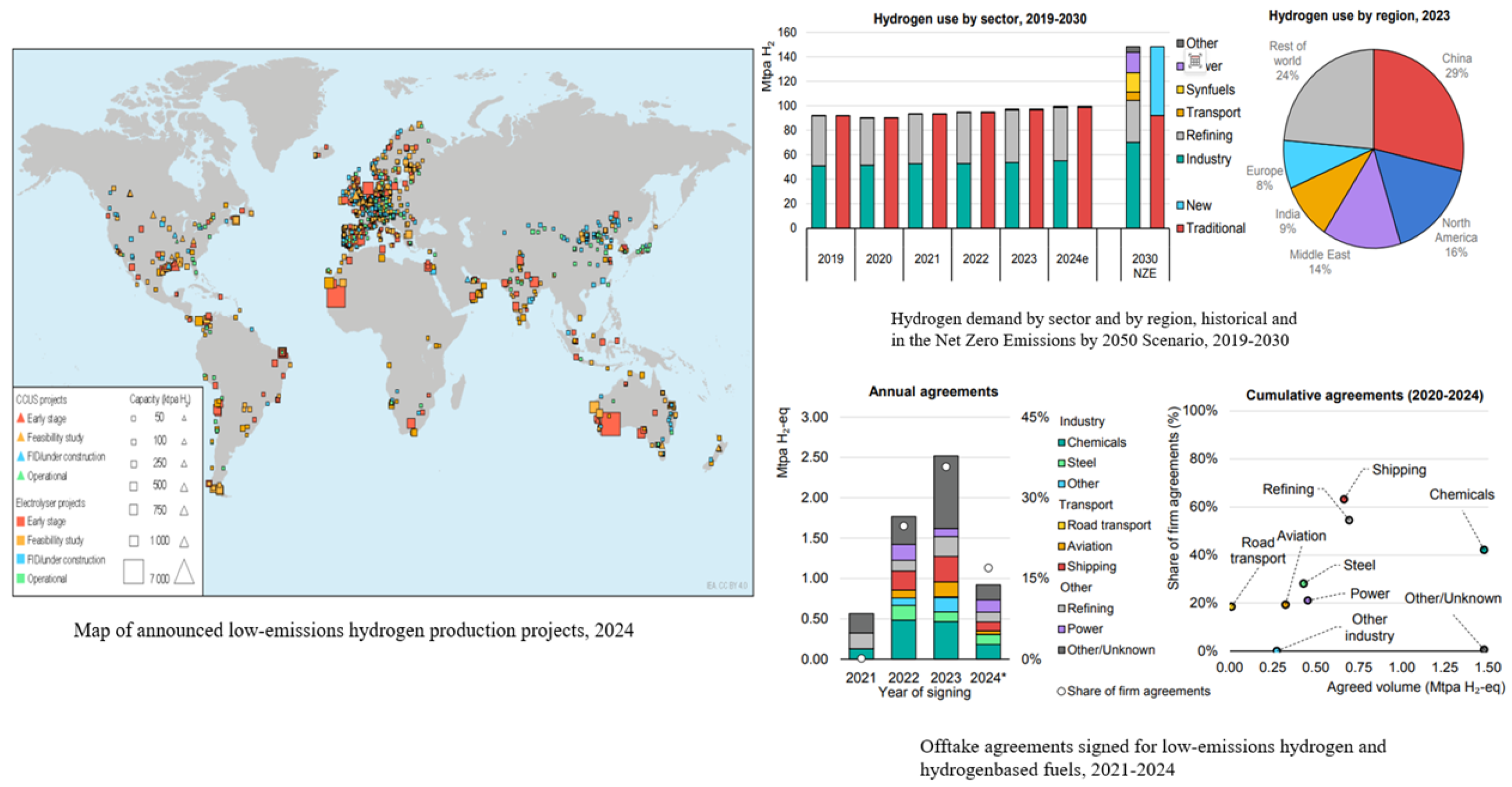

1. Introduction

2. Current Challenges for Marine Hydrogen Pressure Reducing Valves

2.1. Synergistic Material Degradation: Hydrogen Embrittlement and Salt Spray Corrosion

2.2. Weak Anti-Vibration Performance Under Persistent Marine Dynamics

2.3. Poor Temperature Adaptability and Joule–Thomson Effect

2.4. Issues with Dynamic Response and Pressure Stability Under Transient Loads

2.5. Insufficient Environmental Adaptability and Standardization Gaps

3. Scope and Methodology

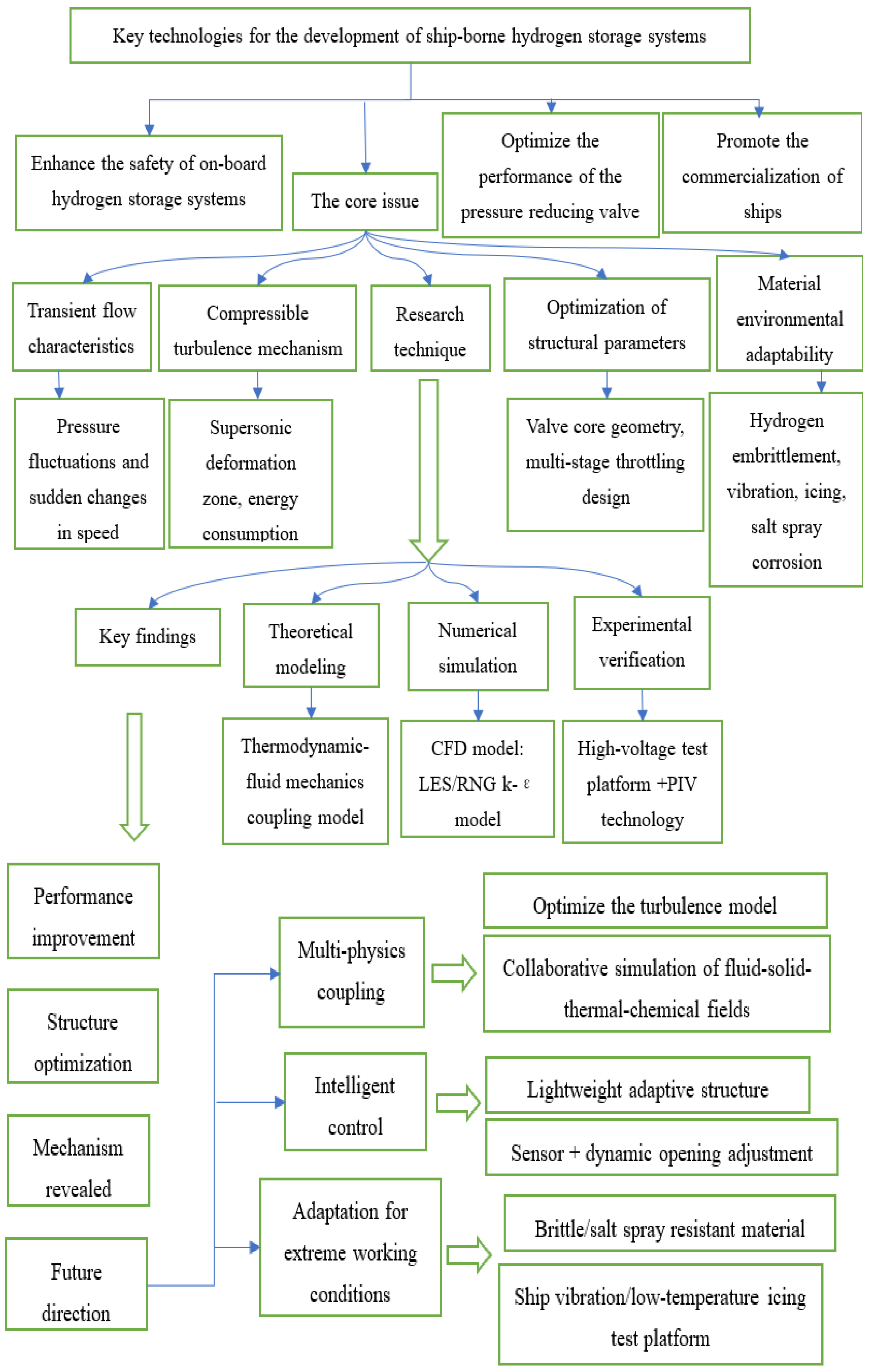

4. Research on the Flow Field of Hydrogen Pressure Reducing Valves—Dynamics

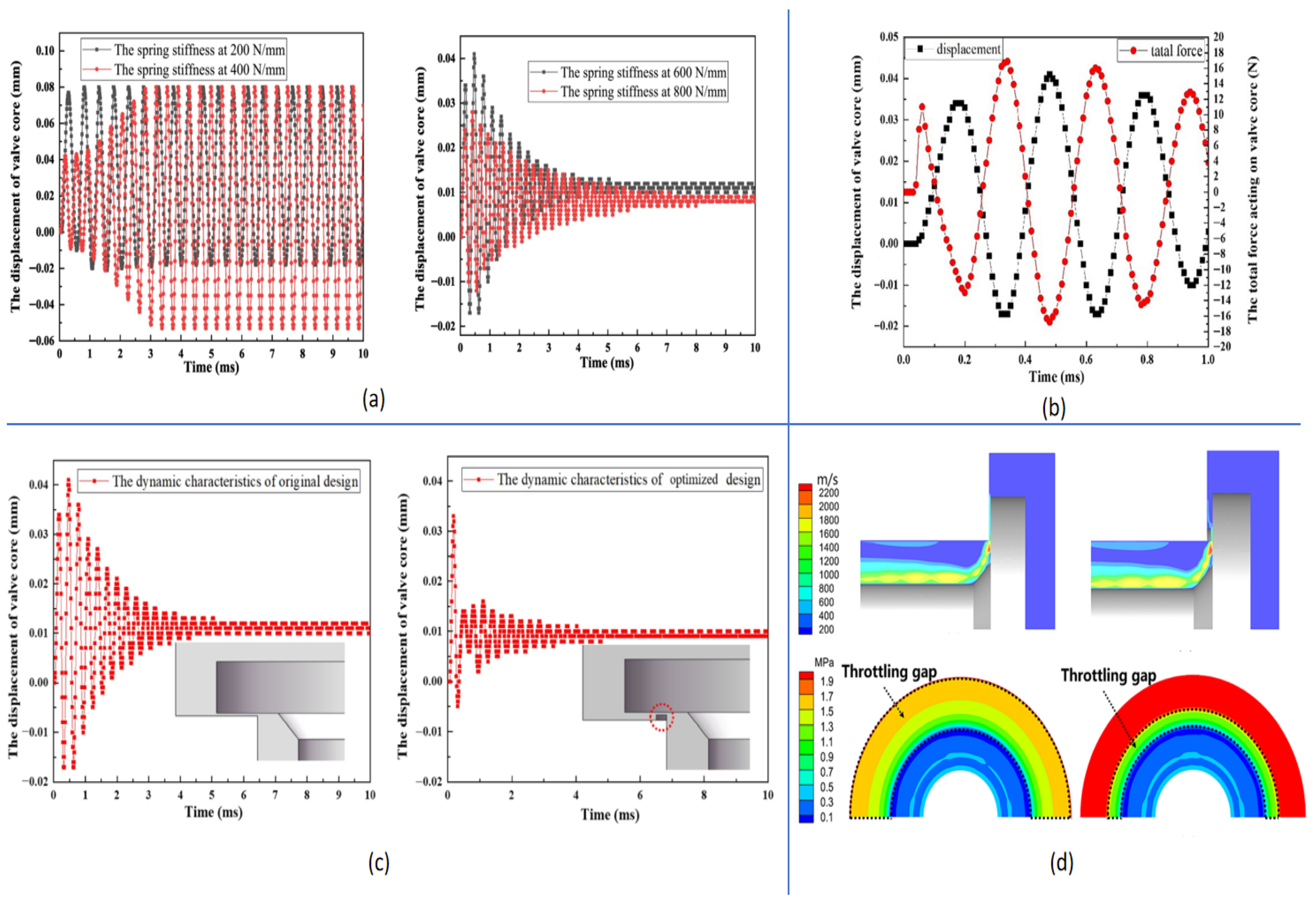

4.1. Transient Flow Dynamics Under Marine-Induced Vibrations

4.2. Turbulence, Compressible Flow and the Marine Acoustic Environment

4.2.1. Multi-Physics Coupling Mechanisms

4.2.2. Comparison of Turbulence Modeling Methods and Their Impact on Prediction Results

4.2.3. Equation of State Selection and Joule–Thomson Effect

- (1)

- Multi-parameter helmholtz free energy formulations implemented in the NIST REFPROP database, which provide high accuracy across a wide range of temperatures and pressures, including the liquid hydrogen domain.

- (2)

- Specially calibrated cubic EOS with parameters rigorously optimized for hydrogen.

4.3. Parameter Analysis and Optimization for Robust Marine Operation

Sensitivity Analysis of Key Parameters on the Outlet Pressure and Temperature

4.4. Valve Core Geometry Effects in a Corrosive and Erosive Marine Setting

- (1)

- Robust to Performance Degradation: Shapes that are less sensitive to minor geometric changes caused by wear.

- (2)

- Resistant to Failure Initiation: Designs that minimize stress concentrations and are conceived from the outset for compatibility with hydrogen embrittlement-resistant alloys and advanced surface coatings.

- (3)

- Adaptive and Intelligent: Exploring designs that can integrate with control systems to maintain optimal performance despite geometric changes or varying operational demands.

4.4.1. Degradation Mechanisms of Precision Engineered Surfaces in Marine Environments and Long-Term Feasibility of Geometric Optimization

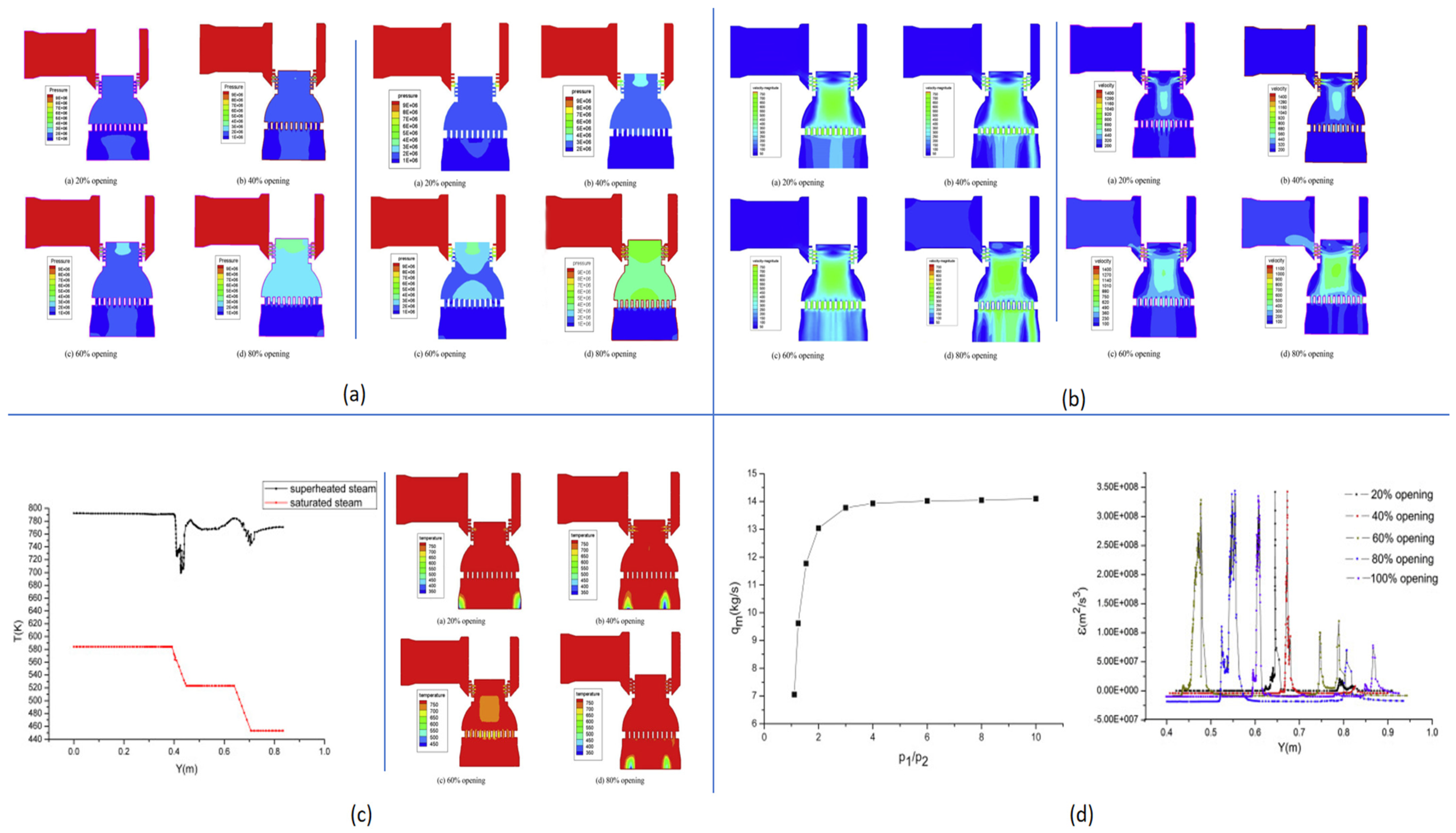

4.5. Multi-Stage Throttling Strategies: Weighing Performance Against Marine Reliability

4.5.1. Porous Plate Structures

4.5.2. Maze Channel-Type Throttling

4.5.3. Tesla Valve Structures

4.5.4. Combined Multi-Stage Structures

4.5.5. Critical Assessment of Simplifications in Multi-Stage Throttling Studies

4.6. Summary of Research Status and Methodologies

5. Conclusions and Future Development Directions

5.1. Main Research Findings and Conclusions

5.2. Future Development Direction

5.2.1. Theoretical Modeling

5.2.2. Numerical Simulation

5.2.3. Experimental Innovation

5.2.4. Structural Design and Material Challenges

5.2.5. Standardization and Regulatory Framework

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, N.; Wan, S.; Du, W.; Zhang, S.; Luo, L. Effects of the geometrical features of flow paths on the flow behaviour of a multi-stage labyrinth pressure reducing valve throttling components. Energy 2024, 296, 130962. [Google Scholar] [CrossRef]

- European Commission. REPowerEU Plan. COM(2022) 230 Final; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- International Maritime Organization (IMO). Strategy on Reduction of GHG Emissions from Ships; International Maritime Organization (IMO): London, UK, 2023. [Google Scholar]

- U.S. Department of Energy. Hydrogen Shot: Hydrogen Earthshot; U.S. Department of Energy: Washington, DC, USA, 2021. [Google Scholar]

- Yin, B.; Qiu, H.; Dong, F.; Wang, Z.; Jia, H.; Xie, X. Study on the pressurization liquid hydrogen supply characteristics in hydrogen fuel cell vehicles. Energy 2025, 138897. [Google Scholar] [CrossRef]

- Opolot, M.; Ramírez, J.R.; Zhao, C. Opportunities and challenges of latent thermal energy usage in the hydrogen economy. Energy Reviews 2025, 1, 00152. [Google Scholar]

- Chen, F.; Jin, Z. Fluid dynamics analysis and optimized throttling design of L-shaped multi-stage high pressure reducing valve. Flow Meas. Instrum. 2023, 89, 102296. [Google Scholar] [CrossRef]

- Elazab, M.A.; Elgohr, A.T.; Bassyouni, M.; Kabeel, A.E.; Elshaarawy, M.K.; Hamed, A.K.; Alzahrani, H.A.H. Green hydrogen: Unleashing the potential for sustainable energy generation. Results Eng. 2025, 27, 106031. [Google Scholar] [CrossRef]

- Weindler, J.; Lehner, H.; Eckstein, J.; Dawoud, B. Performance assessment of a green hydrogen-based household energy system supported by a battery storage at different resolutions of the electrical load profile. Int. J. Hydrogen Energy 2025, 144, 30–41. [Google Scholar] [CrossRef]

- Cheng, P.; Jianjun, X.; Kumar, J.; Almujibah, H.; Alkhalifah, T.; Alkhalaf, S.; Alturise, F.; Ghandour, R. Improving efficiency and optimizing heat transfer in a novel tesla valve through multi-layer perceptron models. Case Stud. Therm. Eng. 2023, 49, 103391. [Google Scholar] [CrossRef]

- Gan, R.; Li, B.; Chu, J.; Yuan, C.; Zhao, Z.; Yang, G. Design optimization of noise reduction for labyrinth control valve in secondary circuit flow regulation system. Nucl. Eng. Des. 2024, 420, 113038. [Google Scholar] [CrossRef]

- U.S. Department of Energy Unveils Updated Hydrogen Program Plan. Available online: https://www.energy.gov/eere/fuelcells/articles/us-department-energy-unveils-updated-hydrogen-program-plan (accessed on 11 October 2025).

- DNV. Rules for Classification of Ships Pt.6 Ch.5 Fuel Cells and Hydrogen; DNV: Oslo, Norway, 2023. [Google Scholar]

- Cheekatamarla, P. Hydrogen and the global energy transition—Path to sustainability and adoption across all economic sectors. Energies 2024, 17, 807. [Google Scholar] [CrossRef]

- Roslan, M.F.; Satpathy, P.R.; Prasankumar, T.; Ramachandaramurthy, V.K.; Mansor, M.; Walker, S.L. Second-life battery energy storage system for energy sustainability: Recent advancements, key takeaways and future perspectives. J. Energy Storage 2025, 123, 116808. [Google Scholar] [CrossRef]

- Zare, S.G.; Amirmoeini, K.; Bahn, O.; Baker, R.C.; Mousseau, N.; Neshat, N.; Trépanier, M.; Wang, Q. The role of hydrogen in integrated assessment models: A review of recent developments. Renew. Sustain. Energy Rev. 2025, 215, 115544. [Google Scholar] [CrossRef]

- Lebrouhi, B.E.; Djoupo, J.J.; Lamrani, B.; Benabdelaziz, K.; Kousksou, T. Global hydrogen development—A technological and geopolitical overview. Int. J. Hydrogen Energy 2022, 47, 7016–7048. [Google Scholar] [CrossRef]

- CG-0241; Hydrogen Fuelled Ship Systems. DNV: Oslo, Norway, 2023.

- IEC 62282-2; Fuel Cell Technologies—Part 2, Fuel Cell Modules. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- Li, N.; Zhang, C.; Li, D.; Jiang, W.; Zhou, F. Review of reactor systems for hydrogen production via ammonia decomposition. Chem. Eng. J. 2024, 495, 153125. [Google Scholar] [CrossRef]

- Taylor, M.; Strezov, V.; Best, R.; Pettit, J.; Hammerle, M.; Beringen, E. Offshore renewable hydrogen potential in Australia: A techno-economic and legal review. Int. J. Hydrogen Energy 2025, 152, 149923. [Google Scholar] [CrossRef]

- Pan, X.; Chen, Y.; Lu, L.; Wang, Z.; Hua, M.; Xiao, J.; Jiang, J. Research on the flow characteristics and spontaneous ignition mechanism of high-pressure hydrogen in semi-closed T-tube. Int. J. Hydrogen Energy 2025, 145, 991–1006. [Google Scholar] [CrossRef]

- Ma, X.; Li, B.; Han, B. Safety discharge strategies of vehicle-mounted type III high-pressure hydrogen storage tanks under fire scenarios. Int. J. Hydrogen Energy 2024, 93, 1227–1239. [Google Scholar] [CrossRef]

- Li, Y.; Fu, C. Hydrogen storage-learning from nature: The air clathrate hydrate in polar ice sheets. Sustain. Energy Technol. Assess. 2024, 72, 104007. [Google Scholar] [CrossRef]

- Shin, D.H.; Hwang, H.K.; Kim, S.J. Effect of plasma ion nitriding on hydrogen embrittlement and wear resistance of martensitic stainless steel for hydrogen valve core of fuel cell electric vehicles. Eng. Fract. Mech. 2024, 306, 110247. [Google Scholar] [CrossRef]

- Aadhithiyan, A.K.; Sreeraj, R. Multi-objective optimization and absorption prediction of complete 3-D design modeled MmNi4.6Al0.4 based hydrogen storage reactor. Int. J. Hydrogen Energy 2024, 87, 641–656. [Google Scholar]

- IEC 62282-3-100; Fuel Cell Technologies—Part 3–100, Stationary Fuel Cell Power Systems—Safety. International Electrotechnical Commission: Geneva, Switzerland, 2019.

- Moretti, B. The FLAGSHIPS project: Demonstrating hydrogen fuel cell solutions for waterborne transport. Int. J. Hydrogen Energy 2023, 48, 29148–29161. [Google Scholar]

- Jamil, H.; Naqvi, S.S.A.; Kim, D.H. Hydrogen storage capability optimization based on multi-objective function for decision of hydrogen production and utilization. Int. J. Hydrogen Energy 2024, 95, 1095–1110. [Google Scholar] [CrossRef]

- Gao, P.; Hu, D.; Lu, D.; Lu, D.; Wang, J.; Cheng, Z.; Yi, F.; Zhou, J. Modeling and analysis of minor seal leakages in high-pressure hydrogen valves under extreme environmental temperatures. Int. J. Hydrogen Energy 2024, 64, 26–38. [Google Scholar] [CrossRef]

- Dai, H.; Chen, Z.; Cao, H.; Tian, Z.; Zhang, M.; Wang, X.; He, S.; Wang, W.; Gao, M. Effect of partition arrangement of metal hydrides and phase change materials on hydrogen absorption performance in the metal hydride reactor. Int. J. Hydrogen Energy 2024, 84, 780–792. [Google Scholar] [CrossRef]

- Liu, X.Y.; Sun, Z.Y.; Yi, Y. Progress in spontaneous ignition of hydrogen during high-pressure leakage with the considerations of pipeline storage and delivery. Appl. Energy Combust. Sci. 2024, 20, 100290. [Google Scholar] [CrossRef]

- Usman, M.; Ghanem, A.S.; Garba, M.D.; Suliman, M.H.; Khan, S.; Ahmed, U.; Humayun, M. Green and blue hydrogen production and purification technologies. Int. J. Hydrogen Energy 2025, 153, 150176. [Google Scholar] [CrossRef]

- Vasiliev, V.P.; Solovev, M.V.; Kravchenko, O.V.; Zyubin, A.S.; Zyubina, T.S. Magnesium borohydride monoammine as hydrogen storage: Structure and pathway analysis for the thermal decomposition reaction. J. Alloys Compd. 2024, 1008, 176738. [Google Scholar] [CrossRef]

- Kumar, D.; Zhang, C.; Holubnyak, E.; Demirkesen, S. Integrated assessment of levelized costs of hydrogen production: Evaluating renewable and fossil pathways with emission costs and tax incentives. Int. J. Hydrogen Energy 2024, 95, 389–401. [Google Scholar] [CrossRef]

- Saha, B.K.; Chattopadhyay, H.; Mandal, P.B.; Gangopadhyay, T. Dynamic simulation of a pressure regulating and shut-off valve. Comput. Fluids 2014, 101, 233–240. [Google Scholar] [CrossRef]

- Meniconi, S.; Brunone, B.; Ferrante, M.; Mazzetti, E.; Laucelli, D.B.; Borta, G. Transient effects of self-adjustment of pressure reducing valves. Procedia Eng. 2015, 119, 1030–1038. [Google Scholar] [CrossRef][Green Version]

- Qian, J.; Yu, L.; Yang, X.; Jin, Z.; Li, W. Dynamic characteristics analysis and valve core optimization for second stage hydrogen pressure reducer of hydrogen decompression valve. J. Energy Storage 2024, 79, 110113. [Google Scholar] [CrossRef]

- Yin, Y.B.; Chen, J.P.; Luo, J.Y.; Ma, J.X. Mechanism and property analysis on ultrahigh-pressure pneumatic decompressing valve for hydrogen vehicles. Chin. J. Constr. Mach. 2008, 6, 310–314, 323. [Google Scholar]

- Yin, Y.B.; Shen, L.; Zhao, Y.P.; Dai, Y. Research on flow of high pressure reducing valve of hydrogen vehicle based on CFD. Fluid Mach. 2010, 38, 23–26. [Google Scholar]

- Yin, Y.B.; Zhang, L.; Li, L.; Shen, L.; Fu, J.Y. Study on pressure and velocity fields of pneumatic high pressure reduction valve for hydrogen vehicles. Chin. J. Constr. Mach. 2011, 9, 1–6. [Google Scholar]

- Beune, A.; Kuerten, J.G.M.; Schmidt, J. Numerical calculation and experimental validation of safety valve flows at pressures up to 600 bar. AIChE J. 2011, 57, 3285–3298. [Google Scholar] [CrossRef]

- Ulanicki, B.; Skworcow, P. Why PRVs tends to oscillate at low flows. Procedia Eng. 2014, 89, 378–385. [Google Scholar] [CrossRef]

- Wang, F.; Zeng, Y.; Wang, W.; Chen, F.; Gao, W.; Hao, Y. Transient flow characteristics for fluid-structure interaction on hydrogen decompression valve in high-pressure hydrogen storage systems. Int. J. Hydrogen Energy 2024, 79, 1250–1266. [Google Scholar] [CrossRef]

- Jian, J.; Shuai, Z.J.; Yu, T.; Wang, X.; Ren, K.X.; Dong, L.Y.; Li, W.Y.; Jiang, C.X. Research on stability characteristics of a spring-loaded valve with two outlets. Ann. Nucl. Energy 2022, 175, 109250. [Google Scholar] [CrossRef]

- Ye, J.; Zhao, Z.; Cui, J.; Hua, Z.; Peng, W.; Peng, C. Transient flow behaviors of the check valve with different spool-head angle in high-pressure hydrogen storage systems. J. Energy Storage 2022, 46, 103761. [Google Scholar] [CrossRef]

- Taghinia, J.; Rahman, M.M.; Siikonen, T. Large eddy simulation of a high-pressure homogenizer valve. Chem. Eng. Sci. 2015, 131, 41–48. [Google Scholar] [CrossRef]

- Gad, O. Modeling and simulation of the steady-state and transient performance of a three-way pressure reducing valve. J. Dyn. Syst. Meas. Control. 2016, 138, 031001-1. [Google Scholar] [CrossRef]

- Ulanicki, B.; Picinali, L.; Janus, T. Measurements and analysis of cavitation in a pressure reducing valve during operation—A case study. Procedia Eng. 2015, 119, 270–279. [Google Scholar] [CrossRef][Green Version]

- Luo, L.; He, X.; Den, B.; Huang, X. Theoretical and experimental research on a pressure-reducing valve for a water hydraulic vane pump. J. Press. Vessel. Technol. 2014, 136, 021601. [Google Scholar] [CrossRef]

- Jin, Z.; Chen, F.; Qian, J.; Zhang, M.; Chen, L.; Wang, F.; Yang, F. Numerical analysis of flow and temperature characteristics in a high multi-stage pressure reducing valve for hydrogen refueling station. Int. J. Hydrogen Energy 2016, 41, 5559–5570. [Google Scholar] [CrossRef]

- Qian, J.; Zhang, M.; Lei, L.; Chen, F.; Chen, L.; Lin, W.; Jin, Z. Mach number analysis on multi-stage perforated plates in high pressure reducing valve. Energy Convers. Manag. 2016, 119, 81–90. [Google Scholar] [CrossRef]

- Qian, J.; Wei, L.; Zhu, G.; Chen, F.; Jin, Z. Transmission loss analysis of thick perforated plates for valve contained pipelines. Energy Convers. Manag. 2016, 109, 86–93. [Google Scholar] [CrossRef]

- Huovinen, M.; Kolehmainen, J.; Koponen, P.; Nissilä, T.; Saarenrinne, P. Experimental and numerical study of a choke valve in a turbulent flow. Flow Meas. Instrum. 2015, 45, 151–161. [Google Scholar] [CrossRef]

- Modesti, D.; Pirozzoli, S. Reynolds and Mach number effects in compressible turbulent channel flow. Int. J. Heat Fluid Flow 2016, 59, 33–49. [Google Scholar] [CrossRef]

- Chen, F.; Qian, J.; Chen, M.; Zhang, M.; Chen, L.; Jin, Z. Turbulent compressible flow analysis on multi-stage high pressure reducing valve. Flow Meas. Instrum. 2018, 61, 26–37. [Google Scholar] [CrossRef]

- Özahi, E. An analysis on the pressure loss through perforated plates at moderate Reynolds numbers in turbulent flow regime. Flow Meas. Instrum. 2015, 43, 6–13. [Google Scholar] [CrossRef]

- Elias, Y.; von Rohr, P.R. Axial dispersion, pressure drop and mass transfer comparison of small-scale structured reaction devices for hydrogenations. Chem. Eng. Process. Process Intensif. 2016, 106, 1–12. [Google Scholar] [CrossRef]

- Ingenito, A.; Cecere, D.; Giacomazzi, E. Large eddy simulation of turbulent hydrogen-fuelled supersonic combustion in an air cross-flow. Shock. Waves 2013, 23, 481–494. [Google Scholar] [CrossRef]

- Ozsaban, M.; Midilli, A. A parametric study on exergetic sustainability aspects of high-pressure hydrogen gas compression. Int. J. Hydrogen Energy 2016, 41, 5321–5334. [Google Scholar] [CrossRef]

- An, Y.J.; Kim, B.J.; Shin, B.R. Numerical analysis of 3-D flow through LNG marine control valves for their advanced design. J. Mech. Sci. Technol. 2008, 22, 1998–2005. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, T.; Hong, H.; Guo, H.; Xi, L.; Xue, Y.; Nie, B.; Hu, Z.; Zou, J. Challenges and opportunities in hydrogen storage and transportation: A comprehensive review. Renew. Sustain. Energy Rev. 2025, 219, 115881. [Google Scholar] [CrossRef]

- Lisowski, E.; Rajda, J. CFD analysis of pressure loss during flow by hydraulic directional control valve constructed from logic valves. Energy Convers. Manag. 2013, 65, 285–291. [Google Scholar] [CrossRef]

- Yu, L.; Yang, X.; Zhang, Z.; Lin, Z.; Jin, Z.; Qian, J. Parametric analysis on throttling elements of conical throttling valve for hydrogen decompression in hydrogen fuel cell vehicles. J. Energy Storage 2023, 65, 107342. [Google Scholar] [CrossRef]

- Kelly, N.A.; Gibson, T.L.; Ouwerkerk, D.B. Generation of high-pressure hydrogen for fuel cell electric vehicles using photovoltaic-powered water electrolysis. Int. J. Hydrogen Energy 2011, 36, 15803–15825. [Google Scholar] [CrossRef]

- Hou, C.; Qian, J.; Chen, F.; Jiang, W.; Jin, Z. Parametric analysis on throttling components of multi-stage high pressure reducing valve. Appl. Therm. Eng. 2018, 128, 1238–1248. [Google Scholar] [CrossRef]

- Chen, F.; Ren, X.; Hu, B.; Li, X.; Gu, C.; Jin, Z. Parametric analysis on multi-stage high pressure reducing valve for hydrogen decompression. Int. J. Hydrogen Energy 2019, 44, 31263–31274. [Google Scholar] [CrossRef]

- Wu, T.; Gong, Z.Y.; Fan, Y.; Ma, H.R.; Li, J.Q.; Quan, J.T.; Zhang, C.Z. A study on the regulation performance of a novel type of multi-stage labyrinth pressure regulator in hydrogen fuel cell systems. Int. J. Hydrogen Energy 2025, 120, 374–384. [Google Scholar] [CrossRef]

- Kim, D.K.; Min, H.E.; Kong, I.M.; Lee, M.K.; Lee, C.H.; Kim, M.S.; Song, H.H. Parametric study on interaction of blower and back pressure control valve for a 80-kW class PEM fuel cell vehicle. Int. J. Hydrogen Energy 2016, 41, 17595–17615. [Google Scholar] [CrossRef]

- Sivakumar, P.; Prasad, R.K. Extended period simulation of pressure-deficient networks using pressure reducing valves. Water Resour. Manag. 2015, 29, 1713–1730. [Google Scholar] [CrossRef]

- Dai, P.D.; Li, P. Optimal pressure regulation in water distribution systems based on an extended model for pressure reducing valves. Water Resour. Manag. 2016, 30, 1239–1254. [Google Scholar] [CrossRef]

- Wright, R.; Abraham, E.; Parpas, P. Optimized control of pressure reducing valves in water distribution networks with dynamic topology. Procedia Eng. 2015, 119, 1003–1011. [Google Scholar] [CrossRef]

- Magda, M.; Sikaitis, K. Pressure-reducing valves optimize detroit water’s distribution system. Flow Control. 2015, 21, SS8e9. [Google Scholar]

- Albadwi, A.; Elzein, A.; Bashir, A.A.A.; Selcuklu, S.B.; Kaya, M.F. Multi-criteria decision-making in hydrogen production, storage, and transportation: An overview. Renew. Sustain. Energy Rev. 2025, 222, 115947. [Google Scholar] [CrossRef]

- Qin, C.; Tian, Y.; Yang, Z.; Dong, H.; Feng, L. Quantitative analysis of hydrogen leakage flow measurement and calculation in the on-board hydrogen system pipelines. Int. J. Hydrogen Energy 2024, 89, 1025–1039. [Google Scholar] [CrossRef]

- Mac Kinnon, M.; Shaffer, B.; Carreras-Sospedra, M. Air quality impacts of fuel cell electric hydrogen vehicles with high levels of renewable power generation. Int. J. Hydrogen Energy 2016, 41, 16592–16603. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Cao, J.; Chen, F.; Chai, J.; Wang, Y. Effects of hydrogen status and compartment structure on hydrogen explosion propagation in utility tunnels. Int. J. Hydrogen Energy 2024, 96, 652–663. [Google Scholar] [CrossRef]

- Ye, J.; Cui, J.; Hua, Z.; Xie, J.; Peng, W.; Wang, W. Study on the high-pressure hydrogen gas flow characteristics of the needle valve with different spool shapes. Int. J. Hydrogen Energy 2023, 48, 11370–11381. [Google Scholar] [CrossRef]

- Shao, L.; Lin, X.; Bian, L.; Wang, Y.; Hu, S.; Han, Y.; Huang, K.; Zhang, N.; Zhang, J.; Hao, J. Engineering control strategy of hydrogen gas direct-heating type Mg-based solid state hydrogen storage tanks: A simulation investigation. Appl. Energy 2024, 375, 124134. [Google Scholar] [CrossRef]

- Chen, R.; Ma, T.; Sun, Z.; Guo, J.; Ding, H.; Su, Y.; Fu, H. The hydrogen absorption behavior of high Nb contained titanium aluminides under high pressure and temperature. Int. J. Hydrogen Energy 2016, 41, 13254–13260. [Google Scholar] [CrossRef]

- Fakhroleslam, M.; Fatemi, S.; Boozarjomehry, R.B. A switching decentralized and distributed extended Kalman filter for pressure swing adsorption processes. Int. J. Hydrogen Energy 2016, 41, 23042–23056. [Google Scholar] [CrossRef]

- Mehrzad, S.; Javanshir, I.; Ranji, A.R. Modeling of fluid-induced vibrations and identification of hydrodynamic forces on flow control valves. J. Cent. South Univ. 2015, 22, 2596–2603. [Google Scholar] [CrossRef]

- Yu, S.P.; Lai, M.W.; Chu, C.Y.; Huang, J.L.; Lin, C.Y. Integration of low-pressure hydrogen storage cylinder and automatic controller for carbon deposit removal in car engine. Int. J. Hydrogen Energy 2016, 41, 21795–21801. [Google Scholar] [CrossRef]

- Mohammedi, A.; Rekioua, D.; Rekioua, T.; Bacha, S. Valve regulated lead acid battery behavior in a renewable energy system under an ideal Mediterranean climate. Int. J. Hydrogen Energy 2016, 41, 20928–20938. [Google Scholar] [CrossRef]

- Rashad, M.; Yong, H.; Zekun, Z. Effect of geometric parameters on spray characteristics of pressure swirl atomizers. Int. J. Hydrogen Energy 2016, 41, 15790–15799. [Google Scholar] [CrossRef]

- Kaneko, W.; Ishii, K. Effects of diaphragm rupturing conditions on self-ignition of high-pressure hydrogen. Int. J. Hydrogen Energy 2016, 41, 10969–10975. [Google Scholar] [CrossRef]

- Liu, C.; Xue, D.; Li, W.; Yu, L.; Zhao, J.; Yang, J.; Jin, Z.; Chen, D.; Qian, J. Dynamic behavior and Joule-Thomson characteristics analysis on flow limiter inside hydrogen On Tank Valve for hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2025, 123, 162–172. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Z.; Li, C.; Wu, X.; Sun, L.; Chen, C. Insight into the effects of hydrogen on inside-valve flow and Joule-Thomson characteristics of hydrogen-blended natural gas: A numerical study. Int. J. Hydrogen Energy 2024, 49, 1056–1074. [Google Scholar] [CrossRef]

- Yang, J.; Yu, Y.; Wang, Y.; Cao, H.; Liu, B.; Wu, H.; Xue, M.; Zhang, C. Refueling process analysis and parameter optimization in liquid hydrogen refueling stations utilizing gas-liquid hydrogen mixed pre-cooling. Int. J. Hydrogen Energy 2025, 147, 150031. [Google Scholar] [CrossRef]

- Qian, J.; Wu, J.; Gao, Z.; Wu, A.; Jin, Z. Hydrogen decompression analysis by multi-stage Tesla valves for hydrogen fuel cell. Int. J. Hydrogen Energy 2019, 44, 13666–13674. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; She, X.; Luo, Y.; Sun, Q.; Lin, T. Numerical study on the behavior and design of a novel multistage hydrogen pressure-reducing valve. Int. J. Hydrogen Energy 2022, 47, 14646–14657. [Google Scholar] [CrossRef]

- Chen, F.; Jin, Z. Effects of perforated plate on hydrogen flow in L-shaped high pressure reducing valve. Int. J. Hydrogen Energy 2023, 48, 1956–1967. [Google Scholar] [CrossRef]

- Filina, O.A.; Malozyomov, B.V.; Shchurov, N.I. Generation of hydrogen fuel on board vehicles with internal combustion engines. Int. J. Hydrogen Energy 2024, 93, 320–327. [Google Scholar] [CrossRef]

- Chen, F.; Jiang, Z. Mach number analysis of hydrogen flow in labyrinth passage under high pressure gradient. Int. J. Hydrogen Energy 2024, 49, 1306–1318. [Google Scholar] [CrossRef]

- Li, J.Q.; Ma, H.R.; Wu, T.; Gong, Z.Y.; Su, Z.L.; Quan, Z.T.; Zhang, C.Z.; Li, J.C. A study on the flow-pressure characteristics & temperature changes of a novel type of pressure regulator for hydrogen decompression. Case Stud. Therm. Eng. 2025, 73, 106587. [Google Scholar] [CrossRef]

| Company | H2 Cargo Containment | Country | Approval in Principle | Volume (m2) |

|---|---|---|---|---|

| Korea Shipbuilding & Offshore Engineering, Hyundai Mipo Dockyard | Spherical | Korea | Korean Register of Shipping (KRS) DNV | 20,000 |

| Samsung Heavy Industries | Type C | Korea | ABS | 20,000 |

| Houlder, Shell, CB&I | Spherical | United Kingdom | DNV (H2 containment) | 20,000 |

| C-Job Naval Architects, LH2 Europe | Spherical | Netherlands | - | 37,500 |

| TotalEnergies, GTT, LMG Marin, Bureau Veritas | Membrane | France | Bureau Veritas | 150,000 |

| Kawasaki Heavy Industries (KHI) | Spherical (technological development completed) | Japan | Nippon Kaiji Kyokai (ClassNK) | 160,000 |

| Samsung Heavy Industries | Membrane | Korea | Lloyd’s Register | 160,000 |

| GasLog | NA | United States | NA | NA |

| Key Parameter | Parameter Variation Range | Impact on Export Pressure (Range of Uncertainty) | Influence on Outlet Temperature (Uncertainty Range) | Main Sources of Literature | Remarks Content |

|---|---|---|---|---|---|

| inlet pressure | 10–70 Mpa | ±(0.5–1.2) Mpa | ±(2–8) K | [43,51,67] | The J-T effect is prominent under high pressure, and the temperature fluctuation is significant. |

| Valve core opening degree | 20–100% | ±(0.3–0.8) Mpa | ±(1–5) K | [44,77,78] | At small opening degrees, the flow field becomes unstable and the pressure fluctuations intensify. |

| inlet temperature | 253–313 K | ±(0.1–0.4) Mpa | ±(3–10) K | [51,68] | The J-T cooling effect is stronger at low temperatures. |

| Diameter of the porous plate | 2–6 mm | ±(0.2–0.6) Mpa | ±(1–4) K | [66,67] | The smaller the aperture, the greater the pressure drop and the more significant the temperature drop. |

| Valve core cone angle | 30–60° | ±(0.4–1.0) Mpa | ±(2–6) K | [44,77] | Small angles are prone to causing turbulence and have poor pressure stability. |

| Throttling Structure Type | Main Advantages | Applicable Scenarios/Conditions | Potential Limitations |

|---|---|---|---|

| Porous plate structure | Simple structure, easy to process, low cost | Medium pressure difference and stable flow rate | Fatigue under high pressure differences, poor adaptability to extreme working conditions |

| Maze passage style | Flow field uniform, suppression effect good, pressure reduction stable | High pressure difference and low flow rate environment | Flow channel complex, processing requirements high, and the flow resistance large |

| Tesla valve structure | No moving parts, strong anti-vibration, high reliability | Vibration-sensitive scenarios requiring high reliability | Pressure reduction efficiency under the number of stages and the geometric shape, and noise prone under large flow conditions |

| Combined structure | Robust performance, strong adaptability, high control accuracy | Complex and variable working conditions | Complex structure, high integration difficulty and high manufacturing cost |

| Research Focus Area | Current Research Status & Core Methodologies | Main Findings/Advancements | Identified Gaps & Lack of Marine Adaptability |

|---|---|---|---|

| Transient Flow Dynamics | Status/Methods: Transient CFD and Fluid–Structure Interaction (FSI) simulations; Dynamic mesh techniques; Optimization of spring stiffness and valve core geometry. | Findings: Valve core optimization can suppress displacement oscillations and improve dynamic response. The depressurization process can be characterized into distinct stages (rapid response, closing, equilibrium). | Gaps: Simulations and validations are predominantly conducted under static, land-based conditions. The performance of optimized designs under broad-spectrum, random marine vibrations remains unproven, risking resonance and instability. |

| Turbulence & Compressible Flow | Status/Methods: Steady-state and transient CFD (RANS, LES); Analysis of Mach number distribution and turbulent dissipation rate; Optimization of multi-stage perforated plates. | Findings: Multi-stage throttling promotes subsonic flow and reduces energy consumption. Structural parameters (e.g., number of stages, hole diameter) significantly influence flow stability and energy loss. | Gaps: Models assume smooth walls and ideal gases, neglecting the impact of marine-induced surface roughening (corrosion) on flow resistance and acoustics. RANS models may underestimate peak Mach numbers and turbulent dissipation, affecting noise and fatigue predictions. |

| Parameter Optimization | Status/Methods: Parametric CFD studies; Steady-state experiments; Determining optimal parameters (orifice size, spring stiffness, valve core angle) for efficiency. | Findings: Quantitative influence ranges of key parameters on outlet pressure and temperature have been established (see Table 2). Optimal parameter sets for peak performance under deterministic conditions are identified. | Gaps: Optimization is performed without considering marine environment as a key input. Lack of Uncertainty Quantification (UQ) and Global Sensitivity Analysis (GSA) to ensure robustness against stochastic marine perturbations (vibration, thermal cycles). |

| Valve Core Geometry | Status/Methods: CFD comparison of different spool shapes (e.g., straight-edge, arc-edge, flat-bottom); FSI-based shape optimization (e.g., convex cylinder). | Findings: Micro-rounding (arc-edge) and specific convex features can reduce vortices, pressure gradients, and improve dynamic stability. | Gaps: The long-term durability of precision-engineered geometries under synergistic erosion-corrosion is unaddressed. Performance advantages may be eroded by geometric degradation. Lack of co-design with HE-resistant materials and coatings. |

| Multi-stage Throttling Strategies | Status/Methods: CFD analysis of various structures (Porous plates, Labyrinth channels, Tesla valves, Combined structures); Comparative performance evaluation. | Findings: Different strategies offer trade-offs: Porous plates (simplicity vs. fatigue), Labyrinths (flow uniformity vs. complexity), Tesla valves (reliability vs. size). Combined structures offer high performance and adaptability. | Gaps: A systematic evaluation framework for marine applications is lacking. Simplifications in studies (steady-state, single-phase, rigid structure) lead to over-optimistic predictions. The reliability of complex structures under vibration and corrosion is questionable. |

| Multi-physics Coupling | Status/Methods: Recognized as critical, but high-fidelity coupled simulations are challenging. Initial attempts with FSI and thermal-stress analysis. | Findings: Highlights the importance of coupled phenomena like transient shock-boundary layer interaction and thermo-structural response. | Gaps: Fully integrated and experimentally validated models are scarce. Key couplings (e.g., vibration-shock interaction, synergistic corrosion-fatigue) are not quantitatively predictable. Models lack real ship vibration data and material degradation models. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Yang, H.-N.; Wang, R.; Dai, Y.-M.; Su, Z.-L.; Li, J.-C.; Li, J.-Q. Marine Hydrogen Pressure Reducing Valves: A Review on Multi-Physics Coupling, Flow Dynamics, and Structural Optimization for Ship-Borne Storage Systems. J. Mar. Sci. Eng. 2025, 13, 2061. https://doi.org/10.3390/jmse13112061

Xu H, Yang H-N, Wang R, Dai Y-M, Su Z-L, Li J-C, Li J-Q. Marine Hydrogen Pressure Reducing Valves: A Review on Multi-Physics Coupling, Flow Dynamics, and Structural Optimization for Ship-Borne Storage Systems. Journal of Marine Science and Engineering. 2025; 13(11):2061. https://doi.org/10.3390/jmse13112061

Chicago/Turabian StyleXu, Heng, Hui-Na Yang, Rui Wang, Yi-Ming Dai, Zi-Lin Su, Ji-Chao Li, and Ji-Qiang Li. 2025. "Marine Hydrogen Pressure Reducing Valves: A Review on Multi-Physics Coupling, Flow Dynamics, and Structural Optimization for Ship-Borne Storage Systems" Journal of Marine Science and Engineering 13, no. 11: 2061. https://doi.org/10.3390/jmse13112061

APA StyleXu, H., Yang, H.-N., Wang, R., Dai, Y.-M., Su, Z.-L., Li, J.-C., & Li, J.-Q. (2025). Marine Hydrogen Pressure Reducing Valves: A Review on Multi-Physics Coupling, Flow Dynamics, and Structural Optimization for Ship-Borne Storage Systems. Journal of Marine Science and Engineering, 13(11), 2061. https://doi.org/10.3390/jmse13112061