1. Introduction

Marine diesel engines are integral to global maritime transportation, providing propulsion and auxiliary power for diverse vessels ranging from large container ships to specialized offshore support vessels. Within this critical sector, low-speed, two-stroke diesel engines have become dominant due to their superior thermal efficiency, reliability, and favorable power-to-weight ratio. These engines are designed to operate efficiently under continuous full-load conditions for long durations, making them particularly suitable for transoceanic voyages. However, increasing environmental concerns, coupled with stringent regulations imposed by the International Maritime Organization (IMO), particularly the NO

x Tier III standards under the MARPOL Annex VI framework, necessitate substantial improvements in engine design and exhaust aftertreatment technologies to reduce emissions while maintaining or improving operational performance [

1].

To address these challenges, various technologies have been developed and implemented, including Exhaust Gas Recirculation (EGR), Selective Catalytic Reduction (SCR), dual-fuel systems, high-pressure turbocharging, and Controllable Pitch Propeller (CPP). Among these, EGR and SCR systems have received significant attention due to their proven effectiveness in mitigating nitrogen oxide (NO

x) emissions [

2]. EGR achieves this by lowering peak combustion temperatures, while SCR reduces NO

x post-combustion through catalytic reactions with urea-based reductants. Additionally, dual-fuel operation—typically involving methanol, liquefied natural gas (LNG), or hydrogen—has emerged as a promising approach to simultaneously lower greenhouse gases and NO

x emissions [

3]. These fuel strategies are further supported by evolving bunkering infrastructure and regulatory incentives for low-carbon operations [

4].

The research literature extensively analyzes these technologies, emphasizing their complex interactions and influences on engine performance, emissions, transient behavior, and overall ship operability [

5]. Although numerous studies have explored hybrid power systems and advanced fuels, real-world data focusing specifically on two-stroke diesel engines equipped with both EGR and CPP systems remain limited [

6].

EGR technology, by recycling a portion of exhaust gases back into the engine cylinders, effectively reduces combustion temperatures, thereby mitigating NO

x formation. However, despite its proven effectiveness, studies indicate potential adverse effects on engine fuel efficiency and transient response [

7]. For instance, a recent study [

3] specifically highlight how high-pressure EGR systems significantly alter engine flow characteristics, requiring meticulous calibration to avoid detrimental performance impacts. Another challenge is the increased soot and particulate matter generation, necessitating improvements in aftercooling and exhaust filtration systems [

8].

Alternatively, SCR provides a complementary post-combustion NO

x reduction method using ammonia-based reductants. SCR systems have shown substantial NO

x reduction capabilities, especially under steady-state and controlled transient conditions [

9]. However, their integration presents challenges, including catalyst sensitivity to operational transients and response delays under dynamic conditions such as rough seas [

10]. The transient behavior analysis of marine engines coupled with SCR further illustrates the critical importance of detailed dynamic modeling and control strategies to maintain performance and compliance under real-world conditions [

11]. The precise dosing of reductant and thermal management across the SCR reactor are also pivotal for system reliability and effectiveness [

12].

High-pressure turbocharging and CPP are also critical for optimizing propulsion efficiency and emissions. High-pressure turbocharging improves air supply efficiency, facilitating cleaner combustion and enhanced power density. Turbocharging systems critically influence thrust efficiency and emission profiles, emphasizing precise power management strategies [

13]. Turbochargers also influence engine backpressure and scavenge air delivery, which are directly tied to EGR and SCR system effectiveness [

14].

On the other hand, CPPs significantly influence propulsion system efficiency by allowing dynamic adjustment of propeller blade angles to suit varying load, speed, and sea conditions. This adjustability enables optimal thrust generation across a range of operating scenarios, improving overall propulsion efficiency and maneuverability [

15]. CPP systems are especially advantageous during frequent speed changes, port maneuvering, or adverse weather, where fixed-pitch propellers may operate inefficiently. Furthermore, by enabling engines to operate closer to their optimal load points, the CPP can indirectly contribute to emission reduction, particularly when integrated with engine control strategies that manage NO

x and fuel consumption trade-offs [

16]. Their integration with advanced engine systems allows for better load control, which in turn enhances the effectiveness of EGR and SCR systems by stabilizing engine conditions conducive to efficient aftertreatment operation.

Studies such as those by Karlsen and Nielsen have detailed the substantial role CPP plays in maneuverability and emissions management, particularly in their ability to maintain optimal engine load profiles during varying operational conditions [

17]. For example, CPP integration allows the engine to adjust propeller pitch rather than throttle input, reducing the likelihood of inefficient combustion and thermal strain. This flexibility supports smoother transitions and load stability, which is beneficial for EGR and SCR systems that require consistent exhaust flow and temperature to function effectively.

Beyond these operational benefits, it is also important to consider the implications for the Energy Efficiency Design Index (EEDI), which regulates CO

2 emissions for newly built ships. As defined by the IMO, EEDI measures transport work per unit CO

2 emitted, meaning that propulsion efficiency, engine–propeller matching, and operational strategies all directly affect compliance. Since engine load profiles and exhaust characteristics under different EGR modes influence both fuel consumption and emissions, the integration of CPP and EGR plays a decisive role not only in emission reduction but also in meeting EEDI targets. Recent studies have emphasized that optimizing operational parameters, such as propeller pitch and EGR calibration, can help reconcile the trade-off between efficiency and emissions within the constraints of EEDI regulations [

18].

While hybrid systems and dual-fuel technologies offer additional pathways for emissions reduction, the current study focuses specifically on the integration and performance effects of EGR and CPP systems in low-speed two-stroke diesel engines [

19]. Comprehensive modeling and simulation studies underscore the essential role of robust computational frameworks for analyzing engine performance and emissions under varying operational scenarios [

20]. These studies provide critical predictive capabilities necessary for optimizing engine design, operational strategy, and compliance with regulatory demands, especially under challenging conditions such as heavy seas and transient operations. Computational models also support virtual testing of control strategies, emission trajectories, and energy management protocols, reducing development costs and accelerating technology validation cycles [

21].

In summary, this study aims to investigate the operational characteristics and exhaust emission behavior of a two-stroke marine diesel engine equipped with both an Exhaust Gas Recirculation (EGR) system and a Controllable Pitch Propeller (CPP). The analysis specifically focuses on the effects of different EGR operation modes (Tier II-FB, ecoEGR, and Tier III) under the practical operating conditions of a CPP-equipped vessel, rather than on variations in CPP modes themselves. While previous research has provided valuable insights into EGR or CPP technologies, most studies have been limited to simulator-based approaches or controlled test-bed conditions, leaving empirical data from actual seagoing vessels extremely scarce. Addressing this gap, the present study utilizes both factory shop test results and real-world onboard measurements obtained from the T/S Baek-Kyung, the first training ship in the Republic of Korea fitted with an EGR system and CPP propulsion. By combining controlled shop data with full-scale sea trial evidence, the analysis reveals comparative trends in emission-performance trade-offs across Tier-regulated EGR modes and quantifies their impact on parameters such as SFOC, Pmax, and NOx emissions. In addition, correlation analyses among CO2, O2, and exhaust gas temperature provide further insight into the complex interactions between combustion efficiency and emission reduction strategies. These contributions not only supply rare empirical evidence from an operational vessel but also offer a methodological framework for evaluating the environmental robustness and performance optimization of future marine diesel systems.

2. Materials and Methods

2.1. Materials

The present study was conducted using the T/S Baek-Kyung, a fishery training vessel operated by Pukyong National University (see

Figure 1 for an overview of the vessel). The vessel’s main specifications are summarized in

Table 1. The T/S Baek-Kyung is a large-scale training ship with a gross tonnage of 3998 tons, an overall length of 97 m, and a beam of 15.4 m. It is powered by a two-stroke diesel engine and equipped with a CPP system, enabling flexible propulsion control. The vessel serves as a marine experimental platform, capable of collecting real-time data on engine performance and exhaust emissions under actual operating conditions at sea.

The main engine installed on the T/S Baek-Kyung is a MAN 5S35ME-B9.5, a two-stroke, electronically controlled diesel engine manufactured by MAN Energy Solutions. This engine is designed to comply with IMO Tier III emission regulations and is equipped with an Exhaust Gas Recirculation with Bypass (EGRBP) system (see

Figure 2 for an overview of the EGR system; the arrows in

Figure 2 indicate the flow of exhaust gas). The EGR system recirculates a portion of the exhaust gas to the intake air, thereby reducing NO

x emissions through combustion temperature control. The specifications of the main engine are summarized in

Table 2.

The EGR system operating modes are classified into three types, as summarized in

Table 3.

The fuel oil used in experiment, as summarized in

Table 4.

The propeller of the T/S Baek-Kyung is a CPP, which allows the adjustment of the blade angle to control the vessel’s forward and reverse motion. The specifications of the propeller are presented in

Table 5, and its operational schematic is shown in

Figure 3. The operation of the propeller is controlled by the Alphatronic 3000 program developed by MAN Energy Solutions SE (Augsburg, Germany).

On the T/S Baek-Kyung, both engine and steering control are performed from the bridge during navigation, with the default operating mode set to combinator mode. In this mode, the engine RPM and propeller pitch change simultaneously according to a predefined combinator curve. In the initial range, the pitch increases rapidly to generate thrust, after which the engine output is controlled by adjusting the RPM. This configuration provides high propulsion efficiency in the low-speed range and enables stable power control in the high-speed range.

In contrast, under constant speed mode, the engine speed is maintained at a preset RPM after startup, and the pitch is manually adjusted using the control lever. The actual control graphs applied to the T/S Baek-Kyung are presented in

Figure 3.

The exhaust gas analysis in this study was performed using the NOVA prime portable gas analyzer manufactured by MRU GmbH (Neckarsulm-Obereisesheim, Germany). Designed for compliance with the EU MCP Directive 2015/2193, the NOVA prime is capable of high-precision exhaust emission measurements in large industrial combustion systems, including marine diesel engines, boilers, gas turbines, and stationary power plants.

The system combines electrochemical sensors (O2, CO, NO, NO2, SO2, H2S) with non-dispersive infrared (NDIR) technology for detecting CO, CO2, and hydrocarbons (HC). Electrochemical sensors operate on gas diffusion principles to produce concentration-proportional electrical signals, whereas NDIR sensors measure gas concentrations through infrared absorption analysis. NDIR technology offers greater stability over time with reduced maintenance requirements compared to electrochemical sensors.

For optimal sample processing, the analyzer employs a Peltier gas cooler to remove moisture and a high-performance filter to eliminate impurities. Additionally, it features an automatic condensate drainage system and integrated humidity and gas flow monitoring to ensure consistent and reliable measurement during long-duration testing.

User interaction is facilitated through a 7-inch touchscreen display, providing intuitive control, real-time data visualization, fuel type selection, and O2 reference adjustments. The device can store up to 1000 measurement datasets internally, with data export available via USB or LAN in .csv format, enabling easy compatibility with data analysis and reporting tools.

The unit operates reliably within an ambient temperature range of +5 °C to +45 °C. Measurement accuracies include: O

2 (0–25.00%, ±0.2%), CO

2 (0–40.00%, ±0.3%), and NO

x (0–5000 ppm, ±5 ppm).

Table 6 presents the parameter specifications of the NOVA prime.

As illustrated in

Figure 4, the analyzer was installed adjacent to the exhaust gas sampling point to minimize transport lag and preserve sample integrity. This configuration ensured accurate detection of NO

x, CO

2, and other regulated pollutants during both shop and sea operations.

In addition to the equipment specifications, the reliability of the exhaust gas measurements was ensured through both verification and uncertainty evaluation procedures. Prior to each experimental campaign, the analyzer accuracy was validated using certified standard calibration gases, thereby confirming consistency with the reference concentrations. The measurement uncertainty was subsequently assessed in accordance with ISO 8178 [

23] and the IMO NO

x Technical Code (2008) [

24], taking into account analyzer accuracy, calibration gas tolerance, and sampling repeatability. Based on this assessment, the overall expanded uncertainty at a 95% confidence level was determined to remain within ±3% of the measured NO

x values, which satisfies internationally recognized compliance requirements.

The AMS functions as the uppermost monitoring system, consolidating all data through the EMS UI. The pressure data acquired from the PMI DAU is processed by the Autotuning Application and subsequently integrated into diagnostic and control data via the EMS Bridge and CoCoS EDS. The ECS and ERCS modules are responsible for engine control and exhaust gas recirculation, respectively, and all this information is displayed on the EMS UI before being reported to the AMS at the supervisory level. Furthermore, the data transmitted from each application is stored within the AMS for monitoring and diagnostic purposes. The schematic representation of the flow is given in

Figure 5.

2.2. Methods

To enable a comparative analysis with the shop test results of the main engine installed on the T/S Baek-Kyung, combustion and exhaust performance were experimentally measured during actual voyages. In these sea operations, the CPP was operated in the constant speed mode, while variations in engine load were achieved by adjusting the propeller pitch under different EGR system operations.

The shop test was conducted at the manufacturer’s facility in accordance with the E2 cycle procedure specified in the IMO NO

x Technical Code (2008) [

24]. This procedure evaluates exhaust gas performance at a constant engine speed while adjusting the engine load to 100%, 75%, 50%, and 25%. During sea operation, however, it was not feasible to operate the main engine at 100% load due to safety considerations; thus, measurements were obtained at 75%, 55%, 45%, and 25% load conditions. For comparative consistency, the 100% load data from the shop test were excluded from the analysis, and the 50% load data were compared against the sea operation data obtained at 45% and 55% loads. The differences in experimental criteria between the shop test and the sea operation are summarized in

Table 7.

During the sea operation, the main engine speed was fixed at 162 rpm, and load variations were achieved solely by adjusting the CPP pitch. The EGR system operation was classified into three modes—Tier II, ecoEGR, and Tier III—and combustion as well as exhaust performance data were collected at each load condition.

Through these experiments, the combustion characteristics and exhaust performance of the main engine under EGR operation could be compared between shop test and actual voyage conditions. Based on this analysis, the study aims to derive optimal performance strategies for each EGR operation mode in real navigation.

2.3. Correlation Analysis Methodology

To elucidate the interdependence among engine performance and emission parameters, a Pearson correlation analysis was conducted. The performance indicators of marine diesel engines, such as SFOC, Pmax, and exhaust gas temperature, are inherently coupled with emission parameters including NO

x, CO

2, and O

2. Evaluating these parameters in isolation may lead to incomplete interpretations; hence, correlation analysis provides a quantitative means to measure the degree of linear dependence between variables [

25].

The Pearson correlation coefficient

is defined as [

26]:

where

and

denote the arithmetic mean of the variables

and

. A value of

indicates a perfect positive correlation,

a perfect negative correlation, and

no linear correlation [

27].

For visualization, the correlation matrix was represented using a heatmap technique, where the color intensity corresponds to the magnitude and direction of the correlation coefficient. This approach facilitates the identification of key variable interactions and trade-offs, such as the inverse relationship between NO

x reduction and fuel efficiency observed under high EGR rates [

28].

3. Results

In this study, a total of nine comparative graphs were constructed based on two key performance indicators: SFOC and NOx emissions. Among them, five graphs are presented with reference to SFOC and four graphs with reference to NOx. This dual-parameter approach was adopted to provide a balanced framework that simultaneously addresses fuel efficiency, directly linked to operational economy and CO2 emissions, and compliance with IMO Tier-regulated NOx emission limits. In the following result graphs, each data point is annotated with the corresponding engine load fraction, thereby providing clearer insight into performance and emission characteristics across different operating conditions.

3.1. Specific Fuel Oil Consumption

3.1.1. SFOC Versus NOx

Figure 6 demonstrates the classical trade-off between SFOC and NO

x emissions. Compared with Tier II-FB, where NO

x reached up to 1464.27 ppm, Tier III mode achieved the strongest abatement, reducing NO

x to as low as 346.00 ppm, equivalent to a 76.4% reduction. This was accompanied by an SFOC rise from 176.59 g/kWh (Tier II-FB minimum) to 206.16 g/kWh (Tier III maximum), corresponding to a 16.8% increase. EcoEGR exhibited intermediate performance, reducing NO

x to 698.00 ppm (a 52.3% decrease from Tier II-FB) while keeping SFOC within 173.38–203.80 g/kWh, showing only marginal penalties. The consistency between shop and sea datasets validates the robustness of these relationships.

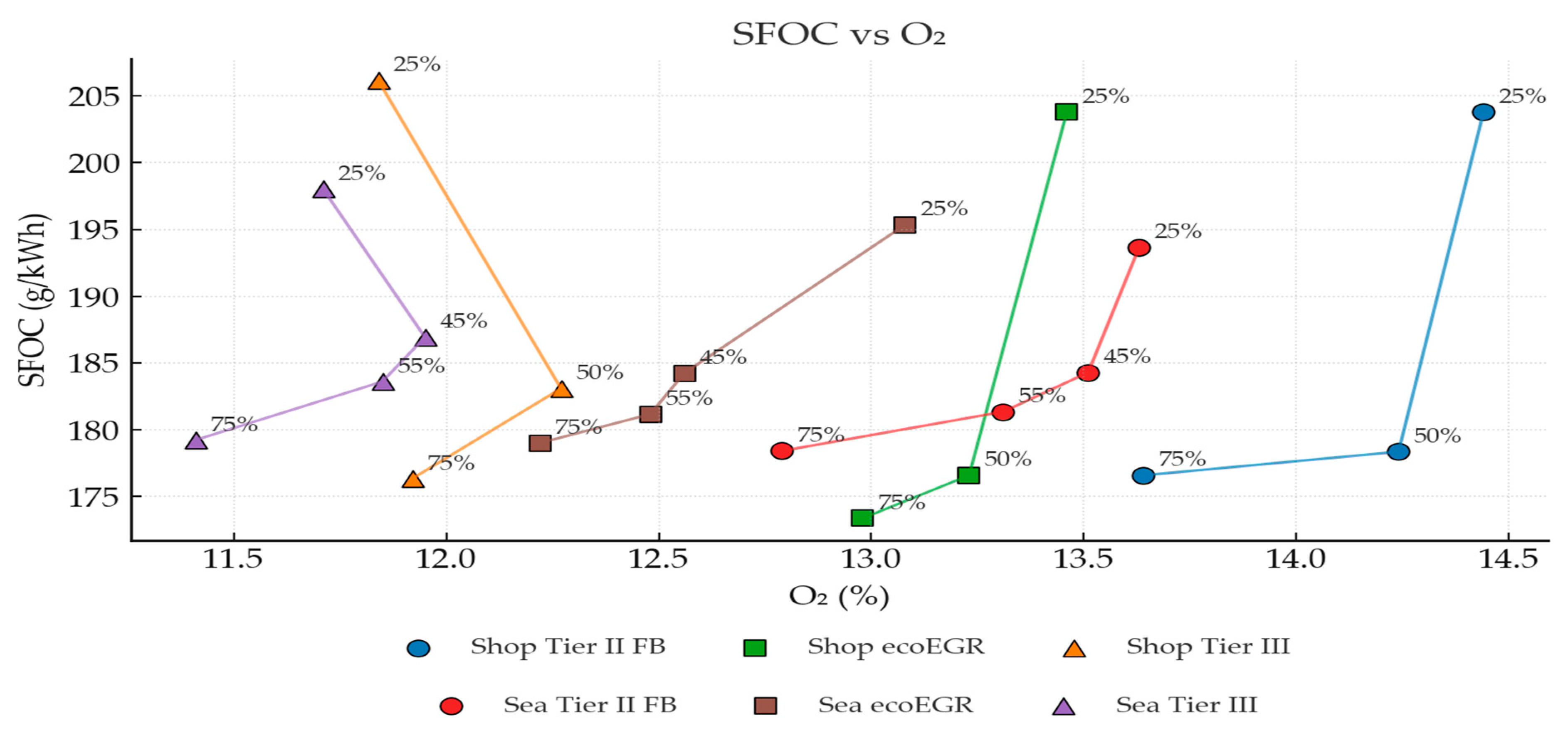

3.1.2. SFOC Versus O2

As shown in

Figure 7, decreasing oxygen concentration correlates with deteriorating combustion efficiency, leading to higher SFOC. Tier II-FB maintained the most favorable oxygen availability (12.79–14.44%) with the lowest SFOC levels (176.59–203.80 g/kWh). By contrast, Tier III exhibited significant oxygen depletion (11.41–12.27%), directly linked to the highest SFOC values (up to 206.16 g/kWh). EcoEGR presented an intermediate range (12.22–13.46% O

2) with moderate efficiency penalties, confirming its partial mitigation of the trade-off.

3.1.3. SFOC Versus CO2

The relationship between CO

2 and SFOC, presented in

Figure 8, further highlights the efficiency–emission penalty. Tier III mode exhibited the steepest gradient, with CO

2 rising from 4.69% (Tier II-FB) to 6.81%, a 45.2% increase, in parallel with SFOC growth of up to 16.8%. EcoEGR moderated this trade-off, maintaining CO

2 within 5.42–6.14% (a 15.6–30.9% increase) and limiting SFOC variation to within 12.9%, indicating its suitability as a Tier III-compliant strategy without substantial efficiency losses.

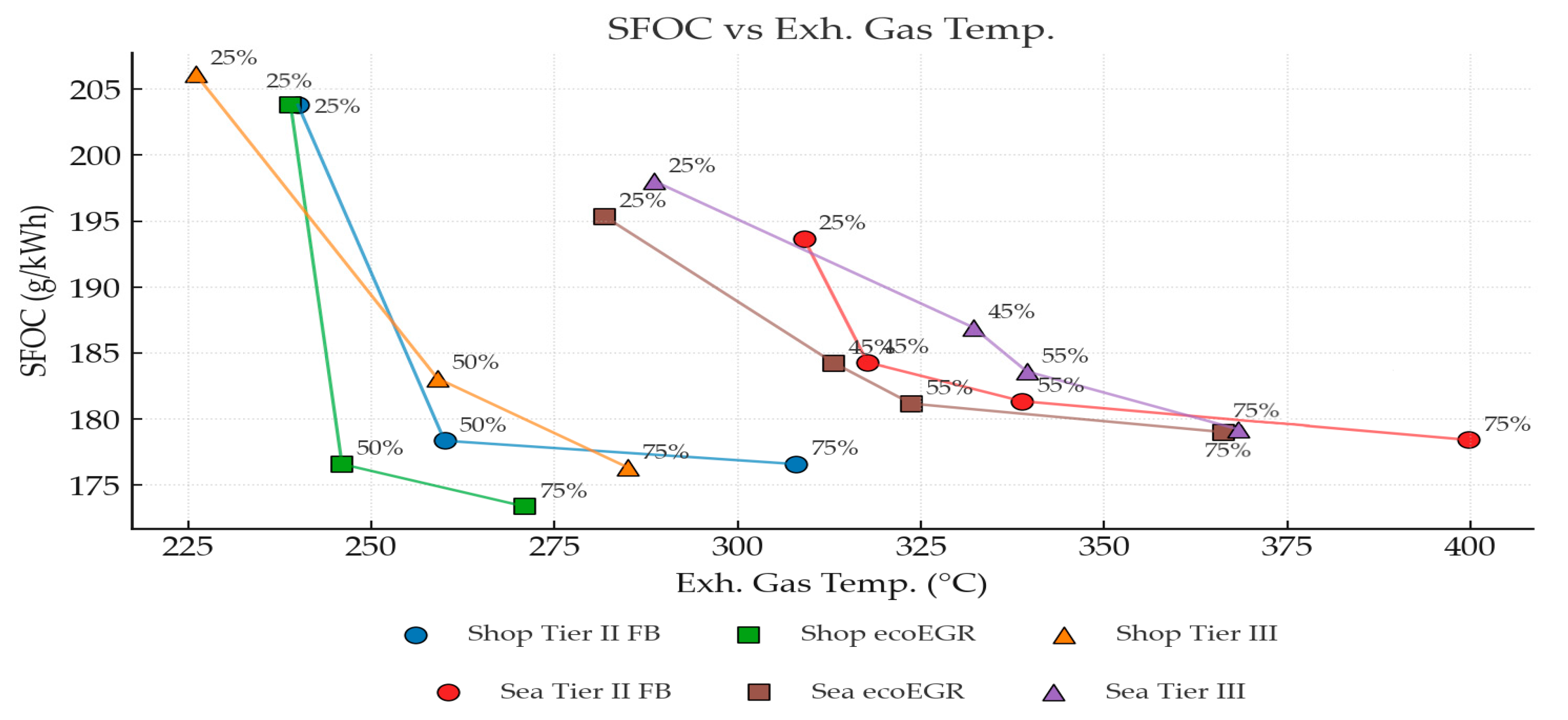

3.1.4. SFOC Versus Exh. Gas Temperature

Figure 9 reveals that higher exhaust gas temperatures are generally associated with elevated SFOC, reflecting less efficient combustion. Tier II-FB recorded the highest temperatures (up to 399.76 °C) with correspondingly lower NO

x, whereas Tier III operation consistently yielded cooler exhaust gas (down to 226.00 °C, a 43.5% reduction) but at the cost of higher SFOC. EcoEGR values (239.00–366.35 °C) overlapped with Tier II-FB, avoiding the extreme cooling of Tier III. The scatter observed in sea trial data compared with shop tests reflects operational variability, but the underlying correlation remains intact.

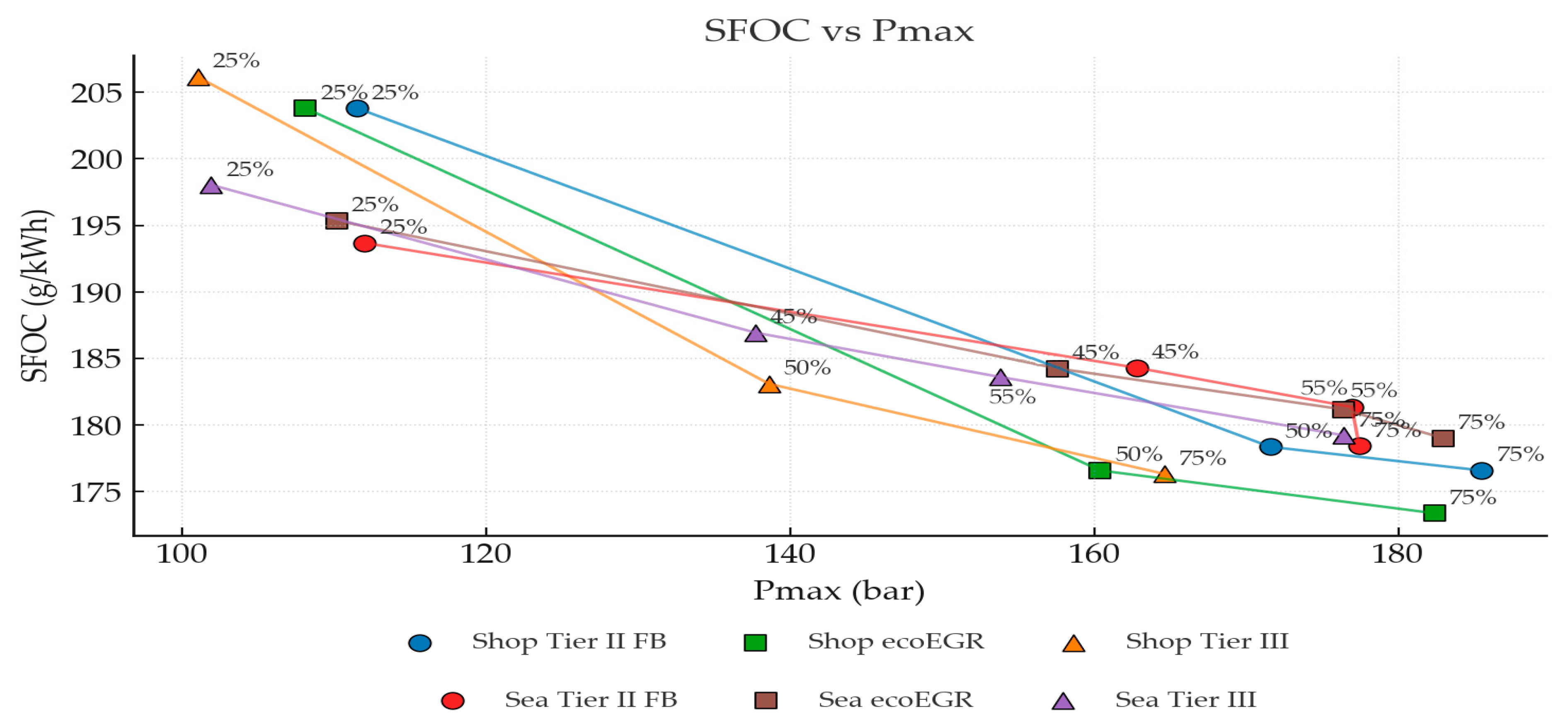

3.1.5. SFOC Versus Pmax

Figure 10 confirms the inverse correlation between Pmax and SFOC. Tier II-FB sustained the highest cylinder pressures (up to 185.50 bar) with relatively favorable fuel consumption (176.59–203.80 g/kWh). In contrast, Tier III recorded substantially reduced pressures (down to 101.00 bar, a 45.6% decrease), directly associated with the highest SFOC values. EcoEGR operated within 108.10–182.98 bar, providing a middle ground with more balanced efficiency outcomes.

3.2. NOx

3.2.1. NOx Versus Pmax

Figure 11 illustrates the strong relationship between Pmax and NO

x emissions. Tier II-FB produced the highest NO

x (up to 1464.27 ppm) alongside peak pressures, while Tier III achieved NO

x suppression to 346.00 ppm (76.4% lower) by reducing Pmax by nearly 46%. EcoEGR again demonstrated intermediate behavior, lowering NO

x by about 52% compared with Tier II FB, while sustaining relatively stable cylinder pressures. Despite some scatter in sea operation data, the overall trends between pressure reduction and NO

x abatement were consistent across datasets.

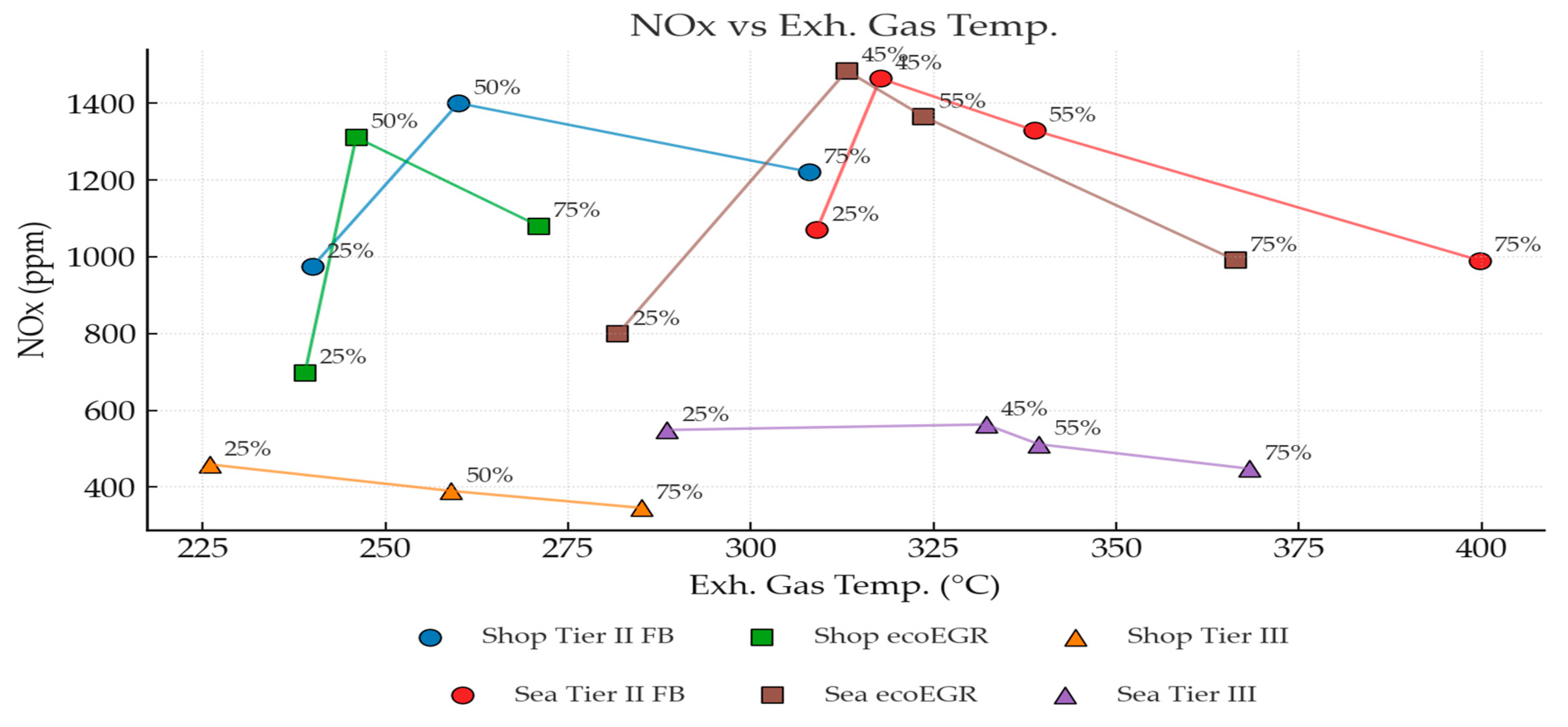

3.2.2. NOx Versus Exh. Gas Temperature

As expected from combustion kinetics,

Figure 12 shows a strong positive correlation between exhaust gas temperature and NO

x formation in Tier II-FB and ecoEGR. However, Tier III diverged from this relationship, producing lower exhaust gas temperatures (226.00–368.27 °C) due to charge dilution, which resulted in markedly lower NO

x emissions (346.00–563.14 ppm). The wider scatter observed in sea trial measurements is attributable to load fluctuations and ambient influences, but the general mechanism remained robust when compared with controlled shop test data.

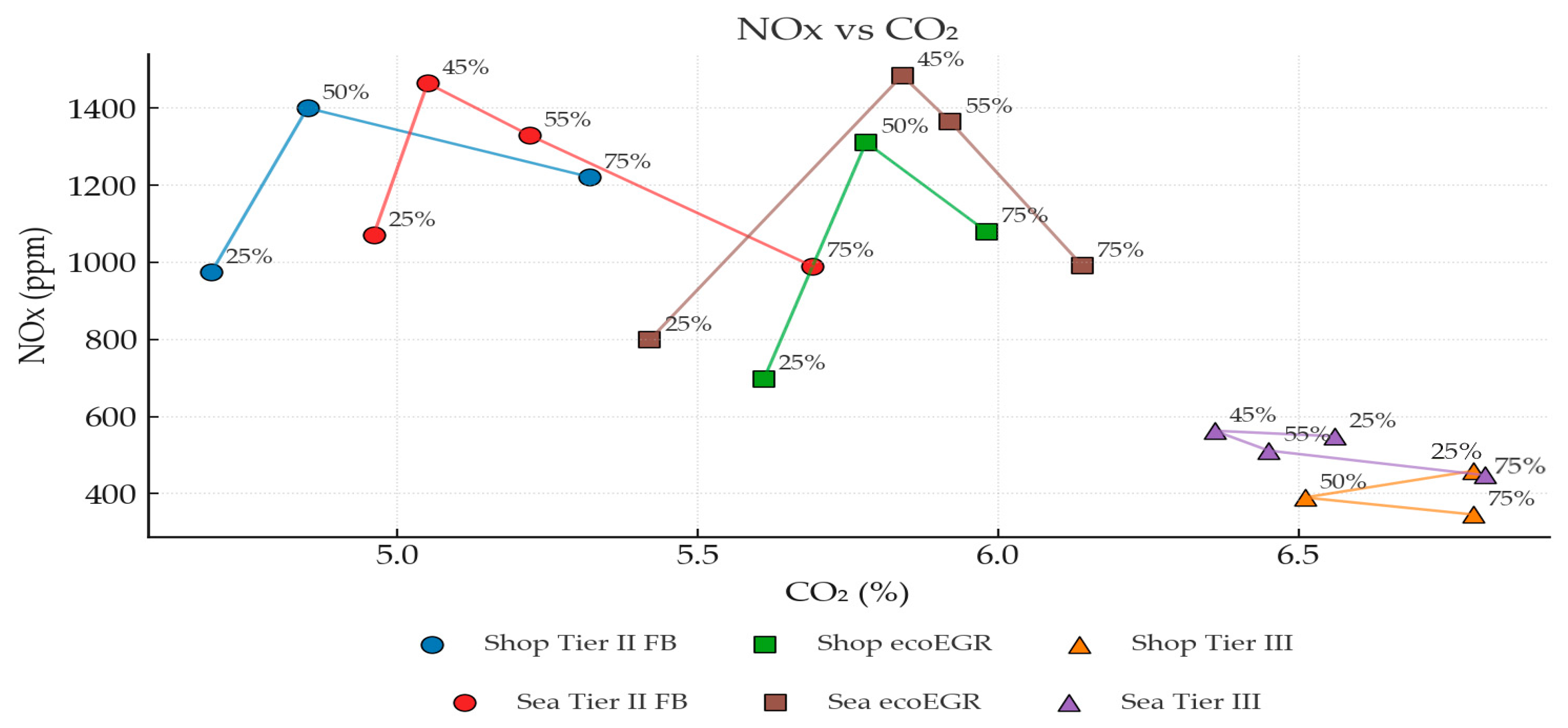

3.2.3. NOx Versus CO2

Figure 13 highlights the trade-off between CO

2 and NO

x. Tier III exhibited the strongest dilution effect, with CO

2 rising by 45.2% compared to Tier II-FB, while NO

x fell by more than 76%. EcoEGR balanced this compromise, limiting CO

2 increases to 30.9% while still achieving NO

x reductions of approximately 52%. This demonstrates ecoEGR’s ability to moderate the efficiency–emission penalty.

3.2.4. NOx Versus O2

Figure 14 confirms the inverse relationship between oxygen concentration and NO

x emissions. Tier II-FB, with O

2 up to 14.44%, produced the highest NO

x values (up to 1464.27 ppm). In contrast, Tier III clustered at low oxygen availability (11.41–12.27%) with minimum NO

x levels (346.00 ppm, a 76.4% reduction). EcoEGR again occupied the intermediate domain, reducing NO

x by approximately 52% while sustaining oxygen levels above 12.22%, reaffirming the dilution mechanism of EGR across both shop and sea conditions.

3.3. Overall Interpretation

The combined analysis of shop test and sea operation data provides a comprehensive understanding of the interaction between combustion pressure, exhaust characteristics, and efficiency parameters under tier-regulated EGR operation. Despite wider scatter in sea operation data due to operational variability, the overall correlations are consistent with controlled shop measurements.

- -

Tier III mode ensures full compliance with IMO Tier III NOx regulations, but incurs substantial penalties in fuel economy and combustion efficiency.

- -

EcoEGR mode demonstrates a favorable compromise, achieving partial NOx abatement with moderated increases in SFOC, highlighting its potential for practical application.

- -

Tier II FB mode delivers optimal fuel efficiency but lacks regulatory compliance with respect to NOx.

These findings provide critical empirical evidence for balancing emission reduction and operational efficiency in CPP-propelled two-stroke marine diesel engines, and can serve as a basis for the development of optimized EGR operating strategies for future IMO-compliant propulsion systems.

4. Discussion

To systematically evaluate the interrelations between combustion performance and emission indicators, Pearson correlation analyses were applied to key parameters including engine load, SFOC, Pmax, exhaust gas temperature (ExhTemp), NOx, CO2, and O2. This approach provides insights into the inherent trade-offs between fuel efficiency and emission control across different EGR strategies. The results demonstrated that correlations varied significantly depending on the operational mode: Tier II-FB exhibited efficiency-oriented patterns with weak NOx sensitivity, ecoEGR provided a balanced profile with moderate NOx reduction, and Tier III emphasized strict compliance through strong NOx suppression at the expense of efficiency.

As shown in

Figure 15, the correlation matrices illustrate the Pearson coefficients among the selected parameters, revealing the distinct combustion–emission characteristics of each operational mode. In Tier II-FB (

Figure 15a), correlations between NO

x and other key parameters remained weak, indicating high fuel efficiency but limited emission control capability. In contrast, ecoEGR (

Figure 15b) exhibited moderate positive correlations between NO

x and CO

2, achieving approximately 25–35% NO

x reduction with only minor increases in fuel consumption and CO

2 emissions. This suggests that ecoEGR, supported by precise EGR calibration and adaptive CPP load management, can serve as a balanced operational strategy under real sea conditions. Tier III (

Figure 15c) showed strong negative correlations between NO

x and both Pmax and ExhTemp, confirming that high EGR rates ensure compliance with IMO Tier III limits, albeit at the expense of increased SFOC and CO

2.

Furthermore, Load% showed consistently strong positive correlations with Pmax and CO2, and strong negative correlations with O2 across all modes, reaffirming the fundamental combustion mechanism whereby increasing load intensifies combustion and CO2 formation while reducing excess oxygen. From an operational perspective, these relationships provide actionable insights: optimized load distribution and propeller pitch control can be employed as practical levers to balance efficiency and emissions during voyage planning.

The influence of ambient conditions on combustion and emission variability is summarized below. The comparison between shop test and sea trial conditions highlights the role of meteorological factors in shaping correlation outcomes.

The data in

Table 8 compare the shop test environment (ambient temperature 8.9–18.5 °C, humidity 15–45%) with the sea trial environment (ambient temperature 37–39 °C, humidity 42–44%). The higher temperature and humidity during sea trials may have reduced air density and oxygen availability, which could have contributed to the wider scatter observed in NO

x and O

2 correlations. This suggests that meteorological factors should be considered when interpreting performance–emission trade-offs in real-world operations.

Compared with recent Tier III compliance technologies, such as selective catalytic reduction (SCR) systems and dual-fuel engines, ecoEGR emerges as a cost-effective and simpler alternative, particularly for retrofitted or training vessels with space and budget constraints. Previous studies have reported that while SCR achieves high NOx removal efficiency, it entails high installation and operating costs as well as risks of ammonia slip, and dual-fuel engines require extensive fuel infrastructure despite their decarbonization potential. By contrast, the present findings confirm that ecoEGR provides a practical balance of NOx reduction, fuel economy, and system simplicity, consistent with earlier reports that moderate EGR rates can maintain combustion stability with limited fuel penalties.

Overall, both graphical trend analysis and heatmap-based statistical evaluation converged on the conclusion that ecoEGR offers the most practical compromise between fuel efficiency and emission reduction for real-world applications, particularly when combined with optimized EGR tuning and CPP load management. Tier III ensures strict regulatory compliance but at the expense of efficiency, reinforcing the importance of strategic mode selection between emission control areas (ECAs) and general waters.

While this study focused on the MAN 5S35ME-B9.5 engine, EGR systems can also be applied to other two-stroke marine diesel engines of different outputs and sizes, and the correlations identified between combustion parameters and emission outcomes may be extended, to some extent, across different engine classes. However, variations in bore size, design features, and fuel type must be carefully considered, and further validation on large-bore and dual-fuel engines is required before the present findings can be fully generalized.

5. Conclusions

This study investigated the combustion and emission characteristics of a MAN 5S35ME-B9.5 two-stroke marine diesel engine equipped with an EGR system and a CPP, by analyzing both shop test and sea operation datasets across Tier II, ecoEGR, and Tier III operating modes. The results derived from the nine correlation graphs lead to the following conclusions:

(1) NOx Reduction Effectiveness

Tier III operation demonstrated the strongest NOx abatement, reducing emissions from 1464.27 ppm (Tier II FB maximum) to 346.00 ppm, corresponding to a 76.4% reduction. This was accompanied by a suppression of Pmax from 185.50 bar to 101.00 bar (45.6% decrease) and a reduction in exhaust gas temperature from 399.76 °C to 226.00 °C (43.5% decrease). EcoEGR provided intermediate mitigation, lowering NOx to 698.00 ppm (52.3% reduction) while maintaining more stable combustion parameters (Pmax 108.10–182.98 bar, Exh. Temp. 239.00–366.35 °C).

(2) Trade-Off with Fuel Consumption and CO2

Although Tier III achieved regulatory compliance, it also led to an increase in SFOC from 176.59 g/kWh (Tier II FB minimum) to 206.16 g/kWh (16.8% increase) and a rise in CO2 concentration from 4.69% to 6.81% (45.2% increase). EcoEGR offered a more favorable compromise: SFOC remained within 173.38–203.80 g/kWh (at worst a 15.4% increase compared to Tier II FB), while CO2 rose moderately to 6.14% (30.9% increase), achieving balanced efficiency and emission control.

(3) Correlation of Performance Indicators

Strong correlations were reaffirmed between NOx and key combustion indicators. NOx reduction of 76.4% under Tier III was directly associated with Pmax reduction of 45.6% and exhaust gas temperature decline of 43.5%. In contrast, correlations involving CO and O2 exhibited greater variability, especially in sea operation data where O2 ranged from 11.41% to 12.27% under Tier III compared with 12.79–14.44% in Tier II FB, reflecting sensitivity to external conditions and load fluctuations.

(4) Shop Test vs. Sea Operation Consistency

Despite operational scatter, sea trial data validated the fundamental patterns observed in shop tests. Tier III consistently clustered at low O2 (11.41–12.27%) and low NOx (346.00–563.14 ppm), while Tier II FB corresponded to higher O2 (12.79–14.44%) and higher NOx (974.00–1464.27 ppm). This reproducibility across datasets emphasizes that even under variable real-world conditions, the quantitative trade-offs remain consistent.

(5) Implications for Engine Optimization

The comparative analysis confirms that Tier III operation ensures IMO Tier III compliance, but with penalties of up to 16.8% higher SFOC and 45.2% higher CO2 emissions. By contrast, ecoEGR achieves moderate NOx reduction of 52.3% while limiting SFOC penalties to ≤15.4% and CO2 increases to ≤30.9%, making it a more attractive strategy for practical applications where efficiency and emissions must be balanced. These quantified results provide a robust empirical foundation for optimizing CPP-equipped two-stroke engines under varying EGR strategies.

In addition to the findings of this study, certain limitations must be acknowledged. First, the availability of Tier III sea-trial data was limited, restricting the ability to fully evaluate the long-term stability and operational variability under this mode. Furthermore, while shop tests provided stable reference conditions, real sea operation data were subject to environmental influences such as weather and load fluctuations, which introduced scatter that could not be fully quantified in this study.

Accordingly, future research should focus on securing extended Tier III operational datasets under actual navigation conditions to verify long-term performance and emission stability. Moreover, investigating the correlations between CO2 and particulate matter (PM), as well as minor emissions such as CO and CH4, would enhance the comprehensiveness of emission assessment. In addition, further research is needed on (i) the integration of after-treatment technologies such as EGR–SCR, (ii) additional sea trials under diverse operating conditions, (iii) the development of experimental data-based digital twin models for engine optimization, and (iv) the applicability of the present results to regulatory evaluations such as CII and EEXI. Finally, the integration of machine-learning or AI-based predictive models with empirical datasets could enable real-time optimization of EGR calibration and CPP load management, thereby contributing to the advancement of practical operational strategies for meeting IMO regulatory requirements.