Experimental Parametric Study on the Primary Efficiency of a Fixed Bottom-Detached Oscillating Water Column Wave Energy Converter in Short-Fetch Sea Conditions

Abstract

1. Introduction and Motivations

2. State of the Art of Laboratory Tests on Fixed OWC Devices

- The hydrodynamic and energy-harvesting performances are still mainstream in the research related to OWC devices. Site-specific studies are fundamental, and most of the previous studies refer to long-fetch wave conditions which may be significantly different from short-fetch ones (e.g., those of the Mediterranean or North Sea).

- Matching studies between the chamber and PTO damping are still needed to provide the manufacturer with the target characteristic functioning of the air turbine to be designed to maximize both the primary and secondary efficiency of the device. Most of the studies on the OWC plant use the orifice or porous media to represent the PTO, given the scaling issues unavailable for the air turbine component. In these studies, the PTO is often characterized in terms of opening ratios only (i.e., the ratio of the area of the orifice to that of the horizontal cross-section of the OWC chamber). The damping coefficient, establishing the relation between the air chamber pressure and airflow rate, is often disregarded, but it could provide more meaningful information for the air turbine’s manufacturing.

3. Description of Laboratory Tests

3.1. Model Description

3.2. Variable Model Design Parameters for the Parametric Study

- (i)

- 3 sizes of the chamber length, W;

- (ii)

- 3 values of the front wall draught, D;

- (iii)

- 9 circular vent duct diameters, V, with an aperture equal to 0.5%, 1%, and 2% of the OWC horizontal section area (as further described in Section PTO Modelling).

PTO Modelling

3.3. Instrumentation and Data Acquisition

3.4. Wave Conditions

3.5. Data Acquisition and Analysis

3.5.1. Assessment of the Natural Frequency of the OWC

3.5.2. Assessment of the OWC Performance

4. Results and Discussion

4.1. Effect of the OWC Chamber Length

4.2. Effect of the OWC Front Wall Draught

4.3. Effect of the Damping Induced by the PTO

4.4. Performance of the OWC Device

Possible Source of Uncertainty in the Estimation of the Performance

- (i)

- the modelling of the PTO component (which, in this case, is schematized only with the damping associated with it);

- (ii)

- specific laboratory effects such as residual motions inside the flume at the beginning of the test, wave reflections, and transverse non-uniformity;

- (iii)

- effect of the sensor accuracy, possible calibration errors, and noise on the signal.

5. Conclusions

- (i)

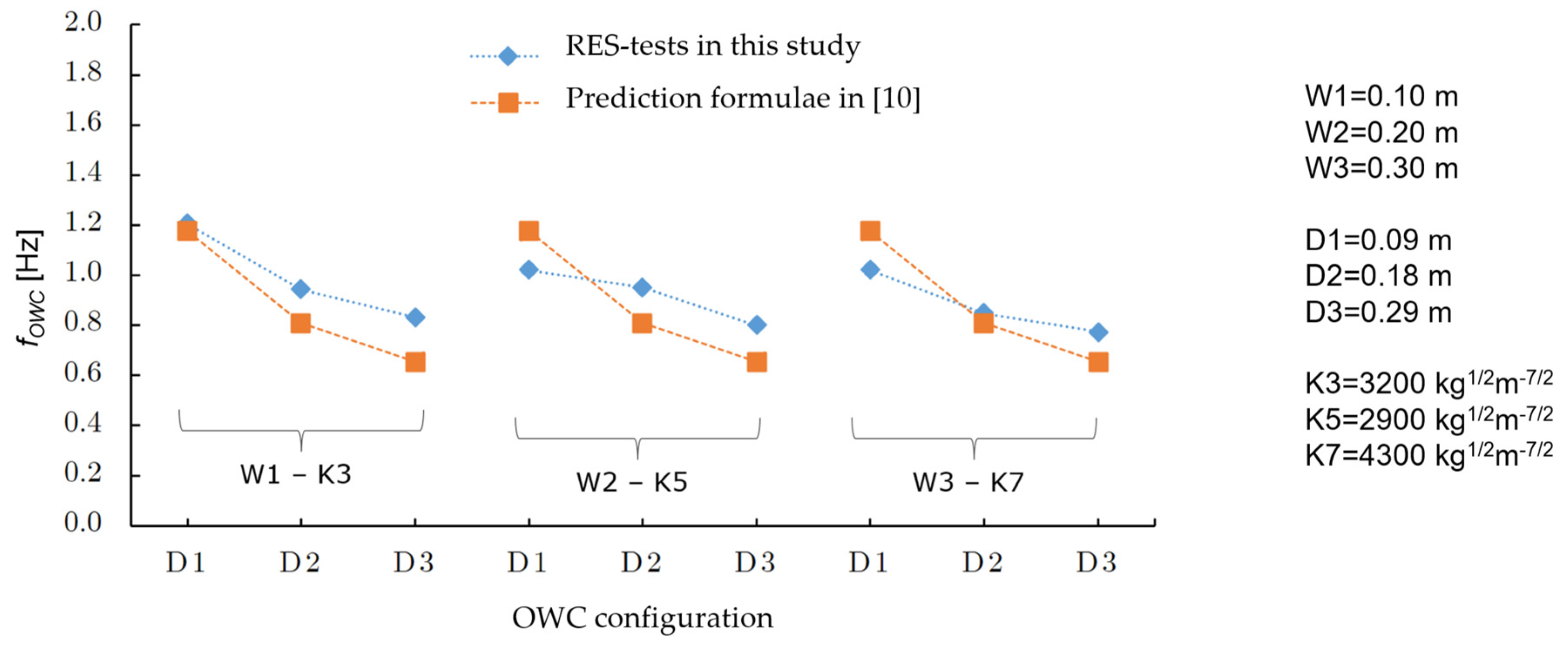

- The natural frequency fOWC of the tested OWC device, as resulting from specifically conceived laboratory tests, is in the range of fOWC = 0.6–1.0 Hz. The value of fOWC is mainly determined by its front wall draught D.

- (ii)

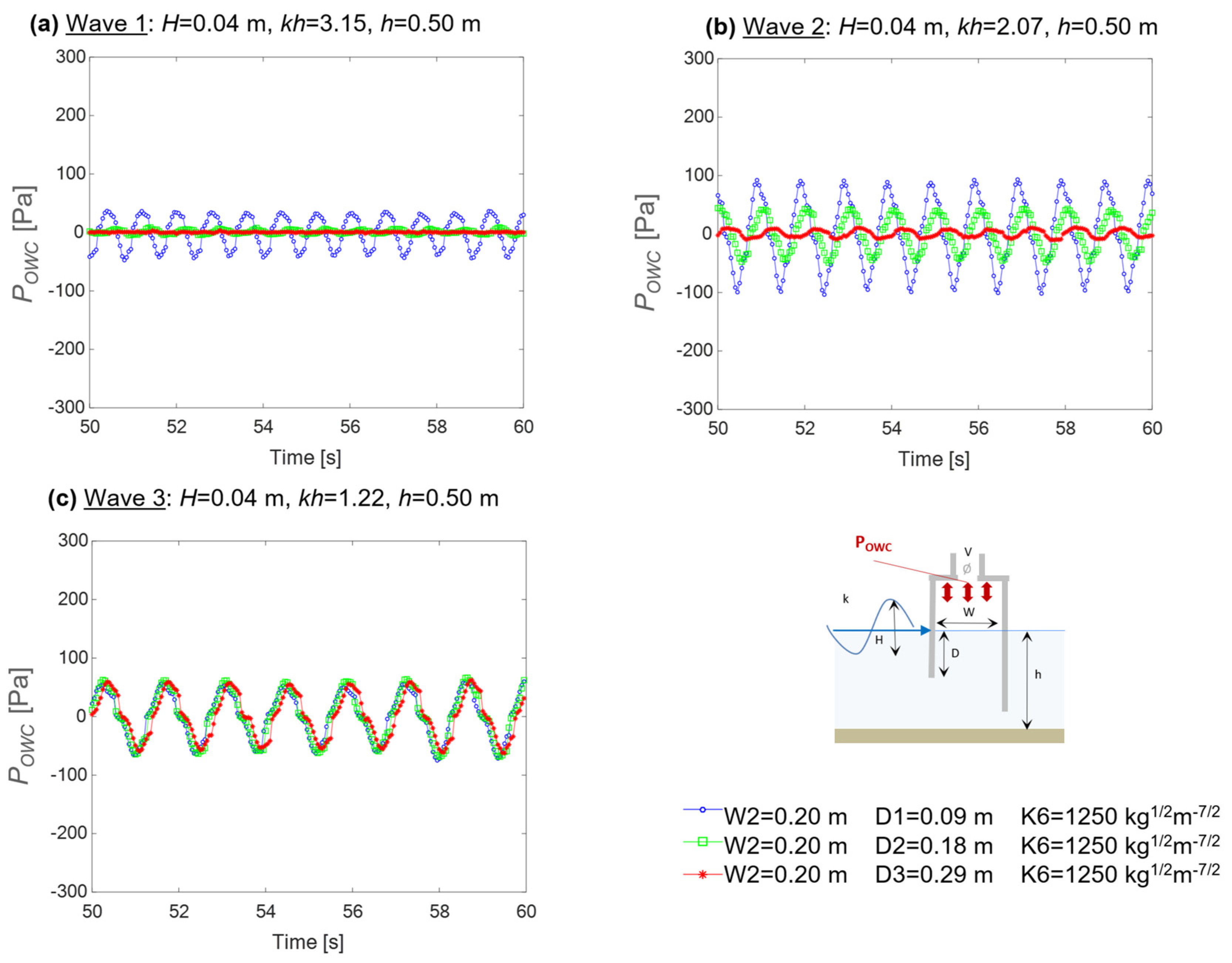

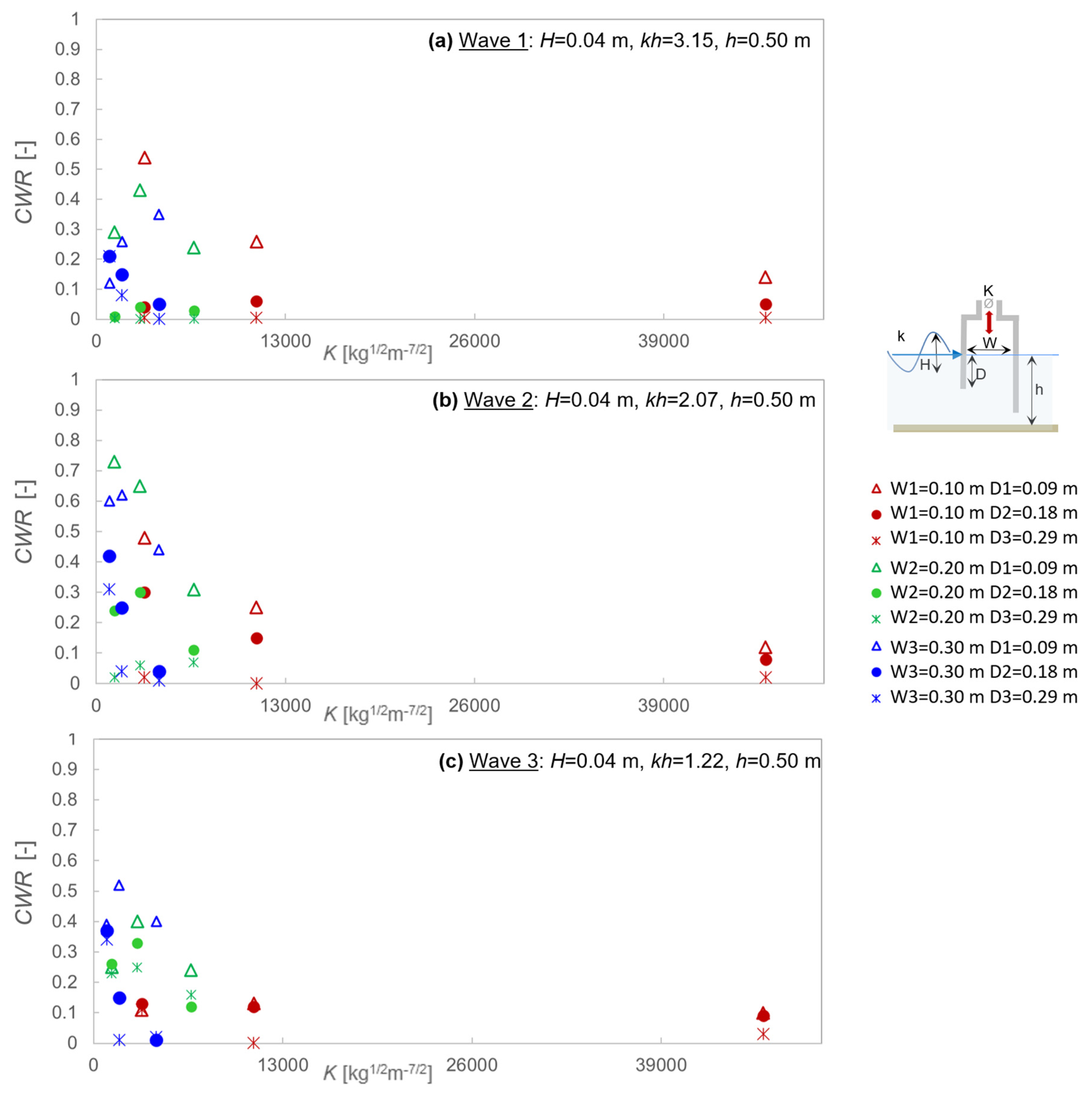

- Increasing values of the damping coefficient K associated with each vent diameter V results in higher inner air pressure POWC, but in lower inner water surface oscillations ηOWC and airflow rates QOWC. An optimal value of damping exists for each geometry of the OWC chamber. In the present study, the optimal PTO-applied damping is in the range of 900–4300 kg1/2 m−7/2.

- (iii)

- For the tested wave conditions and OWC geometries, decreasing the front wall draught D implies an increase in POWC, ηOWC, and QOWC, although, for the longer wave condition (relative water depth kh = 1.22), such differences are strongly attenuated.

- (iv)

- Laboratory tests indicate that, for the short-fetch conditions of this study, higher capture width ratios are obtained for a relative chamber width of W/L = 0.07–0.19 and a relative front wall draught of D/H~2.25. A maximum value of capture width ratio of around 73% is found in such conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Falcão, A.F.O.; Henriques, J.C.C. Oscillating-water-column wave energy converters and air turbines: A review. Renew. Energy 2016, 85, 1391–1424. [Google Scholar] [CrossRef]

- Ozkop, E.; Altas, I.H. Control, power and electrical components in wave energy conversion systems: A review of the technologies. Renew. Sustain. Energy Rev. 2017, 67, 106–115. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C.; Gato, L.M.C. Self-rectifying air turbines for wave energy conversion: A comparative analysis. Renew. Sustain. Energy Rev. 2018, 91, 1231–1241. [Google Scholar] [CrossRef]

- Masuda, Y. Wave-Activated Generator; International Colloq Exposition Oceans: Bordeaux, France, 1971. [Google Scholar]

- Masuda, Y.; McCormick, M.E. Experiences in pneumatic wave energy conversion in Japan, In Utilization of Ocean Waves: Wave to Energy Conversion; McCormick, M.E., Kim, Y.C., Eds.; Amer Society of Civil Engineers: New York, NY, USA, 1986; pp. 1–33. [Google Scholar]

- Whittaker, T.J.T.; McIlhagger, D.S.; Barr, A.G. Wells Turbines for Navigation Buoys; Twidell, J., Riddoch, F., Grainger, B., Eds.; Energy for Rural and Island Communities: Pergamon, Turkey, 1984; pp. 289–297. ISBN 9780080305806. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Gato, L.M.C. Air Turbines. In Comprehensive Renewable Energy; Sayigh, A., Ed.; Elsevier: Oxford, UK, 2012; Volume 8, pp. 111–149. [Google Scholar]

- McCormick, M. Ocean Wave Energy Conversion; John Wiley Sons: New York, NY, USA, 1981. [Google Scholar]

- Evans, D.; Porter, R. Hydrodynamic characteristics of an oscillating water column device. Appl. Ocean Res. 1995, 17, 155–164. [Google Scholar] [CrossRef]

- McCormick, M.E. Ocean Wave Energy Conversion; Dover publications: New York, NY, USA, 2007. [Google Scholar]

- Boccotti, P. Comparison between a U-OWC and a conventional OWC. Ocean. Eng. 2007, 34, 799–805. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C.; Gato, L.M.C.; Gomes, R.P.F. Air turbine choice and optimization for floating oscillating-water-column wave energy converter. Ocean. Eng. 2014, 75, 148–156. [Google Scholar] [CrossRef]

- Ravindran, M.; Koola, P.M. Energy from sea waves e the Indian wave energy program. Curr. Sci. 1991, 60, 676–680. [Google Scholar]

- Heath, T.; Whittaker, T.J.T.; Boake, C.B. The design construction and operation of the LIMPET wave energy converter (Islay, Scotland). In Proceedings of the 4th European Wave Energy Conference, Aalborg, Denmark, 4–6 December 2000; pp. 49–55. [Google Scholar]

- Falcão, A.F.O. The shoreline OWC wave power plant at the Azores. In Proceedings of the 4th European Wave Energy Conference, Aalborg, Denmark, 4–6 December 2000; pp. 42–47. [Google Scholar]

- Suzuki, M.; Arakawa, C.; Takahashi, S. Performance of a wave power generating system installed in breakwater at Sakata port in Japan. In Proceedings of the 14th International Offshore and Polar Engineering Conference, Toulon, France, 23–28 May 2004. [Google Scholar]

- Torre-Enciso, Y.; Ortubia, I.; Lopez de Aguileta, L.I.; Marques, J. Mutriku wave power plant: From the thinking out to the reality. In Proceedings of the 8th European Wave and Tidal Energy Conference, Uppsala, Sweden, 7–10 September 2009; pp. 319–329. [Google Scholar]

- Mustapa, M.A.; Yaakob, O.B.; Yasser, M.A.; Rheem, C.-K.; Koh, K.K.; Adnan, F.A. Wave energy device and breakwater integration: A review. Renew. Sustain. Energy Rev. 2017, 77, 43–58. [Google Scholar] [CrossRef]

- Vicinanza, D.; Di Lauro, E.; Contestabile, P.; Gisonni, G. Review of Innovative Harbor Breakwaters for Wave-Energy Conversion. J. Waterw. Port Coast. Ocean. Eng. 2019, 145, 03119001. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L. Hydraulic performance of oscillating water column structures as anti-reflection devices to reduce harbour agitation. Coast. Eng. 2021, 165, 103837. [Google Scholar] [CrossRef]

- Simonetti, I.; Esposito, A.; Cappietti, L. Experimental Proof-of-Concept of a Hybrid Wave Energy Converter Based on Oscillating Water Column and Overtopping Mechanisms. Energies 2022, 15, 8065. [Google Scholar] [CrossRef]

- Iglesias, G.; Carballo, R. Wave energy and nearshore hot spots: The case of the SE Bay of Biscay. Renew. Energy 2010, 35, 2490–2500. [Google Scholar] [CrossRef]

- Vicinanza, D.; Contestabile, P.; Ferrante, V. Wave energy potential in the north-west of Sardinia (Italy). Renew. Energy 2013, 50, 506–521. [Google Scholar] [CrossRef]

- Hadadpour, S.; Etemad-Shahidi, A.; Jabbari, E.; Kamranzad, B. Wave energy and hot spots in Anzali port. Energy 2014, 74, 529–536. [Google Scholar] [CrossRef]

- Vannucchi, V.; Cappietti, L. Wave Energy Assessment and Performance Estimation of State of the Art Wave Energy Converters in Italian Hotspots. Sustainability 2016, 8, 1300. [Google Scholar] [CrossRef]

- Count, B.; Fry, R.; Haskell, J.; Jackson, N. The MEL Oscillating Water Column; C.E.G.B. Report RD/M/I 157N81; U.K. Marchwood Eng. Lab.: Marchwood, UK, 1981. [Google Scholar]

- Robinson, R.N.; Murray, A. Geometric-wavefield influence on the behaviour of an oscillating water column. In Proceedings of the International Symposium on Hydrodynamics in Ocean Engineering, The Norwegian Institute of Technology, Trondheim, Norway, 24–28 August 1981; pp. 1067–1086. [Google Scholar]

- Maeda, H.; Kinoshita, T.; Masuda, K.; Kato, W. Fundamental research on oscillating water column wave power absorbers. J. Energy Res. Tech. 1985, 150, 81–86. [Google Scholar] [CrossRef]

- Sarmento, A.J.N.A. Wave flume experiments on two-dimensional oscillating water column wave energy devices. Exp. Fluids 1992, 12, 286–292. [Google Scholar] [CrossRef]

- Sarmento, A.J.N.A.; Falco, A.E.d.O. Wave generation by an oscillating surface-pressure and its application in wave-energy extraction. J. Fluid Mech. 1985, 150, 467–485. [Google Scholar] [CrossRef]

- Raghunathan, S. The wells air turbine for wave energy conversion. Prog. Aerosp. Sci. 1995, 31, 335–386. [Google Scholar] [CrossRef]

- McCormick, M.E. Ocean wave energy concepts. In Proceedings of the MTS-IEEE Oceans 79 Conference, San Diego, CA, USA, 17–19 September 1979; pp. 553–557. [Google Scholar]

- Richards, D.; Weiskopf, F.B. Studies with and testing of the McCormick pneumatic wave energy turbine with some comments on PWECS systems. In Utilization of Ocean Waves—Wave to Energy Conversion; McCormick, M.E., Kim, Y.C., Eds.; ASCE: New York, NY, USA, 1986; pp. 80–102. [Google Scholar]

- Sarmento, A.J.N.A. Model test optimization of an OWC. Int. J. Offshore Polar Eng. 1993, 3, 66–72. [Google Scholar]

- Morris-Thomas, M.; Irvin, R.J.; Thiagarajan, K.P. An Investigation into the Hydrodynamic Efficiency of an Oscillating Water Column. J. Offshore Mech. Arct. Eng. 2007, 129, 273. [Google Scholar] [CrossRef]

- Sheng, W.; Lewis, T.; Alcorn, R. On wave energy extraction of oscillating water column device. In Proceedings of the 4th International Conference on Ocean Energy, Dublin, Ireland, 17–19 October 2012; pp. 1–9. [Google Scholar]

- López, I.; Iglesias, G.; Lopez, M.; Castro, F.; Rodríguez, M.A. Turbine−chamber coupling in an OWC Wave Energy Converter. Civ. Eng. 2012, 2, 1–7. [Google Scholar]

- López, I.; Iglesias, G. Efficiency of OWC wave energy converters: A virtual laboratory. Appl. Ocean. Res. 2014, 44, 63–70. [Google Scholar] [CrossRef]

- López, I.; Castro, A.; Iglesias, G. Hydrodynamic performance of an oscillating water column wave energy converter by means of particle imaging velocimetry. Energy 2015, 83, 89–103. [Google Scholar] [CrossRef]

- Lopez, I.; Pereiras, B.; Castro, F.; Iglesias, G. Optimisation of turbine-induced damping for an OWC wave energy converter using a RANS-VOF numerical model. Appl. Energy 2014, 127, 105–114. [Google Scholar] [CrossRef]

- Pereiras, B.; Lopez, I.; Castro, F.; Iglesias, G. Non-dimensional analysis for matching an impulse turbine to an OWC (oscillating water column) with an optimum energy transfer. Energy 2015, 87, 481–489. [Google Scholar] [CrossRef]

- Iturrioz, A.; Guanche, R.; Armesto, J.; Alves, M.; Vidal, C.; Losada, I. Time-domain modeling of a fixed detached oscillating water column towards a floating multi-chamber device. Ocean. Eng. 2014, 76, 65–74. [Google Scholar] [CrossRef]

- Iturrioz, A.; Guanche, R.; Lara, J.; Vidal, C.; Losada, I. Validation of OpenFOAM® for Oscillating Water Column three-dimensional modeling. Ocean. Eng. 2015, 107, 222–236. [Google Scholar] [CrossRef]

- Ning, D.Z.; Wang, R.Q.; Zou, Q.P.; Teng, B. An experimental investigation of hydrodynamics of a fixed OWC Wave Energy Converter. Appl. Energy 2016, 168, 636–648. [Google Scholar] [CrossRef]

- Vyzikas, T.; Deshoulières, S.; Barton, M.; Giroux, O.; Greaves, D.; Simmonds, D. Experimental investigation of different geometries of fixed oscillating water column devices. Renew. Energy 2016, 104, 248–258. [Google Scholar] [CrossRef]

- He, F.; Huang, Z. Hydrodynamic performance of pile-supported OWC-type structures as breakwaters: An experimental study. Ocean. Eng. 2014, 88, 618–626. [Google Scholar] [CrossRef]

- Elhanafi, A.; Macfarlane, G.; Fleming, A.; Leong, Z. Experimental and numerical investigations on the hydrodynamic performance of a floating–moored oscillating water column wave energy converter. Appl. Energy 2017, 205, 369–390. [Google Scholar] [CrossRef]

- Viviano, A.; Naty, S.; Foti, E.; Bruce, T.; Allsop, W.; Vicinanza, D. Large-scale experiments on the behaviour of a generalised Oscillating Water Column under random waves. Renew. Energy 2016, 99, 875–887. [Google Scholar] [CrossRef]

- Pawitan, K.A.; Dimakopoulos, A.S.; Vicinanza, D.; Allsop, W.; Bruce, T. A loading model for an OWC caisson based upon large-scale measurements. Coast. Eng. 2019, 145, 1–20. [Google Scholar] [CrossRef]

- Ashlin, S.J.; Sannasiraj, S.A.; Sundar, V. Performance of an array of oscillating water column devices integrated with an offshore detached breakwater. Ocean. Eng. 2018, 163, 518–532. [Google Scholar] [CrossRef]

- David, D.R.; Vallam, S.; Annamalaisamy, S.S. Effect of Harbor Walls on the Efficiency of an Oscillating Water Column. J. Waterw. Port Coast. Ocean. Eng. 2018, 144, 04017043. [Google Scholar] [CrossRef]

- Perez-Collazo, C.; Greaves, D.; Iglesias, G. Hydrodynamic response of the WEC sub-system of a novel hybrid wind-wave energy converter. Energy Convers. Manag. 2018, 171, 307–325. [Google Scholar] [CrossRef]

- Michele, S.; Renzi, E.; Perez-Collazo, C.; Greaves, D.; Iglesias, G. Power extraction in regular and random waves from an OWC in hybrid wind-wave energy systems. Ocean. Eng. 2019, 191, 106519. [Google Scholar] [CrossRef]

- Zabihi, M.; Mazaheri, S.; Montazeri Namin, M. Experimental hydrodynamic investigation of a fixed offshore Oscillating Water Column device. Appl. Ocean. Res. 2019, 85, 20–33. [Google Scholar] [CrossRef]

- Celik, A.; Altunkaynak, A. Experimental investigations on the performance of a fixed-oscillating water column type wave energy converter. Energy 2019, 188, 116071. [Google Scholar] [CrossRef]

- Ning, D.; Wang, R.; Chen, L.; Sun, K. Experimental investigation of a land-based dual-chamber OWC wave energy converter. Renew. Sustain. Energy Rev. 2019, 105, 48–60. [Google Scholar] [CrossRef]

- López, I.; Carballo, R.; Taveira-Pinto, F.; Iglesias, G. Sensitivity of OWC performance to air compressibility. Renew. Energy 2020, 145, 1334–1347. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. Model-prototype similarity of oscillating water-column wave energy converters. Int. J. Mar. Energy 2014, 6, 18–34. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L.; Elsafti, H.; Oumeraci, H. Evaluation of air compressibility effects on the performance of fixed OWC wave energy converters using CFD modelling. Renew. Energy 2018, 119, 741–753. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, C.; Qu, N.; Cui, Y.; Kim, K. Overall performance evaluation of a model-scale OWC wave energy converter. Renew. Energy 2020, 149, 1325–1338. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, l.; Li, M.; Johanning, L. Experimental investigation on the hydrodynamic performance of a multi-chamber OWC-breakwater. Renew. Sustain. Energy Rev. 2021, 150, 111512. [Google Scholar] [CrossRef]

- Sun, Y.; Ning, D.; Mayon, R.; Chen, Q. Experimental and numerical investigation on hydrodynamic performance of a 3D land-fixed OWC wave energy converter. Appl. Ocean. Res. 2023, 141, 103805. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, C.; Kim, K.; Zhang, X.; Ning, D. Hydrodynamic and energy-harvesting performance of an isolated oscillating water column device: An experimental study. Coast. Eng. 2024, 189, 104459. [Google Scholar] [CrossRef]

- Goda, Y.; Suzuki, Y. Estimation of incident and reflected waves in regular wave experiments. Ocean. Eng. 1995, 22, 77–86. [Google Scholar] [CrossRef]

- Vannucchi, V. Wave Energy Harvesting in the Mediterranean Sea. Ph.D. Thesis, Florence University, Florence, Italy, 2012. [Google Scholar]

- Hasselmann, K.; Barnett, T.P.; Bouws, E.; Carlson, H.; Cartwright, D.E.; Enke, K.; Ewing, J.A.; Gienapp, A.; Hasselmann, D.E.; Kruseman, P.; et al. Measurements of Wind-Wave Growth and Swell Decay during the Joint North Sea Wave Project (JONSWAP). Ergaenzungsheft Dtsch. Hydrogr. Z. Reihe A 1973, 95. [Google Scholar]

- Simonetti, I.; Cappietti, L.; El Safti, H.; Oumeraci, H. Numerical modelling of fixed oscillating water column wave energy conversion devices: Toward geometry hydraulic optimization. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, St. John’s, NL, Canada, 31 May–5 June 2015; Volume 9. [Google Scholar]

- Vyzikas, T.; Deshoulieres, S.; Giroux, O.; Barton, M.; Greaves, D. Numerical study of fixed Oscillating Water Column with RANS-type two-phase CFD model. Renew. Energy 2017, 102, 294–305. [Google Scholar] [CrossRef]

- Celik, A.; Altunkaynak, A. Determination of hydrodynamic parameters of a fixed OWC by performing experimental and numerical free decay tests. Ocean. Eng. 2020, 204, 106827. [Google Scholar] [CrossRef]

- Silva, C.W.d. Vibration: Fundamentals and Practice, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Cruz, J. Ocean Wave Energy Current Status and Future Perspectives; Springer Science & Business Media: New York, NY, USA, 2008. [Google Scholar]

- White, F.M. Fluid Mechanics, 7th ed.; McGraw-Hill Series in Mechanical Engineering: London, UK, 2016; p. 1023. [Google Scholar]

- Simonetti, I.; Cappietti, L.; Elsafti, H.; Oumeraci, H. Optimization of the geometry and the turbine induced damping for fixed detached and asymmetric OWC devices: A numerical study. Energy 2017, 139, 1197–1209. [Google Scholar] [CrossRef]

- Chen, J.; Wen, H.; Wang, Y.; Wang, G. A correlation study of optimal chamber width with the relative front wall draught of onshore OWC device. Energy 2021, 225, 120307. [Google Scholar] [CrossRef]

- Qu, M.; Yu, D.; Li, Y.; Gao, Z. Effect of relative chamber width on energy conversion and mechanical characteristics of the offshore OWC device: A numerical study. Energy 2023, 275, 127372. [Google Scholar] [CrossRef]

- He, F.; Pan, J.; Lin, Y.; Song, M.; Zheng, S. Development of an oscillating water column-type wave absorber for anti-reflection and effective energy extraction. Appl. Ocean. Res. 2024, 144, 103910. [Google Scholar] [CrossRef]

- Simonetti, I.; Crema, I.; Cappietti, L.; El Safti, H.; Oumeraci, H. Site-specific optimization of an OWC wave energy converter in a Mediterranean area. In Progress in Renewable Energies Offshore, Proceedings of the 2nd International Conference on Renewable Energies Offshore, Lisbon, Portugal, 24–26 October 2016; CRC Press: Boca Raton, FL, USA; pp. 343–350.

- Nguyen, D.T.; Chow, Y.; Lin, C. Modeling and performance estimation for L-shaped OWC wave energy converters with a theoretical correction for spring-like air compressibility. Renew. Energy 2024, 237 Pt A, 121499. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C.; Gomes, R.P.F.; Portillo, J.C.C. Theoretically based correction to model test results of OWC wave energy converters to account for air compressibility effect. Renew. Energy 2022, 198, 41–50. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. The spring-like air compressibility effect in oscillating-water-column wave energy converters: Review and analyses. Renew. Sustain. Energy Rev. 2019, 112, 483–498. [Google Scholar] [CrossRef]

- Elhanafi, A.; Macfarlane, G.; Fleming, A.; Leong, Z. Scaling and air compressibility effects on a three-dimensional offshore stationary OWC wave energy converter. Appl. Energy 2017, 189, 1–20. [Google Scholar] [CrossRef]

- Orphin, J.; Nader, J.; Penesis, I. Uncertainty analysis of a WEC model test experiment. Renew. Energy 2021, 168, 216–233. [Google Scholar] [CrossRef]

- Sierra, J.P.; Castrillo, R.; Mestres, M.; Mösso, C.; Lionello, P.; Marzo, L. Impact of Climate Change on Wave Energy Resource in the Mediterranean Coast of Morocco. Energies 2020, 13, 2993. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L. Projected Trends in Wave Energy Potentials along the European Coasts and Implications for Wave Energy Exploitation (1976–2100). J. Mar. Sci. Eng. 2024, 12, 239. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L. Mediterranean coastal wave-climate long-term trend in climate change scenarios and effects on the optimal sizing of OWC wave energy converters. Coast. Eng. 2023, 179, 104247. [Google Scholar] [CrossRef]

| FIXED DESIGN PARAMETERS | |||

|---|---|---|---|

| Notation | Description | [Unit] | Value |

| B | Chamber width | [m] | 0.20 |

| G | Back wall length | [m] | 0.45 |

| Fc | Freeboard | [m] | +0.16 S.W.L. |

| G-Fc | Back wall draught | [m] | 0.29 |

| thfbt | Front-, back-, and top-cover wall thickness | [m] | 0.01 |

| ths | Side wall thickness | [m] | 0.008 |

| VARIED DESIGN PARAMETERS | |||

| Notation | Description | [Unit] | Value |

| W | Chamber length | [m] | W1 = 0.10 W2 = 0.20 W3 = 0.30 |

| D | Front wall draught | [m] | D1 = 0.09 D2 = 0.18 D3 = 0.29 |

| V | Vent duct diameter | [m] | V1 = 0.008 V2 = 0.014 V3 = 0.020 V4 = 0.016 V5 = 0.021 V6 = 0.030 V7 = 0.018 V8 = 0.026 V9 = 0.036 |

| Vent Duct Diameter V [m] | OWC Length W [m] | Damping K [kg1/2 m−7/2]- Best Fit for the Exhalation Phase | Damping Kin [kg1/2 m−7/2]- Best Fit for the Inhalation Phase |

|---|---|---|---|

| V1 = 0.008 | W1 = 0.1 | K1 = 46,000 | Kin1 = 49,000 |

| V2 = 0.014 | W1 = 0.1 | K2 = 11,000 | Kin2 = 15,000 |

| V3 = 0.020 | W1 = 0.1 | K3 = 3300 | Kin3 = 3800 |

| V4 = 0.016 | W2 = 0.2 | K4 = 6700 | Kin4 = 10,000 |

| V5 = 0.021 | W2 = 0.2 | K5 = 3000 | Kin5 = 3600 |

| V6 = 0.030 | W2 = 0.2 | K6 = 1250 | Kin6 = 1700 |

| V7 = 0.018 | W2 = 0.3 | K7 = 4300 | Kin7 = 4900 |

| V8 = 0.026 | W2 = 0.3 | K8 = 1750 | Kin8 = 2150 |

| V9 = 0.036 | W2 = 0.3 | K9 = 900 | Kin9 = 1000 |

| Regular Waves | ||||||

|---|---|---|---|---|---|---|

| Wave | H [m] | T [s] | f [Hz] | kh [-] | H/λ [-] | Sampling Duration [s] |

| 1 | 0.042 | 0.8 | 1.25 | 3.15 | 0.040 | 70 |

| 2 | 0.043 | 1.0 | 1.00 | 2.07 | 0.025 | 70 |

| 3 | 0.042 | 1.4 | 0.71 | 1.22 | 0.013 | 70 |

| Irregular Waves | ||||||

| Wave * | Hs [m] | Tp [s] | fp [Hz] | kh [-] | H/λ [-] | Duration [s] |

| 4 | 0.021 | 0.9 | 1.11 | 2.68 | 0.021 | 100 |

| 5 | 0.021 | 1.0 | 1.00 | 2.28 | 0.019 | 100 |

| 6 | 0.038 | 1.0 | 1.00 | 2.23 | 0.028 | 100 |

| 7 | 0.040 | 1.0 | 1.00 | 1.88 | 0.024 | 100 |

| 8 | 0.057 | 1.1 | 0.91 | 1.85 | 0.034 | 100 |

| OWC Model | TOWC [s] FDA | TOWC [s] LDM | OWC Model | TOWC [s] FDA | TOWC [s] LDM | OWC Model | TOWC [s] FDA | TOWC [s] LDM |

|---|---|---|---|---|---|---|---|---|

| W1D1K1 | - * | - | W2D1K4 | - | 0.98 | W3D1K7 | - | 0.98 |

| W1D2K1 | - | - | W2D2K4 | - | 1.13 | W3D2K7 | - | 1.18 |

| W1D3K1 | - | - | W2D3K4 | 1.23 | 1.25 | W3D3K7 | - | 1.29 |

| W1D1K2 | 0.82 | 0.85 | W2D1K5 | 1.00 | 0.98 | W3D1K8 | 1.03 | 1.02 |

| W1D2K2 | 1.05 | 1.00 | W2D2K5 | 1.10 | 1.05 | W3D2K8 | 1.10 | 1.12 |

| W1D3K2 | 1.21 | 1.23 | W2D3K5 | 1.30 | 1.25 | W3D3K8 | 1.20 | 1.20 |

| W1D1K3 | 0.83 | 0.83 | W2D1K6 | 0.92 | 0.94 | W3D1K9 | 1.04 | 1.05 |

| W1D2K3 | 1.06 | 1.03 | W2D2K6 | 1.10 | 1.09 | W3D2K9 | 1.10 | 1.12 |

| W1D3K3 | 1.20 | 1.18 | W2D3K6 | 1.20 | 1.18 | W3D3K9 | 1.19 | 1.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crema, I.; Esposito, A.; Simonetti, I.; Cappietti, L. Experimental Parametric Study on the Primary Efficiency of a Fixed Bottom-Detached Oscillating Water Column Wave Energy Converter in Short-Fetch Sea Conditions. J. Mar. Sci. Eng. 2024, 12, 2167. https://doi.org/10.3390/jmse12122167

Crema I, Esposito A, Simonetti I, Cappietti L. Experimental Parametric Study on the Primary Efficiency of a Fixed Bottom-Detached Oscillating Water Column Wave Energy Converter in Short-Fetch Sea Conditions. Journal of Marine Science and Engineering. 2024; 12(12):2167. https://doi.org/10.3390/jmse12122167

Chicago/Turabian StyleCrema, Ilaria, Andrea Esposito, Irene Simonetti, and Lorenzo Cappietti. 2024. "Experimental Parametric Study on the Primary Efficiency of a Fixed Bottom-Detached Oscillating Water Column Wave Energy Converter in Short-Fetch Sea Conditions" Journal of Marine Science and Engineering 12, no. 12: 2167. https://doi.org/10.3390/jmse12122167

APA StyleCrema, I., Esposito, A., Simonetti, I., & Cappietti, L. (2024). Experimental Parametric Study on the Primary Efficiency of a Fixed Bottom-Detached Oscillating Water Column Wave Energy Converter in Short-Fetch Sea Conditions. Journal of Marine Science and Engineering, 12(12), 2167. https://doi.org/10.3390/jmse12122167