A Novel Device for the In Situ Enrichment of Gold from Submarine Venting Fluids

Abstract

:1. Introduction

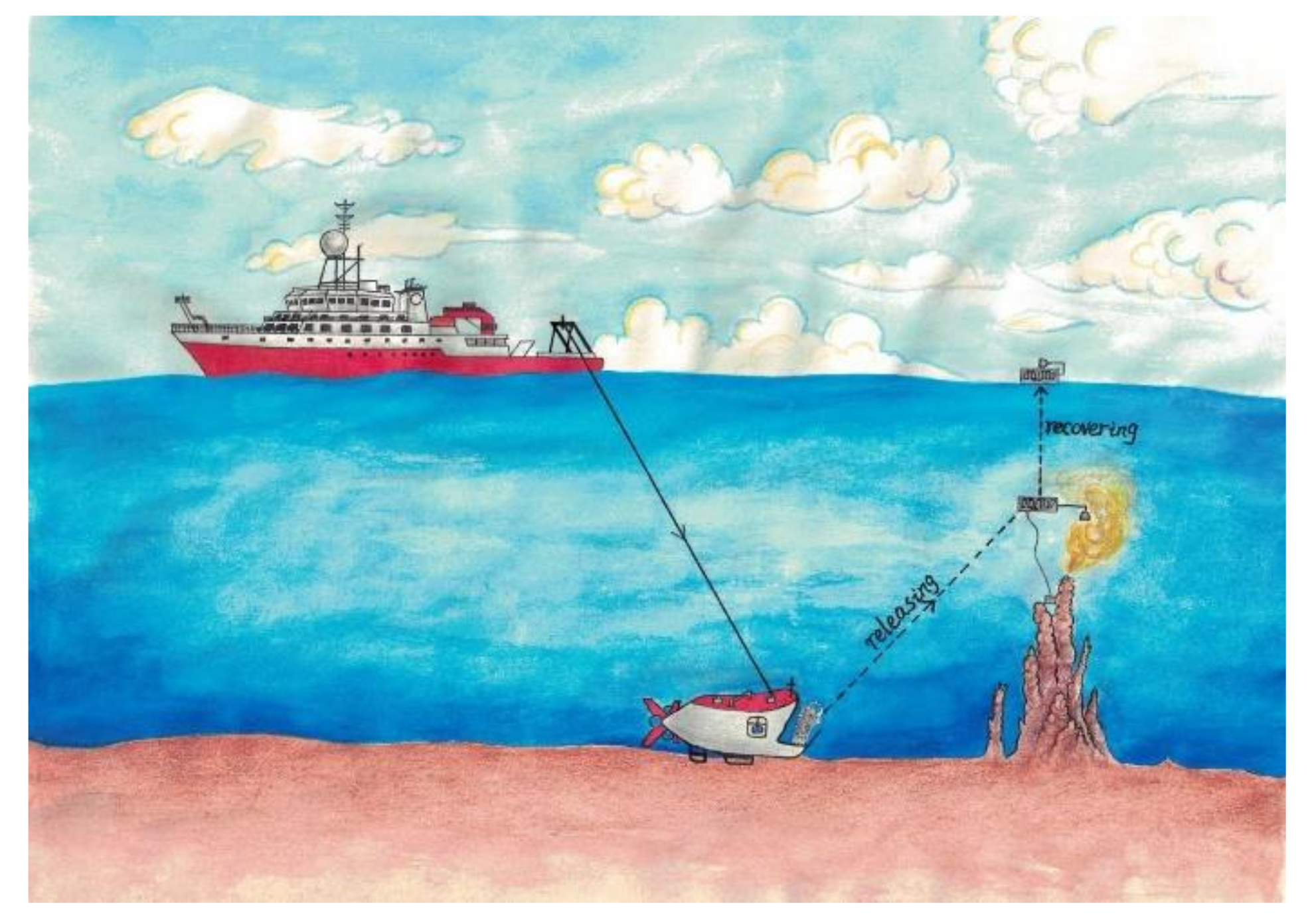

2. Metal Element Extraction Device

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Edmond, J.M.; Measures, C.; McDuff, R.E.; Chan, L.H.; Collier, R.; Grant, B.; Corliss, J.B. Ridge crest hydrothermal activity and the balances of the major and minor elements in the ocean: The Galapagos data. Earth Planet. Sci. Lett. 1979, 46, 1–18. [Google Scholar] [CrossRef]

- Humphris, S.E.; Klein, F. Progress in deciphering the controls on the geochemistry of fluids in seafloor hydrothermal systems. Annu. Rev. Mar. Sci. 2018, 10, 315–343. [Google Scholar] [CrossRef] [PubMed]

- Wolery, T.J.; Sleep, N.H. Hydrothermal circulation and geochemical flux at mid-ocean ridge. J. Geol. 1976, 84, 249–275. [Google Scholar] [CrossRef]

- Von Damm, K.L.; Edmond, J.M.; Grant, B.; Measures, C.I. Chemistry of submarine hydrothermal solutions at 21 °N, East Pacific Rise. Geochim. Cosmochim. Acta 1985, 49, 2197–2220. [Google Scholar] [CrossRef]

- Elderfield, H.; Schultz, A. Mid-ocean ridge hydrothermal fluxes and the chemical composition of the ocean. Annu. Rev. Earth Planet. Sci. Lett. 1996, 24, 191–224. [Google Scholar] [CrossRef]

- Davis, A.C.; Bickle, M.J.; Teagle, D.A.H. Imbalance in the oceanic strontium budget. Earth Planet. Sci. Lett. 2003, 211, 173–187. [Google Scholar] [CrossRef]

- Zhai, S.K.; Wang, X.T.; Yu, Z.H. Heat and mass flux estimation of modern seafloor hydrothermal activity. Acta Oceanol. Sin. 2006, 25, 43–51. [Google Scholar]

- Nielsen, S.G.; Rehkämper, M.; Teagle, D.A.; Butterfield, D.A.; Alt, J.C.; Halliday, A.N. Hydrothermal fluid fluxes calculated from the isotopic mass balance of thallium in the ocean crust. Earth Planet. Sci. Lett. 2006, 251, 120–133. [Google Scholar] [CrossRef]

- German, C.R.; Seyfried, W.E. 8.7 Hydrothermal Processes. In Treatise on Geochemistry, 2nd; Holland, H.D., Turekian, K.K.B., Eds.; Elsevier: Oxford, UK, 2014; pp. 191–233. [Google Scholar]

- Hannington, M.D.; de Ronde, C.E.J.; Petersen, S. Sea-Floor Tectonics and Submarine Hydrothermal Systems; Society of Economic Geologists: Littleton, CO, USA, 2005; pp. 111–141. [Google Scholar]

- Von Damm, K.L. Seafloor hydrothermal activity: Black smoker chemistry and chimneys. Annu. Rev. Earth Planet. Sci. Lett. 1990, 18, 173–204. [Google Scholar] [CrossRef]

- Douville, E.; Charlou, J.L.; Oelkers, E.H.; Bienvenu, P.; Colon, C.J.; Donval, J.P.; Appriou, P. The rainbow vent fluids (36°14′ N, MAR): The influence of ultramafic rocks and phase separation on trace metal content in Mid-Atlantic Ridge hydrothermal fluids. Chem. Geol. 2002, 184, 37–48. [Google Scholar] [CrossRef]

- Fouquet, Y.; Stackelberg, U.V.; Charlou, J.L.; Donval, J.P.; Erzinger, J.; Foucher, J.P.; Herzig, P.; Mühe, R.; Soakai, S.; Wiedicke, M.; et al. Hydrothermal activity and metallogenesis in the Lau back-arc basin. Nature 1991, 349, 778–781. [Google Scholar] [CrossRef]

- Kenison Falkner, K.; Edmond, J.M. Gold in seawater. Earth Planet. Sci. Lett. 1990, 98, 208–221. [Google Scholar] [CrossRef]

- Seyfried, W.E., Jr.; Seewald, J.S.; Berndt, M.E.; Kang, D.; Foustoukos, D.I. Chemistry of hydrothermal vent fluids from the Main Endeavour Field, northern Juan de Fuca Ridge: Geochemical controls in the aftermath of June 1999 seismic events. J. Geophys. Res. 2003, 108, 2429. [Google Scholar] [CrossRef]

- Large, R.R.; Gregory, D.D.; Steadman, J.A.; Tomkins, A.G.; Lounejeva, E.; Danyushevsky, L.V.; Halpin, J.A.; Maslennikov, V.; Sack, P.J.; Mukherjee, I.; et al. Gold in the oceans through time. Earth Planet. Sci. Lett. 2015, 428, 139–150. [Google Scholar] [CrossRef]

- Wohlgemuth-Ueberwasser, C.C.; Viljoen, F.; Petersen, S.; Vorster, C. Distribution and solubility limits of trace elements in hydrothermal black smoker sulfides: An in-situ LA-ICP-MS study. Geochim. Cosmochim. Acta 2015, 159, 16–41. [Google Scholar] [CrossRef]

- Nozaki, T.; Ishibashi, J.I.; Shimada, K.; Nagase, T.; Takaya, Y.; Kato, Y.; Kawagucci, S.; Watsuji, T.; Shibuya, T.; Yamada, R.; et al. Rapid growth of mineral deposits at artificial seafloor hydrothermal vents. Sci. Reps. 2016, 6, 22163. [Google Scholar] [CrossRef] [PubMed]

- Zhigang, Z.; Xuebo, Y.; Haiyan, Q. Device for Enriching Useful Elements in Fluid at Hydrothermal Vent. South. Africa Patent No. 2021/05673, 29 September 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Yin, X.; Wang, X.; Yan, Y.; Zhang, X. A Novel Device for the In Situ Enrichment of Gold from Submarine Venting Fluids. J. Mar. Sci. Eng. 2022, 10, 724. https://doi.org/10.3390/jmse10060724

Zeng Z, Yin X, Wang X, Yan Y, Zhang X. A Novel Device for the In Situ Enrichment of Gold from Submarine Venting Fluids. Journal of Marine Science and Engineering. 2022; 10(6):724. https://doi.org/10.3390/jmse10060724

Chicago/Turabian StyleZeng, Zhigang, Xuebo Yin, Xiaoyuan Wang, Yu Yan, and Xueying Zhang. 2022. "A Novel Device for the In Situ Enrichment of Gold from Submarine Venting Fluids" Journal of Marine Science and Engineering 10, no. 6: 724. https://doi.org/10.3390/jmse10060724

APA StyleZeng, Z., Yin, X., Wang, X., Yan, Y., & Zhang, X. (2022). A Novel Device for the In Situ Enrichment of Gold from Submarine Venting Fluids. Journal of Marine Science and Engineering, 10(6), 724. https://doi.org/10.3390/jmse10060724