Numerical Simulation of Cavitation Flow in a Low Specific-Speed Centrifugal Pump with Different Diameters of Balance Holes

Abstract

:1. Introduction

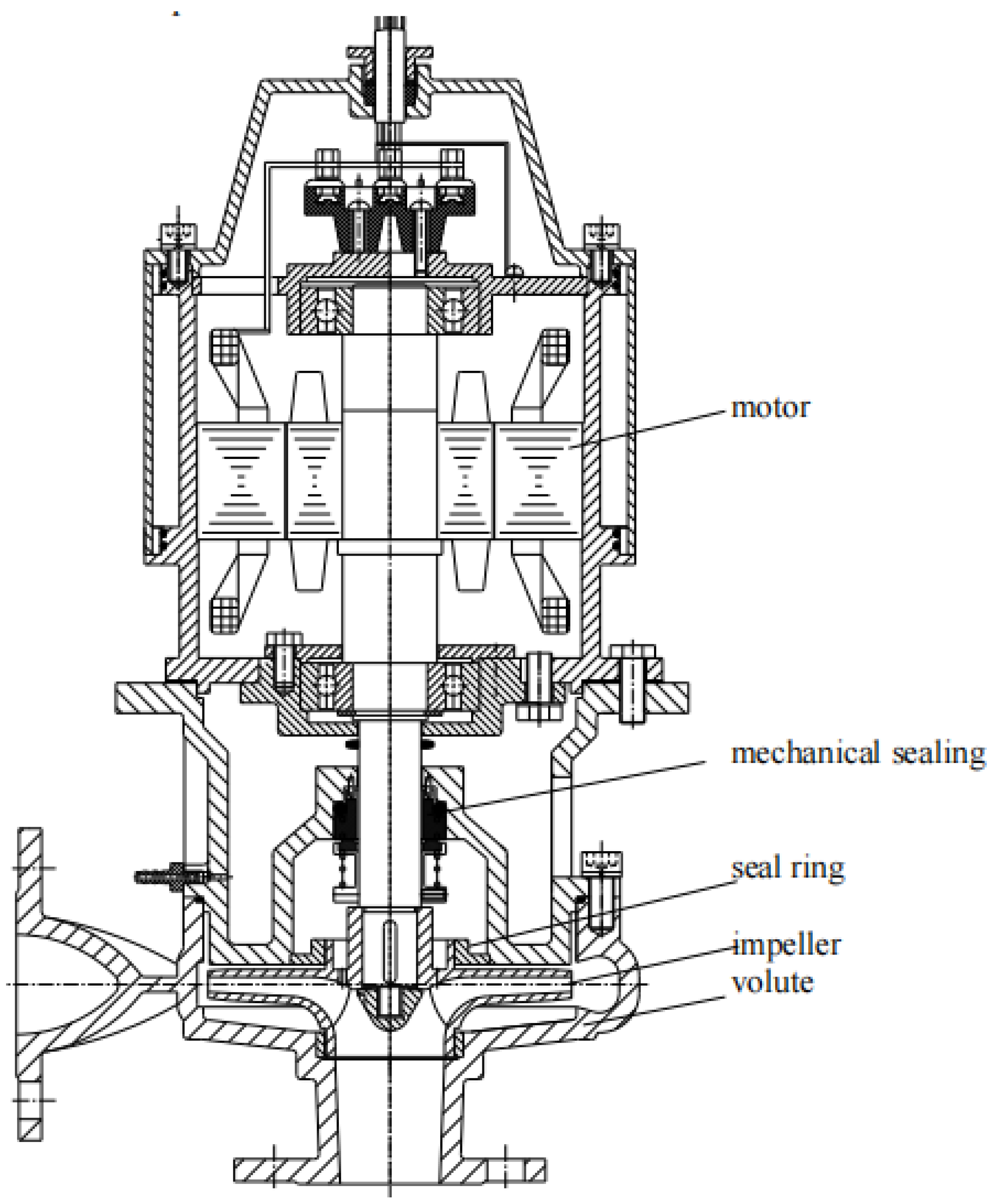

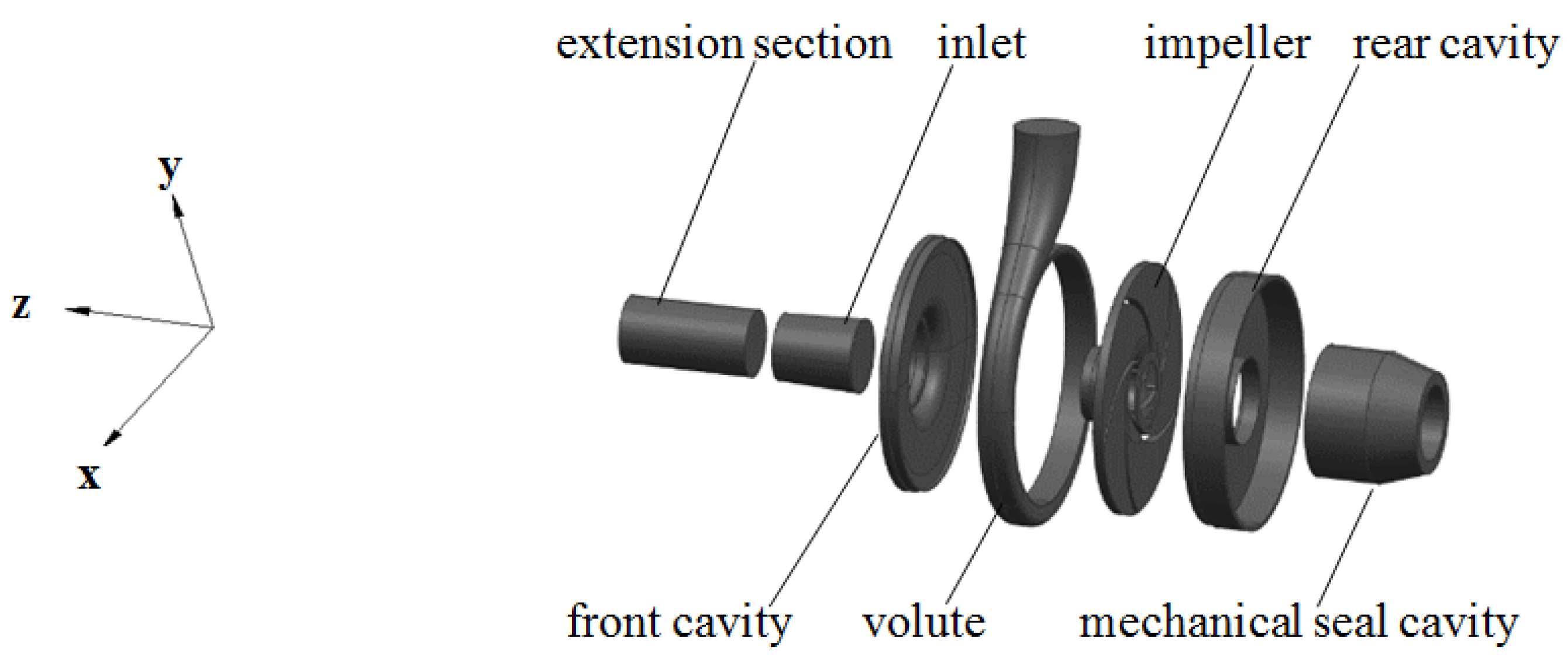

2. Research Object and Meshing

2.1. Research Object

2.2. Balance Hole Sketch

2.3. Computational Domain and Meshing

3. Numerical Simulation Method

3.1. Governing Equation

3.2. Turbulence Model and Cavitation Model

3.3. Boundary Conditions and Solution Control

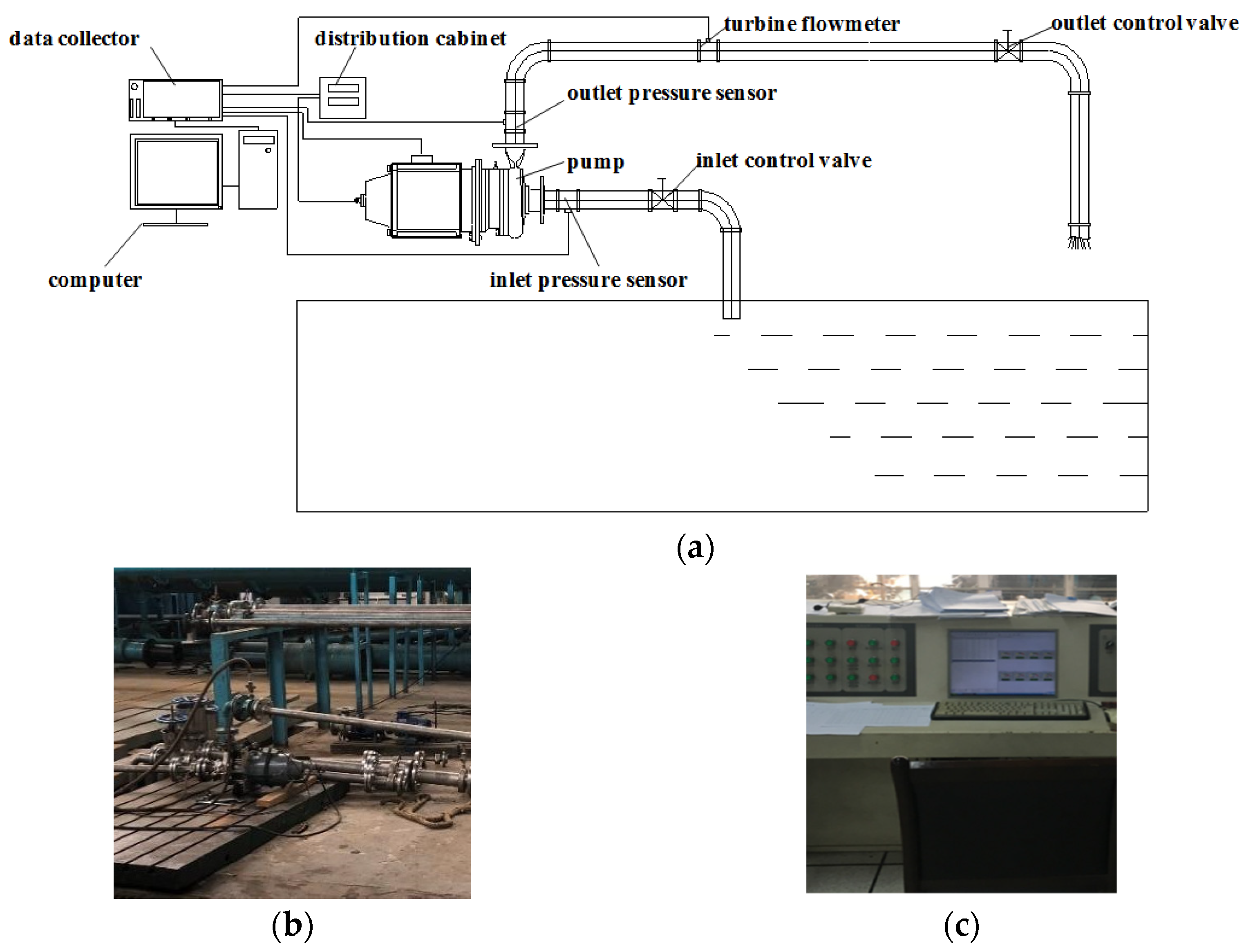

3.4. Experiment Verification

3.4.1. External Characteristic Experiment

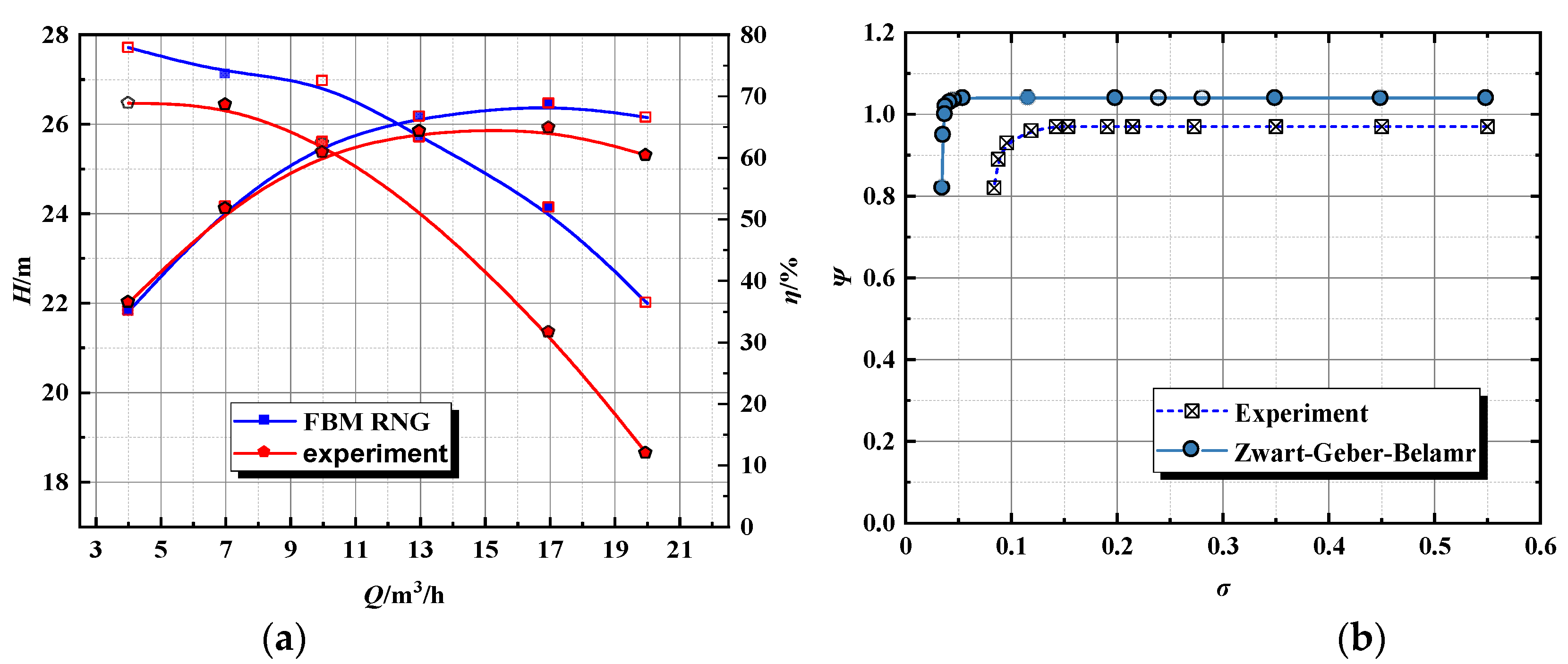

3.4.2. Experimental Results

3.4.3. Comparison of Simulation with Experimental Results

4. Simulation Results Analysis

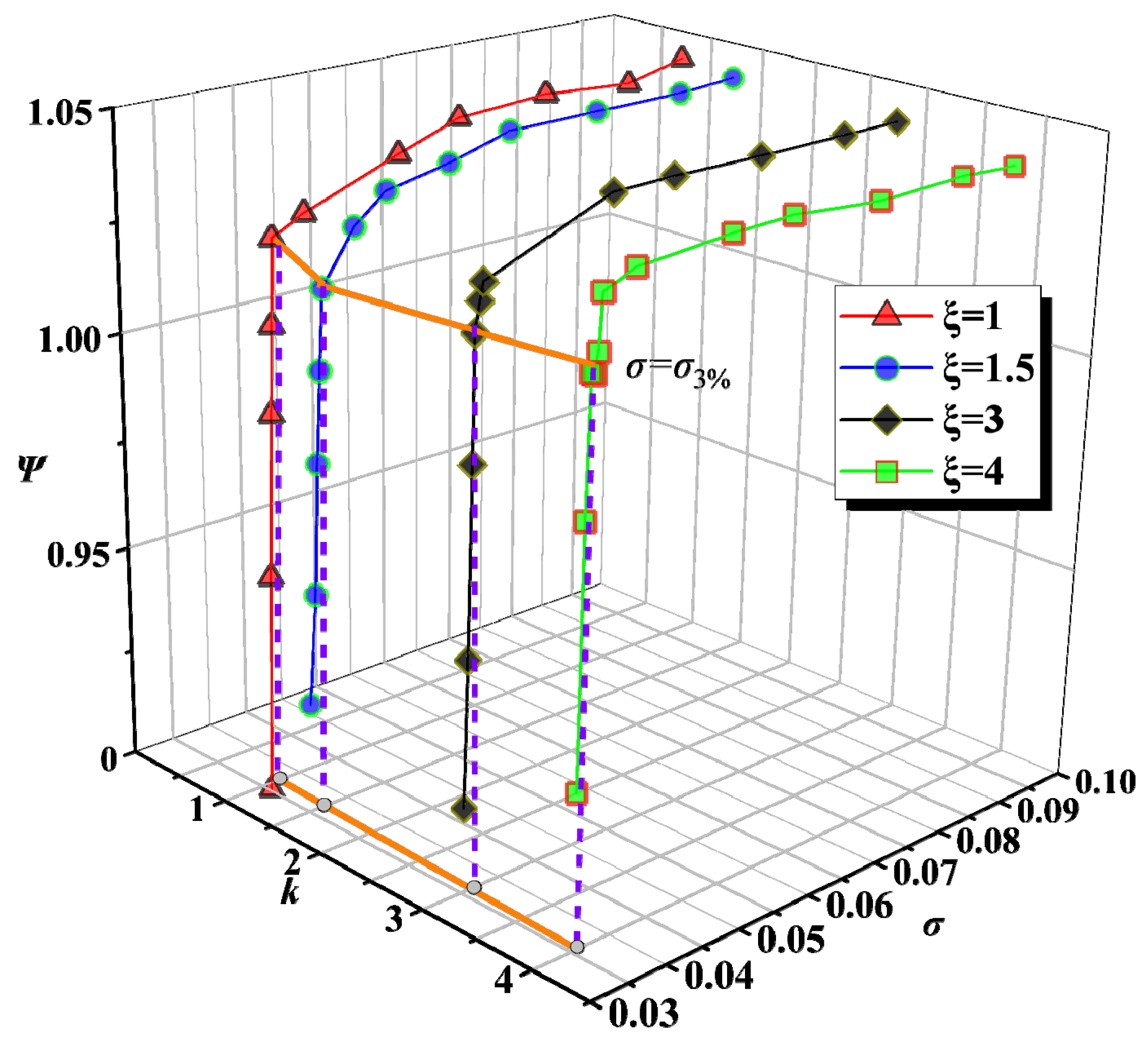

4.1. Influence of Diameter of Balance Holes on External Characteristics

4.2. Influence of Balance Hole Diameter on Cavitation Internal Flow Characteristics

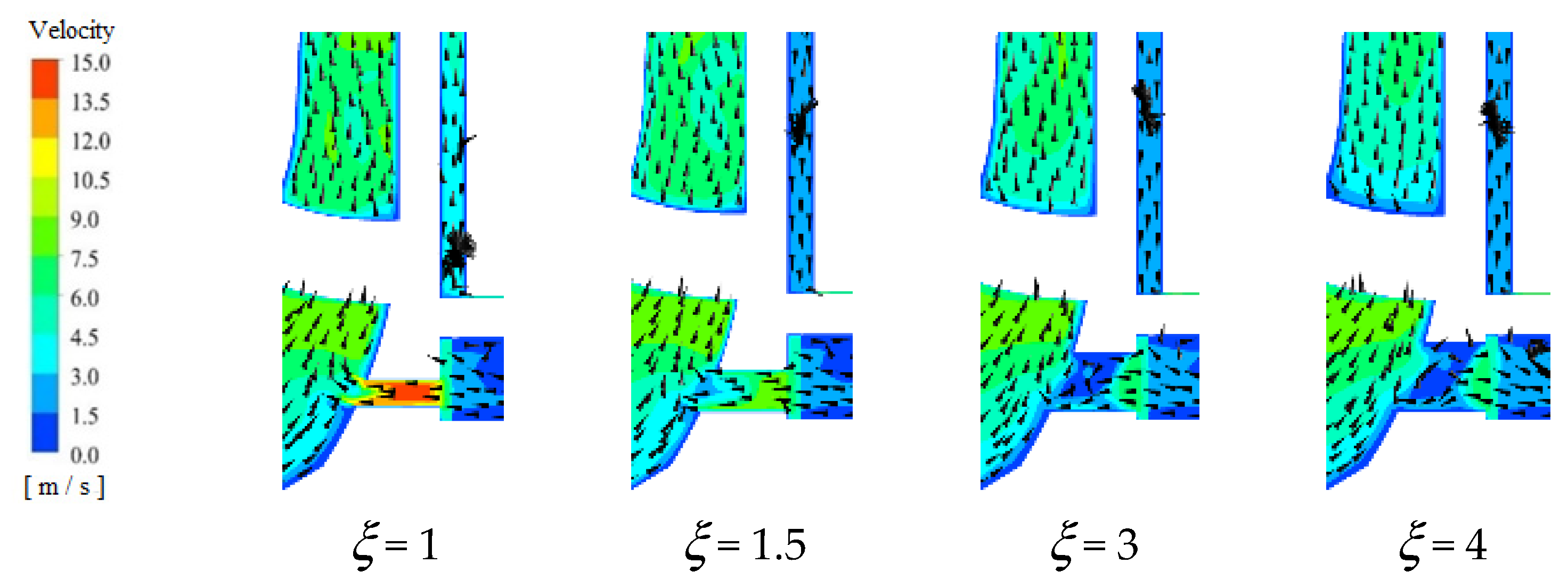

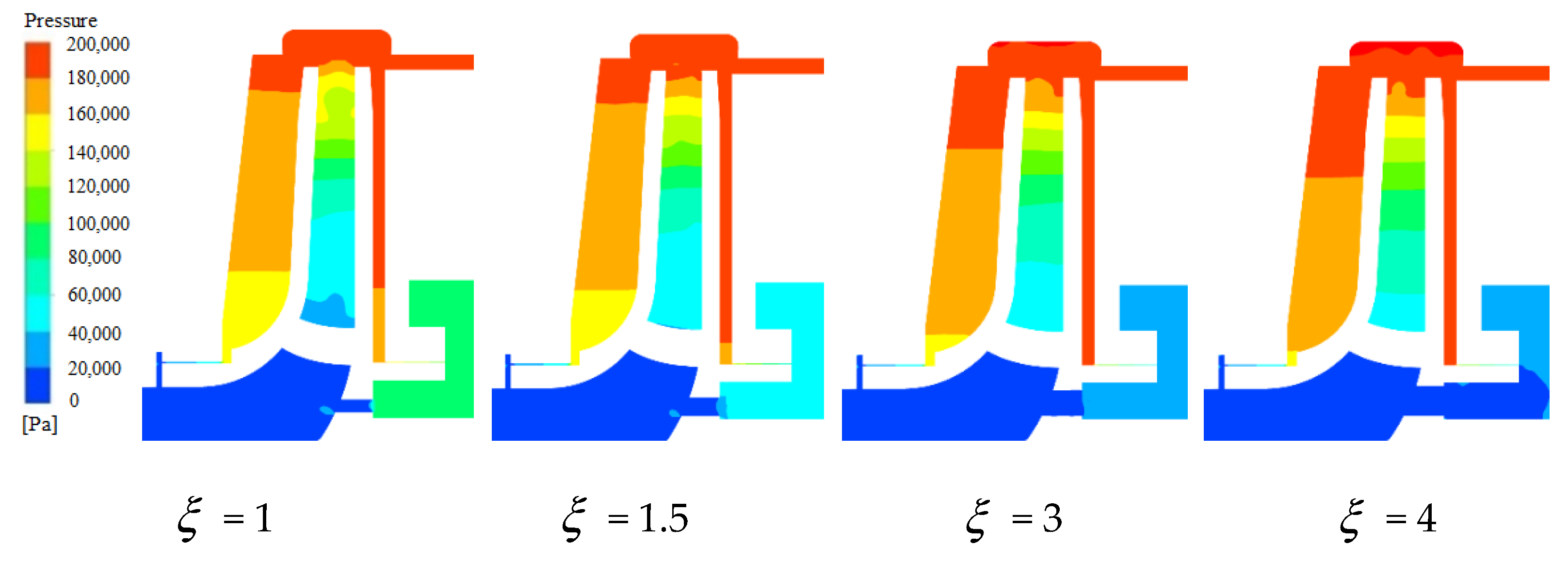

4.2.1. The Influence of Balance Hole Diameter on Flow Velocity and Pressure

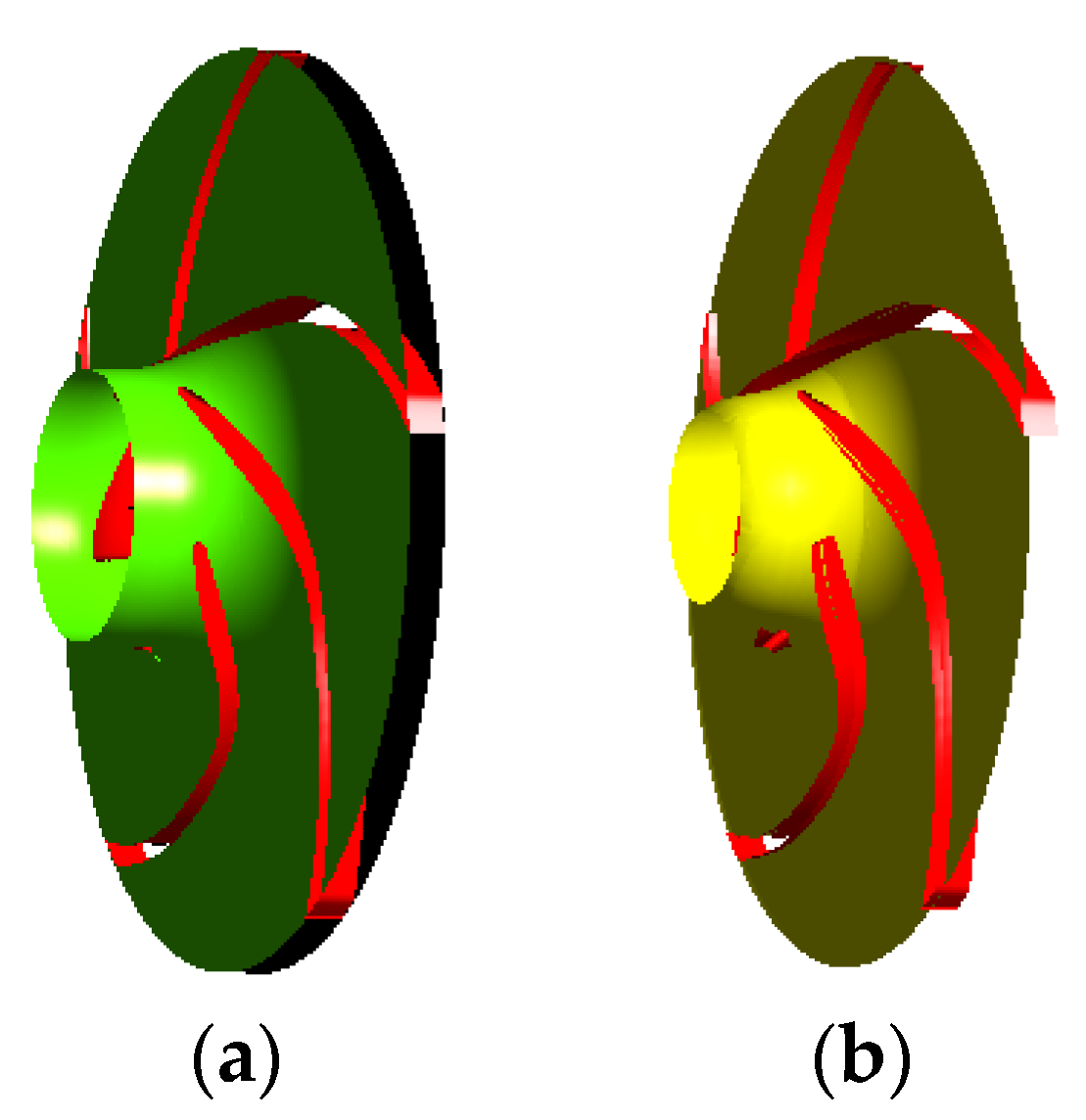

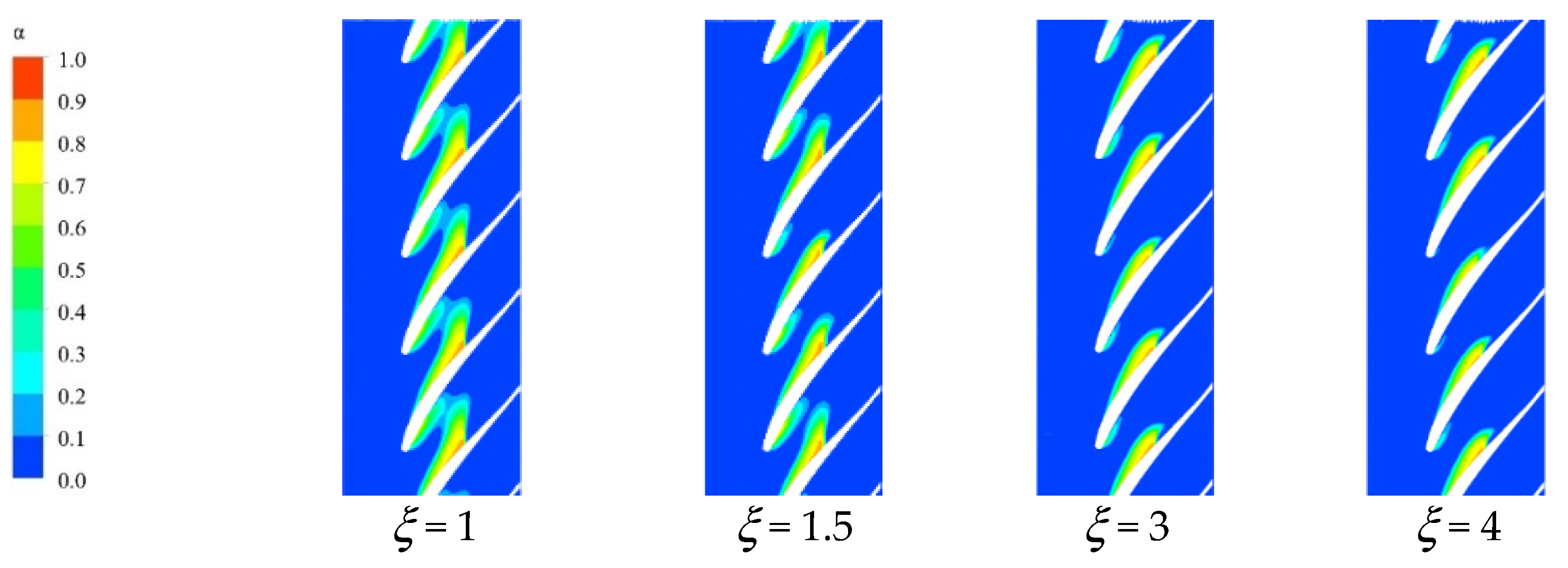

4.2.2. Cavitation Vapor Distribution in Impeller with Different Diameters of Balance Holes

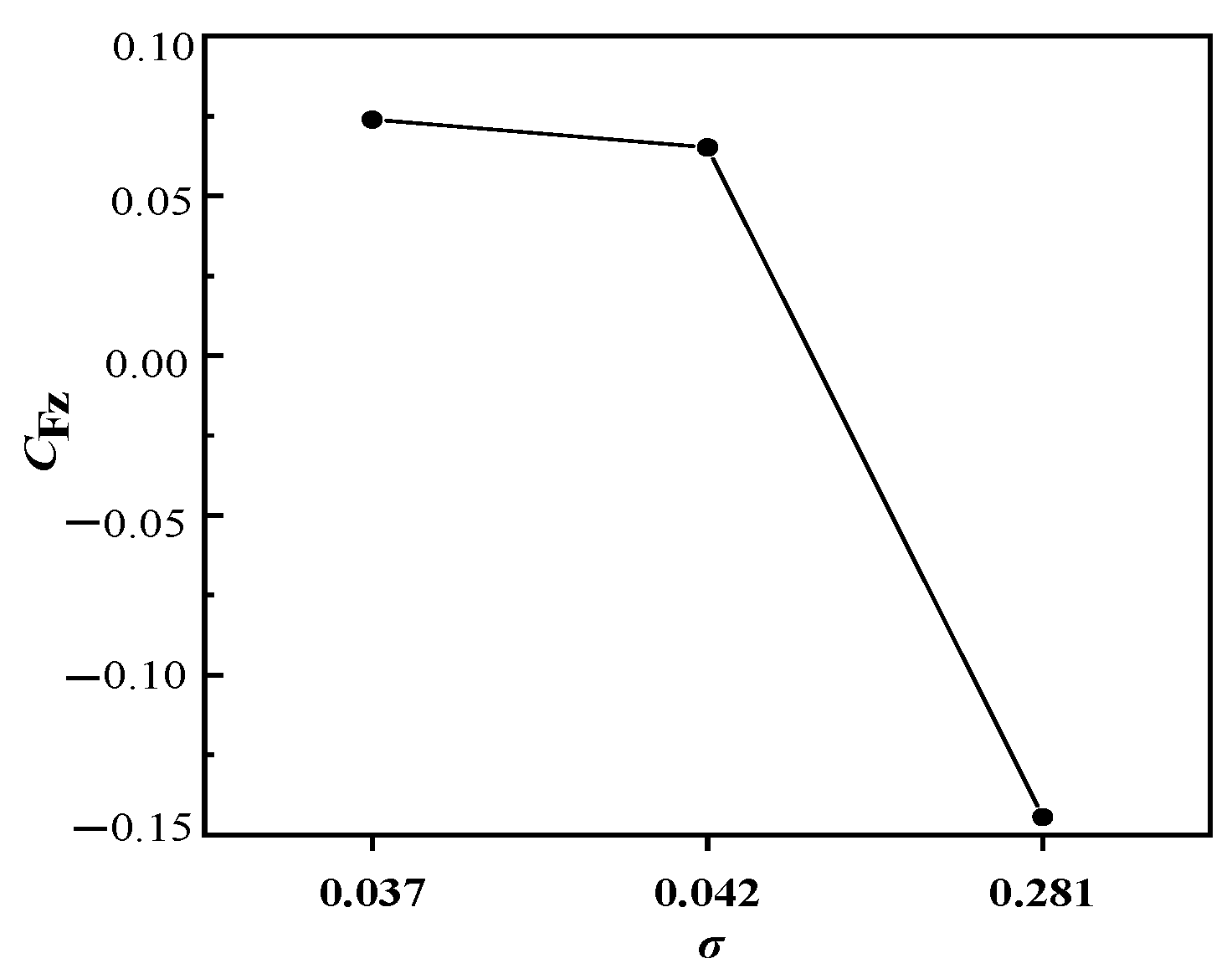

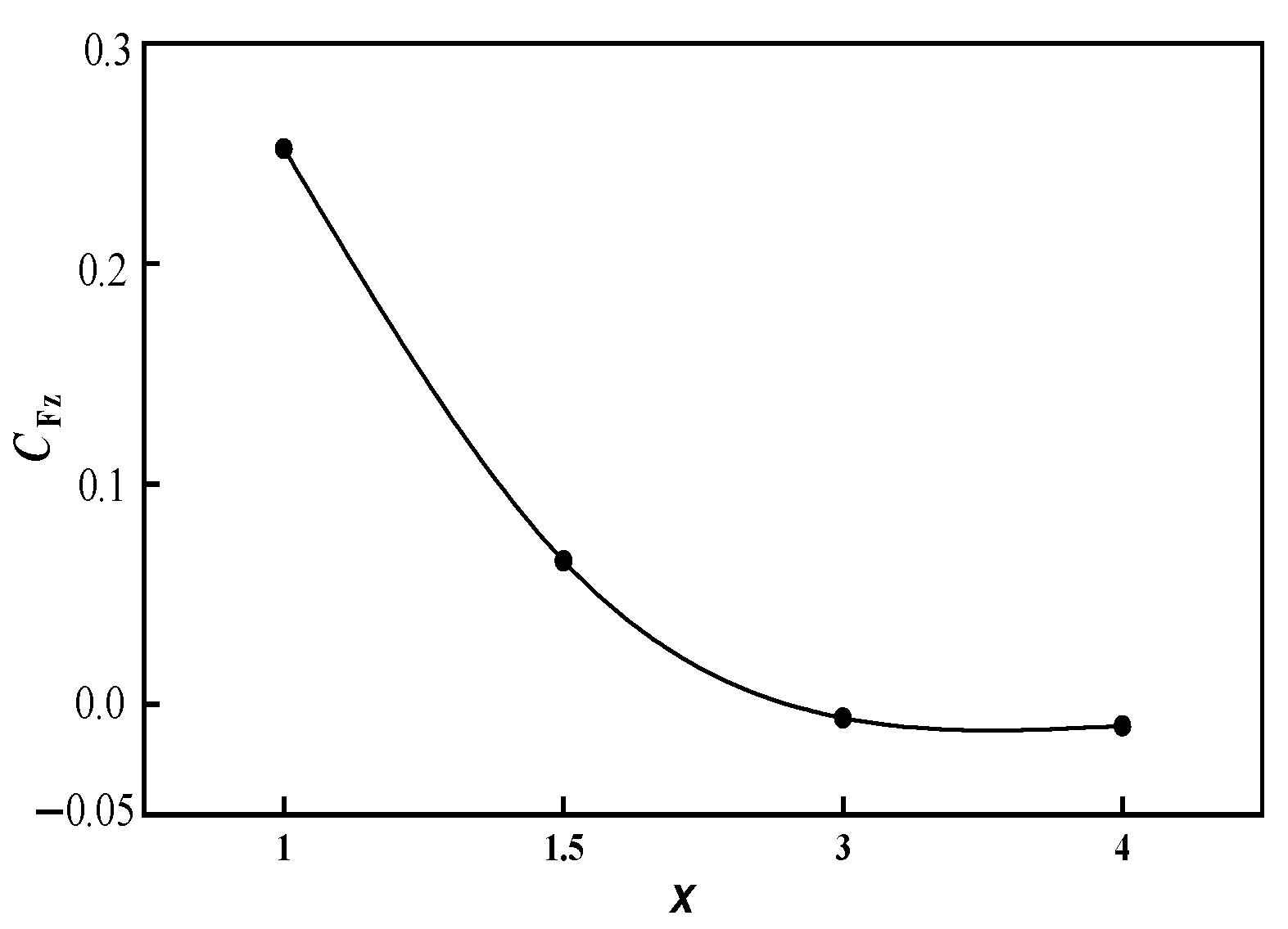

4.3. Influence of Balance Hole Diameter and Cavitation on Axial Force

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Symbols

| Q | flow rate, m3/h |

| QT | flow rate from experimental result, m3/h |

| H | head, m |

| HT | head from experimental result, m |

| n | rotation speed, r/min |

| angular speed, 1/s | |

| N | blade number |

| D1 | impeller inlet diameter, mm |

| D2 | impeller outlet diameter, mm |

| D3 | volute base circle diameter, mm |

| b2 | impeller blade outlet width, mm |

| Dm | seal ring diameter, mm |

| Φ | balance hole diameter, mm |

| Δ | gap size of seal ring, mm. |

| the ratio of total area of balance holes to the gap area of the seal ring | |

| P | power, kW |

| PT | power from experimental result, kW |

| M | torque on the impeller, N·m |

| efficiency, % | |

| efficiency from experimental result, % | |

| density, kg/m3 | |

| the average | |

| simulation result | |

| Ψ | head coefficient |

| σ, | cavitation number |

| u2 | circumferential velocity at the impeller outlet, m/s |

| g | gravity acceleration, 9.81 m/s2 |

| Pin | pump inlet pressure, pa. |

| Pv | saturated vapor pressure, pa. |

| axial force coefficient | |

| Fz | mode synthesized of the axial force vector on the impeller; N |

Acronyms

| CFD | computational fluid dynamics |

| ZGB | Zwart-Gerber-Belamri |

| SD | standard deviation |

| U | uncertainty |

| FBM | RNG filter turbulence model RNG k-ε model |

| LES | large-eddy simulation |

| CEL | CFX expression language |

| BEP | the best efficiency point |

| σ3% | cavitation number when cavitation occurs |

References

- Guam, X. Theory and Design of Modern Pump; China Aerospace Press: Beijing, China, 2011. [Google Scholar]

- Zhao, W.; Wang, D.; Liu, Z. Optimal design of low-to-medium specific speed centrifugal pump based on genetic algorithm. J. Lanzhou Univ. Technol. 2017, 43, 56–59. [Google Scholar]

- Yuan, S. Theory and Design of Low Specific Speed Centrifugal Pump; China Machine Press: Beijing, China, 1996. [Google Scholar]

- Liu, Z.; Lu, W.; Zhao, W.; Chen, T. Effect of balance holes and back blades on axial thrust of centrifugal pump. J. Drain. Irrig. Mach. 2019, 37, 834–840. [Google Scholar]

- Liu, Z.; Yang, K.; Lu, W.; Su, D. Influence of balance hole diameter on flow pattern of centrifugal pump impeller inlet. J. Drain. Irrig. Mach. Eng. 2020, 38, 973–978. [Google Scholar]

- Sha, Y.; Liu, S.; Wu, Y.; Wang, B. Study on the influence of balance holes on the performance of high temperature and high pressure centrifugal pumps. J. Hydroelectr. Eng. 2012, 31, 259–264. [Google Scholar]

- Dong, W.; Chu, W.L.; Liu, Z.L. Influence of the diameter of the balance hole on the flow characteristics in the hub cavity of the centrifugal pump. J. Hydrodyn. 2019, 31, 1060–1068. [Google Scholar] [CrossRef]

- González, J.; Fernández, J.; Blanco, E.; Santolaria, C. Numerical simulation of the dynamic effects due to impeller-volute interaction in a centrifugal pump. ASME J. Fluids Eng. 2002, 124, 348–355. [Google Scholar] [CrossRef]

- Fathi, M.; Raisee, M.; Nourbakhsh, S.A.; Arani, H.A. The effect of balancing holes on performance of a centrifugal pump: Numerical and experimental investigations. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 032017. [Google Scholar] [CrossRef]

- Barrio, R.; Blanco, E.; Parrondo, J.; González, J.; Fernández, J. The effect of impeller cutback on the fluid-dynamic pulsations and load at the blade-passing frequency in a centrifugal pump. ASME J. Fluids Eng. 2018, 130, 111102. [Google Scholar] [CrossRef]

- Ding, H.; Visser, F.C.; Jiang, Y.; Furmanczyk, M. Demostration and validation of a 3D CFD simulation tool predicting pump performance and cavitation for industrial applications. ASME J. Fluids Eng. 2011, 133, 011101. [Google Scholar] [CrossRef]

- Roohi, E.; Pendar, M.R.; Rahimi, A. Simulation of three-dimensional cavitation behind a disk using various turbulence and mass transfer models. Appl. Math. Model. 2016, 40, 542–564. [Google Scholar] [CrossRef]

- Pendar, M.R.; Roohi, E. Investigation of cavitation around 3D hemispherical head-form body and conical cavitators using different turbulence and cavitation models. Ocean. Eng. 2016, 112, 287–306. [Google Scholar] [CrossRef]

- Tran, T.D.; Nennemann, B.; Vu, T.C. Investigation of cavitation models for steady and unsteady cavitating flow simulation. Int. J. Fluid Mach. Syst. 2015, 8, 240–253. [Google Scholar] [CrossRef]

- Wang, K.; Li, H.; Shen, Z. Pressure pulsation characteristics in down-scaled high specific speed centrifugal pump in cavitating state. J. Drain. Irrig. Mach. Eng. 2020, 38, 891–897. [Google Scholar]

- Ye, T.; Si, Q.; Shen, C.; Yang, S.; Yuan, S. Monitoring of primary cavitation of centrifugal pump based on support vector machine. J. Drain. Irrig. Mach. Eng. 2021, 39, 884–889. [Google Scholar]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. A two-phase flow model for predicting cavitation dynamics. In Proceedings of the ICMF 2004 International Conference on Multiphase Flow, Yokohama, Japan, 30 May–3 June 2004; pp. 1–11. [Google Scholar]

- Johansen, S.T.; Wu, J.; Shyy, W. Filter-based unsteady rans computations. Int. J. Heat Fluid Flow 2004, 25, 10–21. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Q.; Shi, W. Numerical Simulation Basis and Application of Vane Pump Design; China Machine Press: Beijing, China, 2015. [Google Scholar]

| Program | Φ (mm) | |

|---|---|---|

| Original model | 1.5 | 3 |

| model 1 | 1 | 2 |

| model 2 | 3 | 4.3 |

| model 3 | 4 | 5 |

| Grid 1 | Grid 2 | Grid 3 | Grid 4 | Grid 5 | |

|---|---|---|---|---|---|

| Impeller grid number | 55,060 | 99,416 | 472,440 | 809,230 | 1,114,004 |

| Hole grid number | 1814 | 3226 | 12,158 | 24,460 | 30,224 |

| Volute grid number | 34,360 | 53,576 | 320,702 | 484,106 | 594,454 |

| Total grid number | 500,143 | 816,030 | 1,597,421 | 2,079,601 | 2,412,153 |

| Head (m) | 26.6423 | 26.3295 | 25.7424 | 25.5283 | 25.5186 |

| Power (kW) | 1.4782 | 1.403 | 1.3682 | 1.3546 | 1.352 |

| Efficiency (%) | 63.81 | 66.44 | 66.61 | 66.72 | 66.82 |

| Property Parameter | Water | Vapor |

|---|---|---|

| Saturated vapor pressure (Pa) | 1938 | 1938 |

| Density (kg/m3) | 998.73 | 0.0145 |

| Specific heat capacity (kJ/kg·K) | 4.187 | 1.902 |

| Specific enthalpy (kJ/kg) | 71.36 | 2532 |

| Specific entropy (kJ·kg·K) | 0.253 | 8.734 |

| Thermal expansion coefficient (10−4·K) | 2.57 | 33.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, W.; Yang, X.; Jia, Z. Numerical Simulation of Cavitation Flow in a Low Specific-Speed Centrifugal Pump with Different Diameters of Balance Holes. J. Mar. Sci. Eng. 2022, 10, 619. https://doi.org/10.3390/jmse10050619

Cao W, Yang X, Jia Z. Numerical Simulation of Cavitation Flow in a Low Specific-Speed Centrifugal Pump with Different Diameters of Balance Holes. Journal of Marine Science and Engineering. 2022; 10(5):619. https://doi.org/10.3390/jmse10050619

Chicago/Turabian StyleCao, Weidong, Xinyu Yang, and Zhixiang Jia. 2022. "Numerical Simulation of Cavitation Flow in a Low Specific-Speed Centrifugal Pump with Different Diameters of Balance Holes" Journal of Marine Science and Engineering 10, no. 5: 619. https://doi.org/10.3390/jmse10050619

APA StyleCao, W., Yang, X., & Jia, Z. (2022). Numerical Simulation of Cavitation Flow in a Low Specific-Speed Centrifugal Pump with Different Diameters of Balance Holes. Journal of Marine Science and Engineering, 10(5), 619. https://doi.org/10.3390/jmse10050619