1. Introduction

Nowadays, renewable energies offshore, such as wind energy, wave energy and tidal energy, have become important due to environmental issues and energy crises [

1,

2]. Wind energy offshore, in particular, emerges as a promising renewable clean alternative, mainly due to its availability and price competitiveness. The potential of marine renewables and, in particular, floating wind for the future of power generation and the energy transition to sustainable sources is known to the scientific community, technologists, and all energy industry [

3,

4].

The quality of the wind at greater distances from the coast is higher, and the resource itself increases, as well as the challenges associated with obtaining this energy. The wind resource assessment in [

5] showed that the Iberian coast had an average annual energy density reaching up to 971, 549 and 398 W/m

2 in the north, centre and southern regions, respectively, values that are representative of what can be found on other areas of the European Atlantic coast. Another study shows typical average values of wave energy of about 40 kW/m in the summer and 10 kW/m in the winter for the corresponding areas [

6].

The European Union has directed resources to develop this type of energy so that it becomes reliable, safe, and profitable [

1]. The study of Wind Europe indicates that the North Sea will have the highest quantity of offshore wind farms by 2030, with a central value closed to 50 GW, higher than the 10 GW of 2016 [

7].

Over recent years, the floating wind industry has suffered an important expansion. Floating wind turbines present an economical and technically feasible approach to access the deeper water sites to obtain the rich resource of wind power. Therefore, they have the potential to be the next generation of wind technology [

8]. Moreover, the saturation of maritime space, the energy demand, and the geographical constraints require new offshore installation areas. All these requirements have created the need to identify locations for floating wind farm installation [

9].

In the design of offshore wind farms, the first stage is often the choice of sites [

10]. Site selection also plays a crucial role in the financial returns of the project, ease of construction, ongoing operations and maintenance, and overall safety. Geographical Information System (GIS)-assisted wind farm location criteria [

11] were typically used, such as [

9,

12,

13,

14,

15]. Díaz and Guedes Soares [

9] identified the most suitable locations for floating offshore wind turbines within the European Atlantic Area (Portugal, Spain and France), considering the available wind resource, existing uses of maritime space and environmental constraints, and the operational needs of a floating wind farm. Díaz and Guedes Soares [

14] developed a decision tool for planning offshore wind farm locations, combining multi-criteria decision analysis and GIS. Díaz et al. [

15] showed that the floating wind farm locations suitability map developed with the AHP and MADA methods integrated into a GIS for the maritime surroundings of the European Atlantic coast is a substantial aid in the land-use management of these waters.

Platforms are an essential element of floating offshore wind turbines. Regarding the offshore wind platforms installed on offshore farms, there are several types of platforms within the main types of bottom-fixed and floating. Uzunoglu et al. [

16] reviewed the main floating wind turbine platform concepts and the design standards for floating platforms. The first types of platforms to reach the commercial stage are the spar [

17] and the semisubmersible type [

18,

19].

The connection of the platforms to the grid is another important component, as discussed in [

20], and substations are often important components of this system. Two types of floating substation configurations were compared in [

21] with respect to technical and cost performance for a 200 MW Wind Farm for the Northeast U.S., showing that the semi-type substation platform cost is lower than the TLP-type cost for the case where each tendon has a dedicated anchor, whereas the cost for the TLP-type with two tendons sharing an anchor is highly comparable to, if not less than, the semi-type platform.

One of the challenges in floating offshore wind turbines continued being the high costs associated [

22]. The investment cost per MW in offshore wind is approximately 50% more expensive than in onshore wind, mostly due to the costs of additional components, underwater equipment, construction, and installation processes [

4]. One of the most important issues in terms of an offshore wind farm is to be competitive in economic terms. Thus, a fundamental aim is to maximize energy production, minimize capital and operating costs, and stay within the constraints imposed by the site. Economic assessment studies have been made for locations in the Atlantic coast showing the relation of the location to the economic feasibility [

23,

24].

The other way of reducing production costs is to scale up the turbines, moving to larger turbines than the 5 MW ones that are more commonly used at present. So, recently, the design of a 10 MW floating offshore wind turbine (FOWTs) has been the main focus of research in order to further reduce the levelized cost of electricity (LCOE) of wind turbines to a more competitive level [

25]. With regards to this, there are several European Union (EU)-funded research projects. For instance, a semi-submersible platform was developed in the INNWIND project [

26]. Two semi-submersible concepts, a barge and a Tension Leg Platform (TLP) were developed in the LIFES50+ project [

27]. Within the ARCWIND project, three novel concepts are being developed, a multi-body floating platform, the so-called TELWIND [

28], a barge type [

29] and a TLP [

30]. Other concepts are also being studied, such as those described in [

27] and [

31].

One of the most important differences between fixed and floating substructures is mooring and anchoring systems. For floating structures, the station-keeping systems based on mooring lines and anchors are crucial to guarantee structure survivability and its components under different met ocean conditions. Traditionally, a successful mooring design considers several limit states (LS) (DNV-OS-E301, 2021 [

32]), such as ultimate (ULS), accidental (ALS), fatigue (FLS) and service (SLS) [

33]. The structural forces into the offshore wind anchoring and mooring systems are calculated either by using the quasi-static method [

34,

35] or dynamic analysis [

36,

37,

38,

39]. Masciola et al. [

36] compared the response of the DeepCwind semisubmersible design in coupled simulations using FAST and the lumped-mass mooring model OrcaFlex, as well as the default quasi-static mooring model, against the 1:50-scale test data. They found that platform motions were influenced by mooring dynamics only in extreme sea states but that mooring dynamics are important to the prediction of mooring line tensions in all load cases. Bae et al. [

37] performed numerical simulations on the performance of a Floating Wind Turbine (FWT) with a broken mooring line using an aero-hydro-servo-elastic-mooring coupled dynamic analysis in the time domain considering the OC4 DeepCwind semi-submersible wind turbine. Dynamic coupling analysis in frequency domain (FD) and time domain (TD) using ANSYS AQWA and Orcaflex were presented by [

39] for two different mooring configurations on the hull of a Paired Column Semisubmersible (PCSemi). The Chain-Polyester-Chain (CPC) mooring concept performed better in deep waters and is more reliable for the PCSemi.

FOWT has several advantages compared with onshore ones, however, the complex and varied marine environment has brought great challenges to the transportation, installation, and operation of the equipment. It was mentioned in [

40] that, currently, installation, operation, and maintenance (IO&M) costs contribute approximately 30% to the LCOE of offshore wind plants. The cost of the mooring and anchoring system is also included. There have been some reported attempts in the literature to minimize the operation and maintenance (O&M) costs of offshore wind farms [

41,

42,

43,

44]. The O&M costs are composed of labour costs (technician costs), material costs (component costs), transportation costs (vessels and associated costs), fixed costs (port, insurance, bidding) and potential revenue losses [

44]. The LEANWIND project studied how to reduce the costs of farms by analysing their installation, operation and maintenance, and logistics and supply-chain [

45].

To have cost-effective installation methods, the relevant numerical simulations of the installation of FOWTs need to be conducted as in [

46,

47,

48]. A novel installation concept using a floating vessel was investigated in Hassan and Guedes Soares [

47] and the coupled dynamic system of the installation vessel and the floating spar were performed using Ansys AQWA software. The numerical simulation of a three-body system, including the assembly, the catamaran vessel and the foundation was performed using SIMO and RIFLEX under the SIMA environment in [

48]. The WindFloat Atlantic project [

19] avoided the use of large offshore heavy-lift vessels by using an onshore crane, also allowing most of the commissioning works to be completed onshore. The offshore activities were greatly simplified, being designed to allow a tow-to-port O&M strategy for large component replacement. A similar strategy is described in [

49].

For the installation of offshore platforms, the site has to be accessible for a certain period called a weather window [

50,

51], in which weather conditions are suitable for the specific work at sea. Deriving detailed information on suitable installation weather windows that will be available for a specific site will be also beneficial for the reduction in installation costs [

52]. To determine it, a limiting operational environmental criterion [

53] is given by the maximum values of wind speed and wave height for safe working and/or transfer conditions of personnel. In addition, there are some additional restrictions on specific cases. The weather window has been investigated for specific sites, such as, the Irish west coast [

54], North Atlantic Ocean [

51] and the south west of England [

55].

Although the development of floating offshore wind turbine technology has increased greatly and the O&M aspects have been discussed for different projects, the installation logistics and cost of mooring components have been rarely discussed. This work addresses that problem by using a methodology based on simulations to assess the duration, costs and risks associated with the installation of an offshore wind farm in weather windows. This method is applied to a case study based on a wind farm in Lannion, located on the northwest coast of France. The selected technology for this study is the TELWIND platform developed by Esteyco.

Section 2 presents the characteristics of the floater, the installation site, the mooring system and the wind farm array design.

Section 3 describes the required installation operations and their limitations and presents the simulation method.

Section 4 presents the results and discussions of the simulation results. Two different installation strategies are studied and compared.

Section 5 provides a summary and draws some conclusions from the present study.

5. Conclusions

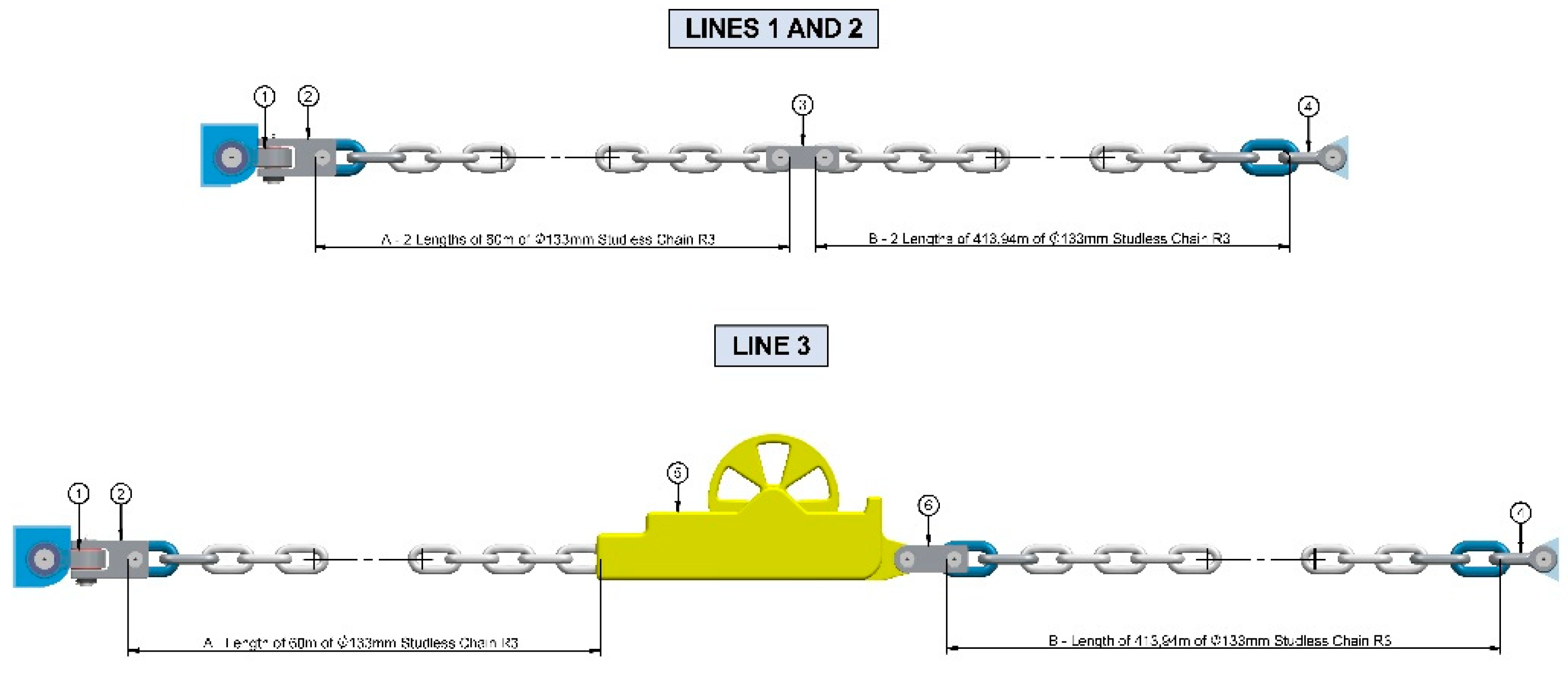

The mooring system transport and installation logistics for a floating offshore wind platform, TELWIND, in Lannion, located on the northwest coast of France, are discussed in this paper. The discussed station keeping system is a spread mooring system designed within the ARCWIND project.

The procedures for carrying out the mooring pre-lay, platform towing, and mooring and cable hook-up campaigns, including the duration and weather limitations for carrying out the operations in terms of maximum Hs, are described and discussed. Based on different transport and installation strategies, the preliminary schedule and cost are estimated.

The most suitable months to perform the drag anchor and mooring installation are the summer months. While it is possible to have good weather windows during the winter and autumn months, the risk is significantly higher. Summer months are also optimal to perform the hook-up campaigns. Compared with the mooring pre-lay, the average installation time and the standard deviation is larger due to the longer operation duration and additional constraints, for the mooring and power cable hook-up campaign.

The cost estimation results for installation show that the strategy with two AHTS vessels working in the months from April to August for a single year proves to be more economical since it avoids the months with low productivity and has a lower standby ratio. For the 47 FWT, it would take approximately 153 days of operation and it would end at the end of August.

Regarding the transports, it was decided to ship them from January to June, employing two vessels per month for the first four months and another vessel per month for the remaining two.

The case study demonstrated that the Mission Planner simulation method is efficient for analysing the marine operations; however, it is suitable for the case when sufficient project data are available. The limitations of this study are related to the scarce data available in the initial stages of the design of a wind farm. For example, the mooring components, location, and the individual tasks are specified for the present study, while the rest of the input data are based on industry knowledge on installation time frames, weather limits and vessel costs. Further optimization can be made when planning the simultaneous offshore operations with dependences between them. The presented costs are highly dependent on the current state of the market.

The simulation study allowed for the assessment of the representative duration for the installation procedure as well as its overall cost, allowing for the conclusion that the use of a simulation tool is the only feasible way to produce these research results that are indispensable for proper costing and planning these operations.

The results of this model could be used on early tenders of Requests For Information (RFIs). The weather risk is significant, and it is recommended that it is considered on the initial stages of the projects through models such as the one presented in this work.