Abstract

China ranks as the world’s leading potato (Solanum tuberosum L.) producer, while the poor seeding machinery performance limited a higher input–output ratio in potato cultivation and impeded sustainable development. We developed an advanced air-suction mulai-arm potato planter (ASPP) that incorporated integrated side-deep fertilization, automated seed feeding, negative-pressure seed filling, seed transportation, positive-pressure seed delivery, soil covering, and compaction. The study proposes a Negative-pressure seed extraction mechanism that minimizes seed damage by precisely controlling suction pressure, and the near-zero-speed seed delivery mechanism synchronizes seed release with ground speed, reducing bounce-induced spacing errors. Furthermore, the structural configuration and operation principle of ASPP were systematically elucidated, and key performance parameters and optimal values were identified. We conducted a randomized complete block design plot trial comparing the spoon-belt potato planter (SBPP) and spoon-chain potato planter (SCPP), evaluating sowing quality, seedling emergence rate (ER), potato yield (PY), and comprehensive economic benefits. The results revealed that plant spacing index (PSI), missed-seeding index (MI), re-seeding index (RI), and coefficient of variation (CV) of ASPP were 90.05%, 3.78%, 2.32%, and 7.93%, respectively. The mean ER values for ASPP, SBPP, and SCPP were 94.76%, 85.42%, and 83.46%, respectively, with the ASPP showing improvements of 10.93% and 13.54% over SBPP and SCPP. However, the SBPP and SCPP exhibited greater emergence uniformity than ASPP. The mean PY value was 37,205.25, 32,973.75, and 34,620 kg·ha−1 for ASPP, SBPP, and SCPP. The ASPP outperformed the SBPP and SCPP by 12.83% and 7.47%. Overall, ASPP demonstrated balanced and superior performance across the above-mentioned indicators, demonstrating its potential to enable precision agriculture in tuber crop cultivation.

1. Introduction

The potato is ranked as the world’s fourth most important staple crop, following rice, wheat, and maize. Serves as a critical component in global food security systems by ensuring food security, improving dietary structure, and promoting agricultural economic development [1,2]. According to FAO statistics, global potato production systems occupied 16.8 Mha in 2024, yielding 383.2 Mt, with major production continents including Asia, Europe, the Americas, and other areas. China dominates global potato production, and the crop holds a crucial position in the country’s food security strategy. FAO data showed that China maintained 4.57 Mha of potato cultivation in 2024, with total production exceeding 93.53 Mt, accounting for 25% of global output. However, the average potato yield per unit area in China was approximately 20.5 tha−1, significantly lower than the U.S. benchmark of 51.5 tha−1. This indicated that China’s potato yields had considerable room for improvement [3,4].

Mechanized potato planting constituted a critical link in simultaneously ensuring the sowing quality, improving planting efficiency, and enabling large-scale production. Conventional manual potato planting suffered from problems such as excessive labour requirements, inconsistent sowing depth, and a high coefficient of variation in planting spacing. These limitations resulted in negative agronomic impacts, including poor seedling emergence, weak seedlings, and inconsistent yields [5,6]. Studies demonstrated that mechanized sowing could improve field efficiency by more than 30%, save seed potatoes by 15% to 20%, and significantly enhance yield [5]. Economically, mechanized sowing reduces per-unit production costs while enhancing yield potential, thereby improving market competitiveness and supporting sustainable industry development. As the critical component, the planter’s performance, determined by seeding accuracy, directly influences subsequent crop growth and final yield. Potato planters were categorized by their seed metering device structure and operation principle into five distinct types: spoon-type planter, needle-type planter, finger-type planter, belt-type planter, and air-suction-type planter.

Among these, the spoon-type potato planter represented the comparatively mature and widely adopted mechanical planting technologies [7]. Compared with the spoon-chain planter, the spoon-belt planter was more prone to belt slippage during operation, resulting in a lower plant spacing index and higher coefficient of variation; however, the spoon-chain planter caused higher mechanical damage to seed potatoes, which led to reduced seedling emergence rates and ultimately lowered yields [7,8]. Spoon-type planters utilized open-configuration metering spoons mounted on flexible drive systems. Terrain irregularities or tractor instability frequently cause seed dislodgement during transport, increasing miss-planting rates [9,10]. Structural optimization studies of metering spoons and conveyor mechanisms [11,12], coupled with loss-monitoring compensation systems [13,14,15], improved seeding reliability without compromising quality. Nevertheless, these systems remained unsuitable for high-speed, large-scale operations due to inherent design limitations.

The belt-type planter comprises two configurations: a flat belt and a grooved belt. The latter, requiring manual seed supply with markedly reduced operational efficiency, was excluded from subsequent analysis. The flat belt design incorporates a central belt and lateral belts operating in counter-rotating directions. Seed potatoes on the central belt are aligned into a single row and delivered to the seeding zone, while excess seeds are transported laterally by the side belts for recirculation [16,17,18]. Compared to spoon-type planters, the flat belt system demonstrates significantly reduced mechanical seed damage. Its sorting-based seed metering mechanism enhances adaptability to seed potato dimensional variations [16]. However, this operational principle results in inferiorly qualified seed spacing indices and higher plant spacing variability post-sowing.

The finger-type planter utilized circumferentially distributed clamping mechanisms that mimicked human finger motion. A cam-follower system with reset springs ensured precise gripper operation, with each unit transporting a single seed potato per rotation to the delivery zone [19,20]. While effective for flat seed potatoes, the design demonstrated significant limitations: (1) elevated miss-planting rates due to poor accommodation of irregularly shaped seeds, and (2) increased mechanical damage from vibration sensitivity [21,22].

The needle-type planter employed elastic plastic needles uniformly distributed along the seed disk perimeter. During operation, each needle captured a single seed potato in the feeding zone and transported it to the furrow via disk rotation and spring-assisted release. This design exhibited notable tolerance to seed dimensional variability, achieving improved seed spacing uniformity with reduced miss-planting rates and lower spacing variability coefficients [23]. However, the system induced significant mechanical injury to seed potatoes, increasing pathogen susceptibility and yield losses. Furthermore, performance degraded in complex soil conditions due to frequent needle deformation, adversely affecting planting accuracy.

The air-suction planter operated by using negative pressure to adsorb seeds onto the seed disc; the seeds were transported to the seed delivery zone with the seed disc rotation, where the disappearance of negative pressure allowed them to free-fall into position at once [24,25]. This mechanism was primarily employed for cereal planting due to its advantages of reduced seed damage rate, superior metering accuracy, and adaptability to varying seed sizes and shapes. Additionally, its high operational speed contributed to significantly improved efficiency [26,27,28]. For high-weight, large-sized, and irregularly shaped seed potatoes, stronger adsorption forces and larger filling spaces were required to ensure stabilisation. This resulted in an inherently inefficient air-suction planter structure that was only suitable for miniature potato seeding [29,30]. Recent studies indicate that air-suction technology could potentially improve planting speed, quality, and seed adaptability for standard potatoes [31,32,33]. However, these findings remain laboratory-confined, lacking validation through controlled field trials to assess practical performance.

In conclusion, the development of a high-performance, multifunctional air-suction potato planter represents a critical requirement for large-scale cultivation systems in Northeast China. Such an innovation would substantially enhance sowing precision and field operational efficiency while reducing production expenditures, thereby facilitating the realisation of high-yield, resource-efficient agricultural practices in the region. This study developed an advanced air-suction mulai-arm potato planter integrated with side-deep fertilization, automated seed feeding, negative-pressure seed filling, seed transportation, positive-pressure seed delivery, soil covering, and compaction.

The study detailed the machine’s structural configuration and operation principle, with particular emphasis on the air-suction seed metering device design. It further identified the key parameters and their optimal values affecting system performance. To validate the operational quality of the air-suction planter and assess the technology’s comprehensive performance, field trials were conducted. The experimental results were systematically analysed and discussed to verify the technical feasibility. These findings established a foundation and provided guidance for more extensive research into this technology.

2. Materials and Methods

2.1. Structure and Operation Principle

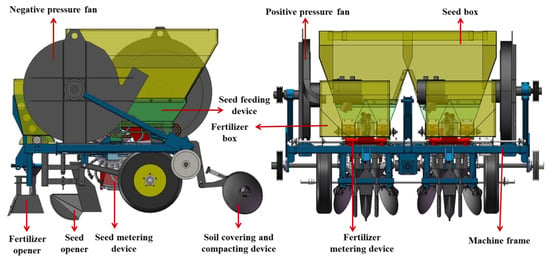

The ASPP comprised the following key components, as shown in Figure 1: machine frame, fertilizer discharge system, fertilizer opener, seed metering device, seed supply device, seed opener, positive pressure fan, negative pressure fan, soil covering and compacting device, as well as the air distribution system and seed-fertilizer transmission system. The fertilizer discharge system consisted of a fertilizer box, a fertilizer metering device, and a fertilizer opener, with power transmission through the ASPP’s seed-fertilizer transmission system. The seeding system integrates a seed box, seed feeding device, seed metering device, seed opener, and soil covering and compacting device, which provides air-pressure seed suction and seed delivery through the air distribution system, with sowing power supplied by the seed-fertilizer transmission system (Figure 2). The planter utilized a three-point hitch suspension system in a backpack configuration, with the tractor’s hydraulic system maintained in a float position during operation.

Figure 1.

Structural composition of ASPP.

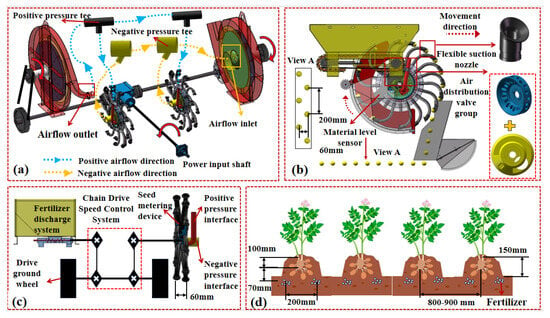

Figure 2.

(a) Working principle of air distribution system; (b) Working principle of seeding; (c) Seed-fertilizer transmission system; (d) Agricultural cultivation model.

The working principle of ASPP is shown in Figure 2. When the planter operated under tractor traction, the seed box was filled with seed potatoes, which rolled downward into the seed supply device by gravity. The seed feeding device then steadily delivered seed potatoes to the seed metering device’s filling zone through a conveyor belt. The seed feeding device was powered by a stepper motor, while the seed filling zone was equipped with a material-level sensor to monitor seed potato volume. When the sensor detected that the inventory had reached the preset threshold, it sent a signal to the stepper motor to either reduce the supply rate or stop operation. Conversely, when the inventory volume fell below the threshold, the motor initiated or increased the supply rate to ensure continuous and regulated seed replenishment in the seed-filling zone. The seed and fertiliser metering devices were powered by the ground drive wheel through a chain-driven speed control system. Their rotational speeds were adjusted by altering the sprocket tooth count, thereby modulating both seed spacing and fertiliser discharge quantity.

The ASPP’s precision pneumatic fans were powered by the tractor through the rear power take-off shaft. The negative pressure fan’s airflow inlet was connected to the seed metering device’s negative pressure interface through a pneumatic pipeline. This system operated through an air distribution valve group and multiple flexible suction nozzles, generating a consistent negative pressure within the pipeline. As the seed metering device rotated through the filling zone, the flexible suction nozzles created localised negative pressure, enabling precise seed potato adsorption. The positive pressure fan’s airflow outlet was connected to the seed metering device’s positive pressure interface through the pneumatic pipeline. During operation, the positive pressure fan is linked to a single flexible suction nozzle through the air distribution valve group, creating positive pressure within the pipeline. As the tractor advanced at a constant speed, the seed metering device adsorbed seed potatoes. Upon reaching the seeding position, the positive pressure fan engaged with the flexible suction nozzle, releasing seeds through positive pressure airflow to complete the seeding operation. The positive pressure airflow generated a horizontal force counteracting the machine’s direction of travel. This force reduced the seed potatoes’ horizontal velocity, enhancing planting spacing uniformity.

Compared to conventional mechanical planters, the ASPP significantly reduced seed damage rates through its flexible suction nozzles, which ensured gentle seed potato contact. The pneumatic seed-filling and transport system demonstrated superior adaptability to diverse seed potato varieties and structures while eliminating missed-seeding issues caused by high-speed operational vibrations, thereby improving field efficiency. The seed discharge system could be integrated with the furrow opener, soil covering, and compaction devices into an independently profiling unit group. This design enhanced seeding depth consistency and stability. Additionally, the positive pressure system reduced both seed potato drop time and horizontal velocity, significantly increasing plant spacing qualification rates and uniformity.

2.2. Key Parameter Determination

2.2.1. Seed Metering Device Structure Parameter

The radial dimension of the seed metering device constituted a critical structural parameter, significantly affecting the machine’s overall design dimensions, including seed filling and feeding performance and fan power consumption [34]. To investigate the influence of radial dimension on seed filling time, a kinematic model was established as Equation (1) based on the working principle.

where l0 is the seed filling arc length, m; v0 is the seed potato linear velocity, m/s; t0 is the seed filling time, s; d is the seed metering device radial dimension, m; n is the seed metering device rotational speed, rpm; θ0 is the seed filling zone arc angle, rad. The mathematical model for seed filling time was derived by organizing Equation (1) as follows:

According to Equation (2), the seed filling time was positively correlated with the seed filling zone arc angle but inversely proportional to the seed metering device’s rotational speed. Notably, the seed filling time could be optimised through increasing the seed filling zone arc angle or reducing the seed metering device rotational speed. The analysis confirmed that seed filling time was independent of the seed metering device’s structural dimensions.

Increasing the radial dimension of the seed metering device enabled a reduction in seed delivery height, which improved seed spacing uniformity and minimised mechanical damage during seeding. However, an excessively large radial dimension positioned the seed filling zone too close to the seed furrow base (Figure 2), compromising machine passability. Additionally, seed potatoes adsorbed by the flexible suction nozzles became prone to leakage due to excessive seed-to-nozzle contact during operation. Based on these considerations, a preliminary radial dimension of 720 mm was selected to simultaneously reduce both mechanical damage and seed rebound probability.

The number of flexible suction nozzles constituted a critical design parameter that directly constrained the planter’s operational speed and performance quality. Current studies indicated that standard Chinese seed potatoes (including both cubed and whole tubers) exhibited average triaxial diameters ranging from 38 to 57 mm [9]. Assuming a maximum permissible seed potato diameter of 60 mm, theoretical calculations indicated that the seed metering device’s radial circumference could accommodate up to 37 seed potatoes without compromising operational reliability. While increasing the number of flexible suction nozzles extended seed-filling time, densely arranged nozzles led to inefficient seed filling. To optimise nozzle quantity without sacrificing functionality, a staggered arrangement was implemented (Figure 2), with an axial circumferential spacing of 60 mm between adjacent nozzle rows. This design required sufficient separation between nozzles on the same circumference to prevent seed jamming. Ultimately, a 20-nozzle configuration was selected. Based on the seed-fertiliser transmission system’s working principles, the quantitative model for determining the optimal nozzle count was established as Equation (3).

where L0 is the theoretical seed potato spacing, m; v is the operational speed, m/s; N0 is the number of flexible suction nozzles.

According to Equation (3), the number of flexible suction nozzles exhibits a positive correlation with the operational velocity, while it demonstrates an inverse relationship with both the theoretical seed potato spacing and seed metering device rotational speed. When theoretical seed spacing and the number of flexible suction nozzles were held constant, increased operational speed resulted in higher rotational speeds of the seed metering device. During abrupt machine acceleration or deceleration, the impulse from seed potato clusters in the filling zone to nozzle-held seeds increased, intensifying inter-particle collisions among the seed potatoes. Concurrently, elevated rotational speed reduces the seed-filling time, thereby increasing the miss-seeding phenomenon. The key mechanical characteristic of the ASPP was its high-speed capability (maximum: 10 km/h). In Heilongjiang Province, standard potato spacing ranges (150–450 mm) meant smaller spacings required higher metering device speeds. Substituting these parameters into Equation (3) yielded a limiting rotational speed of 56 rpm.

2.2.2. Negative and Positive Pressure Determination

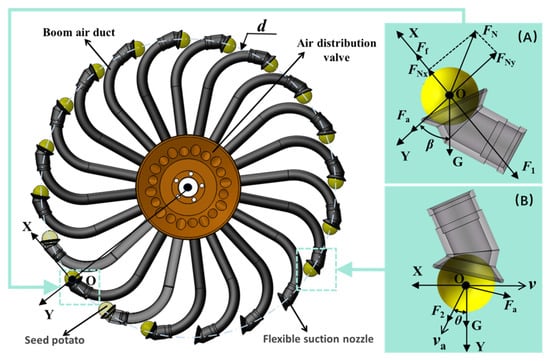

As the seed metering device traversed the seed filling zone, seed potatoes were adsorbed by the flexible suction nozzles and rotated synchronously. The kinematic analysis of the seed potato was governed by a combination of forces, including adsorption force, centrifugal force, normal force, frictional force, and gravity, as illustrated in Figure 3. Based on D’Alembert’s principle, the equilibrium equations describing the seed potato’s motion were established as Equation (4).

where FNx is the x-component of normal force, N; FNy is the y-component of normal force, N; Ff is the frictional force, N; G is the gravity, N; F1 is the adsorption force, N; Fa is the centrifugal force, N; β is the seed-filling angle, (°).

Figure 3.

Force analysis of seed feeding and seed delivery phases. (A) Force analysis of seed feeding phase; (B) Force analysis of seed delivery phase.

Under actual operating conditions, the forces acting on seed potatoes were further influenced by several additional factors, including seed population density, seed potato morphology, seed potato moisture content, operational speed variation, etc. [35]. To account for these variables, the mathematical model for seed potato adsorption was established as Equation (5).

where m is the seed potato weight, kg; ω is the seed metering device angular velocity, rad/s; φ is the friction angle between the suction nozzle and seed potato, (°); γ is the suction nozzle cone angle, (°); k is the proportionality coefficient, S is the effective adsorption area, m2; P1 is the negative pressure, kPa. The limit conditions for stable seed potato transport during filling and conveyance were derived by reorganising Equation (6).

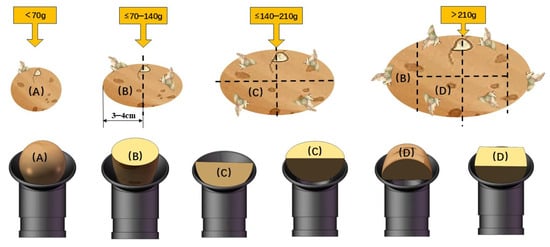

To ensure reliable seed potato adsorption and stable transport during the adsorption phase, the system’s negative pressure required design optimisation based on the limiting effective adsorption area. In alignment with agronomic standards for potato cultivation, larger seed potatoes underwent pre-sowing cutting to meet planting specifications. This cutting process reduced sphericity, thereby decreasing the effective adsorption area and compromising seed-filling quality. The cutting protocol was implemented as follows (Figure 4): the seed potatoes weight < 70 g were uncut; longitudinal cutting for seed potatoes weight about 70–140 g; longitudinal and transverse cutting for seed potatoes weight about 140–210 g; and tri-longitudinal and single-transverse cutting for seed potatoes weight >210 g with the cutting length of 30–45 mm [36].

Figure 4.

Agronomic requirements for seed potato cutting and interaction with nozzles.

The reduced sphericity of cut seed potatoes resulted in variable interfacial dynamics between tubers and flexible suction nozzles. This included diverse seed potato–nozzle contact modalities and posture variations due to random orientation during adsorption. Statistical analysis of seeding operational data identified six predominant contact modalities (Figure 4). The maximum effective adsorption area (0.0020 m2) corresponded to a low seed leakage probability during transport. Conversely, the minimum area (0.0010 m2) led to significantly higher leakage rates due to insufficient adsorption force. However, expanding the seed-filling zone mitigated leakage through supplemental seed replenishment [37].

Based on Equation (6), where the proportionality coefficient was taken as 0.26, the seed metering device angular velocity was taken as the limiting value of 5.9 rad/s, the seed potato weight was taken as the maximum limiting value of 70 g, the suction nozzle cone angle was taken as 90°, the seed metering device radial dimension was taken as 720 mm, the friction angle between the flexible suction nozzle and seed potatoes was taken as 37°, the range of seed filling angle was initially taken as 0–45°, and the effective adsorption area was taken as the minimum value of 0.0010 m2. The maximum theoretical pressure required for the flexible suction nozzle was calculated as 16.13 kPa. The working principle of the ASPP demonstrated that seed potatoes were adsorbed by the flexible suction nozzle and then conveyed to the seed delivery zone through the seed metering device. The negative pressure responsible for seed absorption was terminated. Concurrently, the positive pressure fan provided positive airflow through the pneumatic distribution system into the transport pipeline, and the seed potato detached from the flexible suction nozzle through the synergistic action of the seed potato’s gravity and the positive airflow. At this stage, seeds acquired an initial velocity opposite to the machine’s forward direction. Force analysis of seed potatoes yielded the seed discharge process model as Equation (7).

where F2 is the positive pressure on seed discharge, N; θ is the positive casting pressure F2 and Y-axis angle (seed release angle), (°).

Prior to detachment from the flexible suction nozzle, the seed potato rotated synchro nously with the seed metering device at constant speed while translating linearly with the machine. To minimize the absolute horizontal velocity following discharge during high-speed operation, the system was engineered to ensure seed potatoes entered the seed furrow with minimal slippage and rolled in the direction of machine travel, thereby achieving zero forward velocity at discharge. The dynamic model of the seed potato can be established as Equation (8).

where vg is the initial discharge velocity, m/s; t is the positive pressure duration, s; θ is the seed release arc angle, rad; P2 is the positive pressure, kPa; l is the seed release arc length, m.

By substituting Equation (8) into Equation (7), we derived the mathematical model of positive pressure to quickly detach from the flexible suction nozzle and complete the zero-speed seeding as follows:

The known parameters were incorporated into Equation (9), where the seed potato weight was taken as the minimum limit of 30 g, and the theoretical seed potato spacing was taken as the minimum limit of 150 mm; the number of flexible nozzles was fixed at 20. Additionally, the seed release angle was initially configured at 60°. To prevent excessive seed velocity from causing seed potato rebound upon landing, which would adversely affect plant spacing and potentially damage the seed potatoes. The effective adsorption area was taken as the maximum limit of 0.0020 m2. The minimum theoretical positive pressure required for the flexible nozzle was determined to be 1.47 kPa.

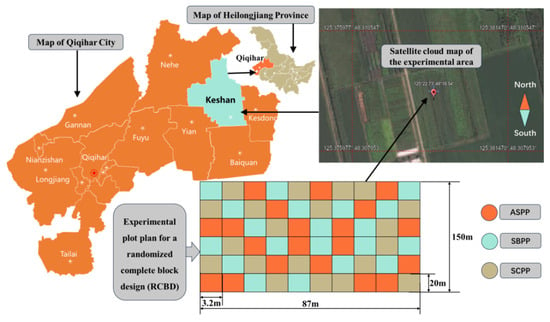

2.3. Test Environments and Materials

The field experiment was conducted at Keshan Farm, Keshan County, Heilongjiang Province (125°22′73″ E, 48°18′54″ N), beginning on 10 May 2024. The site featured a cool-temperate monsoon climate with a mean annual temperature of 1.3 °C, an effective accumulated temperature (≥10 °C) of 2339.8 °C, and annual precipitation of about 500 mm (primarily June–August). The experimental site is characterized by predominantly black calcareous soils exhibiting high fertility levels that are suitable for potato cultivation. The cultivation layer (0–300 mm depth) soil porosity exceeding 45%, thereby creating optimal conditions for tuber expansion. The soil pH value is 5.5 to 6.5 (weakly acidic to neutral), and the soil organic matter content is maintained at 2.8%, indicating adequate nutrient retention capacity. The field underwent standard tillage practices, including stubble breaking, plowing, harrowing, rotary tillage and ridging, and compaction in the fall. The ridge spacing was 800 mm, and the ridge height was 150 mm. Pre-experiment measurements indicated a soil moisture content of 27.7% at a depth of 100 mm.

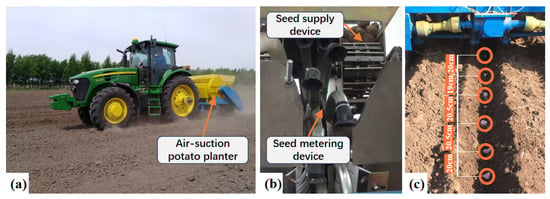

The experimental setup utilized the equipment and instruments, including a 2204 wheeled tractor (Deere&Company, Moline, IL, USA), a two-row air-suction potato planter (Northeast Agricultural University, Harbin, China), a 2CM-2A2 double-ridge single-row potato planter (Hongzhu Agricultural Machinery Co., Ltd., Qingdao, China), and the DGG-9070 AD electric thermostatic forced-air drying oven (Senxin Experimental Instrument Co., Ltd., Shanghai, China). The experiment utilized Zhongshu No. 5 seed potatoes with mean triaxial dimensions of 68.6 × 52.3 × 41.7 mm, the average moisture content was 78.5%, the single-seed mass was 50.9 g, and the netness was >98%. The theoretical seed spacing was configured as 200 mm, and the theoretical seeding depth was 100 mm. Sowing and simultaneous application of compound fertilizer 500 kgha−1, the fertilizer application position is 100 mm at a horizontal seed row and 70 mm below the seed row, as shown in Figure 2.

2.4. Test Methods

To evaluate the performance and operational quality of the ASPP, a comparative field trial was conducted using two conventional planters, the SBPP and SCPP, as controls. The aim was to determine the value of a technical feasibility study of ASPP technology and to provide references for subsequent equipment research and development. Both the SBPP and SCPP operated with the same equipment, with only the seed-carrying mechanism (belt or chain) being replaced during operation. The ASPP average operating speed was 8 km/h, while the SBPP and SCPP average operating speeds were 4 km/h. The experimental design consisted of the ASPP, SBPP, and SCPP, each with an individual plot size of 64 m2 and 20 replications. This resulted in a total of 60 experimental plots, with a cumulative experimental area of 1300 m2, as shown in Figure 5 (protected rows were not depicted in the schematic).

Figure 5.

Randomized complete block design plot trial layout.

The experiment was conducted using a randomised complete block design. Key evaluation indicators included the seed spacing qualification index, missed-seeding index, re-seeding index, plant spacing coefficient of variation, seedling emergence rate, yield, and economic benefits. The trial covered the entire growth cycle, from sowing to harvest, during which the performance metrics of the ASPP, SBPP, and SCPP were measured and statistically analysed. Data processing and visualisation were carried out using OriginPro 2024 (OriginLab Corporation, Northampton, MA, USA). Statistical analyses included normality testing (Shapiro–Wilk test), assessment of homogeneity of variance (Levene’s test), and multiple comparisons (Tukey’s HSD test) [38], with statistical significance set at p < 0.05.

2.4.1. Measurement of Sowing Quality

The sowing quality was evaluated through the qualified seed spacing index, missed-seeding index, re-seeding index, and plant spacing coefficient of variation. All measurements were conducted in accordance with the National Standards of the People’s Republic of China, including the National Standards of the People’s Republic of China, include” Test Methods for Potato Planters” (GB/T 6242-2006) [39] and “Test Methods for Single-Seed (Precision) Planters” (GB/T 6973-2005) [40]. Following sowing, the planting rows were systematically numbered. For each experimental plot, the 5-metre outermost rows at both ends of the area were excluded to mitigate edge effects, and two rows were randomly selected for measurement. The designated row length for measurement was standardised as the sum of 50 cumulative theoretical spacing lengths of seed potatoes, with the measuring position randomly selected. The seed spacing qualification index, missed-seeding index, re-seeding index, and plant spacing coefficient of variation were calculated using Equation (10).

where QSI is the qualified seed spacing index, %; RI is the re-seeding index,%; MI is the missed-seeding index, %; N1 is the number of theoretical seed spacing; n1 is the number of actual measured seed spacing greater than 0.5 times but not more than 1.5 times the theoretical seed spacing; n2 is the number of actual measured seed spacing not greater than 0.5 times the theoretical seed spacing; n3 is the number of actual measured seed spacing greater than 1.5 times the theoretical seed spacing; CV is the coefficient of variation; xi is the actual seed spacing for the measurement i in the plot j, mm; xj is the average seed spacing in the plot j, mm.

2.4.2. Measurement of Seedling Emergence Rate

Following the completion of seeding, daily seedling emergence counts were conducted at 8:00 a.m. until the end of emergence. For each experimental plot, data sampling points were taken within a defined measurement area, spanning 5 metres along the ridge direction and 1.6 metres perpendicular to the ridge direction (the inter-ridge distance between two central ridges). This delineated a sampling zone of 1.6 × 5 m2, and the number of visually detectable ground-breaking potato seedlings was recorded. Within the sampling zone, 20 measurements were taken, and the average value was calculated. The seedling emergence rate, defined as the ratio of the number of emerged seedlings to the theoretical seeding quantity, was calculated using Equation (11).

where ERi is the seedling emergence rate on day i, %; nij is the number of seedlings emerging at the data j sampling point on day i; N is the theoretical seeding quantity within seed potato sampling points.

2.4.3. Measurement of Potato Yields

The potato harvesting process in the experimental area was conducted using a criss-cross sampling method. Sampling points were established along the two diagonal lines, with three replicates. Each sample covered an area of 3.2 m2 (spanning 2 m along the ridge direction and 1.6 m perpendicular to the ridge direction). Samples were collected at evenly distributed points along the diagonals. The tubers were cleaned by removing surface soil and excessive stems and leaves after harvesting. Moisture content was determined using the oven-drying method. The average of six samples from each plot was taken as the actual potato yield of the plot. To ensure consistency across experimental studies and comparability of multi-location data, the post-harvest moisture content of potatoes was measured for each plot. Where significant variations in moisture content were observed, the fresh weight was adjusted to a standardised moisture basis (14%) and then processed according to Equation (12).

where PY is the potato yield, kg·ha−1; PYi is the potato yield per hectare in the plot i, kg·ha−1; QSi is the potato yield in the plot i at harvest, kg·ha−1; pi is the actual moisture content of potato in the plot i, %; p0 is the standard moisture content, %.

2.4.4. Measurement of Comprehensive Economic Benefits

Comprehensive economic efficiency in potato production was calculated as the difference between total revenue and total inputs per cultivated hectare. However, this study specifically examined the comparative effects of different potato planters on comprehensive economic efficiency while maintaining experimental consistency. The analysis excludes the constant factors, such as field tillage and preparation, field management, harvest, field adaptability, equipment maintenance cost, machinery failure rate, field transport, and land leasing. The impact of potato planter type on comprehensive economic benefits was determined by PY, operational efficiency (OE), seed potato seeding rate per unit area (SPSR-PUA), fuel consumption (FC), machine depreciation (MD), labor input (LAB), machinery price (MP), and seven key factors that collectively determined the comprehensive economic performance of different planting systems. The measured data for the main influencing factors were subjected to a dimensionless normalization integration process. These processed datasets were visualized using OriginPro 2024 (OriginLab Corporation, Northampton, MA, USA) to enable qualitative assessment of the comprehensive economic benefits.

3. Results and Discussion

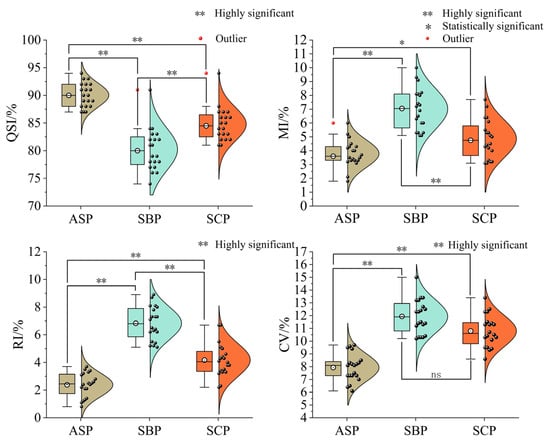

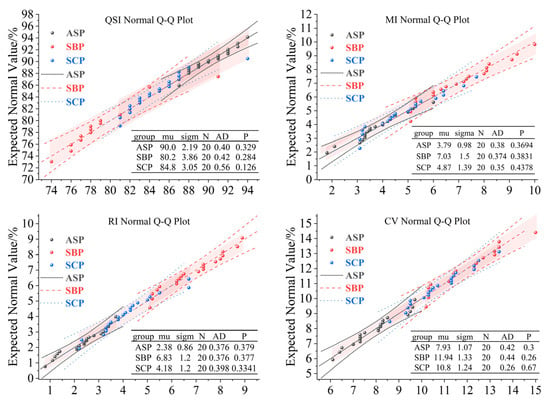

The experimental results demonstrating the effects of ASPP, SBPP, and SCPP on sowing quality are presented in Figure 6. The ASPP achieved mean values of 90.05% for PSI, 3.78% for MI, 2.32% for RI, and 7.93% for CV. In comparison, the SBPP showed inferior performance with respective mean values of 80.25% (PSI), 7.02% (MI), 6.83% (RI), and 11.86% (CV). The SCPP demonstrated intermediate results, with values of 84.80% (PSI), 4.87% (MI), 4.18% (RI), and 10.80% (CV).

Figure 6.

Box-and-whisker plot of sowing quality evaluation indicators.

The measured data and predicted values clustered closely around the diagonal line in the Q-Q plot (Figure 7), providing preliminary evidence that the experimental data approximately followed a normal distribution. This was confirmed through Shapiro–Wilk testing, which yielded p-values all exceeding the 0.05 significance threshold. These results indicated that the experimental data at the 0.05 level were drawn from a normally distributed population. Levene’s test returned p-values of 0.123 (PSI), 0.077 (MI), 0.219 (RI), and 0.514 (CV), demonstrating no significant variance differences at the 0.05 level and thus satisfying the homogeneity of variance assumption. A subsequent one-way ANOVA of the experimental data revealed statistically significant differences (p < 0.05) among the overall means for PSI, MI, RI, and CV. Post-hoc multiple comparisons between treatments were conducted using Tukey’s HSD method, with results presented in Figure 6.

Figure 7.

Q-Q plot for normally distributed sowing quality data.

Statistical analysis revealed significant differences (p < 0.05) between ASPP, SBPP, and SCPP for all evaluation metrics (QSI, MI, RI, and CV). At the same time, significant differences (p < 0.05) were observed between SBPP and SCPP across all evaluation metrics except CV. Comparative analysis of seeding performance revealed that the ASPP demonstrated superior overall sowing quality to both the SBPP and SCPP. And the SCPP exhibited higher values in the QSI, MI, and RI compared to the SBPP. However, there was no significant difference between the CV of SBPP and SCPP. The box-and-whisker plot distributions indicated that ASPP displayed the shortest interquartile ranges across all sowing quality indicators, demonstrating greater operational stability than both comparison models. SCPP showed consistently narrower box ranges than SBPP, suggesting improved stability in sowing quality indicators relative to SBPP. Under identical surface operating conditions, the Spoon-Belt Potato Planter (SBPP) exhibits high dispersion in Plant Spacing irregularity (PSI), primarily attributed to the mismatch between the seed picking cycle and the forward speed caused by factors such as belt slippage, resulting in fluctuations in plant spacing due to speed asynchrony.

The operational status of the ASPP during field trials is shown in Figure 8. All experimental plots were established within a contiguous farmland block to ensure uniform soil conditions. Consistent tillage practices and field preparation equipment were used across all treatments prior to sowing to eliminate confounding variables. All field operations, including field tillage and preparation, ridge formation, and soil compaction, were completed during the autumn 2023 season. This approach effectively reduced the influence of natural environmental factors on the experimental results. To facilitate measurement of sowing quality, the outermost rows for all three implements (ASPP, SBPP, and SCPP) were operated without soil covering or compaction.

Figure 8.

(a) Air-suction potato planter field trials; (b) Critical components; (c) Seeding effectiveness.

Statistical analysis demonstrated that the ASPP exhibited the highest PSI and the lowest CV. The seed spacing uniformity of the ASPP was clearly observable in Figure 8, providing visual validation of the statistical results. The ASPP’s superior performance was primarily attributable to its innovative structural design, in which the flexible seed-picking mechanism of the ASPP seed discharger adsorbs seeds into the interior of the groove opener, thereby significantly reducing the vertical drop height of seed potatoes during sowing. This structural feature minimises the likelihood of seed potato rebound upon contact with the seed groove. Furthermore, the ASPP adoption of an air-blowing auxiliary seeding system to attenuate the horizontal velocity of seed potatoes guaranteed theoretical distance for grain spacing.

Another key feature was that the ASPP’s seed discharger incorporated a rigid-body structure, which maintained minimal vibrational deformation during tractor operation. In contrast, the seed metering spoons of both the SBPP and SCPP were connected to flexible transmission mechanisms, making their seed delivery processes more vulnerable to vibration-induced disturbances. This effect was particularly pronounced in the SBPP, which exhibited significantly greater vibration amplitudes during high-speed operation. The ASPP demonstrated superior performance with lower MI and RI values compared to both the SBPP and SCPP, resulting in reduced missed-seeding and re-seeding rates. This performance advantage was principally attributable to the ASPP’s unique seed discharger working principle.

The air-suction seed discharger achieved single-seed adsorption capability through optimised suction nozzle design. By increasing the negative pressure, the system effectively minimised seed leakage, thereby reducing both the RI and MI. Due to the limited mobility of seed potatoes, the ASPP’s seed discharger permitted greater disturbance of the seed potato layer, which enhanced seed-filling efficiency. This design feature contributed to the system’s overall operational superiority [41]. In contrast to the ASPP, both the SBPP and SCPP employed seed metering spoons mounted on flexible drive mechanisms that made direct contact with the seed potato population. The seed potatoes fall into the seed metering spoon by gravity. To avoid seed leakage, these seed metering spoons were typically oversized relative to individual seed potato dimensions; this design resulted in no guarantee that there would be only one seed potato in each seed metering spoon. Meanwhile, the seed potatoes within the seed metering spoon were susceptible to rolling off during operation, as vibrations or speed variations induce inertial forces on the flexible drive system. Ultimately resulting in increased MI and RI [42].

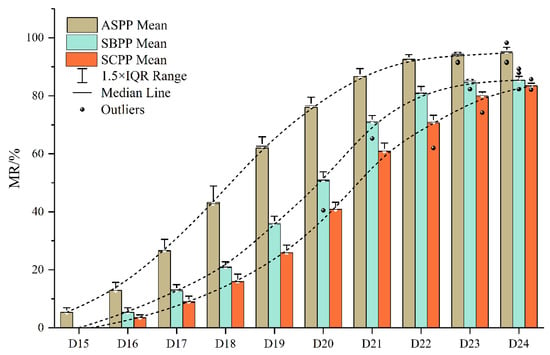

The comparative effects of ASPP, SBPP, and SCPP on potato seedling emergence rates were demonstrated in Figure 9. All three models showed an increasing trend over time in seedling emergence rates, with the rate of increase exhibiting significant attenuation after day 22. The seedling emergence period for the ASPP-treated plot occurred between day 15 and day 24 after planting, whereas both the SBPP and SCPP-treated plots exhibited a slightly delayed emergence, spanning from day 16 to day 24 after sowing. The ASPP-treated plot initiated germination one day earlier than both the SBPP and SCPP-treated plots, demonstrating faster seedling emergence velocity and a higher seedling emergence rate in the same period. The average values of the final seedling emergence rates for ASPP, SBPP, and SCPP were 94.76%, 85.42%, and 83.46%, respectively. The seedling emergence rate of ASPP was 10.93% and 13.54% higher than that of SBPP and SCPP, respectively. This enhanced performance was attributed to more optimal seed–soil contact under the ASPP system.

Figure 9.

Law of change in potato seedling emergence rate with time.

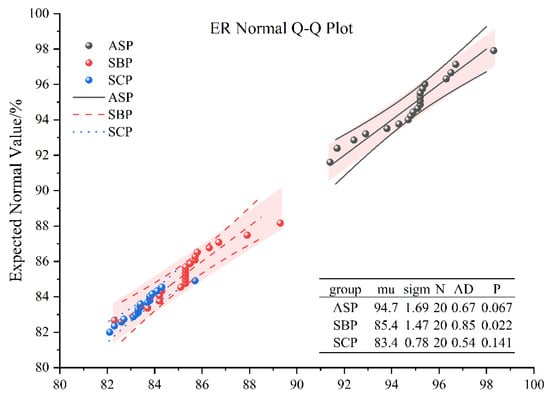

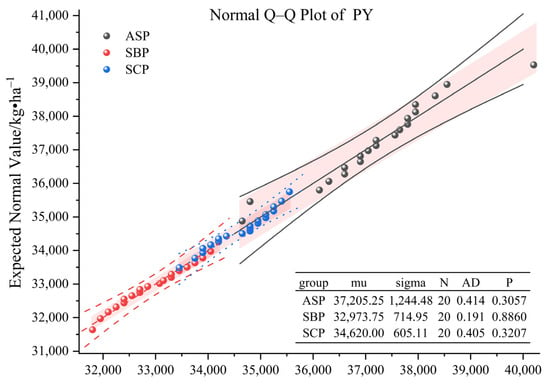

The measured data and predicted values of ER for ASPP, SBPP, and SCPP clustered closely around the diagonal line in the Q-Q plot, as demonstrated in Figure 10. This provided preliminary evidence for the normality assumption in the experimental data distribution. Further testing by the Shapiro–Wilk method revealed that the p-values for ASPP, SBPP, and SCPP were 0.227, 0.081, and 0.115, respectively. As all p-values exceeded 0.05, it could be determined that the measured trial data, at the 0.05 level, were significantly consistent with a normal distribution overall. Levene’s test yielded a p-value of 0.093, which was greater than 0.05, indicating that the overall variance was not significantly different at the 0.05 level and met the requirement for variance homogeneity.

Figure 10.

Q-Q plot for the normal distribution of ER.

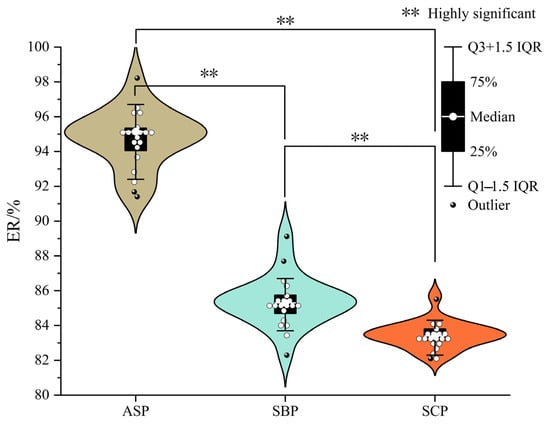

A one-way ANOVA was conducted on the experimental data, and the overall mean of the treatments differed significantly at the 0.05 level. Tukey’s HSD method was employed for multiple comparisons between treatments, and the results are presented in Figure 11. Statistical analysis of ER revealed significant differences (p < 0.05) among ASPP, SBPP, and SCPP, as well as between SBPP and SCPP. The average emergence rate of ASPP was significantly higher than that of SBPP and SCPP, while SBPP was superior to SCPP. Although ASPP demonstrated higher emergence rates and was statistically significant, the distribution patterns observed in the box-and-whisker plot and the longitudinal dimensions of the violin plots showed that SCPP had a shorter box-and-whisker plot and flatter violin plots.

Figure 11.

Violin plot of the final emergence rate.

The results indicated greater stability in potato emergence rates for this model, further substantiating the operational reliability of the SCPP. Notably, the SCPP was (at the time of study) the largest and most widely deployed sowing machine in service across China. Comparative analysis revealed that the SBPP demonstrated better stability in seedling emergence rates relative to the ASPP. Consequently, subsequent design and development processes for the ASPP needed to prioritise enhancing the stability of its operational performance.

Through the evaluation of sowing quality metrics, it was evident that the ASPP achieved a higher seedling emergence rate compared to both the SBPP and SCPP. This superiority could be attributed primarily to two key factors. First, the SBPP and SCPP exhibited significantly higher leakage rates than the ASPP. The mean values of MI for ASPP, SBPP, and SCPP were measured at 3.78%, 7.02% and 4.86%, respectively. The MI of ASPP was 46.15% and 22.22% lower than that of SBPP and SCPP, respectively. Second, from a mechanical perspective, the difference stemmed from the machine’s working principle and structural design. The ASPP’s seed-filling process established direct contact between seed potatoes and flexible suction nozzles, creating surface-to-surface contact between the nozzles and the seed potato population. The flexible nozzles were made of a more elastic material, which significantly reduced mechanical damage to seed potatoes during operation.

Consequently, this established an optimal foundation for subsequent seedling emergence. However, the seed metering spoons in both the SBPP and SCPP were constructed from rigid materials, with initial contact occurring along the edge of the seed potato population in a surface-to-line configuration. This contact geometry concentrated stress on the seed potatoes, resulting in higher applied forces and increasing their susceptibility to mechanical damage. Seed potatoes that experienced mechanical damage subsequently demonstrated a lower seedling emergence rate [22].

The ASPP system maintained zero relative motion at the seed–nozzle interface throughout the entire operational cycle. This design ensured that the seed potatoes interacted exclusively with the flexible nozzle surface, preventing secondary contact with rigid mechanical components. In contrast, the SBPP and SCPP systems employed a flexure-driven mechanism for seed potato transport, which inherently generated relative motion and impact inertia forces between seed potatoes and the rigid seed metering spoon during operation. This significantly increased the risk of mechanical damage to seed tubers [43].

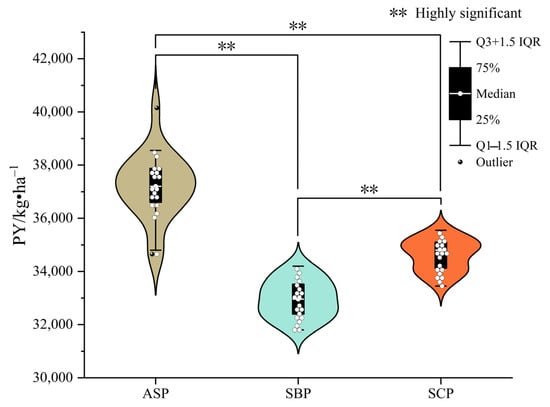

The effects of ASPP, SBPP, and SCPP on potato yield are shown in Figure 12. The principal determinants of potato yield comprised plant population density, tuber set per plant, and individual tuber mass. Plant population density demonstrated a positive correlation with seedling emergence rate, while tuber set per plant showed cultivar-dependent variation and was influenced by main stem branch development. Individual tuber mass was related to field management practices.

Figure 12.

Violin plot of the potato yield.

As this study focused exclusively on evaluating the impact of seeding equipment on yield, with all other agronomic conditions maintained uniformly, secondary yield influences, including tuber number per plant and individual tuber weight, were not recorded in this trial. The mean potato yields following sowing with ASPP, SBPP, and SCPP were 37,205.25, 32,973.75, and 34,620 kg·ha−1, respectively.

The measured data and predicted values of PY for ASPP, SBPP, and SCPP clustered closely around the diagonal line in the Q-Q plot, as demonstrated in Figure 13. This distribution pattern provided preliminary evidence supporting the normality assumption of the experimental data. Further normality testing using the Shapiro–Wilk method revealed p-values of 0.414, 0.739, and 0.402 for ASPP, SBPP, and SCPP, respectively. As all p-values exceeded 0.05, it could be determined that the measured trial data were consistent with a normal distribution at the 0.05 significance level overall.

Figure 13.

Q-Q plot for the normal distribution of PY.

Levene’s test yielded a p-value of 0.087, which was greater than 0.05, indicating that the overall variance was not significantly different at the 0.05 level and met the requirement for variance homogeneity. A one-way ANOVA was performed on the experimental data, revealing significant differences between treatment means at the 0.05 level. The HSD method was employed for multiple comparisons between treatments, with results presented in Figure 13. Statistical analysis of PY demonstrated significant differences (p < 0.05) among ASPP, SBPP, and SCPP, as well as between SBPP and SCPP specifically. The potato yield achieved with ASPP was significantly higher than both SBPP and SCPP, while SCPP was superior to SBPP. ASPP showed average yield increases of 12.83% and 7.47% compared to SBPP and SCPP, respectively.

Although the ASPP’s yield was significantly higher than the other two models, the distribution patterns observed in the box-and-whisker plots and the longitudinal dimensions of the violin plots revealed that both the SBPP and SCPP exhibited shorter box-and-whisker plots and flatter violin plots. This indicated greater stability in potato yield for these models. The aforementioned analysis of potato emergence rates demonstrated that more stable seedling emergence rates ensured greater yield stability in potato production. While this study primarily verified the technical feasibility of the ASPP, it established critical groundwork for subsequent research. The precise mechanistic basis for its yield increase requires focused investigation in future studies.

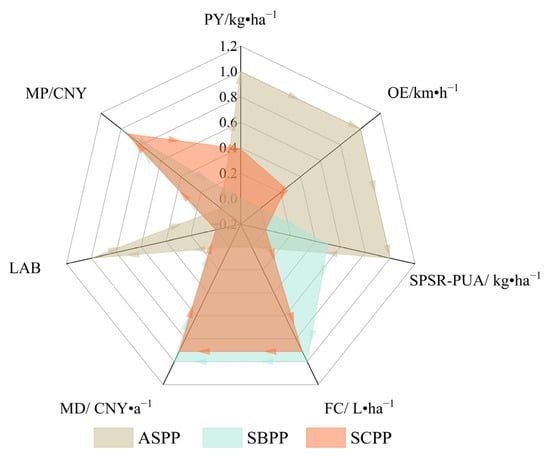

The comprehensive economic efficiency was quantified through seven key indicators: PY, OE, SPSR-PUA, FC, MD, LAB, and MP. PY was derived from experimental measurements conducted in the aforementioned tests; OE was a predefined parameter established artificially; SPSR-PUA was calculated based on statistical analysis of seedling emergence rates; FC was measured by installing a fuel consumption meter into the tractor’s fuel supply system; MD was calculated assuming a 10-year service life for the machinery; LAB was determined in accordance with actual sowing operations; and MP was assessed through a market-based approach. The purchase price of ASPP was obtained by averaging quotations from multiple firms, while the prices of SBPP and SCPP were determined based on market prices.

Among these indicators, PY and OE were classified as positive indicators, whereas SPSR-PUA, FC, MD, LAB, and MP were negative indicators. The raw data for these core evaluation metrics are presented in Table 1.

Table 1.

Measured data on core evaluation indicators.

To enable comparative analysis of the three seeding machines regarding the influence on the significance of each evaluation index and to provide guidance for subsequent design optimisation of air-suction precision planters, the measured data were subjected to dimensionless normalisation. The processed data were visualised using OriginPro 2024 (OriginLab Corporation, Northampton, MA, USA)to attain a qualitative evaluation of comprehensive economic benefits (Figure 14). Through geometric analogy (area and perimeter), it could be observed that the ASPP exhibited the largest polygonal area, indicating balanced and excellent performance across all evaluation indicators. The SCPP showed the smallest perimeter, suggesting lower inter-indicator variability, but demonstrated relatively poor overall performance.

Figure 14.

Radar plot for the normal distribution of PY.

The ASPP demonstrated higher potato yields and faster operational speeds while reducing labour requirements and saving seed potatoes. This made it particularly suitable for large-scale cultivation in regions with elevated labour costs. However, its high equipment purchase cost and rapid depreciation necessitated extended utilisation periods to achieve cost amortisation. The SBPP system required a relatively low initial investment, rendering it suitable for small-scale and economically constrained agricultural operators. However, it resulted in lower potato yields and mechanisation efficiency, along with higher seed potato usage. These factors increased operating costs over extended periods. The SCPP demonstrated intermediate performance in both seed potato usage and fuel consumption. This characteristic made it ideal for cost-sensitive agricultural operators who nevertheless sought operational efficiency.

The selection of an appropriate potato planter involved trade-offs among machinery reliability, labour requirements, and yield stability affected by sowing uniformity. For operators with sufficient budget who pursued superior return on investment, the ASPP represented the optimal choice for maximising long-term returns. The SBPP and SCPP provided lower-cost alternatives for small-scale and economically constrained agricultural operations. While some efficiencies could be sacrificed to reduce initial investment, this approach required careful management of operating costs at subsequent stages.

In terms of design and development priorities, the ASPP needed to focus on field efficiency, fuel consumption, and machine stability. These parameters served as essential indicators for improving both overall economic performance and agricultural productivity.

Comparative experimental studies demonstrated that the ASPP significantly enhanced potato yield through improved planting quality and reduced seed potato damage. Furthermore, compared with the SBPP and SCPP, the ASPP improved production efficiency and reduced seed potato and labour costs. The ASPP had significant cost-saving characteristics while simultaneously offering high efficiency and high quality. However, this study only conducted preliminary structural design and experimental studies on the ASPP, and the design of key components, optimisation of operating parameters, and matching of performance indices were not studied in depth. While the mechanisms of ASPP mechanisation for yield increase remained unclear, it was a high-value target for in-depth research.

4. Conclusions

In this study, an advanced air-suction mulai-arm seed metering system was developed, which integrated side-deep fertilisation, automated seed feeding, pneumatic seed absorption, soil covering, and compaction. Its performance was verified through a comparative field experiment conducted as follows:

- (1)

- The main feature of this machine was its adopted dual pneumatic system, which completed negative-pressure seed filling, seed transportation, and positive-pressure seed delivery. The negative-pressure seed extraction mechanism that minimizes seed damage by precisely controlling suction pressure, and the near-zero-speed seed delivery mechanism synchronizes seed release with ground speed, reducing bounce-induced spacing errors. Therefore, this design minimised the missed-seeding and re-seeding rates while enhancing seed spacing uniformity and seedling emergence rate. It provided feasible equipment and technological support for potato yield increase and stabilisation.

- (2)

- The overall structure and operating parameters of the ASPP were determined. The seed discharger had a radial dimension of 720 mm and incorporated 20 flexible suction nozzles arranged in a circumferentially uniform staggered row, with an axial stagger spacing of 60 mm between adjacent nozzles. The maximum operating speed of the machine was 10 km/h, and the maximum rotational speed of the seed discharger was 56 rpm. The maximum theoretical pressure required by the flexible suction nozzle for seed suction was 16.13 kPa, and the minimum theoretical pressure for seed delivery was 1.47 kPa.

- (3)

- The experimental results showed that the mean values of PSI, MI, RI, and CV for the ASPP were 90.05%, 3.78%, 2.32%, and 7.93%, respectively, with significant differences (p < 0.05). The mean ER of the ASPP, SBPP, and SCPP were 94.76%, 85.42%, and 83.46%, respectively, and the mean PY were 37,205.25, 32,973.75, and 34,620 kg·ha−1, respectively. There were significant differences (p < 0.05) among the three systems.

- (4)

- The ASPP demonstrated higher potato yield and faster operational speeds, reduced labour requirements, and saved seed potatoes, making it suitable for large-scale planting in regions with high labour costs. However, its high equipment purchase cost and machinery depreciation required further optimisation. The SBPP required a relatively low initial investment, making it suitable for small-scale and economically constrained agricultural operators. The SCPP demonstrated intermediate performance in both seed potato usage and fuel consumption.

Author Contributions

Conceptualization, X.Z. and J.L. (Jinqing Lyu); methodology, X.Z. and P.L.; software, X.Z. and Q.G.; validation, X.Z., J.L. (Jinqing Lyu) and H.M.; investigation, X.Z. and P.L.; resources, J.L. (Jicheng Li); data curation, X.Z. and P.L.; writing—original draft preparation, X.Z. and Q.G.; writing—review and editing, X.Z. and H.M.; supervision, Y.C. and Y.Q.; funding acquisition, J.L. (Jinqing Lyu) and J.L. (Jicheng Li). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Creation and application of highly efficient and precise seed cutting technology and equipment for potato under the National Key R&D Programme (grant number: 2023YFD2000901) and the Special Program for Scientists in China Agriculture Research System (grant number: CARS-09-P23).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

All data are presented in this article in the form of figures and tables.

Acknowledgments

The authors would like to acknowledge the Keshan Farm in Keshan County and the Northern Potato Full Mechanization Research Base (Northeast China) of the Ministry of Agriculture and Rural Affairs for providing the machines and experimental site.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| d | Seed metering device radial dimension, m |

| F1 | Adsorption force, N |

| F2 | Positive pressure on seed discharge, N |

| Fa | Centrifugal force, N |

| Ff | Frictional force, N |

| FNx | X-component of normal force, N |

| FNy | Y-component of normal force, N |

| G | Gravity, N |

| k | Proportionality coefficient |

| l | Seed release arc length, m |

| l0 | Seed filling arc length, m |

| m | Seed potato weight, kg |

| n | Seed metering device rotational speed, rpm |

| n1 | Number of actual measured seed spacing greater than 0.5 times but not more than 1.5 times the theoretical seed spacing |

| n2 | Number of actual measured seed spacing not greater than 0.5 times the theoretical seed spacing |

| n3 | Number of actual measured seed spacing greater than 1.5 times the theoretical seed spacing |

| nij | Number of seedling emergence at the data j sampling point on day i |

| N | Theoretical seeding quantity within seed potato sampling points |

| N0 | Number of flexible suction nozzles |

| N1 | Number of theoretical seed spacing |

| p0 | Standard moisture content, % |

| pi | Actual moisture content of potato in the plot i, % |

| P1 | Negative pressure, kPa |

| P2 | Positive pressure, kPa |

| PY | Potato yield, kg·ha-1 |

| PYi | Potato yield per hectare in the plot i, kg·ha−1 |

| S | Effective adsorption area, m2 |

| t | Positive pressure duration, s |

| t0 | Seed filling time, s |

| v | Operational speed, m/s |

| vg | initial discharge velocity, m/s |

| v0 | Seed potato linear velocity, m/s |

| xi | Actual seed spacing for the measurement i in the plot j, mm |

| xj | Average seed spacing in the plot j, mm |

| β | Seed-filling angle, (°) |

| β0 | Seed release arc angle, rad |

| γ | Suction nozzle cone angle, (°) |

| θ | Positive casting pressure F2 and Y-axis angle (seed release angle), (°) |

| θ0 | Seed filling zone arc angle, rad |

| φ | Friction angle between suction nozzle and seed potato, (°) |

| ω | Seed metering device angular velocity, rad/s |

| ASPP | Air-suction mulai-arm potato planter |

| CV | Coefficient of variation |

| FC | Fuel consumption |

| LAB | Labor input |

| MD | Machine depreciation |

| MI | Missed-seeding index, % |

| MP | Machinery price |

| ER | Emergence rate |

| ERi | Seedling emergence rate on day i |

| Mt | Million metric tons |

| OE | Operational efficiency |

| PSI | Plant spacing index, % |

| QSi | Potato yield in the plot i at harvest, kg·ha−1 |

| QSI | Qualified seed spacing index, % |

| RI | Re-seeding index, % |

| SBPP | Spoon-belt potato planter |

| SCPP | Spoon-chain potato planter |

| SPSR-PUA | Seed potato seeding rate per unit area |

References

- Zheng, Z.; Zhao, H.; Liu, Z.; He, J.; Liu, W. Research progress and development of mechanized potato planters: A review. Agriculture 2021, 11, 521. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Zhang, C.; Cao, L.; Li, C.; Xie, S.; Niu, Q. Potato planter and planting technology: A review of recent developments. Agriculture 2022, 12, 1600. [Google Scholar] [CrossRef]

- Ahmad, U.; Sharma, L. A review of best management practices for potato crop using precision agricultural technologies. Smart Agric. Technol. 2023, 4, 100220. [Google Scholar] [CrossRef]

- (FAO), Food and Agriculture Organization of the Unites Nations. FAOSTAT: Crops and Livestock Products. 2024. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 1 March 2025).

- Li, Z.H.; Wen, X.Y.; Lu, J.Q.; Li, J.C.; Yi, S.J.; Qiao, D. Analysis and prospect of research progress on key technologies and equipments of mechanization ofpotato planting. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–16. [Google Scholar] [CrossRef]

- Raigond, B.; Verma, A.; Pathania, S.; Sridhar, J.; Kochhar, T.; Chakrabarti, S.K. Development of a reverse transcription loop-mediated isothermal amplification for detection of potato virus a in potato and in insect vector aphids. Crop Prot. 2020, 137, 105296. [Google Scholar] [CrossRef]

- Zheng, D.T.; Zhao, X.X. Analysis of influencing factors on seeding uniformity of precision seeder. Int. J. Mod. Res. Eng. Technol. 2024, 9, 45–49. [Google Scholar]

- Buitenwerf, H.; Hoogmoed, W.B.; Lerink, P.; Muller, J. Assessment of the behaviour of potatoes in a cup-belt planter. Biosyst. Eng. 2006, 95, 35–41. [Google Scholar] [CrossRef]

- Lyu, J.Q.; Yang, Y.; Li, Z.H.; Tian, Z.E.; Shang, Q.Q.; Wu, J.E. Design and experiment of cup-belt type potato seed-metering device. Trans. Chin. Soc. Agric. Eng. 2016, 32, 17–25. [Google Scholar] [CrossRef]

- Zhang, W.Z.; Liu, C.L.; Lyu, Z.Q.; Qi, X.T.; Lyu, H.Y.; Hou, J.L. Optimized design and experiment on novel combination vacuum and spoon belt metering device for potato planters. Math. Probl. Eng. 2020, 2020, 1504624. [Google Scholar] [CrossRef]

- Wang, J.R.; Liao, M.; Xia, H.L.; Chen, R.; Li, J.J.; Li, J.M.; Yang, J. Design and experimental of metering device of cup-belt type potato planter. Agriculture 2024, 14, 1824. [Google Scholar] [CrossRef]

- Qiu, Z.M.; Fang, Y.; Jin, X.; Ji, J.T.; Li, X.Y.; Li, Y.X. Design and test of potato seeding apparatus based on double-layer seed picking scoop structure. PLoS ONE 2023, 18, 0295022. [Google Scholar] [CrossRef]

- Sun, W.; Wang, G.P.; Wu, J.M. Design and experiment on loss sowing testing and compensation system of spoon-chain potato metering device. Trans. Chin. Soc. Agric. Eng. 2016, 32, 8–15. [Google Scholar] [CrossRef]

- Niu, K.; Fang, X.F.; Liu, Y.C.; Lyu, C.X.; Yuan, Y.W. Optimized design and performance evaluation of an electric cup-chain potato metering device. Int. J. Agric. Biol. Eng. 2017, 10, 36–43. [Google Scholar] [CrossRef]

- Wang, J.R.; Liao, M.; Su, C.; Chen, R.; Xia, H.L.; Li, J.J.; Qiao, C.Y. Study on the excess seeds removing performance of a potato precision seed metering device. Sci. Rep. 2024, 14, 278321. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.Z.; Liu, S.P.; Wang, Q.; Liao, M. Research on device and sensing technology for precision seeding of potato. Agriculture 2024, 14, 2146. [Google Scholar] [CrossRef]

- Liu, W.Z.; He, J.; Li, H.W.; Li, X.Q.; Lu, C.Y.; Wei, Z.C.; Su, G.L.; Zhao, H.B.; Liu, P.; Wang, C.L. Seeding performance optimization on vibration-arranging type seeding device for potato micro-seed. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–11. [Google Scholar] [CrossRef]

- Meijer, E.N.C.; Frederiks, J. Development of an automatic planter for presprouted seed. Potato Res. 1975, 18, 451–454. [Google Scholar] [CrossRef]

- Qiu, T.Y.; Wang, L.L.; Chen, W.P.; Zhang, B.C.; Yang, S.D. Research status and prospects of potato seed-metering device. Am. J. Agric. Res. 2020, 5, 101. [Google Scholar] [CrossRef]

- Ding, Y.G.; Li, H.; Gao, J.F.; Yu, H.M.; Wang, Y.J.; Feng, D.H. Parameter optimization of finger clip plate garlic seed-metering device. Agriculture 2023, 13, 2071. [Google Scholar] [CrossRef]

- Kosariya, Y.K.; Sing, S. Design and development of single row auto-feed potato planter cum fertilizer applicator for small farmers. Pharma Innov. 2022, 11, 1455–1463. [Google Scholar] [CrossRef]

- Boydaş, M.G.; Uygan, F. Influence of seed physical properties and speed onthe external mechanical damage index and in-row spacing uniformity in an automatic potato planter. J. Agric. Sci. 2012, 18, 126–136. [Google Scholar]

- Misener, G.C. Relative performance of cup and pick type potato planters. Can. Agric. Eng. 1979, 21, 131–134. [Google Scholar]

- Hussain, S.; Chen, Y.; Yu, X.; Farid, M.U.; Ghafoor, A.; Alshamali, S.J.; Munirf, T.; Hu, J.J. Design optimization and aerodynamic investigations of air suction seed metering systems through CFD-DEM approach. Smart Agric. Technol. 2025, 12, 101082. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Z.; Zhao, J.; Lu, Q.; Liu, L.; Li, Y. Optimization and experiment of a disturbance-assisted seed filling high-speed vacuum seed-metering device based on DEM-CFD. Agriculture 2022, 12, 1304. [Google Scholar] [CrossRef]

- Zhang, W.P.; Zhao, B.; Gao, S.B.; Zhu, Y.; Zhou, L.M.; Niu, K.; Qiu, Z.M.; Jin, X. Design and experiment of an intelligent testing bench for air-suction seed metering devices for small vegetable seeds. Biosyst. Eng. 2024, 245, 84–95. [Google Scholar] [CrossRef]

- Xu, J.; Sun, S.L.; He, Z.K.; Wang, X.M.; Zeng, Z.H.; Li, J.; Wu, W.B. Design and optimisation of seed-metering plate of air-suction vegetable seed-metering device based on DEM-CFD. Biosyst. Eng. 2023, 230, 277–300. [Google Scholar] [CrossRef]

- Singh, R.C.; Singh, G.; Saraswat, D.C. Optimisation of design and operational parameters of a pneumatic seed metering device for planting cottonseeds. Biosyst. Eng. 2005, 92, 429–438. [Google Scholar] [CrossRef]

- Deng, S.D.; Feng, Y.M.; Cheng, X.P.; Wang, X.L.; Zhang, X.C.; Wei, Z.C. Disturbance analysis and seeding performance evaluation of a pneumatic-seed spoon interactive precision maize seed-metering device for plot planting. Biosyst. Eng. 2024, 247, 221–240. [Google Scholar] [CrossRef]

- Zhao, Z.M.; Lyu, Y.N.; Lyu, J.Q.; Zhu, X.X.; Li, J.C.; Yang, D.Q. The influence of a seeding plate of the air-suction minituber precision seed-metering device on sowing quality. Comput. Electron. Agric. 2024, 227, 109680. [Google Scholar] [CrossRef]

- Lai, Q.H.; Ma, W.P.; Su, W.; Hu, Z.W.; Xing, J.L. Design and experiment of pneumatic disc seed-metering device for mini-tuber. Trans. Chin. Soc. Agric. Mach. 2016, 47, 30–37. [Google Scholar] [CrossRef]

- Lai, Q.H.; Ma, W.P.; Liu, S.; Su, W.; Zhang, Z.H. Simulation and experiment on seed-filling performance of pneumatic disc seed-metering device for mini-tuber.Trans. Chin. Soc. Agric. Mach. 2017, 48, 44–53. [Google Scholar] [CrossRef]

- Lyu, J.Q.; Yi, S.J.; Tao, G.X.; Mao, X. Design and experiment of precision air-suction type seeder for potato. Trans. Chin. Soc. Agric. Eng. 2018, 34, 16–24. [Google Scholar] [CrossRef]

- Anantachar, M.; Kumar, P.G.V.; Guruswamy, T. Neural network prediction of performance parameters of an inclined plate seed metering device and its reverse mapping for the determination of optimum design and operational parameters. Comput. Electron. Agric. 2010, 72, 87–98. [Google Scholar] [CrossRef]

- Abedi, G.; Abdollahpour, S.; Bakhtiari, M.R. The physical and mechanical properties of potato (Solanum tuberosum L.) tubers as related to the automatic separation from clods and stones. Res. Agric. Eng. 2019, 65, 77–84. [Google Scholar] [CrossRef]

- Lyu, J.Q.; Wen, X.Y.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design and experiment of the grading device for a potato seed cutting machine. Trans. Chin. Soc. Agric. Eng. 2020, 36, 76–83. [Google Scholar] [CrossRef]

- Emwinghare, I.; Al-Mallahi, A.A.; Esau, T.J.; Campelo, F. Accurate estimation of tuber size in large potato throughput at potato storage using machine vision and machine learning techniques. Smart Agric. Technol. 2025, 10, 100860. [Google Scholar] [CrossRef]

- Alkhaled, A.Y.; Wang, Y. Developing a robust yield prediction model for potatoes (Solanum tuberosum L.) using multi-faceted and multi-year data. Smart Agric. Technol. 2025, 10, 100734. [Google Scholar] [CrossRef]

- GB/T 6242-2006; Test Methods for Potato Planters. China Standards Press: Beijing, China, 2006.

- GB/T 6973-2005; Test Methods for Single-Seed Precision Drills. Standardization Administration of China: Beijing, China, 2005.

- Wang, G.P.; Sun, W.; Zhang, H.; Liu, X.L.; Li, H.L.; Yang, X.P.; Zhu, L. Research on a kind of seeding-monitoring and compensating control system for potato planter without additional seed-metering channel. Comput. Electron. Agric. 2020, 177, 105681. [Google Scholar] [CrossRef]

- Pareek, C.M.; Tewari, V.K.; Nare, B. A mechatronic seed metering control system for improving sowing uniformity of planters. J. Eng. Res. 2023, 13, 808–819. [Google Scholar] [CrossRef]

- Al-Gaadi, K.A.; Marey, S.A. Effect of forward speed and tuber characteristics on tuber spacing uniformity for a cup-belt potato planter. Mid-East J. Sci. Res. 2011, 8, 753–758. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).