Abstract

This study develops a novel electric-driven metering device to address the mismatch between the seeder rotation speed and vehicle speed in traditional mechanical precision hill direct-seeding metering devices for rice, which is caused by wheel slippage. The device integrates a Global Navigation Satellite System (GNSS) speed measurement module and an optimised incremental Proportional-Integral-Derivative (PID) control algorithm, enabling precise seeding through electric drive. A multidisciplinary collaborative design approach is employed, and field experiments are conducted to evaluate the performance of the novel device under conditions of vehicle speeds ranging from 3 to 5 km/h, theoretical hill spacings of 0.15–0.25 m, and seeding rate adjustment positions of 1/3–1. The experiments use two rice varieties, “Longken 2021” from the northern rice growing region and “Jingliangyou Huazhan” from the southern rice growing region. The results demonstrate that the novel electric-driven metering device significantly outperformed the traditional mechanical device in terms of seeding precision, hill formation performance, and seeding rate accuracy. The novel device achieves a qualified rate of seeds per hill of 90.54%, with seedling omission and seed damage rates reduced to 4.98% and 0.69%, respectively. The hill diameter qualification rate increases to 95.21%, with no empty hills observed. The coefficient of variation of seeds per hill is maintained at 21.98%, meeting the agronomic requirement of 2–12 seeds per hill for conventional rice. However, for seeds with high moisture content and poor flowability (soaked seeds), the seed damage rate increases slightly by 0.47 percentage points. This study provided an efficient and reliable technical solution for the intelligent upgrading of precision rice direct-seeding equipment.

1. Introduction

Rice, the world’s second-most pivotal cereal crop, is the staple sustenance for nearly 50% of the global population [1,2]. The mechanisation level in its cultivation is a critical determinant for achieving high-quality, efficient, and sustainable production [3,4]. Traditional rice planting typically requires substantial inputs of human labour and material resources. In contrast, rice hill direct-seeding technology eliminates the conventional seedling-raising and transplanting stages by directly sowing seeds into fields [5]. This technology is becoming the mainstream development trend in contemporary rice planting, characterised by remarkable advantages, including significant production efficiency enhancements, cost reduction, promotion of sustainable development, yield and quality improvement, and realisation of smart agriculture [6,7].

The 14th Five-Year Plan designates full-process mechanisation and intelligence as keystones of agricultural modernisation. With rice mechanical seeding at approximately 60%, technologies such as precision seeding possess substantial potential for wider adoption. At the global scale, rice direct-seeding technologies mainly include wet seeding, dry seeding, mechanical seeding, and spray seeding [8,9]. Overseas, rice direct seeding predominantly relies on mechanical sowing and aerial seeding. For example, about 80% of rice in the United States is planted via aerial broadcasting, with the remaining 20% using mechanical dry seeding; Australia mainly adopts mechanical dry direct seeding, boasting some of the world’s highest rice yields per unit area [10,11]. Although foreign research on direct-seeding technologies is mature, studies on metering devices for hill direct seeding of rice are relatively scarce. Extensive research has been conducted on metering devices for crops such as maize, soybeans, and wheat, focusing on the optimisation of structural parameters, crop adaptability, and analysis of the working principle [12]. However, most current rice direct-seeding metering devices use fluted wheel designs. They are general-purpose types, unable to meet the special requirements of hill direct seeding for precision and high-speed operation [13]. Additionally, while some progress has been made in electric-driven metering device technologies abroad, their application in rice hill direct-seeding metering devices remains limited, with no systematic solutions yet formed [14]. Therefore, research on electric-driven technologies for rice hill direct-seeding metering devices is of great practical significance and broad application prospects.

In China, with the transfer of rural labour and the expansion of rice direct-seeding areas, research on rice direct-seeding metering devices has gradually gained attention. However, their development remains challenged by regional variations in climate, soil, and agronomic practices [15]. Zhu et al. [16] developed a slide-type hole wheel metering device for rice direct seeding, using simulation analysis to obtain optimal operating parameters. At a rotational speed of 27.12 r min−1 and a seed sphericity of 44.61%, the device achieves precision hill metering of 1–4 seeds per hill with a qualification rate of 83.90%, a miss-seeding index of 5.43%, and a multiple-seeding index of 10.67%. Tian et al. [17] designed a spiral groove-type metering device, determined key component parameters through meticulous analysis of rice bud seed movement trajectories, and verified its performance via experiments. The tests revealed that, at a metering-wheel speed of 23.2 r min−1, the qualified hill-diameter rate reached 91.06% and the qualified seed-number-per-hill rate attained 94.64%. The device was capable of meeting the basic requirements for rice direct seeding and satisfied the agronomic criteria; however, it failed to achieve precision seeding and was unable to adjust the seeding rate. Zhang et al. [18] developed a combined hole-type metering device, which enables the flexible adjustment of seeding rates by varying the size of the combined holes to meet the direct-seeding requirements of different rice varieties. The tests had indicated that the metering device, with its small and large cell configurations, had been capable of delivering 1–4 and 5–8 rice seeds per hill, respectively. For the large cells, the qualified hill-seed-count rate reached 87%, while the coefficient of variation registered 22.60%. For the small cells, the corresponding values were 87.67% and 20.64%. Zhang et al. [19] designed a vertical disc hill-dropping metering device, conducted in-depth research on seed force dynamics at the critical states of the seed-filling zone and transport zone, established a mechanical model to analyse seed-filling performance, and determined optimal parameters such as seed disc rotation speed, hole placement angle, and metering clearance through experiments. Zhang et al. [20] designed a U-shaped cavity channel precision hill-dropping metering device for rice. Field trials showed that the mean hill diameter, hill-diameter qualification rate, mean hill spacing, and coefficient of variation for hill spacing were 4.67 cm, 71.67%, 13.72 cm, and 12.64%, respectively. The metering device was able to deliver 3–8 seeds per hill for direct-seeded rice, and its performance broadly satisfied the agronomic requirements; nevertheless, the hill-diameter qualification rate remained low, and the hill-spacing coefficient of variation was excessive. Xing et al. [21] developed a pneumatic rice metering device that incorporated a seed-stirring mechanism, simulating and analysing key working components to obtain optimal field operation parameters. They verified the feasibility of the pneumatic metering device through field trials.

At present, domestic research has predominantly focused on mechanical seed metering devices valued for simple structure and low cost [22,23]. Nevertheless, mechanical transmissions such as chain drives tend to slip under high-speed conditions, leading to imprecise hole spacing and uneven seed distribution that hinder simultaneous gains in sowing efficiency and accuracy [24]. In contrast, electrically driven seed metering systems employ closed-loop high-precision regulation of drive speed to enable continuous stepless adjustment of hole spacing across the entire operating range, concurrently enhancing seed rate uniformity and operational efficiency [25]. Consequently, these systems have become the core technological route for intelligent precision hill direct seeding in rice [26]. However, the technology remains at an early validation stage, and the materials used in prior experimental studies have been relatively limited [27]. Systematic comparative investigations aimed at clarifying the mechanical electrical control agronomic coupling mechanism are therefore urgently needed to establish the design theory and performance evaluation framework for electrically driven seed-metering devices.

In view of the prevalent limitations of conventional mechanical hill direct-seeding metering devices for rice and the urgent demand for advancing electric-drive seeding technology. This study focuses on the development and performance optimisation of a novel electric-driven precision hill direct-seeding metering device for rice. By integrating multidisciplinary approaches, including theoretical analysis and electric drive technology, this research completes the structural design and prototype development of the electric-driven metering device. It comprehensively evaluates its performance through field trials under actual working conditions. Meanwhile, using traditional mechanical metering devices as a control, this study conducted an in-depth comparative analysis of the differences in seeding accuracy, stability, and operational efficiency between the two, aiming to provide theoretical foundations and practical references for the innovation of rice precision direct-seeding technology and the improvement of metering device performance.

2. Materials and Methods

2.1. Design of the Electric Drive Control System

2.1.1. System Overall Structure

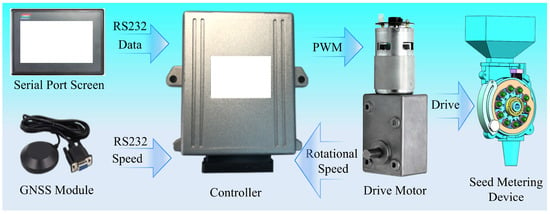

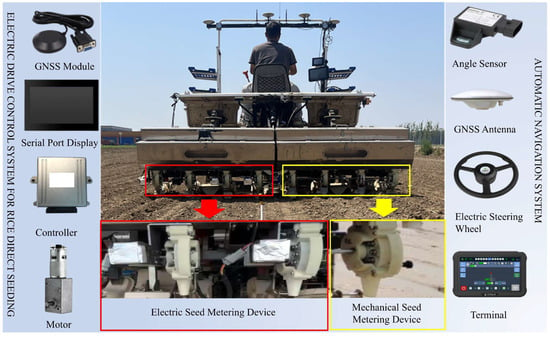

To achieve precise rotational speed control for the rice direct-seeding metering device, an electric drive transformation was carried out based on the designed precision hill direct-seeding metering device, and an electric drive control system for rice hill direct seeding was developed. As shown in Figure 1, this system comprises components such as a GNSS speed measurement module, a serial port display, a controller, a motor, and a metering device. By integrating the GNSS speed measurement module, real-time operational speed data of the rice direct-seeding metering device can be obtained, enabling more accurate control and adjustment. Meanwhile, the serial port display facilitates real-time monitoring and parameter adjustment of the system, enhances the convenience of the experimental process and the reliability of results. As the system’s core component, the controller plays a crucial role in communication and coordinating the operation of each component. At the same time, the motor serves as the driving device for the metering device. Through the design of the electric drive control system and the configuration of the metering device, the precision and stability of the rice direct-seeding metering device can be improved, providing better technical support and solutions for the automation development of rice precision direct-seeding metering devices.

Figure 1.

Overall structure of the electric drive control system.

2.1.2. Hardware Parameters and Structural Design

The motor serves as the execution unit of the electric drive control system for rice hill direct seeding, and its selection must balance requirements for torque, rotational speed, dimensions, and other factors. The output torque parameter is the primary consideration, which can be calculated using Equation (1).

where Tm is the motor driving torque (N·m); KC is the motor driving safety factor, taken as 1.5; TP is the load torque of the metering disc (N·m); and i is the motor reduction ratio.

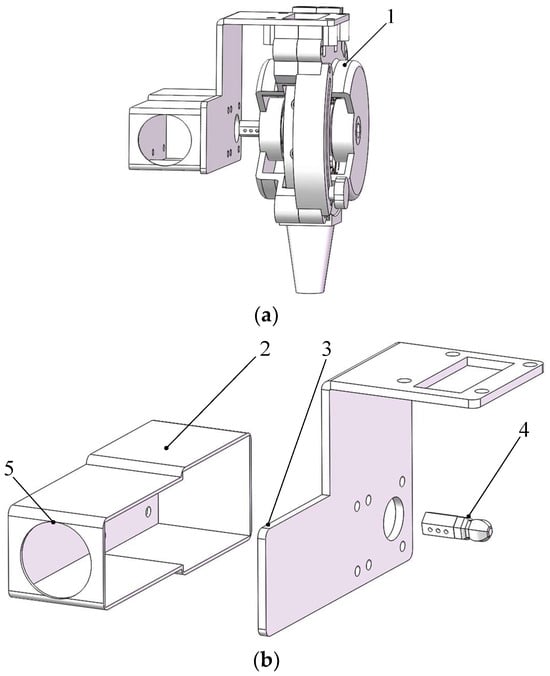

During the operation of the initially developed metering device, the actual torque was measured using a torque meter (JD260, Sanliang, Dongguan, China), yielding a maximum load torque of 0.53 N·m. Consequently, the actual required torque was 0.79 N·m. Considering requirements for torque, rotational speed, and installation dimensions, the worm gear DC motor (WGM5882-775H, Tianshu, Shenzhen, China) was selected. This motor featured a maximum rotational speed of 7000 rpm, a worm gear reducer with a reduction ratio of 100, a maximum output rotational speed of 70 rpm, a load torque of 2.94 N·m, and a stall torque of 11.76 N·m, meeting the rotational speed, torque, and dimensional requirements for driving the rice hill direct-seeding metering device. The motor was equipped with a two-channel incremental magnetic encoder (SCX-775, JuHua, Foshan, China), suitable for various harsh environments with an operating temperature range of −25 °C to 125 °C and a humidity range of 10% to 95%. It could output two square waves with a single-channel output pulse of 13 PPR. Due to the limited sowing row spacing of the rice direct-seeding metering device, the motor installation dimensions are constrained. Additionally, existing couplings on the market do not fully meet the installation requirements; therefore, the design of a motor coupling and bracket was necessary. Based on the motor’s external dimensions and structure, the motor bracket and coupling designs are shown in Figure 2.

Figure 2.

Design of the metering device. (a) Overall assembly drawing: 1. Metering device; (b) Part axonometric drawing: 2. Motor waterproof housing; 3. Motor bracket; 4. Coupling; 5. Ventilation hole.

2.1.3. Real-Time Motor Speed Regulation Model

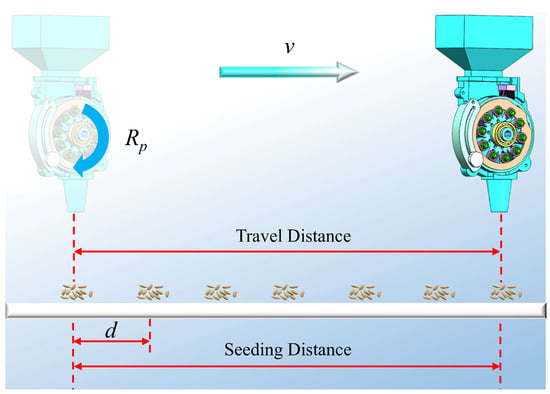

The electric drive control system for rice hill direct seeding used a motor to drive the metering device. According to the hill spacing required by agronomic needs and the operation speed obtained in real time, the motor speed was regulated to achieve speed-adaptive hill seeding. The consistency of hill spacing was a prerequisite for ensuring good seeding quality. To improve the consistency of hill spacing under electric drive control of rice hill direct seeding, it is necessary to clarify the corresponding relationship among the driving motor speed, hill spacing, and the direct-seeding machine’s operation speed, as shown in Figure 3.

Figure 3.

Control model diagram.

Assuming that during the seeding process, the operation speed is v km/h, the motor speed is Rm rpm, the number of holes on the metering disc is n, and the hill spacing is d m. Based on the consistency between the seeding distance and the driving distance of the direct-seeding machine within unit time t, the relationship shown in Equation (2) is established.

By simplifying Equation (2), the rotational speed of the metering disc can be obtained as shown in Equation (3).

The worm gear reduction motor is coaxially connected to the metering device. Assuming the reduction ratio is i and the motor speed is Rm, the motor speed can be expressed in Equation (4).

It can be seen from Equation (4) that the operation speed v, reduction ratio i, number of holes n in the metering device, and hill spacing d are all related to the motor speed Rm. Among them, the reduction ratio i, the number of holes n in the metering device, and the hill spacing d are constant values during operation. Therefore, the accuracy of the measurement method for the operation speed of the rice direct-seeding machine is crucial in ensuring the calculation accuracy of the target speed of the drive motor. In this study, a GNSS module was employed to eliminate the mismatch between the seed-metering drive and the machine’s actual forward velocity caused by ground–wheel slippage in conventional systems, thereby further enhancing seeding accuracy.

2.1.4. Motor Control Algorithm

In this study, optimisation was carried out using trapezoidal integration, integral separation, and anti-windup integration methods. In incremental PID control, the integral term was replaced by the accumulation of the product of the sampling time and the sampling deviation (rectangular integration), as shown in Equation (5).

Due to the differences in deviation values between sampling points, a discrepancy exists between the rectangular and actual integral values. To improve the accuracy of the integral term, this study used the trapezoidal integration method. The formula for the trapezoidal integral term is shown in Equation (6).

where e(t) is the deviation between the target value and the actual motor speed value; T is the system sampling time; k is the current sampling number.

The integral term of the incremental PID controller is designed to eliminate static errors in the system. However, during processes such as motor startup or shutdown, where there is an increase or decrease in the target rotational speed, the system might quickly generate large rotational speed deviations. This can lead to excessive integral accumulation, resulting in a substantial overshoot. To address this issue, this study introduces an integral separation strategy by incorporating a switching coefficient β before the integral term to control its activation. When the deviation is large, β equals 0, suppressing the integral action; when the deviation is slight, β equals 1, enabling the integral term. The value of β is given by Equation (7).

where ek represents the rotational speed deviation at the k-th sampling point, defined as the difference between the target and actual motor speeds. δ is the deviation threshold for integral separation. rk is the target motor speed at k-th samples. When the absolute value of the deviation |ek| is less than or equal to δ, β is set to 1, enabling the integral term to reduce steady-state error. Conversely, when |ek| > δ, β is set to 0, temporarily disabling the integral action to prevent overshoot caused by large deviations.

Based on the preceding theoretical analysis, the control algorithm incorporating integral separation is shown in Equation (8).

where Δuk is the controller increment at the k-th sampling instant; Kp is the proportional coefficient; Ki is the integral coefficient; Kd is the derivative coefficient; ek, ek−1, ek−2 represent the deviations at the k-th, (k − 1)-th, and (k − 2)-th sampling instants, respectively.

In an actual control system, the controller output might exceed the limit value and reach a saturation state for various reasons. However, integration may continue in this state, prolonging the exit time from saturation and slowing down the system response. To improve the system response speed, direct anti-windup integration was adopted. The integration action was directly halted when the controller output reached the limit value of Umax.

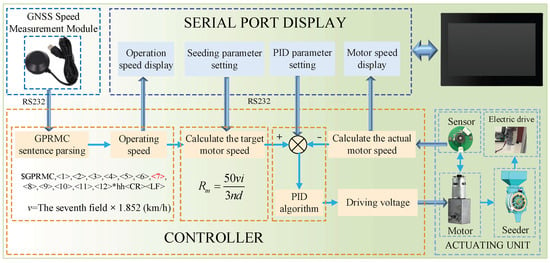

2.1.5. System Workflow

In the electric drive control system for rice hill direct seeding, clarifying each component’s workflow and functions is a fundamental and crucial step. Specifically, the controller acquired high-precision speed from the GNSS module via the RS-232 interface by parsing the $GPRMC sentence in the NMEA-0183 protocol, and subsequently converted the extracted value into kilometers per hour. Subsequently, combined with the preset operation parameters, the controller uses Equation (4) to calculate the target rotational speed of the drive motor, ensuring that the seed metering device accurately dispenses seeds at the preset hill spacing according to the operation speed. Meanwhile, the Hall sensor collected the actual rotational speed signal of the drive motor in real time and fed it back to the controller. Based on the deviation between the target and actual rotational speeds, the controller dynamically adjusted the motor speed using the PID incremental algorithm. Leveraging optimisation strategies such as trapezoidal integration, integral separation, and direct anti-saturation, the motor speed is adjusted quickly and accurately, effectively reducing the overshoot and steady-state error, thereby achieving high-precision speed control. Through a series of collaborative working links, the electric drive control system for rice hill direct seeding could realise the speed-adaptive seed metering function of the seed metering device. Even when the operation speed of the direct-seeding machine changed, it ensured the uniformity and accuracy of sowing, thereby enhancing the sowing quality and operation efficiency. The workflow of the electric drive control system is shown in Figure 4, clearly presenting the information interaction and control logic among the components, providing an important reference for system design, debugging, and optimisation.

Figure 4.

Workflow of the electric drive control system. Note: The “*hh<CR><LF>” in the figure represents the XOR checksum of all preceding content in hexadecimal.

2.2. Experimental Materials

This study selected Longken 2021 and the hybrid rice variety Jingliangyou Huazhan as experimental materials. Longken 2021 is a representative conventional rice variety in the cold-region rice areas of northern China, adapted to low-temperature environments with short growth periods. Jingliangyou Huazhan is a main hybrid rice variety planted in southern rice areas, widely cultivated in the middle and lower reaches of the Yangtze River and southern China. These two varieties represent different planting regions and seed types, enabling a comprehensive evaluation of the performance of the rice direct-seeding metering device under different ecological conditions and providing more targeted references for optimised design. Rice direct seeding can be divided into dryland direct seeding and paddy field direct seeding. Dryland direct seeding involves tilling and sowing dry rice seeds in arid areas, relying on natural precipitation or irrigation to maintain soil moisture and promote seed rooting and emergence. Staged irrigation is applied when seedlings reach the two-leaf and one-heart growth stage. Paddy field direct seeding involves soaking and levelling the paddy field before sowing soaked or sprouted seeds, while maintaining a moist field surface or a shallow water layer. Therefore, this study conducted experiments under different seed states, and the material properties of the experimental materials in various states are shown in Table 1.

Table 1.

Material characteristics of test materials.

2.3. Experimental Methods

In this study, a GNSS-RTK speed measurement module and an incremental PID-based electric closed loop control system were integrated at the drive end of the metering device. The GNSS receiver continuously output GPRMC sentences that were transmitted to the master controller through RS232. According to the theoretical model, the controller translated the real-time operating velocity, the preset hill spacing, and the number of cells on the metering disc into the target motor speed, enabling speed synchronised adjustment. The PID algorithm incorporated trapezoidal integration, integral separation, and anti-windup correction; the integral term was automatically disabled when the rotational speed deviation exceeded 5 percent to suppress overshoot, and the calculated PWM duty cycle was applied to regulate motor speed. System parameters Kp, Ki, and Kd were displayed in real time on an RS232 serial screen and could be modified online, thereby realising a closed-loop control sequence of GNSS speed measurement, algorithmic resolution, PWM actuation, and encoder feedback.

To comprehensively evaluate the metering performance and meet the agronomic requirements of direct-seeded rice, three control factors—maximum stroke ratio of the seed-rate adjustment mechanism, theoretical hill spacing, and operating speed—were tested at three levels each. The stroke ratio was set at one-third, two-thirds, and full stroke; hill spacing at 0.15 m, 0.20 m, and 0.25 m; and operating speed at 3 km h−1, 4 km h−1, and 5 km h−1. These ranges were determined based on preliminary trials and the recommended spacing (0.15–0.25 m) and prevailing field speeds (3–5 km h−1) for the region’s dominant rice cultivars, thereby covering typical production conditions. The factor-level design is shown in Table 2.

Table 2.

Test factors and level.

Because the seeding amount of the metering device varied with different adjustment positions of the seeding rate regulator, a preliminary experiment was conducted before the formal experiment. According to the results of the preliminary experiment, when the seeding rate regulator was set at 1/3, 2/3, and 1 of the maximum adjustment range, the numbers of qualified seeds per hill, missed seeds, and over-seeded seeds under different seed conditions are shown in Table 3.

Table 3.

Evaluation standard for the number of seeds per hill.

To eliminate systematic error and ensure unbiased estimates of factor effects, this study conducted a full-factorial experiment with three factors at three levels each, yielding 27 treatment combinations. Within each block, the order of all treatments was completely randomised; after every sowing pass, the machine ran one idle revolution and was cleaned to remove any residual seed, thereby eliminating carry-over effects. Table 4 shows the comprehensive performance test plan for the seed metering device. To facilitate the subsequent statistical analysis of test data, different test numbers were used to represent various test conditions.

Table 4.

Comprehensive performance evaluation test scheme.

2.4. Experimental Equipment

All field experiments in this study were conducted at the National Precision Agriculture Research and Demonstration Base in Xiaotangshan Town, Changping District, Beijing, from June 2023 to August 2024. Since this study involved a large number of experimental indicators to be explored and a large amount of data to be measured, a large number of field experiments were needed, which resulted in a relatively long overall experimental cycle. This study aimed to investigate the performance of the newly designed electric-driven seed metering device. To accelerate the R&D progress of the seed metering device, the field test platform was modified based on existing equipment rather than designing an entirely new machine structure. The designed electric-driven seed metering device was retrofitted onto the existing equipment, with the complete machine powered by a Xingyueshen 2ZG-8Q2 (8s2, Xingyue Group Co., ltd., Jinhua, China) high-speed riding-type transplanter. The test setup is shown in Figure 5. To facilitate comparative performance research between mechanical and electric-driven seed metering devices during field tests, both types of devices were installed simultaneously during the mounting process.

Figure 5.

Field test device.

2.5. Evaluation Indicators

Following GB/T 25418-2022 [28] and GB/T 6973-2005 [29], experimental results were assessed using qualified rate of seeds per hill Y1, missed seeding rate of seeds per hill Y2, repeated seeding rate of seeds per hill Y3, qualified rate of hill diameter Y4, average hill diameter Y5, coefficient of variation of hill diameter Y6, average hill spacing Y7, coefficient of variation of hill spacing Y8, average number of seeds per hill Y9, coefficient of variation of seeds per hill Y10, empty hill rate Y11, and seed damage rate Y12 [12]. Among them, the qualified rate, missed seeding rate, and repeated seeding rate all refer to the number of seeds per hill. When CR is the theoretical number of seeds per hill, a hill with CR ± 1 seeds is considered a qualified hill, a hill with fewer than CR − 1 seeds is a missed seeding hill, and a hill with more than CR + 1 seeds is a repeated seeding hill. The hill diameter is the straight-line distance between the two farthest rice seeds in a hill, and a hill diameter of less than or equal to 0.05 m is considered qualified. The calculation formulas for the evaluation indicators are shown in Equation (9).

where i takes 1, 2, 3, 4, 11 and Yᵢ represents the qualified rate of seeds per hill, missed seeding rate of seeds per hill, repeated seeding rate of seeds per hill, qualified rate of hill diameter, and empty hill rate, in turn; when i is 1, 2, 3, 4, 5, nᵢ counts the number of qualified seeding hills, number of missed seeding hills, number of repeated seeding hills, number of hills with qualified diameter, and number of empty hills; Y5 is the average hill diameter (m); Y6 is the coefficient of variation of hill diameter; Y7 is the average hill spacing (m); Y8 is the coefficient of variation of hill spacing; Y9 is the average number of seeds per hill (grains); Y10 is the coefficient of variation of seeds per hill; Y12 is the seed damage rate. All Y variables except Y5, Y7, and Y9 are expressed as percentages; N is the theoretical hill count; LB is the till diameter (m); Ls is the hill spacing (m); Ni is number of seeds in the i-th hill; Sd is the standard deviation of seeds per hill; Nb is the total mass of the sample (g); Np is the mass of damaged seeds in the sample (g).

Based on pertinent research findings and the relevant standards, the key performance indices for rice direct-seeding machines are summarised in Table 5.

Table 5.

Performance index of rice hole direct-seeding machines.

3. Results and Analysis

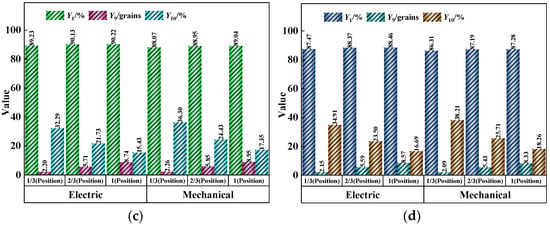

3.1. Analysis of Hill Direct-Seeding Performance of Seed Metering Device

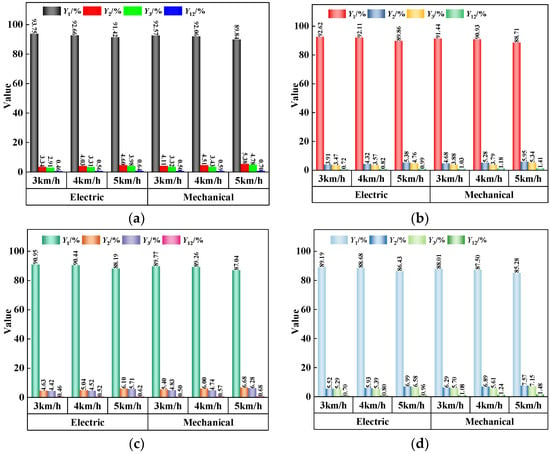

The field hill direct-seeding performance evaluation aims to investigate the seeding effect of the seed metering device when sowing different rice seeds at different vehicle speeds, with the qualified rate, missed seeding rate, repeated seeding rate of seeds per hill, and seed damage rate as evaluation indicators. The test results are shown in Figure 6. It can be seen from the data analysis in the figure that when the vehicle speed was 3–5 km/h, the qualified rate of seeds per hill was 85.28–93.75%, with an average of 89.95%; the missed seeding rate of seeds per hill was 3.34–7.57%, with an average of 5.36%; the repeated seeding rate of seeds per hill was 2.91–7.15%, with an average of 4.69%; the damage rate was 0.46–1.48%, with an average of 0.79%. With the increase in vehicle speed, the seeding performance of the seed metering device decreases, which is consistent with the trend change of the previous simulation study [12].

Figure 6.

Test results of the sowing performance of the seed metering device. (a) Longken 2021 (dry rice seeds); (b) Longken 2021 (chitting treatment); (c) Jingliangyou Huazhan (dry rice seeds); (d) Jingliangyou Huazhan (chitting treatment).

When the vehicle speed was 3–5 km/h, the average qualified rate, missed seeding rate, repeated seeding rate, and seed damage rate of seeds per hill for electric drive (mechanical drive) were 90.54% (89.36%), 4.98% (5.75%), 4.49% (4.89%), and 0.69% (0.92%), respectively. Compared with the mechanical drive mode, the electric drive mode increased the qualified seed rate per hill by 1.17 percentage points, reduced the missed seeding rate by 0.77 percentage points, reduced the repeated seeding rate by 0.39 percentage points, and reduced the damage rate by 0.23 percentage points. The electric drive’s seeding performance was superior to that of a mechanical drive. When the vehicle speed was 3–5 km/h, the average qualified rate, missed seeding rate, repeated seeding rate, and seed damage rate of seeds per hill for dry rice seeds (chitting treatment) were 90.67% (89.23%), 5.00% (5.73%), 4.34% (5.05%), and 0.57% (1.04%), respectively. There was no apparent effect of dry rice seeds and chitting treatment on the qualified rate, missed seeding rate, and repeated seeding rate of seeds per hill. However, they showed apparent advantages in reducing seed damage rates. Compared with dry rice seeds, when sowing whitened seeds, the qualified seed rate per hill was reduced by 1.44 percentage points, the missed seeding rate increased by 0.72 percentage points, the repeated seeding rate increased by 0.71 percentage points, and the damage rate increased by 0.47 percentage points.

3.2. Analysis of Hole Formation Performance of Seed Metering Device

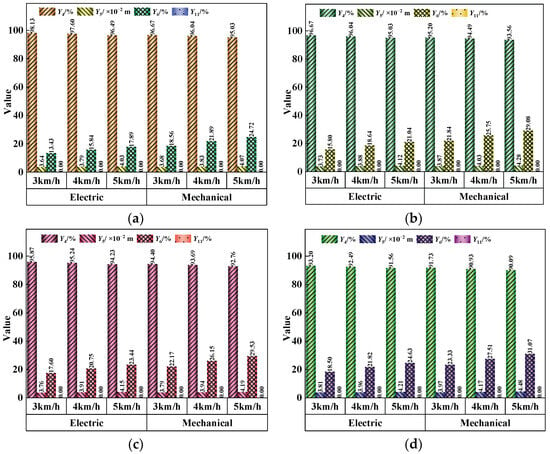

The evaluation of hole formation performance aims to investigate the seeding effect of the seed metering device when sowing different rice seeds at varying vehicle speeds. Evaluation indicators include the qualified rate of hill diameter, average hill diameter, coefficient of variation of hill diameter, and empty hill rate; test results are shown in Figure 7.

Figure 7.

Test results of the hole-forming performance of the seed metering device. (a) Longken 2021 (dry rice seeds); (b) Longken 2021 (chitting treatment); (c) Jingliangyou Huazhan (dry rice seeds); (d) Jingliangyou Huazhan (chitting treatment).

Data analysis showed that at vehicle speeds of 3–5 km/h, the qualified rate of hill diameter ranged from 90.09% to 98.13%, with an average of 94.46%; the average hill diameter was 0.0364–0.0448 m, with an average of 0.0397 m; and the coefficient of variation of hill diameter was 13.43–31.07%, with an average of 22.12%. The empty hill rate was 0% under all test conditions, indicating the excellent hole formation performance of the device. Its hole formation performance decreased with increasing vehicle speed, consistent with the trend observed in single-factor simulation studies mentioned earlier [12]. At vehicle speeds of 3–5 km/h, the electric drive mode achieved a hill diameter qualified rate of 95.21%, an average hill diameter of 0.0392 m, and a coefficient of variation of hill diameter of 19.11%. In contrast, the mechanical drive mode showed 93.72%, 0.0403 m, and 25.13%, respectively. Compared with the mechanical drive mode, the electric drive mode improved the hill diameter qualified rate by 1.5 percentage points, reduced the average hill diameter by 0.0011 m, and decreased the coefficient of variation of hill diameter by 6.02 percentage points, demonstrating superior hole formation performance, particularly in hill diameter uniformity. At vehicle speeds of 3–5 km/h, dry rice seeds had a hill diameter qualified rate of 95.51%, an average hill diameter of 0.039 m, and a coefficient of variation of hill diameter of 21.00%. At the same time, the chitting treatment showed 93.42%, 0.0404 m, and 23.35% increases, respectively. Compared with dry rice seeds, chitting treatment reduced the hill diameter qualified rate by 2.11 percentage points, increased the average hill diameter by 0.0014 m, and raised the coefficient of variation of hill diameter by 2.25 percentage points.

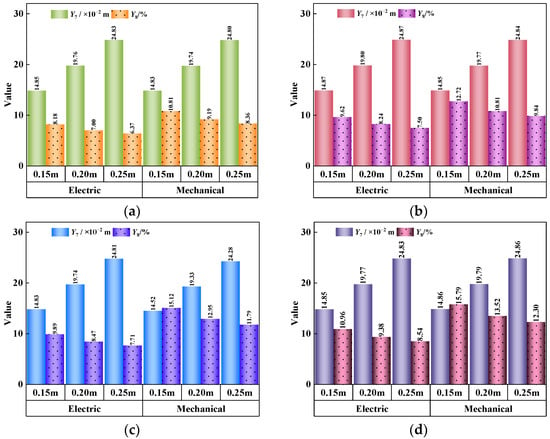

3.3. Analysis of Seeding Rate Adjustment Mechanism Precision

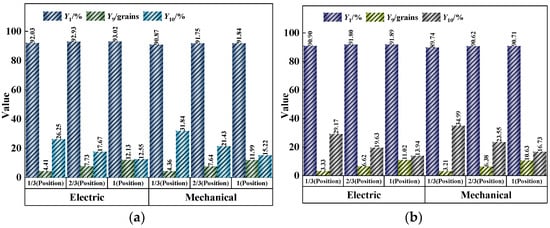

The precision of the seeding rate adjustment mechanism aims to investigate the seeding effect of the seed metering device when sowing different rice seeds under different adjustment positions, with the qualified rate of seeds per hill, average number of seeds per hill, and coefficient of variation of seeds per hill as evaluation indicators. The test results are shown in Figure 8. According to the data analysis in the figure, when the adjustment mechanism was at different positions, and the seed sphericity of rice was 23.56–52.70%, the qualified rate of seeds per hill was 86.31–93.02%, with an average of 89.95%; the average number of seeds per hill was 2.09–12.13, with an average of 6.47; the coefficient of variation of seeds per hill was 12.55–38.21%, with an average of 23.66%. The qualified rate of seeds per hill and the average number of seeds per hill increased with the increase of seed sphericity. In contrast, the coefficient of variation of seeds per hill decreased with an increase in seed sphericity and adjustment angle, which is consistent with previous simulation results [12].

Figure 8.

Accuracy test results of the sowing rate adjusting mechanism. (a) Longken 2021 (dry rice seeds); (b) Longken 2021 (chitting treatment); (c) Jingliangyou Huazhan (dry rice seeds); (d) Jingliangyou Huazhan (chitting treatment).

When the adjustment mechanism was set at different positions, the qualified rate of seeds per hill, average number of seeds per hill, and coefficient of variation of seeds per hill for electric drive (mechanical drive) were 90.54% (89.36%), 6.52 (6.43), and 21.98% (25.34%), respectively. Compared with the mechanical drive mode, the electric drive mode increased the qualified rate of seeds per hill by 1.17 percentage points, increased the average number of seeds per hill by 0.09, and decreased the coefficient of variation of seeds per hill by 3.36 percentage points. The accuracy of the adjustment mechanism under the electric drive mode was better than that under the mechanical drive mode, especially in reducing the coefficient of variation of seeds per hill. When the adjustment mechanism was set at different positions, the qualified rate of seeds per hill, average number of seeds per hill, and coefficient of variation of seeds per hill for dry rice seeds (chitting treatment) were 90.67% (89.23%), 6.83 (6.11), and 22.71% (24.61%), respectively. Compared with the dry rice seeds, sowing chitting treatment seeds reduced the qualified rate of seeds per hill by 1.44 percentage points, reduced the average number of seeds per hill by 0.72, and increased the coefficient of variation of seeds per hill by 1.90 percentage points, mainly because the chitting treatment seeds had higher moisture content and poor fluidity, which was not conducive to the seeds entering the cell. Further analysis revealed that the seed metering device in this study met the precision seeding requirements for both conventional rice (2–12 seeds) and hybrid rice (2–9 seeds).

3.4. Analysis of Seeding Uniformity

The evaluation of seeding uniformity aims to investigate the seeding effect of the seed metering device when sowing different rice seeds under different theoretical hill spacing, with the average hill spacing and coefficient of variation of hill spacing as evaluation indicators. The test results are shown in Figure 9.

Figure 9.

Results of the seeding uniformity test. (a) Longken 2021 (dry rice seeds); (b) Longken 2021 (chitting treatment); (c) Jingliangyou Huazhan (dry rice seeds); (d) Jingliangyou Huazhan (chitting treatment).

Analysis of the data in the figure shows that when the theoretical hill spacing was 0.15–0.25 m, the average hill spacing ranged from 0.1452 to 0.2487 m, with an average of 0.1976 m; the coefficient of variation of hill spacing was 6.37–15.79%, with an average of 10.21%. The coefficient of variation of hill spacing decreased with the increase in seed sphericity, mainly because seeds with higher sphericity were more likely to enter the metering holes and move smoothly, consistent with the results of previous simulation tests. When the theoretical hill spacing was 0.15–0.25 m, the average hill spacing and coefficient of variation of hill spacing for electric drive (mechanical drive) were 0.1892 m (0.2060 m) and 9.56% (10.86%), respectively. Compared with the mechanical drive mode, the electric drive mode reduced the average hill spacing by 0.0168 m and the coefficient of variation of hill spacing by 1.30 percentage points, indicating better seeding uniformity. When the theoretical hill spacing was 0.15–0.25 m, the average hill spacing and coefficient of variation of hill spacing for dry rice seeds (chitting treatment) were 0.1802 m (0.2145 m) and 9.09% (11.33%), respectively. Compared with the dry rice seeds, sowing chitting treatment seeds increased the average hill spacing by 0.0337 m and the coefficient of variation of hill spacing by 2.24 percentage points. According to the analysis of comprehensive performance evaluation test results, the seed metering device designed in this study performed well in field seeding performance, hole formation performance, and seeding uniformity. Meanwhile, the adjustment mechanism had high precision, and all indicators exceeded the national standards, as well as the test results of existing seed metering devices under the same conditions [30,31,32,33,34]. The seed metering device had good comprehensive performance and met the requirements for precision hill direct seeding of rice.

4. Discussion

Precision seeding technology is crucial for enhancing agricultural productivity and sustainability. Given the limitations of traditional mechanical seed meters, this study focuses on the application of electric-driven seed meters in rice precision hill direct seeding. The following discussion provides an in-depth analysis of the study’s results.

- (1)

- The experimental results showed that the new electric-driven seed metering device outperformed traditional mechanical seed meters in seeding precision, hole formation performance, and seeding uniformity. By precisely controlling the motor speed, electric drive technology effectively addressed the wheel slippage issue of traditional seed meters during high-speed operation, thereby enhancing seeding precision and the uniformity of seed distribution. The new seed metering device better met the needs of modern agriculture for precision seeding.

- (2)

- The strengths of this study are reflected in the integration of mechanical design, control theory, and agronomic practices, which enables the achievement of high-precision seeding with the seed metering device. However, electric drive technology may face higher costs and complex maintenance in practical applications, limiting its promotion in some regions. Additionally, due to the limited conditions of field tests, its adaptability under different soil and climatic conditions still requires further verification.

- (3)

- This study explored and experimented with the application of electric drive technology in rice precision hill direct-seeding metering devices, providing new insights for the development of this field. Compared with existing research, this study emphasised the practical application and performance optimisation of electric drive technology, confirming its potential to improve seeding precision and operational efficiency.

- (4)

- Future research should further optimise the design of electric-driven seed metering devices to reduce costs and improve their adaptability in different environments. Meanwhile, the development of simpler maintenance technologies will promote the widespread adoption of this technology. Furthermore, further integrating intelligent control and sensor technologies to enhance the performance and reliability of seed metering devices will be an important direction for future research.

5. Conclusions

In this study, aiming at the problems of traditional mechanical rice precision hill direct-seeding metering devices, a novel electric-driven metering device integrating a GNSS real-time speed measurement module and an optimised PID incremental control algorithm is developed. By integrating mechanical design, control theory, and agronomic methods, and through field experimental validation, this study systematically compares the performance of the novel electric-driven metering device with that of traditional mechanical metering devices under multi-factor working conditions, using representative rice varieties from the northern and southern rice-growing regions as experimental materials. The main conclusions are as follows.

- (1)

- Under the conditions of vehicle speed of less than 5 km/h and theoretical hill spacing of 0.15–0.25 m, the seed metering device achieves precision seeding for conventional rice (2–12 seeds per hill) and hybrid rice (2–9 seeds per hill) with seed sphericity ranging from 23.56% to 52.70%. The maximum qualified rate of seeds per hill is 93.75%, with an average of 89.95%; the empty hill rate is 0%; the coefficient of variation of hill spacing is 6.37–15.79%; the qualified rate of hill diameter is not lower than 90.09%; and the average seed damage rate is 0.79%.

- (2)

- Compared with the conventional mechanical metering device, the newly developed electric metering system demonstrated superior performance across the entire operating range of 3–5 km h−1. The qualification rate of seeds per hill increased by 1.17 percentage points to 90.54%, while the rates of missing, doubling, and seed damage decreased by 0.77, 0.39, and 0.23 percentage points, respectively. Regarding hill formation, the qualification rate of hill diameter rose by 1.5 percentage points to 95.21%, the coefficient of variation of hill diameter declined by 6.02 percentage points to 19.11%, and no blank hills were observed. Seed-rate accuracy was also improved, as the coefficient of variation of seeds per hill decreased by 3.36 percentage points to 21.98%, with the mean value approaching the target more closely.

- (3)

- When the seed metering device sows chitting-treatment rice seeds, its performance is slightly worse, mainly reflected in a 0.47 percentage point increase in the damage rate, a 2.11 percentage point decrease in the qualified rate of hill diameter, a 2.25 percentage point increase in the coefficient of variation of hill diameter, and a 2.24 percentage point increase in the coefficient of variation of hill spacing.

- (4)

- This study integrated real-time GNSS speed measurement with an incremental PID closed-loop control into the precision hill direct-seeding metering device for rice and validated the system through field experiments. Under operating speeds of 3–5 km h−1, the electric-driven device met or exceeded all critical criteria specified in current standards. The results demonstrate that the proposed technical solution and methodology offer valuable insights for accelerating the development of precision rice metering devices, and the novel electric metering unit will contribute to the intelligent upgrade of direct-seeding equipment for rice.

Author Contributions

Conceptualisation, X.G.; Data curation, S.L.; Formal analysis, H.L.; Funding acquisition, B.Y.; Investigation, H.L. and K.Y.; Methodology, H.L.; Project administration, B.Y.; Resources, B.Y. and G.W.; Software, L.L.; Supervision, X.G.; Validation, G.W.; Visualisation, H.L. and L.L.; Writing—original draft, H.L.; Writing—review and editing, H.L. and S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Attack Project administered by the Henan Provincial Department of Science and Technology (No. 252102111175) and the Science and Technology Attack Project administered by the Nanyang Municipal Science and Technology Bureau of Henan Province (No. 2024KJGG0102).

Data Availability Statement

Dataset available on request from the authors. The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zha, X.; Chen, L.; Chen, D.; He, Y.; Yang, R. Design and Testing of a Branched Air-Chamber Type Pneumatic Seed Metering Device for Rice. Agriculture 2024, 14, 1934. [Google Scholar] [CrossRef]

- Xing, H.; Wan, Y.; Zhong, P.; Lin, J.; Huang, M.; Yang, R.; Zang, Y. Design and experimental analysis of real-time detection system for the seeding accuracy of rice pneumatic seed metering device based on the improved YOLOv5n. Comput. Electron. Agric. 2024, 227, 109614. [Google Scholar] [CrossRef]

- Xing, H.; Cao, X.; Zhong, P.; Wan, Y.; Lin, J.; Zang, Y.; Zhang, G. DEM-CFD coupling simulation and optimisation of rice seed particles seeding a hill in double cavity pneumatic seed metering device. Comput. Electron. Agric. 2024, 224, 109075. [Google Scholar] [CrossRef]

- Wang, J.; Yao, Z.; Xu, Y.; Guo, F.; Guan, R.; Li, H.; Tang, H.; Wang, Q. Mechanism Analysis and Experimental Verification of Side-Filled Rice Precision Hole Direct Seed-Metering Device Based on MBD-DEM Simulations. Agriculture 2024, 14, 184. [Google Scholar] [CrossRef]

- Shang, Y.; Zhou, B.; Yang, J.; Zhang, S. Design and experiment of impeller seed guide device for rice internal suction hole direct seeding device. Sci. Rep. 2024, 14, 13300. [Google Scholar] [CrossRef]

- Qian, C.; He, S.; Qin, W.; Jiang, Y.; Huang, Z.; Zhang, M.; Zhang, M.; Yang, W.; Zang, Y. Influence of Shaped Hole and Seed Disturbance on the Precision of Bunch Planting with the Double-Hole Rice Vacuum Seed Meter. Agronomy 2024, 14, 768. [Google Scholar] [CrossRef]

- Mo, Z.; Lu, F.; Zhang, M.; Tao, C.; Wang, B.; Zhang, G. Design and Mechanism Study of Seed Filling room With Staggered Oriented Plates and Vibration. Inmateh Agric. Eng. 2024, 72, 653–662. [Google Scholar] [CrossRef]

- Hou, L.; Han, X.; Lan, Y.; Bai, J.; Ding, Z.; Zhang, X.; Song, M.; Wang, K. Design and Testing of a Sowing Drone Based on Rice Precision Strip Seeding. Inmateh Agric. Eng. 2024, 73, 351–363. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, C.; Wei, Y.; Guo, M.; Chen, C.; Zhang, C.; Zhang, Y. Design and testing of planting unit for rice dry-direct-seeding planter in cold region. Int. J. Agric. Biol. Eng. 2023, 16, 76–84. [Google Scholar] [CrossRef]

- Xia, Q.; Zhang, W.; Qi, B.; Wang, Y. Design and Experimental Study on a New Horizontal Rotary Precision Seed Metering Device for Hybrid Rice. Agriculture 2023, 13, 158. [Google Scholar] [CrossRef]

- Song, W.; Wan, Y.; Zhou, B.; Kuang, F.; Xiong, W.; Liao, J.; Zhu, D.; Zhang, S. Design and Experiment of Combined Cavity-type Precision Hole-drop Seed-metering Device for Rice. Inmateh-Agric. Eng. 2023, 71, 25–43. [Google Scholar] [CrossRef]

- Li, H.; Yan, B.; Meng, Z.; Ling, L.; Yin, Y.; Zhang, A.; Zhao, C.; Wu, G. Study on influencing factors of hole-filling performance of rice precision direct seed-metering device with hole ejection. Biosyst. Eng. 2023, 233, 76–92. [Google Scholar] [CrossRef]

- Albasheer, A.H.; Liao, Q.; Wang, L.; Abdallah, A.D.; Lin, J. Design and Preliminary Evaluation of a Precision Cylindrical Air-Assisted Drill Sowing Device for Rapeseed, Wheat, and Rice. Agriculture 2024, 14, 2355. [Google Scholar] [CrossRef]

- Wang, Y.; Xi, X.; Chen, M.; Shi, Y.; Zhang, Y.; Zhang, B.; Qu, J.; Zhang, R. Design of and experiment on Reciprocating Inter-Row Weeding Machine for Strip-Seeded Rice. Agriculture 2022, 12, 1956. [Google Scholar] [CrossRef]

- He, S.Y.; Zang, Y.; Huang, Z.S.; Tao, W.N.; Xing, H.; Qin, W.; Jiang, Y.C.; Wang, Z.M. Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice. Agriculture 2022, 12, 1239. [Google Scholar] [CrossRef]

- Zhu, D.; Li, L.; Wen, S.; Zhang, S.; Jing, R.; Wu, L. Numerical simulation and experiment on seeding performance of slide hole-wheel precision seed-metering device for rice. Trans. CSAE 2018, 34, 17–26. [Google Scholar] [CrossRef]

- Tian, L.; Wang, J.; Tang, H.; Li, S.; Zhou, W.; She, H. Design and performance experiment of helix grooved rice seeding device. Trans. CSAM 2016, 47, 46–52. [Google Scholar] [CrossRef]

- Zhang, M.; Xiao, M.; Ou, Y.; Jiang, E.; Qiao, J.; Wang, Z.; Liu, S.; Xu, P.; Luo, X. Optimization design and test of seed protecting structure of combined type-hole metering device. J. South China Agric. Univ. 2021, 42, 99–105. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Shi, Z.; Ji, W.; Zhang, H.; Fu, H.; Wang, D. Design and experiment of double-storage turntable cotton vertical disc hole seeding and metering device. Trans. CSAE 2021, 37, 27–36. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Wang, H.; Liao, J.; Li, Z.; Zhu, D. Design and experiment of u-shaped cavity type precision hill-drop seed-metering device for rice. Trans. CSAM 2020, 51, 98–108. [Google Scholar] [CrossRef]

- Xing, H.; Wang, Z.; Luo, X.; Cao, X.; Liu, C.; Zang, Y. General structure design and field experiment of pneumatic rice direct-seeder. Int. J. Agric. Biol. Eng. 2017, 10, 31–42. [Google Scholar] [CrossRef]

- Bu, L.; Kou, Q.; Sugirbay, A.; Chen, J.; Chen, Y. An air-assisted mechanical hill-seeding device for foxtail millet (Setaria italica). J. Agric. Eng. 2024, 55, 1578. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, S.; Dong, J.; Liu, F.; Jia, X.; Huang, Y. Development of high-speed and precision metering device with gradient-feeding and control seed for soybean planting. J. Agric. Eng. 2024, 55, 1574. [Google Scholar] [CrossRef]

- Li, B.; Ahmad, R.; Qi, X.; Li, H.; Nyambura, S.M.; Wang, J.; Chen, X.; Li, S. Design Evaluation and Performance Analysis of a Double-Row Pneumatic Precision Metering Device for Brassica chinensis. Sustainability 2021, 13, 1374. [Google Scholar] [CrossRef]

- Zhai, C.; Lu, C.; Li, H.; He, J.; Wang, Q.; Wang, C.; Jin, W.; Chen, L.; Chang, F.; Bi, J. An electric-driven maize seeding system: Improving the quality of accelerate seeding using Tracking Differential Filtering-Optimal Tracking Control (TDF-OTC) method. Comput. Electron. Agric. 2025, 236, 110488. [Google Scholar] [CrossRef]

- Abdallah, E.; Ahmed, E.; Ahmed, Z.; Ali, S.; Mohamed, A. Development and laboratory evaluation of a novel IoT-based electric-driven metering system for high precision garlic planter. PLoS ONE 2025, 20, e0317203. [Google Scholar] [CrossRef]

- Sharaby, N.; Doroshenko, A.; Butovchenko, A. Modelling and verification of sesame seed particles using the discrete element method. J. Agric. Eng. 2022, 53, 1286. [Google Scholar] [CrossRef]

- GB/T 25418-2022; Method of Grain Direct Seeding Machine. China Agriculture Press: Beijing, China, 2022.

- GB/T 6973-2005; Testing Methods of Single Seed Drills (Precision Drills). Standardization Administration of the P.R.C: Beijing, China, 2005.

- Xing, H.; Wang, Z.; Luo, X.; Zang, Y.; He, S.; Xu, P.; Liu, S. Design and experimental analysis of rice pneumatic seeder with adjustable seeding rate. Int. J. Agric. Biol. Eng. 2021, 14, 113–122. [Google Scholar] [CrossRef]

- Xing, H.; Wang, Z.; Luo, X.; Zang, Y.; Yang, W.; Zhang, M.; Ma, Y. Design of an active seed throwing and cleaning unit for pneumatic rice seed metering device. Int. J. Agric. Biol. Eng. 2018, 11, 62–69. [Google Scholar] [CrossRef]

- Xing, H.; Zang, Y.; Wang, M.Z.; Luo, W.X.; Zhang, H.M.; Fang, Y.L. Design and Experimental Analysis of a Stirring Device for a Pneumatic Precision Rice Seed Metering Device. Trans. Asabe 2020, 63, 799–808. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Z.; Luo, X.; Zang, Y.; Yang, W.; Xing, H.; Wang, B.; Dai, Y. Review of precision rice hill-drop drilling technology and machine for paddy. Int. J. Agric. Biol. Eng. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- He, S.; Qian, C.; Jiang, Y.; Qin, W.; Huang, Z.; Huang, D.; Wang, Z.; Zang, Y. Design and optimisation of the seed feeding device with DEM-CFD coupling approach for rice and wheat. Comput. Electron. Agric. 2024, 219, 108814. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).