Low-Injury Rubber Tapping Robots: A Novel PSO-PID Approach for Adaptive Depth Control in Hevea Brasiliensis

Abstract

1. Introduction

2. Materials and Methods

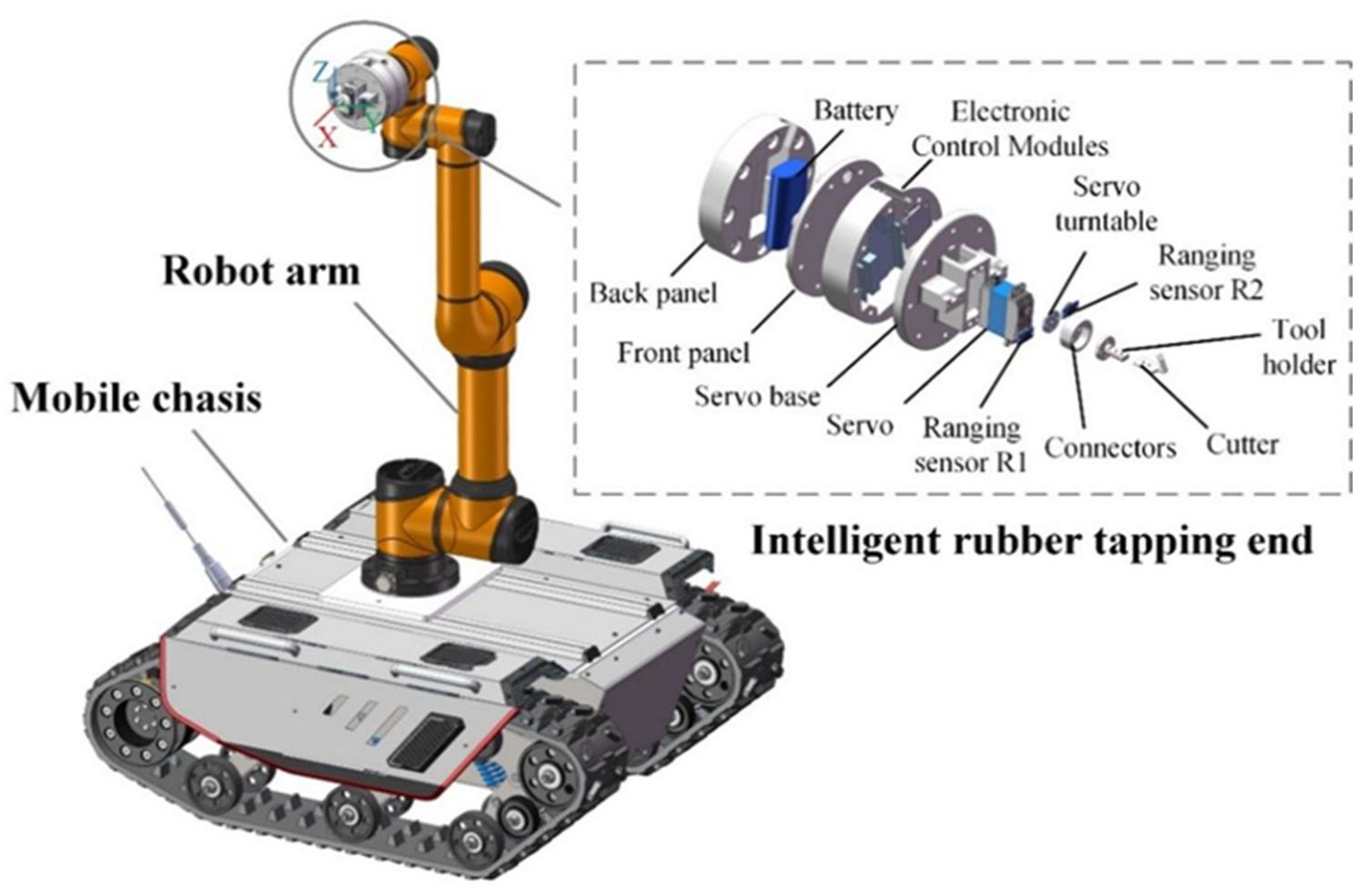

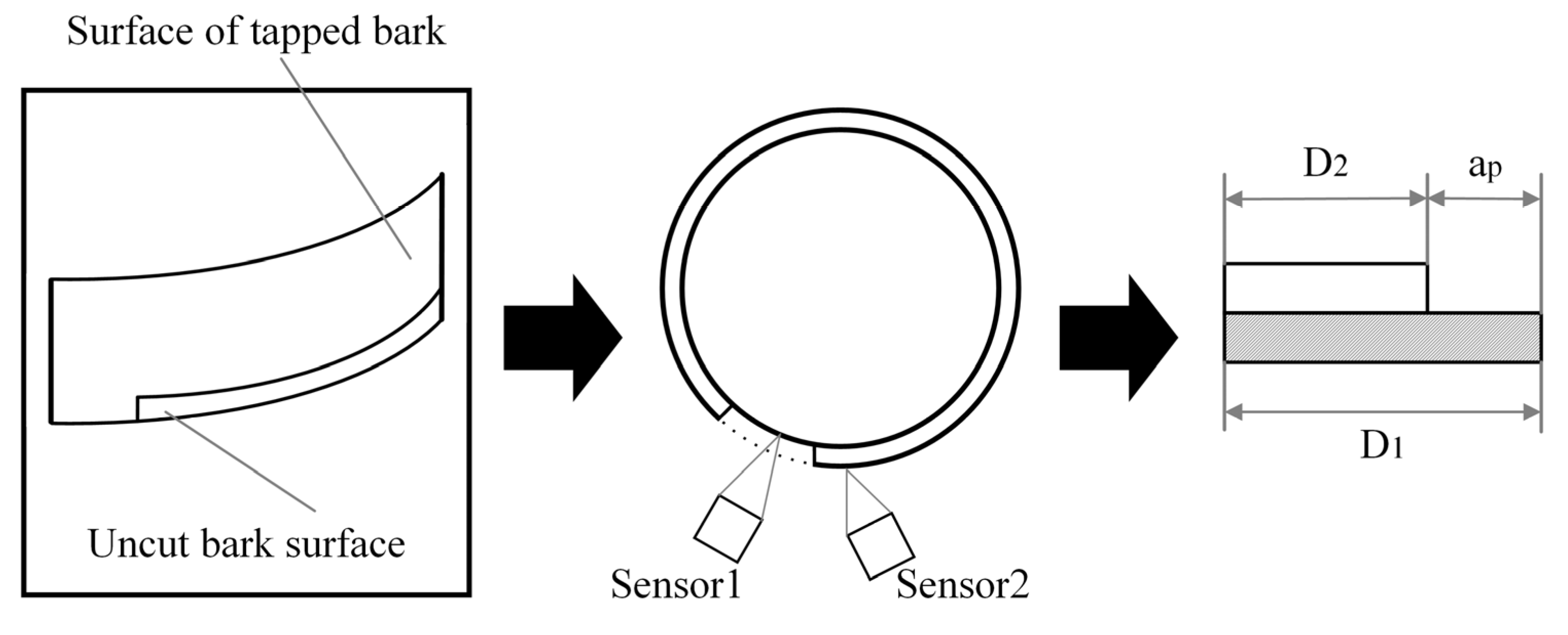

2.1. Structural Design of Rubber Tapping Robot

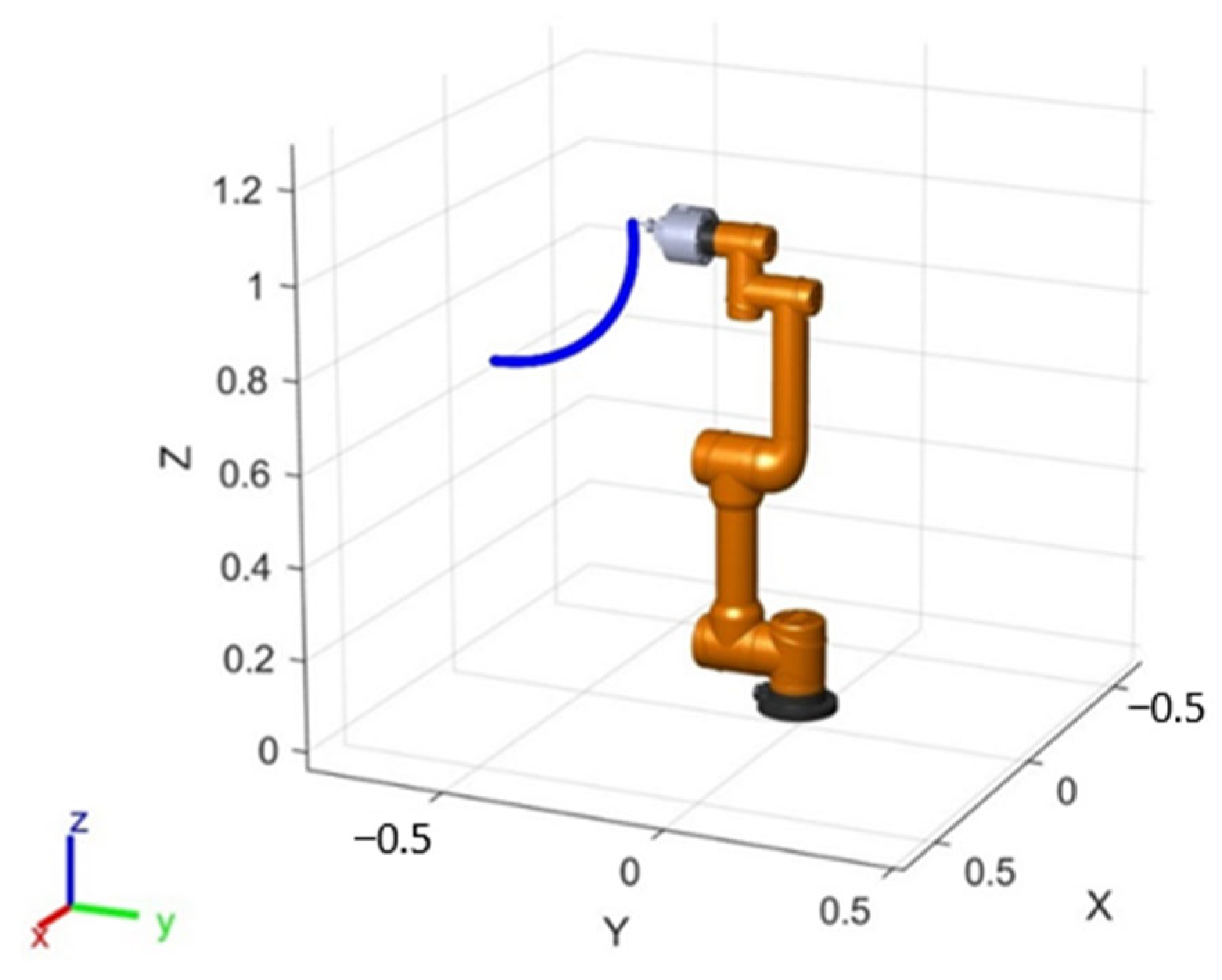

2.2. Modeling of the Robotic Arm of a Rubber Tapping Robot

2.3. Transfer Function of Rubber Tapping Robot System

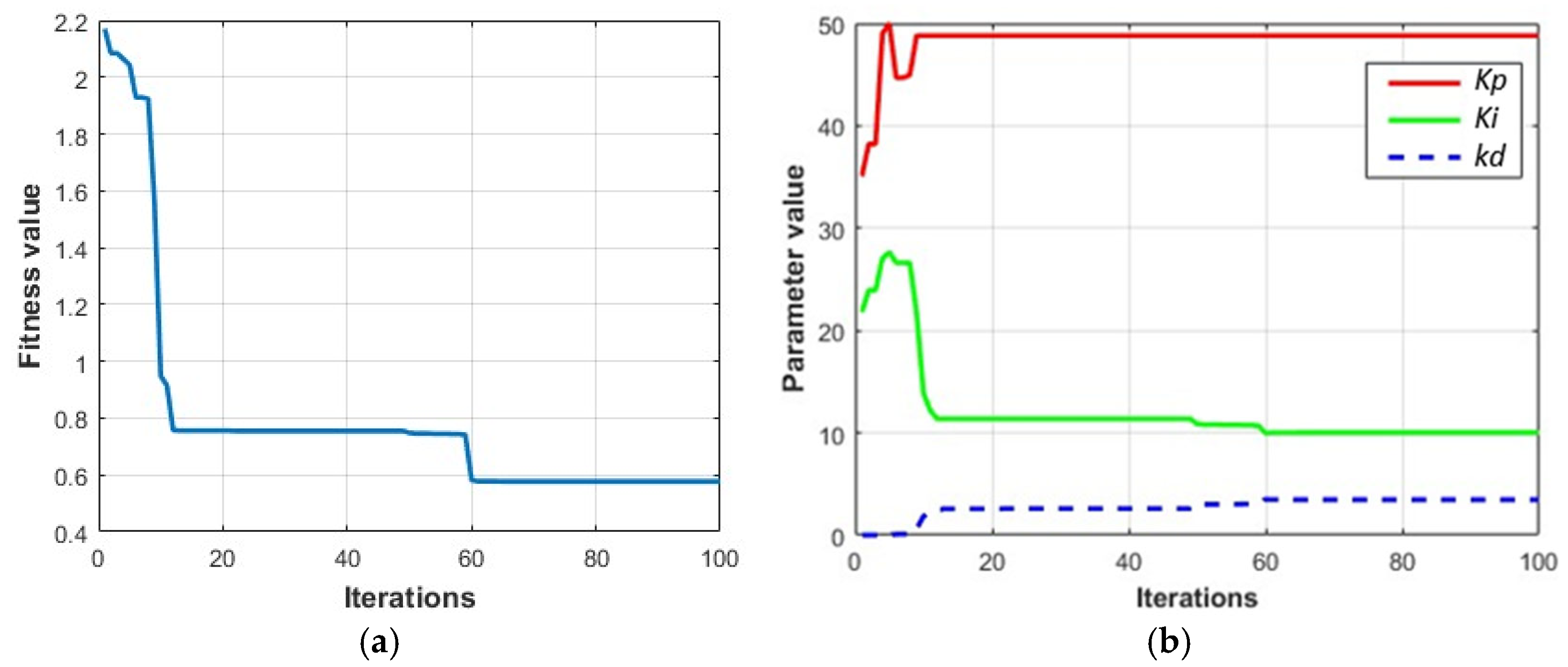

2.4. Analysis of PID Controller Based on PSO Algorithm

2.4.1. Improvement of Inertial Weight

2.4.2. Improvement of Learning Factors

2.4.3. Improved Particle Swarm Optimization Algorithm Process

| Algorithm 1 Improved PSO-PID Algorithm. |

| Input: Number of particles: N; Maximum number: tmax; Inertia weight range: ωmin, ωmax; Learning factor range: c1_min, c1_max, c2_min, c2_max; PID parameter: , , Output: Optimal PID parameters: kp_opt, ki_opt, kd_opt; Minimum fitness value: ITAEMIN

|

2.5. Parameter Configuration

2.6. Experimental Process

3. Results and Discussion

3.1. Simulation Experiment Results

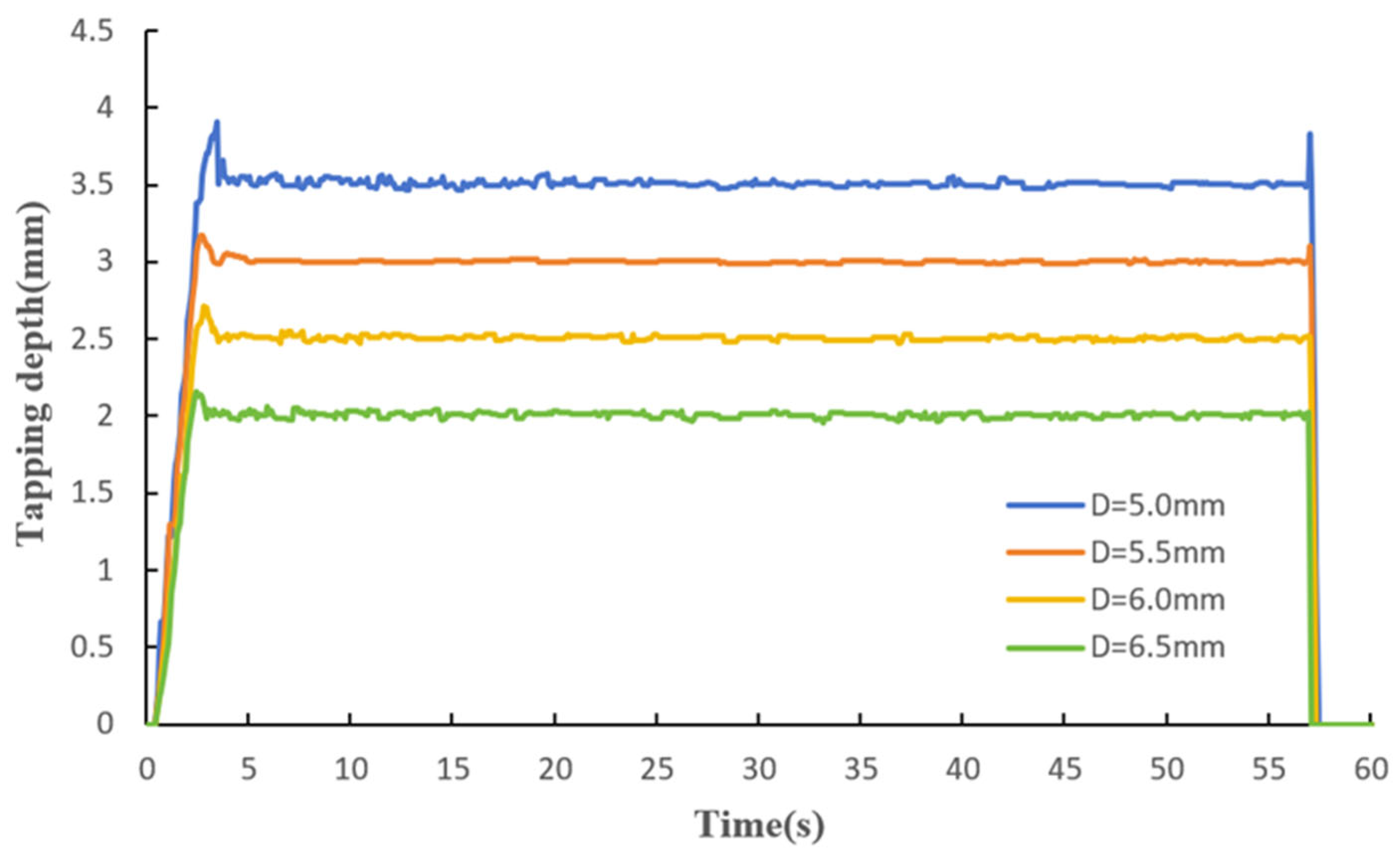

3.2. Forest Tapping Experiment Results

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, H.; Luo, X.; Sun, Z.H.; Yuan, X.; Qiu, S. Multi-model fusion based on Stacking: A predictive model for the price trend of natural rubber. In Proceedings of the 2020 IEEE 16th International Conference on Automation Science and Engineering (CASE), Hong Kong, China, 20–21 August 2020; pp. 1237–1242. [Google Scholar]

- Yang, H.; Sun, Z.J.; Liu, J.X.; Zhang, Z.F.; Zhang, X.R. The Development of Rubber Tapping Machines in Intelligent Agriculture: A Review. Appl. Sci.-Basel 2022, 12, 9304. [Google Scholar] [CrossRef]

- Chambon, B.; Duangta, K.; Promkhambut, A.; Lesturgez, G. Field latex production in Southern Thailand: A study on farmers’ and traders’ practices that may affect the quality of natural rubber latex delivered to the factories. J. Rubber Res. 2020, 23, 125–137. [Google Scholar] [CrossRef]

- Yatawara, Y.; Brito, W.; Perera, M.; Balasuriya, D. “Appuhamy”-the fully automatic rubber tapping machine. Engineer 2019, 27, 27–33. [Google Scholar] [CrossRef]

- Arjun, R.N.; Soumya, S.J.; Vishnu, R.S.; Bhavani, R.R. Semi automatic rubber tree tapping machine. In Proceedings of the 2016 International Conference on Robotics and Automation for Humanitarian Applications (RAHA), Coimbatore, India, 18–20 December 2016; pp. 1–5. [Google Scholar]

- Rodrigo, V.; Kudaligama, K.; Fernando, K.; Yapa, P. Harvesting the rubber tree once in four days; a solution to current issues in the rubber industry in Sri Lanka. J. Rubber Res. Inst. Sri Lanka 2011, 91, 15–35. [Google Scholar] [CrossRef]

- Mi, W. Development and Key Technology Research of Fully Automatic Rubber Tapping Machine. Master’s Thesis, Guangdong Ocean University, Guangdong, China, 2020. [Google Scholar]

- Zhou, H.; Zhang, S.L.; Zhang, J.X.; Zhang, C.L.; Wang, S.; Zhai, Y.H.; Li, W. Design, development, and field evaluation of a rubber tapping robot. J. Field Robot. 2022, 39, 28–54. [Google Scholar] [CrossRef]

- Zhou, H.; Gao, J.; Zhang, F.; Zhang, J.; Wang, S.; Zhang, C.; Li, W. Evaluation of Cutting Stability of a Natural-Rubber-Tapping Robot. Agriculture 2023, 13, 583. [Google Scholar] [CrossRef]

- Zheng, T.; Xu, A.; Xu, X.; Liu, M. Modeling and Compensation of Inertial Sensor Errors in Measurement Systems. Electronics 2023, 12, 2458. [Google Scholar] [CrossRef]

- Cui, W.; Lu, Z.; Li, C.; Han, X. A proactive approach to solve integrated production scheduling and maintenance planning problem in flow shops. Comput. Ind. Eng. 2018, 115, 342–353. [Google Scholar] [CrossRef]

- Nakaya, M.; Yoshizumi, H. Report on Basic Feedback Control Education and a Practical PID Tuning Method for Technical Staff and Operators. In Proceedings of the IEEE 15th International Conference on Control and Automation (ICCA), Edinburgh, Scotland, 16–19 July 2019; pp. 746–751. [Google Scholar]

- Wang, L.; Huang, C.; Li, T.; Cao, J.; Zheng, Y.; Huang, J. An Optimization Study on a Novel Mechanical Rubber Tree Tapping Mechanism and Technology. Forests 2023, 14, 2421. [Google Scholar] [CrossRef]

- Zhang, G.; Daraz, A.; Khan, I.A.; Basit, A.; Khan, M.I.; Ullah, M. Driver Training Based Optimized Fractional Order PI-PDF Controller for Frequency Stabilization of Diverse Hybrid Power System. Fractal Fract. 2023, 7, 315. [Google Scholar] [CrossRef]

- Dai, M.J.; Zhang, Z.L.; Lai, X.; Lin, X.H.; Wang, H. PID controller-based adaptive gradient optimizer for deep neural networks. IET Control Theory Appl. 2023, 17, 2032–2037. [Google Scholar] [CrossRef]

- Ahmadi, A.; Esfanjani, R.M. Automatic tuning of PID controllers using deep recurrent neural networks with pruning based on tracking error. J. Instrum. 2024, 19, P02028. [Google Scholar] [CrossRef]

- Ratre, A.; Pankajakshan, V. Deep Imbalanced Data Learning Approach for Video Anomaly Detection. In Proceedings of the 28th National Conference on Communications (NCC), Online, 24–27 May 2022; pp. 391–396. [Google Scholar]

- Li, W.; Wang, G.G.; Gandomi, A.H. A Survey of Learning-Based Intelligent Optimization Algorithms. Arch. Comput. Methods Eng. 2021, 28, 3781–3799. [Google Scholar] [CrossRef]

- Sahin, A.K.; Cavdar, B.; Ayas, M.S. An adaptive fractional controller design for automatic voltage regulator system: Sigmoid-based fractional-order PID controller. Neural Comput. Appl. 2024, 36, 14409–14431. [Google Scholar] [CrossRef]

- Xiao, Y.; Yu, A.; Qi, H.; Jiang, Y.; Zhou, W.; Gao, N.; Liu, W. Research on the tension control method of lithium battery electrode mill based on GA optimized Fuzzy PID. J. Intell. Fuzzy Syst. 2021, 40, 10211–10234. [Google Scholar] [CrossRef]

- Chen, K.; Xiao, B.; Wang, C.Y.; Liu, X.L.; Liang, S.N.; Zhang, X. Cuckoo Coupled Improved Grey Wolf Algorithm for PID Parameter Tuning. Appl. Sci.-Basel 2023, 13, 12944. [Google Scholar] [CrossRef]

- Chen, C.; Li, J.; Luo, J.; Xie, S.; Li, H. Seeker optimization algorithm for optimal control of manipulator. Ind. Robot: An. Int. J. 2016, 43, 677–686. [Google Scholar] [CrossRef]

- Shami, T.M.; El-Saleh, A.A.; Alswaitti, M.; Al-Tashi, Q.; Summakieh, M.A.; Mirjalili, S. Particle swarm optimization: A comprehensive survey. IEEE Access 2022, 10, 10031–10061. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y. Comparing inertia weights and constriction factors in particle swarm optimization. In Proceedings of the 2000 Congress on Evolutionary Computation (CEC), La Jolla, CA, USA, 16–19 July 2000; pp. 84–88. [Google Scholar]

- Chen, H.T.; Wang, W.C.; Chen, X.N.; Qiu, L. Multi-objective reservoir operation using particle swarm optimization with adaptive random inertia weights. Water Sci. Eng. 2020, 13, 136–144. [Google Scholar] [CrossRef]

- Ni, Q.; Deng, J. A New Logistic Dynamic Particle Swarm Optimization Algorithm Based on Random Topology. Sci. World J. 2013, 2013, 409167. [Google Scholar] [CrossRef]

- Zhang, W.; Li, G.; Zhang, W.; Liang, J.; Yen, G.G. A cluster based PSO with leader updating mechanism and ring-topology for multimodal multi-objective optimization. Swarm Evol. Comput. 2019, 50, 100569. [Google Scholar] [CrossRef]

- Quan, W.; Wang, J.; He, Z.; Zuo, J. Selective Ensemble Based on Probability PSO Algorithm; Springer International Publishing: Heidelberg, NY, USA, 2018; pp. 273–280. [Google Scholar]

- Sharma, M.; Chhabra, J.K. Sustainable automatic data clustering using hybrid PSO algorithm with mutation. Sustain. Comput. Inform. Syst. 2019, 23, 144–157. [Google Scholar] [CrossRef]

- Yadav, R.K.; Anubhav. PSO-GA based hybrid with Adam Optimization for ANN training with application in Medical Diagnosis. Cogn. Syst. Res. 2020, 64, 191–199. [Google Scholar] [CrossRef]

- Gao, G.; Sun, G.; Na, J.; Guo, Y.; Wu, X. Structural parameter identification for 6 DOF industrial robots. Mech. Syst. Signal Process. 2018, 113, 145–155. [Google Scholar] [CrossRef]

- Mu, D.; Wang, G.; Fan, Y. A Time-Varying Lookahead Distance of ILOS Path Following for Unmanned Surface Vehicle. J. Electr. Eng. Technol. 2020, 15, 2267–2278. [Google Scholar] [CrossRef]

- Rake, H. Step Response and Frequency Response Methods. IFAC Proc. Vol. 1979, 12, 519–526. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Yuan, Y.; Zeng, N.; Hone, K.; Liu, X. A novel sigmoid-function-based adaptive weighted particle swarm optimizer. IEEE Trans. Cybern. 2019, 51, 1085–1093. [Google Scholar] [CrossRef]

- Huang, H.; Qin, H.; Hao, Z.; Lim, A. Example-based learning particle swarm optimization for continuous optimization. Inf. Sci. 2012, 182, 125–138. [Google Scholar] [CrossRef]

| ai-1 (mm) | αi-1 (°) | di (mm) | (°) | |

|---|---|---|---|---|

| 1 | 0 | 0 | 122 | 180 |

| 2 | 0 | −90 | 121.5 | −90 |

| 3 | 408 | 180 | 0 | 0 |

| 4 | 376 | 180 | 0 | −90 |

| 5 | 0 | −90 | 102.5 | 0 |

| 6 | 0 | 90 | 94 | 0 |

| Parameters | Value |

|---|---|

| number of particles: N | 100 |

| maximum number of iterations: tmax | 100 |

| Inertia weight: ωmin, ωma | 0.4,1.6 |

| Learning factor: c1_min, c1_max, c2_min, c2_max | 0.8, 1.5, 0.8, 1.5 |

| 40, 15, 1 |

| Setpoint | Algorithm | Settling Time (s) | Overshoot (%) |

|---|---|---|---|

| 5.0 mm | PSO-PID | 0.607 | 2.71 |

| GA-PID | 0.914 | 23.89 | |

| GWO-PID | 0.922 | 10.24 | |

| SOA-PID | 0.899 | 4.15 | |

| PID | 1.473 | 27.82 | |

| 5.5 mm | PSO-PID | 0.298 | 1.23 |

| GA-PID | 0.922 | 9.07 | |

| GWO-PID | 0.983 | 10.14 | |

| SOA-PID | 1.005 | 18.92 | |

| PID | 1.211 | 23.76 | |

| 6.0 mm | PSO-PID | 0.307 | 1.31 |

| GA-PID | 1.102 | 13.02 | |

| GWO-PID | 1.088 | 10.94 | |

| SOA-PID | 1.074 | 8.22 | |

| PID | 1.097 | 25.93 | |

| 6.5 mm | PSO-PID | 0.465 | 3.05 |

| GA-PID | 1.199 | 9.38 | |

| GWO-PID | 0.841 | 19.7 | |

| SOA-PID | 0.986 | 7.29 | |

| PID | 1.305 | 30.56 |

| Tap Depth (mm) | Max Depth (mm) | Min Depth (mm) | Average Depth (mm) | Standard Deviation |

|---|---|---|---|---|

| 2 | 2.19 | 1.88 | 2.01 | 0.02087 |

| 2.5 | 2.63 | 2.39 | 2.51 | 0.01889 |

| 3 | 3.08 | 2.93 | 3.01 | 0.01108 |

| 3.5 | 3.71 | 3.41 | 3.52 | 0.02008 |

| Rubber Tapping Method | Average Rubber Tapping Depth (mm) | Rubber Tapping Injury Tree Rate (%) |

|---|---|---|

| Manual rubber tapping (novice) | 3.71 | 8 |

| Manual rubber tapping (skilled) | 3.11 | 2 |

| Electric Rubber Tapping Cutter | 3.49 | 6 |

| PSO-PID Optimized Rubber Tapping | 3.02 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, R.; Liao, Y.; Liu, J.; Zhang, Z.; Zhang, X. Low-Injury Rubber Tapping Robots: A Novel PSO-PID Approach for Adaptive Depth Control in Hevea Brasiliensis. Agriculture 2025, 15, 1089. https://doi.org/10.3390/agriculture15101089

Xu R, Liao Y, Liu J, Zhang Z, Zhang X. Low-Injury Rubber Tapping Robots: A Novel PSO-PID Approach for Adaptive Depth Control in Hevea Brasiliensis. Agriculture. 2025; 15(10):1089. https://doi.org/10.3390/agriculture15101089

Chicago/Turabian StyleXu, Ruiwu, Yulan Liao, Junxiao Liu, Zhifu Zhang, and Xirui Zhang. 2025. "Low-Injury Rubber Tapping Robots: A Novel PSO-PID Approach for Adaptive Depth Control in Hevea Brasiliensis" Agriculture 15, no. 10: 1089. https://doi.org/10.3390/agriculture15101089

APA StyleXu, R., Liao, Y., Liu, J., Zhang, Z., & Zhang, X. (2025). Low-Injury Rubber Tapping Robots: A Novel PSO-PID Approach for Adaptive Depth Control in Hevea Brasiliensis. Agriculture, 15(10), 1089. https://doi.org/10.3390/agriculture15101089