Intelligent Detection and Automatic Removal Robot for Skinned Garlic Cloves

Abstract

1. Introduction

2. Materials and Methods

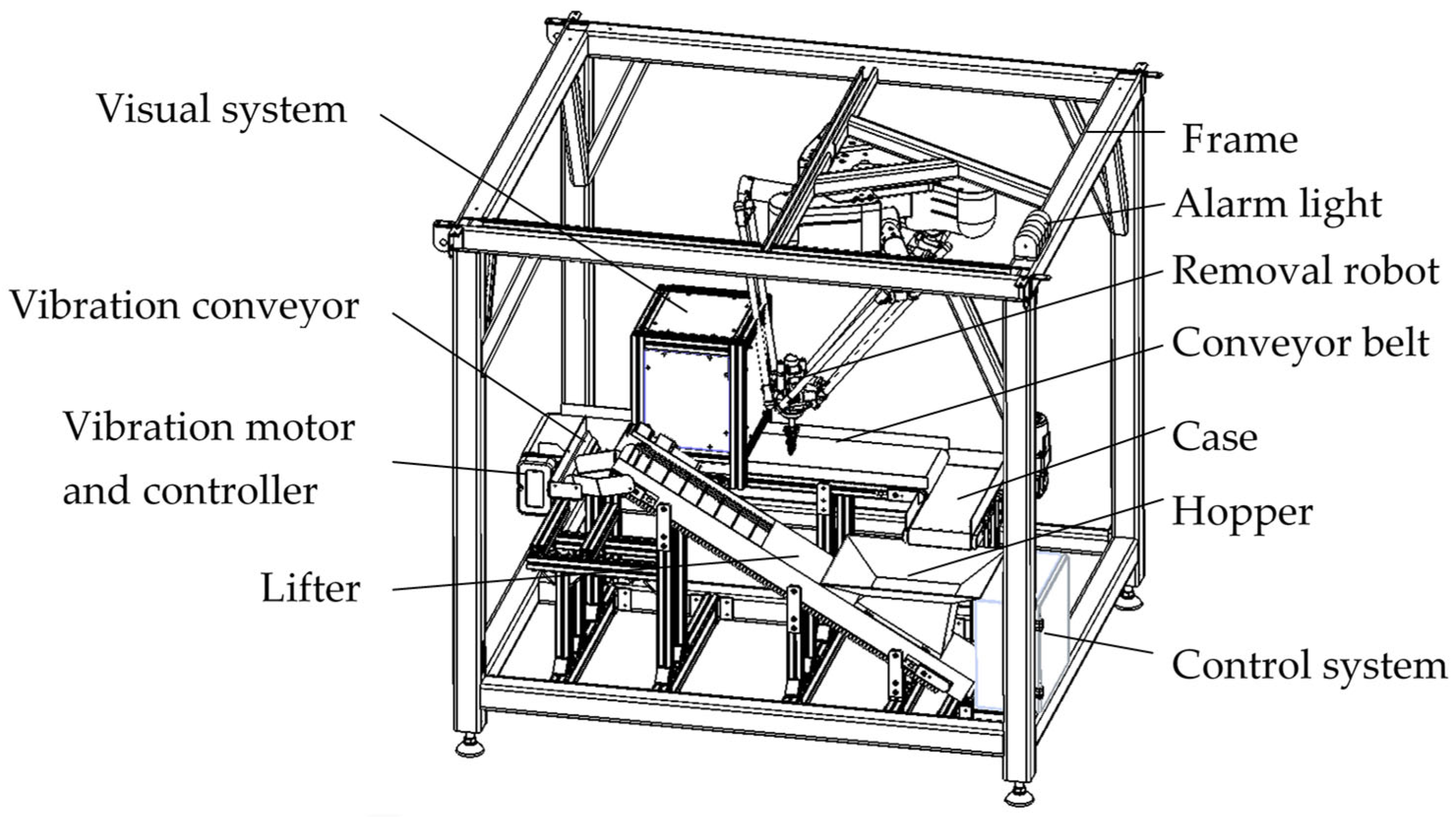

2.1. Overall Design of Intelligent Garlic-Removal Test Bench

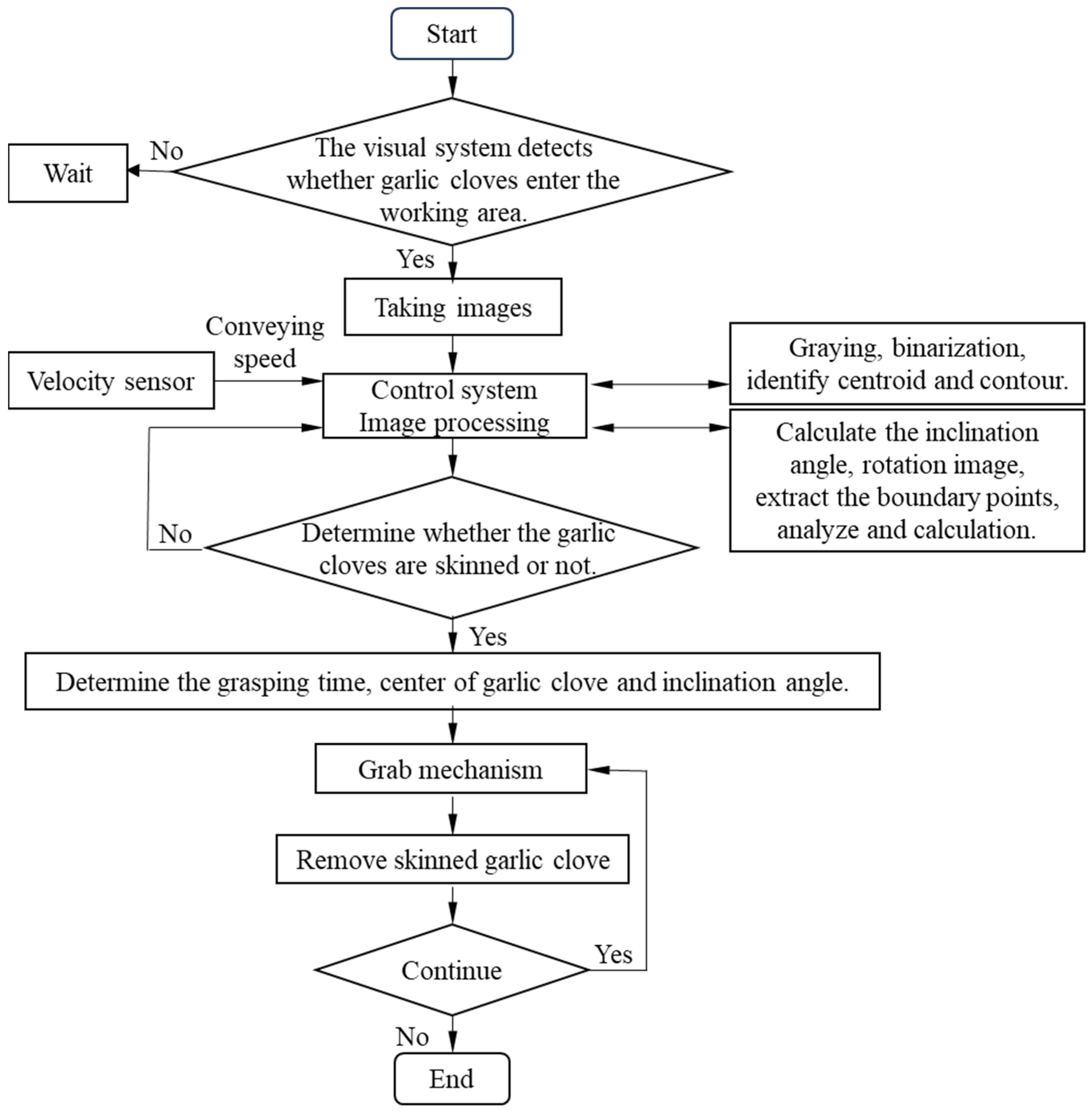

2.1.1. Overall Structure and Working Principle

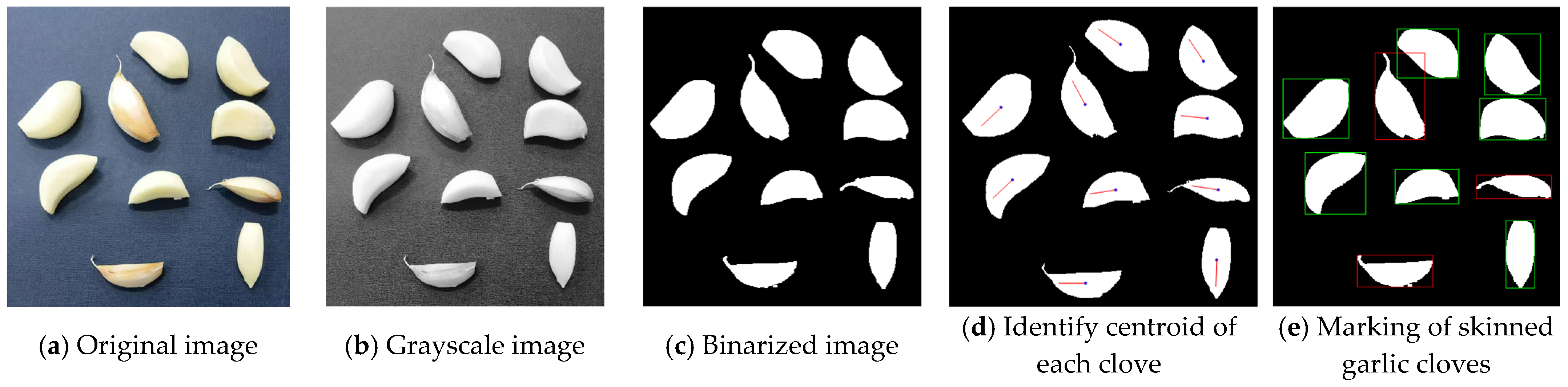

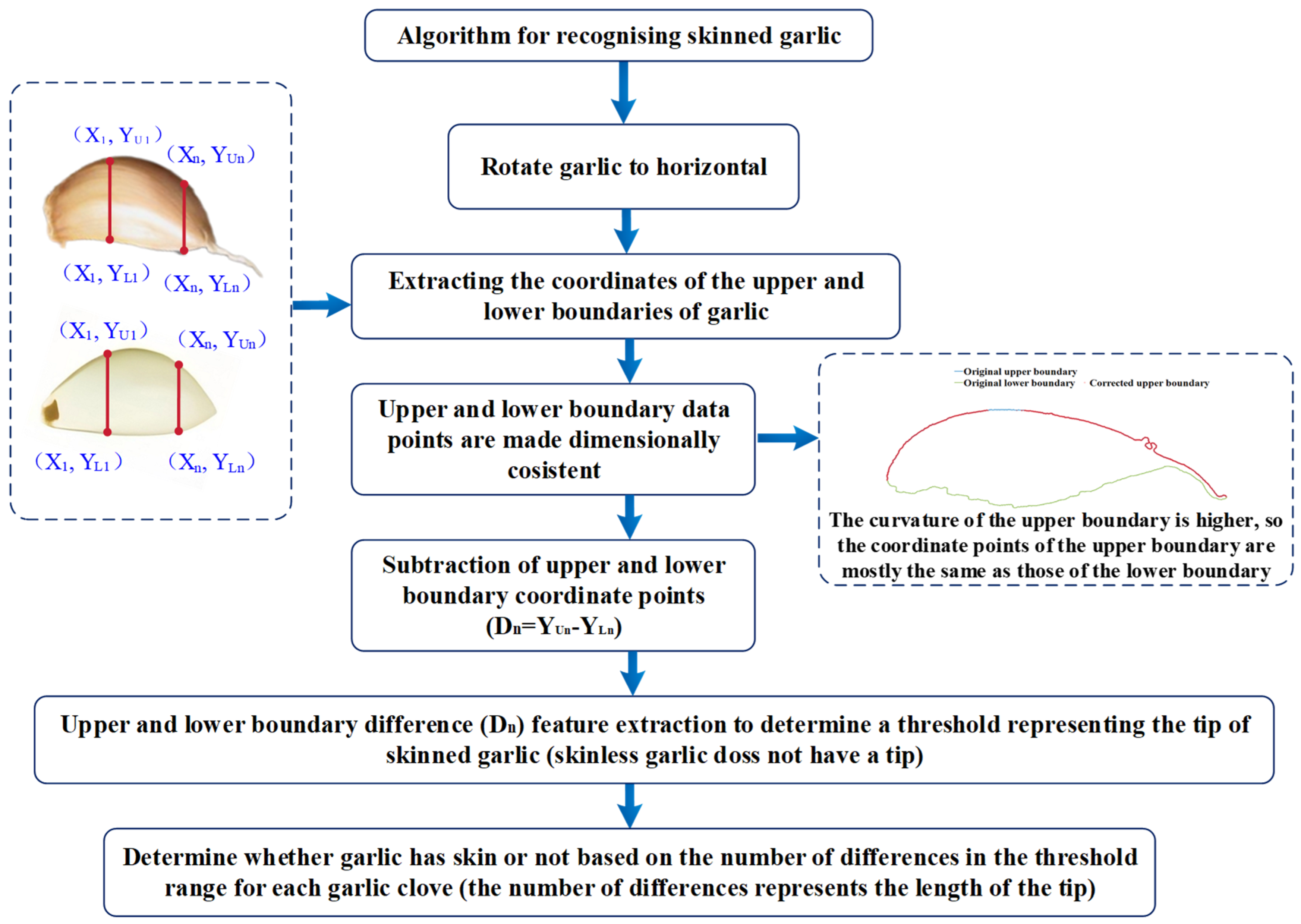

2.1.2. Visual System and Control System

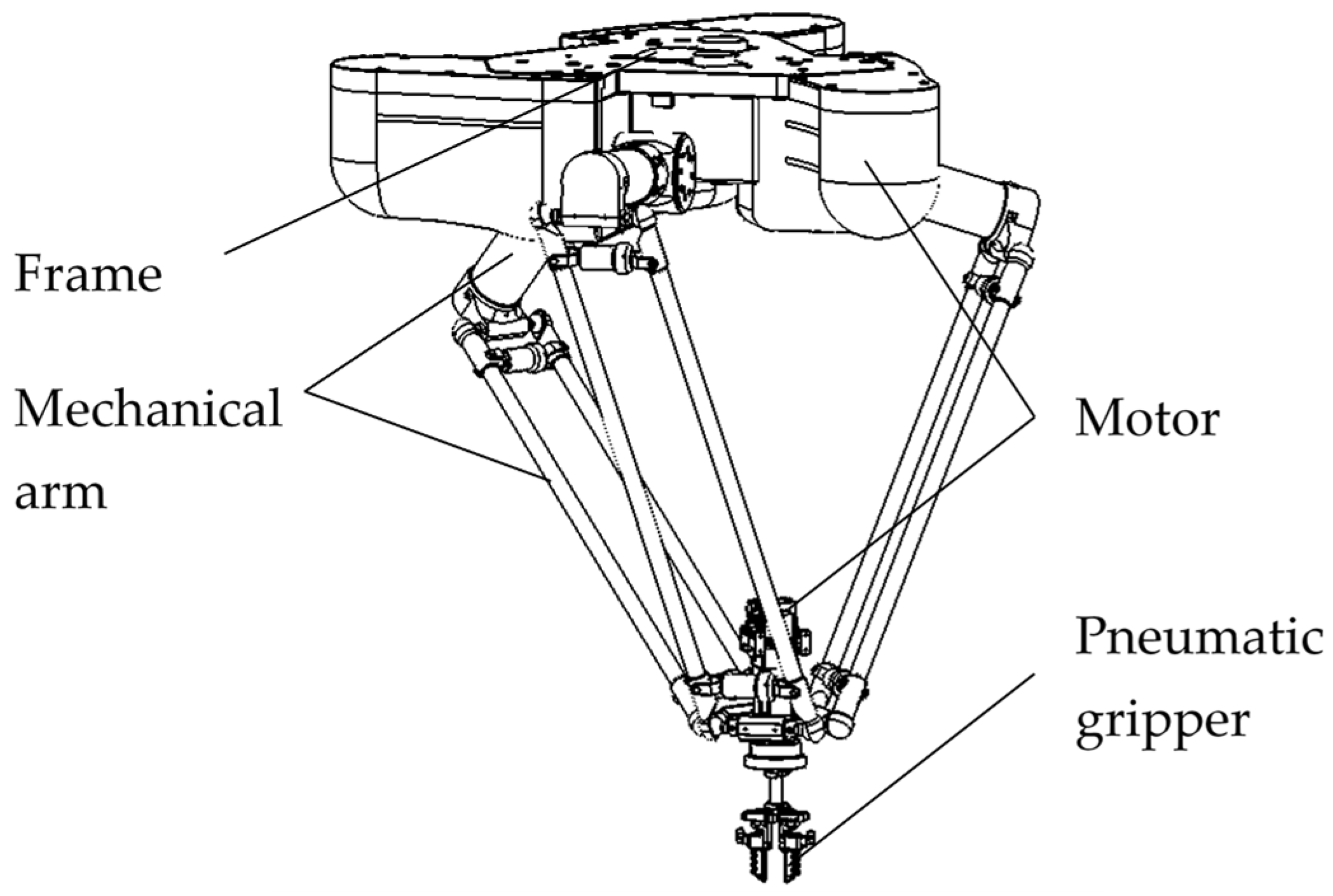

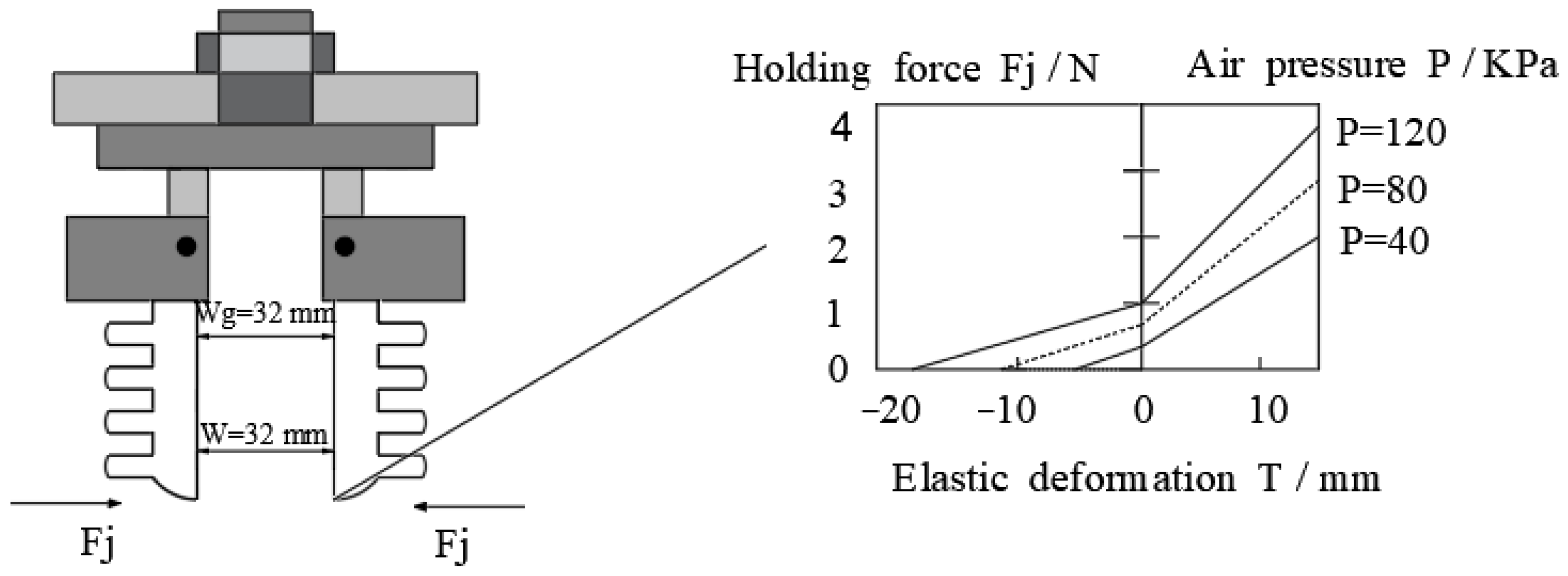

2.1.3. Removal Robot

2.2. Test Materials and Methods

2.2.1. Test of Success Rate of Machine Vision and Removal Robot

2.2.2. Test of Intelligent Garlic-Removal Test Bench

3. Results and Discussion

3.1. Results of Success Rate and Error Rate of Machine Vision and Removal Robot

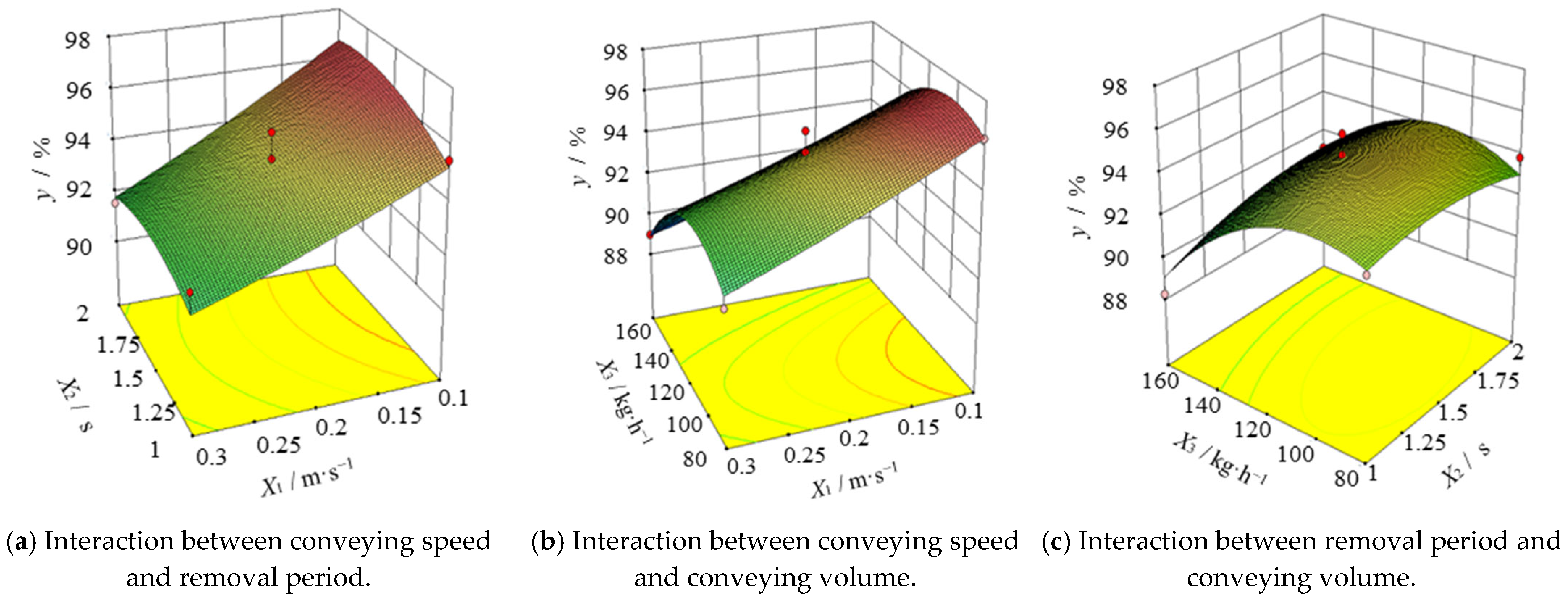

3.2. Results of Regression Orthogonal Test

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, Y.; Zhang, J.; Jiang, S.; Xu, Y.; Show, P.-L.; Han, Y.; Ye, X.; Ye, M. Contacting ultrasound enhanced hot-air convective drying of garlic slices: Mass transfer modeling and quality evaluation. J. Food Eng. 2018, 235, 79–88. [Google Scholar] [CrossRef]

- Thomas, A.; Boobyer, C.; Borgonha, Z.; van den Heuvel, E.; Appleton, K.M. Adding Flavours: Use of and Attitudes towards Sauces and Seasonings in a Sample of Community-Dwelling UK Older Adults. Foods 2021, 10, 2828. [Google Scholar] [CrossRef]

- Netzel, M.E. Garlic: Much More Than a Common Spice. Foods 2020, 9, 1544. [Google Scholar] [CrossRef]

- Furdak, P.; Pieńkowska, N.; Bartosz, G.; Sadowska-Bartosz, I. Extracts of Common Vegetables Inhibit the Growth of Ovary Cancer Cells. Foods 2022, 11, 2518. [Google Scholar] [CrossRef] [PubMed]

- Recinella, L.; Gorica, E.; Chiavaroli, A.; Fraschetti, C.; Filippi, A.; Cesa, S.; Cairone, F.; Martelli, A.; Calderone, V.; Veschi, S.; et al. Anti-Inflammatory and Antioxidant Effects Induced by Allium sativum, L. Extracts on an Ex Vivo Experimental Model of Ulcerative Colitis. Foods 2022, 11, 3559. [Google Scholar] [CrossRef]

- Phan, A.D.T.; Netzel, G.; Chhim, P.; Netzel, M.E.; Sultanbawa, Y. Phytochemical Characteristics and Antimicrobial Activity of Australian Grown Garlic (Allium sativum L.) Cultivars. Foods 2019, 8, 358. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Lan, H.; Wang, W. Effect of garlic supplement in the management of type 2 diabetes mellitus (T2DM): A meta-analysis of randomized controlled trials. Food Nutr. Res. 2017, 61, 1377571. [Google Scholar] [CrossRef] [PubMed]

- Cui, Z.; Liu, X.; Chen, Y.; Guan, C.; Yang, Y.; Xu, B. Status, problems and countermeasures of whole mechanized production of garlic in China. J. Chin. Agric. Mech. 2023, 44, 239–243, 250. [Google Scholar]

- Crop Queries of Production Volume of Data [EB/OL]. Available online: https://www.fao.org/faostat/en/#data (accessed on 10 February 2024).

- Wang, J.; Li, Y.; Yang, X.; Wu, H.; Zhao, J.; Shen, Q. Research on the Processing Technology of Honeyed Garlic. China Condiment 2019, 44, 130–135. [Google Scholar]

- Hao, Q.; Gong, M.; Lu, X. Research Progress of Garlic Drying Technology. China Condiment 2020, 45, 193–195. [Google Scholar]

- Qian, X. Analysis on the Diversity of Related Agricultural Products Processing Types and Market Demand with Garlic as an Example. China Condiment 2020, 45, 192–194. [Google Scholar]

- Zhou, H.; Du, Z.; Wu, Z.; Song, C.; Guo, N.; Lin, Y. Application progress of machine vision technology in the field of modern agricultural equipment. J. Chin. Agric. Mech. 2017, 38, 86–92. [Google Scholar] [CrossRef]

- Guo, Y. Research of the Recognition Method of Garlic Direction in Planting Machinery. Ph.D. Thesis, Northwest Agriculture and Forestry Technology University, Xianyang, China, 2011; pp. 6–36. [Google Scholar]

- Guzmán, E.; Baeten, V.; Pierna, J.A.F.; García-Mesa, J.A. Infrared machine vision system for the automatic detection of olive fruit quality. Talanta 2013, 116, 894–898. [Google Scholar] [CrossRef]

- Liu, H.; Chahl, S.J. A multispectral machine vision system for invertebrate detection on green leaves. Comput. Electron. Agric. 2018, 150, 279–288. [Google Scholar] [CrossRef]

- Cardellicchio, A.; Solimani, F.; Dimauro, G.; Petrozza, A.; Summerer, S.; Cellini, F.; Renò, V. Detection of tomato plant phenotyping traits using YOLOv5-based single stage detectors. Comput. Electron. Agric. 2023, 207, 107757. [Google Scholar] [CrossRef]

- Afonso, M.; Fonteijn, H.; Fiorentin, F.S.; Lensink, D.; Mooij, M.; Faber, N.; Polder, G.; Wehrens, R. Tomato Fruit Detection and Counting in Greenhouses Using Deep Learning. Front. Plant Sci. 2020, 11, 571299. [Google Scholar] [CrossRef] [PubMed]

- Navasardyan, S.; Ohanyan, M. The Family of Onion Convolutions for Image Inpainting. Int. J. Comput. Vis. 2022, 130, 3070–3099. [Google Scholar] [CrossRef]

- Malekabadi, A.J.; Khojastehpour, M.; Emadi, B.; Golzarian, M.R. Development of a machine vision system for determination of mechanical properties of onions. Comput. Electron. Agric. 2017, 141, 131–139. [Google Scholar] [CrossRef]

- Kim, W.S.; Lee, D.H.; Kim, Y.J. Machine vision-based automatic disease symptom detection of onion downy mildew. Comput. Electron. Agric. 2020, 168, 105099. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, Z.; Ding, P.; Wu, P.; Zang, C. Location Identification of Parallel Robot Based on Machine Vision. Manuf. Technol. Mach. Tool 2021, 12, 15–20. [Google Scholar]

- Luo, C.; Di, Z.; Xiang, Y.; Zhao, N.; Zhou, J.; Zhu, Z. Design and Experiment of Garlic Seed Recognition Clamping Test-bed Based on Machine Vision. J. Agric. Mech. Res. 2024, 46, 72–81. [Google Scholar]

- Lei, D.; Zheng, X. Design of Mechanical and Electrical Control System for Combined Harvester of Full Feeding Corn. J. Agric. Mech. Res. 2024, 46, 118–121+126. [Google Scholar]

- Li, C.; Gu, X.; Ren, H. A Cable-Driven Flexible Robotic Grasper With Lego-Like Modular and Reconfigurable Joints. IEEE/ASME Trans. Mechatron. 2017, 22, 2757–2767. [Google Scholar] [CrossRef]

- Ficur, P. A garlic clove direction detection based on pixel counting. In Proceedings of the 2014 1st Student Computer Science Research Conference, Berlin, Germany, 5–6 November 2014. [Google Scholar]

- Lei, P.; Shijian, D.; Ronghua, L. Research on the identification of the roots of garlic base on pattern recognition. J. Agric. Mech. Res. 2010, 32, 51–54. [Google Scholar]

- Saldaña-Robles, N.; Serwatowski Hlawinska, R.J.; Aguilera Hernández, R.A.; Saldaña-Robles, A.; Martínez-Jaime, O.A.; Gutiérrez-Vaca, C. Localización del ápice del ajo mediante técnicas de análisis digital de imagen. Agrociencia 2016, 50, 215–225. [Google Scholar]

- Li, Y.; Wu, Y.; Li, T.; Niu, Z.; Hou, J. Design and experiment of adjustment device based on machine vision for garlic clove direction. Comput. Electron. Agric. 2020, 174, 105513. [Google Scholar] [CrossRef]

- Li, X. Automatic Screening System for Appearance Defects of Garlic Clove Based on Machine Vision. Ph.D. Thesis, Tianjin University of Science and Technology, Tianjin, China, 2023; pp. 7–24. [Google Scholar]

| Level | Conveying Speed X1/(m·s−1) | Removal Period X2/(s) | Conveying Volume X3/(kg·h−1) |

|---|---|---|---|

| −1 | 0.3 | 1 | 80 |

| 0 | 0.2 | 1.5 | 120 |

| 1 | 0.1 | 2 | 160 |

| No. | Success Rate of Machine Vision | Success Rate of Removal Robot | ||||

|---|---|---|---|---|---|---|

| Number of Skinned Garlic Cloves/Total Garlic Cloves in Each Group S1 | Number of Skinned Garlic Cloves Recognized by Machine Vision | Success Rate of Machine Vision y1/(%) | Number of Skinned Garlic Cloves/Total Garlic Cloves in Each Group S2 | Number of Skinned Garlic Cloves Recognized by Machine Vision | Success Rate of Removal Robot Y2/(%) | |

| 1 | 182/3237 | 181 | 99.45 | 181/3223 | 179 | 98.90 |

| 2 | 195/3480 | 193 | 98.97 | 193/3452 | 191 | 98.96 |

| 3 | 201/3601 | 199 | 99.00 | 199/3550 | 198 | 99.50 |

| 4 | 175/3116 | 174 | 99.43 | 174/3104 | 173 | 99.43 |

| 5 | 180/3228 | 178 | 98.89 | 178/3181 | 176 | 98.88 |

| AVE | / | / | 99.15 | / | / | 99.13 |

| No. | Number of Skinned Garlic Cloves/Number of Peeled Garlic Cloves | Error Rate of Machine Vision | Error Rate of Removal Robot | ||||

|---|---|---|---|---|---|---|---|

| Skinned Garlic Cloves | Peeled Garlic Cloves | Totol Error Rate (%) | Skinned Garlic Cloves | Peeled Garlic Cloves | Totol Error Rate (%) | ||

| 1 | 1952/2031 | 6/1952 | 0/2031 | 0.31 | 2/1952 | 1/2031 | 0.15 |

| 2 | 1792/1885 | 4/1792 | 1/1885 | 0.28 | 1/1792 | 0/1885 | 0.06 |

| 3 | 2001/1915 | 8/2001 | 1/1915 | 0.45 | 4/2001 | 1/1915 | 0.25 |

| 4 | 1985/2151 | 5/1985 | 2/2151 | 0.34 | 2/1985 | 2/2151 | 0.19 |

| 5 | 1980/2207 | 10/1980 | 1/2207 | 0.55 | 3/1980 | 0/2207 | 0.15 |

| AVE | 0.39 | 0.16 | |||||

| No. | Conveying Speed X1/(m·s−1) | Removal Period X2/(s) | Conveying Volume X3/(kg·h−1) | Removal Rate y/(%) |

|---|---|---|---|---|

| 1 | −1.00 | −1.00 | 0.00 | 92.49 |

| 2 | 1.00 | −1.00 | 0.00 | 95.48 |

| 3 | −1.00 | 1.00 | 0.00 | 91.55 |

| 4 | 1.00 | 1.00 | 0.00 | 95.98 |

| 5 | −1.00 | 0.00 | −1.00 | 90.94 |

| 6 | 1.00 | 0.00 | −1.00 | 96.35 |

| 7 | −1.00 | 0.00 | 1.00 | 88.98 |

| 8 | 1.00 | 0.00 | 1.00 | 93.14 |

| 9 | 0.00 | −1.00 | −1.00 | 93.14 |

| 10 | 0.00 | 1.00 | −1.00 | 93.87 |

| 11 | 0.00 | −1.00 | 1.00 | 88.24 |

| 12 | 0.00 | 1.00 | 1.00 | 91.15 |

| 13 | 0.00 | 0.00 | 0.00 | 94.15 |

| 14 | 0.00 | 0.00 | 0.00 | 93.77 |

| 15 | 0.00 | 0.00 | 0.00 | 94.42 |

| 16 | 0.00 | 0.00 | 0.00 | 95.41 |

| 17 | 0.00 | 0.00 | 0.00 | 93.96 |

| Source | Removal Rate y | |||

|---|---|---|---|---|

| Sum of Squares | Sum of Mean Squares | F | p | |

| Model | 81.25197 | 9.027997 | 12.4755 | 0.0015 ** |

| X1 | 36.08251 | 36.08251 | 49.86129 | 0.0002 ** |

| X2 | 1.28 | 1.28 | 1.768792 | 0.2252 |

| X3 | 20.44801 | 20.44801 | 28.25646 | 0.0011 ** |

| X1X2 | 0.5184 | 0.5184 | 0.716361 | 0.4253 |

| X1X3 | 0.390625 | 0.390625 | 0.539792 | 0.4864 |

| X2X3 | 1.1881 | 1.1881 | 1.641798 | 0.2409 |

| 0.0858 | 0.0858 | 0.118565 | 0.7407 | |

| 1.565453 | 1.565453 | 2.16325 | 0.1848 | |

| 19.14312 | 19.14312 | 26.45327 | 0.0013 ** | |

| Residual | 5.065605 | 0.723658 | ||

| Lack of fit | 3.408925 | 1.136308 | 2.74358 | 0.1771 |

| Pure error | 1.65668 | 0.41417 | ||

| Total | 86.31758 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Cao, X.; Xiao, Y.; Xin, L.; Xin, L.; Li, S. Intelligent Detection and Automatic Removal Robot for Skinned Garlic Cloves. Agriculture 2025, 15, 1076. https://doi.org/10.3390/agriculture15101076

Zhu Z, Cao X, Xiao Y, Xin L, Xin L, Li S. Intelligent Detection and Automatic Removal Robot for Skinned Garlic Cloves. Agriculture. 2025; 15(10):1076. https://doi.org/10.3390/agriculture15101076

Chicago/Turabian StyleZhu, Zhengbo, Xin Cao, Yawen Xiao, Li Xin, Lei Xin, and Shuqian Li. 2025. "Intelligent Detection and Automatic Removal Robot for Skinned Garlic Cloves" Agriculture 15, no. 10: 1076. https://doi.org/10.3390/agriculture15101076

APA StyleZhu, Z., Cao, X., Xiao, Y., Xin, L., Xin, L., & Li, S. (2025). Intelligent Detection and Automatic Removal Robot for Skinned Garlic Cloves. Agriculture, 15(10), 1076. https://doi.org/10.3390/agriculture15101076