Abstract

According to the conditions of seeding operations in hilly areas of Northeast China, a bidirectional profiling press device (BPPD) was designed. The BPPD mainly consists of a press roller and strength adjusting mechanism which could grant the BPPD horizontal and vertical profile ability. The orthogonal tests L9 (34) in the field were conducted to investigate the press roller types and operating parameters effects of the BPPD working performance. In the field tests, three kinds of press rollers—rubber press roller (RPR), planar press roller (PPR) and squirrel cage-type press roller (SPR)—were tested under the condition of three spring deformations (10 mm, 20 mm, and 30 mm) and three forward speeds (3 km/h, 5 km/h and 7 km/h). The soil moisture content, average emergence time, emergence ratio, and plant height uniformity were tested as test indexes. Using statistical analysis software, the results of the orthogonal test are press roller type, spring deformation and forward speed have significant influence on the test indexes of soil moisture content, average emergence time, emergence ratio, and plant height uniformity which press roller type have highly significant influence on the average emergence time and emergence ratio index. Using a comprehensive weighted algorithm, the sequence of factors affecting the BPPD performance was determined: spring deformation, forward speed, and press roller type; optimal combination: press roller type PPR, a spring deformation of 20 mm, and a forward speed of 5 km/h.

1. Introduction

Cultivated land can be divided into two types: flat cultivated land and sloping cultivated land. The sloping cultivated land is mainly focused on hilly areas [1,2]. In Northeast China, hilly areas total approximately 788,000 hm2, accounting for 37.2% of the total area, and they are mainly distributed in southwestern Heilongjiang Province [3], eastern Jilin Province [4] and western Liaoning Province [5]. These areas are located in the core region of the northeastern black soil region (one of the three major black soil belts in the world) [6,7,8,9], and the region is an important crop-producing area [10,11,12]. However, the hilly areas are characterized by undulating terrain, low altitude, gentle slope [13,14] and the uneven distribution of soil [15]. In addition, the hilly areas are usually in the transition zone between mountains or plateaus and plains [9]. Therefore, this terrain restricts the development of agricultural mechanization, and agricultural mechanization technology in hilly areas is weak [16]. In recent years, researchers have focused on flat cultivated land machinery technology but less on that for hilly areas, especially research on the related technology of seeders in hilly areas. Compaction after sowing is the key link in the mechanization of main crop operations in hilly areas [17]. The technology of compaction is also one of the related technologies of hilly sowing machines and directly affects the quality and performance of sowing. It is necessary to study the compaction technology of seeders in hilly areas to improve the soil environment of the seedbed, increase the emergence rate, and enhance the operational efficiency [18].

To meet the requirements of hilly sowing operations and improve sowing efficiency in hilly areas, researchers introduced the small-scale seeders used in flat cultivated land into hilly areas [19,20]. When sowing in hilly areas, the ditching, sowing and covering abilities of small-sized seeders are well known. When planting crops in hilly areas, farmers often choose to plant crops on the cross slope, along the slope, or on both the cross slope and along the slope [21,22]. Because the small seeders in flat cultivated land do not have the ability of horizontal profiles, the phenomenon of horizontally inhomogeneous compaction appears after operating. Aiming at the above problems, under the condition that the existing seeders can realize longitudinal profiling, it is necessary to design a compaction device with horizontal profile ability.

Soil compaction after sowing has significant effects on soil physical properties [23], such as soil moisture content, soil hardness, and soil temperature [24]. Soil compaction can increase the soil hardness, thereby increasing the soil moisture and maintaining soil temperature [25]. Appropriate soil moisture content and soil temperature are essential for seed germination [26,27]. Therefore, appropriate soil compaction can influence seed germination and seedling growth, such as shortening the emergence time, increasing the emergence ratio and accelerating the growth of seedlings [28,29].

In this study, to solve the problem of inhomogeneous compaction after corn seeding operations in hilly areas, the BPPD was designed. Furthermore, the working effects of three kinds of press rollers (RPR, PPR, and SPR) at three spring deformations (10 mm, 20 mm, and 30 mm) and three operating speeds (3 km/h, 5 km/h, and 7 km/h) were further explored. The purpose of this study was to determine the effects of the BPPD on seedbed properties and corn emergence in hilly areas of Northeast China.

2. Materials and Methods

2.1. Operating Principle of the BPPD

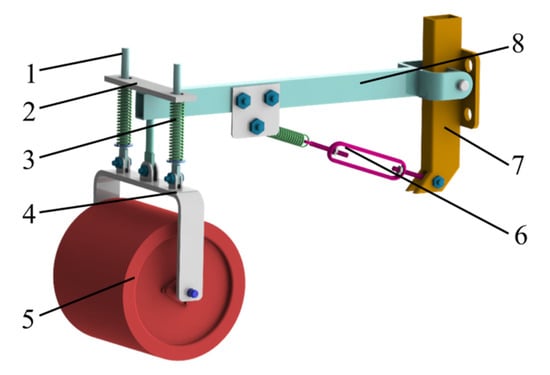

In the process of working in hilly areas, the BPPD can achieve a longitudinal profile through the connection between the upper bracket and front beam (the front beam of the seeder has a longitudinal profile device [30]), and the BPPD achieves a horizontal profile through the connection between the lower bracket and upper bracket. Figure 1 shows the structure of the BPPD. In the longitudinal profile, as the profiling device is between the front beam and the frame, the BPPD will fluctuate with the height of the terrain when the BPPD encounters a bulge on the ground [31].

Figure 1.

A structural diagram of the BPPD: (1) hanger rod, (2) limiting plate, (3) balance spring, (4) lower bracket, (5) press roller, (6) compression strength regulator, (7) front beam and (8) upper bracket.

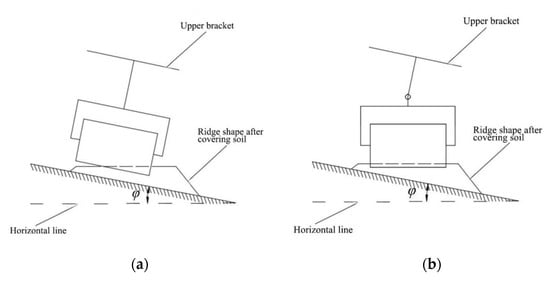

When the seeder works in hilly areas, there is often an angle between the ground and the horizontal line (φ), and the frame is parallel to the inclined plane. The traditional press device is rigidly connected with the upper bracket and cannot rotate horizontally relative to the upper bracket, so there is an angle between the traditional press device and the soil surface after the overlying soil. In this way, the inconsistent penetration depth of the transverse press roller results in uneven transverse compaction, as shown in Figure 2a. The BPPD can rotate around the joint relative frame and can be parallel to the surface of the overlying soil under the action of gravity and a balance spring, so the depth of the press roller is the same and the lateral compaction is uniform, as shown in Figure 2b. When the seeder is not in operation, the press roller can automatically retract so that the impact force on the BPPD can be reduced, and the BPPD can be protected. The function of the compression strength regulator is to change the compaction intensity by changing the spring pre-tightening force and finally to achieve the purpose of enhancing the compaction effect [31]. The main structural parameters of the BPPD are shown in Table 1.

Figure 2.

A motion sketch of the press device: (a) traditional press device; (b) the BPPD.

Table 1.

Structural parameters of the BPPD.

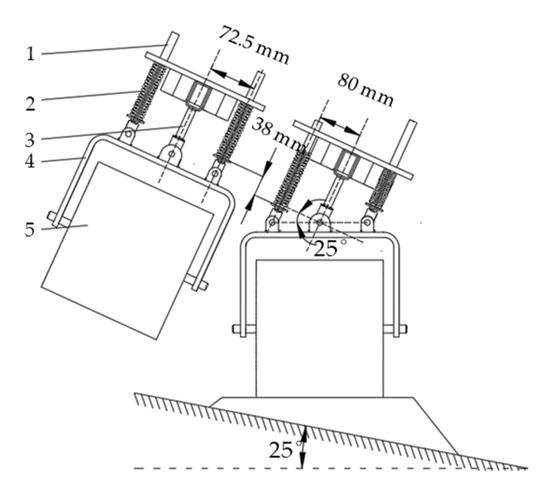

According to the schematic diagram in Figure 3, the horizontal profiling adjustment mechanism is designed. In Northeast China, the hills with slopes of 5° to 25° is mainly corn growing area. Thus, the maximum rotation angle of the press roller is designed to be 25° relative to the limit plate (Figure 3). Figure 3 shows that the vertical and lateral displacement change of the hanger rod is 38 mm and 7.5 mm, which determine the size of the hanger rod and the limiting plate. The function of the compression strength regulator is to change the compaction intensity by changing the spring pre-tightening force and finally to achieve the purpose of enhancing the compaction effect [31]. The main structural parameters of the BPPD are shown in Table 1.

Figure 3.

A motion sketch of the lateral balance state and lateral profiling state of the BPPD: (1) hanger rod, (2) balance spring, (3) upper bracket, (4) lower bracket and (5) press roller.

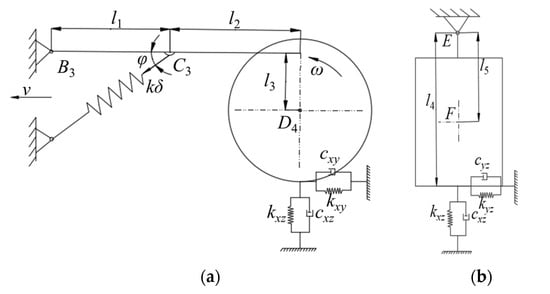

BBPD has 2 degrees of freedom in space: longitudinal rotation and lateral rotation. In order to ensure the rationality of the mathematical model, the following assumptions are made: (1) ignoring the low-frequency vibration of the planter which is caused by the ground; (2) regarding the soil as a viscoelastic body; (3) ignoring the degree of freedom in the forward direction. The mathematical model of the BBPD is shown in Figure 4. D4 is the center point of the press roller in the mathematical model of longitudinal motion, F is the center point of the press roller in the mathematical model of lateral motion, the moment of inertia around point B3 is J1, and the moment of inertia around point E is J2, the initial deformation of the spring quantity δ, the spring stiffness is k, and the angle between the spring and the B3C3 line in equilibrium is φ. Take the rotation angles of the system around the hinge points B3 and E as generalized coordinates (θ3, θ4).

Figure 4.

A 2-DOF mathematical model: (a) longitudinal rotation; (b) lateral rotation.

According to the analysis of dynamic knowledge, the establishment of the system movement differential equation is as follows:

where cxy, cxz, cyz is the soil damping coefficient, kxy, kxz, kyz is the soil stiffness coefficient.

Using the vibration theory, the Equations (1) and (2) are 2 degrees of freedom system general differential equation of forced vibration, verifying the feasibility of the bidirectional copying motion. The working process of the motion mathematical model is related to soil parameter, structure size and spring stiffness. Soil parameters are not controllable factors; therefore, it is necessary for the related structure size design and selection of the spring stiffness and spring deformation. When other conditions are determined, spring deformation is the main factor for the BPPD.

2.2. Experimental Conditions and Equipment

A field test was conducted on the Xiangyang farm of Northeast Agricultural University in Harbin, Heilongjiang, China. The Xiangyang farm is located at Xiangyang Village (45.45° N; 126.53° E; average elevation of 180 m), Xiangfang District, which is in the middle part of the Songneng Plain. The site has a continental climate of the cool temperate zone, which is characterized by strong winds and dry weather in spring, warm and rainy weather in summer and cold and dry weather in winter. The test was conducted on sloping land. The maximum slope angle was smaller than 15°, and the minimum slope angle was larger than 5°. Before this test, stubble cleaning was performed [14] (Figure 5). Ridge planting is a sowing method. Eighteen rows were reserved, and every row was 150 m. In the test, the tractor (John Deere (Ningbo) Agricultural Machinery Co., Ltd., Ningbo, China) and the no-tillage seeder (2BM-2) were used (Figure 5). For the no-tillage seeder, two kinds of press rollers were installed on each side. One side was the BPPD, and the other side was the traditional press roller.

Figure 5.

The field test.

2.3. Experimental Design

An orthogonal design of three-factor and three-level (L9(34)) was used for the experiment. The experimental factors were the kind of press roller and the operating parameters of the BPPD. There were three types of press rollers: rubber (RPR), planar (PPR) and squirrel-cage (SPR) (Figure 6). The operating parameters consisted of the combination of three spring deformations (10 mm, 20 mm, and 30 mm) and three forward speeds (3 km/h, 5 km/h and 7 km/h), as shown in Table 2. Each treatment test was repeated three times test was replicated 3 times; thus, 27 tests were performed in the field.

Figure 6.

The types of press rollers: (a) the RPR and SPR; (b) the PPR and SPR.

Table 2.

Factor coding and experimental levels.

2.4. Experimental Indexes

2.4.1. Measurement of Soil Moisture Content

The soil moisture content was measured manually with TZS-1k (the accuracy error of the precision is less than or equal to 2%). The measurement time was from the beginning of the seeding stage (the height of the sprout was approximately 20 mm) to the elongation stage (when the ear differentiated to elongation, the stem near the soil was approximately 20 mm). Measurements were made at 8:00 a.m. on the 14th day after seeding. Each zone was measured separately 3 times randomly. Figure 7 shows how the soil moisture content was measured in the field.

Figure 7.

Measurements of soil moisture content at the seeding stage.

2.4.2. Measurement of the Emergence Ratio and Average Emergence Time Eight

A 5-m count zone was randomly chosen, and the number of emergences was counted in every experimental zone from the first day of emergence. To reduce the manual counting error, 3 testers were arranged to count the number of emergences in every experimental zone at 5 p.m. The test was finished when the emergence ratio in the experimental zone stopped changing. The calculation formula for the emergence ratio is Formula (3). The calculation formula for the average emergence time is Formula (4) [25].

where S is the total number of emergences in the experimental zone, M is the total seeding number in the experimental zone, PE is the emergence ratio, MET is the average emergence time, N1, …, n is the number of emergences since the time of the previous count and T1, …, n is the number of days after seeding.

2.4.3. Measurement of the Uniformity of the Plant Height

The uniformity of the plant height is one of the most important indexes to evaluate the growth status of corn [32]. It directly influences the ultimate yield. The uniformity of the plant height needs to be measured in the trefoil stage of the corn seedling. Five seedlings were selected for height measurement in each experimental zone. The method of measurement was to measure the height of the seedlings with a dividing ruler on the 21st day after seeding. Then, the measurement data were processed, and the formula for uniformity of the plant height is as follows.

where k is the uniformity of the plant height, is the average height of the seedling, X is the height of the seedling and N is the number of measured seedlings.

2.5. Data Analysis

- (1)

- Analysis of variance

Analysis of variance (ANOVA), which was conducted by statistical software (IBM SPSS Statistic), was used to examine the effects of the experimental factors (speeds, press rollers) on the soil moisture content, emergence time, emergence ratio, and plant height uniformity. The means between treatments were compared with Duncan’s multiple range tests at the significance level of 0.05.

- (2)

- Standardized treatment

The measurement units of the four test indicators are different, the test index values need to be standardized before the comprehensive weighted analysis, and the standardized formula is

where Rin is the n test standard value of the i indicator, Tin is the n test value of the i indicator, TiM and TiN are the maximum and minimum values of the i indicator.

Using Equation (6), we can obtain the corresponding standard values of each indicator, which is composed of a relationship matrix

- (3)

- Indicator Weights

In the process of suppression operations, traction is not the main consideration, but the amount of soil adhesion will have a significant impact on the quality of the operation, according to expert experience, the sovereign weights of the four indicators are determined to be U = [0.2,0.3,0.3,0.2]. Using the formula Y = UR. Finally, the composite score for an indicator was obtained, where the smaller the score, the better.

3. Field Test Results

3.1. Effect of Test Factors on Working Performance

Results of the orthography experiment were shown in Table 3. According to the analysis results, the weight of the factors affecting the soil moisture content is A > C > B, and the optimal levels of the factors is A1, B2 and C2, and the optimal combination is A1B2C2; the weight of the factors affecting the average emergence time is A > C > B, and the optimal levels of the factors is A3, B3 and C1, and the optimal combination is A3B3C1; the weight of the factors affecting the emergence ratio is A > B > C, and the optimal levels of the factors is A2, B2 and C2, and the optimal combination is A2B2C2; the weight of the factors affecting the uniformity of the plant is B > C > A, and the optimal levels of the factors is A2, B1 and C2, and the optimal combination is A2B1C2.

Table 3.

Results of the orthography experiment and range analysis.

The variance of the test results, shown in Table 3, was analyzed by the statistics software Design-expert10.0.4 to study the influence of the test factors on the evaluation indicators.

It can be seen from Table 4 that in the indicators of soil moisture content, factors A, B and C are significant; in the average emergence time index, factors B and C are relatively significant, and factor A is highly significant; in the emergence ratio index, factors B and C are significant, and factor A is highly significant; in the plant height uniformity index, factors A and B are relatively significant, and factor B is significant. The test factors have a significant impact on the evaluation index, which shows that the selection of test factors is reasonable, and the test arrangement is appropriate.

Table 4.

The variance analysis.

3.2. Comprehensive Optimization of Experimental Factors

The index data in Table 3 are standardized, and the data is comprehensively weighted according to the results shown in Table 5. The comprehensive score values, shown in Table 6, are obtained according to Equation (6). The smaller the overall score, the better.

Table 5.

The value of comprehensive evaluation.

Table 6.

The range analysis of comprehensive scores.

The comprehensive score value of A2B2C2 is the smallest, while the optimal parameter combination are selected as: press roller type PPR, spring deformation 20 mm, and forward speed 5 km/h, as shown in Table 6.

4. Discussion

All of the experimental indexes were significantly different among the three press roller under different working conditions in Table 4, which showed that it is necessary to select the appropriate press roller for the BPPD. Table 3 shows that the SPR was different from the former two types and resulted in the lowest soil moisture content. The possible reason for this result is that when the SPR was operating, there was intermittent compaction of the soil, so parts of the soil were not completely compacted which led to an increase in the water evaporation [33]. Under the same loads and forward speed, the PPR made the soil-contact area larger than that of the RPR. The main reason is that the deeper the soil is compacted, the tighter the topsoil will be. This can effectively control water evaporation.

It can be seen from Table 3 that when the operating speed increases, it is difficult to cover the disturbed soil, which could lead to different depths of the seeds. In addition, the higher the working speed, the higher the working efficiency, which is better for agricultural production. However, this is not suitable for agricultural machinery equipment in hilly areas, because the higher the operating speed, the higher the probability of the tractor rolling over, which is not good for the operation. Thus, selecting low forward speed is appropriate for hilly areas. When the BPPD operated at 3 km/h and 5 km/h, the working performance indexes were almost the same, so to guarantee the operating efficiency and effectiveness, operating under 5 km/h is a better choice, which is consistent with the optimization results.

When the press roller type is certain, the compaction performance is determined by the forward speed and press load [25], and there is a positive correlation between velocity and press load. When the spring deformation was 20 mm, the corresponding grounding pressures were within the range 30–50 kPa, which met the grounding pressure requirements of corn growth in strong spring wind conditions in the hilly areas of Northeast China. In conclusion, press roller type PPR, spring deformation 20 mm, and forward speed 5 km/h is the ideal combination for the BPPD. A possible reason is that the soil can maintain the highest moisture content and highest temperature under these conditions. The adequate water and proper temperature shortened the time (from dormancy to germination) that the corn seed needed, accelerating the germination of the seed [28,34].

Compared with the traditional press device, the bidirectional profiling press device, a suitable press device for hilly areas of Northeast China, can be adjusted to meet the pressing strength requirements of different crops, and the spring parts can be replaced quickly. During the experiment, it was found that a certain profiling lag phenomenon occurs, which has little impact on the operation quality, but it is still necessary to improve the overall structure of the device, especially the longitudinal dimension. Besides, the real-time adaptive system of strength and profiling adjustment are the development direction of the press device. In follow-up studies, an intelligent control system will be added to improve the working performance of the bidirectional profiling press device.

5. Conclusions

Aiming at the ridge cultivation mode of corn in the hilly area of Northeast China, this study designed the BPPD, which had good effects on the seedbed properties and corn emergence. In this study, field tests were conducted to measure the soil moisture content, average emergence time, emergence ratio, and the uniformity of the plant height of three kinds of press rollers (RPR, PPR, and SPR) with three spring deformations (10 mm, 20 mm, and 30 mm) and three forward speeds (3 km/h, 5 km/h, and 7 km/h). Using statistical analysis software, the result of the orthogonal test are: factors press roller type, spring deformation and forward speed have significant influence on the test indexes of soil moisture content, average emergence time, emergence ratio, and plant height uniformity which factor press roller type have highly significant influence on the average emergence time and emergence ratio index. Using a comprehensive weighted algorithm, the sequence of factors affecting the BPPD performance was determined: spring deformation, forward speed, and press roller type; optimal combination: press roller type PPR, a spring deformation of 20 mm, and a forward speed of 5 km/h.

Author Contributions

Conceptualization, methodology, resources, formal analysis, investigation, validation, writing—original draft, data curation, visualization, H.L. and W.Z.; supervision, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the rice-wheat green full unmanned production equipment and technology popularization and application (Grant No. NJ2021-58), the National Key Research and Development Program of China (Grant No. 2021YFD2000401), the Jiangsu Provincial Natural Science Foundation of China (Grant No. BK20211021), the Jiangsu Province Agricultural Science and Technology Independent Innovation Fund (Grant No. CX(21)3143) and the Technology Support Plan (Grant No. 2016YFD0300803-09).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tian, Y.G. GIS-Based National Soil Quality Assessment Methodology and Its Application. Ph.D. Thesis, Huazhong Agricultural University, Wuhan, China, 2003. [Google Scholar]

- Chen, Y.; Xiao, B.; Fang, L.; Ma, H.; Yang, R.; Yi, X.; Li, Q. The quality analysis of cultivated land in China. Sci. Agric. Sin. 2011, 44, 3557–3564. [Google Scholar]

- Liu, H.R. Study on Evaluation Parameters of Cultivated Land-Taking Heilongjiang Province as an Case; China University of Geosciences: Beijing, China, 2018. [Google Scholar]

- Han, C.; Chen, S.; Yu, Y.; Xu, Z.; Zhu, B.; Xu, X.; Wang, Z. Evaluation of agricultural land suitability based on RS, AHP, and MEA: A case study in Jilin Province, China. Agriculture 2021, 11, 370. [Google Scholar] [CrossRef]

- Wang, L.; Hao, D.C.; Fan, S.; Xie, H.; Bao, X.; Jia, Z.; Wang, L. N2O emission and nitrification/denitrification bacterial communities in upland black soil under combined effects of early and immediate moisture. Agriculture 2022, 12, 330. [Google Scholar] [CrossRef]

- Jia, H.L.; Ma, C.L.; Li, H.Z.; Cheng, Z.L. Tillage soil protection of black soil zone in Northeast of China based on analysis of conservation tillage in the United States. Trans. Chin. Soc. Agric. Mach. 2010, 41, 28–34. [Google Scholar]

- Yang, W.; Zhang, M.; Song, F.; Liu, S.; Li, X.; Zhu, X. Comparative Analysis of Arbuscular Mycorrhizal Fungal Communities between Farmland and Woodland in the Black Soil Region of Northeast China. Agriculture 2021, 11, 866. [Google Scholar] [CrossRef]

- Gao, H.; Li, W.; Li, H. Conservation tillage technology with Chinese characteristics. Trans. Chin. Soc. Agric. Eng. 2003, 19, 1–4. [Google Scholar]

- Liu, H.J.; Han, J.Y.; Chen, J.Q.; Lv, J.Q.; Zhao, S.H. Performance simulation and experiment on rigid press wheel for hilly area. Trans. Chin. Soc. Agric. Mach. 2018, 49, 114–126. [Google Scholar]

- Liu, X.B.; Zhang, S.L.; Zhang, X.Y.; Ding, G.W.; Cruse, R.M. Soil erosion control practices in Northeast China: A mini-review. Soil Tillage Res. 2011, 117, 44–48. [Google Scholar] [CrossRef]

- Chen, X. Study on Comprehensive Productivity in the Northeast Region of China Based on Cultivated Land Classification; China University of Geosciences: Beijing, China, 2008. [Google Scholar]

- Zhang, P. Resource Estimation and Potential of Main Crop Straw and Stalk in Heilongjiang Land-Reclamation Area; Northeast Agricultural University: Harbin, China, 2017. [Google Scholar]

- Luo, J.; Zhan, J.Y.; Lin, Y.Z.; Zhao, C.H. An equilibrium analysis of the land use structure in the Yunnan Province, China. Front. Earth Sci. 2014, 8, 393–404. [Google Scholar] [CrossRef]

- Liu, H. Research on Key Technologies of Press Device for Planter in Hilly Region of Northeast China; Northeast Agricultural University: Harbin, China, 2019. [Google Scholar]

- Vaibhav, C.; Alfred, S.; Hari, S.; Justin, G.K.; Fakhereh, A. Assessing and transferring soil health information in a hilly terrain. Geoderma 2019, 343, 130–138. [Google Scholar]

- He, J.; Li, H.W.; Chen, H.T.; Lu, C.Y.; Wang, Q.J. Research progress of conservation tillage technology and machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar]

- Jia, H.L.; Zhao, J.L.; Jiang, X.M.; Jiang, T.J.; Wang, Y.; Guo, H. Design and experiment of anti-blocking mechanism for inter-row no-tillage seeder. Trans. Chin. Soc. Agric. Eng. 2013, 29, 16–25. [Google Scholar]

- Xu, Y. Study on Agricultural Mechanization Development in Hilly and Mountain Areas of Zhejiang Province; Zhejiang University: Hangzhou, China, 2017. [Google Scholar]

- Duan, H.; Chen, Z.; Song, B.; Yu, C.; Xu, T. Design and experiment of triangular chain half cup spoon-shaped potato precision planter in hilly mountainous areas. Trans. Chin. Soc. Agric. Mach. 2019, 50, 96–104. [Google Scholar]

- Yao, L.; Cao, X.; Dong, L.; Chen, D. Design and experiment on small-size peanut planter in red soil hilly region. Acta Agric. Jiangxi 2015, 27, 78–80. [Google Scholar]

- Wang, L.; He, C.; Zheng, F.; Bian, F.; Qin, C.; Xu, X. Soil-bin experiment on effects of contour ridge tillage for controlling hillslope soil erosion in black soil region. Trans. Chin. Soc. Agric. Eng. 2018, 34, 141–148. [Google Scholar]

- Guo, J.; Fu, H.; Yang, Z.; Li, J.; Jiang, Y.; Jiang, T.; Liu, E.; Duan, J. Research on the physical characteristic parameters of banana bunches for the design and development of postharvesting machinery and equipment. Agriculture 2021, 11, 362. [Google Scholar] [CrossRef]

- Altikat, S.; Celik, A.; Turgut, N. The effects of different soil particle size distribution and seed row compaction levels on the germination and yield of spring wheat. Ataturk Univ. J. Agric. Fac. 2006, 37, 197–205. [Google Scholar]

- Altikat, S.; Celik, A. The effects of tillage and intra-row compaction on seedbed properties and red lentil emergence under dry land conditions. Soil Tillage Res. 2011, 114, 1–8. [Google Scholar] [CrossRef]

- Jia, H.L.; Wang, W.J.; Luo, X.F.; Zheng, J.X.; Guo, M.Z.; Zhuang, J. Effects of profiling elastic press roller on seedbed properties and soybean emergence under double row ridge cultivation. Soil Tillage Res. 2016, 162, 34–40. [Google Scholar] [CrossRef]

- Wilkes, L.H.; Hobgood, P. A new approach to field production. Trans. ASAE 1969, 12, 529–532. [Google Scholar]

- Gan, Y.; Stobe, E.; Moes, J. Relative data of wheat seedling emergence and its impact on grain yields. Crop Sci. 1992, 32, 1275–1281. [Google Scholar] [CrossRef]

- Gemtos, T.A.; Lellis, T.H. Effects of soil compaction, water and organic matter contents on emergence and initial plant growth of cotton and sugar beet. J. Agric. Eng. Res. 1997, 66, 121–134. [Google Scholar] [CrossRef]

- Nasr, H.M.; Selles, F. Seedling emergence as influenced by aggregate size, bulk density, and penetration resistance of the seedbed. Soil Tillage Res. 1995, 34, 61–76. [Google Scholar] [CrossRef]

- Zhao, S.; Jiang, E.; Yan, Y.; Yang, Y.; Tian, B. Design and motion simulation of opener with bidirectional parallelogram linkage profiling mechanism on wheat seeder. Trans. Chin. Soc. Agric. Eng. 2013, 29, 26–32. [Google Scholar]

- Zhao, S.H.; Liu, H.J.; Tan, H.W.; Yang, Y.Q.; Zhang, X.M. Design and experiment of bidirectional profiling press device for hilly area. Trans. Chin. Soc. Agric. Mach. 2017, 48, 82–89. [Google Scholar]

- Liu, W.; Tollenaar, M.; Stewart, G.; Deen, W. Within-row plant spacing variability does not affect corn yield. Agron. J. 2004, 96, 275–280. [Google Scholar] [CrossRef]

- Shafiq, M.; Hassan, A.; Ahmad, S. Soil physical properties as influenced by induced compaction under laboratory and field conditions. Soil Tillage Res. 1994, 29, 13–22. [Google Scholar] [CrossRef]

- Mosaddeghi, M.R.; Hajabbasi, M.A.; Hemmat, A.; Afyuni, M. Soil compactibility as affected by soil moisture content and farmyard manure in central Iran. Soil Tillage Res. 2000, 55, 87–97. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).