Quality Assurance of International Fruit Supply Chains via Techno-Management

Abstract

1. International Tropical Fruit Supply Chain Situation in the Present Day

2. Techno-Managerial Perspectives in International Tropical Fruit Supply Chains

2.1. Technological Approach

- Initial bacterial load (Presence of a high initial bacterial load can increase spoilage, which causes shorter shelf life.)

- Temperature (Low temperature reduces the respiration rate due to lower oxygen diffusion gradient.)

- Humidity (High relative humidity (RH) is favorable for growth of molds because of high water activity for mold to grow.)

- Atmosphere (Controlled atmosphere is an agricultural storage method in which the concentrations of oxygen, carbon dioxide, and nitrogen are regulated, which can slow down respiration and decay.) [13].

2.2. Techno-Managerial Approach

- Agricultural products are often perishable and likely to decay rapidly due to physiological processes and/or microbiological contamination.

- Most agricultural products are harvested seasonally.

- Products are often variable owing to different cultivation and seasonal variables, which may be difficult to monitor.

- Numerous farms operate production on a small scale.

- Food safety-based standards

- Accredited, recognized standards

- Defined auditor criteria

- Third-party certification

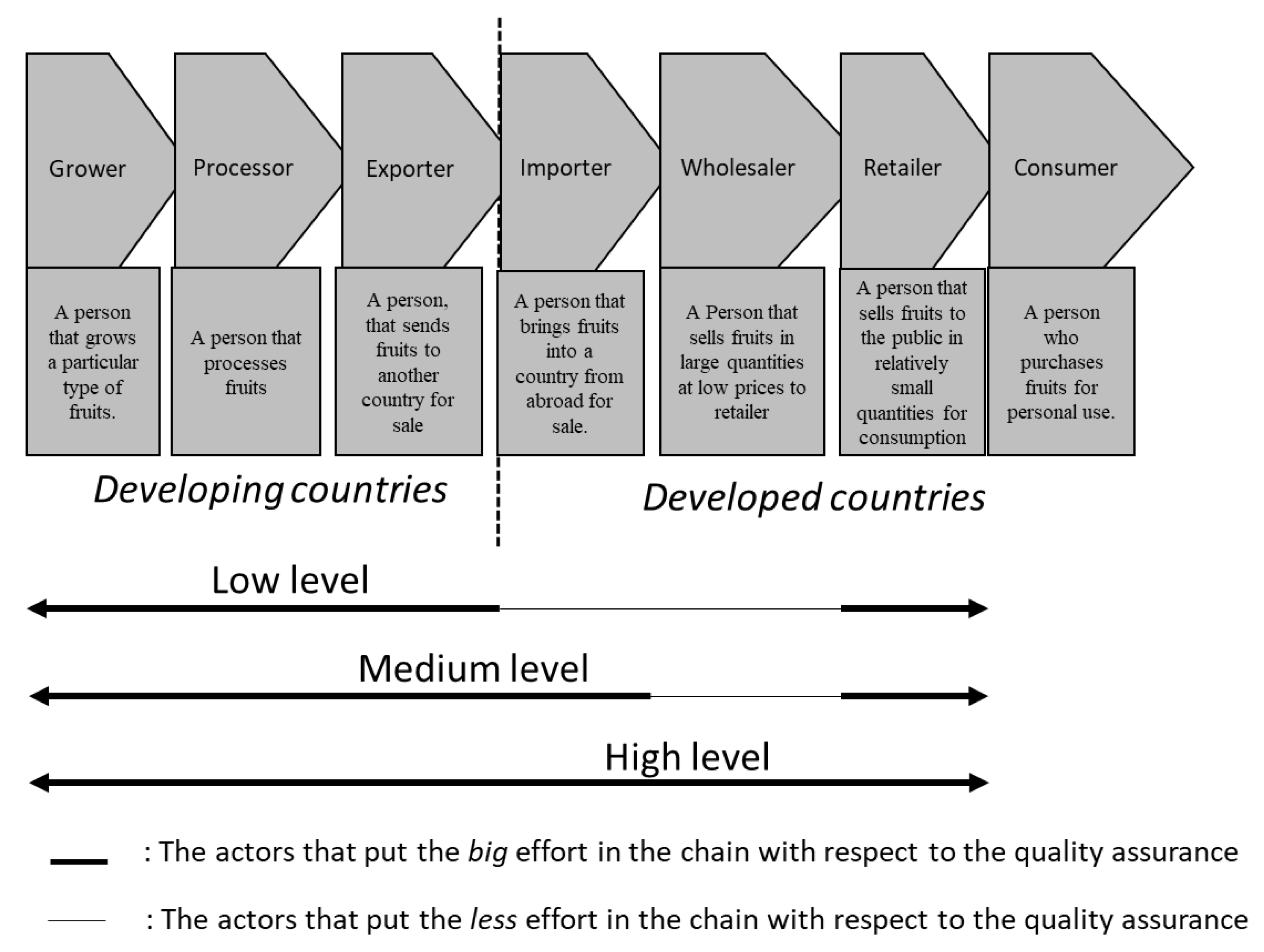

2.3. Managerial Approach

Chain Participation

3. Materials and Methods

3.1. Development of the Research Model

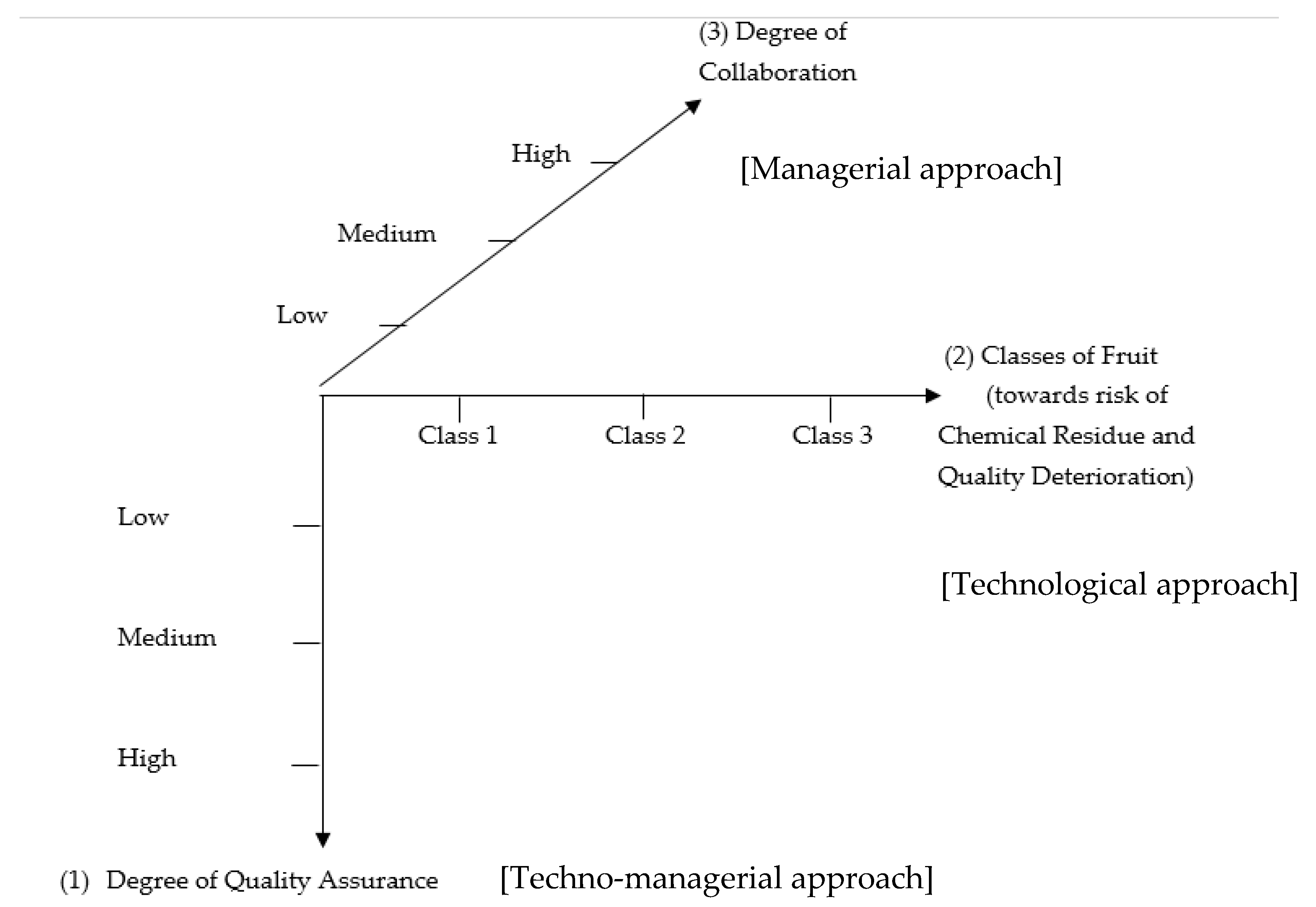

3.2. Explanation of Three Axes

3.2.1. Axis 1: The Degree of Quality Assurance

3.2.2. Axis 2: The Degree of Exposure to Safety and Constant Quality

3.2.3. Axis 3: The Degree of Collaboration Complexity of the Chains

3.3. Model Assessment

3.4. Evaluation of Research Model

3.4.1. Questionnaire

3.4.2. Qualitative Approach

4. Results

4.1. The Result of Part 1

4.2. The Result of Part 2

4.3. The Result of Part 3

5. Discussion

6. Conclusions and Implications for Future Research

Author Contributions

Funding

Conflicts of Interest

References

- King, T.; Cole, M.; Farber, J.M.; Eisenbrand, G.; Zabaras, D.; Fox, E.M.; Hill, J.P. Food safety for food security: Relationship between global megatrends and developments in food safety. Trends Food Sci. Technol. 2017, 68, 160–175. [Google Scholar] [CrossRef]

- Abdullah, D.; Hamir, N.; Nor, N.M.; Krishnaswamy, J.; Rostum, A.M.M. Food quality, service quality, price fairness and restaurant re-patronage intention: The mediating role of customer satisfaction. Int. J. Acad. Res. Bus. Soc. Sci. 2018, 8, 211–226. [Google Scholar]

- Beitzen-Heineke, E.F.; Balta-Ozkan, N.; Reefke, H. The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J. Clean. Prod. 2017, 140, 1528–1541. [Google Scholar] [CrossRef]

- Calicioglu, O.; Flammini, A.; Bracco, S.; Bellù, L.; Sims, R. The Future Challenges of Food and Agriculture: An Integrated Analysis of Trends and Solutions. Sustainability 2019, 11, 222. [Google Scholar] [CrossRef]

- Artés-Hernández, F.; Martinez-Hernández, G.B.; Aguayo, E.; Gómez, P.A.; Artés, F. Fresh-cut fruit and vegetables: Emerging eco-friendly techniques for sanitation and preserving safety. Postharvest Handl. 2017, 7–45. [Google Scholar] [CrossRef]

- Iqbal, M.; Kachroo, J.; Sehar, H.; Kachroo, D. Income and employment increasing potentiality in various farming systems of various zones of Jammu regions. J. Pharmacogn. Phytochem. 2018, 7, 180–185. [Google Scholar]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Harvest and Postharvest Factors Affecting Bruise Damage of Fresh Fruits. Hortic. Plant J. 2020, 6, 1–13. [Google Scholar] [CrossRef]

- Milios, K.; Zoiopoulos, P.E.; Pantouvakis, A.; Mataragas, M.; Drosinos, E.H. Techno-managerial factors related to food safety management system in food businesses. Br. Food J. 2013, 115, 1381–1399. [Google Scholar] [CrossRef]

- Salman, L.; Ahmed, I. Evaluation of Some Pesticide Residues in Fruits import by High Performance Liquid Chromatography. Al-Mustansiriyah J. Sci. 2017, 27. [Google Scholar] [CrossRef]

- Sudheer, K.; Indira, V. Post Harvest Technology of Horticultural Crops; New India Publishing: New Delhi, India, 2007; Volume 7. [Google Scholar]

- Farcuh, M.; Rivero, R.M.; Sadka, A.; Blumwald, E. Ethylene regulation of sugar metabolism in climacteric and non-climacteric plums. Postharvest Biol. Technol. 2018, 139, 20–30. [Google Scholar] [CrossRef]

- Park, S.; Szonyi, B.; Gautam, R.; Nightingale, K.; Anciso, J.; Ivanek, R. Risk factors for microbial contamination in fruits and vegetables at the preharvest level: A systematic review. J. Food Prot. 2012, 75, 2055–2081. [Google Scholar] [CrossRef] [PubMed]

- Nirmal, N.P.; Benjakul, S.; Ahmad, M.; Arfat, Y.A.; Panichayupakaranant, P. Undesirable Enzymatic Browning in Crustaceans: Causative Effects and Its Inhibition by Phenolic Compounds. Crit. Rev. Food Sci. Nutr. 2015, 55, 1992–2003. [Google Scholar] [CrossRef] [PubMed]

- Chudnova, O.A.; Oleinik, E.A.; Melnikov, P.A. Dairy products quality assurance at the consumer market in compliance with EEC requirements. IOP Conf. Ser. Earth Environ. Sci. 2020, 422, 012041. [Google Scholar] [CrossRef]

- Bhat, R.; Jõudu, I. Chapter 2—Emerging issues and challenges in agri-food supply chain. In Sustainable Food Supply Chains; Accorsi, R., Manzini, R., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 23–37. ISBN 978-0-12-813411-5. [Google Scholar]

- Dudin, M.N.; Frolova, E.E.; Gryzunova, N.V.; Shuvalova, E.B. The deming cycle (PDCA) concept as an efficient tool for continuous quality improvement in the agribusiness. Asian Soc. Sci. 2014, 11, 239–246. [Google Scholar] [CrossRef]

- He, Y.; Huang, H.; Li, D.; Shi, C.; Wu, S.J. Quality and Operations Management in Food Supply Chains: A Literature Review. J. Food Qual. 2018, 2018, 1–14. [Google Scholar] [CrossRef]

- Basir, S.A.; Davies, J.; Douglas, J.; Douglas, A. The influence of academic culture on quality management system ISO 9001 maintenance within Malaysian universities. J. High. Educ. Policy Manag. 2017, 39, 320–340. [Google Scholar] [CrossRef]

- Wognum, P.M.; Bremmers, H.; Trienekens, J.H.; van der Vorst, J.G.A.J.; Bloemhof, J.M. Systems for sustainability and transparency of food supply chains—Current status and challenges. Adv. Eng. Inform. 2011, 25, 65–76. [Google Scholar] [CrossRef]

- MacCarthy, B.L.; Blome, C.; Olhager, J.; Srai, J.S.; Zhao, X. Supply chain evolution—Theory, concepts and science. Int. J. Oper. Prod. Manag. 2016, 36, 1696–1718. [Google Scholar] [CrossRef]

- Al-Tabbaa, O.; Ankrah, S. Social capital to facilitate ‘engineered’ university–industry collaboration for technology transfer: A dynamic perspective. Technol. Forecast. Soc. Chang. 2016, 104, 1–15. [Google Scholar] [CrossRef]

| Actors in the Chain and Quality Perception | |||||

|---|---|---|---|---|---|

| Breeder | Grower | Auction | Distribution and Storage | Retailer | Consumer |

| Vitality seeds, yield | Productivity, uniformity, disease resistance | Uniformity, reliable supply, constant quality | Keepability, availability, damage sensitivity | Good shelf-life, diversity, appearance, low waste | Taste, health, sustainable, convenience, constant quality |

| Qualifications | Degree of Quality Assurance | ||

|---|---|---|---|

| Low Level | Medium Level | High Level | |

| Legislation | Yes | Yes | Yes |

| Food Safety-Based Standard | Yes | Yes | Yes |

| Constant Quality Standard | Low | Low | High |

| Transparency in its Safety | Medium | High | High |

| Third-Party Certification (regarding food safety and constant quality) | No | Yes | Yes |

| Standards that will be applied to the chain | MRLS, GAP or GMP, and CODEX | MRLS, GAP or GMP, HACCP, and CODEX | MRLS, GAP or GMP, HACCP, BRC and/or EUREP-GAP, and ISO |

| Factors | Classes of the Fruits with Respect to Safety and Constant Quality | ||

|---|---|---|---|

| Class 1 | Class 2 | Class 3 | |

| Product characteristics towards safety | Fruits enclosed with thick peels which are removed before consumption | Fruits enclosed with peels which are permeable (Chemical residue can penetrate the skin.) | Fruits which are normally consumed with skin |

| Degree of perishability towards constant quality | Slow perishable rate or long shelf life | Moderately fast perishable rate or medium-short shelf life | Moderately fast perishable rate or medium-short shelf life |

| Examples of commodities | Durian | Pineapple, mango, banana, papaya, and passion fruit | Guava |

| Classes of Tropical Fruits towards Safety and Constant Quality | Degree of Quality Assurance | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Low | Medium | High | |||||||

| Degree of Collaboration | Degree of Collaboration | Degree of Collaboration | |||||||

| Low | Medium | High | Low | Medium | High | Low | Medium | High | |

| Class 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Class 2 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Class 3 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 |

| Factor | Situation | ||||

|---|---|---|---|---|---|

| Situation 1 | Situation 2 | Situation 3 | Situation 4 | Situation 5 | |

| Class of fruits | Fruits that have thick peels and low perish-ability rate, such as pineapple | Fruits that have permeable peels which are removed before consumption, such as mango and banana | Fruits that have permeable peels which are removed before consumption, such as mango and banana | Fruits that have peels which are consumed, such as guava | Fruits that have peels which are consumed, such as guava |

| Degree of quality assurance | MRLs, GAP or GMP, and Codex | MRLs, GAP or GMP, and Codex | MRLs, GAP or GMP, and HACCP and Codex | MRLs, GAP or GMP, and HACCP and Codex | MRLs, GAP or GMP or Hygiene Code, HACCP, EUREP-GAP and/or BRC, and ISO |

| Degree of chain collaboration | There is participation between retailer, grower, processor, and exporter | There is participation between retailer, grower, processor, and exporter | There is participation between retailer, grower, processor, exporter, and importer | There is participation between retailer, grower, processor, exporter, and importer | There is participation between retailer, grower, processor, exporter, importer, and wholesaler |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodjanatham, T.; Rabgyal, T. Quality Assurance of International Fruit Supply Chains via Techno-Management. Agriculture 2020, 10, 107. https://doi.org/10.3390/agriculture10040107

Rodjanatham T, Rabgyal T. Quality Assurance of International Fruit Supply Chains via Techno-Management. Agriculture. 2020; 10(4):107. https://doi.org/10.3390/agriculture10040107

Chicago/Turabian StyleRodjanatham, Tippawong, and Tenzin Rabgyal. 2020. "Quality Assurance of International Fruit Supply Chains via Techno-Management" Agriculture 10, no. 4: 107. https://doi.org/10.3390/agriculture10040107

APA StyleRodjanatham, T., & Rabgyal, T. (2020). Quality Assurance of International Fruit Supply Chains via Techno-Management. Agriculture, 10(4), 107. https://doi.org/10.3390/agriculture10040107