Applications of Reverse Osmosis and Nanofiltration Membrane Process in Wine and Beer Industry

Abstract

1. Introduction

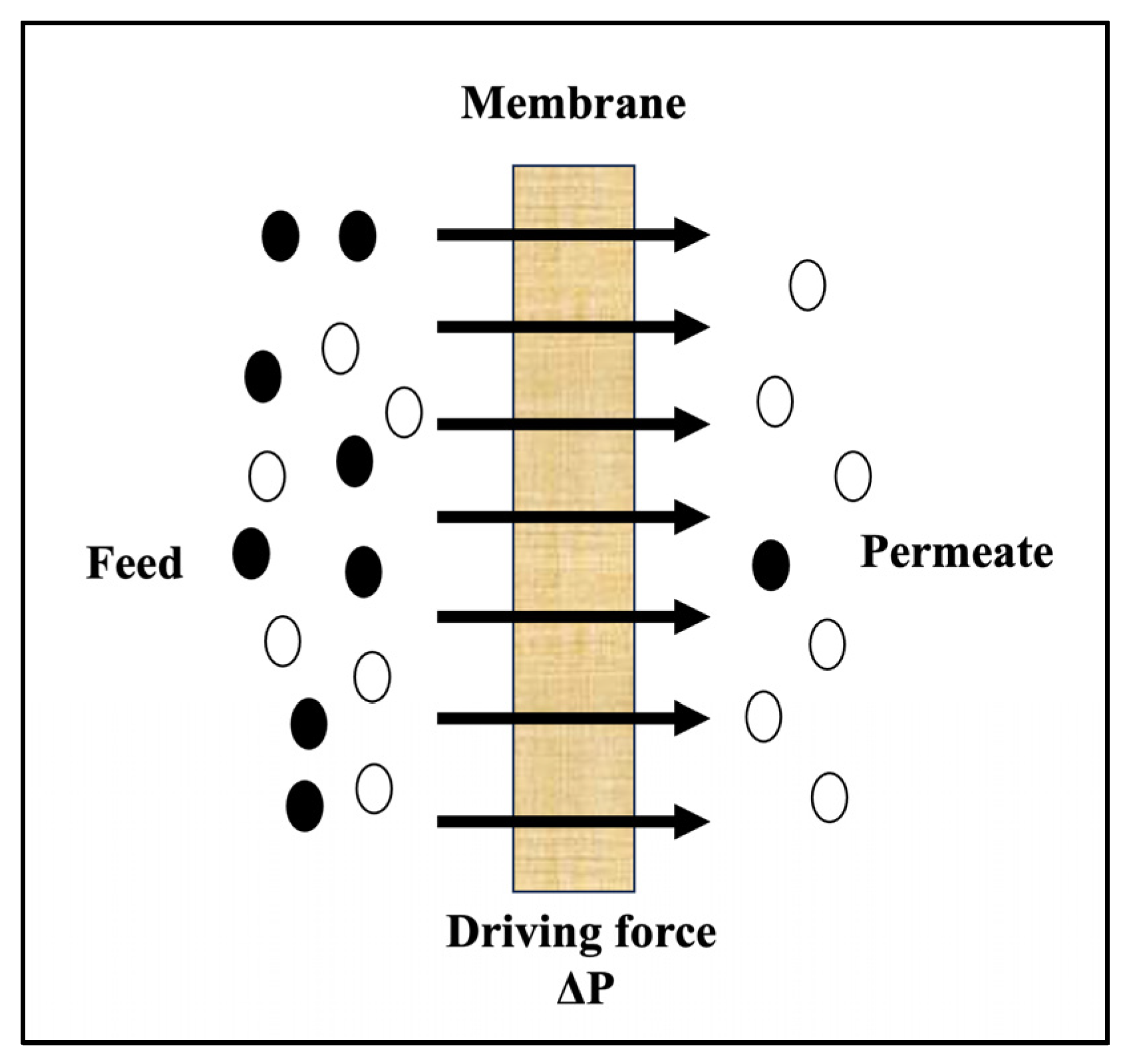

2. Fundamentals of RO and NF Membrane Processes

- J (L/m2h) = permeate flux;

- Lp (L/m2hbar) = permeability;

- P (bar) = applied pressure;

- V (L) = collected permeate volume during the process;

- A (m2) = effective membrane area;

- t (h) = operating time.

- Cpi = concentration of i compound in the permeate;

- Cri = concentration of i compound in the retentate side.

3. Wine Industry

3.1. Concentration of Must and Sugar Adjustment

3.2. Dealcoholization

3.3. Recovery of Valuable By-Products

3.4. Wastewater Treatment

4. Beer Industry

4.1. Alcohol-Free and Low-Alcohol Beer Production

4.2. Removal of Undesirable Components

4.3. Innovations in Hop and Flavor Compound Retention During Dealcoholization

4.4. Water Reuse and Treatment in Breweries

4.5. Impact on Energy Efficiency and Sustainability

5. Challenges and Limitations of RO and NF in the Industry

5.1. Membrane Fouling and Cleaning Requirements

5.2. Energy Consumption and Operational Costs

5.3. Impact on Sensory Quality and Product Stability

5.4. Regulatory Considerations and Consumer Acceptance

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chan, S.M.; Adzahan, N.M.; Ab Karim, M.S.; Karim, R.; Lasekan, O.; Regenstein, J.M. Consumer Preferences and Perceptions on Dealcoholised Wine. J. Food Prod. Mark. 2012, 18, 65–77. [Google Scholar] [CrossRef]

- Silva, P. Low-Alcohol and Nonalcoholic Wines: From Production to Cardiovascular Health, along with Their Economic Effects. Beverages 2024, 10, 49. [Google Scholar] [CrossRef]

- Kumar, Y.; Ricci, A.; Parpinello, G.P.; Versari, A. Dealcoholized Wine: A Scoping Review of Volatile and Non-Volatile Profiles, Consumer Perception, and Health Benefits. Food Bioprocess Technol. 2024, 17, 3525–3545. [Google Scholar] [CrossRef]

- Sam, F.E.; Ma, T.-Z.; Salifu, R.; Wang, J.; Jiang, Y.-M.; Zhang, B.; Han, S.-Y. Techniques for Dealcoholization of Wines: Their Impact on Wine Phenolic Composition, Volatile Composition, and Sensory Characteristics. Foods 2021, 10, 2498. [Google Scholar] [CrossRef]

- Teow, Y.H.; Sum, J.Y.; Ho, K.C.; Mohammad, A.W. Principles of Nanofiltration Membrane Processes. In Osmosis Engineering; Elsevier: Amsterdam, The Netherlands, 2021; pp. 53–95. ISBN 978-0-12-821016-1. [Google Scholar]

- Shenvi, S.S.; Isloor, A.M.; Ismail, A.F. A Review on RO Membrane Technology: Developments and Challenges. Desalination 2015, 368, 10–26. [Google Scholar] [CrossRef]

- Kumar, Y.; Cassano, A.; Conidi, C.; Gottardi, D.; Ricci, A.; Parpinello, G.P.; Versari, A. Evaluation of Physicochemical Characteristics, Color and Volatile Profile of Low Alcohol Beverage Based on Concentrated White Wine Produced by NF and RO Membranes. Sep. Purif. Technol. 2025, 367, 132847. [Google Scholar] [CrossRef]

- Bóna, Á.; Varga, Á.; Galambos, I.; Nemestóthy, N. Dealcoholization of Unfiltered and Filtered Lager Beer by Hollow Fiber Polyelectrolyte Multilayer Nanofiltration Membranes—The Effect of Ion Rejection. Membranes 2023, 13, 283. [Google Scholar] [CrossRef]

- Ramsey, I.; Yang, Q.; Fisk, I.; Ayed, C.; Ford, R. Assessing the Sensory and Physicochemical Impact of Reverse Osmosis Membrane Tech-nology to Dealcoholize Two Different Beer Styles. Food Chem. X 2021, 10, 100121. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A Review on Reverse Osmosis and Nanofiltration Membranes for Water Purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef]

- Sam, F.E.; Ma, T.; Liang, Y.; Qiang, W.; Atuna, R.A.; Amagloh, F.K.; Morata, A.; Han, S. Comparison between Membrane and Thermal Dealcoholization Methods: Their Impact on the Chemical Parameters, Volatile Composition, and Sensory Characteristics of Wines. Membranes 2021, 11, 957. [Google Scholar] [CrossRef]

- García-Martín, N.; Perez-Magariño, S.; Ortega-Heras, M.; González-Huerta, C.; Mihnea, M.; González-Sanjosé, M.L.; Palacio, L.; Prádanos, P.; Hernández, A. Sugar Reduction in Musts with Nanofiltration Membranes to Obtain Low Alcohol-Content Wines. Sep. Purif. Technol. 2010, 76, 158–170. [Google Scholar] [CrossRef]

- García-Martín, N.; Perez-Magariño, S.; Ortega-Heras, M.; González-Huerta, C.; Mihnea, M.; González-Sanjosé, M.L.; Palacio, L.; Prádanos, P.; Hernández, A. Sugar Reduction in White and Red Musts with Nanofiltration Membranes. Desalination Water Treat. 2011, 27, 167–174. [Google Scholar] [CrossRef]

- El Rayess, Y.; Castro-Muñoz, R.; Cassano, A. Current Advances in Membrane Processing of Wines: A Comprehensive Review. Trends Food Sci. Technol. 2024, 147, 104453. [Google Scholar] [CrossRef]

- Ivić, I.; Kopjar, M.; Obhođaš, J.; Vinković, A.; Pichler, D.; Mesić, J.; Pichler, A. Concentration with Nanofiltration of Red Wine Cabernet Sauvignon Produced from Conventionally and Ecologically Grown Grapes: Effect on Volatile Compounds and Chemical Composition. Membranes 2021, 11, 320. [Google Scholar] [CrossRef]

- Giacobbo, A.; Moura Bernardes, A.; Filipe Rosa, M.; De Pinho, M. Concentration Polarization in Ultrafiltration/Nanofiltration for the Recovery of Polyphenols from Winery Wastewaters. Membranes 2018, 8, 46. [Google Scholar] [CrossRef]

- Oro, C.E.D.; Puton, B.M.S.; Venquiaruto, L.D.; Dallago, R.M.; Arend, G.D.; Tres, M.V. The Role of Membranes in Modern Winemaking: From Clarification to Dealcoholization. Membranes 2025, 15, 14. [Google Scholar] [CrossRef]

- Genova, J.; Dencheva-Zarkova, M.; Yankov, D.; Tsibranska, I. Influence of Transmembrane Pressure on the Retention of Bioactive Compounds and Alcohol Content in Red Wine Nanofiltration. WSEAS Trans. Biol. Biomed. 2024, 22, 67–71. [Google Scholar] [CrossRef]

- Artiga, P.; Carballa, M.; Garrido, J.M.; Méndez, R. Treatment of Winery Wastewaters in a Membrane Submerged Bioreactor. Water Sci. Technol. 2007, 56, 63–69. [Google Scholar] [CrossRef]

- Tapia-Quirós, P.; Montenegro-Landívar, M.F.; Reig, M.; Vecino, X.; Saurina, J.; Granados, M.; Cortina, J.L. Integration of Nanofiltration and Reverse Osmosis Technologies in Polyphenols Recovery Schemes from Winery and Olive Mill Wastes by Aqueous-Based Processing. Membranes 2022, 12, 339. [Google Scholar] [CrossRef]

- López-Borrell, A.; López-Pérez, M.-F.; Cardona, S.C.; Lora-García, J. Experimental Study and Mathematical Modeling of a Nanofiltration Membrane System for the Recovery of Polyphenols from Wine Lees. Membranes 2022, 12, 240. [Google Scholar] [CrossRef]

- Salanță, L.C.; Coldea, T.E.; Ignat, M.V.; Pop, C.R.; Tofană, M.; Mudura, E.; Borșa, A.; Pasqualone, A.; Anjos, O.; Zhao, H. Functionality of Special Beer Processes and Potential Health Benefits. Processes 2020, 8, 1613. [Google Scholar] [CrossRef]

- Nehra, M. Non Alcoholic Beers: Review and Methods. Madridge J. Food Technol. 2022, 7, 200–206. [Google Scholar] [CrossRef]

- Maeda, Y. Fouling of Reverse Osmosis (RO) and Nanofiltration (NF) Membranes by Low Molecular Weight Organic Compounds (LMWOCs), Part 1: Fundamentals and Mechanism. Membranes 2024, 14, 221. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Amin, S.; Mohamed, A.A. Fouling in Reverse Osmosis Membranes: Monitoring, Characterization, Mitigation Strategies and Future Directions. Heliyon 2023, 9, e14908. [Google Scholar] [CrossRef]

- Balcik, C. Understanding the Operational Problems and Fouling Characterization of RO Membrane Used for Brackish Water Treatment via Membrane Autopsy. Water Sci. Technol. 2021, 84, 3653–3662. [Google Scholar] [CrossRef]

- Charcosset, C. Ultrafiltration, Microfiltration, Nanofiltration and Reverse Osmosis in Integrated Membrane Processes. In Integrated Membrane Systems and Processes; Basile, A., Charcosset, C., Eds.; Wiley: Hoboken, NJ, USA, 2016; pp. 1–22. ISBN 978-1-118-73908-2. [Google Scholar]

- Charcosset, C. Classical and Recent Applications of Membrane Processes in the Food Industry. Food Eng. Rev. 2021, 13, 322–343. [Google Scholar] [CrossRef]

- Kumar, Y.; Cassano, A.; Conidi, C.; Ricci, A.; Parpinello, G.P.; Versari, A. Evaluating Membrane Behavior to Ethanol-Water Mixtures and Wine: A Comparative Investigation. LWT 2024, 201, 116228. [Google Scholar] [CrossRef]

- Destani, F.; Naccarato, A.; Tagarelli, A.; Cassano, A. Recovery of Aromatics from Orange Juice Evaporator Condensate Streams by Reverse Osmosis. Membranes 2020, 10, 92. [Google Scholar] [CrossRef]

- Ivić, I.; Kopjar, M.; Jukić, V.; Bošnjak, M.; Maglica, M.; Mesić, J.; Pichler, A. Aroma Profile and Chemical Composition of Reverse Osmosis and Nanofiltration Concentrates of Red Wine Cabernet Sauvignon. Molecules 2021, 26, 874. [Google Scholar] [CrossRef]

- Choi, J.-S.; Hwang, T.-M.; Lee, S.; Hong, S. A Systematic Approach to Determine the Fouling Index for a RO/NF Membrane Process. Desalination 2009, 238, 117–127. [Google Scholar] [CrossRef]

- Banvolgyi, S.; Savaş Bahçeci, K.; Vatai, G.; Bekassy, S.; Bekassy-Molnar, E. Partial Dealcoholization of Red Wine by Nanofiltration and Its Effect on Anthocyanin and Resveratrol Levels. Food Sci. Technol. Int. 2016, 22, 677–687. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, B.; Molino, B.; Catalano, F.; Giametta, F.; Molino, A.J.; Ambrosone, L. A Novel Approach to Optimize the Industrial Process of Membrane Concentration of Grape Musts. ChemEngineering 2023, 7, 48. [Google Scholar] [CrossRef]

- Gurak, P.D.; Cabral, L.M.C.; Rocha-Leão, M.H.M.; Matta, V.M.; Freitas, S.P. Quality Evaluation of Grape Juice Concentrated by Reverse Osmosis. J. Food Eng. 2010, 96, 421–426. [Google Scholar] [CrossRef]

- Drioli, E.; Fontananova, E. Membrane Technology and Sustainable Growth. Chem. Eng. Res. Des. 2004, 82, 1557–1562. [Google Scholar] [CrossRef]

- Pati, S.; La Notte, D.; Clodoveo, M.L.; Cicco, G.; Esti, M. Reverse Osmosis and Nanofiltration Membranes for the Improvement of Must Quality. Eur. Food Res. Technol. 2014, 239, 595–602. [Google Scholar] [CrossRef]

- Rosa Santos, F.; Catarino, I.; Geraldes, V.; Pinho, M.N. Concentration and Rectification of Grape Must by Nanofiltration. Am. J. Enol. Vitic. 2008, 59, 446–450. [Google Scholar] [CrossRef]

- Versari, A.; Ferrarini, R.; Parpinello, G.P.; Galassi, S. Concentration of Grape Must by Nanofiltration Membranes. Food Bioprod. Process. 2003, 81, 275–278. [Google Scholar] [CrossRef]

- Kiss, I.; Vatai, G.; Bekassy-Molnar, E. Must Concentrate Using Membrane Technology. Desalination 2004, 162, 295–300. [Google Scholar] [CrossRef]

- Mihnea, M.; González-SanJosé, M.L.; Ortega-Heras, M.; Pérez-Magariño, S.; García-Martin, N.; Palacio, L.; Prádanos, P.; Hernández, A. Impact of Must Sugar Reduction by Membrane Applications on Volatile Composition of Verdejo Wines. J. Agric. Food Chem. 2012, 60, 7050–7063. [Google Scholar] [CrossRef]

- Kumar, Y.; Cassano, A.; Conidi, C.; Gottardi, D.; Ricci, A.; Parpinello, G.P.; Versari, A. White Wine Dealcoholization by Osmotic Distillation: An Experimental Study and Impact on Key Quality Parameters. J. Food Eng. 2025, 391, 112456. [Google Scholar] [CrossRef]

- Italiano, L.; Kumar, Y.; Matthias, S.; Christmann, M. Evaluation of Dialysis Membrane Efficiency in Wine Dealcoholisation Process. In Proceedings of the 45th World Congress of Vine and Wine (OIV 2024), Dijon, France, 14–18 October 2024. [Google Scholar]

- Catarino, M.; Mendes, A. Dealcoholizing Wine by Membrane Separation Processes. Innov. Food Sci. Emerg. Technol. 2011, 12, 330–337. [Google Scholar] [CrossRef]

- Gil, M.; Estévez, S.; Kontoudakis, N.; Fort, F.; Canals, J.M.; Zamora, F. Influence of Partial Dealcoholization by Reverse Osmosis on Red Wine Composition and Sensory Characteristics. Eur. Food Res. Technol. 2013, 237, 481–488. [Google Scholar] [CrossRef]

- Pham, D.-T.; Ristic, R.; Stockdale, V.J.; Jeffery, D.W.; Tuke, J.; Wilkinson, K. Influence of Partial Dealcoholization on the Composition and Sensory Properties of Cabernet Sauvignon Wines. Food Chem. 2020, 325, 126869. [Google Scholar] [CrossRef]

- Peng, P.; Lan, Y.; Liang, L.; Jia, K. Membranes for Bioethanol Production by Pervaporation. Biotechnol. Biofuels 2021, 14, 10. [Google Scholar] [CrossRef]

- Verhoef, A.; Figoli, A.; Leen, B.; Bettens, B.; Drioli, E.; Van Der Bruggen, B. Performance of a Nanofiltration Membrane for Removal of Ethanol from Aqueous Solutions by Pervaporation. Sep. Purif. Technol. 2008, 60, 54–63. [Google Scholar] [CrossRef]

- Thai, P.T.N.; Pham, X.M.; Nguyen, T.B.; Le, T.M.; Viet Tran, C.B.; Phong, M.T.; Tran, L.-H. Preparation and Characterization of PVA Thin-Film Composite Membrane for Pervaporation Dehydration of Ethanol Solution. IOP Conf. Ser. Earth Environ. Sci. 2021, 947, 012010. [Google Scholar] [CrossRef]

- Kontogiannopoulos, K.N.; Patsios, S.I.; Mitrouli, S.T.; Karabelas, A.J. Tartaric Acid and Polyphenols Recovery from Winery Waste Lees Using Membrane Separation Processes: Tartaric Acid and Polyphenols Recovery from Winery Waste Lees. J. Chem. Technol. Biotechnol. 2017, 92, 2934–2943. [Google Scholar] [CrossRef]

- Bolzonella, D.; Papa, M.; Da Ros, C.; Anga Muthukumar, L.; Rosso, D. Winery Wastewater Treatment: A Critical Overview of Advanced Biological Processes. Crit. Rev. Biotechnol. 2019, 39, 489–507. [Google Scholar] [CrossRef]

- Bolzonella, D.; Fatone, F.; Pavan, P.; Cecchi, F. Application of a Membrane Bioreactor for Winery Wastewater Treatment. Water Sci. Technol. 2010, 62, 2754–2759. [Google Scholar] [CrossRef]

- Nataraj, S.K.; Hosamani, K.M.; Aminabhavi, T.M. Distillery Wastewater Treatment by the Membrane-Based Nanofiltration and Reverse Osmosis Processes. Water Res. 2006, 40, 2349–2356. [Google Scholar] [CrossRef]

- Víctor-Ortega, M.D.; Martins, R.C.; Gando-Ferreira, L.M.; Quinta-Ferreira, R.M. Recovery of Phenolic Compounds from Wastewaters Through Micellar Enhanced Ultrafiltration. Colloids Surf. Physicochem. Eng. Asp. 2017, 531, 18–24. [Google Scholar] [CrossRef]

- Santos, J.R.F.; Rodrigues, R.P.; Quina, M.J.; Gando-Ferreira, L.M. Recovery of Value-Added Compounds from Winery Wastewater: A Review and Bibliometric Analysis. Water 2023, 15, 1110. [Google Scholar] [CrossRef]

- Ioannou, L.A.; Michael, C.; Vakondios, N.; Drosou, K.; Xekoukoulotakis, N.P.; Diamadopoulos, E.; Fatta-Kassinos, D. Winery Wastewater Purification by Reverse Osmosis and Oxidation of the Concentrate by Solar Photo-FENTON. Sep. Purif. Technol. 2013, 118, 659–669. [Google Scholar] [CrossRef]

- Alcantara, B.M.; Marques, D.R.; Chinellato, M.M.; Marchi, L.B.; Costa, S.C.; Monteiro, A.R.G. Assessment of Quality and Production Process of a Non-Alcoholic Stout Beer Using Reverse Osmosis. J. Inst. Brew. 2016, 122, 714–718. [Google Scholar] [CrossRef]

- Varga, Á.; Bihari-Lucena, E.; Ladányi, M.; Szabó-Nótin, B.; Galambos, I.; Koris, A. Experimental Study and Modeling of Beer Dealcoholization via Reverse Osmosis. Membranes 2023, 13, 329. [Google Scholar] [CrossRef]

- Krogerus, K.; Gibson, B.R. 125th Anniversary Review: Diacetyl and Its Control During Brewery Fermentation: Diacetyl and Its Control During Brewery Fermentation. J. Inst. Brew. 2013, 119, 86–97. [Google Scholar] [CrossRef]

- Kebede, T.B. Waste Water Treatment in Brewery Industry, Review. Int. J. Eng. Dev. Res. 2018, 6, 716–722. [Google Scholar]

- Fillaudeau, L.; Blanpain-Avet, P.; Daufin, G. Water, Wastewater and Waste Management in Brewing Industries. J. Clean. Prod. 2006, 14, 463–471. [Google Scholar] [CrossRef]

- Simate, G.S.; Cluett, J.; Iyuke, S.E.; Musapatika, E.T.; Ndlovu, S.; Walubita, L.F.; Alvarez, A.E. The Treatment of Brewery Wastewater for Reuse: State of the Art. Desalination 2011, 273, 235–247. [Google Scholar] [CrossRef]

- Toran, M.S.; Labrador, P.F.; Ciriza, J.F.; Asensio, Y.; Reigersman, A.; Arevalo, J.; Rogalla, F.; Monsalvo, V.M. Membrane-Based Processes to Obtain High-Quality Water From Brewery Wastewater. Front. Chem. Eng. 2021, 3, 734233. [Google Scholar] [CrossRef]

- Muller, C.; Neves, L.E.; Gomes, L.; Guimarães, M.; Ghesti, G. Processes for Alcohol-Free Beer Production: A Review. Food Sci. Technol. 2020, 40, 273–281. [Google Scholar] [CrossRef]

- Catarino, M.; Mendes, A.; Madeira, L.M.; Ferreira, A. Alcohol Removal From Beer by Reverse Osmosis. Sep. Sci. Technol. 2007, 42, 3011–3027. [Google Scholar] [CrossRef]

- Sánchez, R.J.; Figueroa Paredes, D.A.; Laoretani, D.S.; Villada, Y.; Fuentes, M.; Espinosa, J. On the Conceptual Design of the Hybrid Nanofiltration/Distillation Process in the Production of Alcohol-Free Beers. Sep. Purif. Technol. 2021, 267, 118625. [Google Scholar] [CrossRef]

- Labanda, J.; Vichi, S.; Llorens, J.; López-Tamames, E. Membrane Separation Technology for the Reduction of Alcoholic Degree of a White Model Wine. LWT Food Sci. Technol. 2009, 42, 1390–1395. [Google Scholar] [CrossRef]

- Diban, N.; Arruti, A.; Barceló, A.; Puxeu, M.; Urtiaga, A.; Ortiz, I. Membrane Dealcoholization of Different Wine Varieties Reducing Aroma Losses. Modeling and Experimental Validation. Innov. Food Sci. Emerg. Technol. 2013, 20, 259–268. [Google Scholar] [CrossRef]

- OIV. New CAP Gives Official Status to ‘De-Alcoholised Wines’ According to the OIV’s Adopted Framework; OIV: Dijon, France, 2021. [Google Scholar]

- European Parliament; Council of the European Union. EU Regulation 2117/2021. Establishing a Common Organisation of the Markets in Agricultural Products, (EU) No 1151/2012 on Quality Schemes for Agricultural Products and Foodstuffs, (EU) No 251/2014 on the Definition, De-scription, Presentation, Labelling and the Protection of Geographical Indications of Aromatised Wine Products and (EU) No 228/2013 Laying down Specific Measures for Agriculture in the Outermost Regions of the Union. Off. J. Eur. Union L 2021, 435, 270. [Google Scholar]

- Kumar, Y.; Ricci, A.; Wang, G.; Parpinello, G.P.; Versari, A. The Effect of Ethanol, SO2, and Transition Metals on Browning Kinetics in Low- and No-Alcohol Model Wine. J. Food Biochem. 2024, 2024, 2318470. [Google Scholar] [CrossRef]

- Kumar, Y.; Italiano, L.; Schmitt, M.; Ricci, A.; Parpinello, G.P.; Versari, A. Exploring Changes in Browning Kinetics, Color, and Antioxidants Due to Dealcoholization of Wine. In Proceedings of the 45th World Congress of Vine and Wine (OIV 2024), Dijon, France, 14–18 October 2024. [Google Scholar]

- Meillon, S.; Urbano, C.; Guillot, G.; Schlich, P. Acceptability of Partially Dealcoholized Wines—Measuring the Impact of Sensory and Information Cues on Overall Liking in Real-Life Settings. Food Qual. Prefer. 2010, 21, 763–773. [Google Scholar] [CrossRef]

| Membrane Process | Driving Force | Pressure Range | Pore Diameter | Membrane Material | Principle Changes in Wine Composition | Principle Changes in Beer Composition |

|---|---|---|---|---|---|---|

| NF | Pressure gradient | 2–40 bar | 0.001–0.005 μm | Asymmetrical polymeric or thin-film composite membranes |

|

|

| RO | Pressure gradient | 10–100 bar | <0.001 μm | Thin-film or dense composite or polymeric membranes |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, Y.; Khalangre, A.; Suhag, R.; Cassano, A. Applications of Reverse Osmosis and Nanofiltration Membrane Process in Wine and Beer Industry. Membranes 2025, 15, 140. https://doi.org/10.3390/membranes15050140

Kumar Y, Khalangre A, Suhag R, Cassano A. Applications of Reverse Osmosis and Nanofiltration Membrane Process in Wine and Beer Industry. Membranes. 2025; 15(5):140. https://doi.org/10.3390/membranes15050140

Chicago/Turabian StyleKumar, Yogesh, Atul Khalangre, Rajat Suhag, and Alfredo Cassano. 2025. "Applications of Reverse Osmosis and Nanofiltration Membrane Process in Wine and Beer Industry" Membranes 15, no. 5: 140. https://doi.org/10.3390/membranes15050140

APA StyleKumar, Y., Khalangre, A., Suhag, R., & Cassano, A. (2025). Applications of Reverse Osmosis and Nanofiltration Membrane Process in Wine and Beer Industry. Membranes, 15(5), 140. https://doi.org/10.3390/membranes15050140