Comparison of Anion-Exchange Membranes for Diffusion Dialysis of Mixtures of Acids and Their Iron Salts

Abstract

:1. Introduction

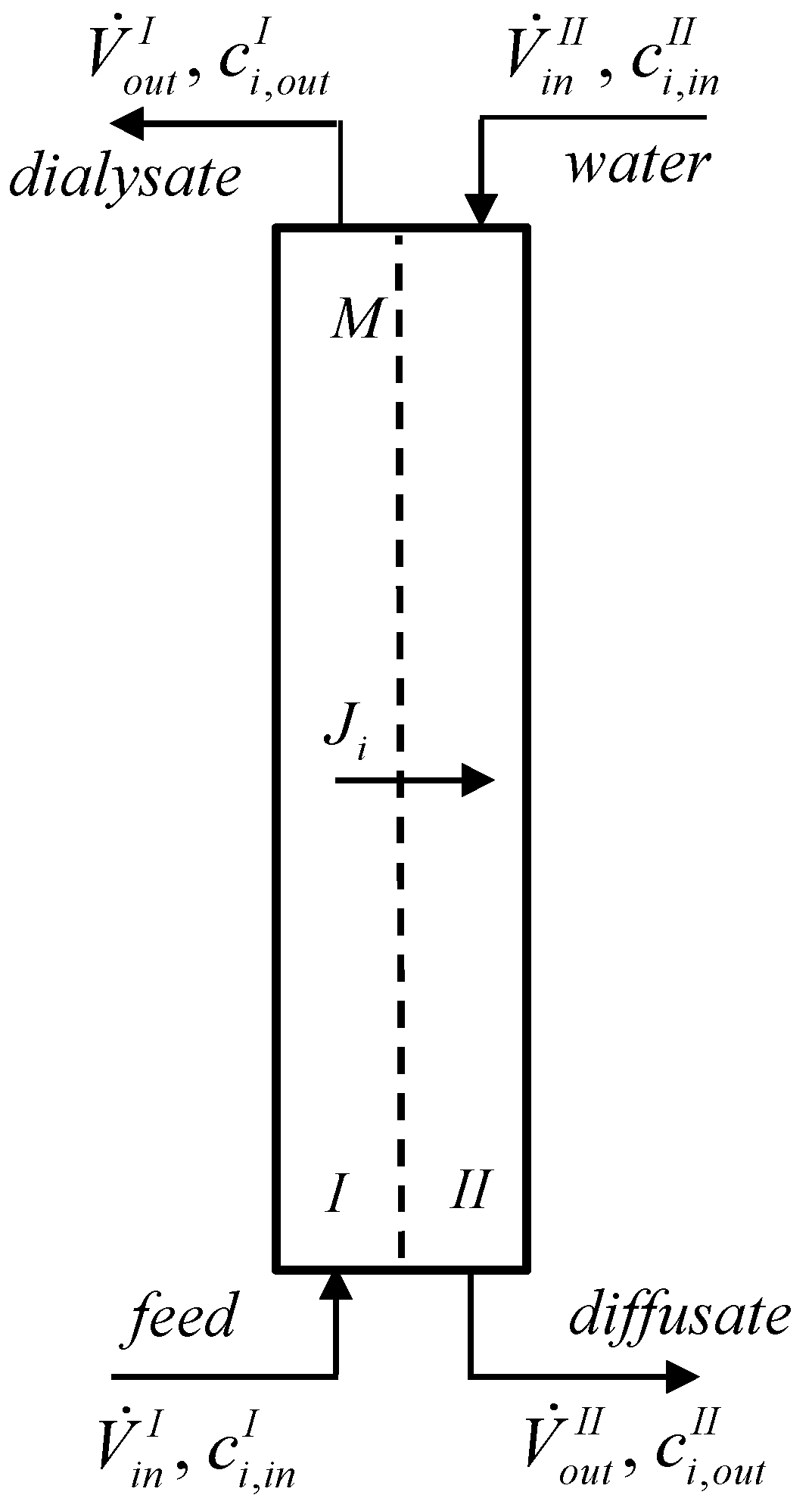

2. Theory

3. Materials and Methods

4. Results and Discussion

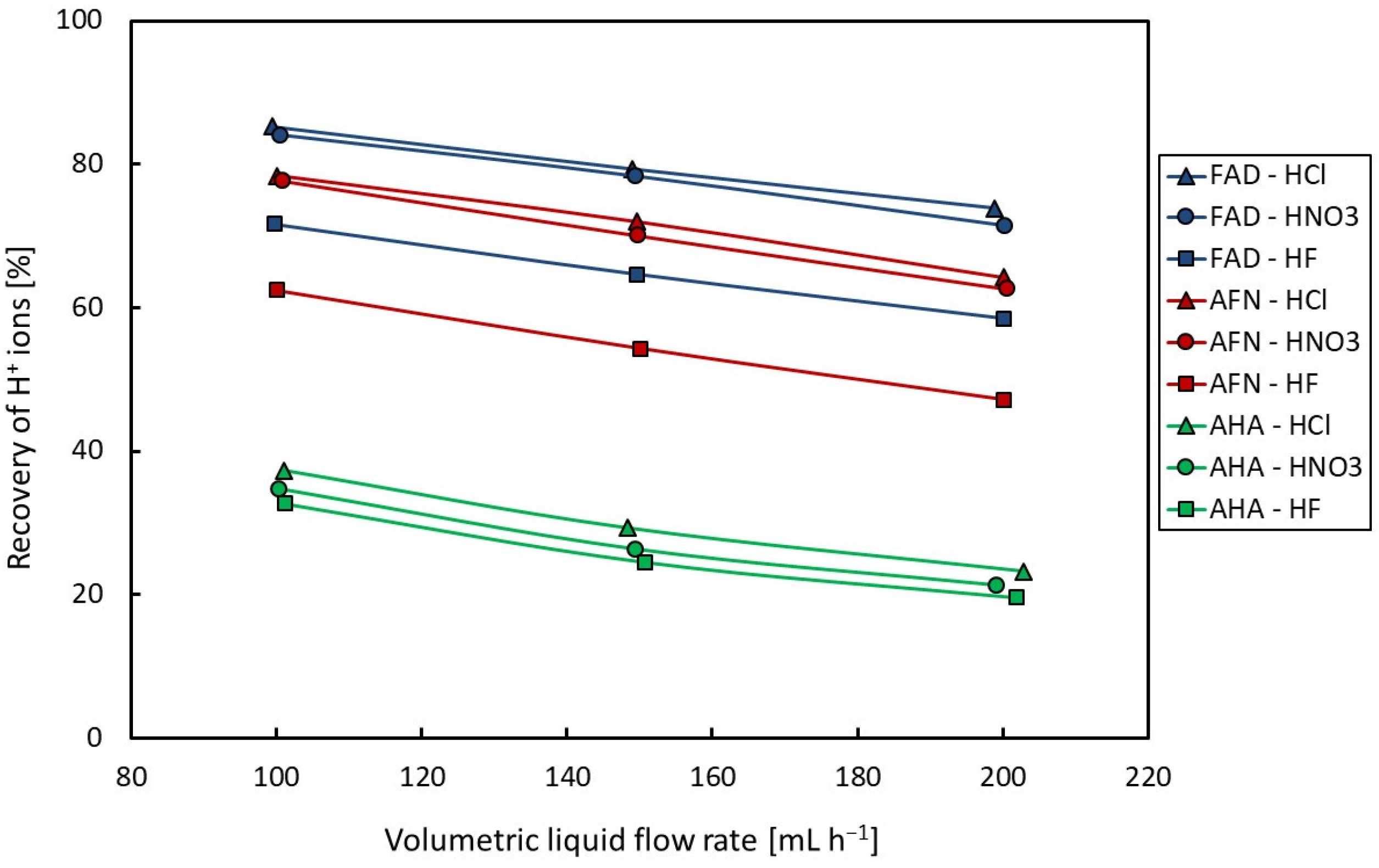

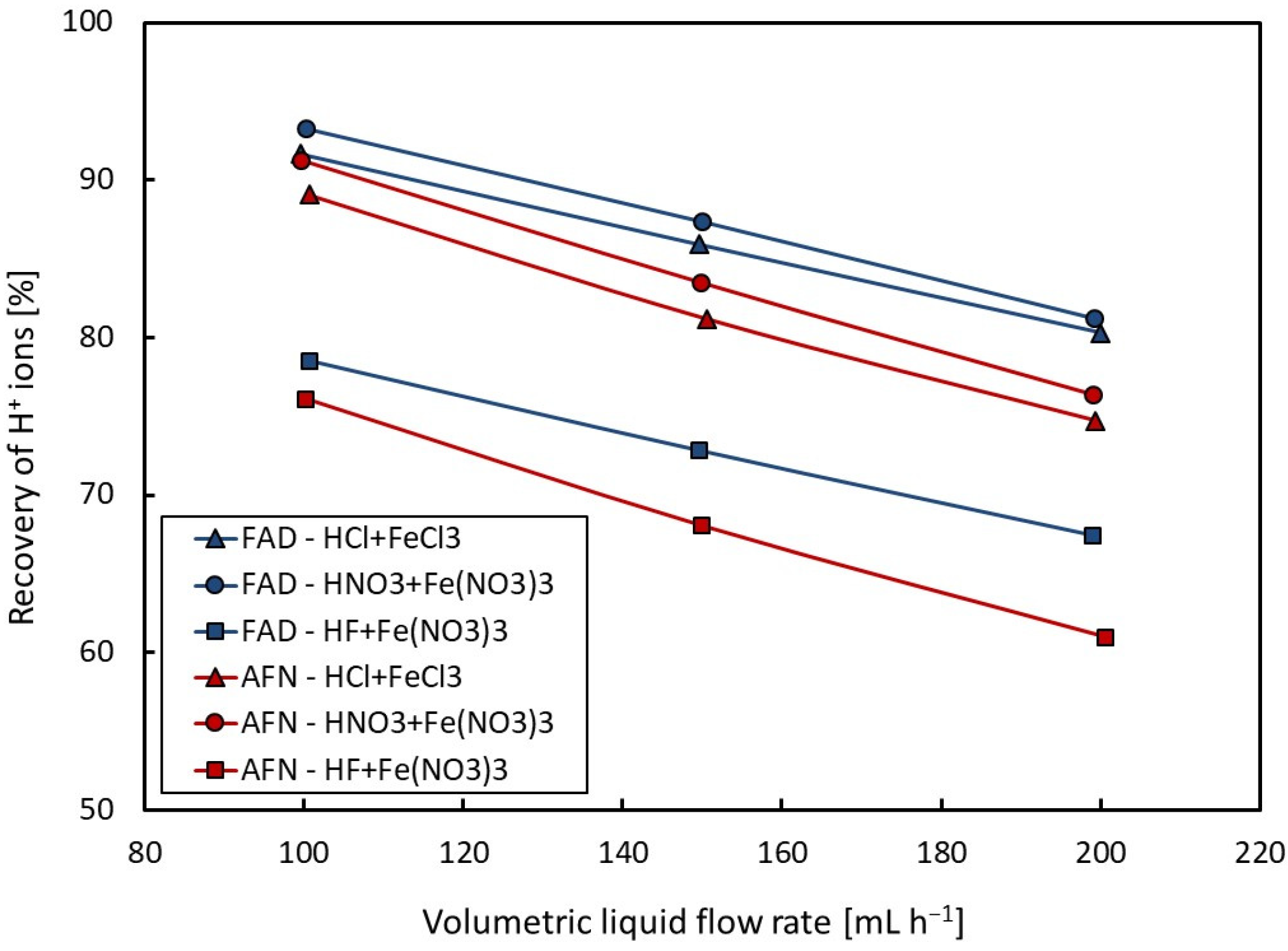

4.1. Recovery Yield of Acid

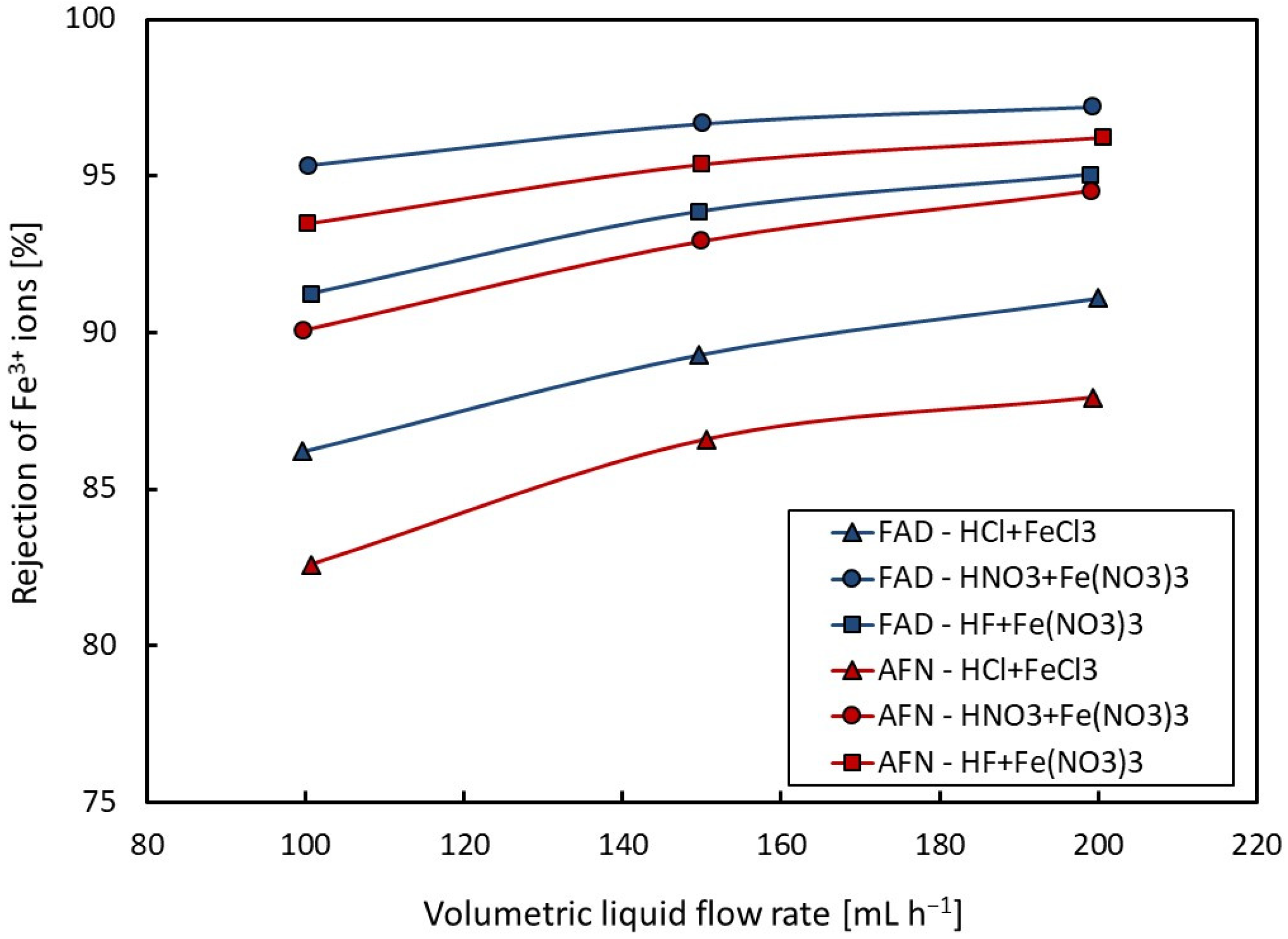

4.2. Rejection Coefficient of Iron

4.3. Overall Dialysis Coefficients

4.4. Separation Factor

4.5. Water Transport through the Membrane

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |

| A | membrane area, m2 |

| C | concentration, mol L−1 (M) |

| J | molar flux, kmol m−2 s−1 |

| Jw | water transport through the membrane, % |

| K | overall dialysis coefficient, m s−1 |

| R | rejection, % |

| S | separation factor, − |

| volumetric flow rate, m3 s−1 (mL h−1) | |

| ν | recovery, % |

| z | length, m |

| Subscripts and Superscripts | |

| I | related to compartment I |

| II | related to compartment II |

| i | related to i ion |

| in | inlet |

| out | outlet |

References

- Regel-Rosocka, M. A review on methods of regeneration of spent pickling solutions from steel processing. J. Hazard. Mater. 2010, 177, 57–69. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhang, W.; Wang, Y. Diffusion dialysis for acid recovery from acidic waste solutions: Anion exchange membranes and technology integration. Membranes 2020, 10, 169. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.W.; Ryu, S.H.; Kim, T.Y. Recovery of tin and nitric acid from spent solder stripping solutions. Korean J. Met. Mater. 2015, 53, 426–431. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Y.M.; Huang, J.; Liu, T.; Wang, J.P. Recovery of sulfuric acid from a stone coal acid leaching solution by diffusion dialysis. Hydrometallurgy 2017, 173, 9–14. [Google Scholar] [CrossRef]

- Amrane, C.; Lalmi, A.; Bouhidel, K.E. Coupling diffusion dialysis with precipitation cementation to separate and recover nitric acid, Cu plus plus, Zn plus plus and Pb plus plus from the wastewater of a brass pickling bath. Int. J. Glob. Warm. 2017, 11, 337–357. [Google Scholar] [CrossRef]

- Bendova, H.; Weidlich, T. Application of diffusion dialysis in hydrometallurgical separation of nickel from spent Raney Ni catalyst. Sep. Sci. Technol. 2018, 53, 1218–1222. [Google Scholar] [CrossRef]

- Gueccia, R.; Aguirre, A.R.; Randazzo, S.; Cipollina, A.; Micale, G. Diffusion Dialysis for Separation of Hydrochloric Acid, Iron and Zinc Ions from Highly Concentrated Pickling Solutions. Membranes 2020, 10, 129. [Google Scholar] [CrossRef]

- Culcasi, A.; Gueccia, R.; Randazzo, S.; Cipollina, A.; Micale, G. Design of a novel membrane-integrated waste acid recovery process from pickling solution. J. Clean. Prod. 2019, 236, 117623. [Google Scholar] [CrossRef]

- Gueccia, R.; Winter, D.; Randazzo, S.; Cipollina, A.; Koschikowski, J.; Micale, G.D.M. An integrated approach for the HCl and metals recovery from waste pickling solutions: Pilot plant and design operations. Chem. Eng. Res. Des. 2021, 168, 383–396. [Google Scholar] [CrossRef]

- Gueccia, R.; Bogle, D.; Randazzo, S.; Tamburini, A.; Cipollina, A.; Winter, D.; Koschikowski, J.; Micale, G. Economic Benefits of Waste Pickling Solution Valorization. Membranes 2022, 12, 114. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, M.Q.; Li, W.J.; Wu, C.M.; Han, X.Z.; Zhong, S.; Chen, Y.S. Application and modeling of pressure-concentration double-driven diffusion dialysis. J. Membr. Sci. 2020, 595, 117478. [Google Scholar] [CrossRef]

- Loza, S.; Loza, N.; Korzhov, A.; Romanyuk, N.; Kovalchuk, N.; Melnikov, S. Hybrid Membrane Technology for Acid Recovery from Wastewater in Coated Steel Wire Production: A Pilot Scale Study. Membranes 2022, 12, 1196. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.F.; Zhu, H.T.; Wu, Y.Q.; Li, S.A.; Zhang, G.Q.; Miao, Z.W. Resourceful Treatment of Battery Recycling Wastewater Containing H2SO4 and NiSO4 by Diffusion Dialysis and Electrodialysis. Membranes 2023, 13, 570. [Google Scholar] [CrossRef] [PubMed]

- Upadhyay, P.; Mishra, S.; Sharma, J.; Panja, S.; Kulshrestha, V. Recovery and enrichment of acid from metallurgical wastewater model by electrodialysis integrated diffusion dialysis system using poly(ethylene) based IEMs. Sep. Purif. Technol. 2023, 304, 122353. [Google Scholar] [CrossRef]

- Bendová, H.; Dušek, L. Treatment of Spent Pickling Solutions by Diffusion Dialysis Using Anion-Exchange Membrane Neosepta-AFN. Membranes 2023, 13, 9. [Google Scholar] [CrossRef] [PubMed]

- Palatý, Z.; Bendová, H. Separation of HCl + FeCl2 mixture by anion-exchange membrane. Sep. Purif. Technol. 2009, 66, 45–50. [Google Scholar] [CrossRef]

- Palatý, Z.; Bendová, H. Dialysis of aqueous solutions of nitric acid and ferric nitrate. Chem. Eng. Process. 2011, 50, 160–166. [Google Scholar] [CrossRef]

- Merkel, A.; Copak, L.; Dvorak, L.; Golubenko, D.; Seda, L. Recovery of Spent Sulphuric Acid by Diffusion Dialysis Using a Spiral Wound Module. Int. J. Mol. Sci. 2021, 22, 11819. [Google Scholar] [CrossRef]

- Merkel, A.; Copak, L.; Golubenko, D.; Dvorak, L.; Vavro, M.; Yaroslavtsev, A.; Seda, L. Recovery of Hydrochloric Acid from Industrial Wastewater by Diffusion Dialysis Using a Spiral-Wound Module. Int. J. Mol. Sci. 2022, 23, 6212. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Y.H.; Hu, X.Y.; Wu, C.M.; Ding, J.C. Tubular bag membrane for simple diffusion dialysis. J. Membr. Sci. 2023, 683, 121828. [Google Scholar] [CrossRef]

- Loza, S.; Loza, N.; Korzhov, A.; Romanyuk, N.; Kovalchuk, N.; Melnikov, S. Comparative Study of Different Ion-Exchange Membrane Types in Diffusion Dialysis for the Separation of Sulfuric Acid and Nickel Sulfate. Membranes 2023, 13, 396. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Aguirre, A.; Lopez, J.; Gueccia, R.; Randazzo, S.; Cipollina, A.; Cortina, J.L.; Micale, G. Diffusion dialysis for the treatment of H2SO4-CuSO4 solutions from electroplating plants: Ions membrane transport characterization and modelling. Sep. Purif. Technol. 2021, 266, 118215. [Google Scholar] [CrossRef]

- Bendová, H.; Palatý, Z.; Žáková, A. Continuous dialysis of inorganic acids: Permeability of Neosepta-AFN membrane. Desalination 2009, 240, 333–340. [Google Scholar] [CrossRef]

- Palatý, Z.; Bendová, H. Continuous dialysis of sulphuric acid and sodium sulphate mixture. J. Membr. Sci. 2016, 497, 36–46. [Google Scholar] [CrossRef]

- BWT. Available online: https://www.bwt.com/en/-/media/bwt/fumatech/datasheets/new/fumasep/water-treatment-processes/fumasep-fadpet75-dry-formv22.pdf?rev=5f58a24a39f245129d578c25c72c0948 (accessed on 28 November 2023).

- ASTOM. Available online: http://www.astom-corp.jp/en/product/10.html (accessed on 28 November 2023).

- MEGA. Available online: https://www.mega.cz/membranes/ (accessed on 28 November 2023).

| Membrane | Fumasep-FAD | Neosepta-AFN | Neosepta-AHA |

|---|---|---|---|

| Producer | Fumatech BWT GmbH (Bietigheim-Bissingen, Germany) | Astom Corp. (Tokyo, Japan) | Astom Corp. (Tokyo, Japan) |

| Counter ion | Bromide | Chloride | Chloride |

| Thickeness (wet) | 100 μm | 160 μm | 220 μm |

| pH stability | 0–8 | 0–8 | 0–14 |

| Temperature (°C) | 15–40 | ≤40 | ≤40 |

| Electric resistence (Ω cm2) | 1.2 | 2.6 | 4.1 |

| Delivery form | dry | wet | Wet |

| Fumasep-FAD | Neosepta-AFN | Neosepta-AHA | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Flow rate (mL h−1) | 100 | 150 | 200 | 100 | 150 | 200 | 100 | 150 | 200 |

| 3 M HCl | 85% | 79% | 74% | 78% | 72% | 64% | 37% | 29% | 23% |

| 3 M HNO3 | 84% | 78% | 71% | 78% | 70% | 63% | 35% | 26% | 21% |

| 3 M HF | 72% | 65% | 58% | 62% | 54% | 47% | 33% | 25% | 20% |

| 3 M HCl + 0.5 M FeCl3 | 92% | 86% | 80% | 89% | 81% | 75% | |||

| 3 M HNO3 + 0.5 M Fe(NO3)3 | 93% | 87% | 81% | 91% | 83% | 76% | |||

| 3 M HF + 0.7 M Fe(NO3)3 | 79% | 73% | 67% | 76% | 68% | 61% | |||

| Fumasep-FAD | Neosepta-AFN | |||||

|---|---|---|---|---|---|---|

| Flow rate (mL h−1) | 100 | 150 | 200 | 100 | 150 | 200 |

| 3 M HCl + 0.5 M FeCl3 | 86% | 89% | 91% | 83% | 87% | 88% |

| 3 M HNO3 + 0.5 M Fe(NO3)3 | 95% | 97% | 97% | 90% | 93% | 95% |

| 3 M HF + 0.7 M Fe(NO3)3 | 91% | 94% | 95% | 93% | 95% | 96% |

| Fumasep-FAD | Neosepta-AFN | Neosepta-AHA | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Flow rate (mL h−1) | 100 | 150 | 200 | 100 | 150 | 200 | 100 | 150 | 200 |

| 3 M HCl | 3.8 | 4.0 | 4.1 | 2.6 | 2.7 | 2.8 | 0.49 | 0.51 | 0.51 |

| 3 M HNO3 | 3.2 | 3.4 | 3.4 | 2.4 | 2.5 | 2.5 | 0.44 | 0.44 | 0.45 |

| 3 M HF | 2.0 | 2.2 | 2.2 | 1.3 | 1.4 | 1.5 | 0.40 | 0.41 | 0.42 |

| 3 M HCl + 0.5 M FeCl3 | 9.2 | 7.7 | 6.3 | 5.9 | 4.8 | 4.7 | |||

| 3 M HNO3 + 0.5 M Fe(NO3)3 | 11.2 | 8.0 | 6.8 | 7.3 | 5.4 | 4.9 | |||

| 3 M HF + 0.7 M Fe(NO3)3 | 4.5 | 3.8 | 3.6 | 2.6 | 2.6 | 2.5 | |||

| Fumasep-FAD | Neosepta-AFN | |||||

|---|---|---|---|---|---|---|

| Flow rate (mL h−1) | 100 | 150 | 200 | 100 | 150 | 200 |

| 3 M HCl + 0.5 M FeCl3 | 1.5 | 1.6 | 1.7 | 1.8 | 2.0 | 2.1 |

| 3 M HNO3 + 0.5 M Fe(NO3)3 | 0.39 | 0.41 | 0.43 | 0.94 | 1.0 | 1.0 |

| 3 M HF + 0.7 M Fe(NO3)3 | 0.86 | 0.86 | 0.88 | 0.63 | 0.65 | 0.7 |

| Fumasep-FAD | Neosepta-AFN | |||||

|---|---|---|---|---|---|---|

| Flow rate (mL h−1) | 100 | 150 | 200 | 100 | 150 | 200 |

| 3 M HCl + 0.5 M FeCl3 | 63 | 47 | 38 | 33 | 24 | 22 |

| 3 M HNO3 + 0.5 M Fe(NO3)3 | 285 | 194 | 157 | 77 | 54 | 48 |

| 3 M HF + 0.7 M Fe(NO3)3 | 52 | 46 | 40 | 42 | 39 | 36 |

| Fumasep-FAD | Neosepta-AFN | Neosepta-AHA | |

|---|---|---|---|

| 3 M HCl | −10% | −8% | −2% |

| 3 M HNO3 | −13% | −10% | −4% |

| 3 M HF | −3% | −4% | −2% |

| 3 M HCl + 0.5 M FeCl3 | −2% | −5% | |

| 3 M HNO3 + 0.5 M Fe(NO3)3 | −1% | −5% | |

| 3 M HF + 0.7 M Fe(NO3)3 | 7% | −2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bendová, H.; Dušek, L.; Palarčík, J. Comparison of Anion-Exchange Membranes for Diffusion Dialysis of Mixtures of Acids and Their Iron Salts. Membranes 2024, 14, 6. https://doi.org/10.3390/membranes14010006

Bendová H, Dušek L, Palarčík J. Comparison of Anion-Exchange Membranes for Diffusion Dialysis of Mixtures of Acids and Their Iron Salts. Membranes. 2024; 14(1):6. https://doi.org/10.3390/membranes14010006

Chicago/Turabian StyleBendová, Helena, Libor Dušek, and Jiří Palarčík. 2024. "Comparison of Anion-Exchange Membranes for Diffusion Dialysis of Mixtures of Acids and Their Iron Salts" Membranes 14, no. 1: 6. https://doi.org/10.3390/membranes14010006

APA StyleBendová, H., Dušek, L., & Palarčík, J. (2024). Comparison of Anion-Exchange Membranes for Diffusion Dialysis of Mixtures of Acids and Their Iron Salts. Membranes, 14(1), 6. https://doi.org/10.3390/membranes14010006