Application of Vibrating Reverse Osmosis Technology for Nutrient Recovery from Pig Slurry in a Circular Economy Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Selection of Feedstocks

2.2. Vibratory Shear Enhanced Processing System

2.3. Vibratory Shear Enhanced Processing Operation

2.4. Analytical Methods

2.5. Seedling Growth Tests

2.6. Pot-Test

3. Results and Discussion

3.1. Feedstock Characterization

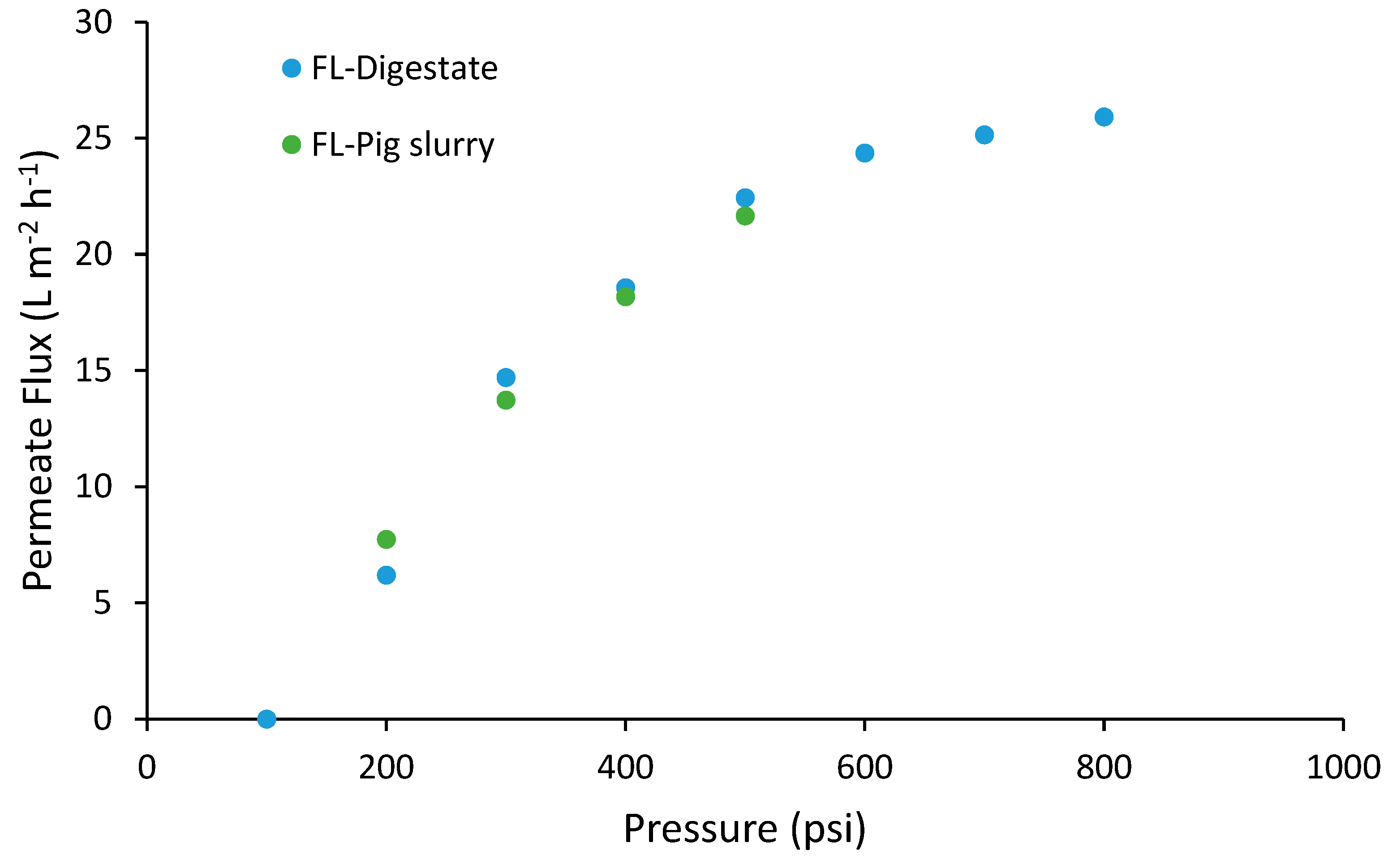

3.2. Determination of the Optimal Operating Pressure

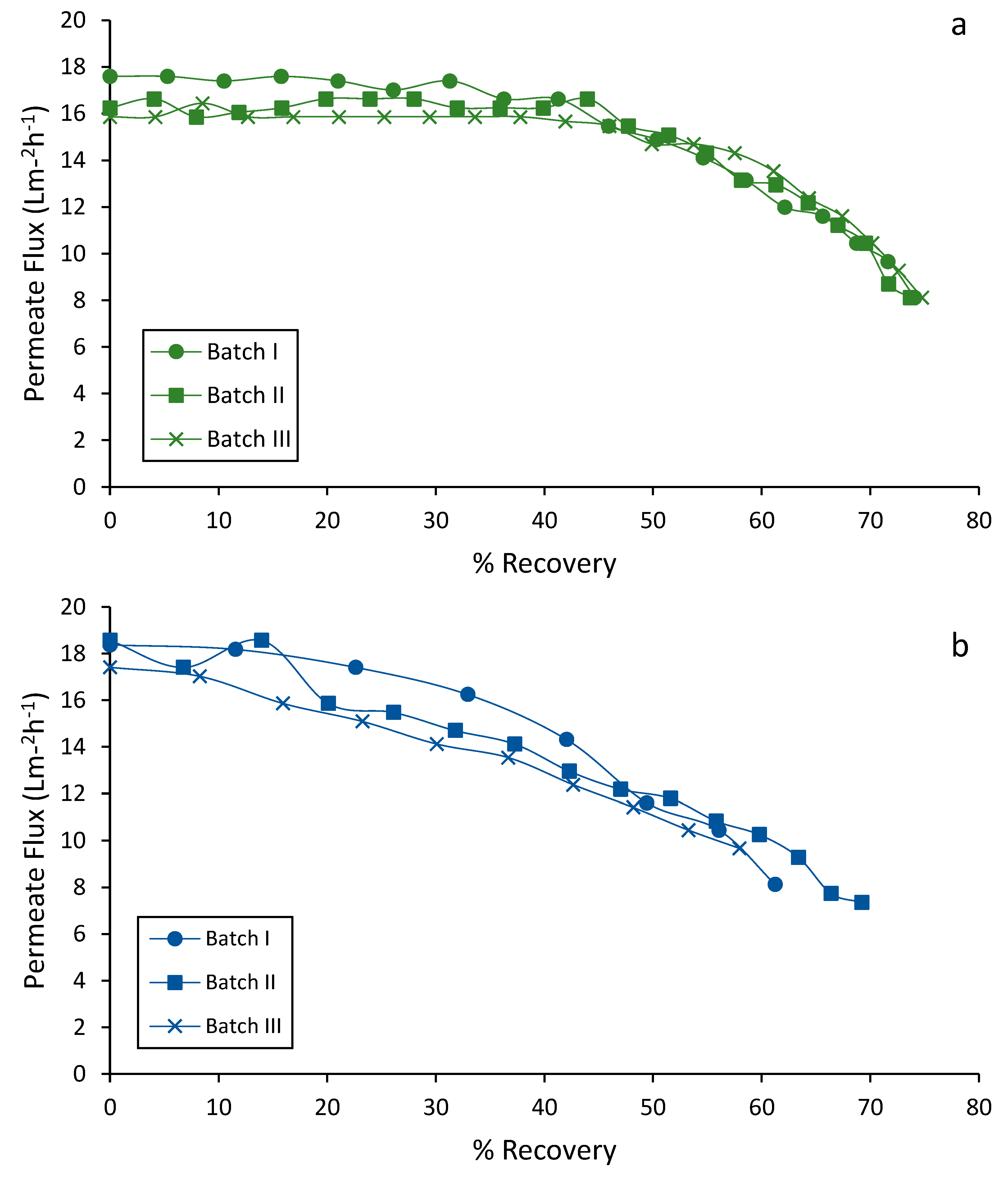

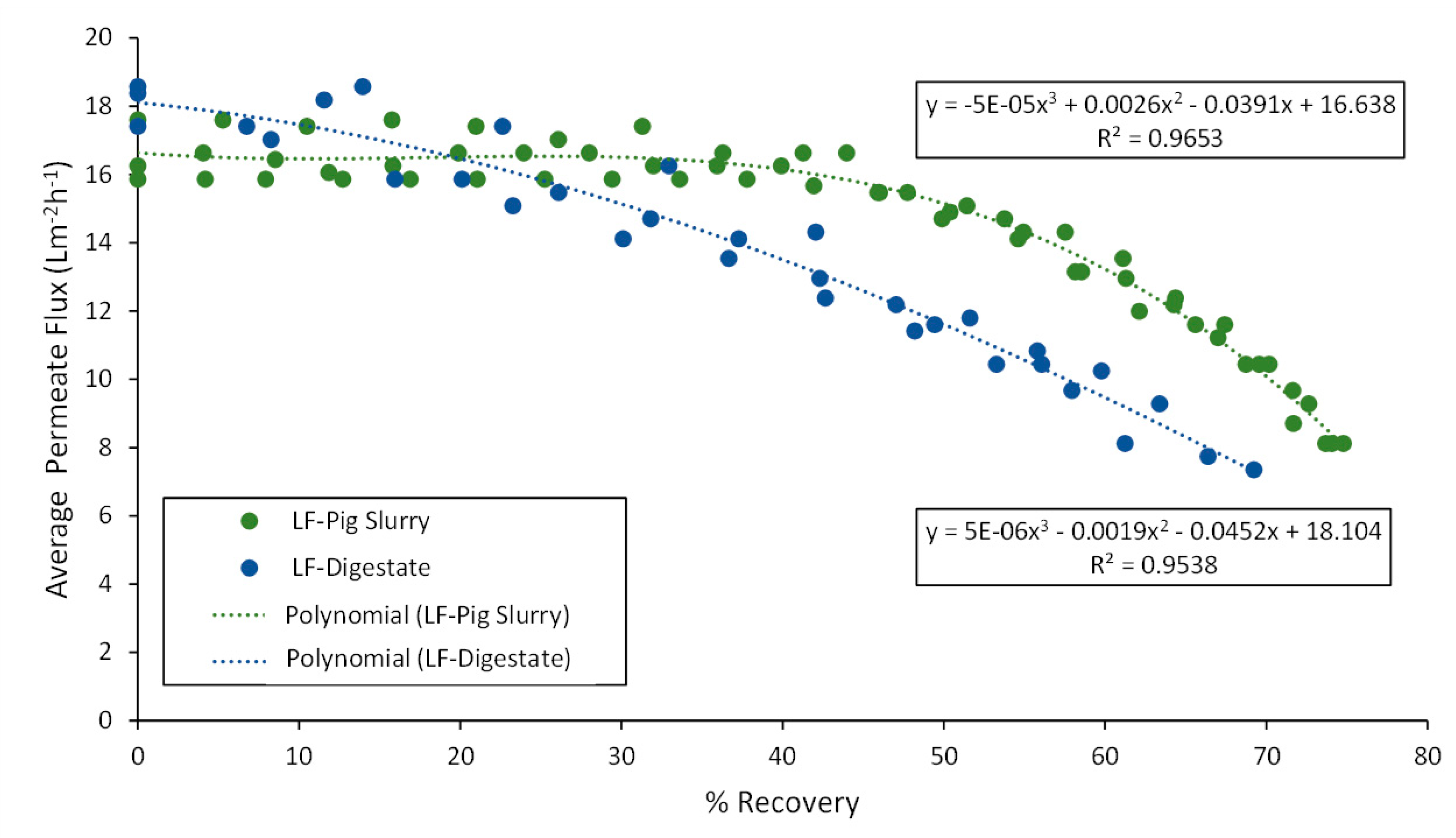

3.3. Performance of Water Recovery

3.4. Performance of Nutrient Recovery

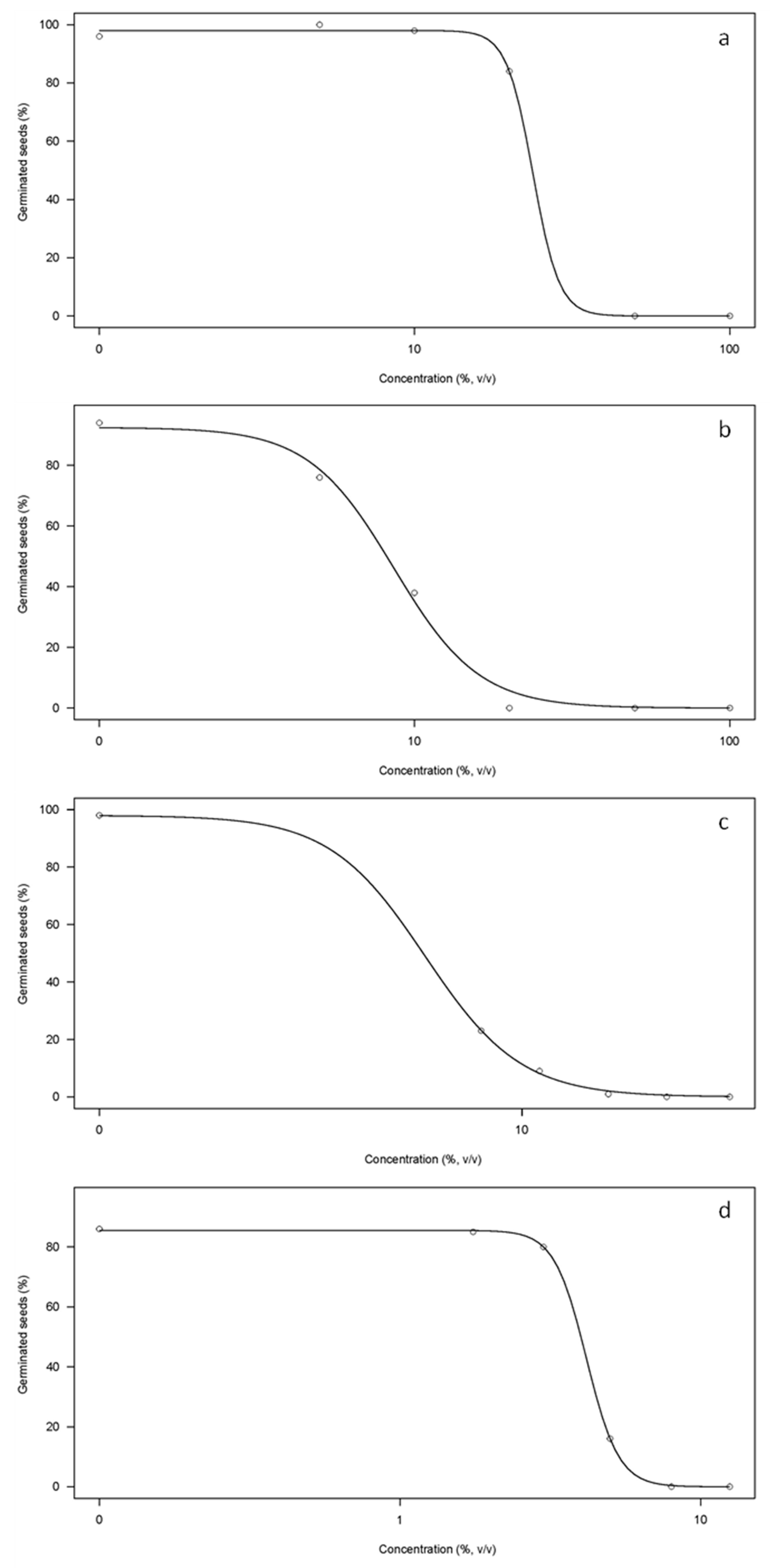

3.5. Seedling Growth Tests

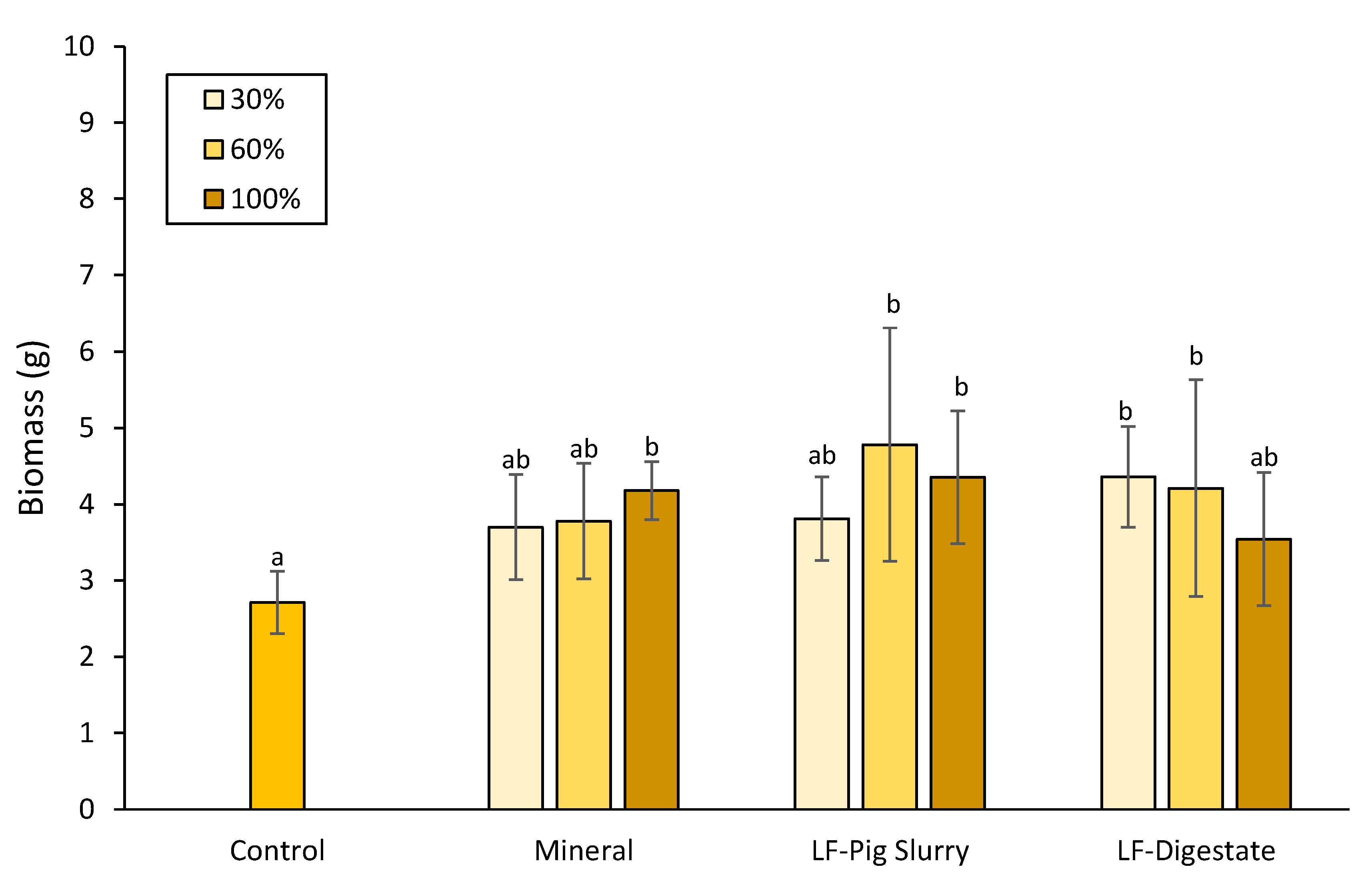

3.6. Pot-Test

4. Conclusions and Future Perspective

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Sekaran, U.; Kumar, S.; Luis Gonzalez-Hernandez, J. Integration of crop and livestock enhanced soil biochemical properties and microbial community structure. Geoderma 2021, 381, 114686. [Google Scholar] [CrossRef]

- Rayne, N.; Aula, L. Livestock manure and the impacts on soil health: A review. Soil Syst. 2020, 4, 64. [Google Scholar] [CrossRef]

- Du, L.; Liu, W. Occurrence, fate, and ecotoxicity of antibiotics in agro-ecosystems. A review. Agron. Sustain. Dev. 2012, 32, 309–327. [Google Scholar] [CrossRef]

- Sun, J.; Khan, E.; Simsek, S.; Ohm, J.-B.; Simsek, H. Bioavailability of dissolved organic nitrogen (DON) in wastewaters from animal feedlots and storage lagoons. Chemosphere 2017, 186, 695–701. [Google Scholar] [CrossRef] [PubMed]

- Council Directive 91/66/EEC. Protection of waters against pollution caused by nitrates from agricultural sources. In Bulletin of the European Communities; Commission of the European Communities: Brussels, Belgium, 1991. [Google Scholar]

- Buckweel, A.; Nadeu, E. Nutrient recovery and reuse (NRR) in European agriculture: A review of the issues, opportunities, and actions. In The Sustainable Intensification of European Agriculture; Technical Report; RISE Foundation: Brussels, Belgium, 2016. [Google Scholar]

- Bolzonella, D.; Fatone, F.; Gottardo, M.; Frison, N. Nutrients recovery from anaerobic digestate of agro-waste: Techno-economic assessment of full scale applications. J. Environ. Manag. 2018, 216, 111–119. [Google Scholar] [CrossRef] [PubMed]

- Khoshnevisan, B.; Duan, N.; Tsapekos, P.; Awasthi, M.K.; Liu, Z.; Mohammadi, A.; Angelidaki, I.; Tsang, D.C.W.; Zhang, Z.; Pan, J.; et al. A critical review on livestock manure biorefinery technologies: Sustainability, challenges, and future perspectives. Renew. Sustain. Energy Rev. 2021, 135, 110033. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Sarsaiya, S.; Wainaina, S.; Rajendran, K.; Kumar, S.; Quan, W.; Duan, Y.; Awasthi, S.K.; Chen, H.; Pandey, A.; et al. A critical review of organic manure biorefinery models toward sustainable circular bioeconomy: Technological challenges, advancements, innovations, and future perspectives. Renew. Sustain. Energy Rev. 2019, 111, 115–131. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Kumar, M.; Sarsaiya, S.; Ahluwalia, V.; Chen, H.; Kaur, G.; Sirohi, R.; Sindhu, R.; Binod, P.; Pandey, A.; et al. Multi-criteria research lines on livestock manure biorefinery development towards a circular economy: From the perspective of a life cycle assessment and business models strategies. J. Clean. Prod. 2022, 341, 130862. [Google Scholar] [CrossRef]

- Masse, L.; Massé, D.I.; Pellerin, Y. The use of membranes for the treatment of manure: A critical literature review. Biosyst. Eng. 2007, 98, 371–380. [Google Scholar] [CrossRef]

- Ledda, C.; Schievano, A.; Salati, S.; Adani, F. Nitrogen and water recovery from animal slurries by a new integrated ultrafiltration, reverse osmosis and cols stripping process: A case study. Water Res. 2013, 15, 6157–6166. [Google Scholar] [CrossRef]

- Sun, Y.; Qin, Z.; Chen, Q.; Hou, Q.; Lin, H.; Jiang, L.; Liu, J.; Du, Z. Membrane fouling mechanisms and permeate flux decline model soy sauce microfiltration. J. Food Process. Eng. 2017, 41, e12599. [Google Scholar] [CrossRef]

- Rana, D.; Matsuura, T. Surface modification for antifouling membrane. Chem. Rev. 2010, 4, 2448–2471. [Google Scholar] [CrossRef]

- Pabby, A.; Rizvi, A.; Sastre, A. Handbook of Membrane Separation: Chemical, Pharmaceutical and Biotechnological Application; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Shi Wei Benjamin, M.M. Fouling of RO membranes in a vibratory shear enhanced filtration process (VSEP) system. J. Membr. Sci. 2009, 331, 11–20. [Google Scholar] [CrossRef]

- Johnson, G.; Culkin, B.; Monroe, M. Vibratory shear guards against mineral scale membrane fouling. Filtr. Sep. 2003, 40, 24–29. [Google Scholar] [CrossRef]

- Huuilo, T.; Väisänen, P.; Nuortilla-Jokinen, J.; Nyström, M. Influence of shear on flux in membrane of integrated Pulp and paper mill circulation water. Desalination 2001, 141, 245–258. [Google Scholar] [CrossRef]

- Kertész, S.; László, Z.; Forgács, E.G.; Hodúr, C. Dairy wastewater purification by vibratory shear enhanced processing. Desalination Water Treat. 2011, 35, 195–201. [Google Scholar] [CrossRef]

- Kertész, S.; Szerencsés, S.G.; Veréb, G.; József, C.; László, Z.; Hodúr, C. Single- and multi-stage dairy wastewater treatment by vibratory membrane separation processes. Membr. Water Treat. 2020, 11, 383–389. [Google Scholar] [CrossRef]

- Szerencsés, S.G.; Beszédes, S.; László, Z.; Veréb, G.; Szalay, D.; Hovorkáné Horváth, Z.; Hodúr, C.; Rákhely, G.; Kertész, S. Assessment of vibration amplitude and transmembrane pressure on vibratory shear enhanced membrane filtration for treating dairy wastewater. Acta Aliment. 2021, 50, 42–53. [Google Scholar] [CrossRef]

- Zouboulis, A.I.; Petala, M.D. Performance of VSEP vibratory membrane filtration system during the treatment of landfill leachates. Desalination 2008, 222, 165–175. [Google Scholar] [CrossRef]

- Yenal, U.; Corral, A.F.; Nixon, J.; Hill, C.; Ela, W.P.; Arnold, R.G. Economics of ion exchange versus vibratory shear enhanced processing for minimization of reverse osmosis concentrate volume. J. Environ. Eng. 2014, 140, 05014001. [Google Scholar] [CrossRef]

- Afrasiabi, N.; Shahbazali, E. RO brine treatment and disposal methods. Desalination Water Treat. 2011, 35, 39–53. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Choi, J.; Hwang, H.; Cha, M.; Kim, J. Tertiary treatment of biologically treated piggery wastewater using vibratory shear-enhanced RO membrane. Water Sci. Technol. 2004, 49, 435–442. [Google Scholar] [CrossRef]

- Atkinson, S. Vibratory membrane filtration system treats hog manure. Membr. Technol. 2005, 1, 10–11. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Meers, E.; Michels, E.; Christiaens, P.; Tack, F.-M.-G. Fate of macronutrients in water treatment of digestate using vibrating reverse osmosis. Water Air Soil Pollut. 2012, 223, 1593. [Google Scholar] [CrossRef]

- Vaneeckhaute, C.; Darveau, O.; Meers, E. Fate of micronutrients and heavy metals in digestate processing using vibrating reversed osmosis as resource recovery technology. Sep. Purif. Technol. 2019, 1603, 81–87. [Google Scholar] [CrossRef]

- Yoon, Y.; Ok, Y.-S.; Kim, D.-Y.; Kim, J.-G. Agricultural recycling of the by-product concentrate of livestock wastewater treatment plant processed with VSEP RO and bio-ceramic SBR. Water Sci. Technol. 2004, 49, 405–412. [Google Scholar] [CrossRef]

- Gros, M.; Marti, E.; Balcázar, J.L.; Boy-Roura, M.; Busquets, A.; Colon, J.; Ponsà, S.; Petrovic, M. Fate of pharmaceuticals and antibiotic resistance genes in a full-scale on-farm livestock waste treatment plant. J. Hazard. Mater. 2019, 378, 120716. [Google Scholar] [CrossRef]

- Marti, E.; Gros, M.; Boy-Roura, M.; Ovejero, J.; Busquets, A.M.; Colón, J.; Ponsá, S. Pharmaceuticals removal in an on-farm pig slurry treatment plant based on solid-liquid separation and nitrification-denitrification systems. Waste Manag. 2020, 102, 412–419. [Google Scholar] [CrossRef] [PubMed]

- Kertész, S.; Beszédes, S.; László, Z.; Szabó, G.; Hodúr, C. Nanofiltration and reverse osmosis of pig manure: Comparison of results from vibratory and classical modules. Desalination Water Treat. 2010, 14, 233–238. [Google Scholar] [CrossRef][Green Version]

- APHA. Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association: Washington DC, USA, 2017. [Google Scholar]

- Directive 86/278/EEC. Protection of the environment and, in particular, of soils, in the use of sewage sludge in agriculture. CELEX-EUR Off. J. L 1986, 181, 6–12. [Google Scholar]

- Nikiema, B.C.W.-Y.; Ito, R.; Guizani, M.; Funamizu, N. Estimation of water flux and solute movement during the concentration process of hydrolysed urine by forward osmosis. J. Water Environ. Technol. 2017, 15, 163–173. [Google Scholar] [CrossRef][Green Version]

- Johnson, G.; Culkin, B.; Stowell, L. Membrane Filtration of Manure Wastewater; Technical Report; New Logic Research Inc.: Emeryville, CA, USA, 2004. [Google Scholar]

- Munns, R.; Tester, N. Mechanisms of Salinity Tolerance. Annu. Rev. Plant. Biol. 2008, 59, 651–681. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, R.; Ashraf, M.A.; Parveen, S.; Iqbal, M.; Hussain, I. Effect of salt stress on different growth and biochemical attributes in two canola (Brassica napus L.) cultivars. Commun. Soil Sci. Plant Anal. 2014, 45, 669–679. [Google Scholar] [CrossRef]

- Velthof, G.L.; Rietra, R.P. Nitrogen Use Efficiency and Gaseous Nitrogen Losses from the Concentrated Liquid Fraction of Pig Slurries. Int. J. Agron. 2019, 2019, 928310. [Google Scholar] [CrossRef]

- Velthof, G.; Ehlert, P.; Schröder, J.; Van Middelkoop, J.; Van Geel, W.; Holshof, G. Application of Mineral Concentrates from Processed Manure. In Biorefinery of Inorganics (Recovering Mineral Nutrients from Biomass and Organic Waste); Meers, E., Velthof, G., Michels, E., Rietra, R., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 259–269. [Google Scholar] [CrossRef]

- Walsh, J.J.; Jones, D.L.; Edwards-Jones, G.; Williams, A.P. Replacing inorganic fertilizer with anaerobic digestate may maintain agricultural productivity at less environmental cost. J. Plant Nutr. Soil Sci. 2012, 175, 840–845. [Google Scholar] [CrossRef]

- Thomas, B.; Xiaomei, L.; Nelson, V.; Xiying, H. Anaerobically digested beef cattle manure supplied more nitrogen with less phosphorus accumulation than undigested manure. Agron. J. 2017, 109, 836–844. [Google Scholar] [CrossRef]

- Baral, K.R.; Labouriau, R.; Olesen, J.E.; Petersen, S.O. Nitrous oxide emissions and nitrogen use efficiency of manure and digestates applied to spring barley. Agric. Ecosyst. Environ. 2017, 239, 188–198. [Google Scholar] [CrossRef]

- Alburquerque, J.A.; De la Fuente, C.; Campoy, M.; Carrasco, L.; Nájera, I.; Baixauli, C.; Caravaca, F.; Roldán, A.; Cegarra, J.; Bernal, M.P. Agricultural use of digestate for horticultural crop production and improvement of soil properties. Eur. J. Agron. 2012, 43, 119–128. [Google Scholar] [CrossRef]

| pH | 8.5 |

|---|---|

| EC (dS m−1) | 0.12 |

| N-NO3− (mg kg−1 d.b.) | 8.7 |

| Olsen P (mg kg−1 d.b.) | 11.4 |

| Exchangeable K (mg kg−1 d.b.) | 90.1 |

| Organic matter (mg kg−1 d.b.) | 1.3 |

| Ca (mg kg−1 d.b.) | 5289 |

| Mg (mg kg−1 d.b.) | 82 |

| Na (mg kg−1 d.b.) | 15 |

| LF-Pig slurry | LF-Digestate | |||||

|---|---|---|---|---|---|---|

| Batch I | Batch II | Batch III | Batch I | Batch II | Batch III | |

| pH | 8.23 ± 0.02 | 8.19 ± 0.02 | 8.07 ± 0.03 | 8.86 ± 0.06 | 8.73 ± 0.03 | 8.72 ± 0.08 |

| EC (mS cm−1) | 17.7 ± 0.1 | 16.8 ± 0.1 | 16.85 ± 0.06 | 28.8 ± 0.4 | 28.7 ± 0.7 | 28.8 ± 0.2 |

| TS (%) | 2.18 ± 0.01 | 1.8 ±0.1 | 4.16 ± 0.06 | 2.15 ± 0.01 | 2.2 ± 0.2 | 2.20 ± 0.06 |

| VS (% db) | 53.2 ± 0.2 | 52.3 ± 0.5 | 54.0 ± 0.1 | 70.6 ± 0.2 | 70.8 ± 0.1 | 70.6 ± 0.6 |

| N-NH4+ (g L−1) | 2.2 ± 0.1 | 2.26 ± 0.03 | 2.71 ± 0.05 | 3.03 ± 0.05 | 5.13 ± 0.08 | 4.99 ± 0.08 |

| TKN (g L−1) | 2.86 ± 0.05 | 2.75 ± 0.01 | 3.81 ± 0.05 | 6.18 ± 0.03 | 6.1 ± 0.4 | 6.2 ± 0.3 |

| P (mg L−1) | 750 ± 20 | 622 ± 95 | 636 ± 14 | 357 ± 1 | 380 ± 15 | 359 ± 12 |

| K (mg L−1) | 1591 ± 59 | 1538 ± 20 | 1497 ± 26 | 517 ± 7 | 435 ± 11 | 532 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vega, E.; Paredes, L.; Marks, E.A.N.; Singla, B.; Castaño-Sánchez, O.; Casas, C.; Vilaplana, R.; Mora, M.; Ponsá, S.; Llenas, L. Application of Vibrating Reverse Osmosis Technology for Nutrient Recovery from Pig Slurry in a Circular Economy Model. Membranes 2022, 12, 848. https://doi.org/10.3390/membranes12090848

Vega E, Paredes L, Marks EAN, Singla B, Castaño-Sánchez O, Casas C, Vilaplana R, Mora M, Ponsá S, Llenas L. Application of Vibrating Reverse Osmosis Technology for Nutrient Recovery from Pig Slurry in a Circular Economy Model. Membranes. 2022; 12(9):848. https://doi.org/10.3390/membranes12090848

Chicago/Turabian StyleVega, Esther, Lidia Paredes, Evan A. N. Marks, Berta Singla, Omar Castaño-Sánchez, Carme Casas, Rosa Vilaplana, Mabel Mora, Sergio Ponsá, and Laia Llenas. 2022. "Application of Vibrating Reverse Osmosis Technology for Nutrient Recovery from Pig Slurry in a Circular Economy Model" Membranes 12, no. 9: 848. https://doi.org/10.3390/membranes12090848

APA StyleVega, E., Paredes, L., Marks, E. A. N., Singla, B., Castaño-Sánchez, O., Casas, C., Vilaplana, R., Mora, M., Ponsá, S., & Llenas, L. (2022). Application of Vibrating Reverse Osmosis Technology for Nutrient Recovery from Pig Slurry in a Circular Economy Model. Membranes, 12(9), 848. https://doi.org/10.3390/membranes12090848