Current Status and Future Trend of Dominant Commercial Reverse Osmosis Membranes

Abstract

:1. Introduction

1.1. President Kennedy’s Speech

If we could ever competitively, at a cheap rate, get fresh water from salt water, that it would be in the long-range interests of humanity which could really dwarf any other scientific accomplishments. I am hopeful that we will intensify our efforts in that area.

1.2. Tambo’s Prediction

2. Discussion

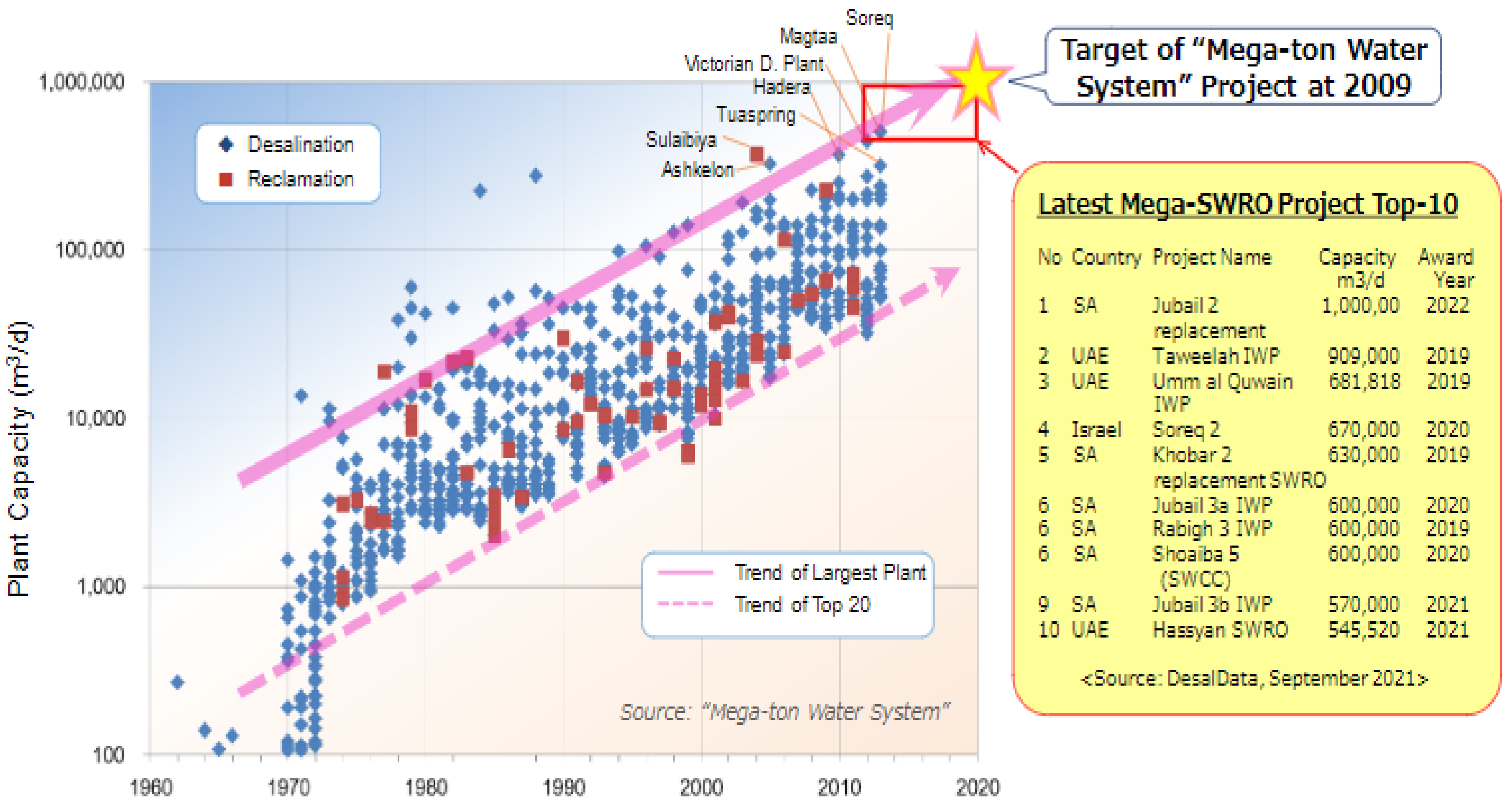

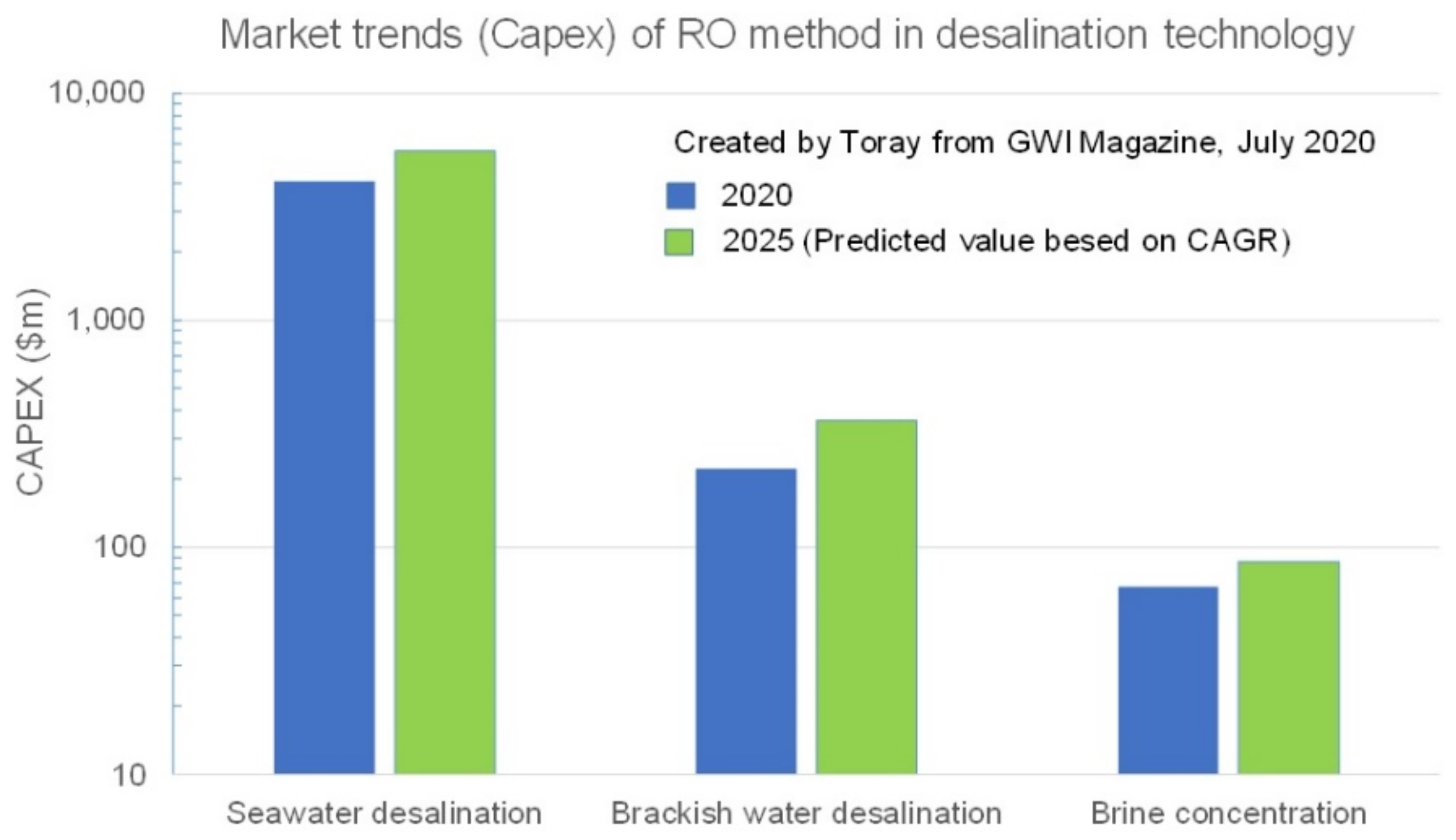

2.1. Current Global Market Status of SWRO Desalination Plants

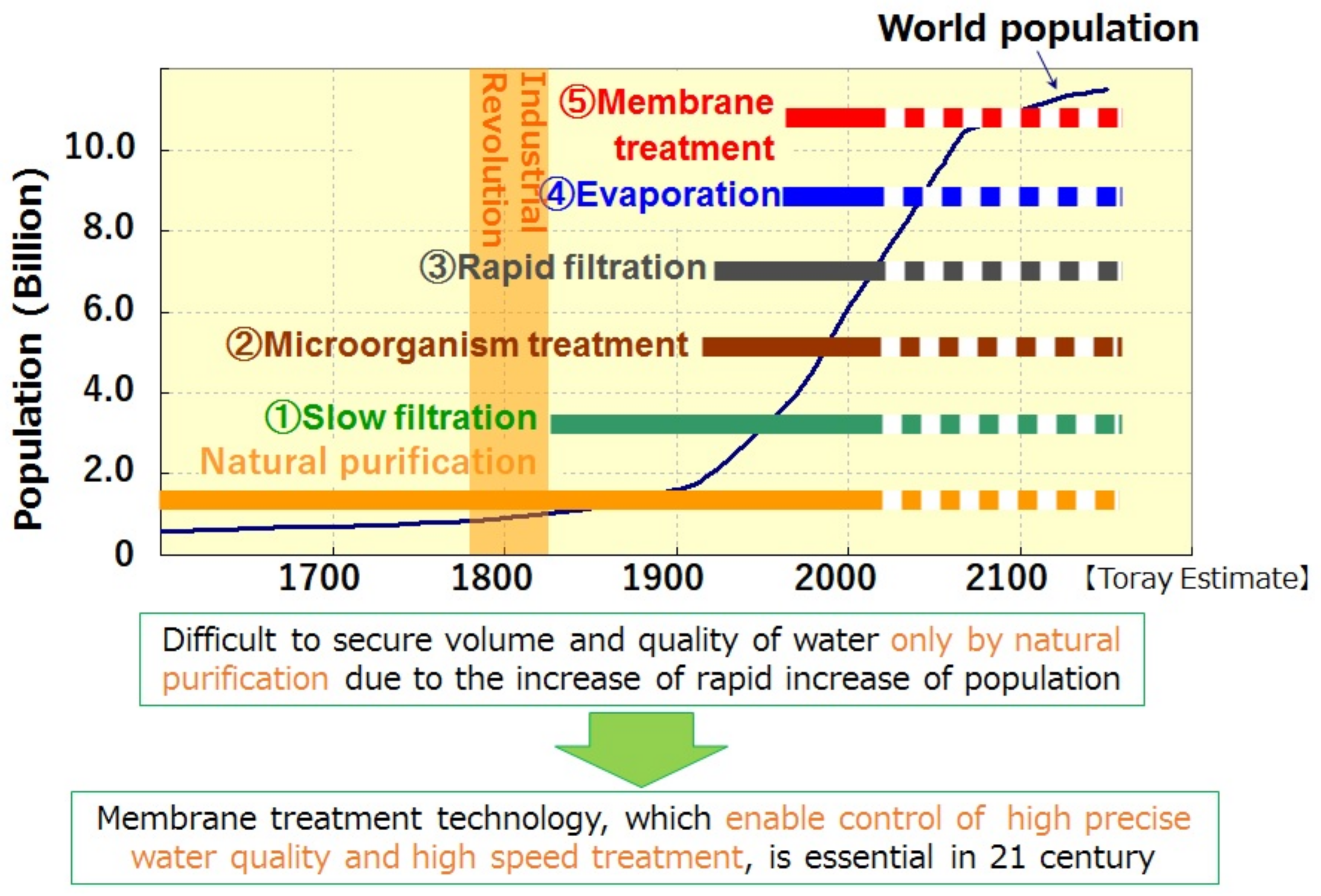

2.1.1. Technology Transition from Distillation to Membrane Method

2.1.2. From Small Plants to “Mega-size SWRO” Plants

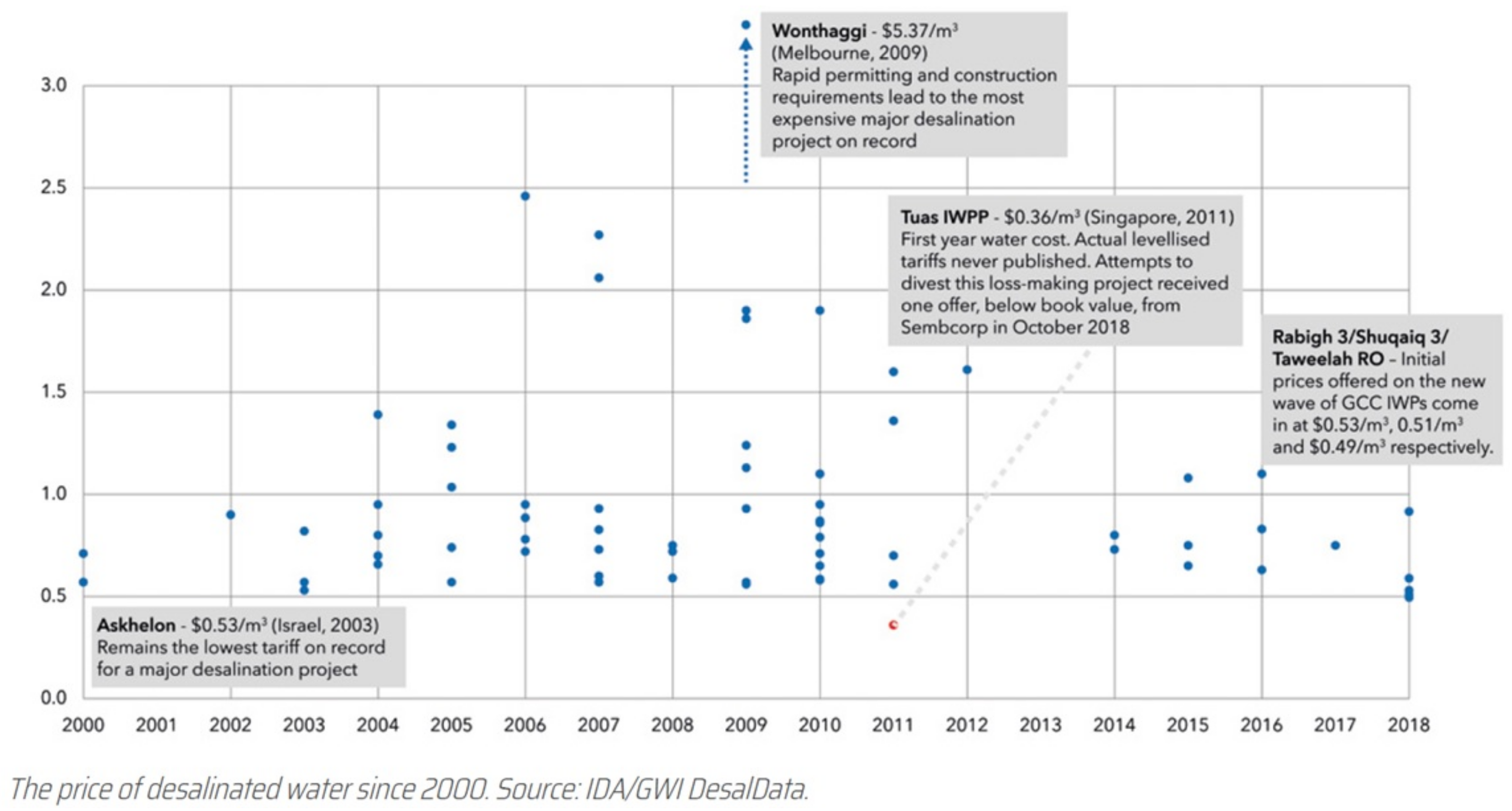

2.1.3. Affordable Price of Desalinated Water

- Rabihg 3 (Saudi Arabia): 600,000 m3/d, $0.53/m3

- Shuqaiq 3 (Saudi Arabia): 380,000 m3/d, $0.51/m3

- Taweelah (UAE): 909,200 m3/d, $0.49/m3

- Jubail 3A (Saudi Arabia): 600,000 m3/d, $0.41/m3

- Soreq 2 (Israel): 672,000 m3/day, $0.40/m3

- Hassyan (UAE) (Saudi Arabia): 545,000 m3/d, $0.28/m3

- The price has dropped to $0.28/m3 in December 2020.

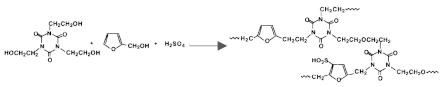

2.2. History of RO Membrane Materials Configuration: Hollow Fiber, Spiral Wound Element, and Module

2.2.1. History of Membrane Materials and Configuration

- Seawater desalination process: One-stage or two-stage.

- Water recovery: 10–20% or 30–40%

- Chemical stability of the membrane against chlorine and dissolved oxygen in seawater.

- Physical stability of the membranes to the temperature of seawater.

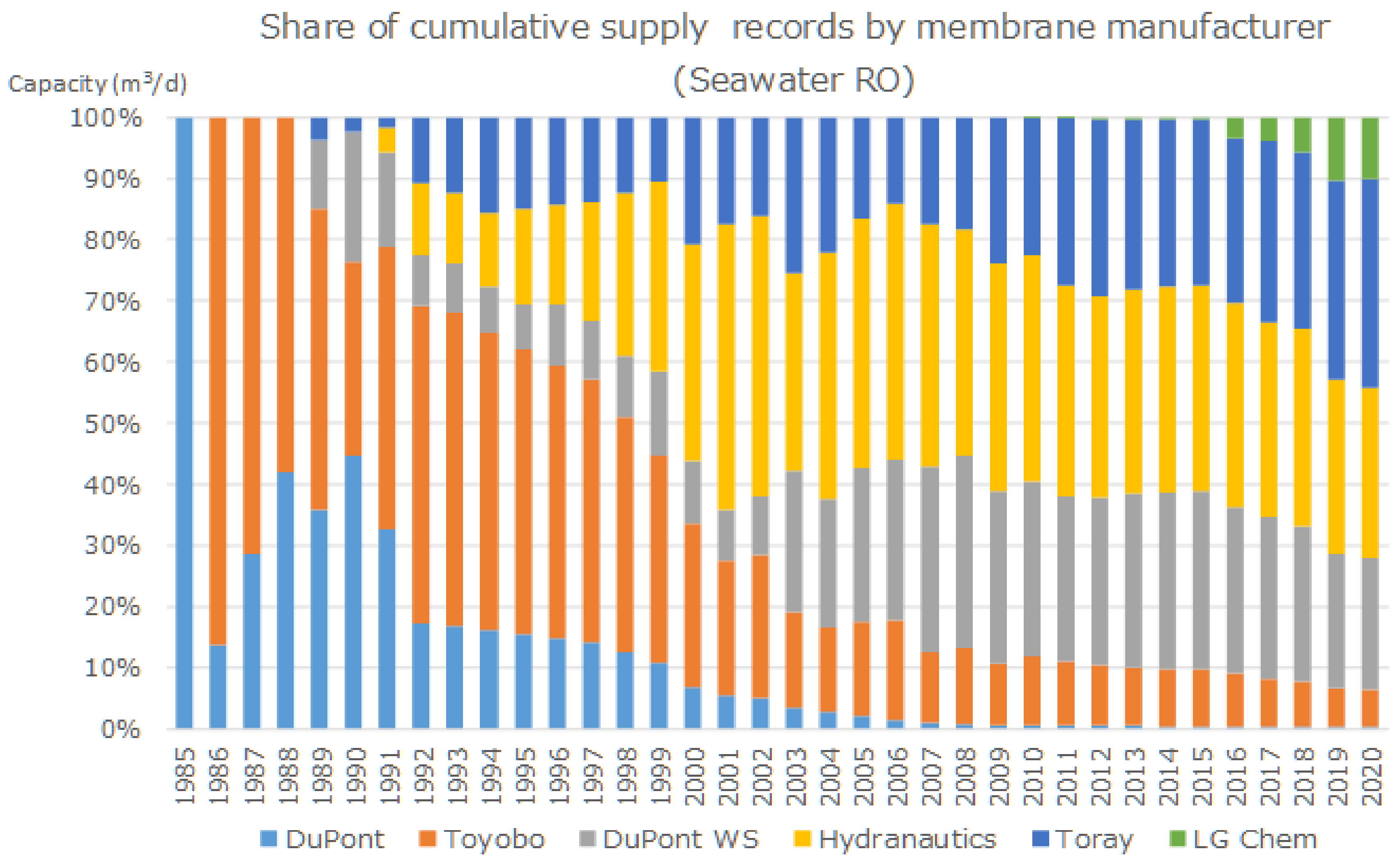

2.2.2. The Global Market Share of Spiral-Wound Element and Hollow Fiber Type Element

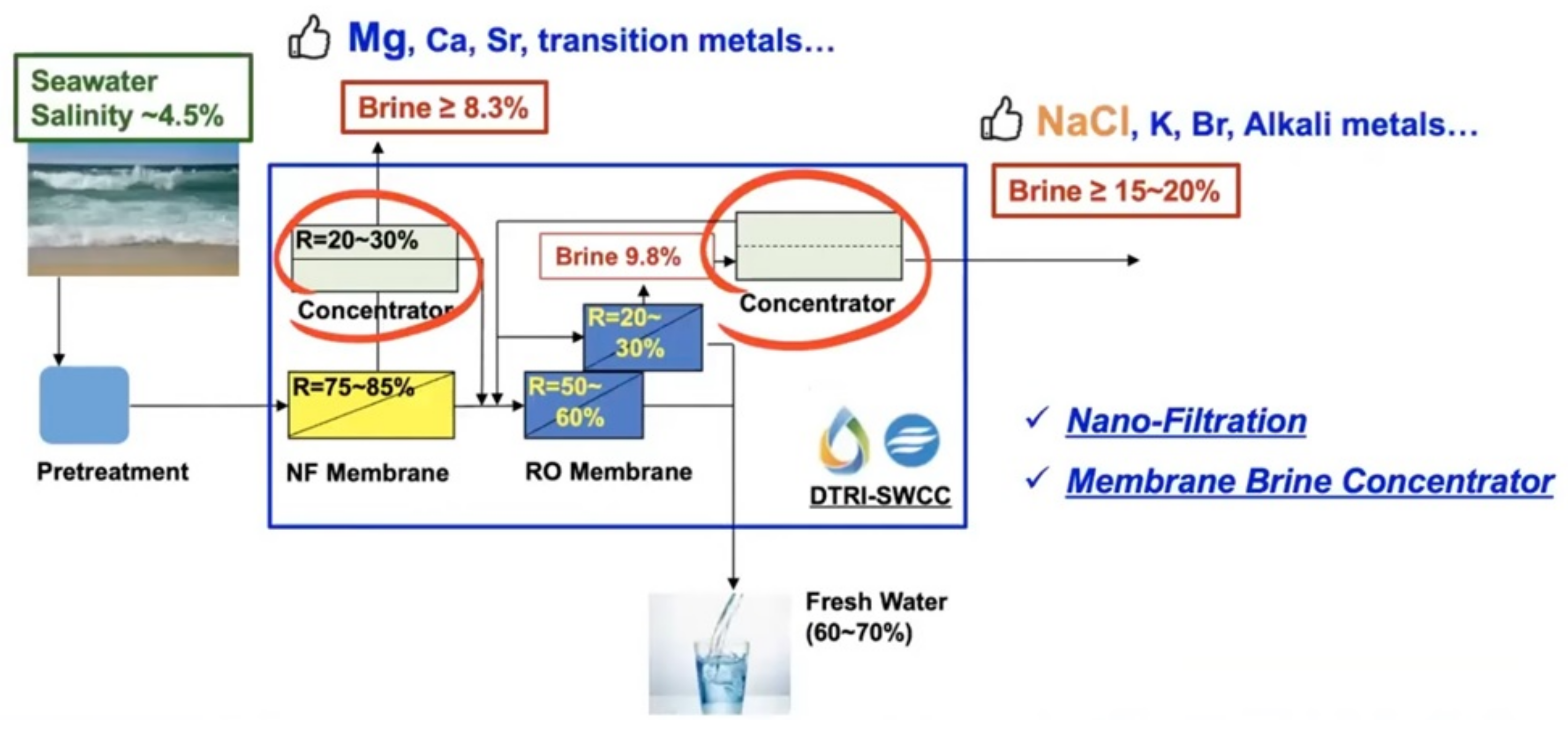

2.2.3. SWCC’s Vision for the Future

2.3. The Pursuits of Existing Ultimate Membrane Technology and Membrane Process

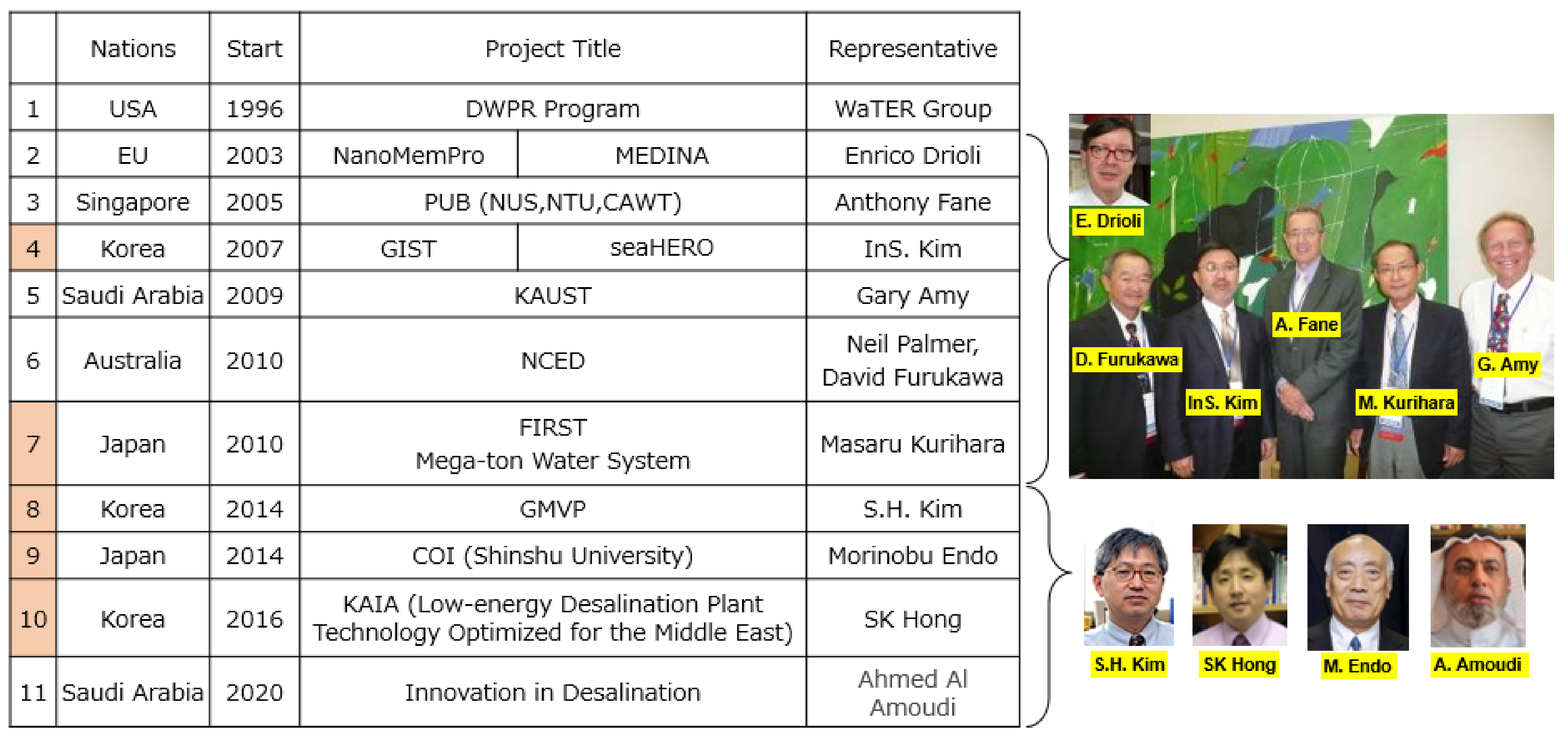

2.3.1. Trend of Global Membrane Research on SWRO Membranes

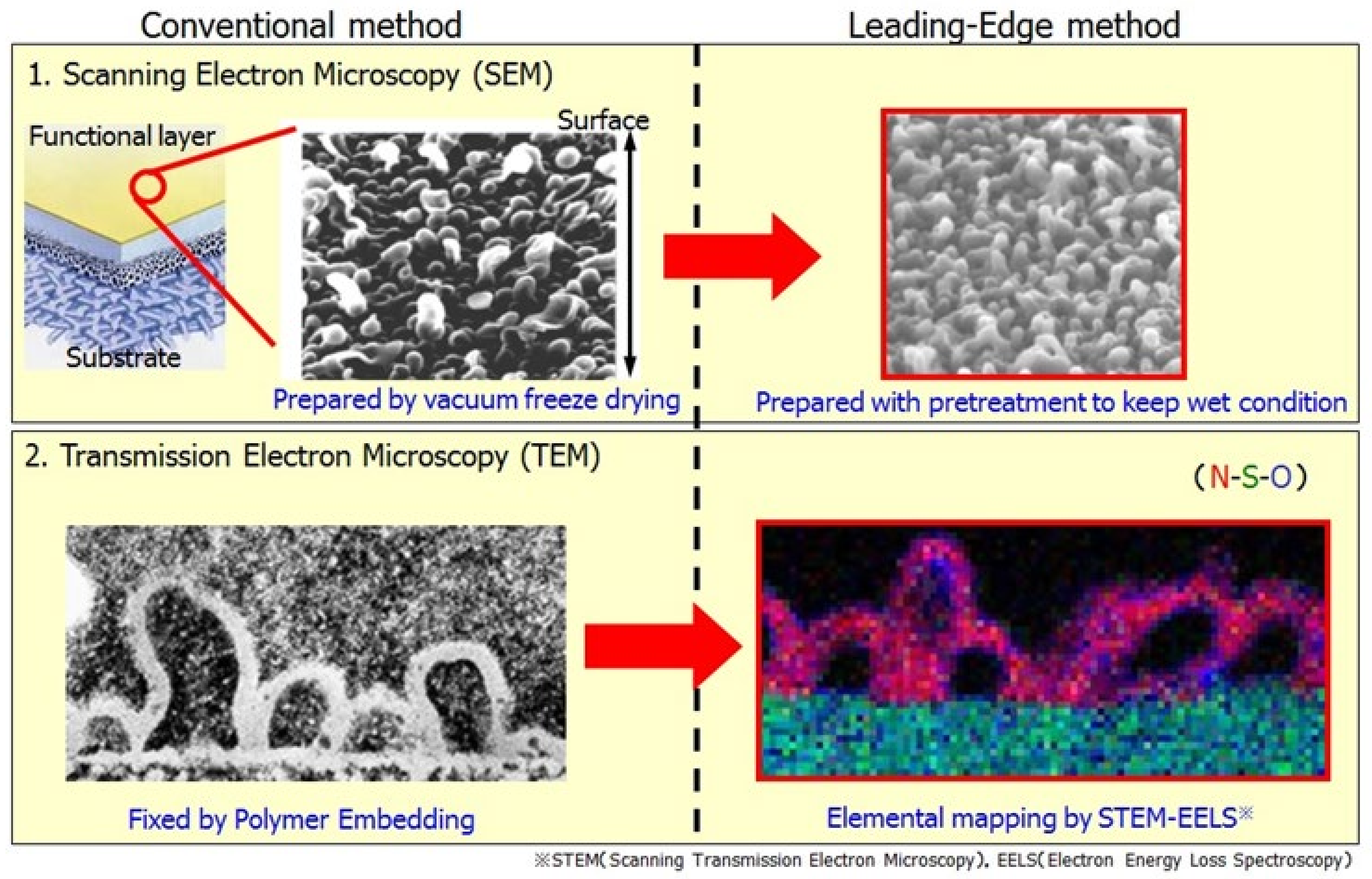

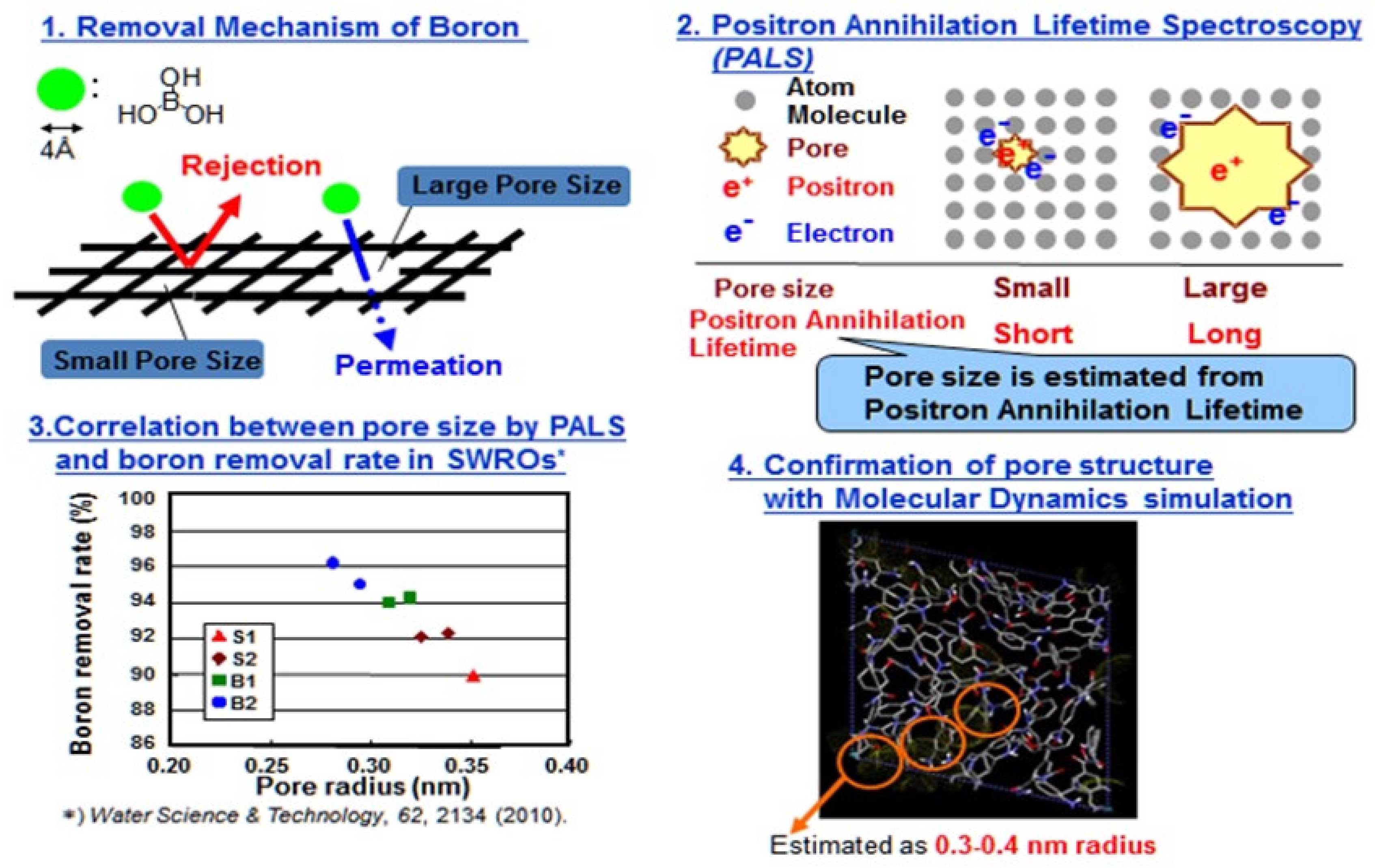

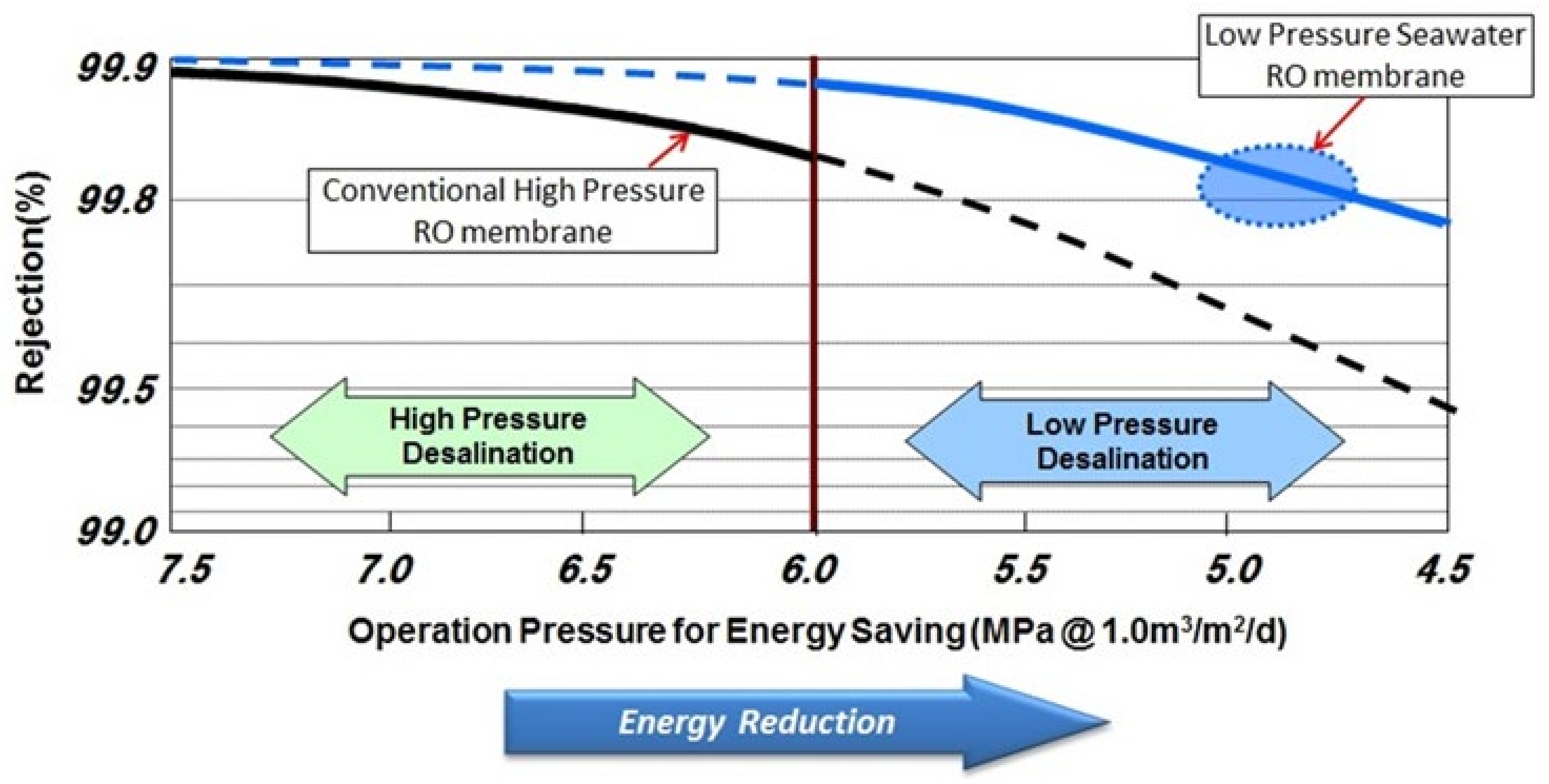

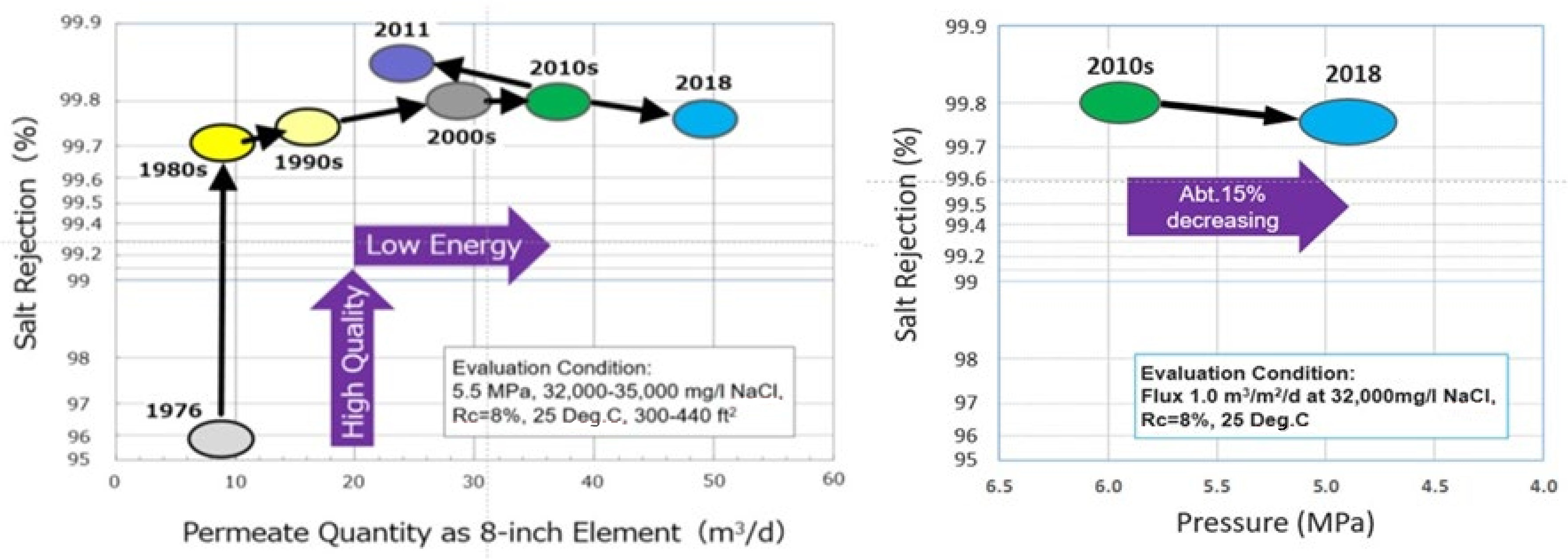

2.3.2. Progress of SWRO Membrane Technology in “Mega-Ton Water System” Project

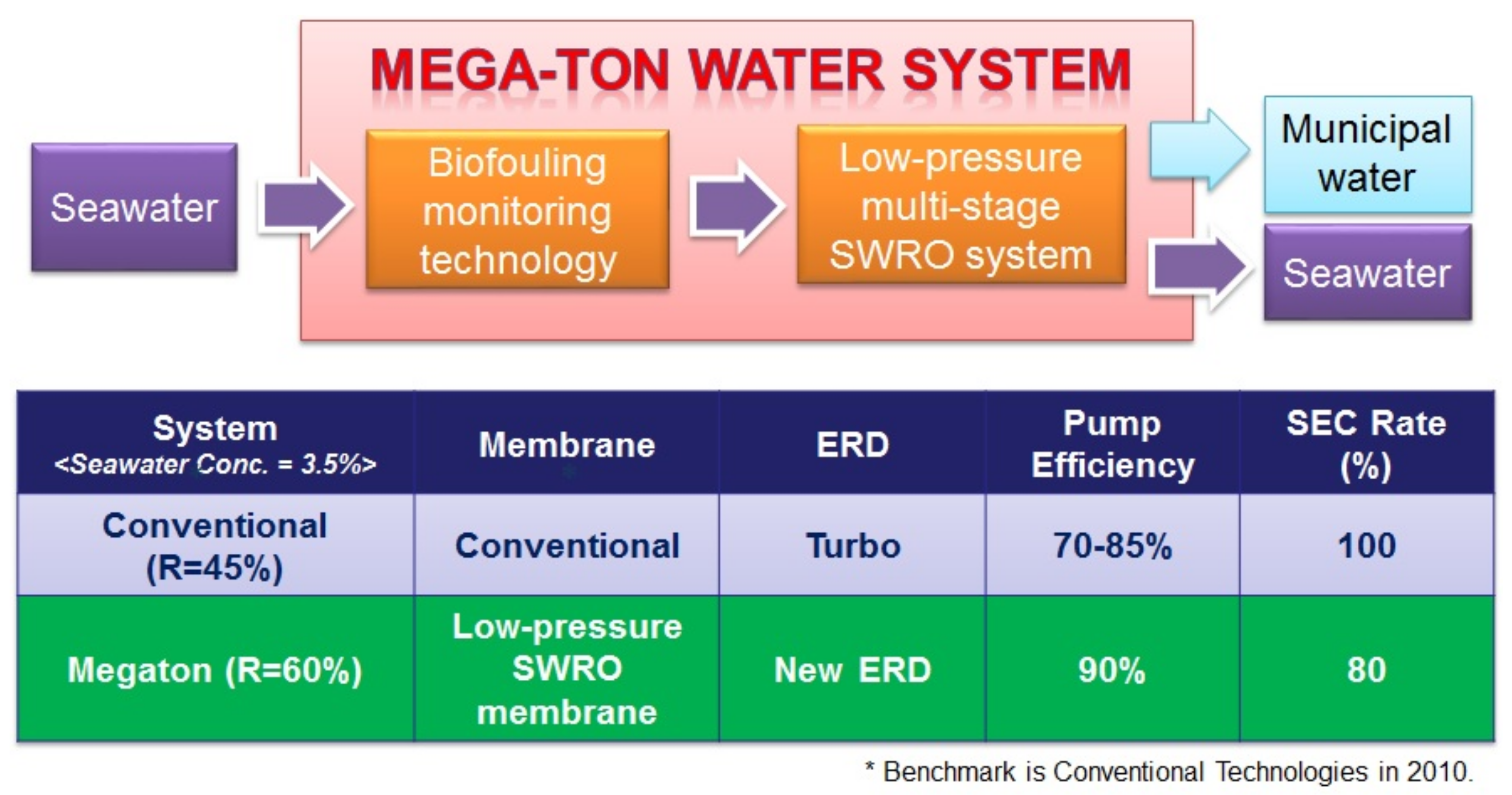

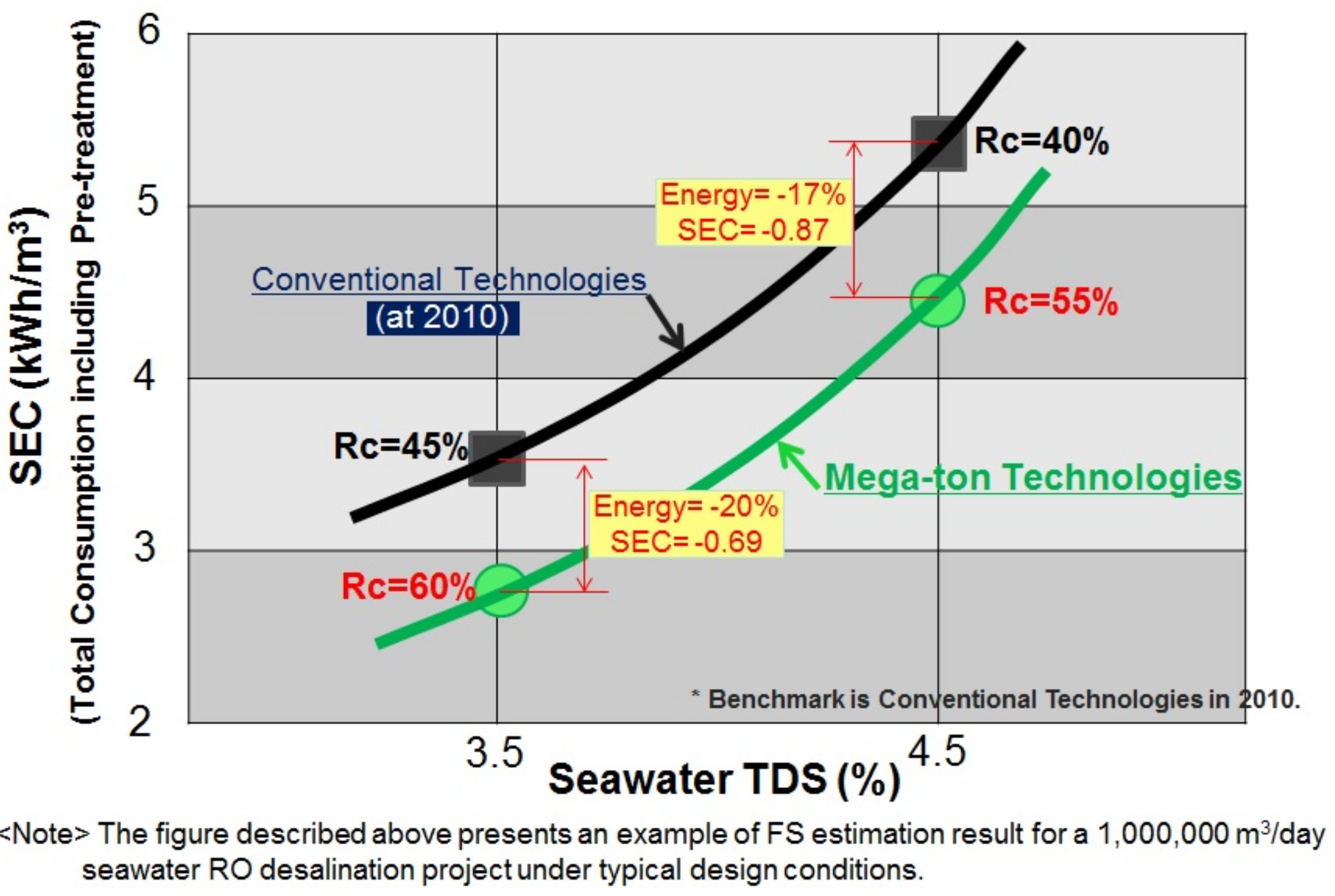

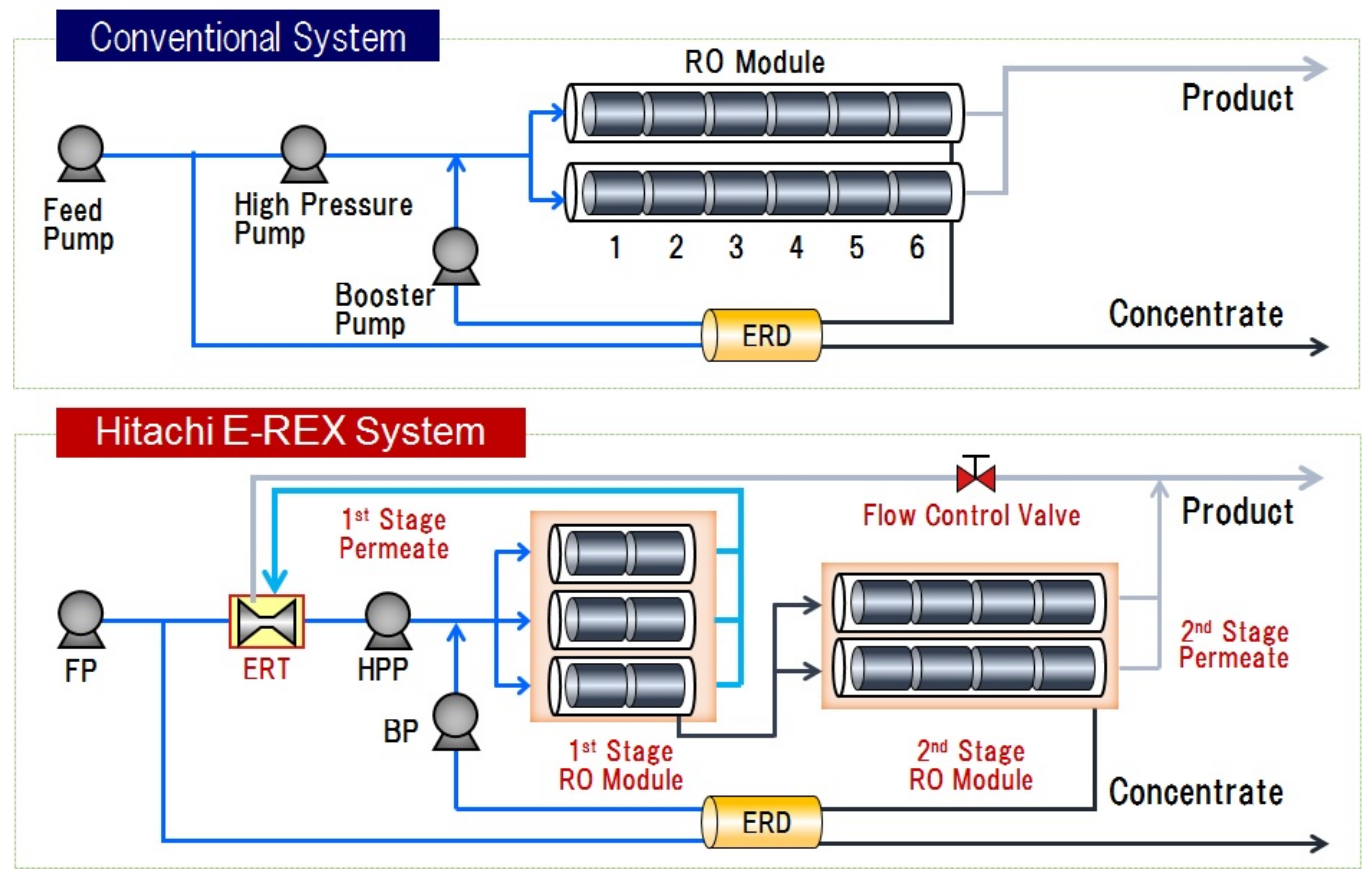

3. SEC Rate Comparison of Conventional SWRO and “Mega-Ton Water System” (LMS)

3.1. Low Environmental Impact and Reliable Plant Operation: Green Desalination

3.1.1. Green Desalination

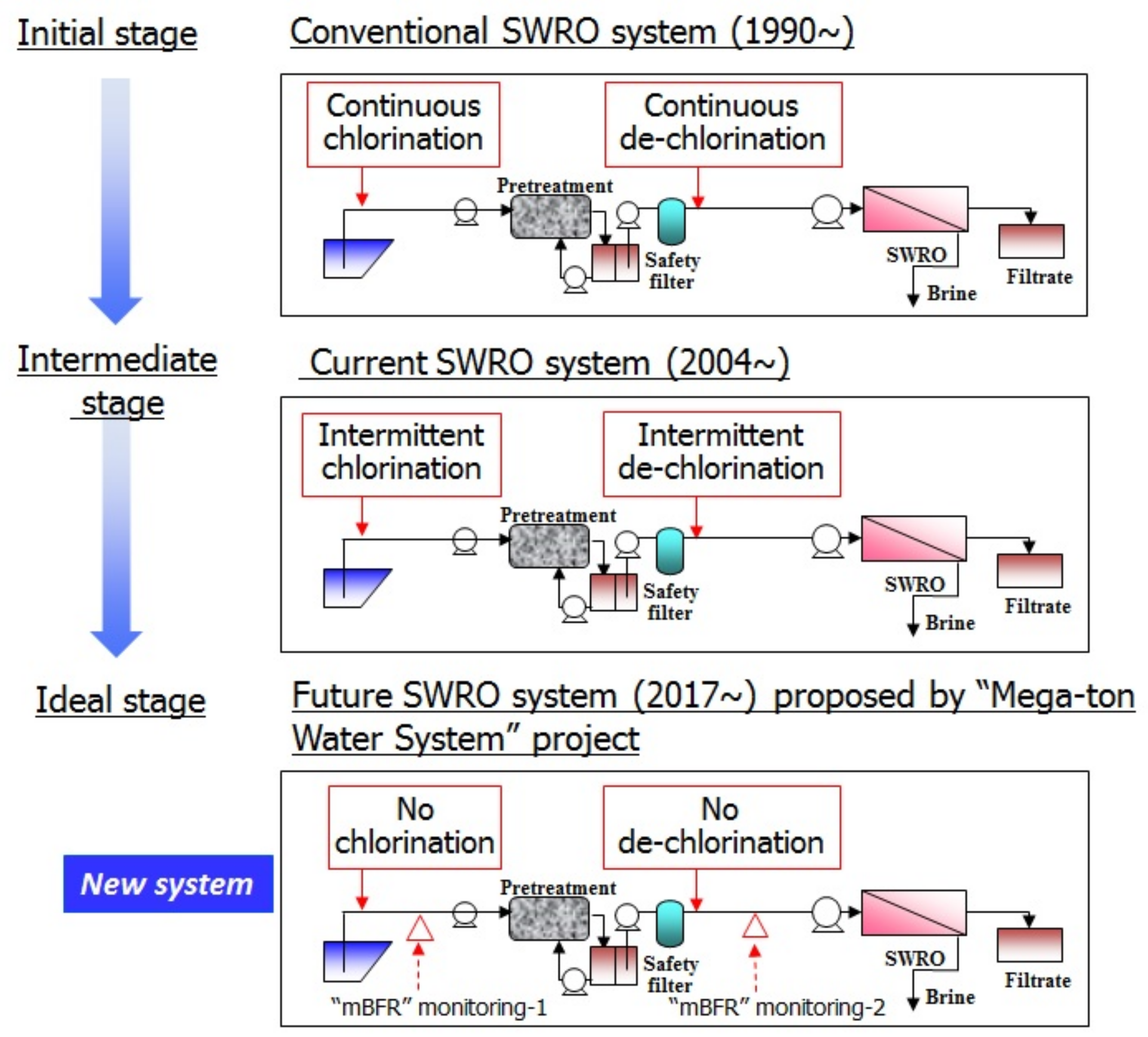

3.1.2. History of Anti-Biofouling Trials

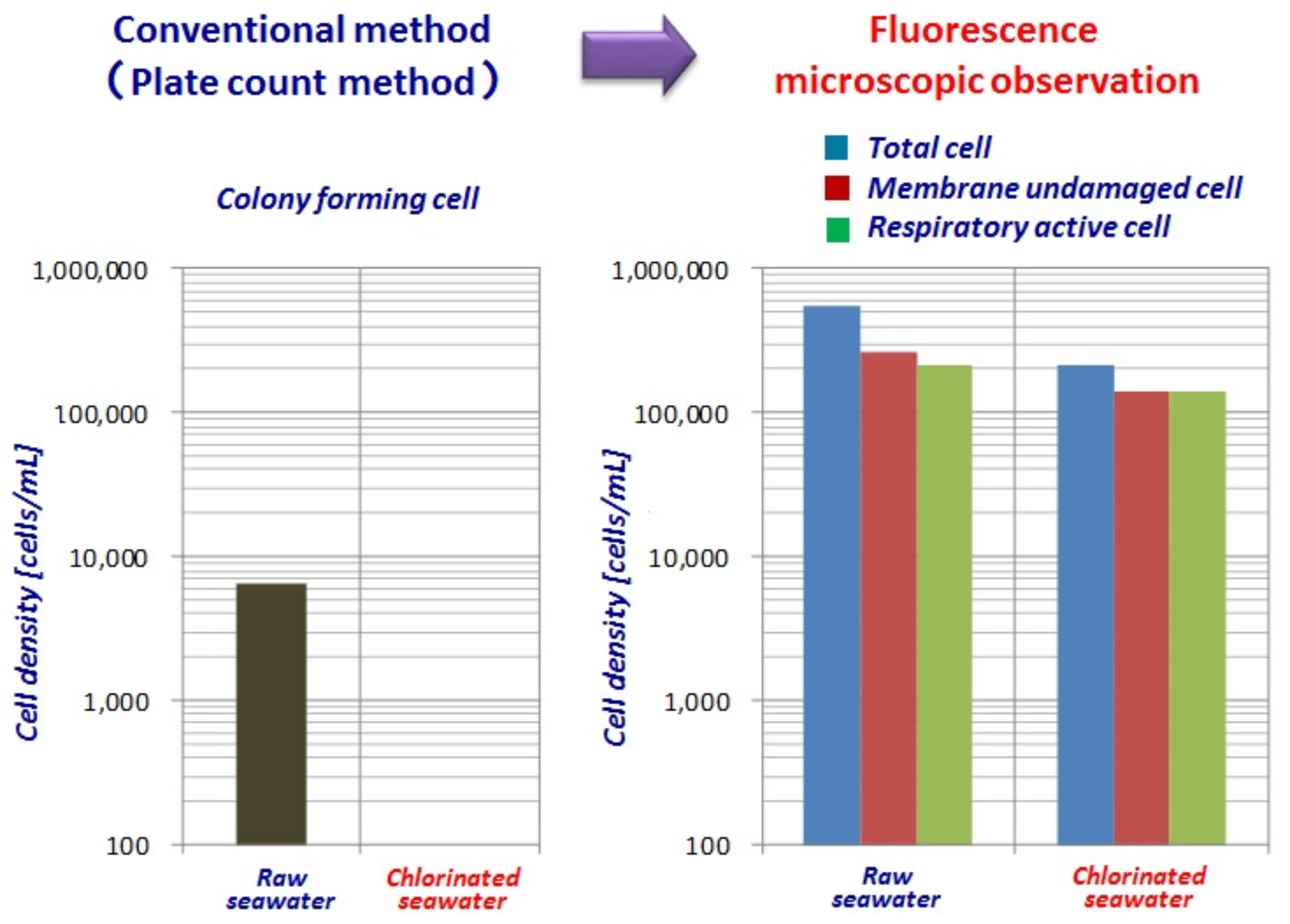

3.1.3. Chlorine Sterilization Has No Effect on Marine Bacteria

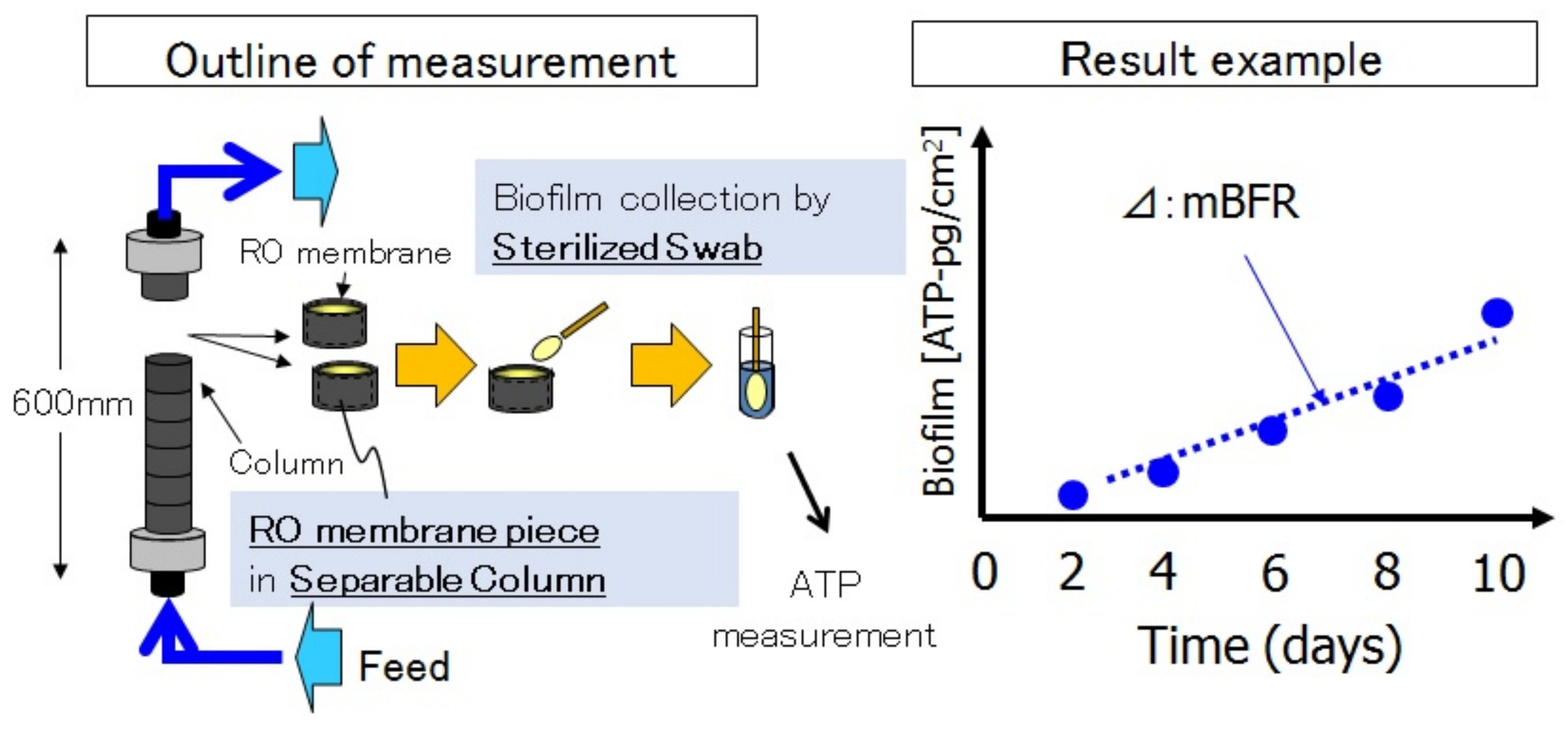

3.1.4. “mBFR”: Membrane Biofilm Formation Rate

3.1.5. Chlorine Sterilization and SBS Dosing Triggers Biofouling

3.1.6. Quantitative RO Chemical Cleaning Interval Due to Biofouling

4. Future and Challenge of Membrane and Membrane Process

4.1. Prof. Rong Wong’s Review on SWRO Membrane Fabrication

4.2. SWCC Future Plans for SWRO

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations:

| Reverse osmosis (RO) | A method of separating water from dissolved salts by passing feed water through a semipermeable membrane at a pressure greater than the osmotic pressure caused by the dissolved salts. |

| Multi-stage flash evaporation (MSF) | A desalination process where a stream of brine flows through the bottom of chambers, or stages, each operating at a successively lower pressure and a proportions of it flashes into stream and is then condensed. |

| Multiple effect distillation (MED) | A thin film evaporation process where the vapor formed in a chamber, or effect con-denses in the next, providing a heat source for further evaporation. |

| Biofouling | Condition caused when bacteria growth forms a deposit on a filter membrane or heat transfer surface. |

| Pressure retarded osmosis (PRO) | PRO, proposed by Sidney Loeb, is a method of recovering the concentration difference (osmotic pressure) of energy using a separation membrane. |

| Seawater reverse osmosis (SWRO) | Desalination of seawater using reverse osmosis (RO) membrane. |

| High recovery SWRO system | High yield of permeate water from the feed seawater in SWRO system. |

| Green desalination | No chemical or less chemical system in SWRO system to save marine pollution and chemical cleaning of the plant. |

| “Mega-SWRO” | Large plants of the mega-ton per day scale (500,000 to 1,000,000 m3/day) |

| SWRO-PRO hybrid system | New energy recovery system from the brine of SWRO with the treated wastewater to use the salinity difference. |

| Brine concentration | SWRO needs the new technology for zero liquid discharge (ZLD) and precious material recovery from the brine SWRO plants. |

| “Mega-ton Water System” project | This project was funded by a grant from the Japanese Society of the Promotion of Science (JSPS). |

| GCC countries | UAE, Qatar, Kuwait, Saudi Arabia, Oman, and Bahrain |

| SEC | Specific energy consumption of the plant system (SEC: kWh/m3). |

| Renewable energy | Solar power and wind power energies. |

| BCS | Brine conversion system reducing the footprint, power, and cost of SWRO plants by high recovery operations. |

References

- Kennedy, J.F. The American Presidency Project. The President’s News Conference, 12 April 1961. Available online: https://www.presidency.ucsb.edu/documents/the-presidents-news-conference-211 (accessed on 18 November 2021).

- Tambo, N. Infrastructure Development Under Decreasing Population–A Design from Expansion to Shrink; Japan Society of Civil Engineers: Tokyo, Japan, 2002. [Google Scholar]

- Global Water Intelligence. DesalData, Desalination Projects, 27 December 2020. Available online: https://www.desaldata.com/projects (accessed on 18 November 2021).

- Kurihara, M.; Sakai, H.; Tanioka, A.; Tomioka, H. Role of Pressure-Retarded Osmosis (PRO) in the Mega-ton Water Project. Desalin. Water Treat. 2016, 57, 26518–26528. [Google Scholar] [CrossRef]

- Kurihara, M.; Hanakawa, M. Mega-ton Water System: Japanese National Research and Development Project on Seawater Desalination and Wastewater Reclamation. Desalination 2013, 308, 131–137. [Google Scholar] [CrossRef]

- Althman, T. Accelerating Innovation in Desalination, Water Forum, Riyadh Saudi Arabia 19 March 2019. Available online: https://swforum.sa/en/media-center-2019 (accessed on 18 November 2021).

- Kurihara, M. Sustainable Seawater Reverse Osmosis Desalination as Green Desalination in the 21st Century. J. Membr. Sci. Res. 2020, 6, 20–29. [Google Scholar]

- Loeb, S.; Sourijan, S. Saline Advance. Chem. Ser. 1962, 38, 117. [Google Scholar]

- Cadotte, J.E. Evolution of Composite Reverse Osmosis Membranes. In Material Science of Synthetic Membranes; Lloyd, D.R., Ed.; American Chemical Society: Washington, DC, USA, 1985; pp. 273–294. [Google Scholar]

- Petersen, R.J. Composite Reverse Osmosis and Nanofiltration Membranes. J. Membr. Sci. 1993, 83, 81–150. [Google Scholar] [CrossRef]

- Kurihara, M. Evolution of Composite Reverse Osmosis Membranes; IDA Global Connections: Spring Topsfield, MA, USA, 2021; pp. 43–45. [Google Scholar]

- Takabatake, H.; Taniguchi, M.; Kurihara, M. Advanced Technologies for Stabilization and High Performance of Seawater RO Membrane Desalination Plants. Membranes 2021, 11, 138. [Google Scholar] [CrossRef] [PubMed]

- Created by Toray from GWI/Desal Data on 2 July 2021.

- Al-Abdulkareem, A.B.I. Governor of Saline Water Connection Corporation (SWCC), SWCC’s Vision for the Future; IDA Global Connections: Spring Topsfield, MA, USA, 2021; pp. 19–23. Available online: https://issuu.com/idadesal/docs/ida_global_connections_winter19 (accessed on 18 November 2021).

- Kurihara, M.; Sasaki, T. The Pursuits of Ultimate Membrane Technology including Low Pressure Seawater Reverse Osmosis Membrane developed by “Mega-ton Water System” Project. J. Membr. Sci. Res 2017, 3, 157–173. [Google Scholar]

- Kurihara, M.; Sasaki, T. 4.7 The Most Advanced Membrane Analysis and the Save-Energy Type Membrane-Low-Pressure Seawater Reverse Osmosis Membrane Developed by “Mega-ton Water System” Project. In Comprehensive Membrane Science and Engineering; Elsevier BV: Amsterdam, The Nederlands, 2017; Volume 4, pp. 131–149. [Google Scholar]

- Kurihara, M.; Sasaki, T.; Nakatsuji, K.; Kimura, M.; Henmi, M. Low pressure SWRO membrane for desalination in the Mega-ton Water System. Desalination 2015, 368, 135–139. [Google Scholar] [CrossRef]

- Kim, I.S. Pressure-Assisted Forward Osmosis (PAFO), Reverse osmosis (RO) Hybrid process, Step Toward Commercial Reality. In Proceedings of the 12th SWA-APDA Joint Conference, Singapore, 11 July 2018. [Google Scholar]

- Kim, J.; Park, K.; Yang, D.R.; Hong, S. Osmotic dilution and osmotic energy recovery for low-energy seawater reverse osmosis desalination. In Proceedings of the IDA World Congress, Dubai, United Arab Emirates, 20–24 October 2019. [Google Scholar]

- Endo, M.; Cruz-Silva, R.; Morelos-Gomez, A. Antifouling and chlorine resistant carbon nanotubes-aromatic polyamide de-salination membranes. In Proceedings of the IDA World Congress, Dubai, United Arab Emirates, 20–24 October 2019. [Google Scholar]

- Endo, M. New Development of Carbon Nanotube-Aromatic Polyamide Desalination Membrane; JDA Forum: Tokyo, Japan, 2018. [Google Scholar]

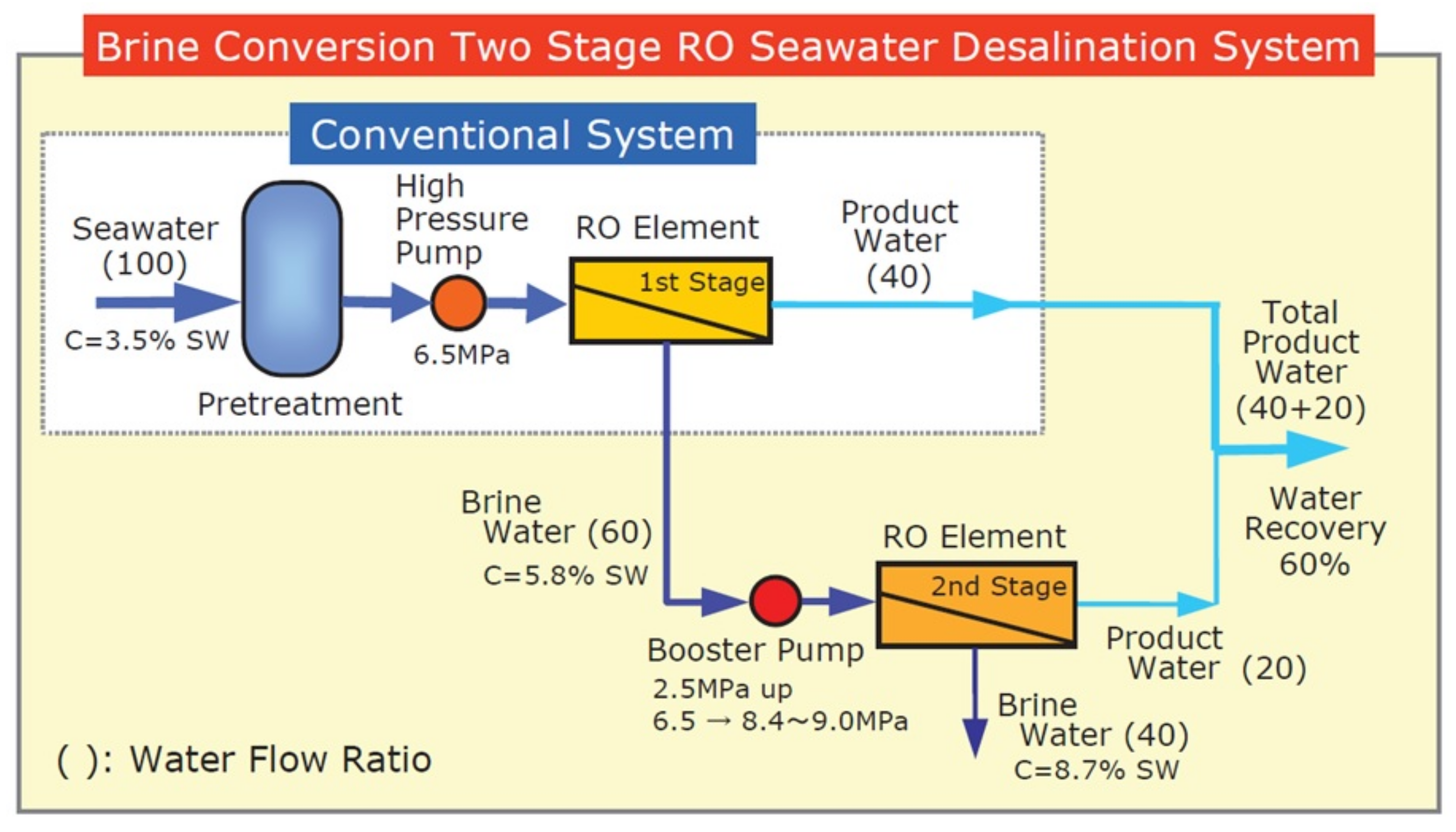

- Kurihara, M.; Yamamura, H.; Nakanishi, T. High Recovery/High Pressure Membranes for Brine Conversion SWRO Process Development and its Performance data. Desalination 1999, 125, 9–15. [Google Scholar] [CrossRef]

- Wei, Q.J.; McGovern, R.K. Saving Energy with an Optimized Two-Stage Reverse Osmosis System. Environ. Sci. Water Res. Technol. 2017, 3, 659–670. [Google Scholar] [CrossRef] [Green Version]

- Wei, Q.; McGovern, R.; Lienhard, J.H.V. Two-Stage Reverse Osmosis: Optimal Element Configuration and Energy Savings. In Proceedings of the IDA World Congress, São Paulo, Brazil, 15–20 October 2017. [Google Scholar]

- Kurihara, M.; Takeuchi, H. SWRO-PRO System in “Mega-ton Water System” for Energy Reduction and Low Environmental Impact. Water 2018, 10, 48. [Google Scholar] [CrossRef] [Green Version]

- Kishizawa, N.; Tsuzuki, K.; Hayatsu, M. Low pressure multi-stage RO system developed in “Mega-ton Water System” for large-scaled SWRO plant. Desalination 2015, 368, 81–88. [Google Scholar] [CrossRef]

- Takahashi, T.; Shinoda, M.; Takita, S.; Goto, A. A Next-Generation Isobaric Energy Recovery Device with Piston-less and No-Leakage Concepts for SWRO Desalination; IDAWC: Tianjin, China, 2013. [Google Scholar]

- Kurihara, M.; Takeuchi, H.; Ito, Y. A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact. Environments 2018, 5, 127. [Google Scholar] [CrossRef] [Green Version]

- Kurihara, M. Comparison Between Conventional Technologies and Mega-ton Technologies on the SEC (kWh/m3) Consumption; Saudi Water Forum: Riyadh, Saudi Arabia, 2019. [Google Scholar]

- Kurihara, M.; Kurokawa, H. Further Progress of “Mega-ton Water System”. In Proceedings of the 12th, SWA-APDA Joint Conference, Singapore, 11 July 2018. [Google Scholar]

- Nikolay, V. In Proceedings of the Saudi Water Forum Workshop, Riyadh, Saudi Arabia, 17 March 2019.

- Lattemann, S.; Höpner, T. Environmental impact and impact assessment of seawater desalination. Desalination 2008, 220, 1–15. [Google Scholar] [CrossRef]

- Jones, E.; Qadir, M.; van Vliet, M.T.; Smakhtin, V.; Kang, S.-M. The state of desalination and brine production: A global outlook. Sci. Total. Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef] [PubMed]

- Hayward, K. Desalination and the Drive for Progress with Unconventional March 2019. Available online: https://www.thesourcemagazine.org/desalination-and-thedrive-for-progress-with-unconventional-resources/ (accessed on 18 November 2021).

- Al-Hazmi, A. SWCC Provides Stewardship to the Aquatic Environment by Applying advanced Technology and Science; IDA Global Connections: Spring Topsfield, MA, USA, 2019; pp. 15–16. Available online: https://issuu.com/idadesal/docs/ida_global_connections_spring19 (accessed on 18 November 2021).

- The State of Desalination, Water Reuse and Environmental Stewardship. In Views from the Experts; IDA Global Connections Spring: Topsfield, MA, USA, 2019; pp. 26–41. Available online: https://issuu.com/idadesal/docs/ida_global_connections_spring19 (accessed on 18 November 2021).

- Kimura, T.; Ito, Y.; Nakaoki, Y. Innovative Biofouling Prevention on Seawater Desalination Reverse Osmosis Membrane; International Desalination Association: Oxford, UK, 2001. [Google Scholar]

- Ito, Y.; Hanada, S.; Kitada, T.; Tanaka, Y.; Kurihara, M. Clarification of Impact of Biofouling Triggered by Chemical Addition for Designing a Mega-ton SWRO Plant; IDAWC: Tianjin, China, 2013. [Google Scholar]

- Ito, Y.; Kantan, S.; Maeda, T.; Okubo, K.; Taniguchi, M. Innovative Biofouling Monitoring Device and its Criteria for Reverse Osmosis plant Operation and Optimization; IDAWC: San Diego, CA, USA, 2015. [Google Scholar]

- Ayumantakath, M.F.; Al Shaiae, M.M.; Green, T.N.; Miyakawa, H.; Ito, Y.; Kurokawa, H.; Fusaoka, Y.; Al Amomudi, A.S. Reliable Seawater RO Operation with High Water Recovery and No-Chlorine/No-SBS Dosing in Arabian Gulf; IDAWC: Dubai, UAE, 2019. [Google Scholar]

- Lim, Y.J.; Goh, K.; Kurihara, M.; Wang, R. Seawater desalination by reverse osmosis: Current development and future challenges in membrane fabrication—A review. J. Membr. Sci. 2021, 629, 119292. [Google Scholar] [CrossRef]

- Al-Abdulkareem, A.B.I. SWCC Governor Interview; IDA Global Connection Summer: Topsfield, MA, USA, 2020. [Google Scholar]

- Al-Abdulkareem, A.B.I. In Proceedings of the Innovation in Desalination Brine Mining IDA Webinar SWCC Governor, online, 29 July 2020.

- Water Desalination Report, Volume 56, Number 33, p. 7, September 2020. Available online: https://www.desalination.com/issues/2766 (accessed on 18 November 2021).

- Global Water Intelligence Magazine, 5 July 2020. Available online: https://www.globalwaterintel.com/subscribe (accessed on 18 November 2021).

| Company | Membrane/ Element | Chemical Formula | Product in 2020 | Data Resources |

|---|---|---|---|---|

| Dupont | B-10 -Asymmetric hollowfiber- |  | ✖ | 1 |

| A-15 -Composite spiral- |  | ✖ | 2 | |

| FilmTec/ Dow/Dupont Water Solutions | FT-30 -Composite spiral- |  | ○ | 2 |

| Toyobo | HOLLOSEP -Asymmetric hollowfiber- |  | ○ | 3 |

| Toray | PEC-1000 -Composite spiral- |  | ✖ | 2 |

| UTC-80 -Composite spiral- |  | ○ | 2 | |

| Nitto Hydranautics | -Composite spiral- | Similar to FT-30 | ○ | - |

| LG Chem | -Composite spiral- | Similar to FT-30 | ○ | - |

| Data Resources: 1. USP 3567632A 2. Peterson, R. J. Journal of Membrane Science,83(1993)81-150,Elsevier Science Publishers B. B:Amsterdam. 3. Takahito Nakao, Yuki Miura, Kenji Furuichi and Masahiro Yasukawa, Membranes2021, 11, 183. https://doi.org/10.3390/membranes11030183. | ||||

| Specifications | |||

|---|---|---|---|

| Product | TDS Rejection (%) | Water Productivity (GDP, (m3/day)) | Boron Rejection (%) |

| TM820A | 99.75 | 6000 (22.7) | 93 |

| TM820C | 99.75 | 6500 (24.6) | 93 |

| TM820E | 99.75 | 7500 (28.0) | 91 |

| TM820S | 99.75 | 9000 (34.1) | 90 |

| TM820R | 99.80 | 9400 (35.6) | 95 |

| TM820C | 99.2 | 8800 (33.3) | 94 |

| TM820K | 99.86 | 6400 (24.2) | 96 |

| SWCC Future Plans |

|---|

| Exploration of renewable power alternative |

| Development of new generation of energy recovery devices, high pressure pumps and membranes |

| Energy use for desalination: less than 2.45 kWh/m3 as total energy |

| CO2 emission reduction for desalination plants: over 30% |

| Total energy use for new brine mining: less than 50% lower than the most advanced ZLD technologies at present |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurihara, M. Current Status and Future Trend of Dominant Commercial Reverse Osmosis Membranes. Membranes 2021, 11, 906. https://doi.org/10.3390/membranes11110906

Kurihara M. Current Status and Future Trend of Dominant Commercial Reverse Osmosis Membranes. Membranes. 2021; 11(11):906. https://doi.org/10.3390/membranes11110906

Chicago/Turabian StyleKurihara, Masaru. 2021. "Current Status and Future Trend of Dominant Commercial Reverse Osmosis Membranes" Membranes 11, no. 11: 906. https://doi.org/10.3390/membranes11110906

APA StyleKurihara, M. (2021). Current Status and Future Trend of Dominant Commercial Reverse Osmosis Membranes. Membranes, 11(11), 906. https://doi.org/10.3390/membranes11110906