A Real-Time Numerical Decoupling Method for Multi-DoF Magnetic Levitation Rotary Table

Abstract

1. Introduction

- Look-up table or curving fitting model using the measurements and results from finite-element method (FEM) software [29].

2. Magnetic Levitation Rotary Table and Modeling Method

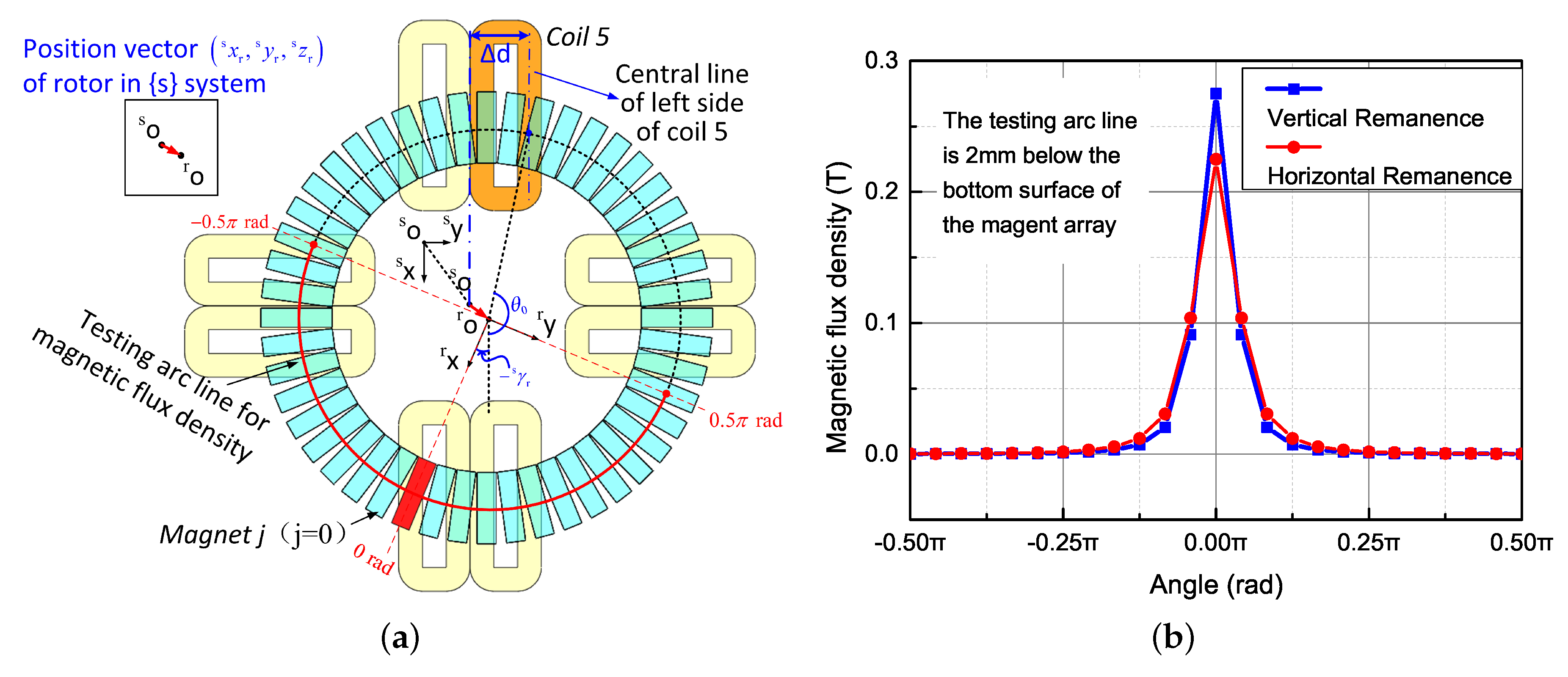

2.1. Working Principle of Maglev Actuator

- This prototype is more suitable to realize translation in the horizontal plane because the area of one phase coil under the magnet array is constant when the rotor translates in the stroke.

- The design expense of the rotor is significantly reduced because it is not required to decrease the gap between the neighboring permanent magnets like the existing actuator in the maglev rotary table.

- The racetrack coil is easier to fabricate, install, and alter to other design parameters.

2.2. Force and Torque Computation

2.2.1. Magnetic Force between Current-Carrying Region and Magnet

2.2.2. Permanent Magnet Selection Law for Magnetic Force Computation

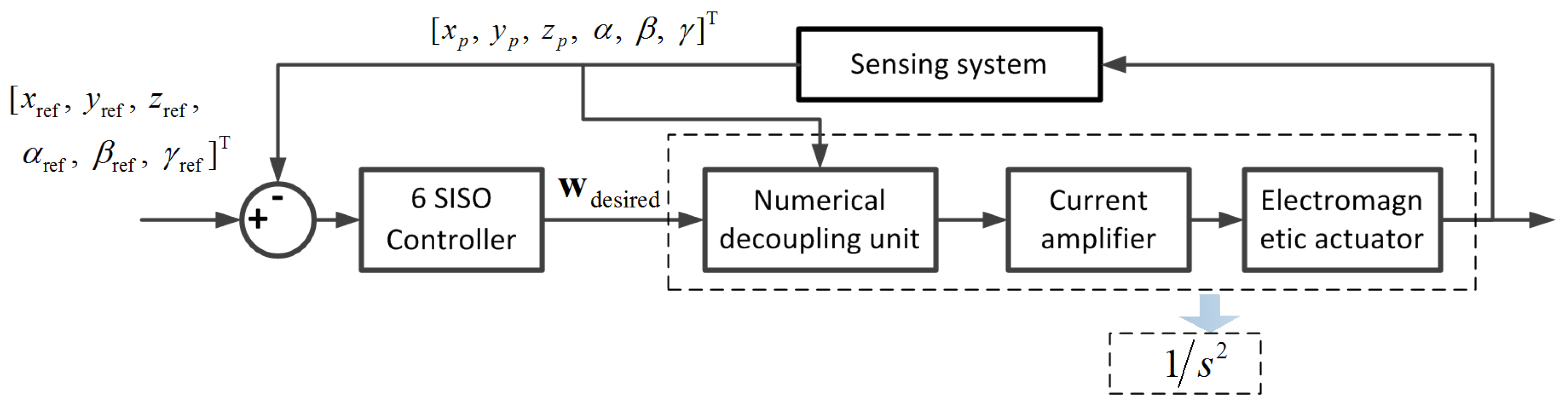

3. Real-Time Decoupling Unit Implemented on FPGA

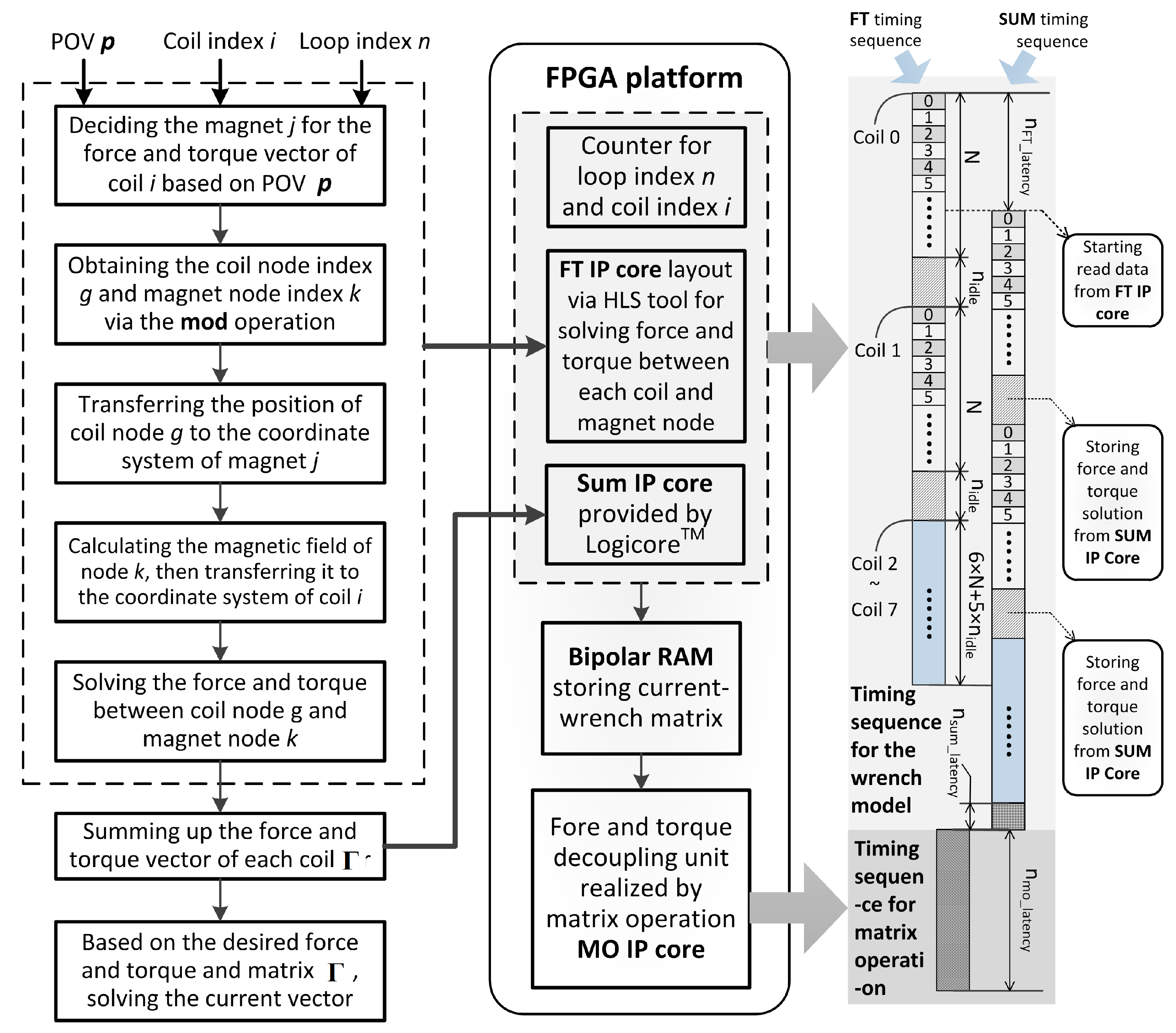

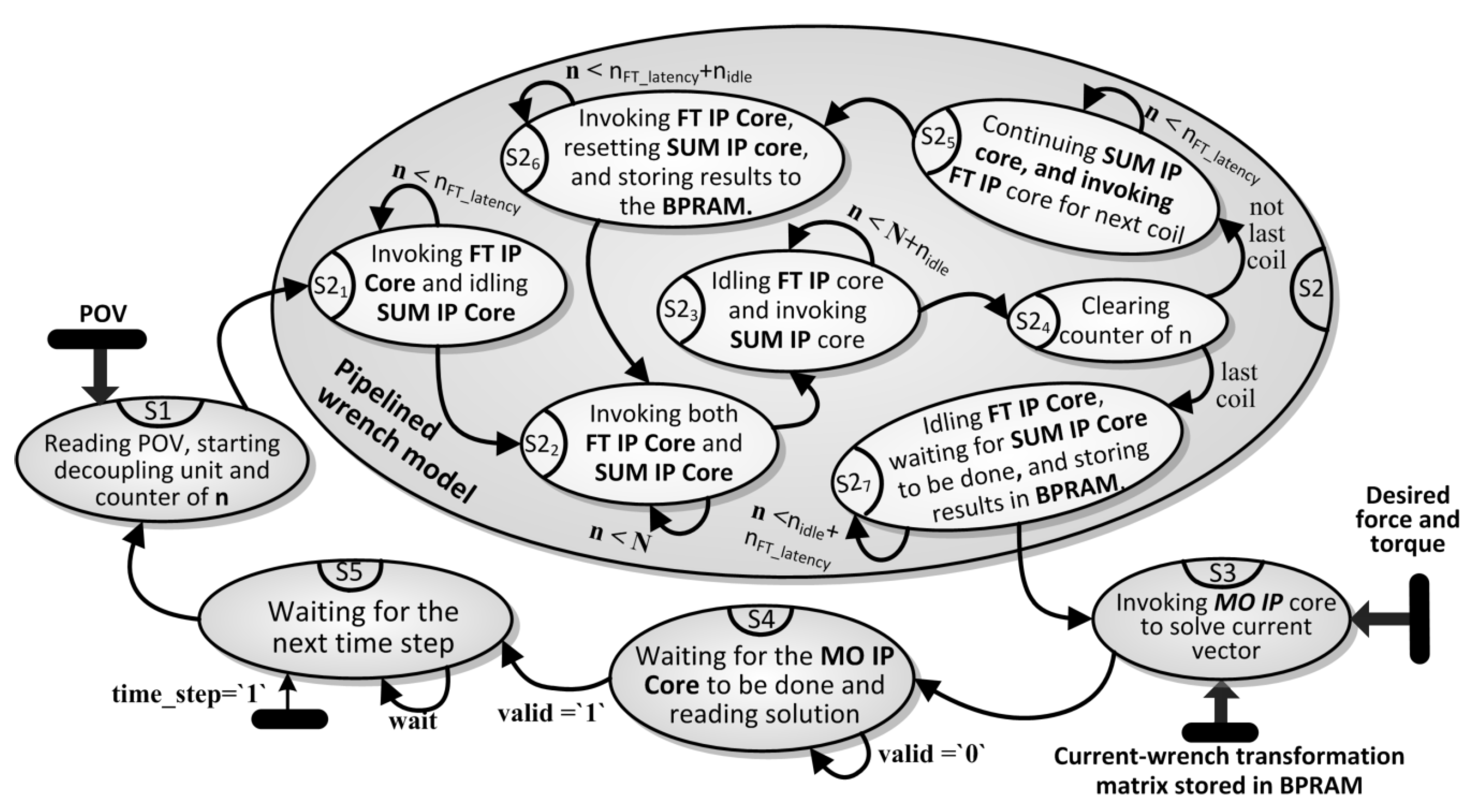

3.1. Implementation on FPGA via High-Level Synthesis (HLS) Tool

3.2. Current Decoupling Unit Implementation

4. Experiment Results

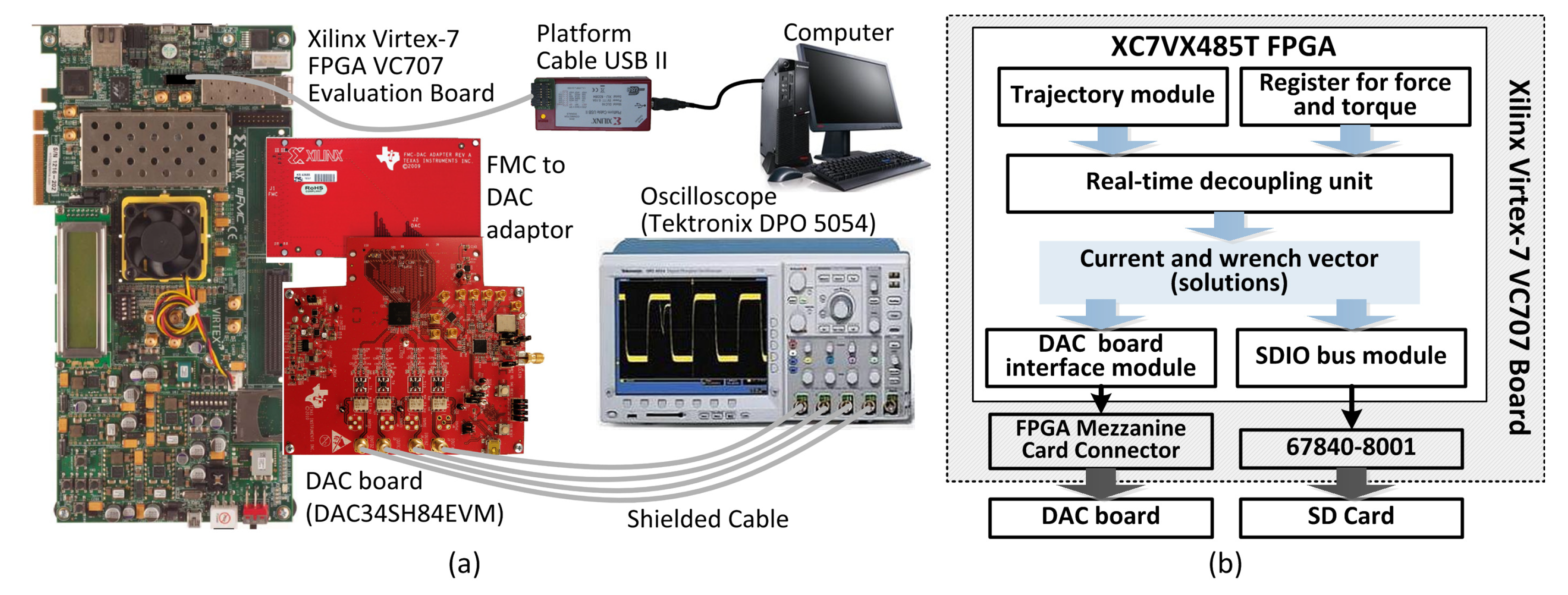

4.1. Experiment Setup

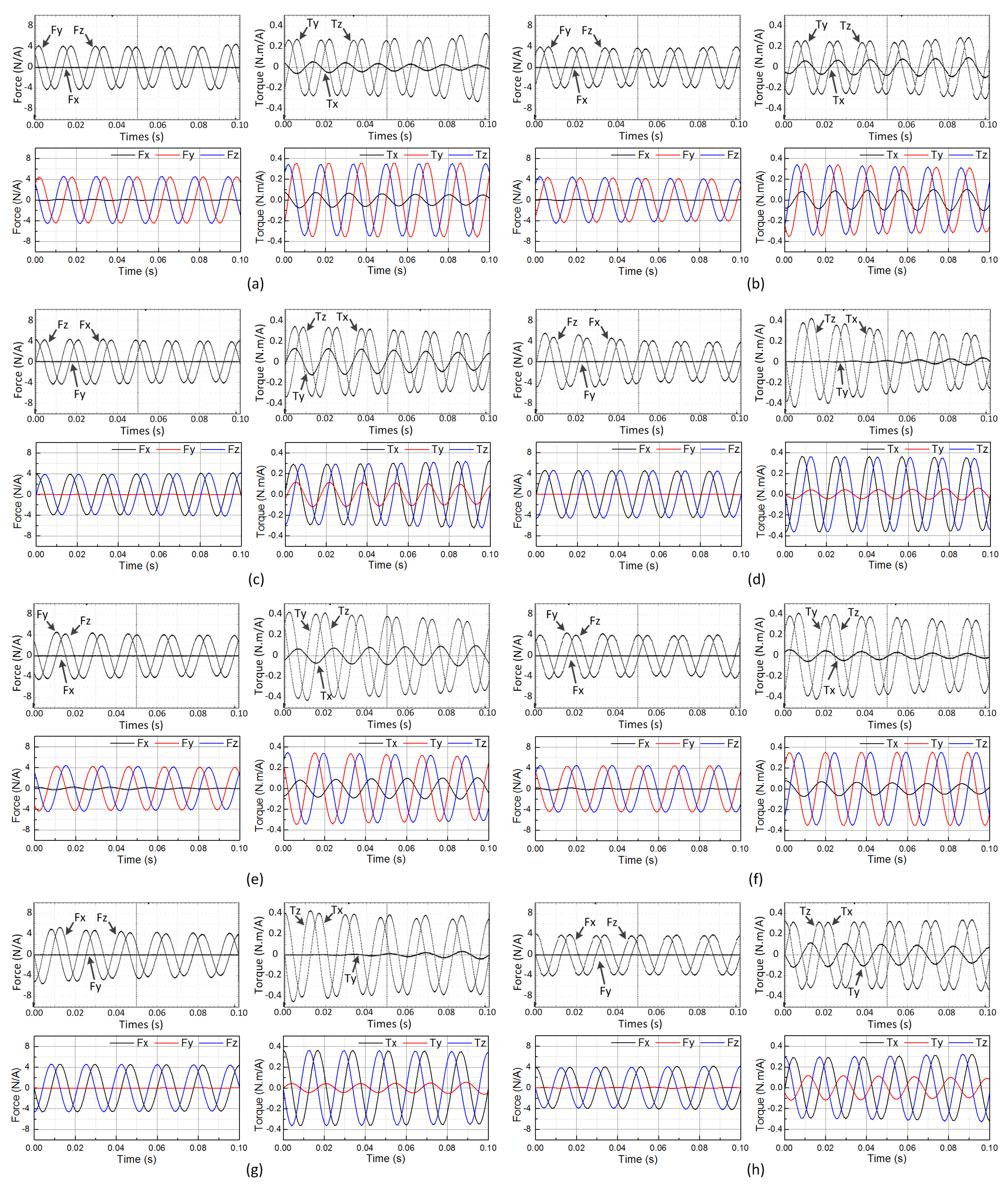

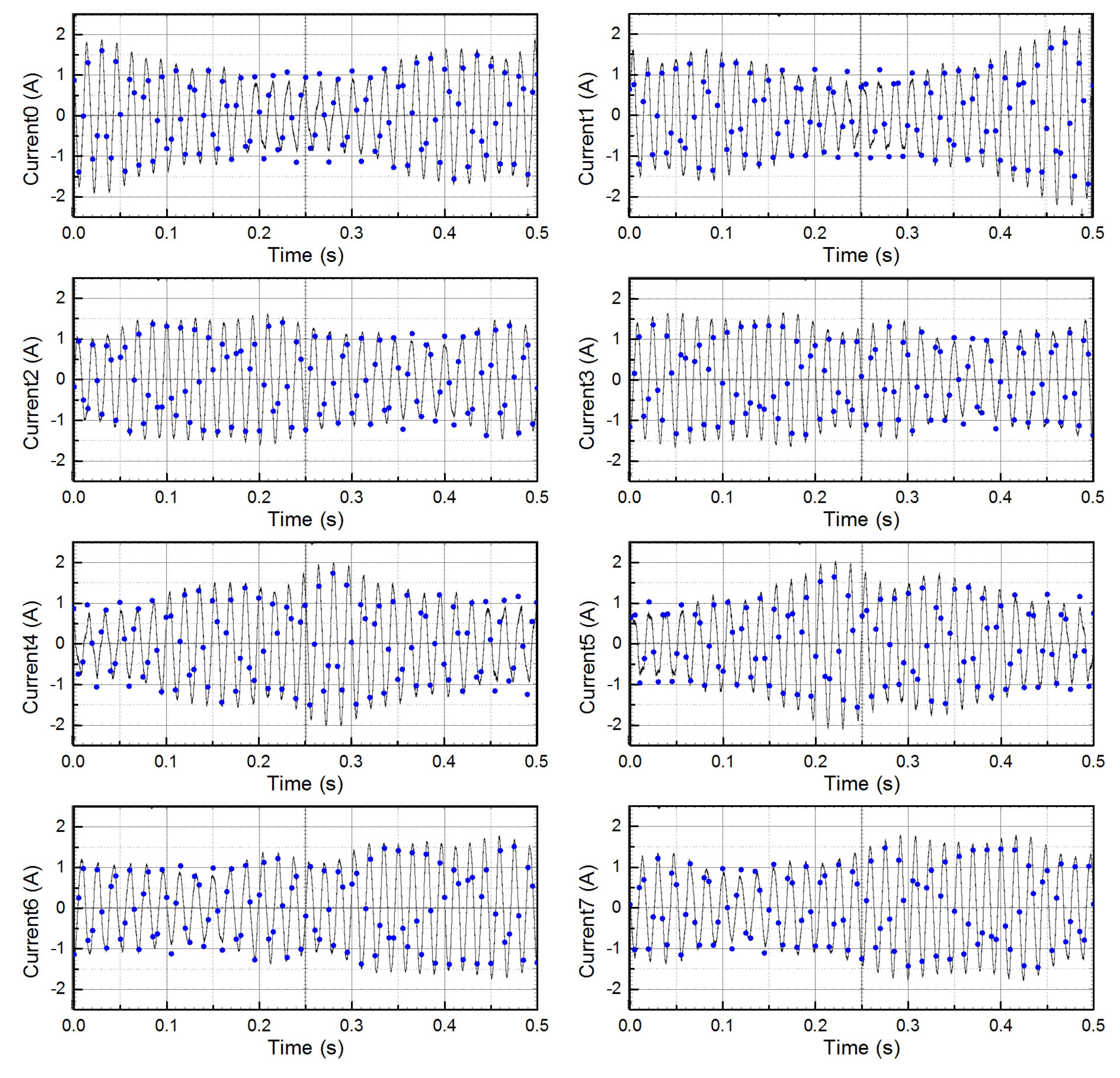

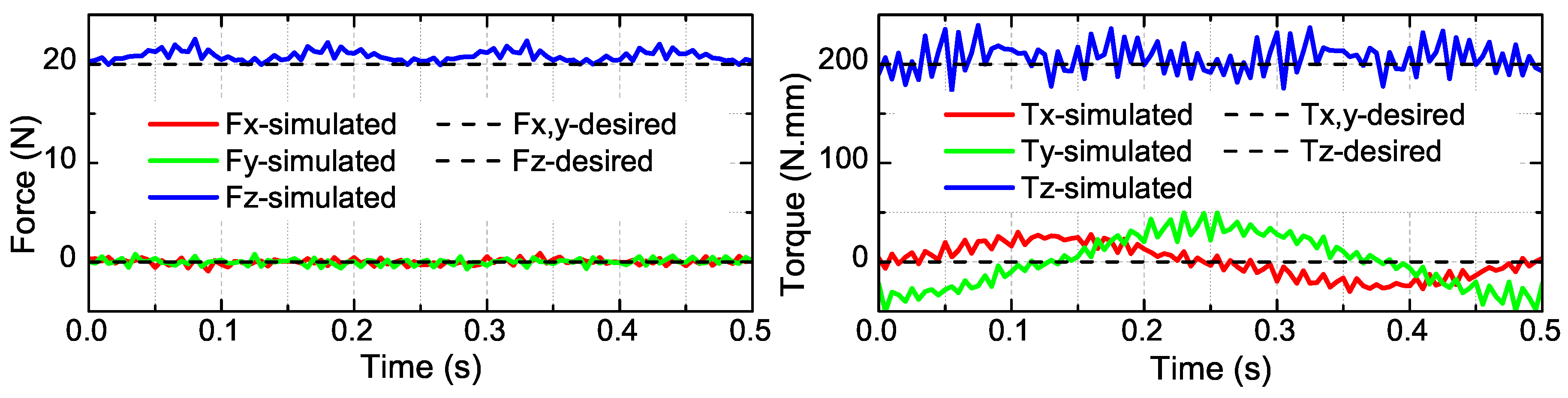

4.2. Validation of the Real-Time Wrench Model and Current Decoupling Unit

4.3. Computation Resource

5. Discussion of FPGA-Based Numerical Current Decoupling Unit for Magnetically Levitated Rotary Actuator

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jansen, J.W.; Van Lierop, C.M.M.; Lomonova, E.A. Magnetically Levitated Planar Actuator with Moving Magnets. IEEE Trans. Ind. Appl. 2008, 44, 1108–1115. [Google Scholar] [CrossRef]

- Hu, C.; Wang, Z.; Zhu, Y.; Zhang, M.; Liu, H. Performance-Oriented Precision LARC Tracking Motion Control of a Magnetically Levitated Planar Motor With Comparative Experiments. IEEE Trans. Ind. Electron. 2016, 63, 5763–5773. [Google Scholar] [CrossRef]

- Kim, W.J.; Verma, S.; Shakir, H. Design and precision construction of novel magnetic-levitation-based multi-axis nanoscale positioning systems. Prec. Eng. 2007, 31, 337–350. [Google Scholar] [CrossRef]

- Zhang, Z.; Menq, C.H. Six-Axis Magnetic Levitation and Motion Control. IEEE Trans. Robot 2007, 23, 196–205. [Google Scholar] [CrossRef]

- Tong, Q.; Yuan, Z.; Liao, X.; Zheng, M.; Yuan, T.; Zhao, J. Magnetic Levitation Haptic Augmentation for Virtual Tissue Stiffness Perception. IEEE Trans. Vis. Comput. Graph. 2018, 24, 3123–3136. [Google Scholar] [CrossRef] [PubMed]

- Pedram, S.A.; Klatzky, R.L.; Berkelman, P. Torque contribution to haptic rendering of virtual textures. IEEE Trans. Haptics 2017, 10, 567–579. [Google Scholar] [CrossRef] [PubMed]

- Pieters, R.; Tung, H.W.; Charreyron, S.; Sargent, D.S.; Nelson, B.J. RodBot: A Rolling Microrobot for Micromanipulation. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4042–4047. [Google Scholar]

- Casson, J.; O’Kane, S.; Smith, C.A.; Dalby, M.; Berry, C. Interleukin 6 plays a role in the migration of magnetically levitated mesenchymal stem cells spheroids. Appl. Sci. 2018, 8, 412. [Google Scholar] [CrossRef]

- Xu, F.; Xu, X.; Chen, M. Prototype of 6-DOF Magnetically Levitated Stage Based on Single Axis Lorentz force Actuator. J. Electr. Eng. Technol. 2016, 11, 1216–1228. [Google Scholar] [CrossRef]

- Zhang, H.; Kou, B.; Jin, Y.; Zhang, H. Modeling and Analysis of a New Cylindrical Magnetic Levitation Gravity Compensator With Low Stiffness for the 6-DOF Fine Stage. IEEE Trans. Ind. Electron. 2015, 62, 3629–3639. [Google Scholar] [CrossRef]

- Dyck, M.; Lu, X.; Altintas, Y. Magnetically Levitated Rotary Table with Six Degrees of Freedom. IEEE/ASME Trans. Mechatron. 2017, 22, 530–540. [Google Scholar] [CrossRef]

- Ouyang, P.R.; Tjiptoprodjo, R.C.; Zhang, W.J.; Yang, G.S. Micro-motion Devices Technology: The State of Arts Review. Int. J. Adv. Manuf. Technol. 2008, 38, 463–478. [Google Scholar] [CrossRef]

- Yuan, L.; Zhang, J.; Chen, S.; Liang, Y.; Chen, J.; Zhang, C. Design and Optimization of a Magnetically Levitated Inductive Reaction Sphere for Spacecraft Attitude Control. Energies 2019, 12, 1553. [Google Scholar] [CrossRef]

- Zhang, H.; Kou, B. Design and Optimization of a Lorentz-Force-Driven Planar Motor. IEEE Trans. Magn. 2007, 23, 196–205. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, J.; Yang, J. Raising Power Loss Equalizing Degree of Coil Array by Convex Quadratic Optimization Commutation for Magnetic Levitation Planar Motors. Appl. Sci. 2019, 9, 79. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Luo, X.; Zhang, L. Analysis and Optimization of a Novel 2-D Magnet Array with Gaps and Staggers for a Moving-Magnet Planar Motor. Sensors 2018, 18, 124. [Google Scholar] [CrossRef] [PubMed]

- Ueda, Y.; Ohsaki, H. A Planar Actuator with a Small Mover Travelling Over Large Yaw and Translational Displacements. IEEE Trans. Magn. 2008, 44, 609–616. [Google Scholar] [CrossRef]

- Lu, X.; Usman, I.U.R. 6D Direct-drive Technology for Planar Motion Stages. CIRP Ann.-Manuf. Technol. 2012, 61, 359–362. [Google Scholar] [CrossRef]

- Xu, F.; Lv, Y.; Xu, X.; Dinavahi, V. FPGA-Based Real-Time Wrench Model of Direct Current Driven Magnetic Levitation Actuator. IEEE Trans. Ind. Electron. 2018, 65, 9635–9645. [Google Scholar] [CrossRef]

- Kou, B.; Xing, F.; Zhang, L.; Zhang, C.; Zhou, Y. A Real-Time Computation Model of the Electromagnetic Force and Torque for a Maglev Planar Motor with the Concentric Winding. Appl. Sci. 2017, 7, 98. [Google Scholar] [CrossRef]

- Xing, F.; Kou, B.; Zhang, L.; Yin, X.; Zhou, Y. Design of a Control System for a Maglev Planar Motor Based on Two-Dimension Linear Interpolation. Energies 2017, 10, 1132. [Google Scholar] [CrossRef]

- Jansen, J.W.; Smeets, J.P.C.; Overboom, T.T.; Rovers, J.M.M.; Lomonova, E.A. Overview of Analytical Models for the Design of Linear and Planar Motors. IEEE Trans. Magn. 2014, 50, 8206207. [Google Scholar] [CrossRef]

- Castellanos, M.L.; Galluzzi, R.; Bonfitto, A.; Tonoli, A.; Amati, N. Magnetic Levitation Control Based on Flux Density and Current Measurement. Appl. Sci. 2018, 8, 2545. [Google Scholar] [CrossRef]

- Jeyasenthil, R.; Choi, S.B. A Robust Controller for Multivariable Model Matching System Utilizing a Quantitative Feedback Theory: Application to Magnetic Levitation. Appl. Sci. 2019, 9, 1753. [Google Scholar] [CrossRef]

- Lahdo, M.; Ströhla, T.; Kovalev, S. Repulsive magnetic levitation force calculation for a high precision 6-DoF magnetic levitation positioning system. IEEE Trans. Magn. 2017, 53, 7020106. [Google Scholar] [CrossRef]

- Yuan, D.; Zhang, M.; Zhu, Y.; Li, X.; Wang, L. Demonstrating the Potential of a Hybrid Model to Increase the 360 Degrees Rotational Motion Freedom of Ironless Permanent Magnet Planar Motors. In ASME International Mechanical Engineering Congress and Exposition; V010T13A007; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar]

- Zhu, Y.; Yuan, D.; Zhang, M.; Liu, F.; Hu, C. Unified wrench model of an ironless permanent magnet planar motor with 2D periodic magnetic field. IET Electr. Power Appl. 2017, 12, 423–430. [Google Scholar] [CrossRef]

- Jansen, J.W.; Van Lierop, C.M.M.; Lomonova, E.A.; Vandenput, A.J.A. Modeling of Magnetically Levitated Planar Actuators With Moving Magnets. IEEE Trans. Magn. 2007, 43, 15–25. [Google Scholar] [CrossRef]

- Estevez, P.; Mulder, A.; Schmidt, R.H.M. 6-DoF Miniature Maglev Positioning Stage for Application in Haptic Micro-manipulation. Mechatronics 2012, 22, 1015–1022. [Google Scholar] [CrossRef]

- Xu, F.; Peng, R.; Zheng, T.; Xu, X. Development and Validation of Numerical Magnetic Force and Torque Model for Magnetically Levitated Actuator. IEEE Trans. Magn. 2019, 55, 4900109. [Google Scholar] [CrossRef]

- Xu, F.; Xu, X.; Li, Z.; Chu, L. Numerical Calculation of the Magnetic Field and Force in Cylindrical Single-Axis Actuator. IEEE Trans. Magn. 2014, 50, 7200506. [Google Scholar] [CrossRef]

- Peng, J.; Zhou, Y.; Liu, G. Calculation of a New Real-time Control Model for the Magnetically Levitated Ironless Planar Motor. IEEE Trans. Magn. 2013, 49, 1416–1422. [Google Scholar] [CrossRef]

- Xu, F.; Dinavahi, V.; Xu, X. Parallel Computation of Wrench Model for Commutated Magnetically Levitated Planar Actuator. IEEE Trans. Ind. Electron. 2016, 63, 7621–7631. [Google Scholar] [CrossRef]

- Bancel, F. Magnetic Nodes. J. Phys. D Appl. Phys. 1999, 32, 2155–2161. [Google Scholar] [CrossRef]

| Order Number | 2-Order | 4-Order | ||||

|---|---|---|---|---|---|---|

| Gaussian node | ||||||

| Gaussian weight | ||||||

| Parameter | Remanence | Coil Turns | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Value | 300 |

| Error Ratio | Coil 0 | Coil 1 | Coil 2 | Coil 3 | Coil 4 | Coil 5 | Coil 6 | Coil 7 |

|---|---|---|---|---|---|---|---|---|

| FPGA Resources | Current Decoupling Module | Data Displaying and Storing Modules | |||

|---|---|---|---|---|---|

| Wrench Model | Matrix Operation | Trajectory | DAC Connector | SDIO Driver | |

| LUT | |||||

| FF | |||||

| DSPs | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zheng, C.; Xu, F. A Real-Time Numerical Decoupling Method for Multi-DoF Magnetic Levitation Rotary Table. Appl. Sci. 2019, 9, 3263. https://doi.org/10.3390/app9163263

Xu X, Zheng C, Xu F. A Real-Time Numerical Decoupling Method for Multi-DoF Magnetic Levitation Rotary Table. Applied Sciences. 2019; 9(16):3263. https://doi.org/10.3390/app9163263

Chicago/Turabian StyleXu, Xianze, Chenglin Zheng, and Fengqiu Xu. 2019. "A Real-Time Numerical Decoupling Method for Multi-DoF Magnetic Levitation Rotary Table" Applied Sciences 9, no. 16: 3263. https://doi.org/10.3390/app9163263

APA StyleXu, X., Zheng, C., & Xu, F. (2019). A Real-Time Numerical Decoupling Method for Multi-DoF Magnetic Levitation Rotary Table. Applied Sciences, 9(16), 3263. https://doi.org/10.3390/app9163263