Maintenance Process Simulation Based Maintainability Evaluation by Using Stochastic Colored Petri Net

Abstract

1. Introduction

2. Definitions Related to Stochastic Colored Petri Nets

2.1. Linear Function L(X)

2.2. Stochastic Colored Petri Net

- is the set of places.

- is the set of transitions.

- is the set of arcs.

- is the set of token colors.

- is the capacity function of the place.

- is the weight function of the arc.

- ( is the marking of the place, and .

- is the set of firing rates, and is the firing rate of the ith transition.

2.3. Pre-Set and Post-Set

2.4. Enabled and Fired

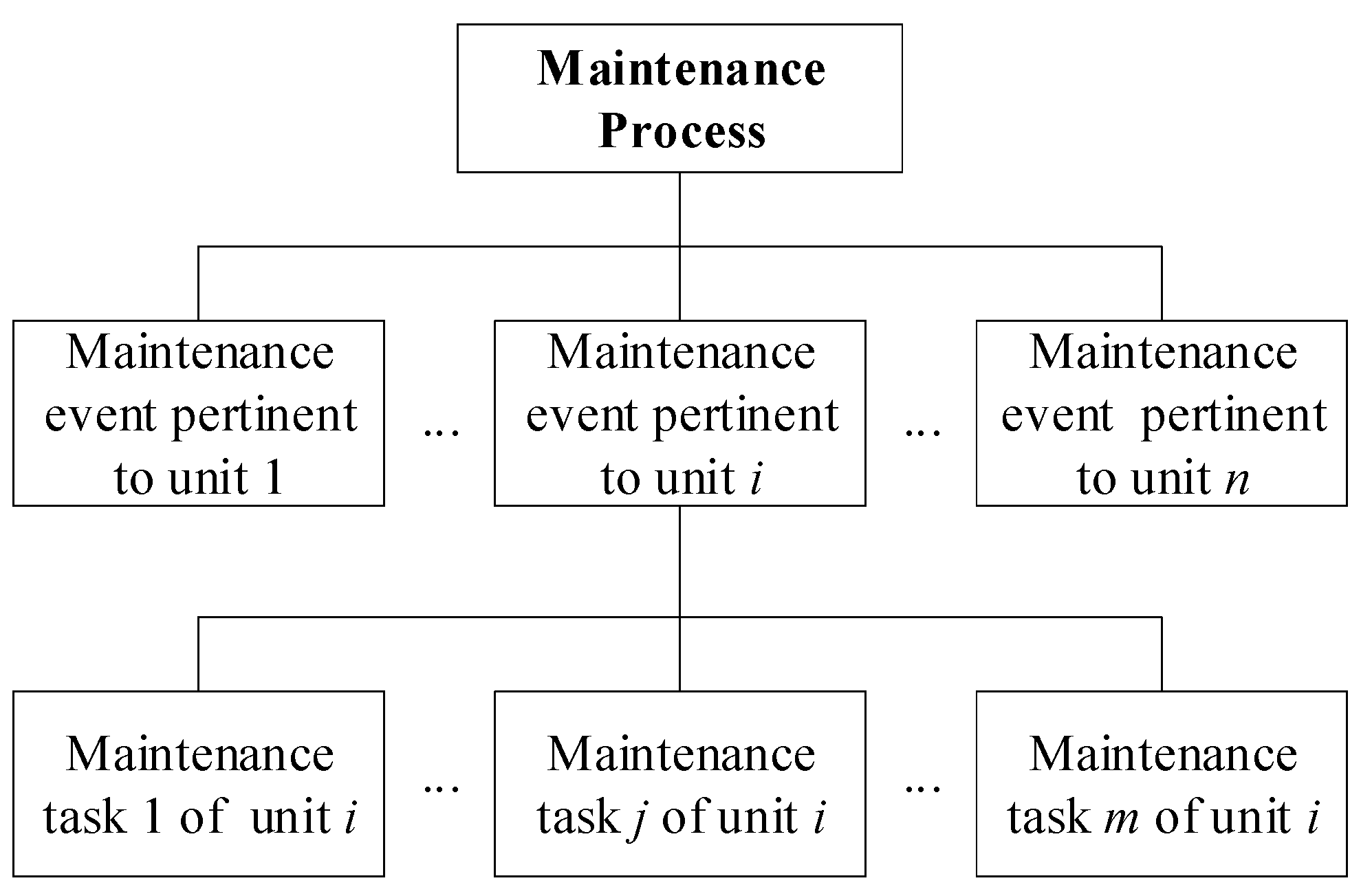

3. Maintenance Process Modeling Based on SCPN

3.1. Maintenance Task Expression

3.2. Maintenance State and Resource Expression

3.2.1. Expression of System States

3.2.2. Expression of Consumable Resources

3.2.3. Expression of Reusable Resources

3.3. Relationship Expression for Maintenance Tasks, States and Resources

3.4. Structure Expression of Maintenance Process

3.4.1. Expression of Serial Structures

3.4.2. Expression of Parallel Structures

3.4.3. Expression of Competitive Structures

4. Maintainability Evaluation Approaches Using the Maintenance Process Model

4.1. Maintenance Resource Calculation

4.1.1. Method of Calculating Consumable Resources

4.1.2. Method of Calculating Reusable Resources

4.2. Maintenance Time Simulation

5. Case Study

6. Conclusions

- (1)

- Compared with the traditional maintainability evaluation method given in MIL-STD-471A, the maintenance demonstration is not required to be conducted for the whole maintenance process, maintenance time samples of the whole maintenance process can be obtained by our discrete-event simulation procedure in terms of the time distribution of each maintenance task.

- (2)

- As the constituents of the maintenance process including maintenance tasks, system states, maintenance resources and their relationships are expressed by tuples of the SCPN in our maintenance process model, the detailed information related to maintenance resources of each maintenance tasks can be obtained. Whereas, the requirements of maintenance resources are neglected in most maintainability evaluation methods, particularly the processed based maintainability evaluation method.

- (3)

- As the maintenance time and the requirements of maintenance personnel, tools or equipment, and spare parts can be calculated via our proposed methods, both the time related parameters and the economic parameters of the system maintainability can be evaluated quantitatively. Whereas, the multiple attribute decision based maintainability evaluation method can only present a general and qualitative assessment of system maintainability.

Author Contributions

Funding

Conflicts of Interest

References

- Yu, Y.L.; Zhu, X.D.; Hao, J.P.; Zhang, L. System Maintainability Modeling Theory and Technology; National Defense Industry Press: Beijing, China, 2007; pp. 41–58. [Google Scholar]

- Barabadi, A.; Barabady, J.; Markeset, T. Maintainability analysis considering time-dependent and time-independent covariates. Reliab. Eng. Syst. Saf. 2011, 96, 210–217. [Google Scholar] [CrossRef]

- Zhou, D.; Jia, X.; Lv, C.; Li, Y.X. Maintainability Allocation Method Based on Time Characteristics for Complex Equipment. Eksploat. Niezawodn. 2013, 15, 441–448. [Google Scholar]

- Guo, Z.Y.; Zhou, D.; Chen, J.Y.; Geng, J.; Lv, C.; Zeng, S.K. Using Virtual Reality to Support the Product’s Maintainability Design: Immersive Maintainability Verification and Evaluation System. Comput. Ind. 2018, 101, 41–50. [Google Scholar] [CrossRef]

- Peng, G.L.; Yu, H.Q.; Liu, X.H.; Yang, J.A.; He, X. A desktop virtual reality-based integrated system for complex product maintainability design and verification. Assem. Autom. 2010, 30, 333–344. [Google Scholar]

- Yu, H.Q.; Peng, G.L.; Liu, W.J. A practical method for measuring product maintainability in a virtual environment. Assem. Autom. 2011, 31, 53–61. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, J.Y.; Lv, C.; Cao, Q.L. A method for integrating ergonomics analysis into maintainability design in a virtual environment. Int. J. Ind. Ergon. 2016, 54, 154–163. [Google Scholar] [CrossRef]

- Wani, M.F.; Gandhi, O.P. Development of maintainability index for mechanical systems. Reliab. Eng. Syst. Saf. 1999, 65, 259–270. [Google Scholar] [CrossRef]

- Wani, M.F.; Gandhi, O.P. Maintainability design and evaluation of mechanical systems based on tribology. Reliab. Eng. Syst. Saf. 2002, 77, 181–188. [Google Scholar] [CrossRef]

- Meier, J.R.; Russell, J.S. Model process for implementing maintainability. J. Constr. Eng. Manag. 2000, 126, 440–450. [Google Scholar] [CrossRef]

- Chen, L.; Cai, J.G. Using Vector Projection Method to evaluate maintainability of mechanical system in design review. Reliab. Eng. Syst. Saf. 2003, 81, 147–154. [Google Scholar] [CrossRef]

- Tjiparuro, Z.; Thompson, G. Review of maintainability design principles and their application to conceptual design. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2004, 218, 103–113. [Google Scholar] [CrossRef]

- Slavila, C.A.; Decreuse, C.; Ferney, M. Fuzzy approach for maintainability evaluation in the design process. Concurrent Eng. Res. Appl. 2005, 13, 291–300. [Google Scholar] [CrossRef]

- Desai, A.; Mital, A. Improving maintainability of products through the adoption of a comprehensive design for maintainability method. Int. J. Ind. Eng. Theory. 2010, 17, 103–114. [Google Scholar]

- Luo, X.; Yang, Y.M.; Ge, Z.X.; Wen, X.S.; Guan, F.J. Fuzzy grey relational analysis of design factors influencing on maintainability indices. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2015, 229, 78–84. [Google Scholar] [CrossRef]

- Ertas, A.; Smith, M.W.; Tate, D.; Lawson, W.D.; Baturalp, T.B. Complexity of system maintainability analysis based on the interpretive structural modeling methodology: Transdisciplinary approach. J. Syst. Sci. Syst. Eng. 2016, 25, 254–268. [Google Scholar] [CrossRef]

- Tu, M.X.; Lv, C.; Wang, M.H.; Zhou, D.; Xu, Y.L.; Wan, B.L.; He, W.X. Maintainability Analysis and Evaluation of Flexible Cables Based on Delmia. Trans. Can. Soc. Mech. Eng. 2016, 40, 995–1005. [Google Scholar] [CrossRef]

- Jian, X.G.; Cai, S.B.; Chen, Q.F. A Study on the Evaluation of Product Maintainability Based on the Life Cycle Theory. J. Clean Prod. 2017, 141, 481–491. [Google Scholar] [CrossRef]

- Guo, C.H.; Lyu, C.; Chen, J.Y.; Zhou, D. A Design Approach Based on a Correlative Relationship between Maintainability and Functional Construction. Eksploat. Niezawodn. 2018, 20, 115–124. [Google Scholar] [CrossRef]

- Kondo, H.A.; Wang, Z.H. Optimizing the reliability, maintainability and safety data collection process through lifecycle. In Proceedings of the 2017 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017. [Google Scholar]

- Li, T.P.; Li, Y.; Qian, Y.L.; Xu, Y. Optimizing reliability, maintainability and testability parameters of equipment based on GSPN. J. Syst. Eng. Electron. 2015, 26, 633–643. [Google Scholar] [CrossRef]

- Zhang, J.; Haskins, C.; Liu, Y.; Lundteigen, M.A. A systems engineering-based approach for framing reliability, availability, and maintainability: A case study for subsea design. Syst. Eng. 2018, 21, 576–592. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, H.; Roberts, C. Rail maintenance analysis using Petri nets. Struct. Infrastruct. E 2017, 13, 783–793. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, H.; Roberts, C.; Dai, L. Developing a life cycle cost model for real-time condition monitoring in railways under uncertainty. Proc. Inst. Mech. Eng. Part F-J. Rail Rapid Transit. 2017, 231, 111–121. [Google Scholar] [CrossRef]

- Xie, N.; Duan, M.; Chinnam, R.B.; Li, A.; Xue, W. An energy modeling and evaluation approach for machine tools using generalized stochastic Petri Nets. J. Clean. Prod. 2016, 113, 523–531. [Google Scholar] [CrossRef]

- Cavone, G.; Dotoli, M.; Epicoc, N.; Franceschelli, M.; Seatzu, C. Hybrid Petri Nets to Re-design Low-Automated Production Processes: The Case Study of a Sardinian Bakery. In Proceedings of the 14th IFAC International Workshop on Discrete Event Systems, Sorrento Coast, Italy, 30 May–1 June 2018. [Google Scholar]

- Moore, K.E.; Gupta, S.M. Stochastic coloured Petri net (SCPN) models of traditional and flexible kanban systems. Int. J. Prod. Res. 1999, 37, 2135–2158. [Google Scholar] [CrossRef]

- Lu, Z.; Zhou, J.; Li, N.X. Maintainability fuzzy evaluation based on maintenance process virtual simulation for aircraft system. Eksploat. Niezawodn. 2015, 17, 504–512. [Google Scholar] [CrossRef]

| Transition | Maintenance Task | Distribution | Parameter (Minutes) |

|---|---|---|---|

| t1 | Hoist the aircraft | Lognormal | μ = 1.28, σ = 1.16 |

| t2 | Fault diagnosis | Lognormal | μ = 0.88, σ = 1.14 |

| t3 | Not applicable | Not applicable | Not applicable |

| t4 | Get the spare part of the steering control motor | Exponential | θ = 5.53 |

| t5 | Dismantle hoses and cables | Lognormal | μ = 1.12, σ = 0.29 |

| t6 | Dismantle connectors (Nuts and screws) | Normal | μ = 0.95, σ = 0.06 |

| t7 | Replace the steering control motor | Exponential | θ = 1.2 |

| t8 | Install the connectors (Nuts and screws) | Normal | μ = 1.35, σ = 0.06 |

| t9 | Install hoses and cables | Lognormal | μ = 1.43, σ = 0.24 |

| t10 | Not applicable | Not applicable | Not applicable |

| t11 | Dismantle the torque link | Normal | μ = 0.9, σ = 0.08 |

| t12 | Install the new torque link | Normal | μ = 1.22, σ = 0.06 |

| t13 | Adjustment | Lognormal | μ = 0.91, σ = 0.29 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Z.; Liu, J.; Dong, L.; Liang, X. Maintenance Process Simulation Based Maintainability Evaluation by Using Stochastic Colored Petri Net. Appl. Sci. 2019, 9, 3262. https://doi.org/10.3390/app9163262

Lu Z, Liu J, Dong L, Liang X. Maintenance Process Simulation Based Maintainability Evaluation by Using Stochastic Colored Petri Net. Applied Sciences. 2019; 9(16):3262. https://doi.org/10.3390/app9163262

Chicago/Turabian StyleLu, Zhong, Jie Liu, Li Dong, and Xihui Liang. 2019. "Maintenance Process Simulation Based Maintainability Evaluation by Using Stochastic Colored Petri Net" Applied Sciences 9, no. 16: 3262. https://doi.org/10.3390/app9163262

APA StyleLu, Z., Liu, J., Dong, L., & Liang, X. (2019). Maintenance Process Simulation Based Maintainability Evaluation by Using Stochastic Colored Petri Net. Applied Sciences, 9(16), 3262. https://doi.org/10.3390/app9163262