Effect of Mix Proportion Parameters on Behaviors of Basalt Fiber RPC Based on Box-Behnken Model

Abstract

1. Introduction

2. Experimental

2.1. Materials and Mixture Proportions

2.2. Fabrication of BFRPC

2.3. Experimental Method

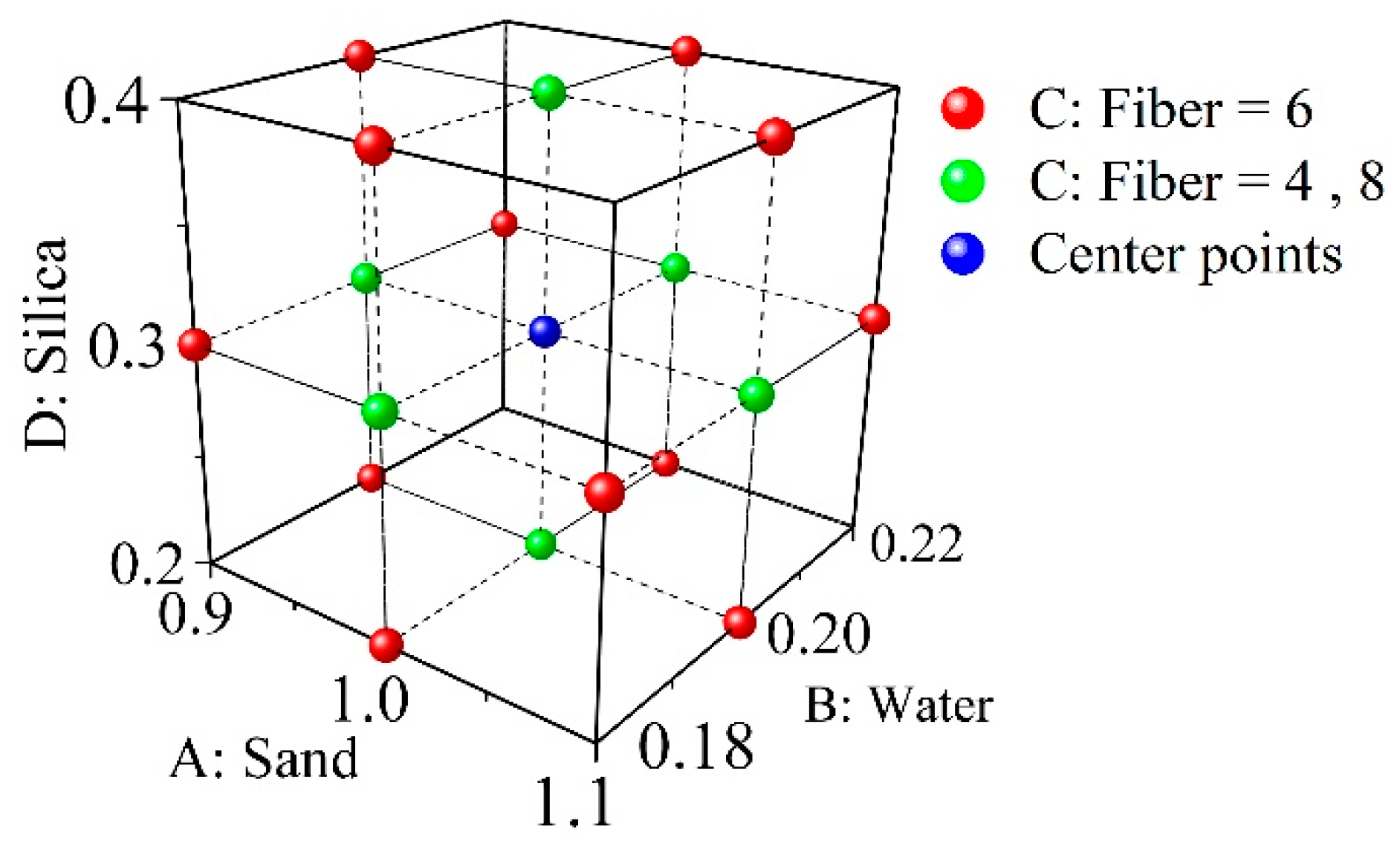

2.4. Box-Behnken Design (BBD)

3. Results and Discussion

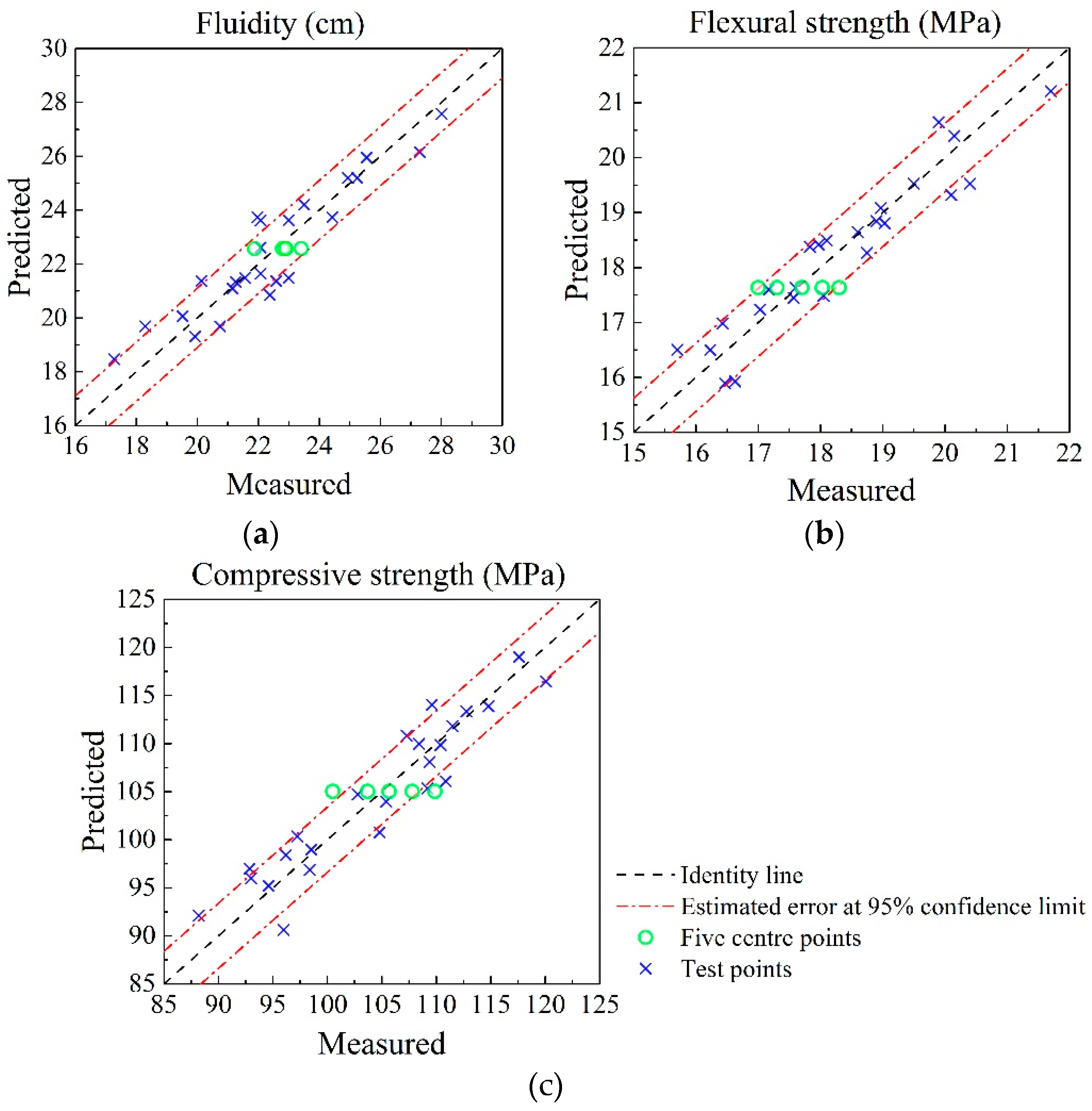

3.1. Establishment and Verification of Response Surface Model

3.2. Influence of Parameters on the Performance of BFRPC

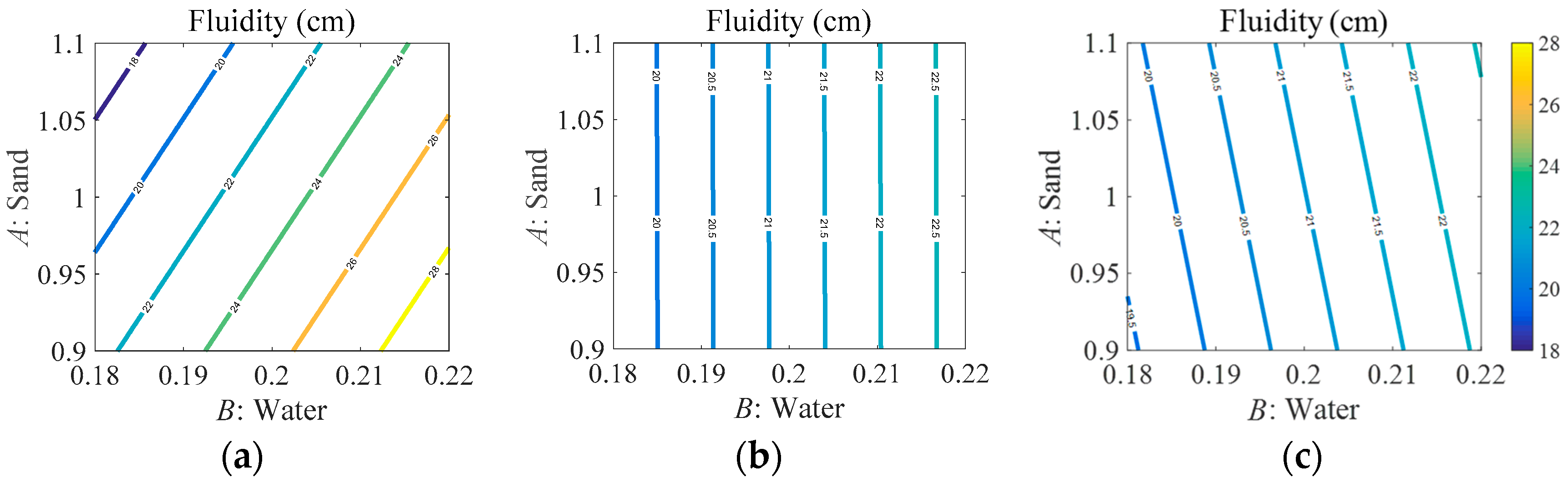

3.2.1. Fluidity

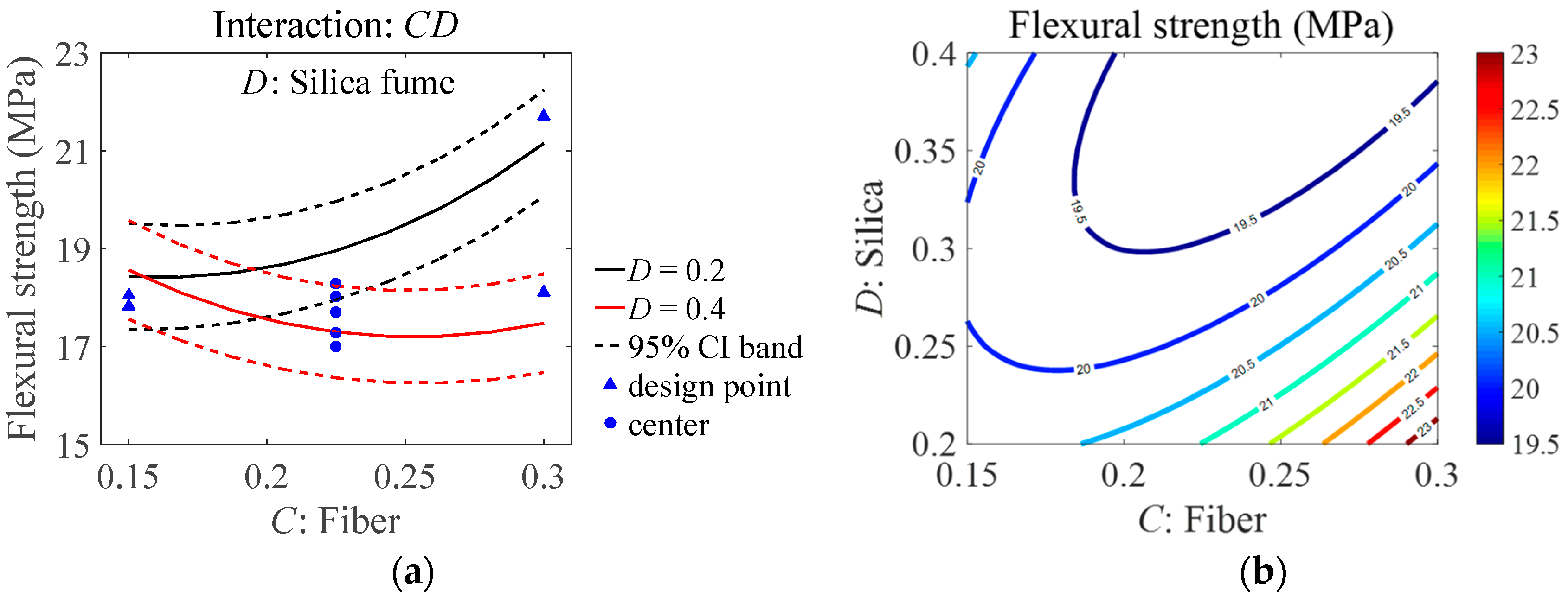

3.2.2. Flexural Strength

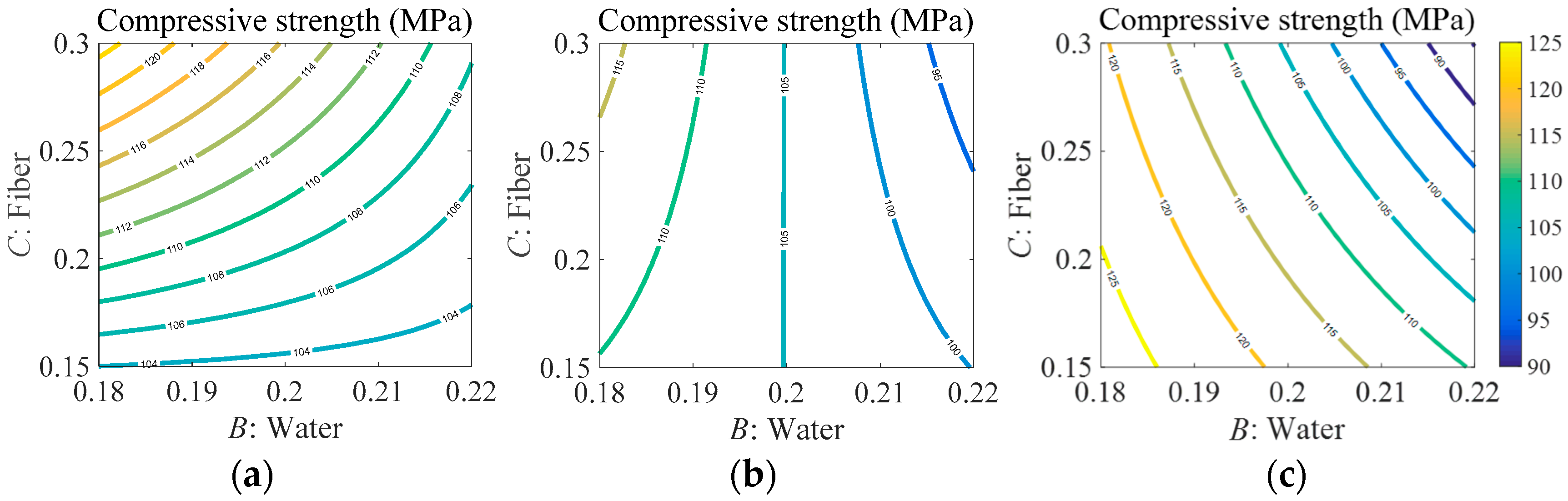

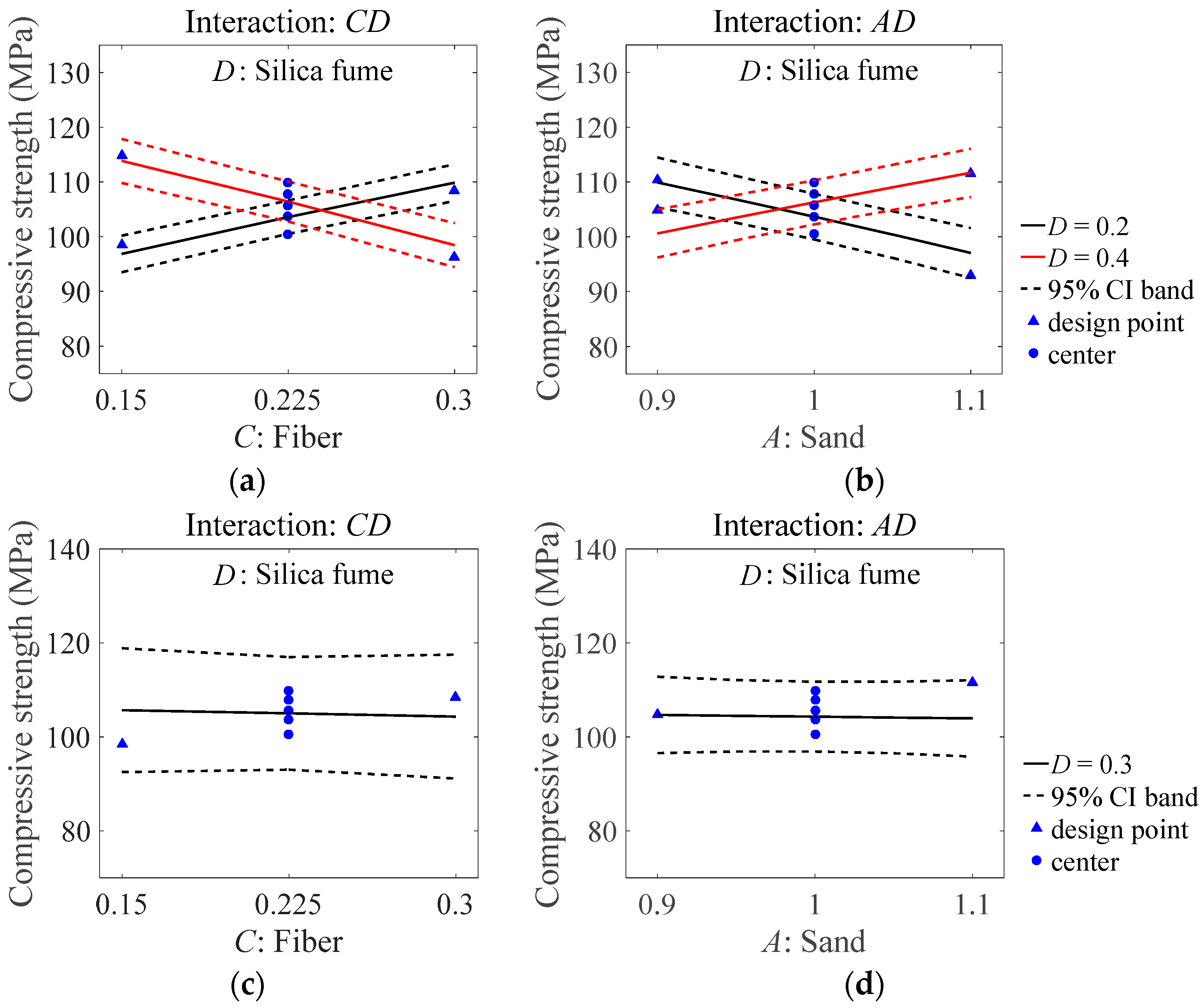

3.2.3. Compressive Strength

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Zdeb, T. Ultra-high performance concrete—Properties and technology. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 183–193. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Nikoo, M.R.; Hosseini, S.A. Determination of optimized mix design and curing conditions of reactive powder concrete (RPC). Constr. Build. Mater. 2016, 123, 754–767. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. 2011, 45, 309–324. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part. B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.H.A.; Johari, M.A.M.; Voo, Y.L. Utilization of Ultra-high Performance Fibre Concrete (UHPFC) for Rehabilitation—A Review. Procedia Eng. 2013, 54, 525–538. [Google Scholar] [CrossRef]

- Bae, B.-I.; Choi, H.-K.; Lee, B.-S.; Bang, C.-H. Compressive Behavior and Mechanical Characteristics and Their Application to Stress-Strain Relationship of Steel Fiber-Reinforced Reactive Powder Concrete. Adv. Mater. Sci. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef]

- Chan, Y.-W.; Chu, S.-H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Pyo, S.; Tafesse, M.; Kim, H.; Kim, H.-K. Effect of chloride content on mechanical properties of ultra high performance concrete. Cem. Concr. Compos. 2017, 84, 175–187. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part. B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Lipatov, Y.V.; Gutnikov, S.I.; Manylov, M.S.; Zhukovskaya, E.S.; Lazoryak, B.I. High alkali-resistant basalt fiber for reinforcing concrete. Mater. Des. 2015, 73, 60–66. [Google Scholar] [CrossRef]

- Militký, J.; Kovačič, V.; Rubnerova, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Branston, J.; Das, S.; Kenno, S.Y.; Taylor, C. Mechanical behaviour of basalt fibre reinforced concrete. Constr. Build. Mater. 2016, 124, 878–886. [Google Scholar] [CrossRef]

- Iyer, P.; Kenno, S.Y.; Das, S. Mechanical properties of fiber-reinforced concrete made with basalt filament fibers. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical Properties of High-performance Concrete Reinforced with Basalt Fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Sakr, M.; Hanafi, R.; Fouad, M.; Al-Easa, H.; El-Moghazy, S. Design and optimization of a luminescent Samarium complex of isoprenaline: A chemometric approach based on Factorial design and Box-Behnken response surface methodology. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2019, 208, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Ipek, M.; Yilmaz, K.; Sümer, M.; Saribiyik, M. Effect of pre-setting pressure applied to mechanical behaviours of reactive powder concrete during setting phase. Constr. Build. Mater. 2011, 25, 61–68. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Assessing drying shrinkage and water permeability of reactive powder concrete produced in Hong Kong. Constr. Build. Mater. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- Wille, K.; Boisvert-Cotulio, C. Material efficiency in the design of ultra-high performance concrete. Constr. Build. Mater. 2015, 86, 33–43. [Google Scholar] [CrossRef]

- Cwirzen, A.; Penttala, V.; Vornanen, C. Reactive powder based concretes: Mechanical properties, durability and hybrid use with OPC. Cem. Concr. Res. 2008, 38, 1217–1226. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Sifeng, L.; Chujie, J.; Jianzhong, L. Preparation of C200 green reactive powder concrete and its static–dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, J.; Liu, J.; Ke, J.; Wang, F. Properties and microstructure of reactive powder concrete having a high content of phosphorous slag powder and silica fume. Constr. Build. Mater. 2015, 101, 482–487. [Google Scholar] [CrossRef]

- National Standard of the People’s Republic of China. Method of Testing Cements–Determination of Strength (GB/T 17671-1999); Quality and Technology Supervision Bureau of the People’s Republic of China: Beijing, China, 1999.

- National Standard of the People’s Republic of China. Test. Methods for Cement and Concrete for Highway Engineering (JTG E30-2005); Ministry of Transport of the People’s Republic of China: Beijing, China, 2006.

- Al-Amoudi, R.H.; Taylan, O.; Kutlu, G.; Can, A.M.; Sagdic, O.; Dertli, E.; Yilmaz, M.T. Characterization of chemical, molecular, thermal and rheological properties of medlar pectin extracted at optimum conditions as determined by Box-Behnken and ANFIS models. Food Chem. 2019, 271, 650–662. [Google Scholar] [CrossRef]

- Rumky, J.; Ncibi, M.C.; Burgos-Castillo, R.C.; Deb, A.; Sillanpaa, M. Optimization of integrated ultrasonic-Fenton system for metal removal and dewatering of anaerobically digested sludge by Box-Behnken design. Sci. Total Environ. 2018, 645, 573–584. [Google Scholar] [CrossRef]

- Muthukumar, M.; Mohan, D.; Rajendran, M. Optimization of mix proportions of mineral aggregates using Box Behnken design of experiments. Cem. Concr. Compos. 2003, 25, 751–758. [Google Scholar] [CrossRef]

- Şimşek, B.; İç, Y.T.; Şimşek, E.H.A. RSM-Based Multi-Response Optimization Application for Determining Optimal Mix Proportions of Standard Ready-Mixed Concrete. Arab. J. Sci. Eng. 2015, 41, 1435–1450. [Google Scholar] [CrossRef]

- Asadzadeh, S.; Khoshbayan, S. Multi-objective optimization of influential factors on production process of foamed concrete using Box-Behnken approach. Constr. Build. Mater. 2018, 170, 101–110. [Google Scholar] [CrossRef]

- Shengli, S.; Junping, L.; Qi, L.; Fangru, N.; Jia, F.; Shulian, X. Optimized preparation of Phragmites australis activated carbon using the Box-Behnken method and desirability function to remove hydroquinone. Ecotoxicol. Environ. Saf. 2018, 165, 411–422. [Google Scholar] [CrossRef]

| Materials | Chemical Compositions (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | SO3 | |

| Cement | 22.6 | 5.6 | 62.7 | 1.7 | 4.3 | 2.5 |

| Silica fume | 93.3 | 0.73 | 0.85 | 1.21 | 0.49 | 1.02 |

| Fiber Type | Length (mm) | Diameter (μm) | Linear Density (tex) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Breaking Strength (N/tex) | Elongation (%) |

|---|---|---|---|---|---|---|---|

| Basalt fiber | 22 | 23 | 2392 | 2836 | 62 | 0.69 | 3 |

| Mineral Compositions | SiO2 | Fe | Al2O3 | K2O | Na2O | H2O |

|---|---|---|---|---|---|---|

| Content (%) | 99.68 | 0.0062 | 0.0122 | 0.0011 | 0.002 | 0.02 |

| Mix | Cement (kg) | Silica Fume (kg) | Quartz Sand (kg) | Quartz Powder (kg) | Basalt Fiber (kg) | Water (kg) | Water Reducer (kg) | |

|---|---|---|---|---|---|---|---|---|

| 0.15–0.3 (mm) | 0.3–0.6 (mm) | |||||||

| B-1 | 826.72 | 248.02 | 372.02 | 595.24 | 264.55 | 6 | 154.76 | 53.74 |

| B-2 | 761.27 | 228.38 | 418.70 | 669.91 | 243.61 | 6 | 142.51 | 49.48 |

| B-3 | 812.74 | 243.82 | 365.73 | 585.18 | 260.08 | 6 | 185.96 | 52.83 |

| B-4 | 749.40 | 224.82 | 412.17 | 659.47 | 239.81 | 6 | 171.46 | 48.71 |

| B-5 | 844.59 | 168.92 | 389.81 | 623.70 | 270.27 | 4 | 162.16 | 50.68 |

| B-6 | 844.59 | 168.92 | 389.81 | 623.70 | 270.27 | 8 | 162.16 | 50.68 |

| B-7 | 735.29 | 294.12 | 395.93 | 633.48 | 235.29 | 4 | 164.71 | 51.47 |

| B-8 | 735.29 | 294.12 | 395.93 | 633.48 | 235.29 | 8 | 164.71 | 51.47 |

| B-9 | 880.28 | 176.06 | 365.66 | 585.05 | 281.69 | 6 | 169.01 | 52.82 |

| B-10 | 811.69 | 162.34 | 412.09 | 659.34 | 259.74 | 6 | 155.84 | 48.70 |

| B-11 | 766.87 | 306.75 | 371.64 | 594.62 | 245.40 | 6 | 171.78 | 53.68 |

| B-12 | 706.21 | 282.49 | 418.30 | 669.27 | 225.99 | 6 | 158.19 | 49.44 |

| B-13 | 792.64 | 237.79 | 396.32 | 634.12 | 253.65 | 4 | 148.38 | 51.52 |

| B-14 | 779.79 | 233.94 | 389.89 | 623.83 | 249.53 | 4 | 178.42 | 50.69 |

| B-15 | 792.64 | 237.79 | 396.32 | 634.12 | 253.65 | 8 | 148.38 | 51.52 |

| B-16 | 779.79 | 233.94 | 389.89 | 623.83 | 249.53 | 8 | 178.42 | 50.69 |

| B-17 | 819.67 | 245.90 | 368.85 | 590.16 | 262.30 | 4 | 170.49 | 53.28 |

| B-18 | 755.29 | 226.59 | 415.41 | 664.65 | 241.69 | 4 | 157.10 | 49.09 |

| B-19 | 819.67 | 245.90 | 368.85 | 590.16 | 262.30 | 8 | 170.49 | 53.28 |

| B-20 | 755.29 | 226.59 | 415.41 | 664.65 | 241.69 | 8 | 157.10 | 49.09 |

| B-21 | 851.50 | 170.30 | 393.00 | 628.80 | 272.48 | 6 | 147.14 | 51.09 |

| B-22 | 837.80 | 167.56 | 386.68 | 618.68 | 268.10 | 6 | 176.94 | 50.27 |

| B-23 | 741.40 | 296.56 | 399.22 | 638.74 | 237.25 | 6 | 149.47 | 51.90 |

| B-24 | 729.29 | 291.72 | 392.69 | 628.31 | 233.37 | 6 | 179.70 | 51.05 |

| B-25 | 786.16 | 235.85 | 393.08 | 628.93 | 251.57 | 6 | 163.52 | 51.10 |

| B-26 | 786.16 | 235.85 | 393.08 | 628.93 | 251.57 | 6 | 163.52 | 51.10 |

| B-27 | 786.16 | 235.85 | 393.08 | 628.93 | 251.57 | 6 | 163.52 | 51.10 |

| B-28 | 786.16 | 235.85 | 393.08 | 628.93 | 251.57 | 6 | 163.52 | 51.10 |

| B-29 | 786.16 | 235.85 | 393.08 | 628.93 | 251.57 | 6 | 163.52 | 51.10 |

| Symbol | Factors | Actual Values | Code Values | |||||

|---|---|---|---|---|---|---|---|---|

| A | Quartz sand/binder ratio | 0.9 | 1 | 1.1 | −1 | 0 | 1 | |

| B | Water/binder ratio | 0.18 | 0.2 | 0.22 | −1 | 0 | 1 | |

| C | Basalt fiber | By weight (kg/m3) | 4 | 6 | 8 | −1 | 0 | 1 |

| By volume (%) | 0.15 | 0.225 | 0.3 | |||||

| D | Silica fume/cement ratio | 0.2 | 0.3 | 0.4 | −1 | 0 | 1 | |

| Mix Number | Code Level of Variables | Response Values | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | R1: Fluidity (cm) | R2: Flexural Strength (MPa) | R3: Compressive Strength (MPa) | |

| B-1 | −1 | −1 | 0 | 0 | 22.0 | 19.5 | 109.6 |

| B-2 | 1 | −1 | 0 | 0 | 17.0 | 18.9 | 112.8 |

| B-3 | −1 | 1 | 0 | 0 | 26.8 | 15.7 | 93.0 |

| B-4 | 1 | 1 | 0 | 0 | 23.1 | 16.6 | 94.6 |

| B-5 | 0 | 0 | −1 | −1 | 24.0 | 17.8 | 98.4 |

| B-6 | 0 | 0 | 1 | −1 | 21.6 | 21.7 | 108.4 |

| B-7 | 0 | 0 | −1 | 1 | 22.2 | 18.1 | 114.8 |

| B-8 | 0 | 0 | 1 | 1 | 19.8 | 18.1 | 96.2 |

| B-9 | −1 | 0 | 0 | −1 | 25.1 | 20.1 | 110.4 |

| B-10 | 1 | 0 | 0 | −1 | 20.9 | 18.6 | 92.9 |

| B-11 | −1 | 0 | 0 | 1 | 20.8 | 17.2 | 104.8 |

| B-12 | 1 | 0 | 0 | 1 | 21.7 | 16.4 | 111.5 |

| B-13 | 0 | −1 | −1 | 0 | 18.0 | 20.4 | 107.3 |

| B-14 | 0 | 1 | −1 | 0 | 24.5 | 16.2 | 97.2 |

| B-15 | 0 | −1 | 1 | 0 | 20.4 | 20.2 | 120.1 |

| B-16 | 0 | 1 | 1 | 0 | 24.8 | 17.0 | 96.0 |

| B-17 | −1 | 0 | −1 | 0 | 22.6 | 18.8 | 110.9 |

| B-18 | 1 | 0 | −1 | 0 | 21.2 | 17.6 | 109.2 |

| B-19 | −1 | 0 | 1 | 0 | 21.7 | 19.0 | 102.8 |

| B-20 | 1 | 0 | 1 | 0 | 22.6 | 18.0 | 105.4 |

| B-21 | 0 | −1 | 0 | −1 | 19.6 | 19.9 | 109.4 |

| B-22 | 0 | 1 | 0 | −1 | 27.5 | 17.6 | 98.5 |

| B-23 | 0 | −1 | 0 | 1 | 19.2 | 19.0 | 117.6 |

| B-24 | 0 | 1 | 0 | 1 | 21.7 | 16.5 | 88.2 |

| B-25 | 0 | 0 | 0 | 0 | 23.0 | 17.3 | 109.9 |

| B-26 | 0 | 0 | 0 | 0 | 22.5 | 17.0 | 100.5 |

| B-27 | 0 | 0 | 0 | 0 | 22.4 | 17.7 | 103.7 |

| B-28 | 0 | 0 | 0 | 0 | 21.5 | 18.3 | 107.8 |

| B-29 | 0 | 0 | 0 | 0 | 22.5 | 18.0 | 105.7 |

| Property | R1: Fluidity | R2: Flexural Strength | R3: Compressive Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Transformation | None | Ln (R2) | (R3)² | ||||||

| R² | 0.85 | 0.87 | 0.86 | ||||||

| Estimated Coefficient | F Value | p Value | Estimated Coefficient | F Value | p Value | Estimated Coefficient | F Value | p Value | |

| Intercept | 6.75 | − | − | 4.14 | − | − | 774.04 | − | − |

| A | −48.67 | 13.38 | 0.0013 | −0.166 | 3.03 | 0.0962 | −38373.37 | 0.13 | 0.72 |

| B | 336.67 | 88.79 | <0.0001 | −4.3 | 80.98 | <0.0001 | 173,679 | 77.82 | <0.0001 |

| C | NS | NS | NS | −1.007 | 4.82 | 0.0394 | 161,764 | 0.44 | 0.51 |

| D | −3.58 | 15.15 | 0.0007 | −0.61 | 23.8 | <0.0001 | 23425.17 | 1.59 | 0.22 |

| AD | 127.5 | 6.68 | 0.0166 | NS | NS | NS | 125,313 | 11.13 | 0.0033 |

| BC | NS | NS | NS | NS | NS | NS | −520,259 | 4.37 | 0.0495 |

| BD | 675 | 7.49 | 0.0117 | NS | NS | NS | −505,066 | 7.23 | 0.0141 |

| CD | NS | NS | NS | −6.6 | 9.03 | 0.0067 | −198,720 | 15.95 | 0.0007 |

| C² | NS | NS | NS | 7.21 | 10.6 | 0.0038 | NS | NS | NS |

| D² | NS | NS | NS | 2.728 | 4.68 | 0.0423 | NS | NS | NS |

| Model | − | 26.30 | <0.0001 | − | 19.32 | <0.0001 | − | 14.83 | <0.0001 |

| Lack of fit | − | 3.76 | 0.1040 | − | 1.28 | 0.4465 | − | 0.96 | 0.5831 |

| Statistical Parameters | Fluidity (cm) | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| Std. Dev. | 0.99 | 0.03 | 738.06 |

| Mean | 22.09 | 2.90 | 11031.73 |

| Coefficient of Variation (COV, %) | 3.98 | 0.92 | 5.56 |

| Adeq Precision | 19.76 | 17.48 | 14.48 |

| E95%CI | 1.19 | 0.64 | 3.49 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Liu, S.; Wang, S.; Gao, X.; Gong, Y. Effect of Mix Proportion Parameters on Behaviors of Basalt Fiber RPC Based on Box-Behnken Model. Appl. Sci. 2019, 9, 2031. https://doi.org/10.3390/app9102031

Liu H, Liu S, Wang S, Gao X, Gong Y. Effect of Mix Proportion Parameters on Behaviors of Basalt Fiber RPC Based on Box-Behnken Model. Applied Sciences. 2019; 9(10):2031. https://doi.org/10.3390/app9102031

Chicago/Turabian StyleLiu, Hanbing, Shiqi Liu, Shurong Wang, Xin Gao, and Yafeng Gong. 2019. "Effect of Mix Proportion Parameters on Behaviors of Basalt Fiber RPC Based on Box-Behnken Model" Applied Sciences 9, no. 10: 2031. https://doi.org/10.3390/app9102031

APA StyleLiu, H., Liu, S., Wang, S., Gao, X., & Gong, Y. (2019). Effect of Mix Proportion Parameters on Behaviors of Basalt Fiber RPC Based on Box-Behnken Model. Applied Sciences, 9(10), 2031. https://doi.org/10.3390/app9102031