3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Printing

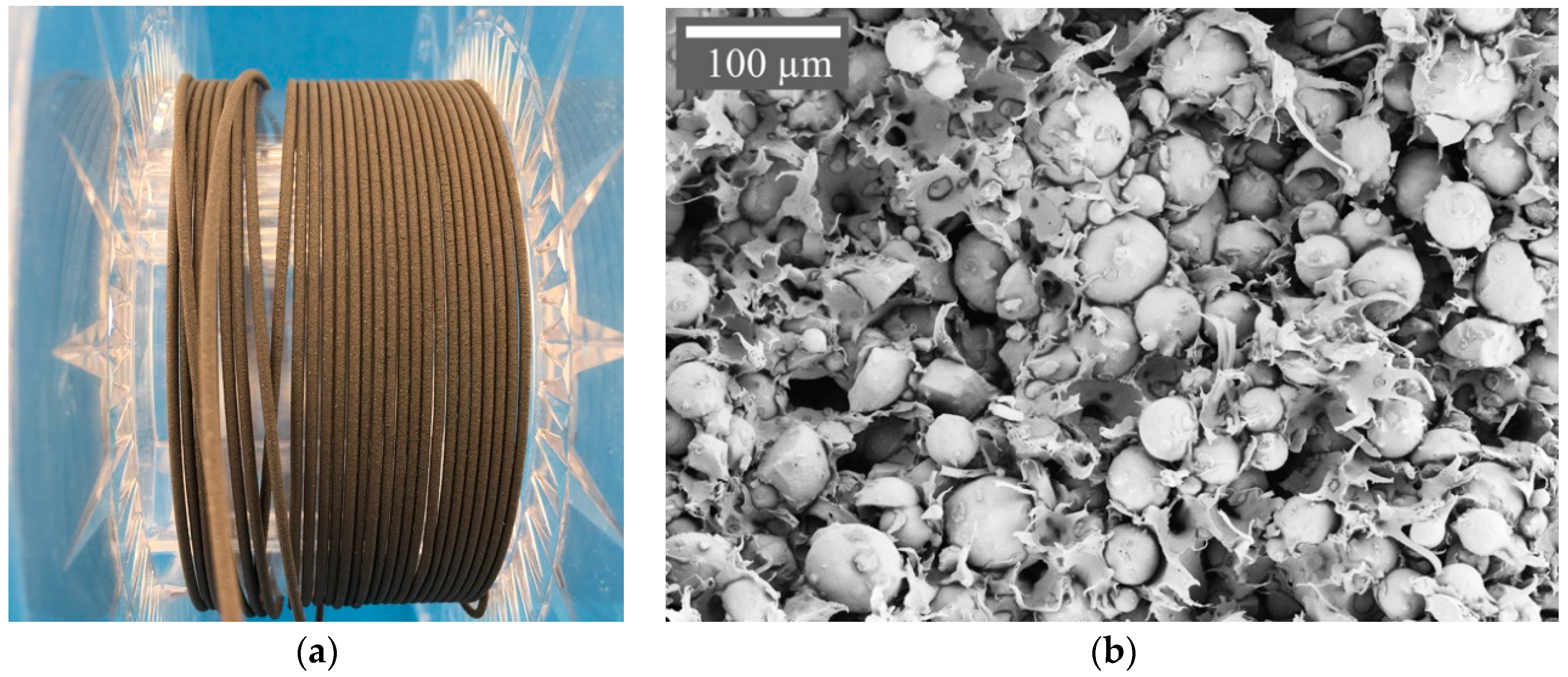

2.2. Filament Materials

2.3. Magnetization

2.4. Material Characterization

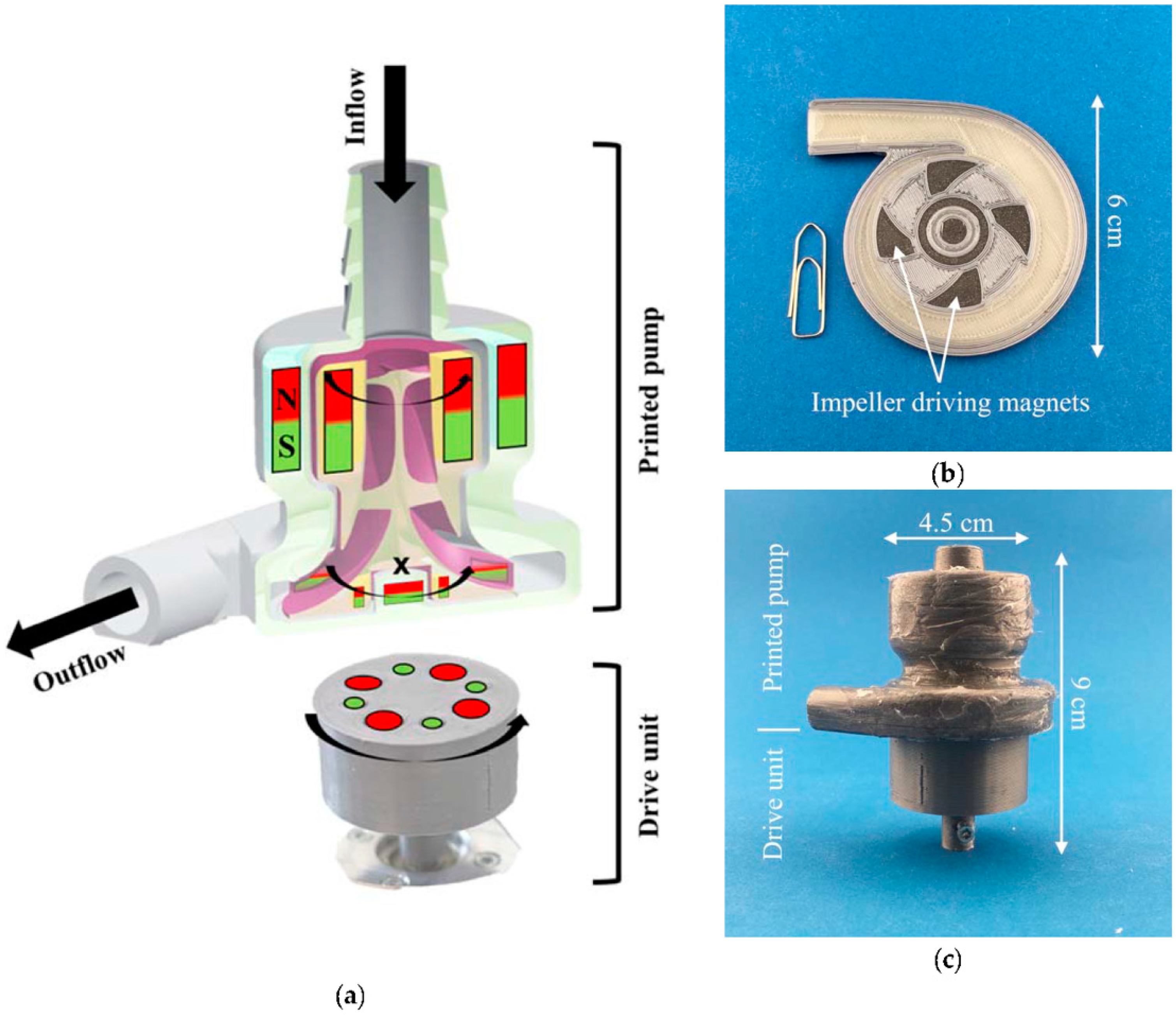

2.5. Pump Demonstrator Design and Testing

3. Results and Discussion

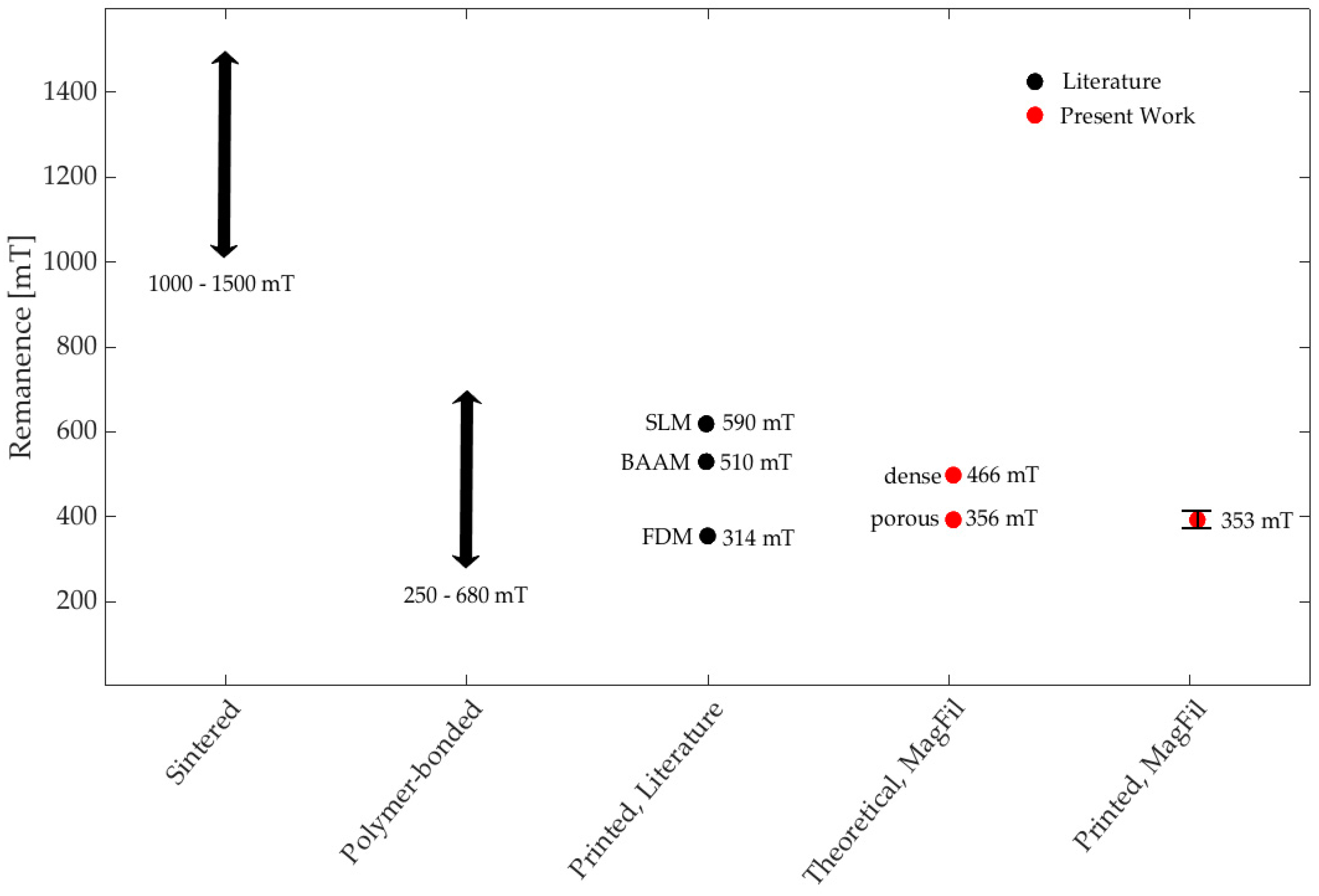

3.1. Material Characterization

3.2. Pump Demonstrator Manufacturing and Testing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brown, D.; Ma, B.-M.; Chen, Z. Developments in the processing and properties of NdFeb-type permanent magnets. J. Magn. Magn. Mater. 2002, 248, 432–440. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef] [PubMed]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Vogler, C.; et al. 3D print of polymer bonded rare-earth magnets, and 3D magnetic field scanning with an end-user 3D printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Pfaff, C.; Kriwet, J.; Groenefeld, M.; Teliban, I.; Vogler, C.; Suess, D. Topology optimized and 3D printed polymer-bonded permanent magnets for a predefined external field. J. Appl. Phys. 2017, 122, 053904. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Schuschnigg, S.; Teliban, I.; Vogler, C.; Wautischer, G.; Windl, R.; Suess, D. 3D Printing of Polymer-Bonded Rare-Earth Magnets With a Variable Magnetic Compound Fraction for a Predefined Stray Field. Sci. Rep. 2017, 7. [Google Scholar] [CrossRef] [PubMed]

- Jaćimović, J.; Binda, F.; Herrmann, L.G.; Greuter, F.; Genta, J.; Calvo, M.; Tomše, T.; Simon, R.A. Net Shape 3D Printed NdFeB Permanent Magnet: Net Shape 3D Printed NdFeB Permanent Magnet. Adv. Eng. Mater. 2017, 19, 1700098. [Google Scholar] [CrossRef]

- Paranthaman, M.P.; Shafer, C.S.; Elliott, A.M.; Siddel, D.H.; McGuire, M.A.; Springfield, R.M.; Martin, J.; Fredette, R.; Ormerod, J. Binder Jetting: A Novel NdFeB Bonded Magnet Fabrication Process. JOM 2016, 68, 1978–1982. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, L.; Ding, C.; Nguyen, L.; Moss, J.; Mei, Y.; Lu, G.Q. Additive Manufacturing of Magnetic Components for Heterogeneous Integration. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Lake Buena Vista, FL, USA, 30 May–2 June 2017; pp. 324–330. [Google Scholar]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-write 3D printing of NdFeB bonded magnets. Mater. Manuf. Process. 2018, 33, 109–113. [Google Scholar] [CrossRef]

- Li, L.; Jones, K.; Sales, B.; Pries, J.L.; Nlebedim, I.C.; Jin, K.; Bei, H.; Post, B.K.; Kesler, M.S.; Rios, O.; et al. Fabrication of highly dense isotropic Nd-Fe-B nylon bonded magnets via extrusion-based additive manufacturing. Addit. Manuf. 2018, 21, 495–500. [Google Scholar] [CrossRef]

- Schumer, E.M.; Black, M.C.; Monreal, G.; Slaughter, M.S. Left ventricular assist devices: Current controversies and future directions. Eur. Heart J. 2016, 37, 3434–3439. [Google Scholar] [CrossRef] [PubMed]

- Schmid Daners, M.; Kaufmann, F.; Amacher, R.; Ochsner, G.; Wilhelm, M.J.; Ferrari, A.; Mazza, E.; Poulikakos, D.; Meboldt, M.; Falk, V. Left Ventricular Assist Devices: Challenges Toward Sustaining Long-Term Patient Care. Ann. Biomed. Eng. 2017, 45, 1836–1851. [Google Scholar] [CrossRef] [PubMed]

- Wiegmann, L.; Boës, S.; de Zélicourt, D.; Thamsen, B.; Schmid Daners, M.; Meboldt, M.; Kurtcuoglu, V. Blood Pump Design Variations and Their Influence on Hydraulic Performance and Indicators of Hemocompatibility. Ann. Biomed. Eng. 2018, 46, 417–428. [Google Scholar] [CrossRef] [PubMed]

- Nishida, M.; Negishi, T.; Sakota, D.; Kosaka, R.; Maruyama, O.; Hyakutake, T.; Kuwana, K.; Yamane, T. Properties of a monopivot centrifugal blood pump manufactured by 3D printing. J. Artif. Organs 2016, 19, 322–329. [Google Scholar] [CrossRef] [PubMed]

- Throckmorton, A.L.; Kapadia, J.Y.; Chopski, S.G.; Bhavsar, S.S.; Moskowitz, W.B.; Gullquist, S.D.; Gangemi, J.J.; Haggerty, C.M.; Yoganathan, A.P. Numerical, Hydraulic, and Hemolytic Evaluation of an Intravascular Axial Flow Blood Pump to Mechanically Support Fontan Patients. Ann. Biomed. Eng. 2011, 39, 324–336. [Google Scholar] [CrossRef] [PubMed]

- Chan, W.K.; Wong, Y.W.; Chua, C.K.; Lee, C.W.; Feng, C. Rapid manufacturing techniques in the development of an axial blood pump impeller. Proc. Inst. Mech. Eng. 2003, 217, 469–475. [Google Scholar] [CrossRef] [PubMed]

- Lalehpour, A.; Barari, A. Post processing for Fused Deposition Modeling Parts with Acetone Vapour Bath. IFAC-Pap. 2016, 49, 42–48. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. Chemical vapor treatment of ABS parts built by FDM: Analysis of surface finish and mechanical strength. Int. J. Adv. Manuf. Technol. 2017, 89, 2175–2191. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Lavecchia, F.; Percoco, G. Experimental study aiming to enhance the surface finish of fused deposition modeled parts. CIRP Ann. 2009, 58, 189–192. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A.E. Surface Roughness Quality and Dimensional Accuracy—A Comprehensive Analysis of 100% Infill Printed Parts Fabricated by a Personal/Desktop Cost-Effective FDM 3D Printer. Mater. Sci. Appl. 2018, 9, 11–40. [Google Scholar] [CrossRef]

- VACODYM-VACUUMSCHMELZE GmbH & Co. KG. Available online: https://www.vacuumschmelze.de/de/produkte/dauermagnete-systeme/dauermagnete/nd-fe-b/vacodym.html (accessed on 10 July 2018).

- Magnetfabrik Bonn. Produkte::. Magnete nach Formgebung::. Spritzguss. Available online: https://www.magnetfabrik.de/magnetfabrik_de/produkte.php?category=12&page=606 (accessed on 10 July 2018).

- Linneweber, J.; Dohmen, P.M.; Kerzscher, U.; Affeld, K.; Nosé, Y.; Konertz, W. The Effect of Surface Roughness on Activation of the Coagulation System and Platelet Adhesion in Rotary Blood Pumps. Artif. Organs 2007, 31, 345–351. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Extruder temperature | 220 °C |

| Layer height | 0.15–0.25 mm |

| Printer speed | 25 mm/s |

| Infill density | 100% |

| Infill pattern | Rectilinear |

| Bed temperature | 60 °C |

| Ingredient | Type | Weight Fraction | Volume Fraction |

|---|---|---|---|

| NdFeB powder | MQP-S-11-9 (NdPrFeCoTiZrB), Magnequench (Singapore) | 66.03% | 42.34% |

| NdFeB/PA12 compound | BMNPi-60HR, Bomatec (Höri, Switzerland) | 24.46% | 23.07% |

| POM | F10-01, Kepital (Wiesbaden, Germany) | 7.34% | 24.79% |

| Dispersing agent | Edaplan 935, Münzing (Abstatt, Germany) | 1.98% | 9.35% |

| Fumed silica | Aerosil, Evonik (Essen, Germany) | approx. 0.20% | approx. 0.44% |

| Total magnet powder 1 | - | 88.53% 2/91.40% 3 | 56.19% 2 |

| Parameter | NdFeB Powder | NdFeB/PA12 Compound | MagFil Material |

|---|---|---|---|

| Remanence (mT) | 730–760 1 | 515–575 2 | 353 (SD = 6%) |

| Intrinsic coercivity (kA/m) | 670–750 1 | 620–800 2 | 711 (SD = 0.2%) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Von Petersdorff-Campen, K.; Hauswirth, Y.; Carpenter, J.; Hagmann, A.; Boës, S.; Schmid Daners, M.; Penner, D.; Meboldt, M. 3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump. Appl. Sci. 2018, 8, 1275. https://doi.org/10.3390/app8081275

Von Petersdorff-Campen K, Hauswirth Y, Carpenter J, Hagmann A, Boës S, Schmid Daners M, Penner D, Meboldt M. 3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump. Applied Sciences. 2018; 8(8):1275. https://doi.org/10.3390/app8081275

Chicago/Turabian StyleVon Petersdorff-Campen, Kai, Yannick Hauswirth, Julia Carpenter, Andreas Hagmann, Stefan Boës, Marianne Schmid Daners, Dirk Penner, and Mirko Meboldt. 2018. "3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump" Applied Sciences 8, no. 8: 1275. https://doi.org/10.3390/app8081275

APA StyleVon Petersdorff-Campen, K., Hauswirth, Y., Carpenter, J., Hagmann, A., Boës, S., Schmid Daners, M., Penner, D., & Meboldt, M. (2018). 3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump. Applied Sciences, 8(8), 1275. https://doi.org/10.3390/app8081275