1. Introduction

Lithium-ion batteries, which are secondary rechargeable batteries, have a higher energy density than other secondary batteries such as Ni–Cd batteries and Pd batteries if compared under the same conditions. Therefore, they can be used for energy storage devices, electronic devices, and electric vehicles, and demand for them has increased significantly [

1]. The lithium-ion manufacturing process can be categorized into two parts: (1) electrode coating and (2) cell assembly [

2]. During this manufacturing process, electrode cutting is one of the most important processes since poor cut quality leads to performance degradation. Moreover, defects such as burr and dross result in separator protrusion and local electric stress concentration. This may, eventually, lead to malfunction of lithium-ion batteries or explosion [

3]. Currently, die cutting or rotary knife cutting is used to cut electrodes. Since this process is a contact process, tools can be worn out and process instability can be observed with high possibility. Hence, this process instability has more chance to result in poor cut quality with defects such as burr and delamination. Furthermore, the lack of a standardized battery cell design leads to frequent changes in manufacturing specification, whenever the cell design is changed. Therefore, these frequent tool and design changes cause unexpected additional manufacturing cost. These disadvantages observed with current manufacturing methods can be improved by a laser cutting process due to its many advantages, such as being a noncontact process, with a high energy concentration, fast processing time, and higher flexibility for manufacturing design change.

Laser cutting has been applied with high popularity compared to other laser-aided manufacturing processes [

4,

5,

6,

7,

8,

9]. Recently, laser cutting was applied to cut electrodes of lithium-ion batteries [

10]. The first laser technology using cost-efficient nanosecond laser cutting of electrodes was applied and successfully transferred to industry [

10]. Lee et al. [

2,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20] investigated physical phenomena during laser electrode cutting theoretically and experimentally with a continuous single-mode fiber laser. Lutely et al. [

21,

22] used a continuous(CW) and pulsed laser to cut lithium iron phosphate battery electrodes. They characterized the process efficiency and quality. They found that the cutting efficiency increases with shorter pulses, higher velocity, and shorter wavelength. Luetke et al. [

23] investigated a comparative study on cutting electrodes for lithium-ion batteries with lasers. They compared a CW and pulsed laser to evaluate the cut quality by defining frazzling and clearance widths. They concluded that due to the high power range of the CW laser cutting system, it is advantageous in terms of cutting speed. In addition, the pulsed laser cutting system provides more opportunities for further improvements of the cutting quality. Demir et al. [

24] compared the cut quality of laser cutting of lithium-ion electrodes with green (λ = 532 nm, τ = 1 ns) and infrared (λ = 1064 nm, τ = 250 ns) pulsed lasers. They found that the green laser provided a clearance width below 20 μm. In addition, the infrared laser met the high-productivity criterion with laser power of 54 W and a cutting speed of 30 m/min.

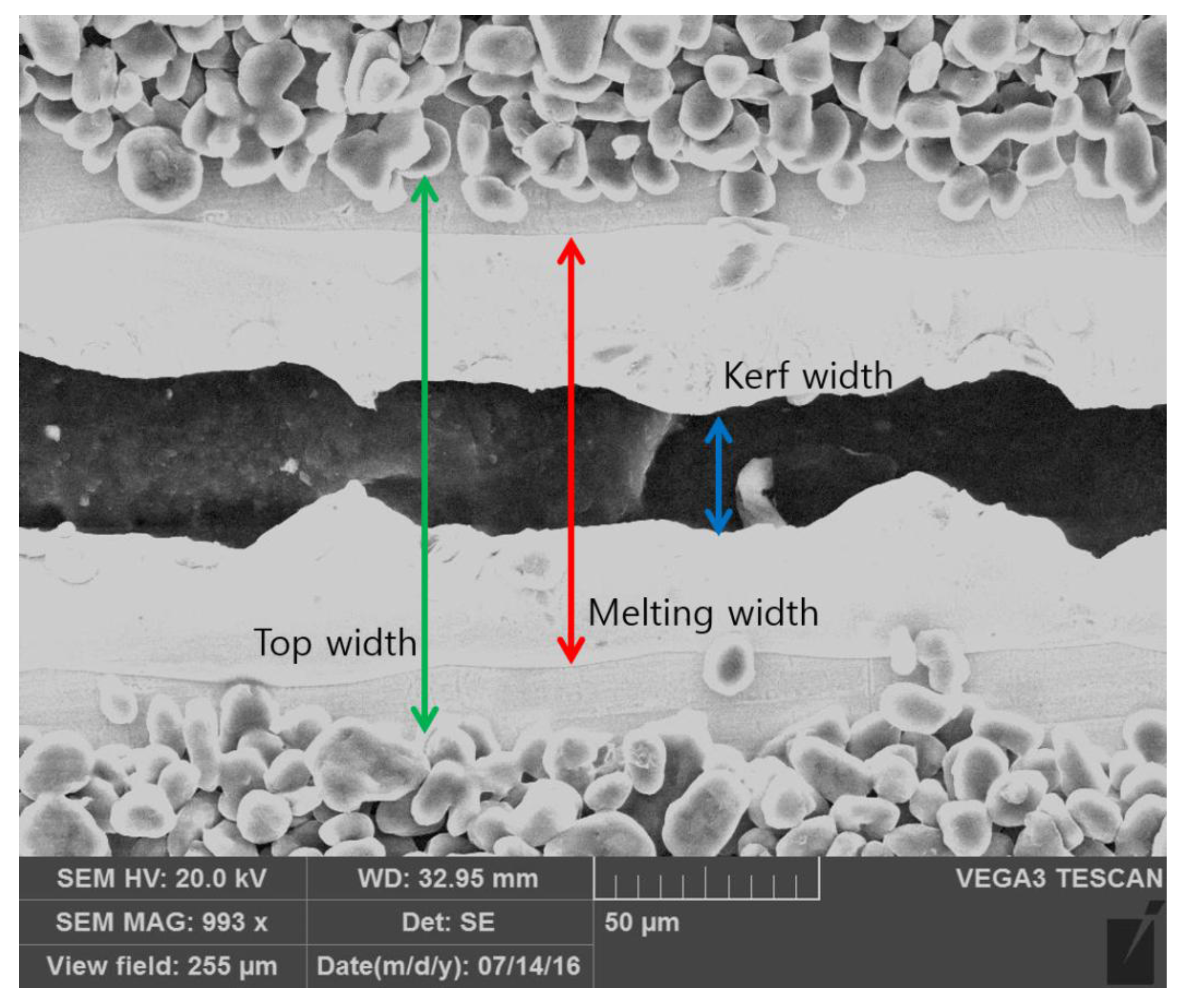

While many physical phenomena occur during laser cutting, conventional parameters have been still used for the analysis of laser cutting, such as kerf width and penetration depth. Therefore, this study proposes specific parameters such as melting width, top width, and kerf width to analyze multiphysical phenomena more intuitively during the laser cutting of electrodes in addition to the conventional parameters. Moreover, the relationship between laser parameters and multiphysical phenomena with the proposed specific widths are investigated with cutting efficiency. This study is composed as follows. First, experimental setup and material used are explained. Second, the analysis of the cutting efficiency is explained. Third, the specific widths for the analysis of multiphysical phenomena are proposed. Further, the relationship between the laser parameters and the proposed specific parameters is discussed. Finally, the conclusions are presented.

3. Analysis of Processing Efficiency

The heat transfer efficiency (

) [

26] is the efficiency of energy transmission from the source to the workpiece and defined as

where

is power actually absorbed by the workpiece and

is total power available at the laser source. The processing efficiency (

) is the thermal efficiency of energy conversion in the workpiece and defined as

where

is the power required to melt, evaporate, and thus remove a given volume of material. From the measured widths and geometrical information, the power required to remove the material can be estimated. In addition, the total laser power available at the laser source is also estimated. Therefore, these efficiencies can be combined as

Since there is no clear definition of this term, this term is named as the cutting efficiency (). Hence, first, the assumptions required to use the cutting efficiency need to be explained. Furthermore, the power required to melt, evaporate, and remove a given volume of material, as well as the total power available at the laser source, needs to be calculated.

3.1. Assumptions

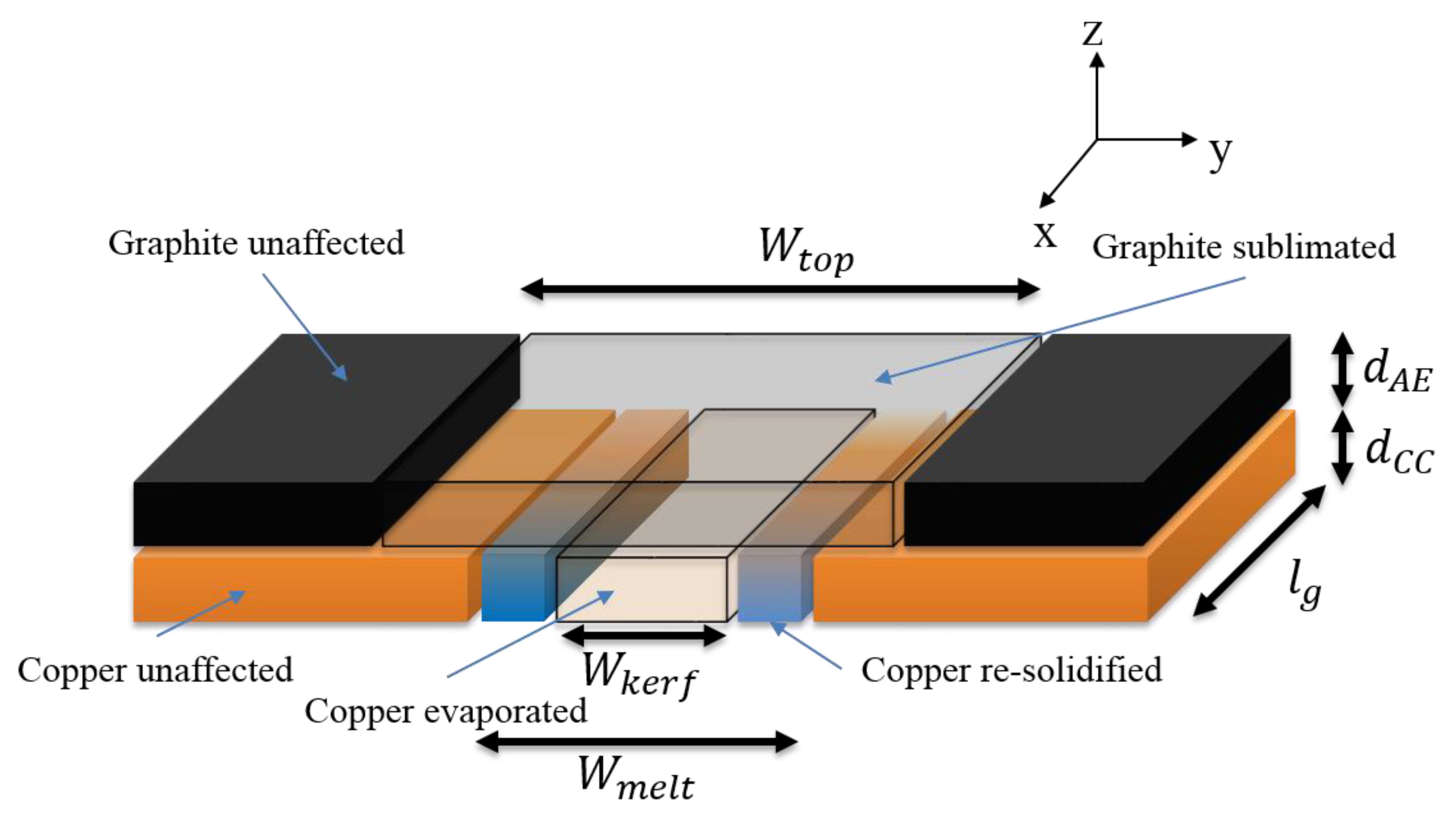

The geometrical assumption is shown in

Figure 2. For simplicity, several rectangular parallelepipeds were assumed to express the material deformed by sublimation, melting, and evaporation. Since the cutting efficiency is estimated not during the laser cutting but after the laser cutting, no melting flow, boiling, or plasma formation was considered. A Gaussian laser beam distribution was assumed. The beam profile and radius do not change in the

z-direction.

3.2. Laser Power Input (

Laser intensity distribution can be expressed by a combination of a Gaussian beam profile and a Laguerre polynomial [

15]. This expression can be written as

where

is the laser intensity,

is a parameter related to the laser beam radius (

) and distance

from the heat source, and

is the angle between the reference direction on the chosen plane. The laser beam radius, which is one half of the beam diameter, was set to 11.5 μm in this study. The line from the origin,

, is the radial distance, and

is the associated Laguerre polynomial of order

and index

. The Laguerre polynomial is expressed as

From Equations (4) and (5), the laser power can be obtained and expressed as

From Equation (4), when

and

, the Gaussian distribution can be expressed as

where

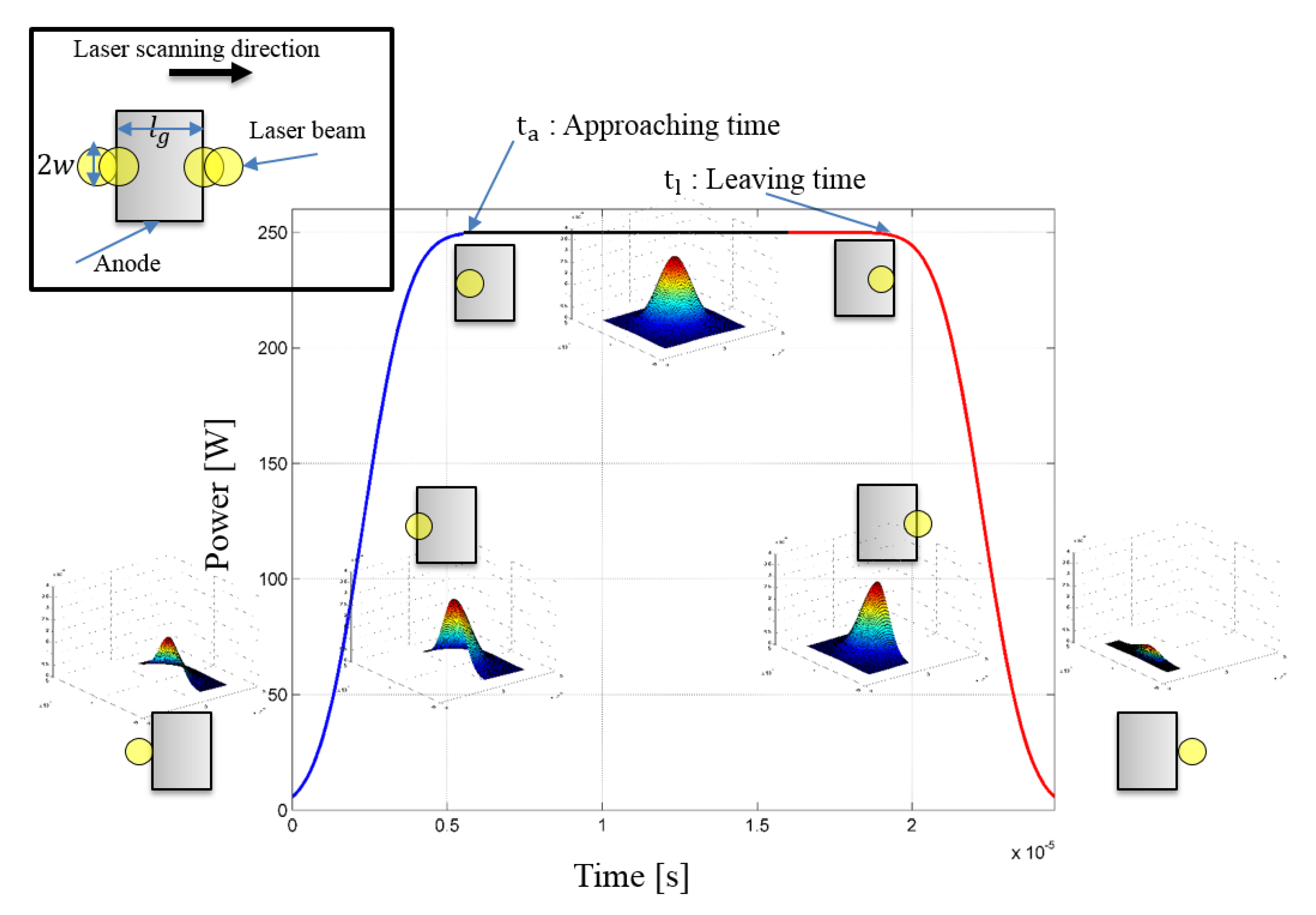

is a given laser power by a laser cutting system. Even though the laser power is given by the system, the real laser energy irradiated on the material surface could be different. Therefore, this study calculated a more precise laser power considering its approaching and leaving time. Laser power irradiation is shown in

Figure 3. First, at the beginning of the laser cutting process, the laser is approaching the given area (

and the laser power is increased to the certain laser power (

. After the laser is moving inside the given area with the given length (

, a constant laser power is maintained; then the laser power decreases as the laser is moving further away from the given area. The given length (

was set to 1 mm in this study. The length is cancelled out when calculating the efficiency. Based on this, the function of the laser power can be expressed as follows:

where

is the approaching time,

is the leaving time, and

is the final time. The detailed derivation is given in

Appendix A. The total laser energy input irradiated in the given area can be calculated by integrating the graph shown in

Figure 3 and its expression is shown as follows:

where

is the total laser energy,

is the laser energy irradiated from the beginning to the approaching time,

is the laser energy where the laser is fully irradiating the given area, and

is the laser energy irradiated from the leaving time to the final time. Finally, the laser power input can be calculated by dividing the total laser energy by the working time.

3.3. Power Used for the Laser Cutting of Anode Pp

Power used in cutting to sublimate, melt, and evaporate the anode can be derived from the geometrical volume removed and shown in

Figure 2. The volume removed by sublimation is expressed by

where

is the thickness of an active electrode material. The energy required to sublimate the given volume is expressed by

where

is the specific heat of the active electrode material,

is the mass of the active electrode material,

is the density of the active electrode material,

is the sublimation temperature of the active electrode material, and

is the ambient temperature. Volumes removed by melting and evaporation are, respectively, expressed by

where

is the thickness of a current collector. In addition, the energy required to melt and evaporate, respectively, can be expressed by

where

and

are the specific heat of the solid and liquid current collector, respectively;

and

are the mass of the solid and liquid current collector, respectively;

is the melting temperature of the current collector;

is the evaporation temperature of the current collector;

is the latent heat of fusion; and

and

are the density of the solid and liquid current collector, respectively.

The total energy used to remove an anode is obtained as follows:

Finally, the laser power used in the cutting of an anode can be calculated by dividing the total laser energy by the final time, or

4. Result and Discussion

Since various physical phenomena such as melting, molten pool formation, sublimation, evaporation, and re-solidification exist together, the above-mentioned widths were defined and used to explain the laser cutting process of electrodes for lithium-ion batteries.

The top width indicates that heat conduction and sublimation play a major role in removing the active electrode material or graphite due to sublimation. Hence, laser energy is absorbed on the top surface and transferred by conduction from the top surface to the body of graphite in the radial direction. When the body of the graphite reaches the sublimation temperature, the graphite is sublimated and the mass is removed. These heat transfer and material removal mechanisms are observable by investigating the top width. The physical phenomena such as melting, molten pool formation, and re-solidification are related to the melting width. From the kerf width, material removal caused by evaporation can be clearly observed.

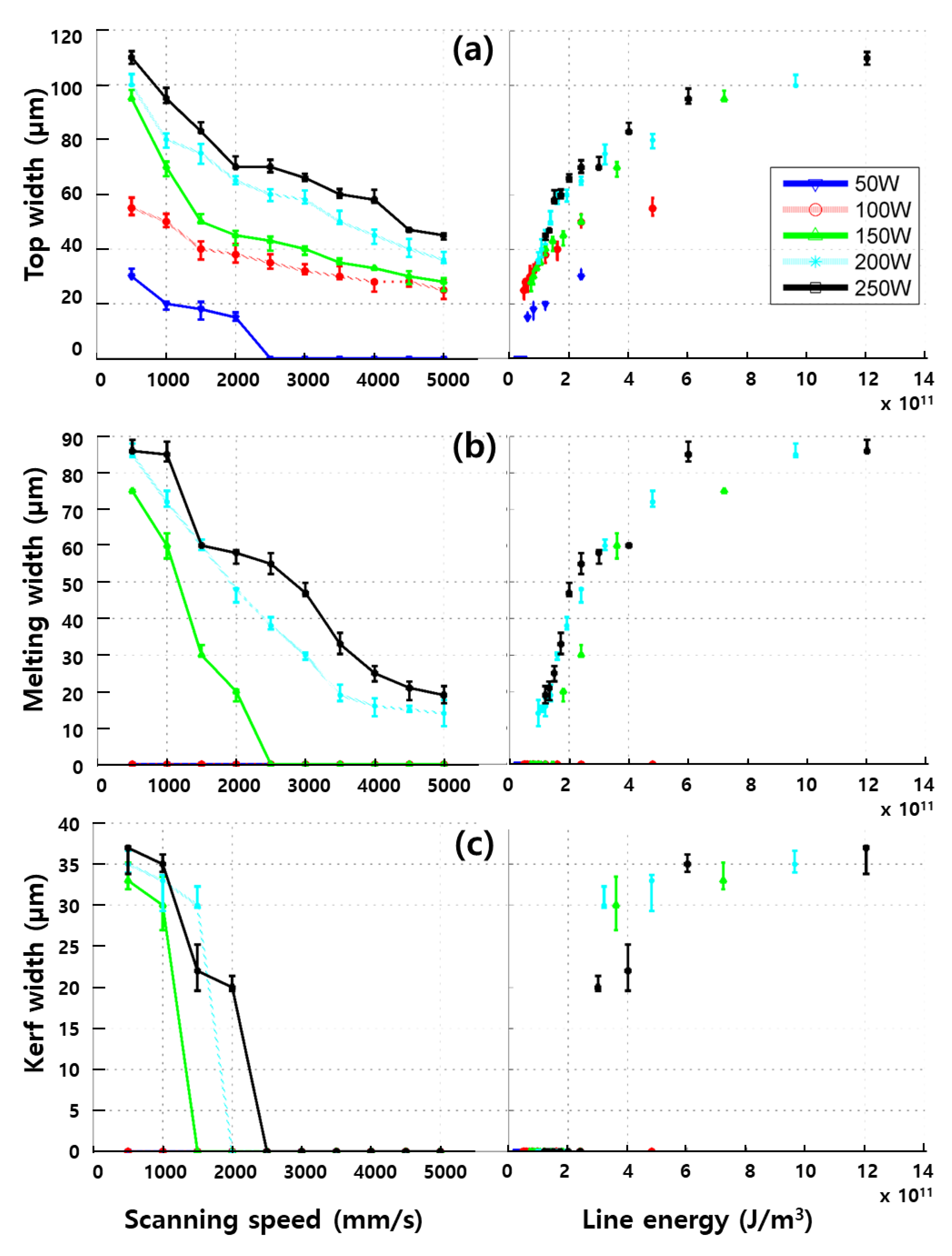

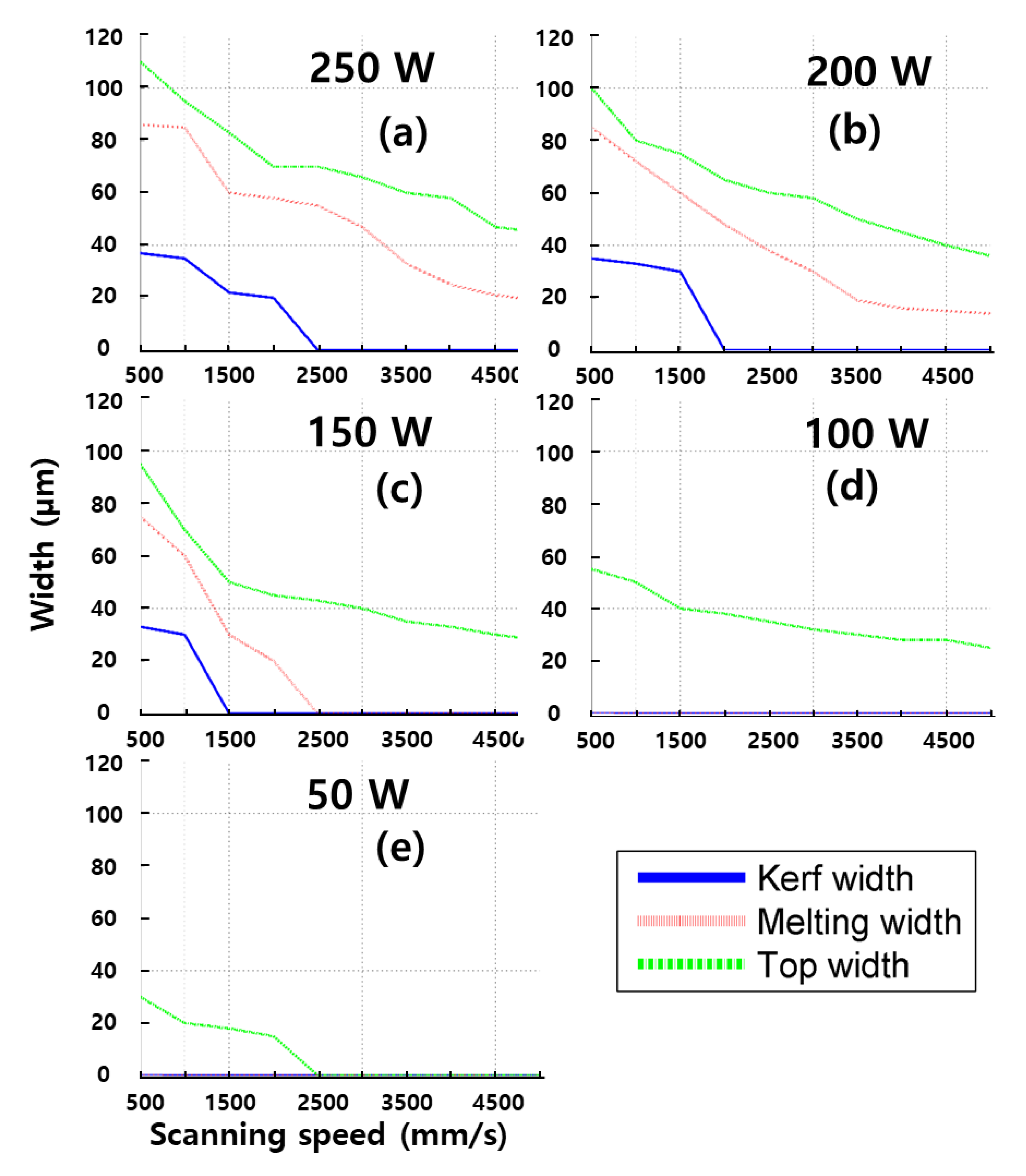

Figure 4 shows the top width, melting width, and kerf width. From the figures, the

x-axis is depicted with two variables—laser scanning speed (Left) and line energy (Right). The definition of line energy

can be referred to [

2,

11].

Figure 4a shows that increasing the scanning speed decreases the top width. With a laser power of 50 W, no top width is shown when the scanning speed is faster than 2000 mm/s. The top width is always observed when the laser power is greater than 50 W. In addition, increasing line energy increases top width. However, no active electrode material is removed when the line energy is less than 4.814 × 10

10 J/m

3. Therefore, it is 4.814 × 10

10 J/m

3 that is the line energy required to remove an active electrode material.

Figure 4b shows the melting width. Increasing scanning speed decreases the melting width. No melting width is formed when the laser power is less than 150 W. When the scanning speed is faster than 2000 mm/s, the melting width is not formed with a laser power of 150 W. A melting width is always observable when the laser power is greater than 150 W. According to the line energy, a line energy greater than 0.963 × 10

10 J/m

3 is required to form the melting width.

The comparison of the kerf width is shown in

Figure 4c. Increasing the scanning speed decreases the kerf width. No kerf width is observed when the laser power is less than 150 W. To fully penetrate the anode, a scanning speed less than 1500 mm/s is required with a laser power of 150 W. Furthermore, scanning speeds less than 2000 mm/s and 2500 mm/s are required to fully penetrate the anode with laser powers of 200 W and 250 W, respectively. Full penetration can be achieved when the line energy is greater than 3.009 × 10

10 J/m

3.

Figure 4 and

Figure 5 show the variation of widths depending on laser power. SEM images are taken after the cutting is completed using the laser power of 250–50 W. Five types of classification with regard to physical phenomena are introduced and shown in

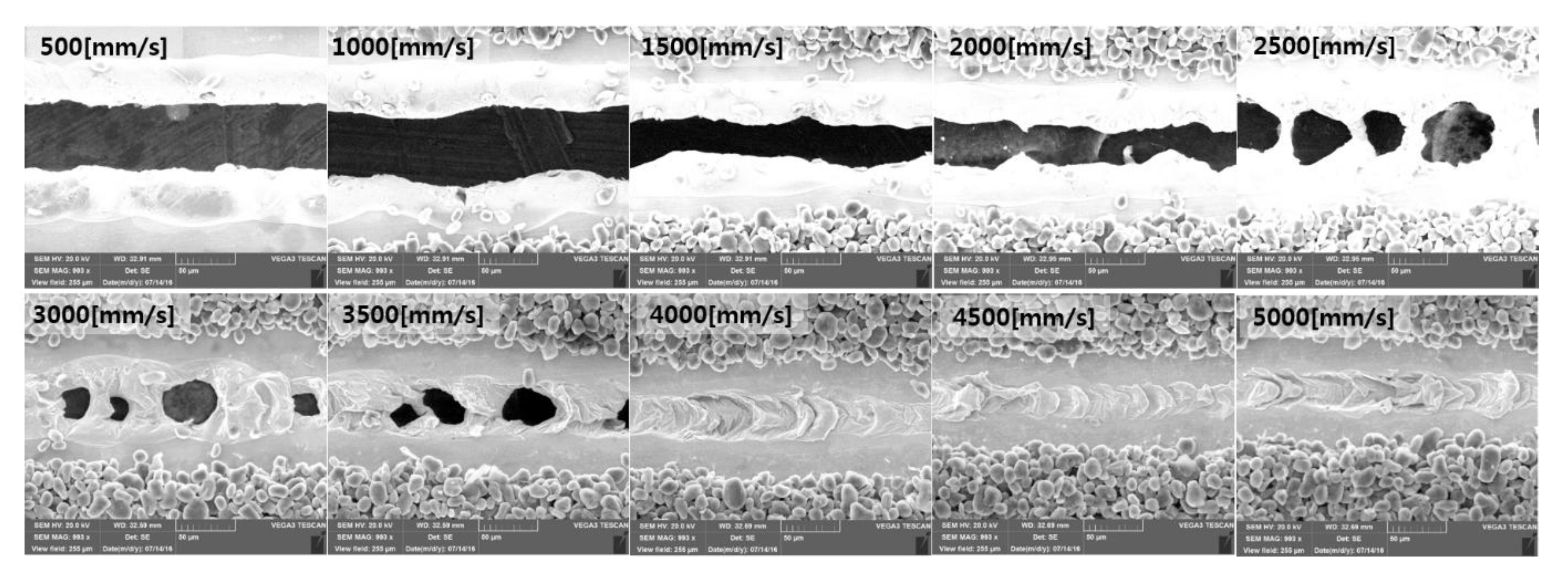

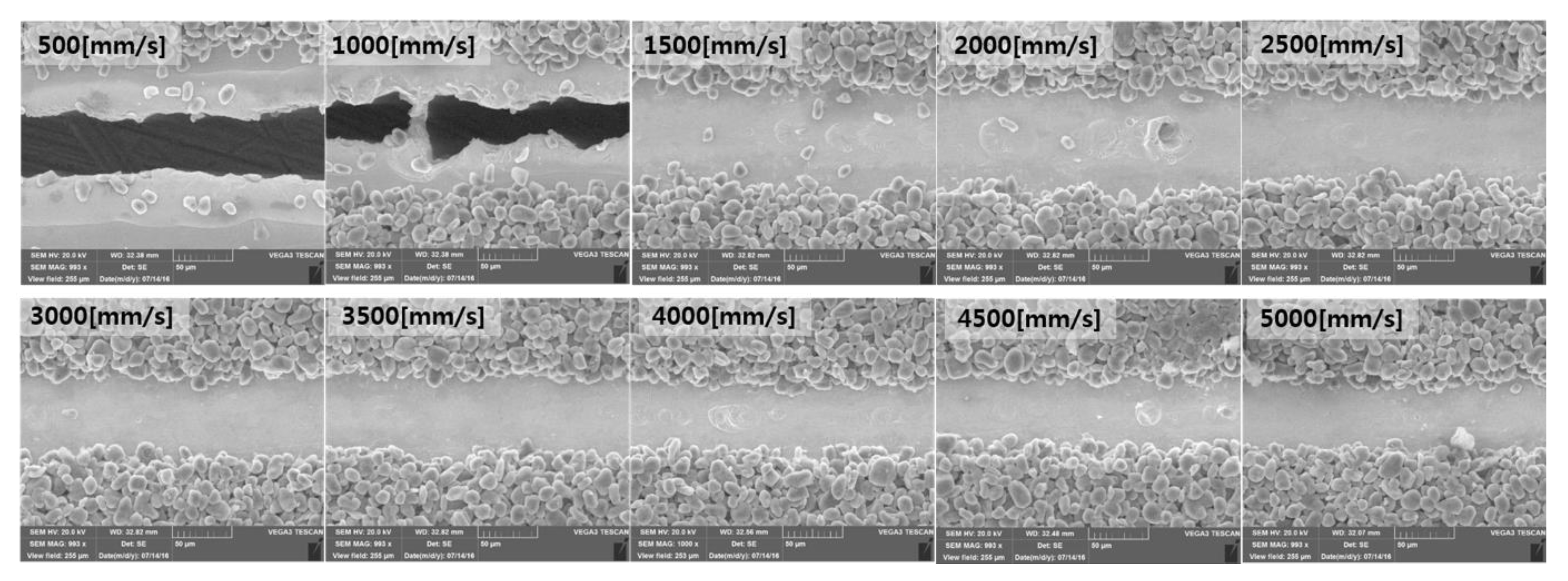

Figure 6: (1) full penetration with wider top width of electrode; (2) partial penetration of current collector; (3) partial melting of current collector; (4) full ablation of active electrode material; and (5) partial ablation of active electrode material. It is interesting that full penetration with a narrower top width of the electrode is hardly observable.

Figure 7 shows SEM images with a laser power of 250 W and these show very significant changes in terms of physical phenomena from the full penetration to the partial penetration to the partial melting. With a laser scanning speed of 500 mm/s to 2000 mm/s, full penetration with a wider top width of the electrode is observed. The melting widths are clearly observed and these are relatively wide compared to the widths observed for cathode materials. Moreover, the difference between the top width and melting width is narrower than the difference between the melting width and kerf width. With a laser scanning speed of 2500 mm/s to 3500 mm/s, partial penetration of the current collector is observed. This may have occurred due to sporadic evaporation as illustrated in

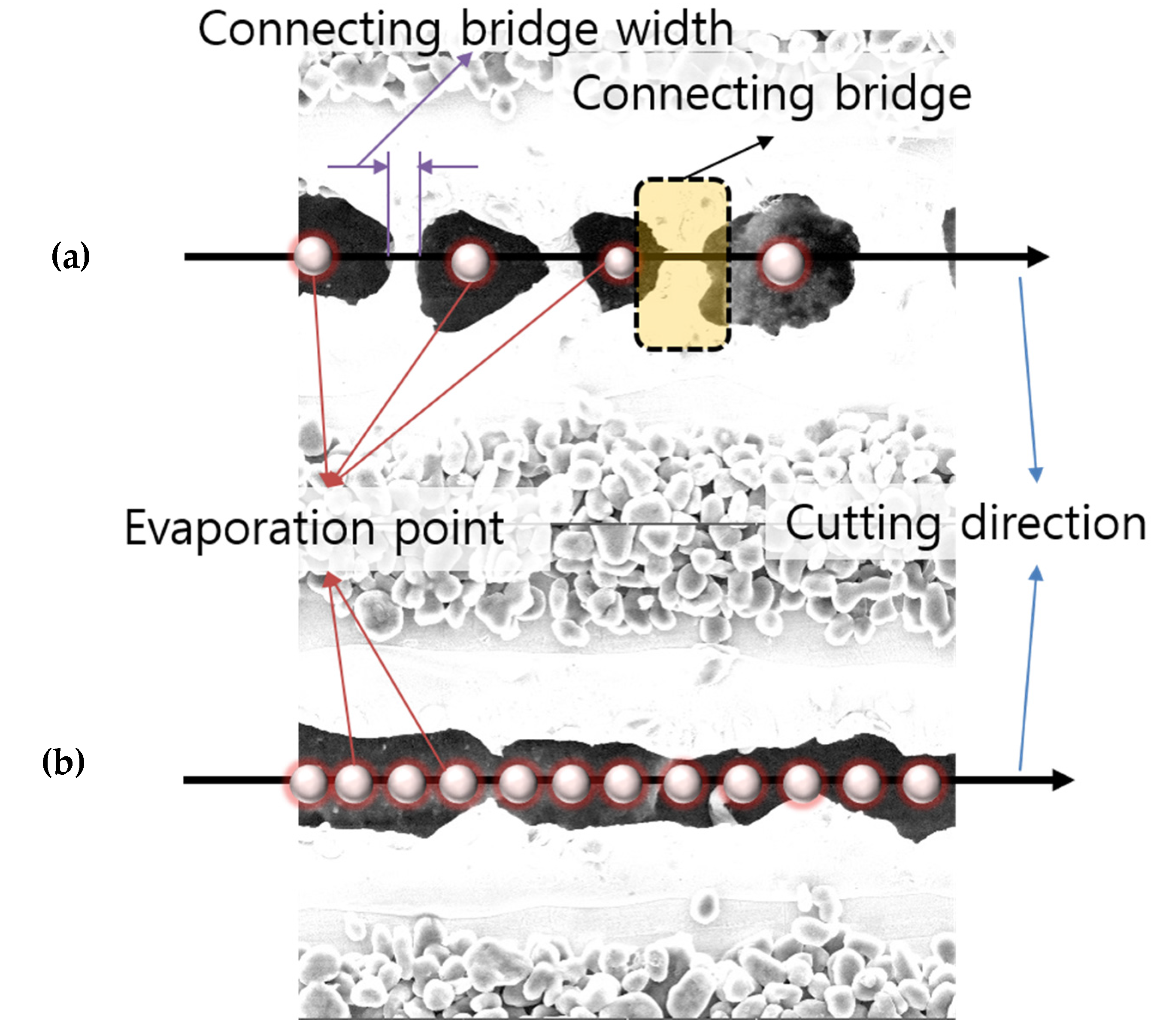

Figure 8. Thus, partial penetration occurs at the point where the evaporation occurs. On the other hand, more frequent evaporation occurrence may lead to full penetration. The physical mechanism of partial penetration was explained by Lee et al. [

27]. The forces caused by surface tension and recoil pressure are in a state of equilibrium and maintain a metastable state. When the force caused by surface tension increases, it leads to the formation of a connecting bridge as shown in

Figure 8. On the other hand, increasing force caused by the recoil pressure results in full penetration. With a scanning speed of 4000 mm/s to 5000 mm/s, partial melting of the current collector is observed. The given laser parameters provide enough energy to remove the active electrode, but not enough energy to fully penetrate the current collector.

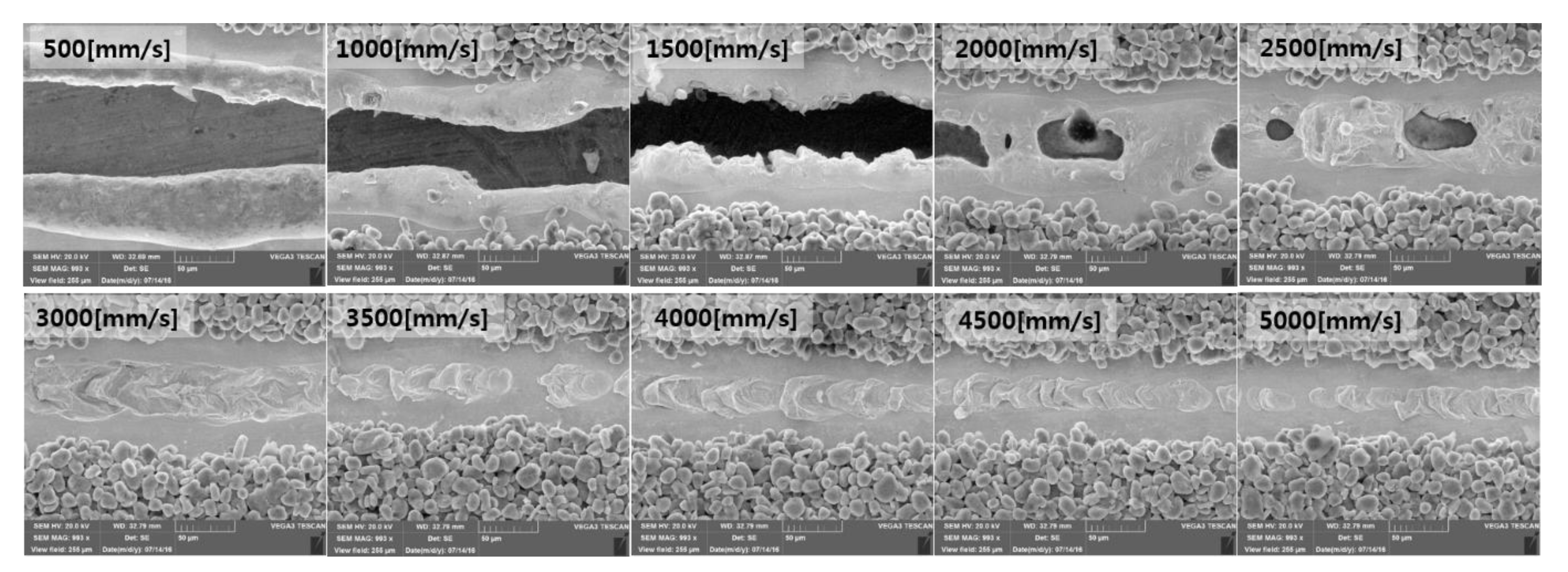

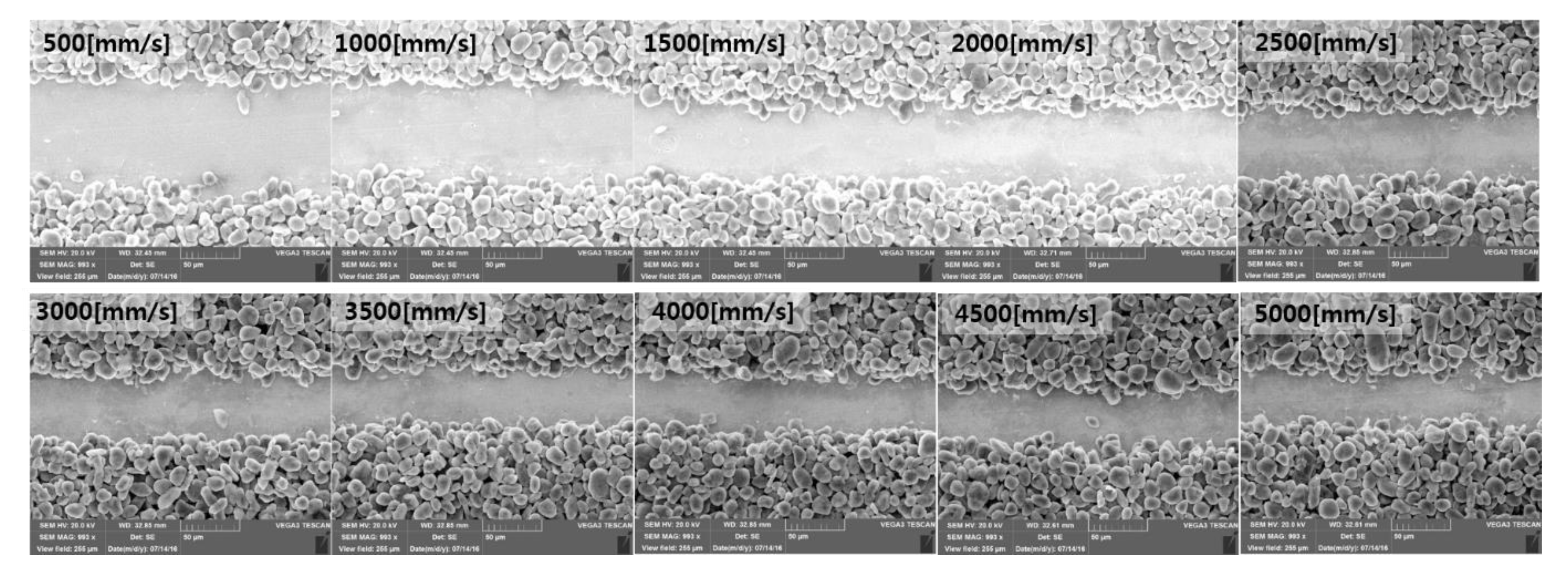

SEM images with a laser power of 200 W are shown in

Figure 9. This also shows three types of physical phenomena such as full penetration of the electrode (laser scanning speed of 500 mm/s to 1500 mm/s), partial penetration of the current collector (laser scanning speed of 2000 mm/s to 2500 mm/s), and partial melting of the current collector (laser scanning speed of 3000 mm/s to 5000 mm/s). Under this laser power, a wider connecting bridge width is observed compared to the case of 250 W laser power. The full penetration and partial penetration of the current collector occur due to a combination of multiphysical phenomena such as heat conduction, heat convection, evaporation, melting, and re-solidification. On the contrary, the full and partial ablation of the active electrode material occurs with relatively simple physical phenomena such as heat conduction and the sublimation of graphite.

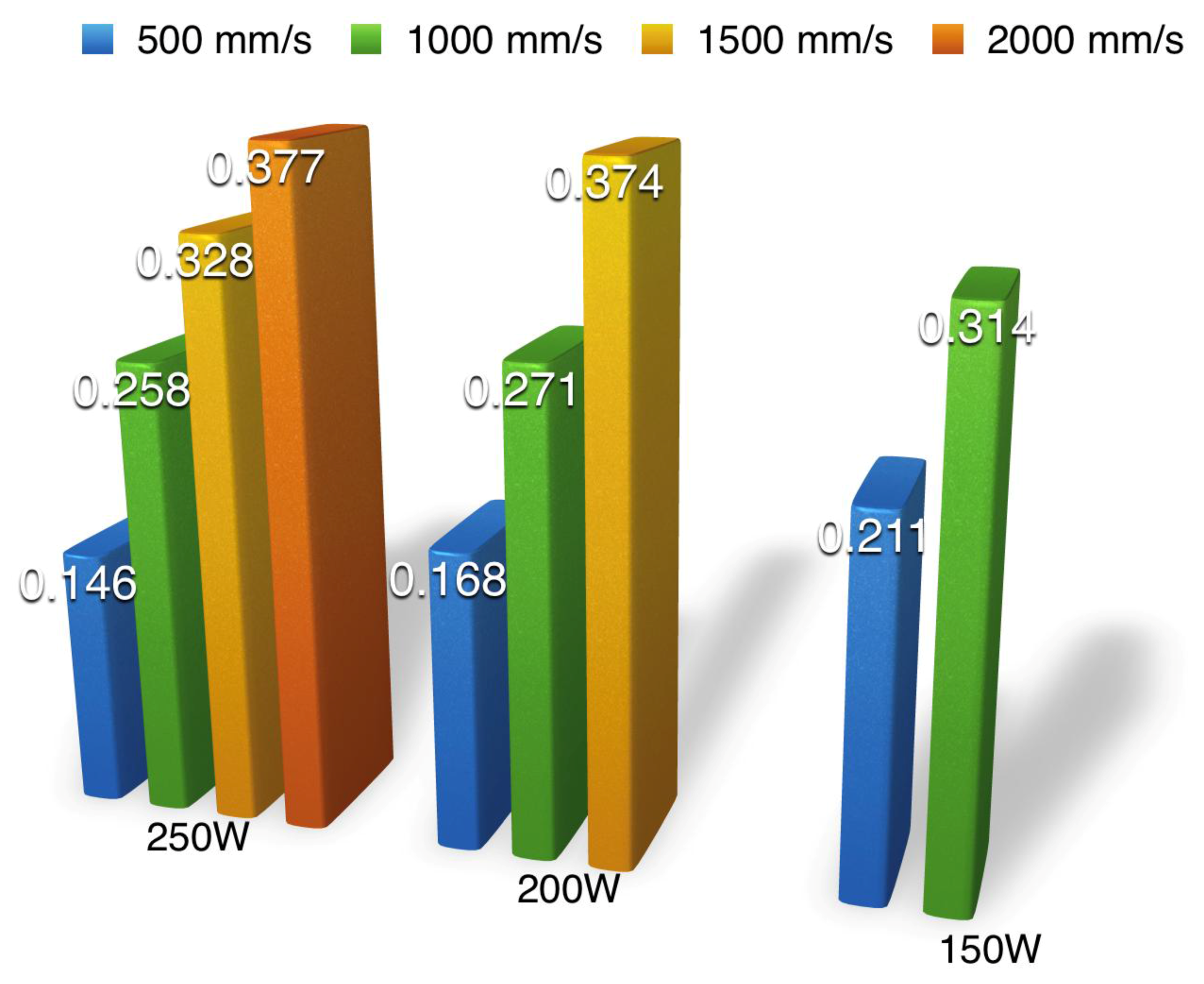

According to the analysis of the cutting efficiency discussed above, the cutting efficiency with appropriate material properties [

15] for the case of full penetration is shown in

Figure 10. The cutting efficiency varies from 14.6% to 37.7%. It is interesting that the cutting efficiency increases as the laser scanning speed increases. This is because losses due to thermal conduction make up a smaller portion of the absorbed energy [

28]. Therefore, a higher laser cutting speed providing full penetration leads to higher cutting efficiency and productivity.

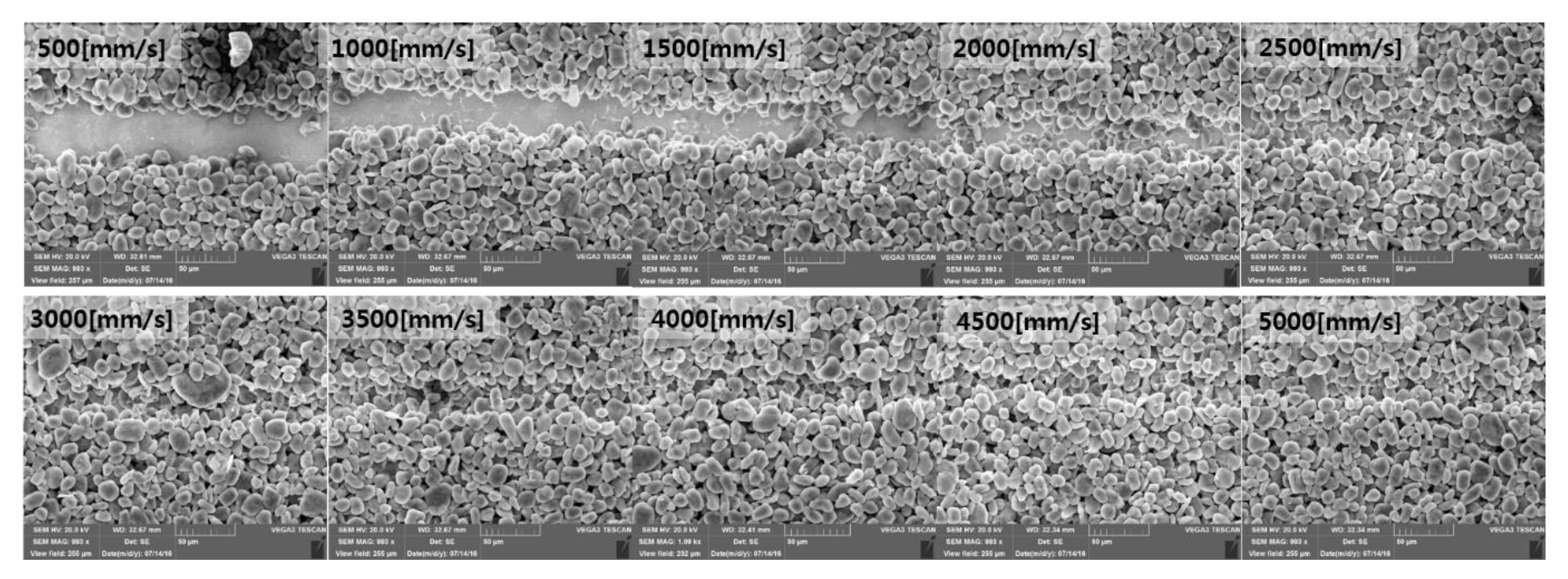

SEM images with a laser power of 150 W are shown in

Figure 11. In this figure, full penetration of the electrode and full ablation of the active electrode material are observed. Moreover, SEM images with a laser power of 100 W, as shown in

Figure 12, show only one type of physical phenomenon—the full ablation of the active electrode material. With the given laser power, full ablation of the active electrode material is introduced between 1500 mm/s and 5000 mm/s. In addition, full ablation of the active electrode material is the only geometrical classification observable with the given laser power of 100 W. Contrary to the partial melting observed in

Figure 9, no geometrical change is observed on a current collector with a laser power of 150 W or 100 W. The full ablation is the dominant physical phenomenon observed in

Figure 11 and

Figure 12. Due to the wide processing window, these parameters causing the full ablation can be robustly used for the selective removal of the active electrode material with minimal damage to the current collector.

Figure 13 shows SEM images with a laser power of 50 W and two types of geometrical classification—the full and partial penetration of the active electrode material. With the given laser scanning speed of 500 mm/s and 2000 mm/s, full ablation of the active electrode material is seen. On the other hand, partial ablation of the active electrode material is observed when the laser scanning speed is between 2500 mm/s to 5000 mm/s. Under the given laser power, the top width is very similar to the laser spot size, or 23 μm, and the width of the partial ablation is less than the laser spot size. This can be possible since the Gaussian distribution of the laser beam is used.