Influence of Interfacial Intermetallic Growth on the Mechanical Properties of Sn-37Pb Solder Joints under Extreme Temperature Thermal Shock

Abstract

1. Introduction

2. Materials and Methods

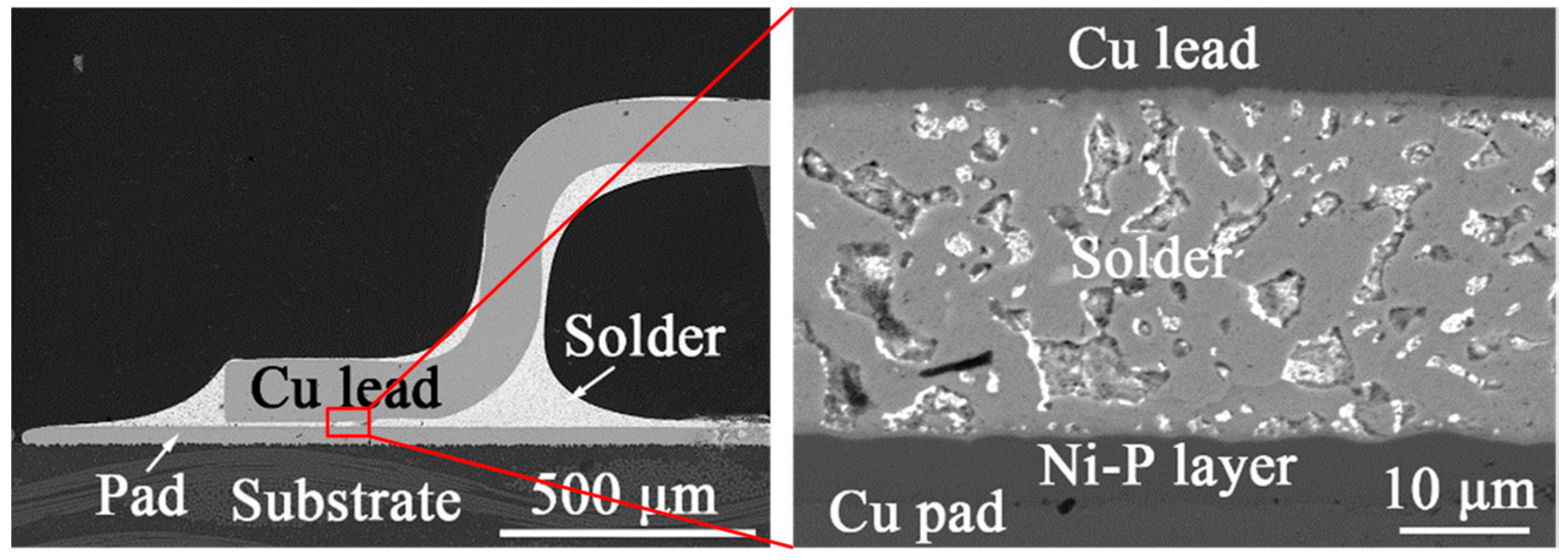

2.1. Sample Preparation

2.2. Extreme Temperature Thermal Shock Test

2.3. Microstructure Examination

2.4. Pull Test and Fractography

3. Results and Discussion

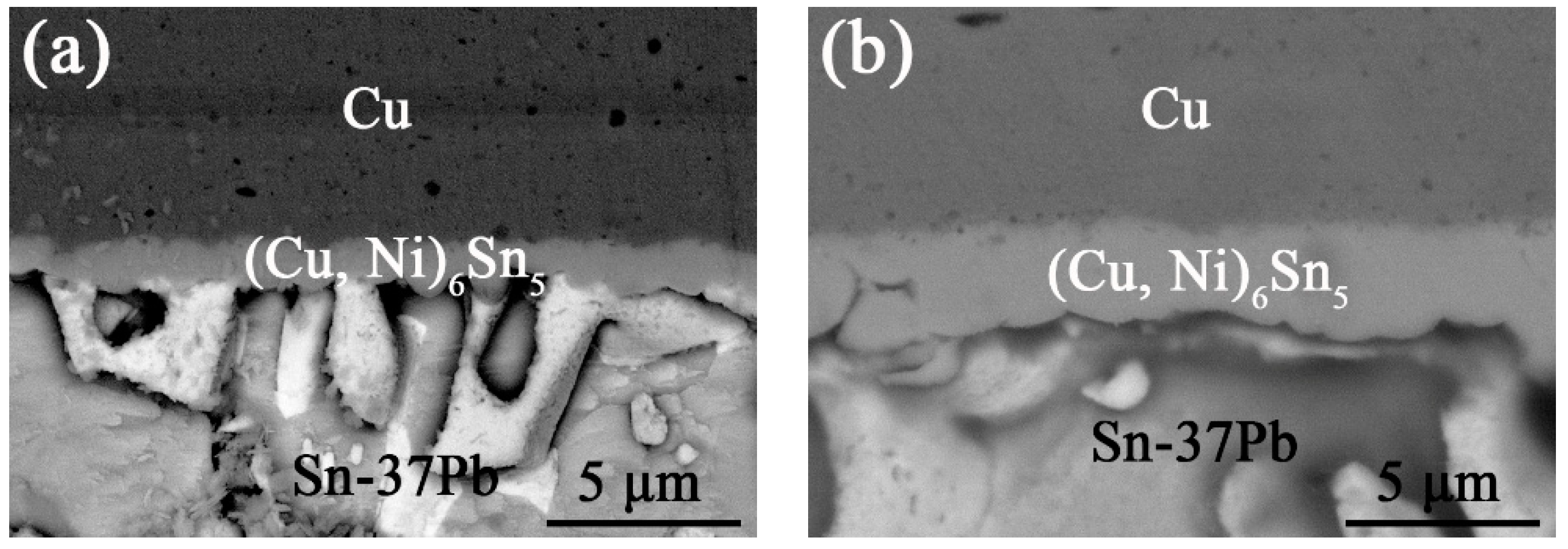

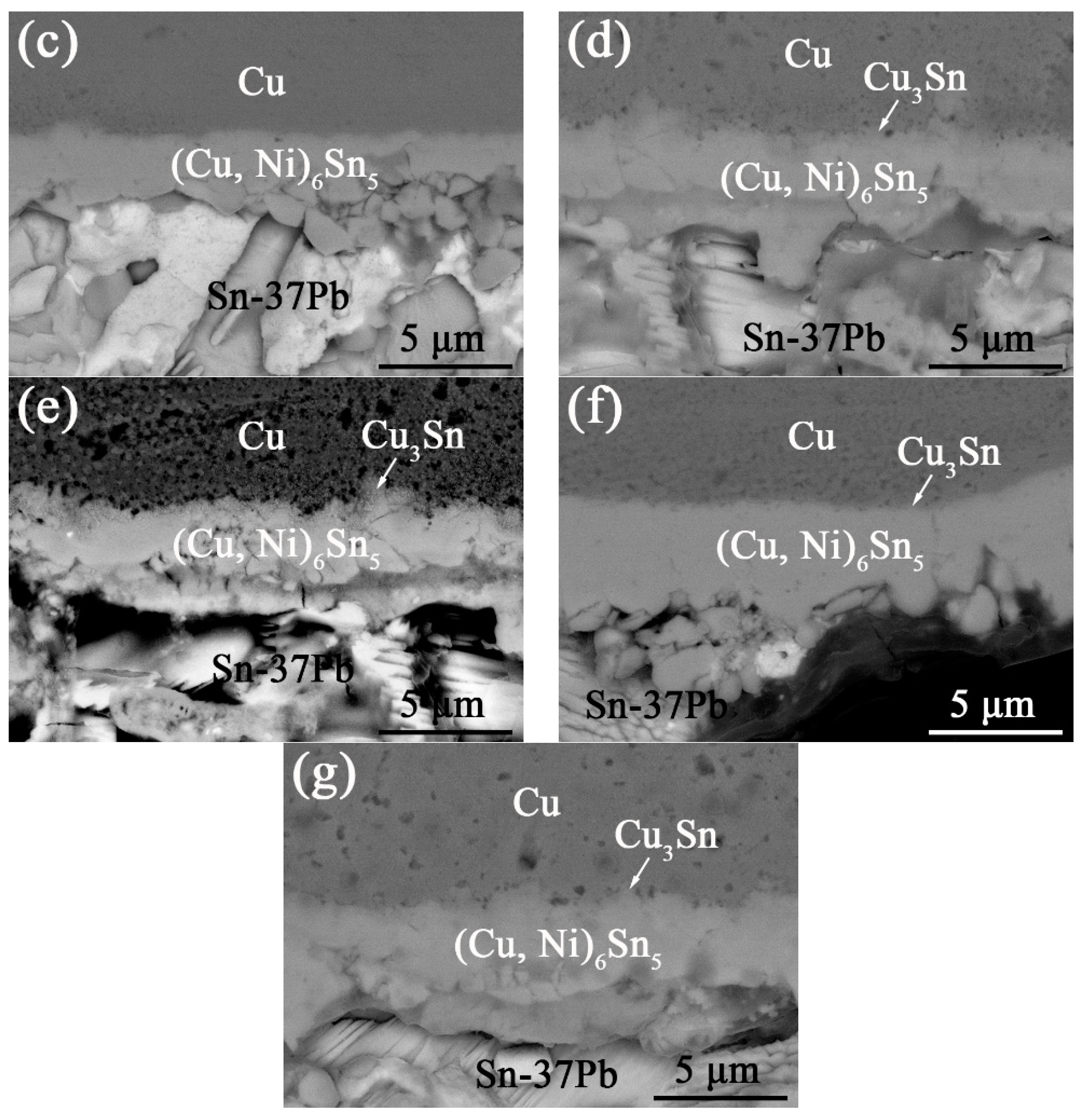

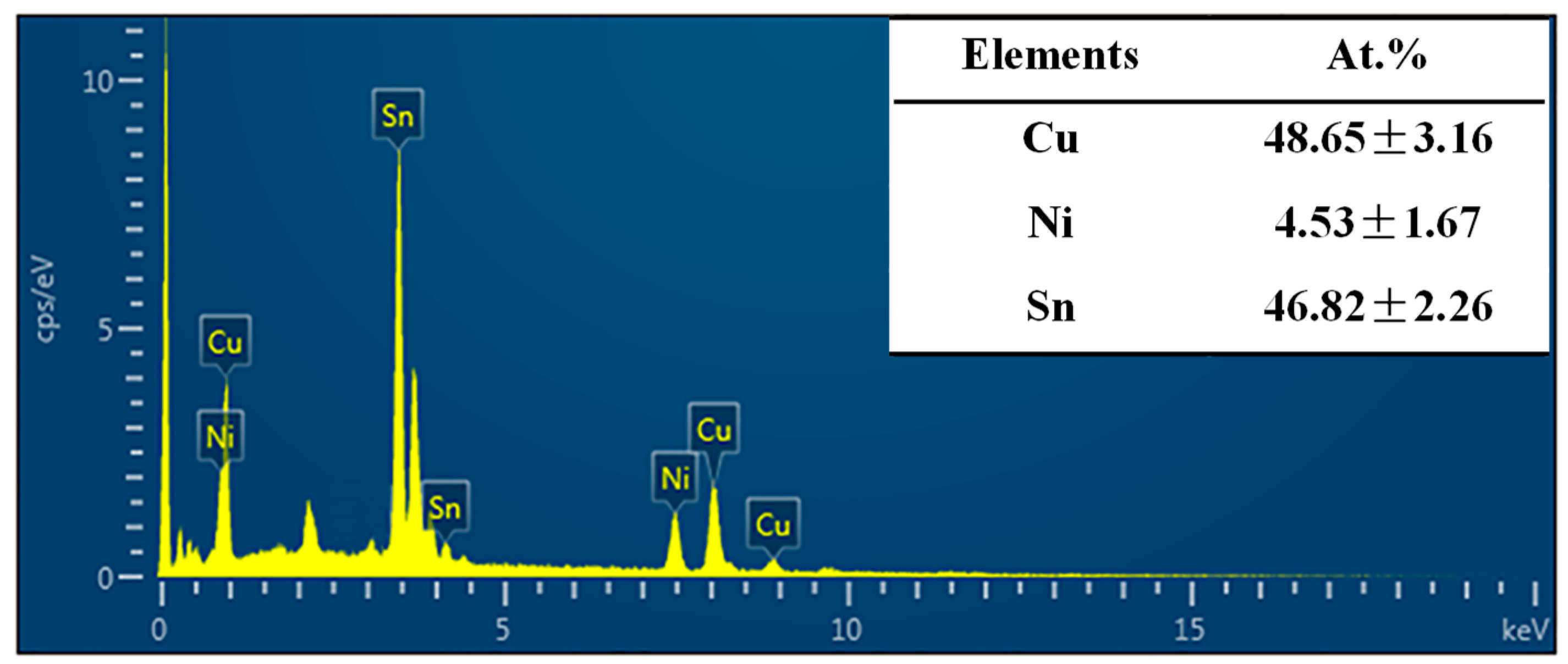

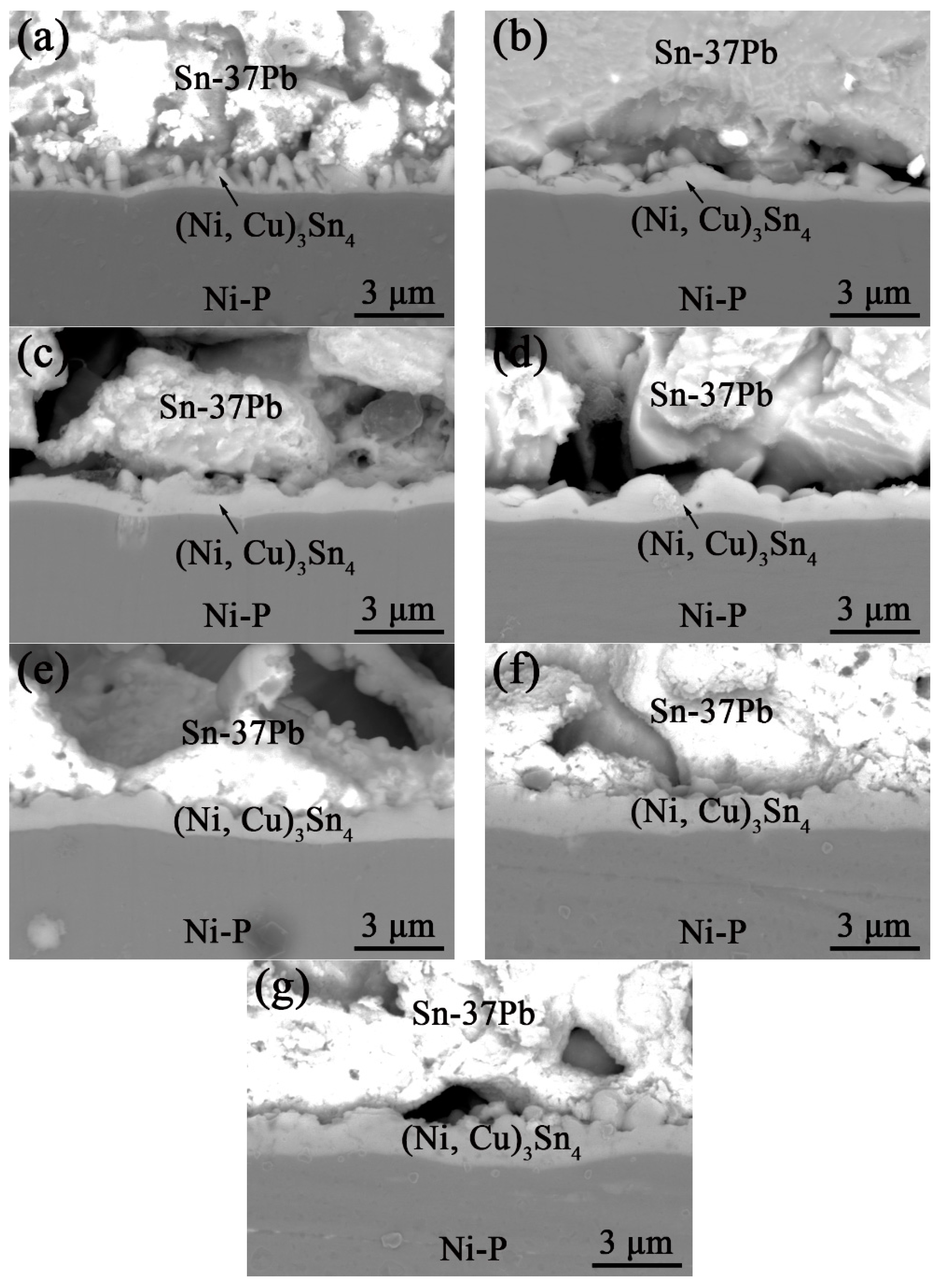

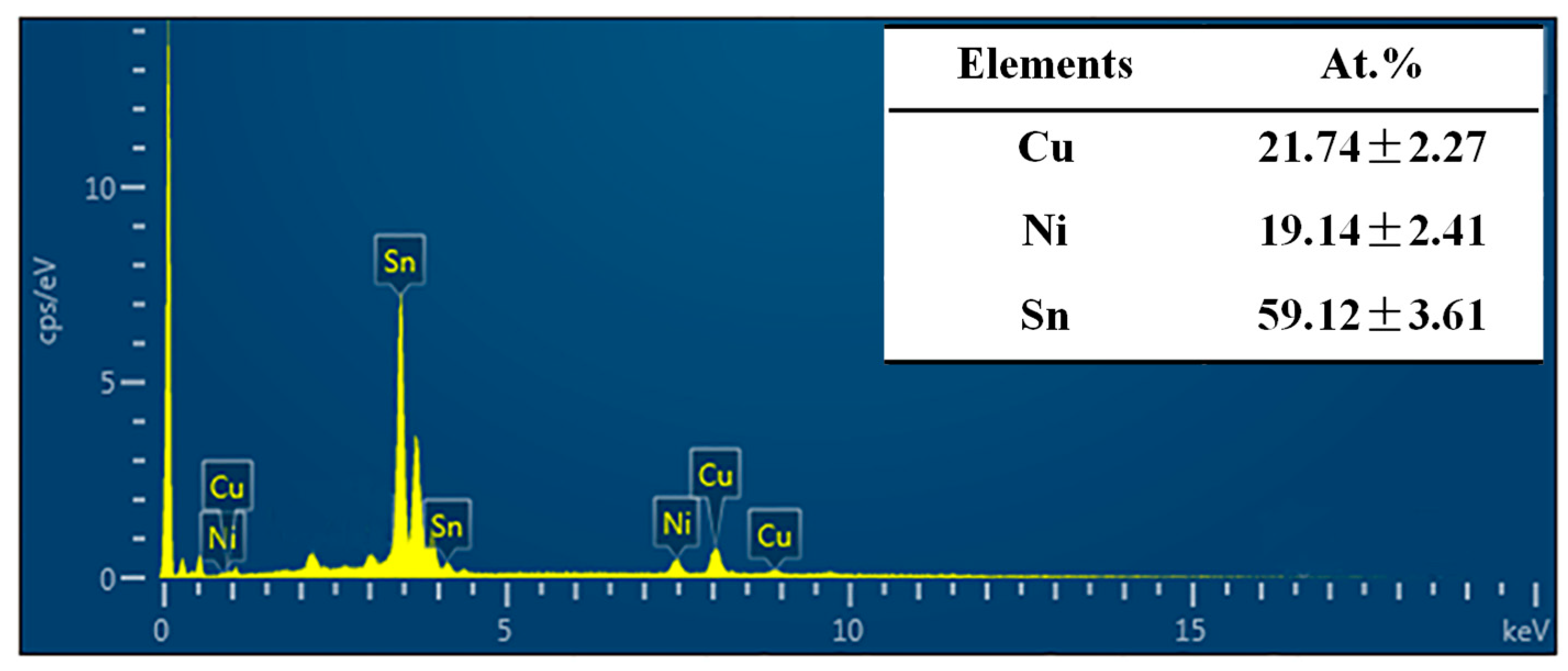

3.1. Microstructure Evolution of Interfacial IMCs

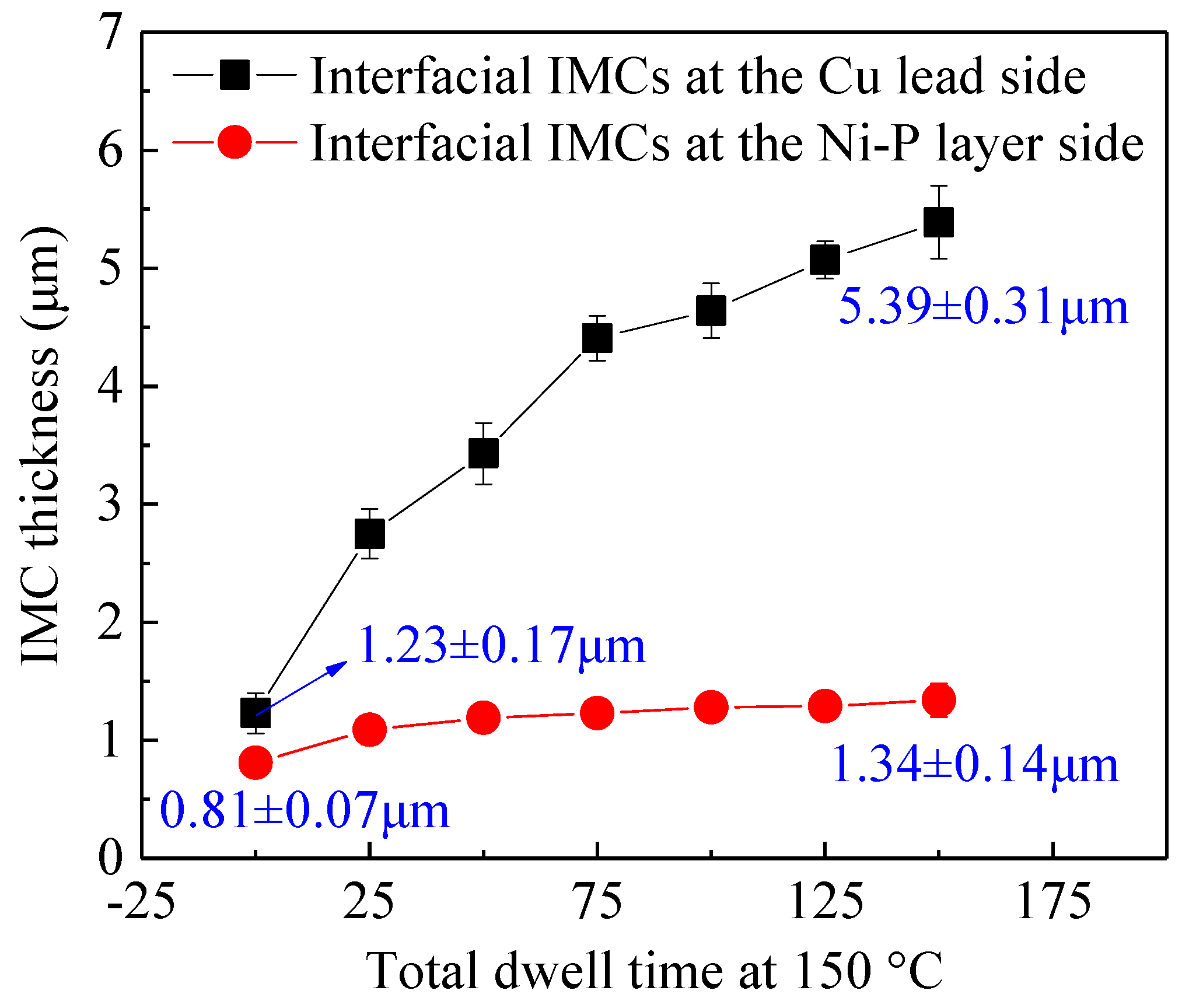

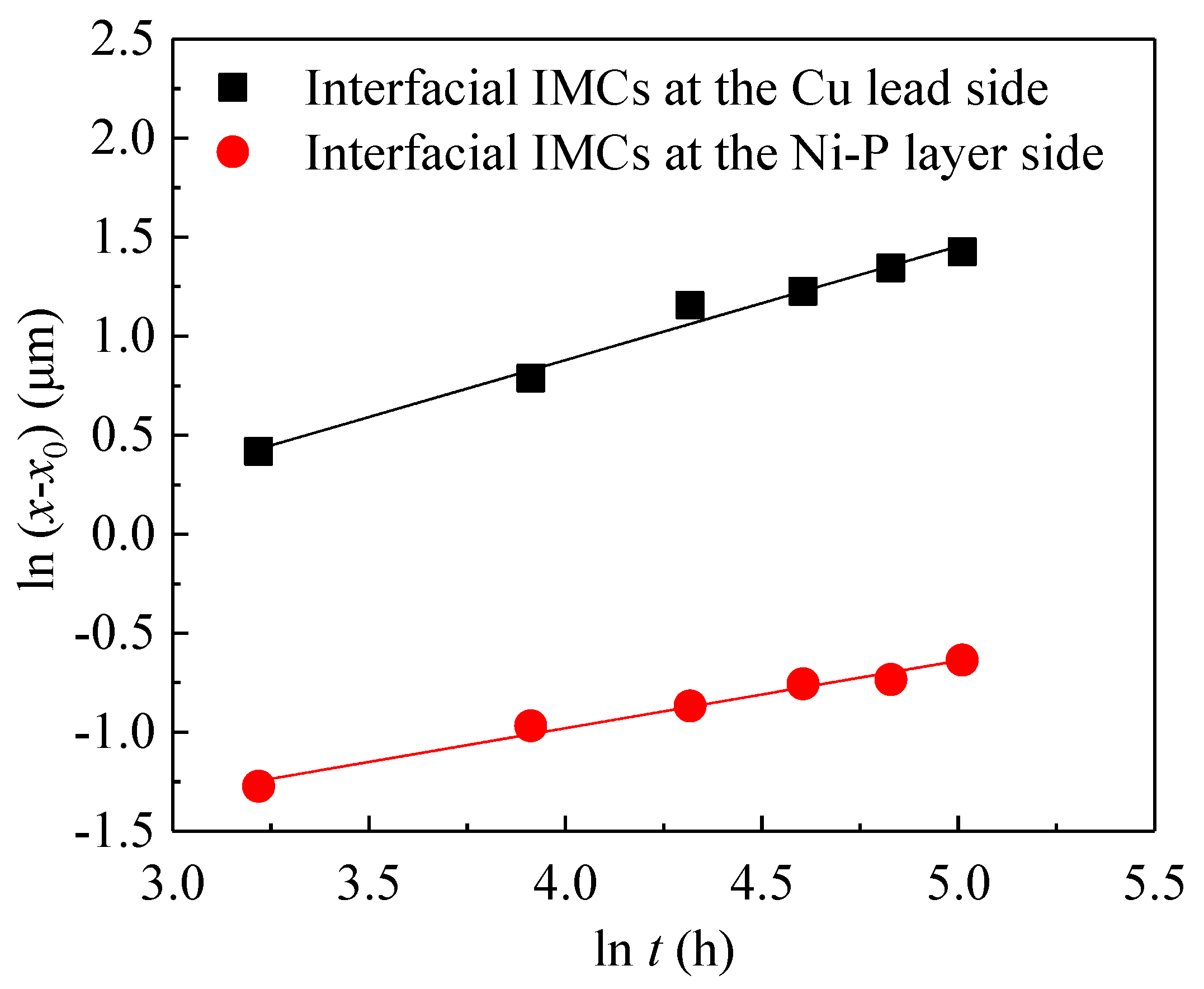

3.2. Growth Mechanism of Interfacial IMCs

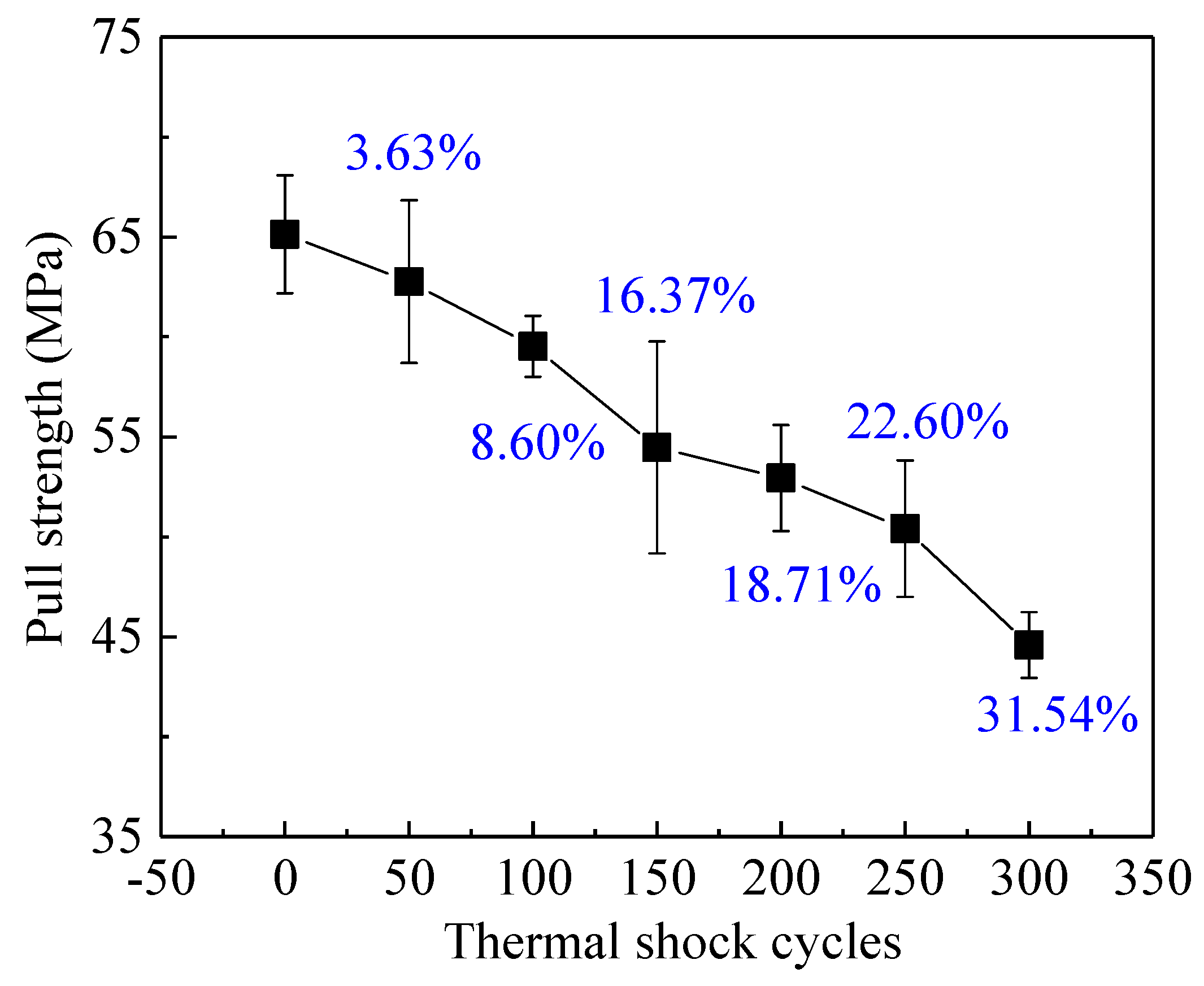

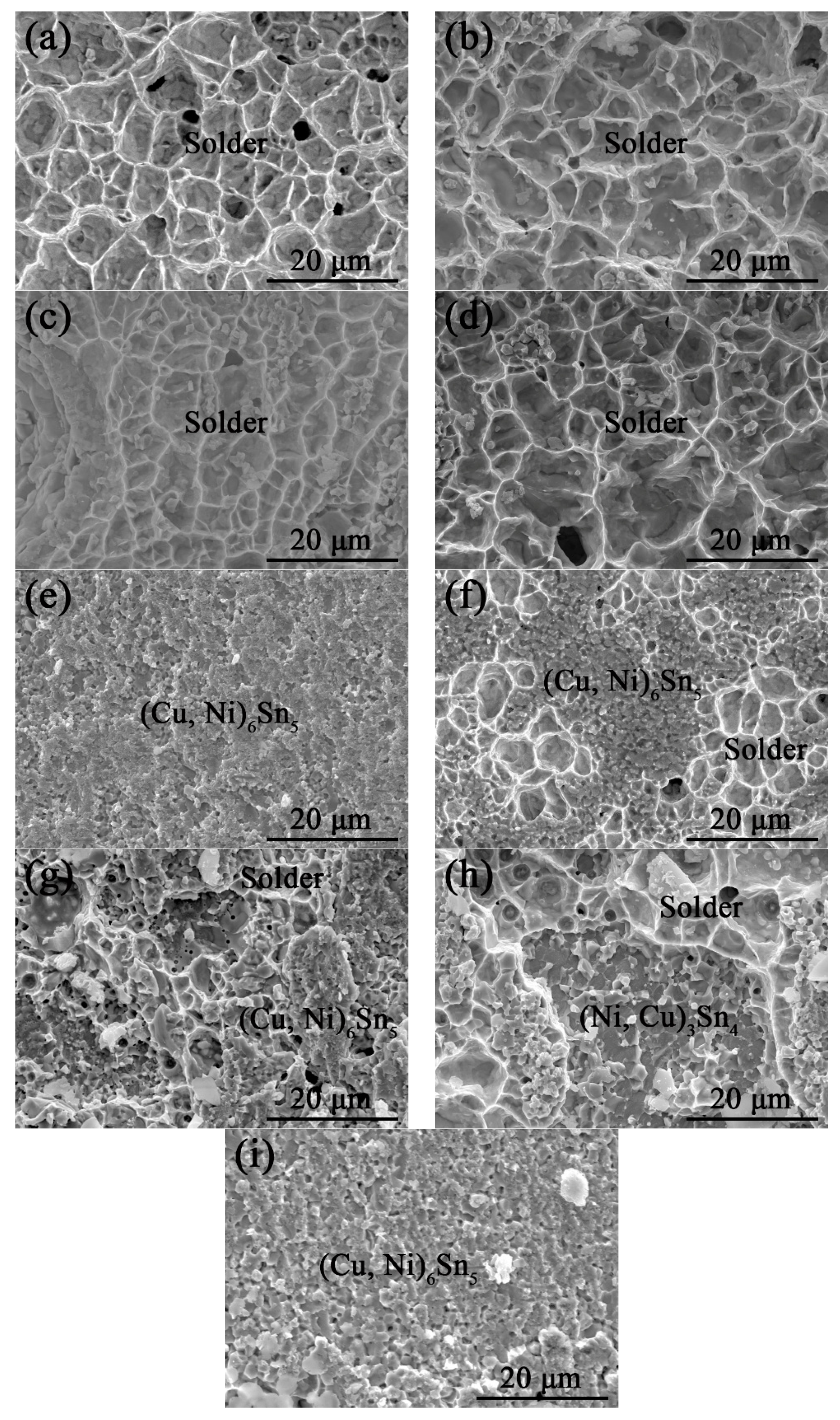

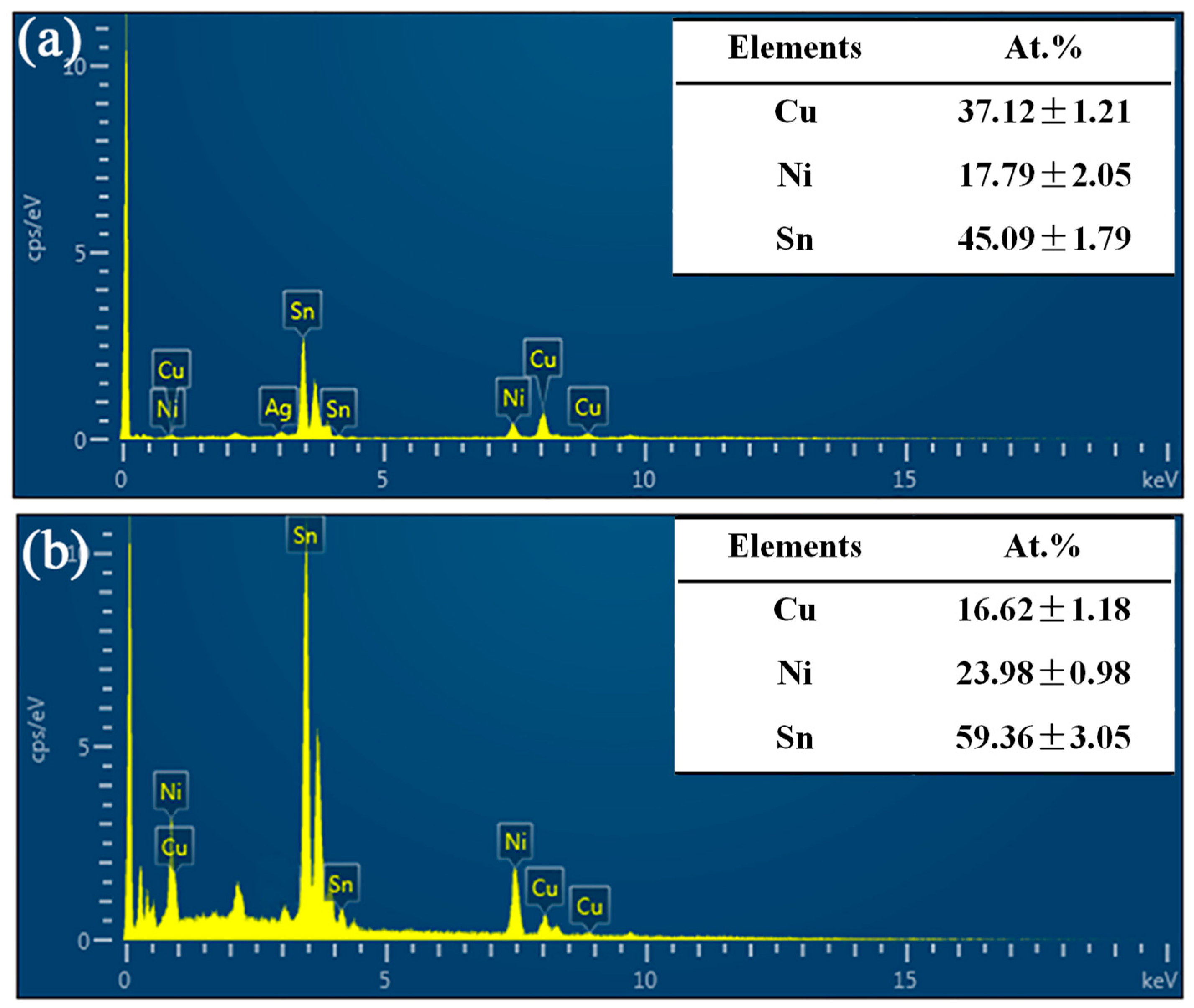

3.3. Mechanical Properties and Fractography

4. Conclusions

- (1)

- A continuous (Cu, Ni)6Sn5 IMC layer was formed at the interface between the Cu lead and the Sn-37Pb solder after reflowing, and the IMCs formed between the solder and Ni-P layer was (Ni, Cu)3Sn4 IMCs. A thin layer of Cu3Sn IMCs was formed between the Cu lead and (Cu, Ni)6Sn5 IMC layer after 150 cycles.

- (2)

- The morphology of interfacial (Cu, Ni)6Sn5 IMCs changed from scallop-type to plane-type, and the morphology of interfacial (Ni, Cu)3Sn4 IMCs evolved from needle-type to scallop-type, and finally to plane-type during extreme temperature thermal shock.

- (3)

- The thickness of the interfacial IMCs both at the Cu lead side and at the Ni-P layer side gradually increased with extreme temperature thermal shock. The growth of interfacial IMCs at the Cu lead side was found to be much faster than that at the Ni-P layer side. The growth of the interfacial IMCs at the lead side was dominated by bulk diffusion, and the growth of the interfacial (Ni, Cu)3Sn4 IMCs at the Ni-P layer side was dominated by grain-boundary diffusion.

- (4)

- With increasing thermal shock cycles, the pull strength of the joints decreased, and the fracture mechanism changed from ductile fracture to mixed ductile–brittle fracture. The pull strength was reduced about 31.54% after 300 cycles.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Rahim, M.K.; Suhling, J.C.; Jaeger, R.C.; Lall, P.; Knight, R. Reliability of flip chip assemblies subjected to extreme low temperatures. In Proceedings of the 10th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–2 June 2006; pp. 1379–1389. [Google Scholar]

- Yoon, J.M.; Chun, H.S.; Koo, J.M.; Lee, H.J.; Jung, S.B. Microstructural evolution of Sn-rich Au-Sn/Ni flip-chip solder joints under high temperature storage testing conditions. Scr. Mater. 2007, 56, 661–664. [Google Scholar] [CrossRef]

- Sharif, A.; Islam, M.N.; Chan, Y.C. Interfacial reactions of BGA Sn-3.5%Ag-0.5%Cu and Sn-3.5%Ag solders during high-temperature aging with Ni/Au metallization. Mater. Sci. Eng. B 2004, 113, 184–189. [Google Scholar] [CrossRef]

- Lee, H.T.; Chen, M.H.; Jao, H.M.; Liao, T.L. Influence of interfacial intermetallic compound on fracture behavior of solder joints. Mater. Sci. Eng. A 2003, 358, 134–141. [Google Scholar] [CrossRef]

- Xue, P.; Xue, S.; Zhang, L.; Shen, Y.F.; Gao, L.L.; Yu, S.L.; Zhu, H.; Han, Z.L.; Chen, Y. Tensile strength of fine pitch QFP lead-free soldered joints with diode laser soldering. Solder. Surf. Mt. Technol. 2011, 23, 177–183. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, T.; Liu, W.; Huang, Y.F.; Tang, S.W.; Wang, Y.K. Interfacial microstructure evolution and shear behavior of Au–12Ge/Ni solder joints during isothermal aging. J. Mater. Sci. Mater. Electron. 2017, 28, 3685–3694. [Google Scholar] [CrossRef]

- Deng, X.; Sidhu, R.S.; Johnson, P.; Chawla, N. Influence of reflow and thermal aging on the shear strength and fracture behavior of Sn-3.5Ag solder/Cu joints. Metall. Mater. Trans. A 2005, 36, 55–64. [Google Scholar] [CrossRef]

- Kim, D.G.; Kim, J.W.; Jung, S.B. Effect of aging conditions on interfacial reaction and mechanical joint strength between Sn-3.0Ag-0.5Cu solder and Ni-P UBM. Mater. Sci. Eng. B 2005, 121, 204–210. [Google Scholar] [CrossRef]

- Tian, R.Y.; Hang, C.J.; Tian, Y.H.; Zhao, L.Y. Growth behavior of intermetallic compounds and early formation of cracks in Sn-3Ag-0.5Cu solder joints under extreme temperature thermal shock. Mater. Sci. Eng. A 2018, 709, 125–133. [Google Scholar] [CrossRef]

- Ghaffarian, R. CCGA packages for space applications. Microelectron. Reliab. 2006, 46, 2006–2024. [Google Scholar] [CrossRef]

- Li, X.Y.; Li, F.H.; Guo, F.; Shi, Y.W. Effect of isothermal aging and thermal cycling on interfacial IMC growth and fracture behavior of SnAgCu/Cu joints. J. Electron. Mater. 2001, 40, 51–61. [Google Scholar] [CrossRef]

- Zeng, K.; Vuorinen, V.; Kivilahti, J.K. Interfacial reactions between lead-free SnAgCu solder and Ni(P) surface finish on printed circuit boards. IEEE Trans. Electron. Packag. Manuf. 2002, 25, 162–167. [Google Scholar] [CrossRef]

- Deng, X.; Piotrowski, G.; Williams, J.J.; Chawla, N. Influence of initial morphology and thickness of Cu6Sn5 and Cu3Sn intermetallics on growth and evolution during thermal aging of Sn-Ag solder/Cu joints. J. Electron. Mater. 2003, 32, 1403–1413. [Google Scholar] [CrossRef]

- Shen, J.; Zhao, M.; He, P.; Pu, Y. Growth behaviors of intermetallic compounds at Sn-3Ag-0.5Cu/Cu interface during isothermal and non-isothermal aging. J. Alloys Compd. 2013, 574, 451–458. [Google Scholar] [CrossRef]

- Davis, J.A.; Bozack, M.J.; Evans, J.L. Effect of (Au, Ni)Sn4 evolution on Sn-37Pb/ENIG solder joint reliability under isothermal and temperature-cycled conditions. IEEE Trans. Compon. Packag. Technol. 2007, 30, 32–41. [Google Scholar] [CrossRef]

- Shen, J.; Zhai, D.; Cao, Z.; Zhao, M.; Pu, Y. Fracture behaviors of Sn-Cu intermetallic compound layer in ball grid array induced by thermal shock. J. Electron. Mater. 2013, 43, 567–578. [Google Scholar] [CrossRef]

- Xia, Y.H.; Me, X.M. Reliability of lead-free solder joints with different PCB surface finishes under thermal cycling. J. Alloys Compd. 2008, 454, 174–179. [Google Scholar] [CrossRef]

- Tu, P.L.; Chan, Y.C.; Hung, K.C.; Lai, J.K.L. Growth kinetics of intermetallic compounds in chip scale package solder joint. Scr. Mater. 2001, 44, 317–323. [Google Scholar] [CrossRef]

- Choudhury, S.F.; Ladani, L. Local shear stress-strain response of Sn-3.5Ag/Cu solder joint with high fraction of intermetallic compounds: Experimental analysis. J. Alloys Compd. 2016, 680, 665–676. [Google Scholar] [CrossRef]

- Xu, L.H.; Pang, J.H.L.; Prakash, K.H.; Low, T.H. Isothermal and thermal cycling aging on IMC growth rate in lead-free and lead-based solder interface. IEEE Trans. Compon. Packag. Technol. 2005, 28, 408–414. [Google Scholar] [CrossRef]

- Perkins, A.; Sitaraman, S.K. Analysis and prediction of vibration-induced solder joint failure for a ceramic column grid array package. J. Electron. Packag. 2008, 130, 011012. [Google Scholar] [CrossRef]

- Pang, J.H.L.; Xu, L.H.; Shi, X.Q.; Zhou, W.; Ngoh, S.L. Intermetallic growth studies on Sn-Ag-Cu lead-free solder joints. J. Electron. Mater. 2004, 33, 1219–1226. [Google Scholar] [CrossRef]

- Qian, Z.F.; Liu, S. On the life prediction and accelerated testing of solder joints. Int. J. Microcircuits Electron. Packag. 1999, 22, 288–304. [Google Scholar] [CrossRef]

- Zhang, B.; Ding, H.; Sheng, X. Reliability study of board-level lead-free interconnections under sequential thermal cycling and drop impact. Microelectron. Reliab. 2009, 49, 530–536. [Google Scholar] [CrossRef]

- Blair, H.D.; Pan, T.Y.; Nicholson, J.M. Intermetallic compound growth on Ni, Au/Ni, and Pd/Ni substrates with Sn/Pb, Sn/Ag, and Sn solders. In Proceedings of the 48th Electronic Components & Technology Conference, Seattle, WA, USA, 25–28 May 1998; pp. 259–267. [Google Scholar]

| Interfacial IMCs | Time Exponent n | Correlation Factor R2 |

|---|---|---|

| Interfacial IMCs at the lead side | 0.57 | 0.98 |

| Interfacial IMCs at the Ni-P layer side | 0.34 | 0.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hang, C.; Tian, R.; Zhao, L.; Tian, Y. Influence of Interfacial Intermetallic Growth on the Mechanical Properties of Sn-37Pb Solder Joints under Extreme Temperature Thermal Shock. Appl. Sci. 2018, 8, 2056. https://doi.org/10.3390/app8112056

Hang C, Tian R, Zhao L, Tian Y. Influence of Interfacial Intermetallic Growth on the Mechanical Properties of Sn-37Pb Solder Joints under Extreme Temperature Thermal Shock. Applied Sciences. 2018; 8(11):2056. https://doi.org/10.3390/app8112056

Chicago/Turabian StyleHang, Chunjin, Ruyu Tian, Liyou Zhao, and Yanhong Tian. 2018. "Influence of Interfacial Intermetallic Growth on the Mechanical Properties of Sn-37Pb Solder Joints under Extreme Temperature Thermal Shock" Applied Sciences 8, no. 11: 2056. https://doi.org/10.3390/app8112056

APA StyleHang, C., Tian, R., Zhao, L., & Tian, Y. (2018). Influence of Interfacial Intermetallic Growth on the Mechanical Properties of Sn-37Pb Solder Joints under Extreme Temperature Thermal Shock. Applied Sciences, 8(11), 2056. https://doi.org/10.3390/app8112056