1. Introduction

In recent years, the strengthening of existing concrete structures using externally bonded composite sheets of fiber reinforced polymer (FRP) has gained significant popularity. One common technique is wrapping unidirectional FRPs around the circumference of a concrete column to increase its axial strength and ductility. It is well-known that a concrete core expands laterally under uniaxial compression, but such expansion is confined by the FRP. Therefore, the core is subjected to a three-dimensional compressive state of stress in which the performance of the concrete core is significantly influenced by the confining pressure [

1,

2,

3,

4,

5].

Many researchers studied the behavior of FRP-confined concrete and proposed a variety of confinement models for the ultimate condition of confined concrete under uniaxial compression loadings [

6,

7]. The majority of FRP confinement models are design-oriented and were developed using a regression analysis [

8,

9,

10,

11,

12]. There have also been several analysis-oriented models developed based on the mechanics of confinement and strain compatibility between concrete and the FRP wrap [

13,

14,

15]. Recently, a new category of models has been proposed based on soft computing methods, such as artificial neural networks, generic algorithms, and fuzzy logic. Models in this category can handle complex databases containing a large number of independent variables, identify the sensitivity of input parameters, and provide mathematical solutions between dependent and independent variables [

16]. Pham and Hadi [

16] proposed the utilization of neural networks to compute the strain and compressive strength of FRP-confined columns, and the results show agreement between proposed neural network models and experimental data. Also, there are several studies related to design-oriented and analysis-oriented models [

9,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29].

Lim et al. [

30] proposed a new model for evaluating the ultimate condition of FRP-confined concrete using genetic programming (GP). The model was the first to establish the ultimate axial strain and hoop rupture strain expressions for FRP-confined concrete on the basis of evolutionary algorithms. The results showed that the predictions from the suggested model aligned with a database compiled by the authors. The proposed models provided improved predictions compared to the existing artificial intelligence models. The model proved that more accurate results can be achieved in explaining and formulating the ultimate condition of FRP-confined concrete. The model assessment presented in that study clearly illustrated the importance of the size of the test databases and the selected test parameters used in the development of artificial intelligence models on their overall performance.

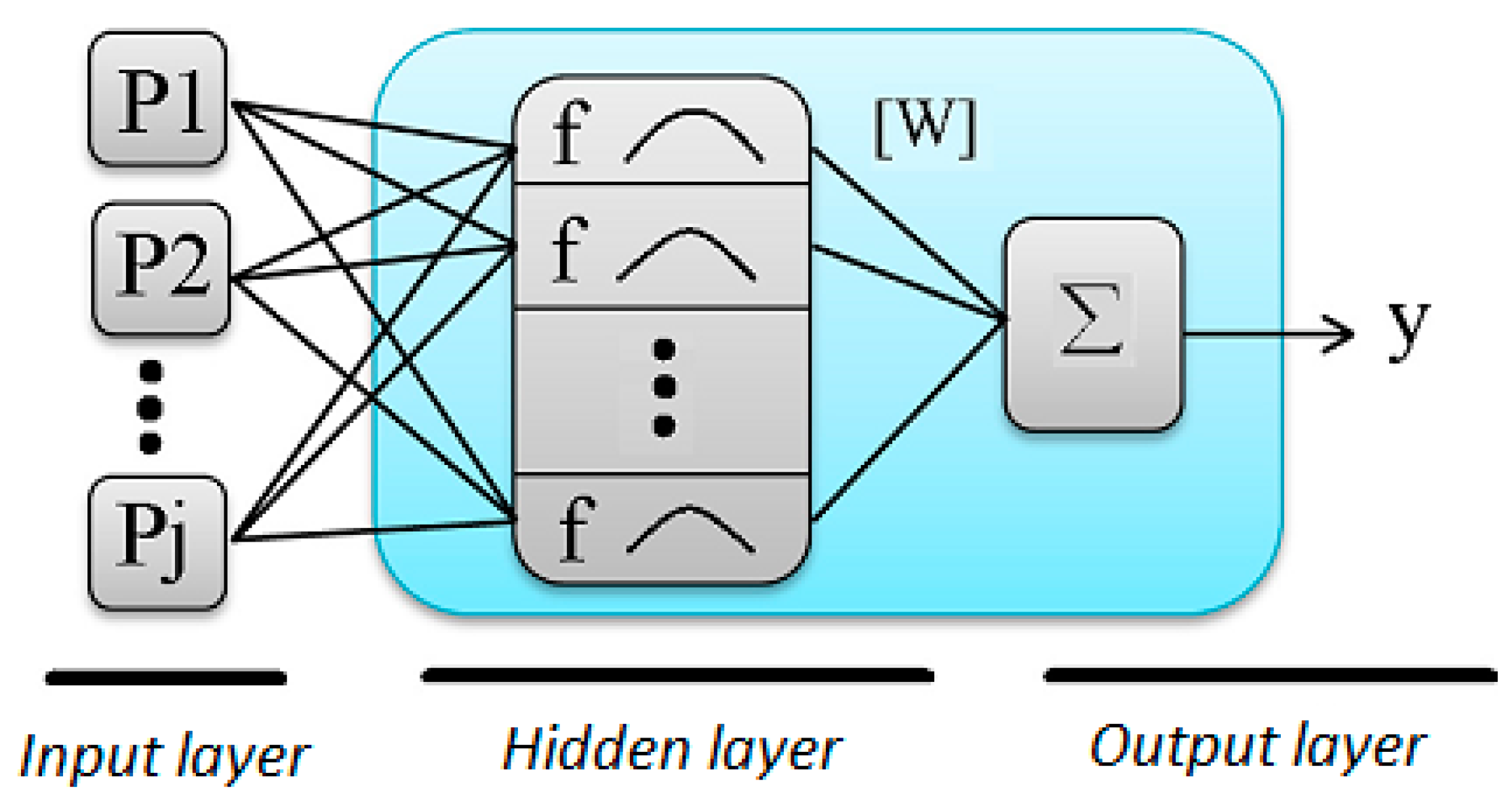

This paper studies the capability of four soft computing techniques for predicting the ultimate strength and strain of FRP-confined concrete cylindrical specimens. The computing techniques include radial basis neural network (RBNN), adaptive neuro fuzzy inference system (ANFIS) with subtractive clustering (ANFIS-SC), ANFIS with fuzzy c-means clustering (ANFIS-FCM), and M5 model tree (M5Tree).

3. Results

In this study, four different soft computing techniques, i.e., RBNN, ANFIS-SC, ANFIS-FCM and M5 Tree, are employed for predicting strength (

/

) and strain (

εcc/

εco). For the model simulations, a MATLAB neural network and fuzzy tool boxes are used, and 519 experimental data are adopted from Sadeghian and Fam [

48,

49].

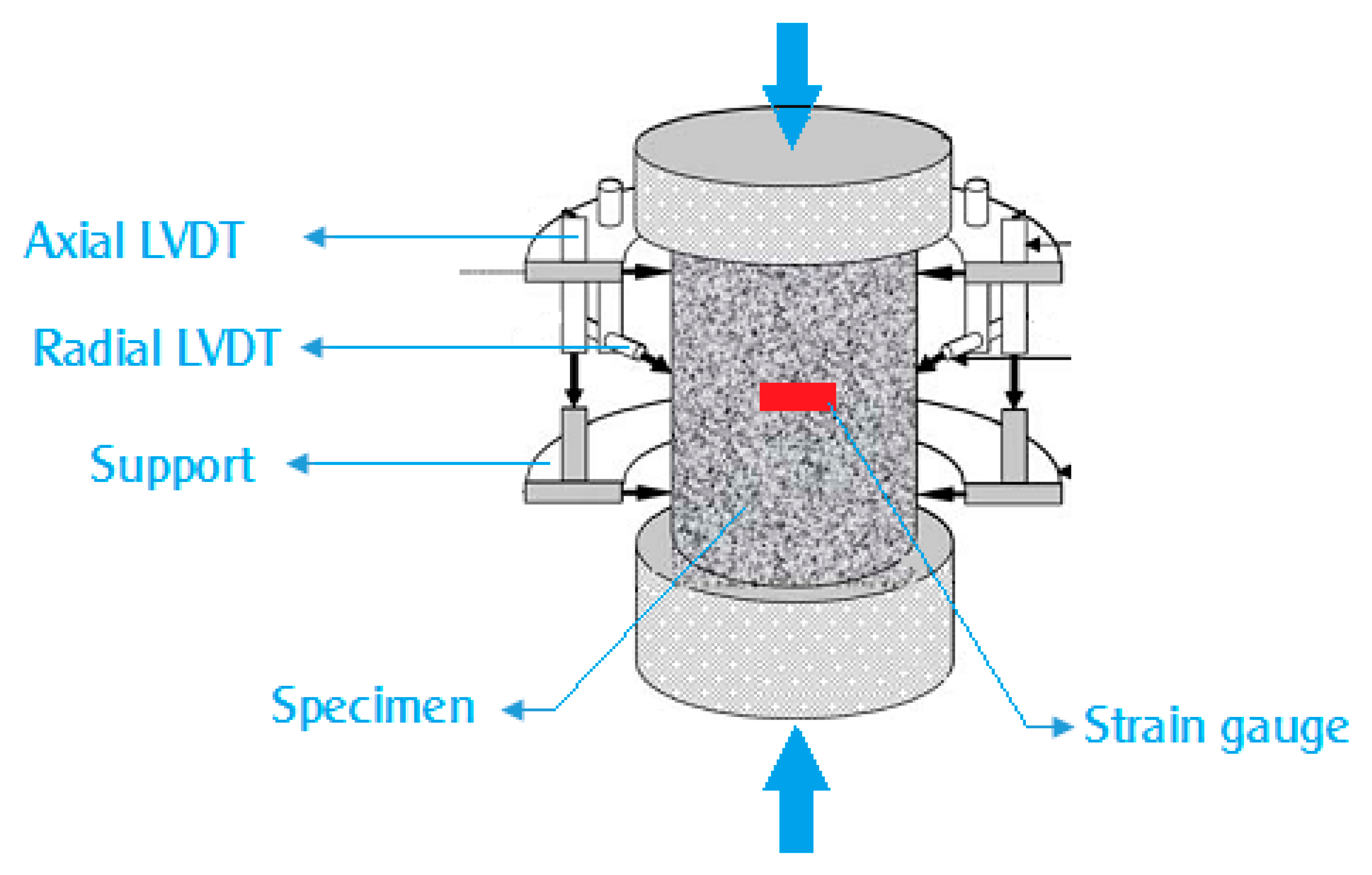

Figure 3 shows the usual test setup for confined cylinders. Also, the statistical analyses of the input data employed in this study are summarized in

Table 1. The data are used to develop models for ultimate strength and strain based on the strain ratio (

ρє) and the confinement stiffness ratio (

ρK) inputs, which are defined as follows [

48]:

In the equations,

is the unconfined concrete strength,

εco is the corresponding axial strain of

,

Ef is the elastic modulus of the FRP wrap in the hoop direction,

t is the total thickness of the FRP wrap,

εh,rup is the actual hoop rupture strain of the FRP wrap, and

D is the diameter of the concrete core. The confinement ratio (

fl/) is a frequently used parameter in existing confinement models, which is equal to the product of

ρK and

ρε. Several equations have been proposed for estimating the strain and strength of FRP-confined concrete cylinders which depend on

ρK and

ρε [

9,

48]. According to Teng et al. [

11], instead of the more approximate value of 0.002 for

εco, it is assumed as follows:

The data set is randomly grouped into two subsets; the first data set is adopted for training, and the second data set (20% of the whole database) is adopted for the testing stage. Before application of the RBNN, the training values of input and output are normalized between 0.2 and 0.8 as follows:

In the equation,

xmax and

xmin are the maximum and minimum values of the training data. Here values of 0.6 and 0.2 are respectively assigned for

b1 and

b2, and the input data are normalized within a range of 0.2 to 0.8, as recommended in Cigizoglu [

51]. According to that study, input parameters ranging from 0.2 to 0.8 allow the artificial neural network the flexibility to appraise beyond the training range.

The applied models are compared with the mean absolute relative error (MARE), root mean square error (RMSE) and determination coefficient (

R2). The definitions of statistical parameters are given as follows:

where

N,

Xoi and

Xei are the number of samples, and the observed and estimated values, respectively.

3.1. Ultimate Strength Prediction

Testing and training results for the prediction of strength of the RBNN, ANFIS-SC, ANFIS-FCM and M5Tree models are listed in

Table 2. The control parameter values of the optimal models are also provided in the second column. Different numbers of parameters and structures were tried for each method and the optimal ones were selected. Gaussian membership functions are used in ANFIS-SC and ANFIS-FCM models. The RBNN, ANFIS-SC and ANFIS-FCM methods can be easily obtained and applied by using new RBNN, genfis2 and genfis3 tools in MATLAB command windows. For the M5Tree method, code which is available for free online (

http://www.cs.rtu.lv/jekabsons/regression.html) is used.

In the table, 0.8 and 15 indicate the spread value and the number of hidden layer neuron of the RBNN model, respectively, while 0.1 and 10 show the radii and cluster number of the ANFIS-SC and ANFIS-FCM models. A radii value of 0.1 in ANFIS-FCM corresponds to 15 clusters. This means that the ANFIS-FCM has fewer membership functions and parameters (10 Gaussian membership function each have 2 parameters, or 20 parameters in total) than those of ANFIS-SC.

Table 2 implies that RBNN and ANFIS-FCM have almost the same accuracy, and they both are more efficient than the ANFIS-SC and M5Ttree models with respect to RMSE, MARE and

R2. It is interesting that the M5Tree approximated training data very well whereas its test results are worse than those of the other models. This implies that this method cannot adequately learn the investigated phenomenon. Different statistical indices were obtained for each of the methods. The main reason for this may be the fact that each method has different assumptions in developing models and their behaviors with the used data are distinct from each other. The rule base of the optimal ANFIS-FCM model is given in

Table 3.

Table 3 demonstrates that the model has 10 clusters and one rule for each of them.

Figure 4 illustrates the strength estimates of the applied models in the forms of time variation and scatterplot.

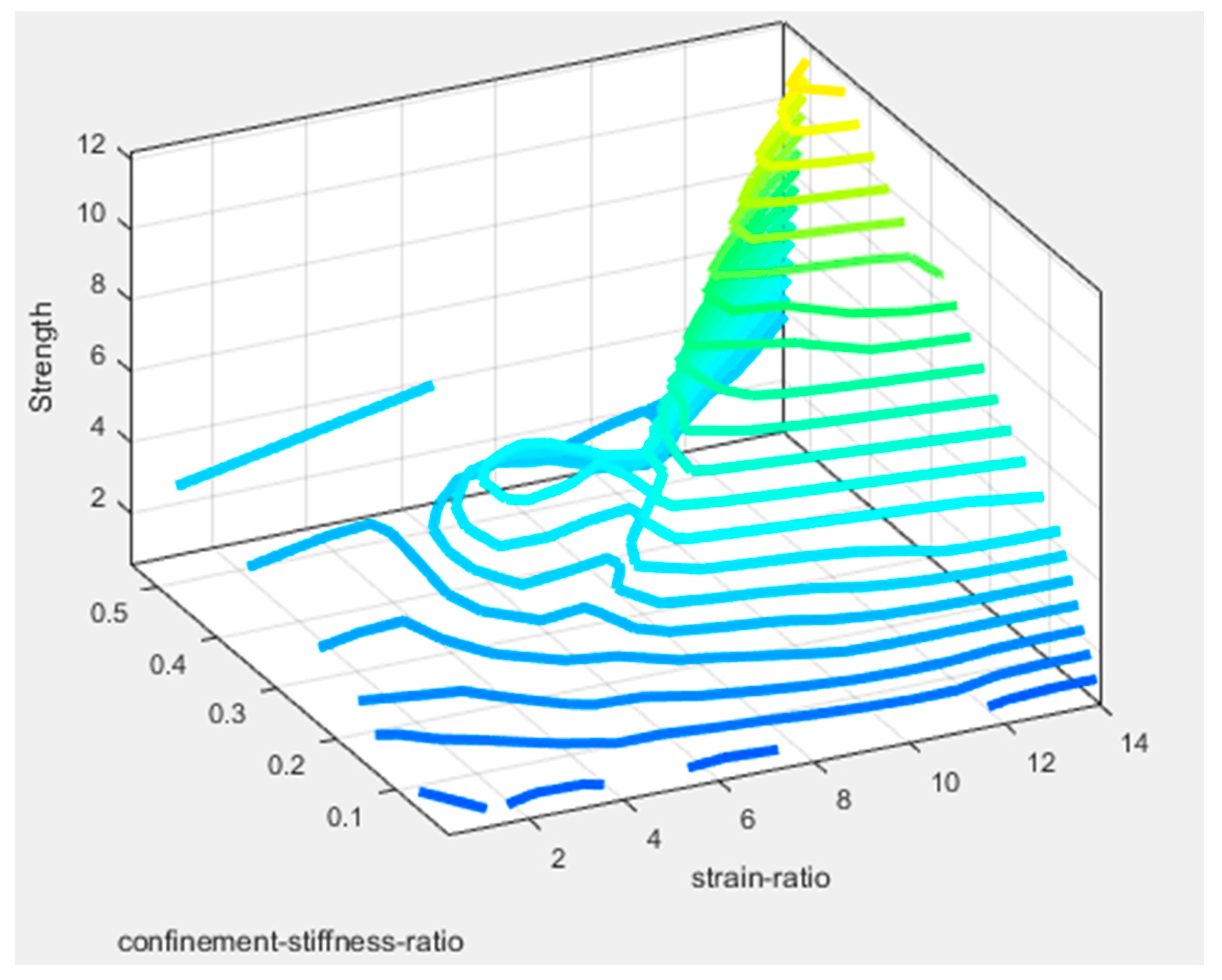

From the figure, it is apparent that the RBNN and ANFIS-FCM models have less scattered assessments than other models, and the M5Tree model gave the most scattered estimates. This reveals that the investigated phenomenon is nonlinear, and therefore linear M5Tree cannot adequately simulate strength behavior. The variation of strength versus strain ratio and confinement stiffness ratio for the optimal ANFIS-FCM model is illustrated in

Figure 5, in which it is clear that strength takes its maximum value when the strain ratio is also at its maximum.

The linear behavior for a confinement-stiffness-ratio greater than 0.3 is observed in

Figure 5. This is because of the exponent of the confinement-stiffness-ratio in equations is usually 0.7; therefore, values greater than 0.3

0.7 behave linearly.

3.2. Ultimate Strains Prediction

Strain predictions for the RMSE, MARE and

R2 values of the applied models are compared in

Table 4.

This tables shows that the ANFIS-SC models outperform other models. Here also RBNN and ANFIS-FCM have similar accuracy, and they are slightly worse than the ANFIS-SC model. A radii value of 0.1 in ANFIS-SC corresponds to 13 clusters. Similar to the previous application, here too ANFIS-SC has many more membership functions and parameters compared to ANFIS-FCM.

Table 5 gives the rule base of the optimal ANFIS-SC model. The estimated results of the optimal RBNN, ANFIS-FCM and ANFIS-SC models are shown in

Figure 6.

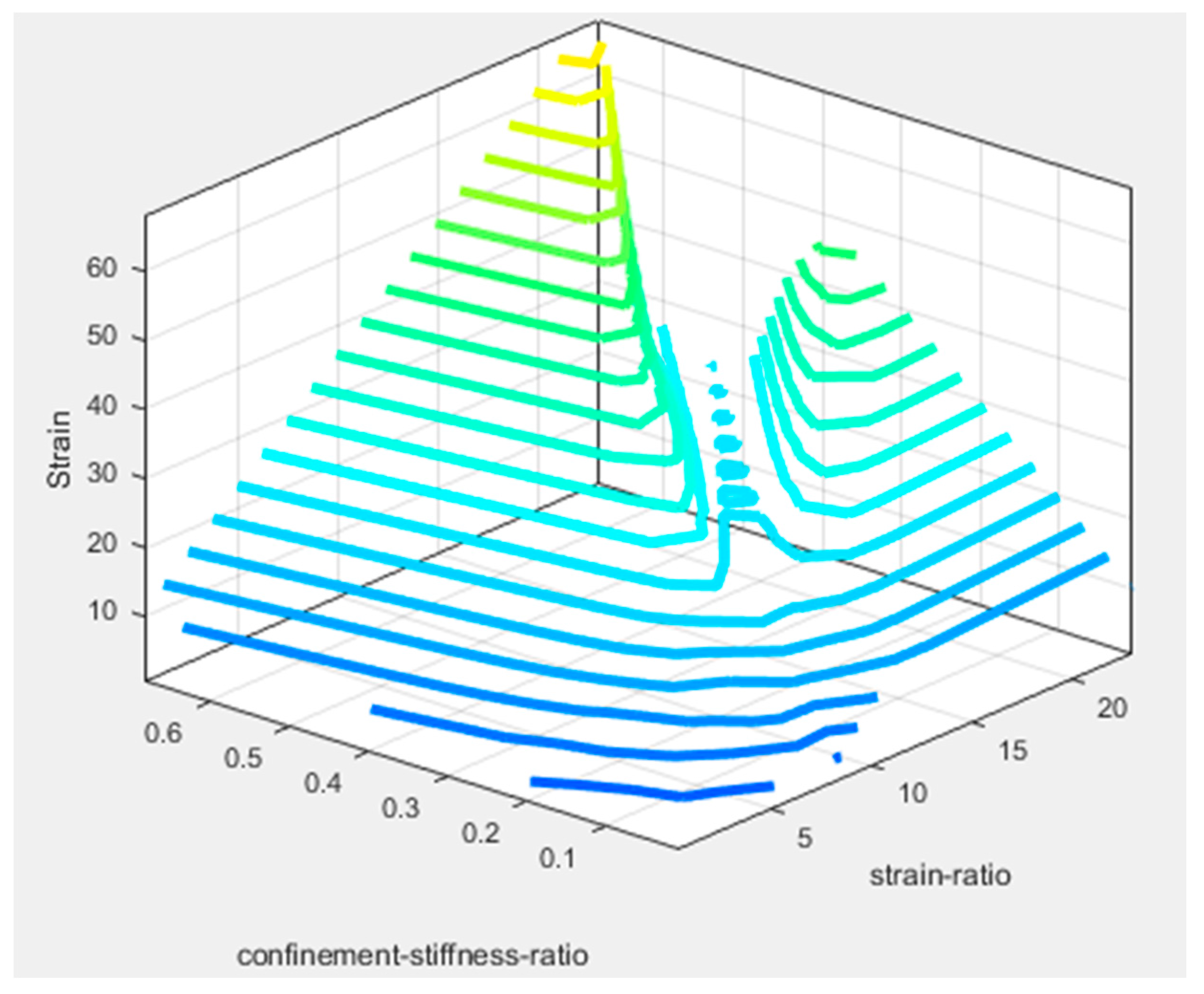

This figure shows that the estimates of the ANFIS-SC model are closer to the corresponding measured values, especially for high strain values. The variation of strength versus strain ratio and confinement stiffness ratio for the optimal ANFIS-SC model is shown in

Figure 7. It is clear from the figure that strain takes its maximum value when the strain ratio and confinement stiffness ratio are both at their maximum values. The linear relationship between strain and strain ratio is clearly seen in the range of confinement-stiffness-ratio between 0.4 and 0.6.

The effects of strain ratio and the confinement stiffness ratio inputs on strength and strain were also investigated using the ANFIS-SC method because it has less control parameters than RBNN. For the RBNN models, the optimal radii and hidden node numbers should be determined whereas, in obtaining ANFIS-SC model, the radii value which indicates the number of clusters is only distinguished. The simulation results of the ANFIS-SC models are reported in

Table 6.

This table indicates that the effect of ρK is more significant than ρє in strength and strain. The relative RMSE differences between ρK and ρє based ANFIS-SC models are 19.4% and 1.7% for strength and strain, respectively.

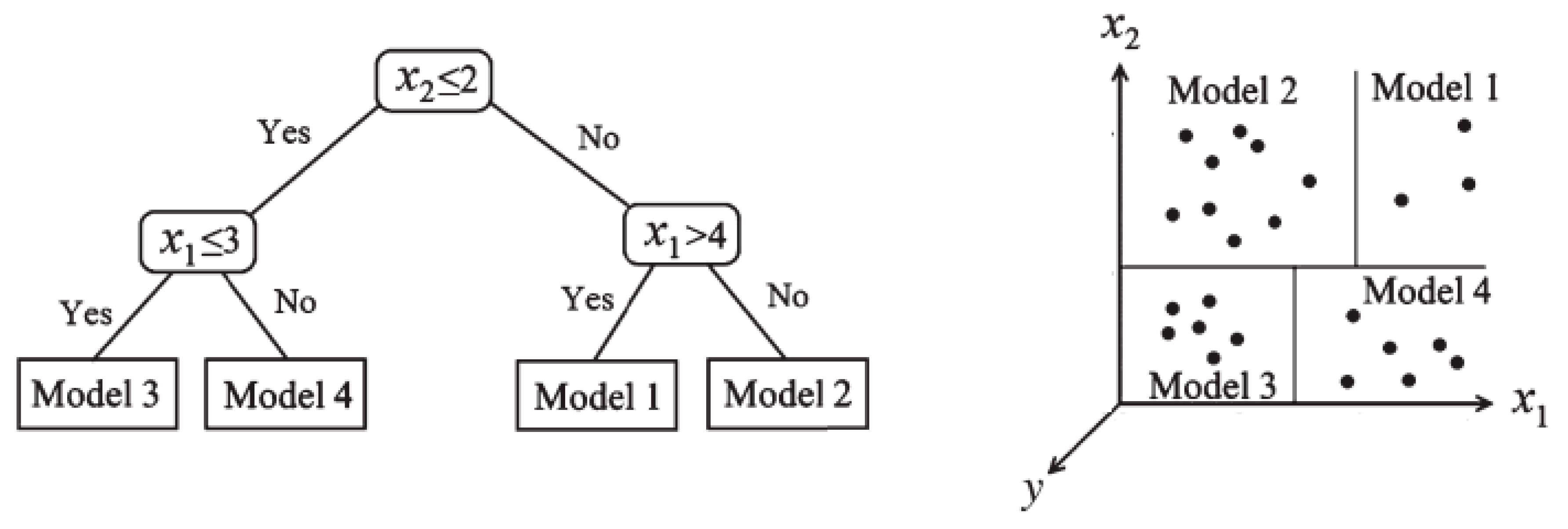

It should be noted that providing explicit formulation for the RBNN, ANFIS-SC and ANFIS-FCM is impossible because they are black-box models. However, the regression tree of the optimal M5Tree models for the strain and strength modeling are provided in

Appendix A.

4. Conclusions

In this paper, the ultimate strength and strain of cylindrical concrete specimens confined with FRP composites were studied using four soft computational methods. The optimal RBNN, ANFIS-SC, ANFIS-FCM and M5Tree models obtained by trying different control parameters were compared with respect to RMSE, MARE and R2 statistics. RBNN and ANFIS-FCM provided almost the same level of accuracy, and they performed better than the other models in estimating strength of FRP-confined concrete cylindrical specimens by using the inputs of strain ratio and the confinement stiffness ratio. In estimating strain of FRPs, however, the ANFIS-SC model performed slightly better than the RBNN and ANFIS-FCM models. Among the applied models, the M5Tree model was the least accurate at estimating strength and strain of FRPs. The effects of strain ratio and the confinement stiffness ratio inputs on strength and strain were also examined using ANFIS-SC, and the confinement stiffness ratio was found to be more significant than strain ratio in strength and strain.