1. Introduction

Wheat is one of the three major crops in the world, along with rice and corn. It grows well even in barren and arid environments, and serves as a staple food for approximately 30% of the global population [

1]. In Korea, the annual per capita wheat consumption is 36 kg, making it the second most consumed crop after rice [

2]. However, the majority of wheat consumed is imported (approximately 2.5 million tons), resulting in a self-sufficiency rate of approximately only 1% [

3]. Alongside initiatives such as the Wheat Industry Development Act [

4], the government, academia, and industry are actively working to increase domestic wheat production and consumption in South Korea. With the growing influence of a Westernized diet, the consumption of wheat-based products such as bread, cake, cookies, crackers, and noodles has increased [

5]. Rising consumer interest in health has driven the demand for wheat-based products that use whole wheat flour (WWF) and wheat bran [

6].

WWF is richer in fiber than refined wheat flour and may reduce the risk of cardiovascular disease, metabolic syndrome, type 2 diabetes, and certain cancers. Wheat bran, a major source of dietary fiber, predominantly contains insoluble fiber [

7] and effectively prevents constipation and intestinal diseases such as colon cancer in the Korean population [

8]. To promote domestic wheat production and encourage whole-grain consumption, the National Institute of Crop Science under the Rural Development Administration developed a purple wheat variety called Ariheuk (AH). This variety is particularly rich in anthocyanins and polyphenol compounds compared with regular wheat [

9], showing potential as a health-promoting ingredient [

10].

Besides AH, the National Institute of Crop Science has introduced other purple wheat varieties, including Arijinheuk (AJ), Ariheukchal (AC), and Sintong (ST), each with distinct amylose contents that contribute to their functional properties. Amylose content in wheat is regulated by Wx-A1, Wx-B1, and Wx-D1, which encode GBSSI expressed during starch synthesis. Normal expression of these proteins produces non-waxy wheat, whereas reduced expression results in waxy characteristics [

11]. Partially waxy wheat with desirable swelling and gelatinization properties is suitable for noodle production [

11]. Consequently, breeding partially waxy wheat is a global objective for developing varieties suitable for noodle production [

12].

Numerous studies have explored the quality and applications of WWF because of their health benefits. However, most studies have focused on the use of separated bran rather than examining WWF without separating the bran, necessitating further exploration [

9,

13]. Particle size is a crucial factor affecting the processing characteristics of WWF. Optimizing particle size through milling is essential for producing uniform quality flours [

14]. Commercially, WWF is produced using various mills, including stone, hammer, and roller mills. However, the reconstitution process can result in the loss of some bran fractions, complicating the assessment of the particle size effects. Laboratory ultra-centrifugal mills allow researchers to examine the influence of particle size on WWF quality by varying the milling parameters, such as sieve size and rotation speed [

13,

15].

This study investigated the effects of milling conditions on the quality of purple WWF with varying amylose contents (AC, AH, AJ, and ST), including particle size, physicochemical properties, and bread-making performance. Additionally, nutritional components, such as phenolic compounds and anthocyanins, and the antioxidant activities of purple WWF and breads were evaluated.

2. Materials and Methods

2.1. Materials

Four Korean domestic purple wheat cultivars, AC, AH, AJ, and ST, were supplied by the National Institute of Crop Science, Rural Development Administration, Republic of Korea. The hardness values of the wheat kernels were 77.1, 68.3, 40.2, and 26.0, respectively [

16]. The ingredients for bread making, including sugar (CJ Jeiljedang, Seoul, Republic of Korea), shortening (Lotte Foods, Seoul, Republic of Korea), yeast (Societe Industrielle Lesaffre, Marcq, France), salt (Samyang, Seoul, Republic of Korea), and skim milk powder (Seoulmilk, Seoul, Republic of Korea), were purchased locally. All reagents used in the analyses were of first-grade quality.

2.2. Preparation of Purple WWF

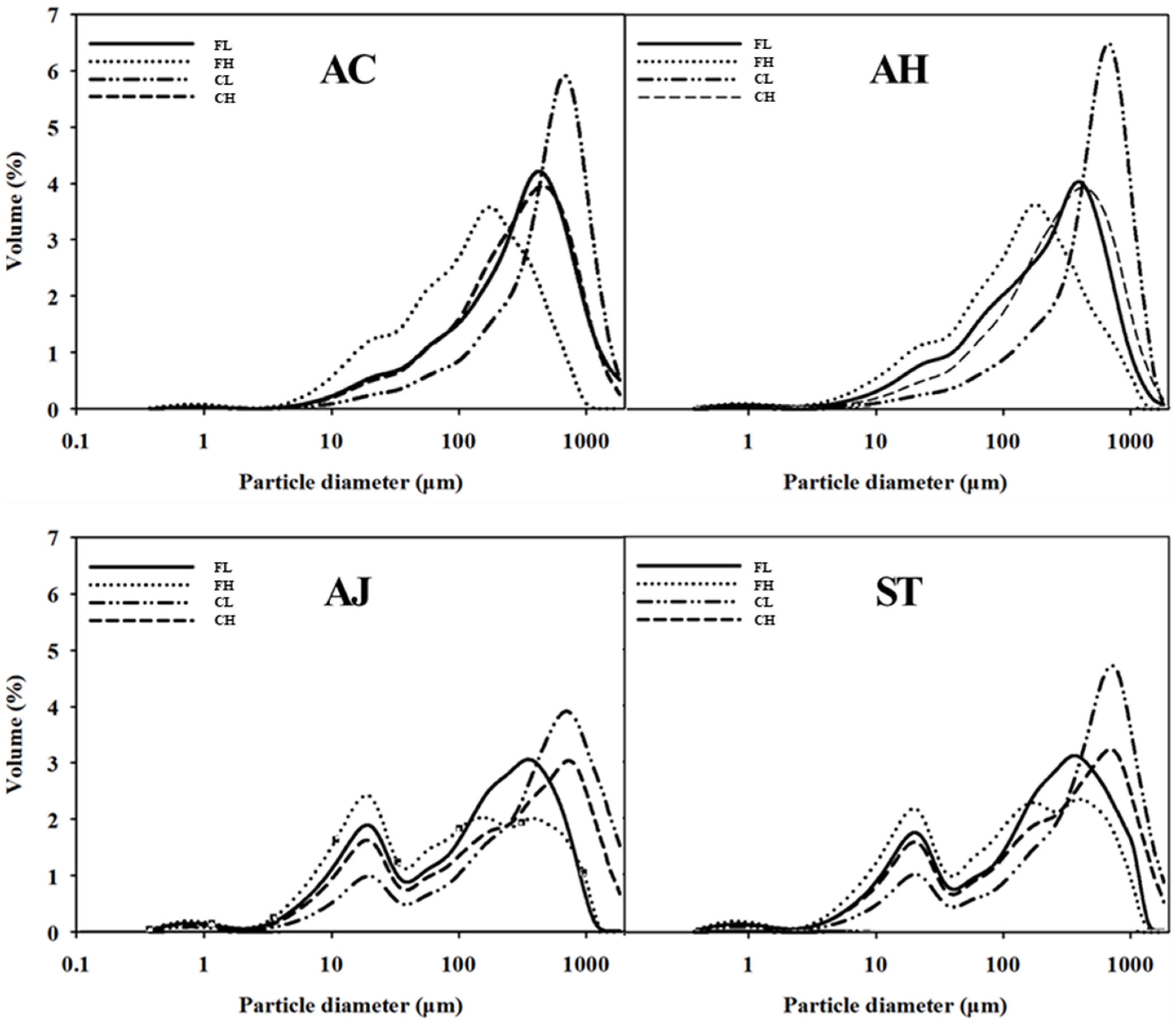

WWF was prepared by milling “as is” kernels without conditioning in an ultra-centrifugal mill equipped with either a 0.5 mm (Fine, F) or 1.0 mm (Coarse, C) sieve at rotational speeds of 6000 rpm (Low, L) or 14,000 rpm (High, H). The mill operates in a single-pass mode. Four WWF types (fine–low [FL], fine–high [FH], coarse–low [CL], and coarse–high [CH]) were produced for each variety. The feed rate per 500 g was recorded for all milling conditions to evaluate the milling performance.

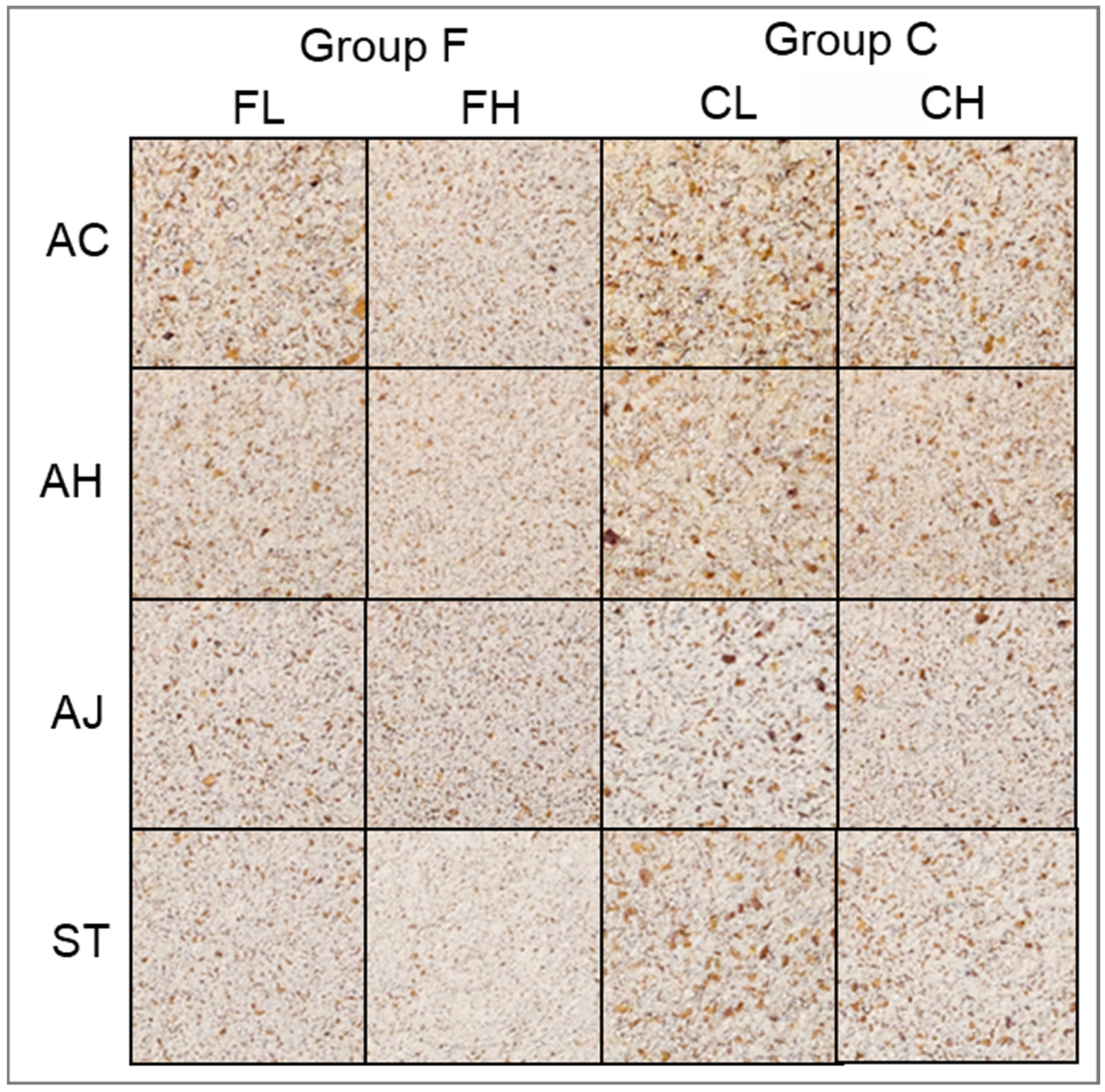

2.3. Analysis of Color and Particle Size Distribution of Purple WWF

The color of the purple WWF was measured using a colorimeter (CR-20, Minolta, Tokyo, Japan) to determine the L* (brightness), a* (redness), and b* (yellowness) values. Particle size distribution was analyzed using the dry method with a particle size analyzer (LS 13 320; Beckman Coulter, Brea, CA, USA).

2.4. Analysis of Physicochemical Properties of Purple WWF

The moisture and ash contents of the purple WWF were determined using the American Association of Cereal Chemists (AACC) Methods 44-15.02 and 08-01.01, respectively [

17].

Amylose content was determined using the iodine-binding method. A standard curve was prepared by blending amylose and amylopectin in different ratios. For the analysis, 20 mg of WWF was dissolved in 2 mL of 1.0 N NaOH and 4 mL of distilled water, heated at 100 °C for 30 min, cooled, and mixed with 25 mL of 0.5% trichloroacetic acid. Then, 0.25 mL of iodine solution was added, allowed to react for 30 min, and the absorbance was measured at 620 nm.

2.5. Analysis of Solvent Retention Capacity (SRC) of Purple WWF

Solvent retention capacity (SRC) analysis of purple WWF was performed following the AACC Method 56-11.02 [

18] to evaluate flour quality. Water SRC and sodium carbonate SRC were only determined to assess the water absorption capacity and contribution of damaged starch. Lactic acid and sucrose SRC (reflecting gluten strength and arabinoxylans, respectively) were excluded due to bran interference, which can cause errors by preventing precipitation after centrifugation and leaving bran particles suspended in the supernatant [

17]. Flour (5 g) was placed in a pre-weighed 50 mL conical tube and mixed with 25 g of distilled water or 5% (

w/

w) sodium carbonate solution. The suspension was shaken for 20 min for hydration and then centrifuged at 1000×

g for 15 min (LaboGene 1248; Gyrozen Inc., Daejeon, Republic of Korea). After discarding the supernatant, the tubes and pellets were weighed to calculate SRC values.

2.6. Measurement of Sodium Dodecyl Sulfate (SDS) Sedimentation Volume of Purple WWF

The sodium dodecyl sulfate (SDS) sedimentation volume of purple WWF was measured using AACC Method 56-70.01 [

18]. The flour (5 g) was placed in a 100 mL graduated cylinder with 50 mL of distilled water, capped, and shaken vigorously for 15 s. The cylinder was inverted at 2, 4, and 6 min to ensure a complete dispersion. Next, 50 mL of SDS–lactic acid solution (3% SDS in 1.2 N lactic acid) was added, and the cylinder was inverted again at 0, 2, 4, and 6 min. The swollen volume was recorded at 20 and 40 min and the final SDS sedimentation volume was determined.

2.7. Measurement of Total Phenol and Anthocyanin Contents of Purple WWF

Total phenolic content (TPC) of the purple WWF was determined following the method of Yu and Beta [

19]. Lyophilized and sieved flour (2 g) was extracted with 20 g of 80% methanol by stirring (60 min), sonication (10 min and 40 kHz), and centrifugation (12,000×

g, 10 min, and 4 °C). Combined supernatants were stored at −20 °C for TPC, 2,2-diphenyl-1-picrylhydrazyl (DPPH), and 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid (ABTS) analyses. TPC was measured using tenfold-diluted Folin–Ciocalteu reagent, followed by neutralization with sodium carbonate (60 g/L) and absorbance measurement at 725 nm. Results were expressed as mg gallic acid equivalents (GAE)/100 g.

Total anthocyanin content (TAC) was determined similarly, except that acidified methanol (1 N HCl) was used instead of 80% methanol. Absorbance was measured at 535 nm using cyanidin-3-glucoside as the standard, and TAC was expressed as mg cyanidin-3-glucoside equivalents (C3GE)/100 g.

2.8. Analysis of Antioxidant Activity of Purple WWF

The antioxidant activity of purple WWF was evaluated using DPPH and ABTS radical scavenging assays, following the protocol described by Yu and Beta [

19]. For DPPH analysis, a 250 μmol/L DPPH solution (absorbance 1.1–1.2 at 515 nm) was mixed with 0.5 mL of flour extract and reacted for 30 min at 20–25 °C. The absorbance was measured at 515 nm against a control containing 80% methanol.

For ABTS analysis, 7 mM ABTS and 2.45 mM K2S2O8 solutions were mixed (1:1), incubated in the dark for 12 h, and diluted 50-fold. Then, 0.1 mL of flour extract was mixed with 1.85 mL of diluted ABTS solution, and the absorbance was measured at 734 nm.

For both assays, Trolox was used as a standard, and the antioxidant activity was expressed as mg Trolox equivalents (TE)/100 g.

2.9. Measurement of Dough Properties of Purple WWF Using a Mixograph

The dough properties of the purple WWF were evaluated using a 10 g mixograph (National Manufacturing Co., Lincoln, NE, USA) following the AACC Method 54-40.02 [

18]. A 10 g WWF sample was placed into the mixing bowl and, based on each WWF’s water SRC value, 6.2–7.8 g of distilled water were added. The sample was then mixed for 10 min, and the resulting mixogram was recorded to assess the dough’s mixing characteristics.

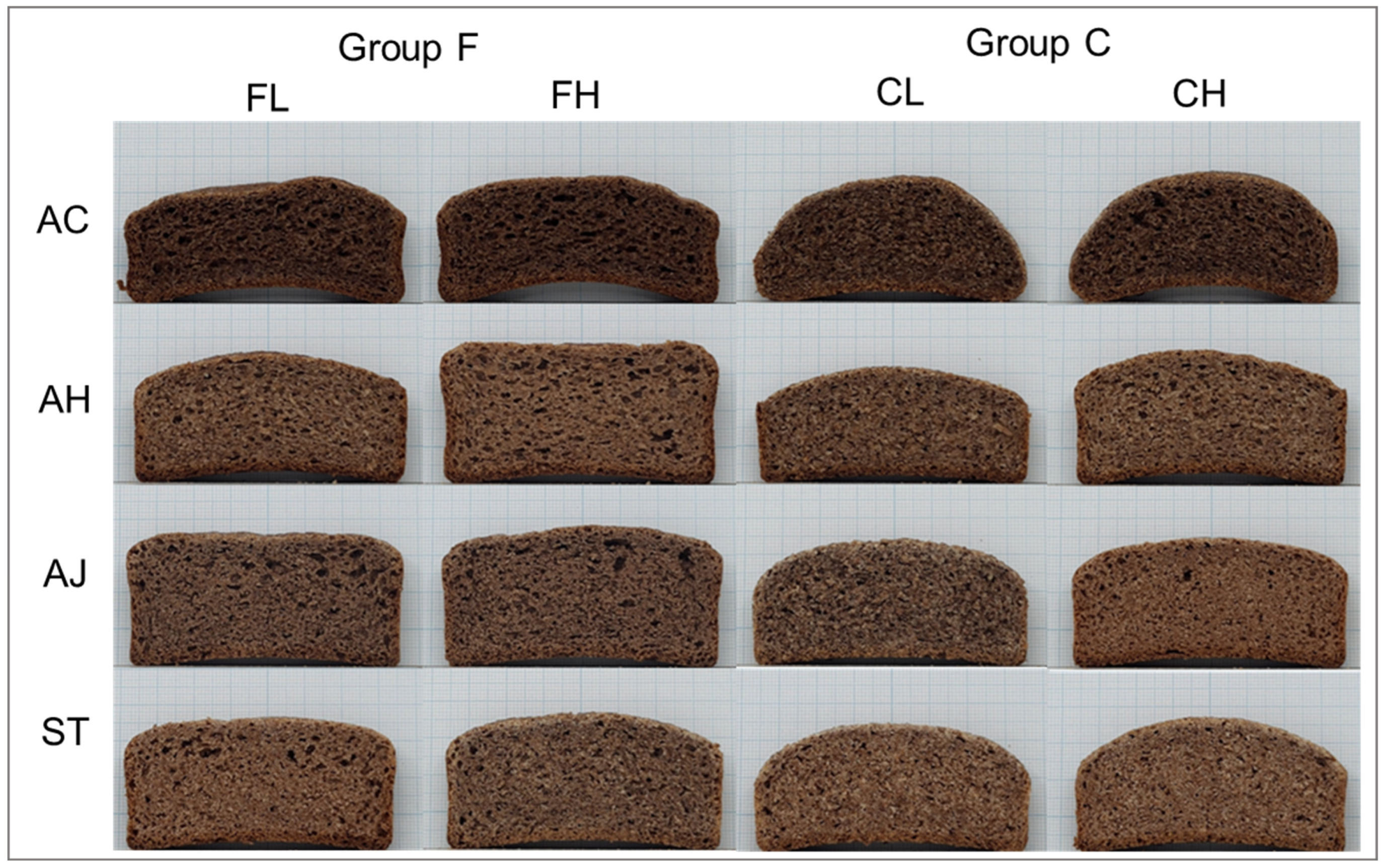

2.10. Preparation of Bread with Purple WWF

Bread was prepared with slight modifications to the AACC Method 10-10.03 [

18]. Briefly, 100 g WWF, 4 g non-fat dry milk, 14 g sugar–salt solution (containing 4.54 g sugar and 1.25g salt: 4.54% and 1.25% based on flour weight), and 3 g shortening were mixed in a micropin mixer (100 g, National Manufacturing Inc., Lincoln, NE, USA). The sugar–salt solution was prepared by dissolving 1090 g sugar and 272.2 g salt in 2 L distilled water. Yeast (2 g) was added to 62–78 g of water (30 ± 0.5 °C), adjusted by the flour’s water SRC value. The dough was mixed for 3–4.5 min, sheeted to 0.47 cm thickness, fermented at 35 °C and 85% RH for 60 min, and baked at 215 °C for 21 min (Phantom M301 Combi, Samjung, Gyeonggi, Republic of Korea). After cooling for 30 min in the baking pan and an additional 20 min after removal from the pan, the bread quality was analyzed.

2.11. Measurement of the Quality of Bread Prepared with Purple WWF

Bread volume was determined using a rapeseed replacement method (AACC Method 10–05.01) [

18] with minor modifications: the bread was placed in a 1.0 L container filled with millet, the displaced weight was measured, and the volume was calculated; measurements were repeated twice per sample.

Bread firmness was assessed using a Texture Analyzer (Brookfield CT3, Middleboro, MA, USA) according to the AACC Method 74-09.01 [

18]. Firmness was measured at the center of the sliced bread using a TA-AACC36 probe in compression mode with pre-test and test speeds of 2.0 mm/s, a post-test speed of 5.0 mm/s, and a penetration distance of 15 mm.

2.12. Measurement of Total Phenol and Anthocyanin Contents, and Antioxidant Activity of the Bread Prepared with Purple WWF

The total phenolic and anthocyanin contents of bread prepared from purple WWF were determined following the method of Yu and Beta [

19]. The bread samples were lyophilized for 48 h, ground, and extracted using the same procedure as for the flour. Total phenolic content (TPC) and total anthocyanin content (TAC) were measured using the same methods applied to the flour and expressed as mg gallic acid equivalents (GAE)/100 g and TAC as mg cyanidin-3-glucoside equivalents (C3GE)/100 g.

The antioxidant activities of bread crumbs and crusts were assessed via DPPH and ABTS radical scavenging assays, following the same procedures as for the flour extracts. The results were expressed as mg Trolox equivalents (TE)/100 g.

2.13. Statistical Analysis

All experiments were conducted at least in duplicate. Data were analyzed using ANOVA, followed by Tukey’s HSD test for multiple comparisons using SPSS ver. 25.0 (IBM Corp., Armonk, NY, USA). Differences were considered statistically significant at p < 0.05.

4. Conclusions

This study evaluated the bread-making performance of four colored whole wheat flour (AC, AH, AJ, and ST) with varying amylose contents and milled under different sieve sizes and rotation speeds. Amylose content increased in the order of AC < AH < AJ < ST, with AC being fully waxy and the others being partially waxy. Kernel hardness was highest in AC and AH. Flours with smaller particle size (group F) showed higher water and sodium carbonate SRC values, indicating more starch damage, which is likely linked to kernel hardness. AC and AH exhibited higher SDS sedimentation volumes, reflecting stronger gluten quality. Higher rotation speeds also improved protein quality.

Breads from the group F had greater height and volume but lower firmness, confirming that finer bran particles enhanced bread quality. AC produced the smallest loaf volume and greatest firmness due to its low amylose content. Furthermore, ST showed the lowest total phenolic content, anthocyanin content, and antioxidant activity among all the WWF. Baking increased the phenolic content and antioxidant activity in the crust, but reduced anthocyanin content. For optimal bread-making quality with purple WWF, finer milling (0.5 mm sieve) is recommended, particularly for harder, high-amylose varieties like AH, which produced the best loaf volume. The full-waxy variety AC, despite high water absorption, is not suitable for bread but may be explored for other applications like noodles. Overall, the particle size was impacted by kernel hardness and milling conditions, and amylose content strongly influenced the quality and bread-making performance of purple WWF. Future research should focus on controlling the particle size of WWF by optimizing milling conditions and modifying formulations to balance functional improvements with sensory qualities.