Partial Substitution of Rye Flour with Sea Buckthorn (Hippophae rhamnoides L.) Fruit Pomace in Three-Stage Rye Sourdough Breadmaking: Fermentation Dynamics and Bread Quality

Featured Application

Abstract

1. Introduction

- the dynamics of changes in microbial counts (CFU/g) of yeasts, moulds and lactic acid bacteria (LAB; reported as Lactobacillus spp., s.l.) during sourdough fermentation,

- the physicochemical parameters of baking blends (moisture content, falling number, amylograph parameters, acidity) and of sourdoughs (pH and acidity),

- the quality attributes of the resulting bread (baking yield, loaf volume, texture, colour, crumb porosity and crumb stability).

2. Materials and Methods

2.1. Raw Materials and Experimental Design

2.2. Physicochemical Analysis of Flour Blends

2.3. Sourdough Preparation, Fermentation and Baking Trials

2.4. Microbiological Analysis Before and During Fermentation

- Yeasts, using selective YGC agar (Merck, Darmstadt, Germany). The plates were incubated at 25 °C for 96 h [33],

- Lactic acid bacteria (LAB; reported as Lactobacillus spp. s.l.), using MRS agar (Merck, Darmstadt, Germany). The plates were incubated under anaerobic conditions at 30 °C for 72 h [34]. For comparability with culture-based literature, LAB counts are reported as Lactobacillus spp. (sensu lato), acknowledging that the former broad genus Lactobacillus has been reclassified into multiple genera [35].

- Moulds, using selective YGC agar (Merck, Darmstadt, Germany). The plates were incubated at 25 °C for 96 h,

- Spore-forming rods of the genus Bacillus. After pasteurisation, samples were surface plated on nutrient agar (Merck, Darmstadt, Germany) and incubated at 30 °C for 72 h. Pasteurisation at 80 °C for 15 min was applied in order to eliminate the accompanying vegetative microflora.

2.5. Technological Parameters of Dough and Bread

- dough final yield—DFY:where a—the mass of dough obtained, in g; m—the mass of the flour or flour blend used, in g, with its moisture content determined and taken into account when calculating the target final dough yield of 165%.DFY = a × 100/m [%]

- total baking loss (Tbl) was calculated using the following equation:where a—the mass of the dough piece shaped for baking, in [g]; c—the mass of the cooled bread, in [g].Tbl = (a − c) × 100/a [%]

- bread yield (By) was calculated using the following equation:where c—the mass of the cooled bread, in [g]; DFY—the dough final yield, in [%]; a—the mass of the dough piece shaped for baking, in [g].By = c × DFY/a [%]

2.6. Physical and Structural Properties of Bread

2.7. Textural and Colour Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Characteristics of Breadmaking Blends and Sourdough Fermentation Dynamics

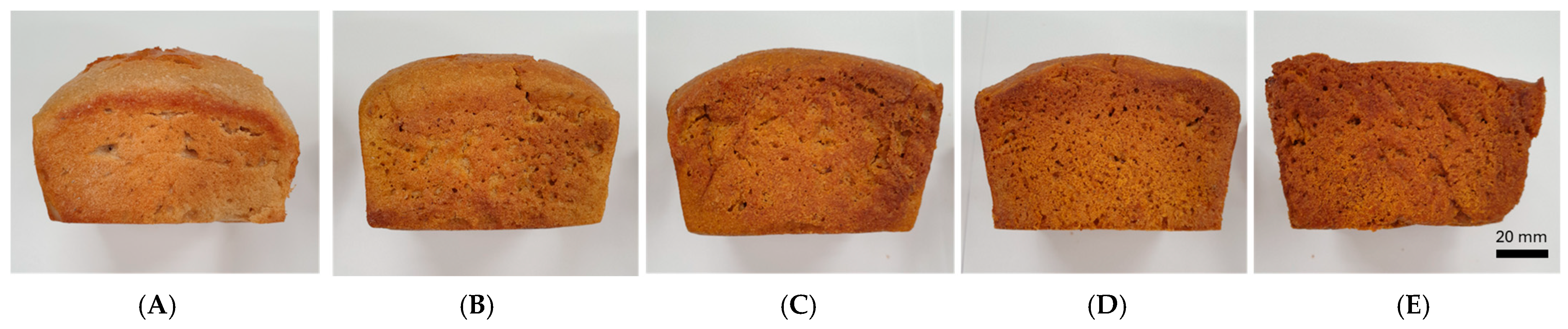

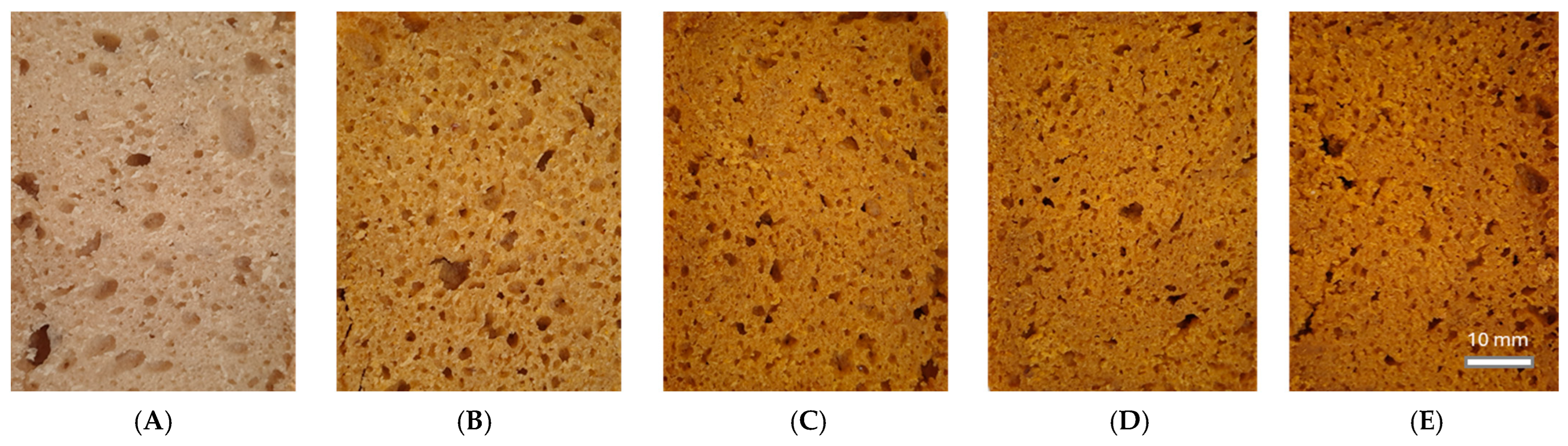

3.2. Dough, Bread and Crumb Characteristics

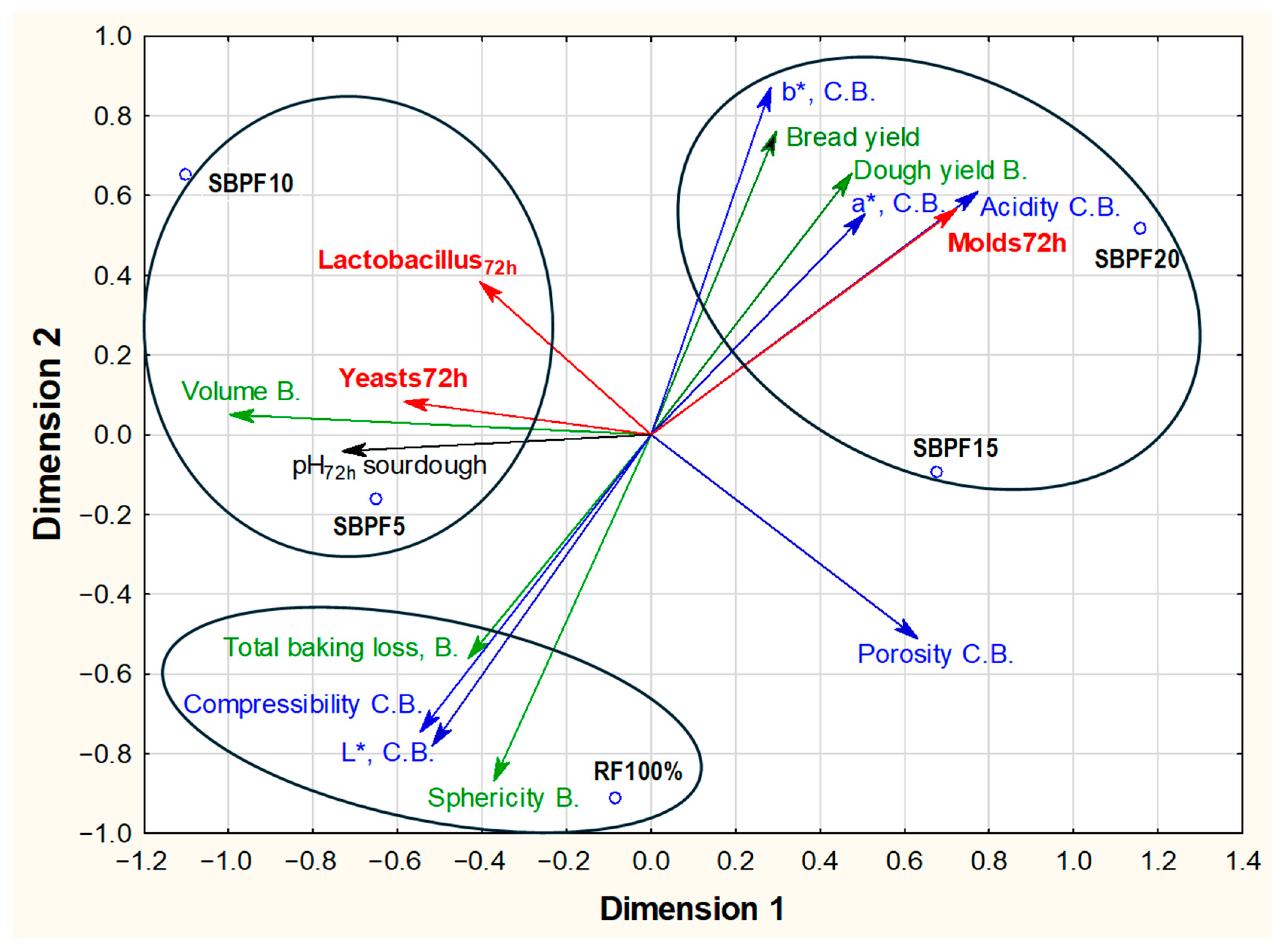

3.3. Correlation Analysis

4. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Łopaciuk, W. (Ed.) Rynek Zbóż; Stan i Perspektywy. Analizy Rynkowe (Cereal Market. Status and Prospects. Market Analyses), Nr 65; Instytut Ekonomiki Rolnictwa i Gospodarki Żywnościowej–Państwowy Instytut Badawczy (IERiGŻ-PIB): Warsaw, Poland, 2023; ISSN 1231-3149. (In Polish) [Google Scholar]

- Piasecka, I.; Górska, A. Possible uses of fruit pomaces in food technology as a fortifying additive—A review. Zesz. Probl. Postępów Nauk Rol. 2020, 600, 43–54. (In Polish) [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple pomace as a functional and healthy ingredient in food products: A review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- Raczkowska, E.; Serek, P. Health-promoting properties and the use of fruit pomace in the food industry—A Review. Nutrients 2024, 16, 2757. [Google Scholar] [CrossRef] [PubMed]

- Jurevičiūtė, I.; Keršienė, M.; Bašinskienė, L.; Leskauskaitė, D.; Jasutienė, I. Characterization of berry pomace powders as dietary fiber-rich food ingredients with functional properties. Foods 2022, 11, 716. [Google Scholar] [CrossRef] [PubMed]

- Samad, A.; Zhang, B.; Liu, Z.; Zhang, W. Fruit pomace as an emerging source of dietary fiber and phytochemicals in bakery products: A review. Fermentation 2025, 11, 376. [Google Scholar] [CrossRef]

- Chiarini, M.; Azzolini, M.; Dall’Asta, M.; Del Rio, D.; Galaverna, G. Fermentation of fruit and vegetable by-products for food applications: A systematic review. Foods 2024, 13, 3715. [Google Scholar] [CrossRef]

- Cantatore, V.; Gallo, M.A.; Sinigaglia, M.; Corbo, M.R. Impact of fermentation on cereal matrix and its possible use in bread-making applications. Front. Microbiol. 2019, 10, 2574. [Google Scholar] [CrossRef]

- Petrova, P.; Petrov, K. Lactic acid fermentation of cereals and pseudocereals: Ancient nutritional biotechnologies with modern applications. Nutrients 2020, 12, 1118. [Google Scholar] [CrossRef]

- Ziarno, M.; Cichońska, P. Lactic acid bacteria-fermentable cereal-and pseudocereal-based beverages. Microorganisms 2021, 9, 2532. [Google Scholar] [CrossRef]

- Martău, G.A.; Mihai, M.; Vodnar, D.C.; Teleky, B.-E. Sustainable use of apple pomace in sourdough fermentation: A functional approach for bakery applications. Sustainability 2021, 13, 13981. [Google Scholar] [CrossRef]

- Torreggiani, D.; Manzocco, L.; Nicoli, M.C. Grape pomace powder fermented by lactic acid bacteria: A promising functional ingredient for bakery applications. Foods 2023, 12, 3274. [Google Scholar] [CrossRef]

- Gumul, D.; Korus, J.; Ziobro, R.; Kruczek, M. Enrichment of wheat bread with apple pomace as a way to increase pro-health constituents. Qual. Assur. Saf. Crops Foods 2019, 11, 231–240. [Google Scholar] [CrossRef]

- Gumul, D.; Ziobro, R.; Korus, J.; Kruczek, M. Apple pomace as a source of bioactive polyphenol compounds in gluten-free breads. Antioxidants 2021, 10, 807. [Google Scholar] [CrossRef]

- Valková, V.; Ďúranová, H.; Havrlentová, M.; Ivanišová, E.; Mezey, J.; Tóthová, Z.; Gabriny, L.; Kačániová, M. Selected physico-chemical, nutritional, antioxidant and sensory properties of wheat bread supplemented with apple pomace powder as a by-product from juice production. Plants 2022, 11, 1256. [Google Scholar] [CrossRef] [PubMed]

- Tolve, R.; Simonato, B.; Rainero, G.; Bianchi, F.; Rizzi, C.; Cervini, M.; Giuberti, G. Wheat bread fortification by grape pomace powder: Nutritional, technological, antioxidant, and sensory properties. Foods 2021, 10, 75. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Parol-Nadłonek, N.; Kalisz, S.; Krajewska, A.; Stępniewska, S. Wheat bread enriched with black chokeberry (Aronia melanocarpa L.) pomace: Physicochemical properties and sensory evaluation. Appl. Sci. 2023, 13, 6936. [Google Scholar] [CrossRef]

- Pecyna, A.; Krzywicka, M.; Buczaj, A.; Blicharz-Kania, A.; Kobus, Z. The effect of fruit pomace addition on the color, texture and sensory properties of gluten-free bread. Sci. Rep. 2025, 15, 24510. [Google Scholar] [CrossRef]

- Gaglio, R.; La Rosa, L.; Serio, G.; Mannino, G.; Alfonzo, A.; Franciosi, E.; Settanni, L.; Gentile, C. Rubus idaeus by-products: Sustainable improvement of the antioxidant value of sourdough bread by a new end-use of exhausted seeds still containing bioactive compounds. Innov. Food Sci. Emerg. Technol. 2023, 90, 103517. [Google Scholar] [CrossRef]

- Banach, J.K.; Majewska, K.; Piłat, B.; Grzywińska-Rąpca, M. Benefits of using pomace from sea buckthorn fruit in the production of rye bread for a strategy of sustainable production and consumption. Appl. Sci. 2024, 14, 11067. [Google Scholar] [CrossRef]

- Stanciu, I.; Ungureanu, E.L.; Popa, E.E.; Geicu-Cristea, M.; Draghici, M.; Mitelut, A.C.; Mustatea, G.; Popa, M.E. The experimental development of bread with enriched nutritional properties using organic sea buckthorn pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Padureanu, S.; Deseatnicova, O.; Turculet, N.; Boestean, O.; Niculaua, M. Potential application of Hippophae rhamnoides in wheat bread production. Molecules 2020, 25, 1272. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, F.; Wei, P.; Chai, X.; Hou, G.; Meng, Q. Phytochemistry, health benefits, and food applications of sea buckthorn (Hippophae rhamnoides L.): A comprehensive review. Front. Nutr. 2022, 9, 1036295. [Google Scholar] [CrossRef]

- Fernández-Peláez, J.; Paesani, C.; Gómez, M. Sourdough Technology as a Tool for the Development of Healthier Grain-Based Products: An Update. Agronomy 2020, 10, 1962. [Google Scholar] [CrossRef]

- Koj, K.; Pejcz, E. Rye dietary fiber components upon the influence of fermentation inoculated with probiotic microorganisms. Molecules 2023, 28, 1910. [Google Scholar] [CrossRef]

- Bieniek, A.; Buksa, K. The Influence of Arabinoxylan on the Properties of Sourdough Wheat Bread. Appl. Sci. 2024, 14, 2649. [Google Scholar] [CrossRef]

- Zarzycki, P.; Wirkijowska, A.; Teterycz, D.; Łysakowska, P. Innovations in wheat bread: Using food industry by-products for better quality and nutrition. Appl. Sci. 2024, 14, 3976. [Google Scholar] [CrossRef]

- PN-EN ISO 712:2012; Cereals and Cereal Products—Determination of Moisture Content—Reference Method. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Horubałowa, A.; Haber, T. Analiza Techniczna w Piekarstwie (Technical Analysis in Baking), 4th ed.; WSiP: Warszawa, Poland, 1994. [Google Scholar]

- PN-EN ISO 3093:2010; Wheat, Rye and Flours Obtained from Them, Durum Wheat and Semolina—Determination of the Falling Number by the Hagberg-Perten Method. Polish Committee for Standardization: Warsaw, Poland. (In Polish)

- PN-ISO 7973:2001; Ziarno Zbóż i Przetwory Zbożowe—Oznaczanie Lepkości Mąki—Metoda z Zastosowaniem Amylografu/Cereals and Milled Cereal Products—Determination of the Viscosity of Flour—Method Using an Amylograph. Polish Committee for Standardization: Warsaw, Poland, 2001. (In Polish)

- Lubczyńska, H.; Lipińska, H.; Jarosz, K.; Woźniakowski, A.; Kosakowska, J.; Walewska, M. Vademecum Piekarza do Nauki Zawodu (Baker’s Vademecum for Learning the Profession); Handlowo-Usługowa Spółdzielnia, Samopomoc Chłopska: Warszawa, Poland, 2006; ISBN 83-919549-5-1. (In Polish) [Google Scholar]

- PN EN ISO 21527-1: 2009; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds. Polish Committee for Standardization: Warsaw, Poland, 2009.

- PN-EN ISO 15214: 2002; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria—Colony-Count Technique at 30 °C. Polish Committee for Standardization: Warsaw, Poland, 2002.

- Zheng, J.; Wittouck, S.; Salvetti, E.; Franz, C.M.A.P.; Harris, H.M.B.; Mattarelli, P.; O’Toole, P.W.; Pot, B.; Vandamme, P.; Walter, J.; et al. A taxonomic note on the genus Lactobacillus: Description of 23 novel genera, emended description of the genus Lactobacillus Beijerinck 1901, and union of Lactobacillaceae and Leuconostocaceae. Int. J. Syst. Evol. Microbiol. 2020, 70, 2782–2858. [Google Scholar] [CrossRef] [PubMed]

- Majewska, K.; Dąbkowska, E. Ocena możliwości wykorzystania mąki z ziarna płaskurki. Przegląd Piek. I Cukier. 2011, 59, 36–37. (In Polish) [Google Scholar]

- PN-A-74108:1996; Pieczywo—Metody Badań i Ocena Punktowa/Bread—Research Methods and Scoring. Polish Committee for Standardization: Warsaw, Poland, 1996. (In Polish)

- Tańska, M.; Roszkowska, B.; Czaplicki, S.; Borowska, E.J.; Bojarska, J.; Dąbrowska, A. Effect of fruit pomace addition on shortbread cookies to improve their physical and nutritional value. Plant Foods Hum. Nutr. 2016, 71, 307–313. [Google Scholar] [CrossRef] [PubMed]

- Sagan, A. Analiza preferencji konsumentów z wykorzystaniem programu Statistica–analiza conjoint i skalowanie wielowymiarowe. StatSoft Pol. Sp. Z oo 2009, 3–22. (In Polish) [Google Scholar]

- Zaborski, A. Analiza PROFIT i jej wykorzystanie w badaniu preferencji. Pr. Nauk. Uniw. Ekon. We Wrocławiu 2012, 242, 479–487. (In Polish) [Google Scholar]

- Kauf, S.; Tluczak, A. PROFIT analysis and its use in building a preference map of logistics customer service parameters. Sci. Pap. Wars. Univ. Life Sci. Econ. Organ. Logist. 2017, 2, 1. [Google Scholar]

- Błażejczyk-Majka, L.; Boczar, P. Zastosowanie metod wielowymiarowych w charakterystyce preferencji konsumentów. Metod. Ilościowe W Badaniach Ekon. 2016, 7, 18–32. [Google Scholar]

- Di Nunzio, M.; Picone, G.; Pasini, F.; Chiarello, E.; Caboni, M.F.; Capozzi, F.; Gianotti, A.; Bordoni, A. Olive oil by-product as functional ingredient in bakery products. Influence of processing and evaluation of biological effects. Food Res. Int. 2020, 131, 108940. [Google Scholar] [CrossRef]

- Reißner, A.-M.; Beer, A.; Struck, S.; Rohm, H. Pre-Hydrated berry pomace in wheat bread: An approach considering requisite water in fiber enrichment. Foods 2020, 9, 1600. [Google Scholar] [CrossRef]

- Almoumen, A.; Mohamed, H.; Sobti, B.; Ayyash, M.; Kamleh, R.; Al-Marzouqi, A.H.; Kamal-Eldin, A. Quality of bread rolls fortified with date fruit pomace: Structure, proximate composition, staling, and sensory evaluation. NFS J. 2025, 38, 100214. [Google Scholar] [CrossRef]

- Antonić, B.; Jančíková, S.; Dordević, D.; Tremlová, B. Grape pomace valorization: A systematic review and meta-analysis of its application as a functional ingredient in food. Foods 2020, 9, 1627. [Google Scholar] [CrossRef]

- Muñoz-Bernal, Ó.A.; Coria-Oliveros, A.J.; Vázquez-Flores, A.A.; Subiria-Cueto, C.R.; De la Rosa, L.A.; Reyes-Vega, M.D.L.L.; Rodrigo-García, J.; Martinez-Ruiz, N.D.R.; Alvarez-Parrilla, E. Functional and sensory evaluation of bread made from wheat flour fortified with wine byproducts. Food Prod. Process. Nutr. 2024, 6, 94. [Google Scholar] [CrossRef]

| Parameters | Rye Flour | SBPF5 | SBPF10 | SBPF15 | SBPF20 |

|---|---|---|---|---|---|

| Falling number [s] | 286 ± 1 a | 298 ± 8 a | 377 ± 15 b | 399 ± 3 c | 367 ± 2 d |

| Acidity [°] | 4.60 ± 0.00 a | 6.50 ± 0.08 b | 9.70 ± 0.08 c | 15.40 ± 0.00 d | 19.33 ± 0.09 e |

| Moisture content [%] | 12.38 ± 0.04 e | 12.12 ± 0.01 d | 11.62 ± 0.00 c | 11.37 ± 0.01 b | 11.09 ± 0.02 a |

| Tpk [°C] | 53.3 ac | 52.9 ab | 50.2 d | 51.8 b | 54.4 c |

| Tkk [°C] | 69.4 a | 69.1 a | 80.3 b | 88.9 c | 89.3 c |

| η max [B. U.] | 438 a | 294 b | 325 c | 1350 d | 1420 e |

| Microorganisms/Parameter | Time [h] | Control | SBPF5 | SBPF10 | SBPF15 | SBPF20 |

|---|---|---|---|---|---|---|

| Yeasts [log CFU/g] | 0 | 0.60 ± 0.19 a | 1.39 ± 0.59 a | 1.55 ± 0.92 a | 1.82 ± 0.76 a | 2.00 ± 0.77 a |

| 24 | 2.15 ± 0.17 a | 4.04 ± 1.73 a | 4.16 ± 2.10 a | 5.14 ± 2.07 a | 4.25 ± 2.04 a | |

| 48 | 4.59 ± 1.00 a | 6.63 ± 1.35 a | 6.47 ± 1.17 a | 6.63 ± 1.22 a | 5.12 ± 2.10 a | |

| 72 | 6.52 ± 1.21 a | 7.72 ± 0.29 a | 7.81 ± 0.30 a | 7.92 ± 0.17 a | 5.89 ± 2.26 a | |

| Moulds [log CFU/g] | 0 | 1.58 ± 0.25 a | 1.46 ± 0.33 a | 1.46 ± 0.53 a | 1.40 ± 0.54 a | 1.89 ± 0.26 a |

| 24 | 1.76 ± 0.19 a | 2.13 ± 0.18 a | 2.25 ± 0.23 a | 3.33 ± 1.60 a | 2.69 ± 0.52 a | |

| 48 | 1.89 ± 0.11 a | 2.88 ± 0.84 a | 3.67 ± 1.23 a | 4.02 ± 1.72 a | 4.60 ± 2.36 a | |

| 72 | 1.93 ± 0.08 a | 2.88 ± 0.85 a | 3.07 ± 1.33 a | 4.83 ± 2.32 a | 4.82 ± 2.25 a | |

| * LAB [log CFU/g] | 0 | 2.09 ± 0.22 a | 2.05 ± 0.18 a | 1.90 ± 0.26 a | 1.88 ± 0.11 a | 1.72 ± 0.21 a |

| 24 | 7.28 ± 0.43 a | 6.36 ± 0.76 a | 6.14 ± 0.71 a | 5.66 ± 0.56 a | 5.34 ± 1.43 a | |

| 48 | 8.42 ± 0.58 a | 8.37 ± 0.75 a | 8.36 ± 0.74 a | 8.37 ± 0.72 a | 7.88 ± 0.12 a | |

| 72 | 8.86 ± 0.43 a | 8.86 ± 0.42 a | 8.96 ± 0.39 | 8.64 ± 0.36 a | 8.93 ± 0.56 a | |

| Sourdough pH | 0 | 6.25 ± 0.02 e | 4.52 ± 0.02 d | 4.10 ± 0.00 c | 3.81 ± 0.00 b | 3.48 ± 0.02 a |

| 24 | 4.70 ± 0.01 e | 4.35 ± 0.02 d | 3.90 ± 0.00 c | 3.62 ± 0.01 b | 3.38 ± 0.00 a | |

| 48 | 3.72 ± 0.01 c | 3.50 ± 0.01 d | 3.72 ± 0.02 c | 3.56 ± 0.02 b | 3.35 ± 0.02 a | |

| 72 | 3.47 ± 0.08 b | 3.42 ± 0.04 c | 3.58 ± 0.06 b | 3.48 ± 0.04 b | 3.30 ± 0.03 a |

| Sample | Dough Yield [%] | Bread | |||

|---|---|---|---|---|---|

| Total Baking Loss [%] | Bread Yield [%] | Volume [cm3/100 g] | Sphericity | ||

| Control (SBPF0) | 164.0 ± 0.4 b | 16.33 ± 0.55 d | 134.59 ± 2.40 a | 255 ± 6.7 e | 0.78 ± 0.01 e |

| SBPF5 | 161.1 ± 0.4 a | 14.55 ± 1.04 c | 143.49 ±2.09 b | 272 ± 4.5 d | 0.68 ± 0.02 Dd |

| SBPF10 | 169.9 ± 1.0 c | 14.22 ± 0.48 c | 147.06 ± 2.05 c | 289 ± 12.6 c | 0.66 ± 0.01 bC |

| SBPF15 | 170.5 ± 0.9 c | 12.23 ± 1.13 a | 151.03 ± 2.93 d | 238 ± 5.7 b | 0.65 ± 0.00 b |

| SBPF20 | 171.0 ± 0.5 c | 13.66 ± 0.69 b | 147.82 ± 1.52 ec | 221 ± 3.3 a | 0.61 ± 0.00 a |

| Sample | Porosity [Dallmann Score] | Acidity [°] | Colour | Compressibility [N] | ||

|---|---|---|---|---|---|---|

| L* | a* | b* | ||||

| Control (SBPF0) | 69 ± 3.9 a | 5.2 ± 0.00 a | 56.68 ± 0.18 e | 4.87 ± 0.25 a | 19.44 ± 0.64 a | 16.4 ± 0.58 d |

| SBPF5 | 63 ± 3.3 a | 6.4 ± 0.25 b | 51.56 ± 0.08 d | 10.69 ± 0.23 b | 31.74 ± 0.27 b | 14.51 ± 1.24 c |

| SBPF10 | 64 ± 3.8 a | 7.0 ± 0.52 c | 47.97 ± 0.21 c | 7.73 ± 0.24 c | 37.91 ± 0.10 c | 11 ± 0.39 b |

| SBPF15 | 67 ± 3.8 a | 9.4 ± 0.09 d | 44.57 ± 0.16 b | 10.98 ± 0.37 b | 39.46 ± 0.07 d | 8.7 ± 0.62 a |

| SBPF20 | 67 ± 3.3 a | 10.8 ± 0.52 e | 43.75 ± 0.40 a | 12.04 ± 0.54 d | 40.07 ± 0.57 d | 8.55 ± 1.60 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Majewska, K.; Banach, J.K.; Kłębukowska, L.; Grzywińska-Rąpca, M.; Piłat, B.; Pietrzak-Fiećko, R. Partial Substitution of Rye Flour with Sea Buckthorn (Hippophae rhamnoides L.) Fruit Pomace in Three-Stage Rye Sourdough Breadmaking: Fermentation Dynamics and Bread Quality. Appl. Sci. 2026, 16, 15. https://doi.org/10.3390/app16010015

Majewska K, Banach JK, Kłębukowska L, Grzywińska-Rąpca M, Piłat B, Pietrzak-Fiećko R. Partial Substitution of Rye Flour with Sea Buckthorn (Hippophae rhamnoides L.) Fruit Pomace in Three-Stage Rye Sourdough Breadmaking: Fermentation Dynamics and Bread Quality. Applied Sciences. 2026; 16(1):15. https://doi.org/10.3390/app16010015

Chicago/Turabian StyleMajewska, Katarzyna, Joanna Katarzyna Banach, Lucyna Kłębukowska, Małgorzata Grzywińska-Rąpca, Beata Piłat, and Renata Pietrzak-Fiećko. 2026. "Partial Substitution of Rye Flour with Sea Buckthorn (Hippophae rhamnoides L.) Fruit Pomace in Three-Stage Rye Sourdough Breadmaking: Fermentation Dynamics and Bread Quality" Applied Sciences 16, no. 1: 15. https://doi.org/10.3390/app16010015

APA StyleMajewska, K., Banach, J. K., Kłębukowska, L., Grzywińska-Rąpca, M., Piłat, B., & Pietrzak-Fiećko, R. (2026). Partial Substitution of Rye Flour with Sea Buckthorn (Hippophae rhamnoides L.) Fruit Pomace in Three-Stage Rye Sourdough Breadmaking: Fermentation Dynamics and Bread Quality. Applied Sciences, 16(1), 15. https://doi.org/10.3390/app16010015