Investigation of Mechanical and Fresh Properties of Ultra-High-Performance Concrete Incorporating Second-Generation Superplasticizers

Abstract

1. Introduction

2. Literature Review

2.1. Literature on Superplasticizers

2.2. Literature on Numerical Methods

3. Significance of the Investigation

- Economic aspect

- •

- Superplasticizer is a crucial material in the production of UHPC. However, its high cost in large projects has led to a search for more economically efficient approaches. Research has primarily focused on evaluating third-generation superplasticizers, while the potential of second-generation superplasticizers for UHPC has been largely overlooked, with limited studies conducted.

- •

- The results of ANN and FL models were compared with the results of experimental tests (which are costly and time-consuming)

- Environmental aspect

- •

- Various percentages (15%, 20%, and 25%) of silica fume were studied as a partial substitute for cement.

- Industrial application

- •

- The key practical aspect of this study was the construction workshop for prefabricated parts production. To efficiently create parts in the workshop, quick molding and removal from the mold are essential. Speed (enhancing construction pace) and cost reduction are crucial in such workshops. The second-generation superplasticizer (naphthalene-based) holds promise, with a shorter processing time and lower cost than the third-generation alternative (polycarboxylate-based), offering potential time and cost savings.

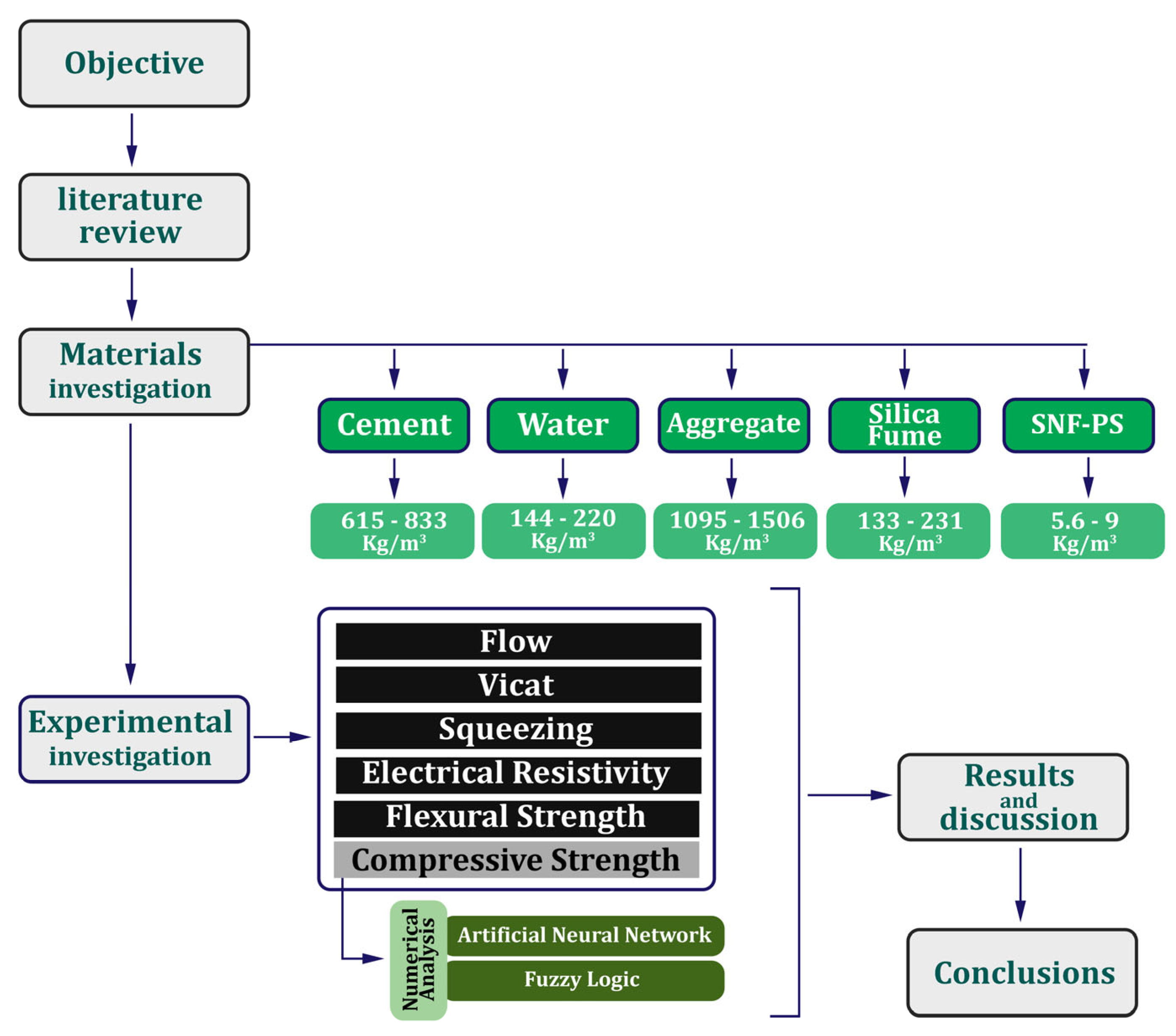

4. Materials and Test Methods

4.1. Materials

4.2. Mix Designs

4.3. Test Methods

- The setting time was determined using the Vicat needle test (ASTM C191 [62]). The test procedure involved pouring the concrete mix into a mold and smoothing the surface. The Vicat needle was then introduced into the sample at predetermined intervals (starting at 30 min after mixing) to measure the depth of penetration. The initial setting time was recorded when the penetration depth fell below 25 mm, and the test continued until the needle penetration reached zero, indicating the final setting.

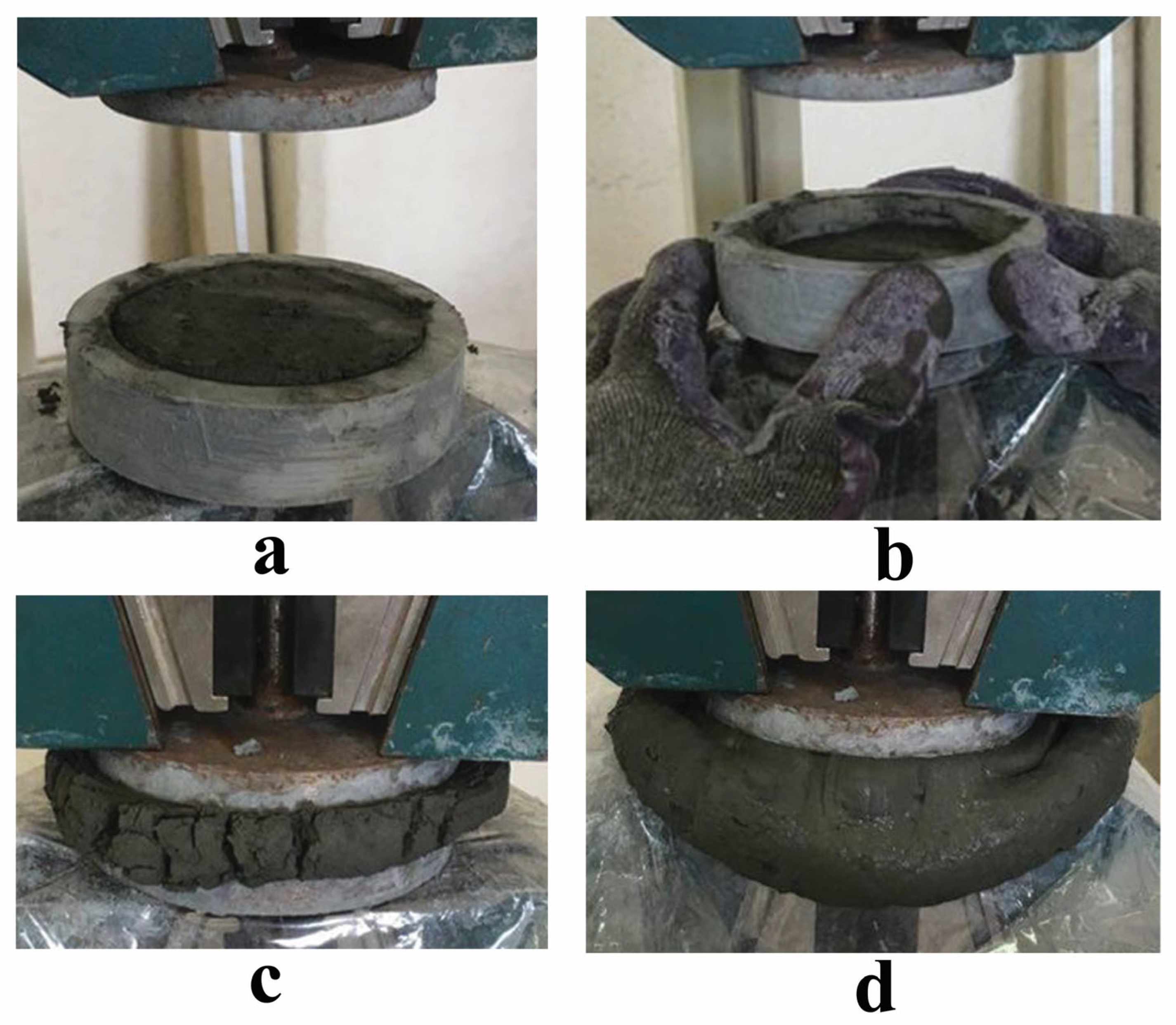

- The squeezing test, adapted from the work of Cardoso et al. [63], was employed to characterize the basic rheological properties of the fresh concrete. This test utilized a universal testing machine equipped with two grooved steel disks (diameter: 6 cm) positioned 21.5 cm apart within the clamps. An excess amount of concrete mix was placed between the disks, ensuring a uniform distribution. Excess material around the disks was removed with a spatula. Subsequently, the concrete was subjected to constant loading rates of 30 mm/min and 3000 mm/min, and the resulting load–displacement curve was recorded. A visual representation of the squeezing test setup is presented in Figure 4.

- Dry unit weight and water absorption were determined in accordance with ASTM C642 [64] on three specimens from each mixture.

- Electrical resistivity was measured at 28 days using the AASHTO TP119 [65] procedure on three samples per mix.

- Compressive strength was assessed at 7 and 28 days on 5 cm × 5 cm × 5 cm cube specimens following ASTM C109 [66].

- Flexural strength was determined at 28 days on 4 cm × 4 cm × 16 cm prism specimens, as per ASTM C348 [67].

| Hardened Test | Fresh Test | |||

|---|---|---|---|---|

| Test | Standard | Curing | Test | Standard |

| Compressive strength | ASTM C109 [66] | 7, 28 | Flow | ASTM C1437 [61] |

| Electrical Resistivity | AASHTO TP119 [65] | 28 | Vicat (Setting Time) | ASTM C191 [62] |

| Dry Unit Weight | ASTM C642 [64] | 28 | Squeezing | Cardoso et al. [63] |

| Water Absorption | ASTM C642 [64] | 28 | Cube | Prism |

| Flexural strength | ASTM C348 [67] | 28 |  |  |

5. Prediction Models

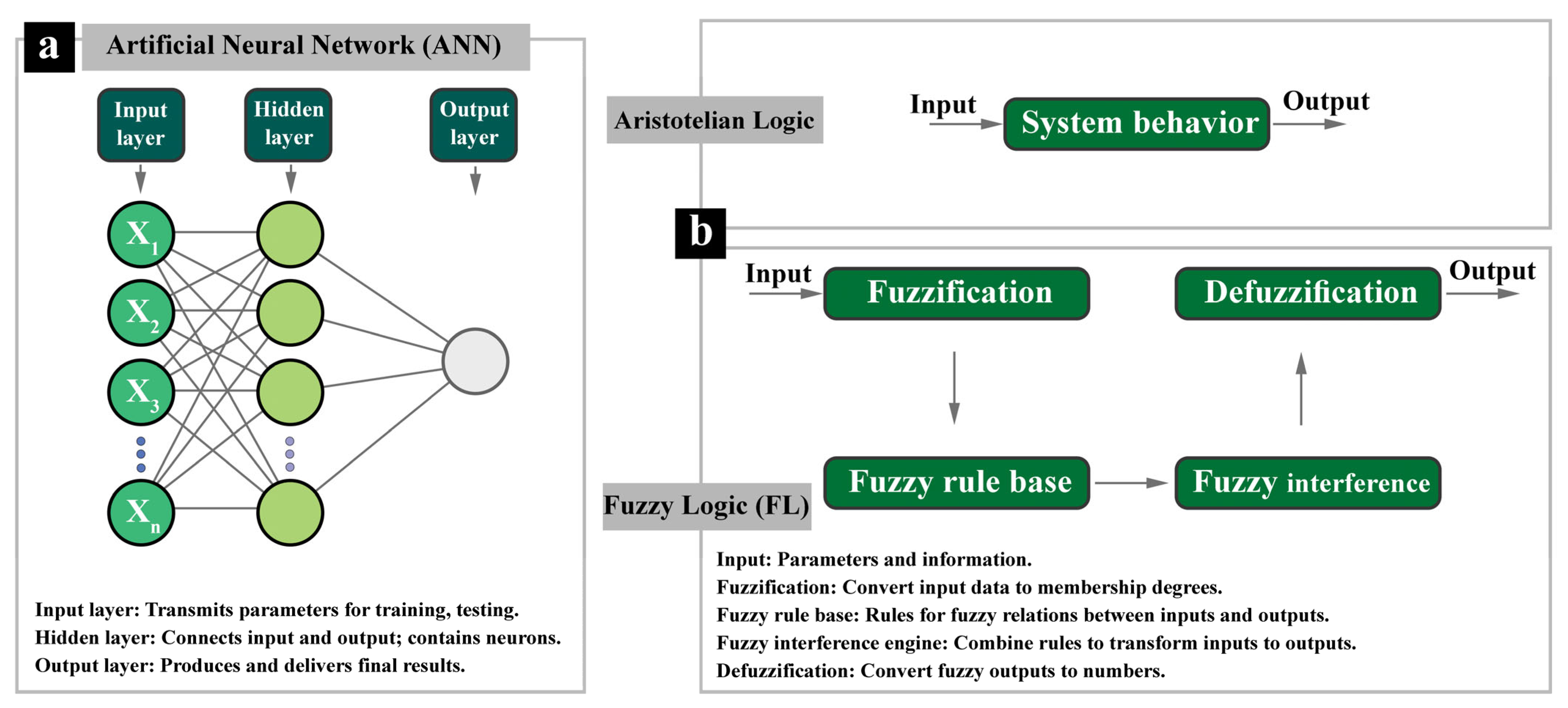

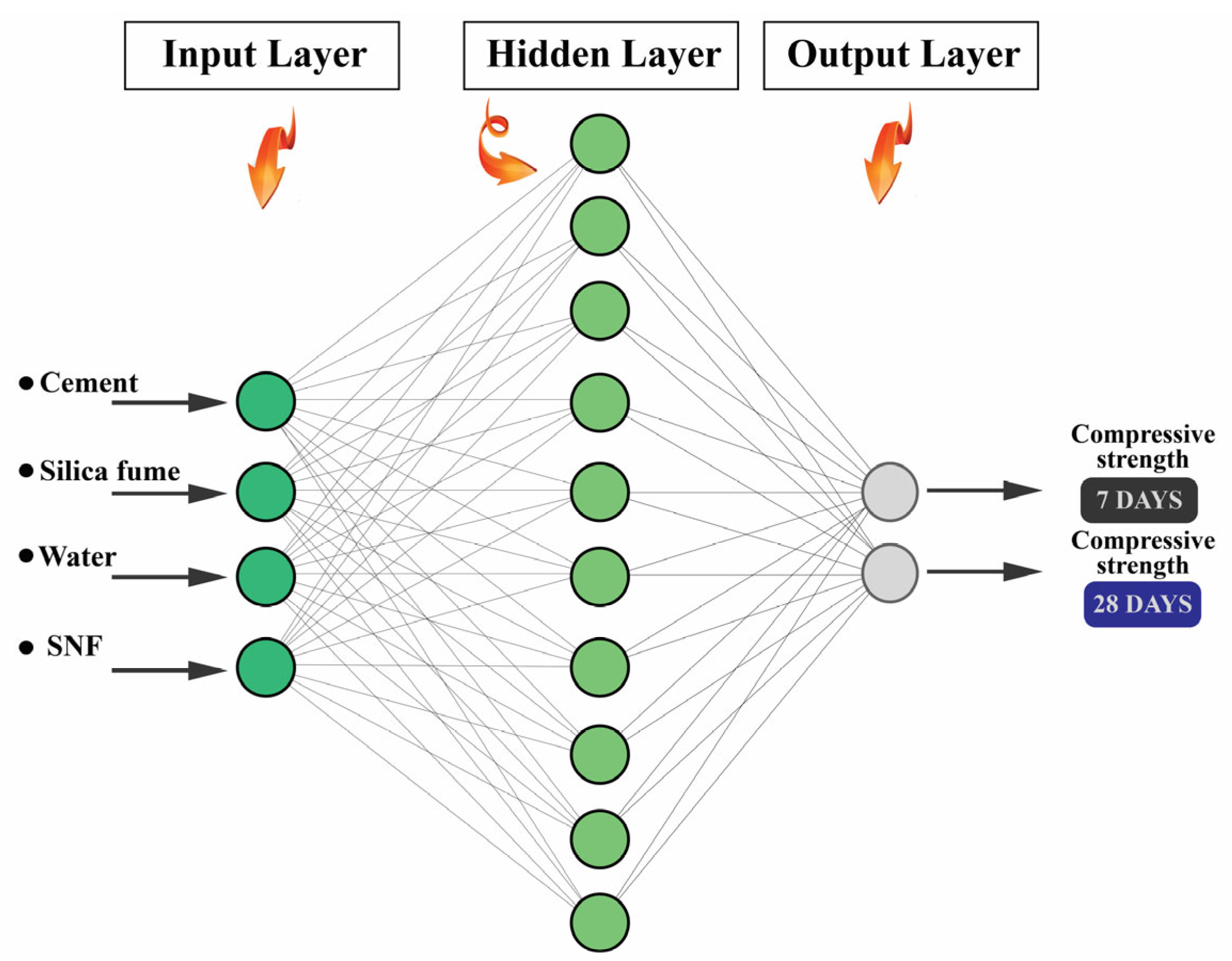

5.1. Artificial Neural Network (ANN)

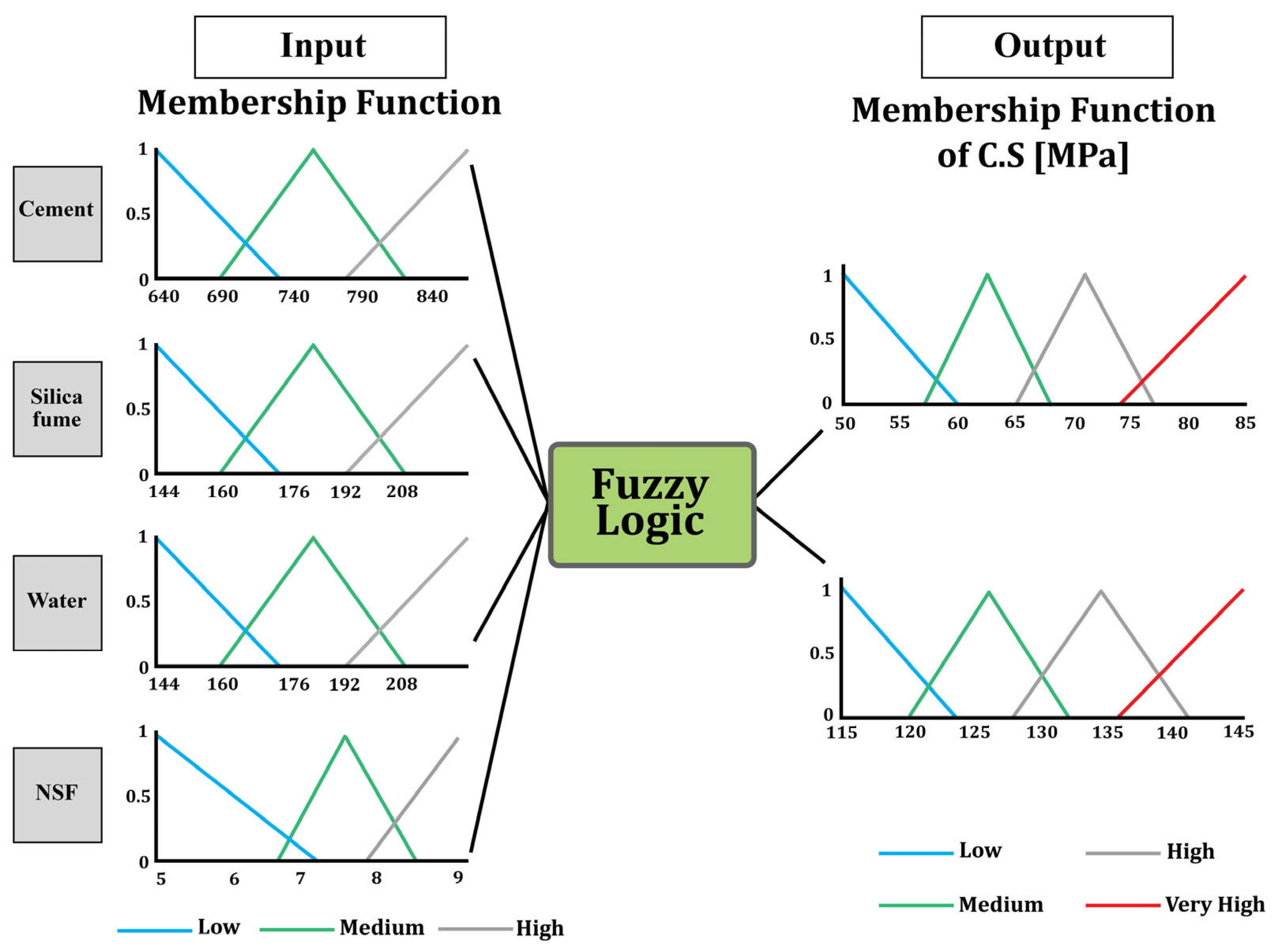

5.2. Fuzzy Logic (FL)

6. Results and Discussion

6.1. Fresh Tests

6.1.1. Slump Flow Test

6.1.2. Vicat Needle Test (Setting Time)

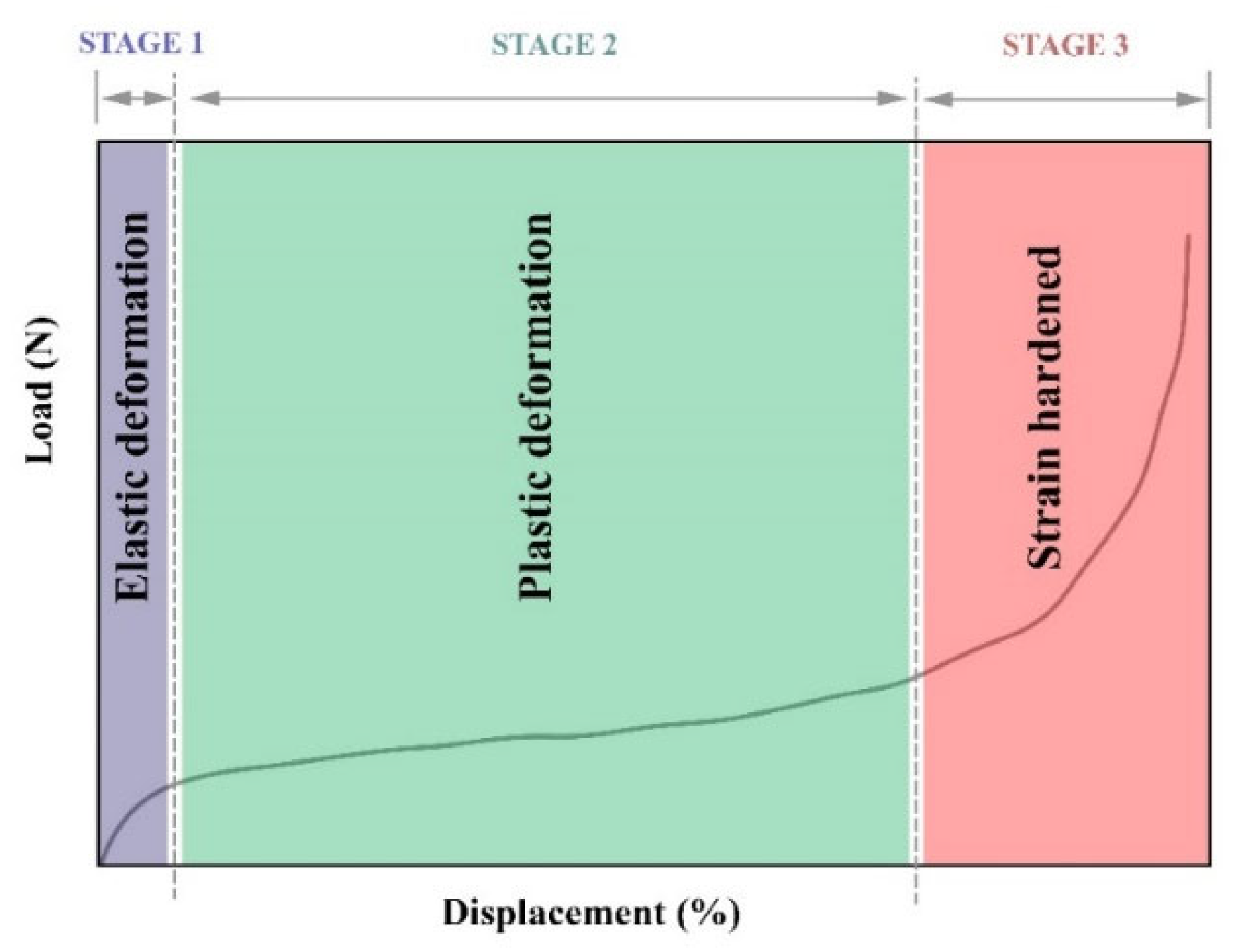

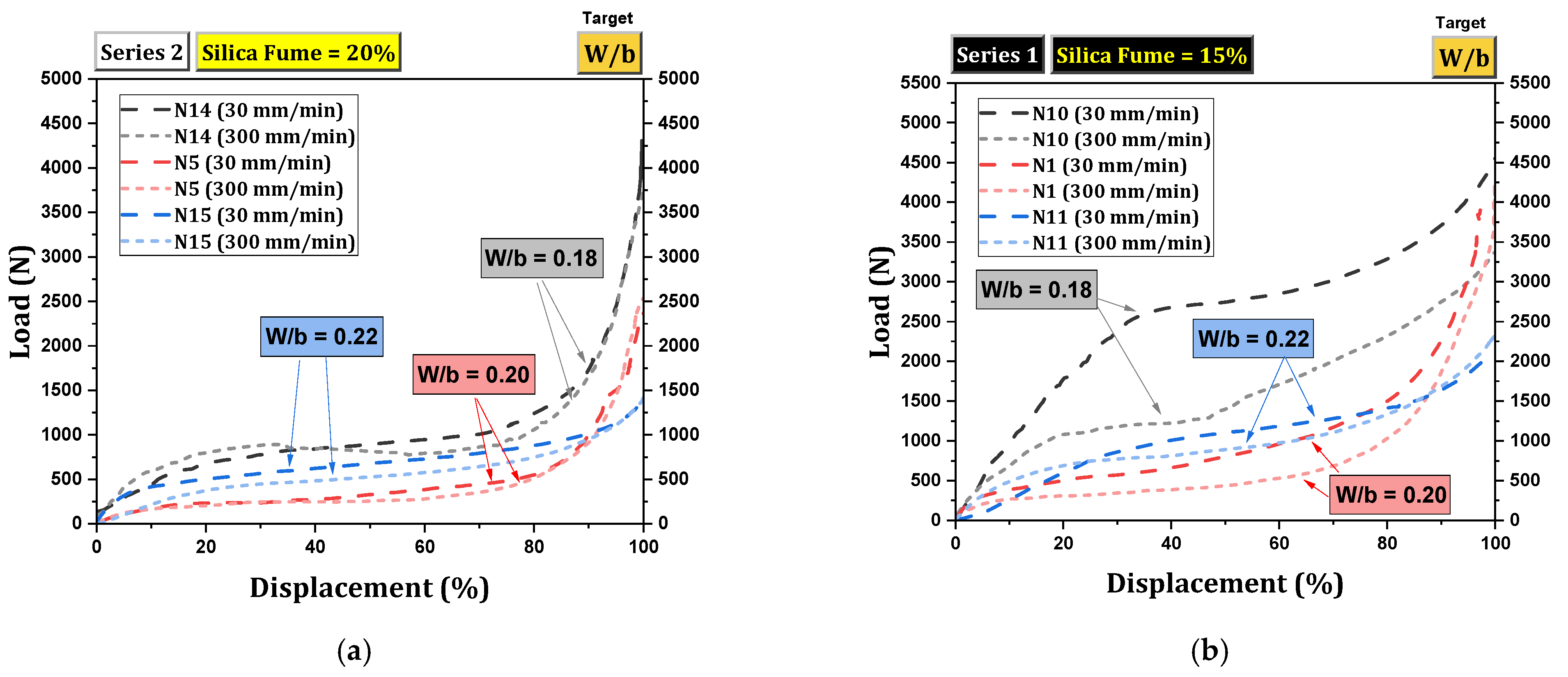

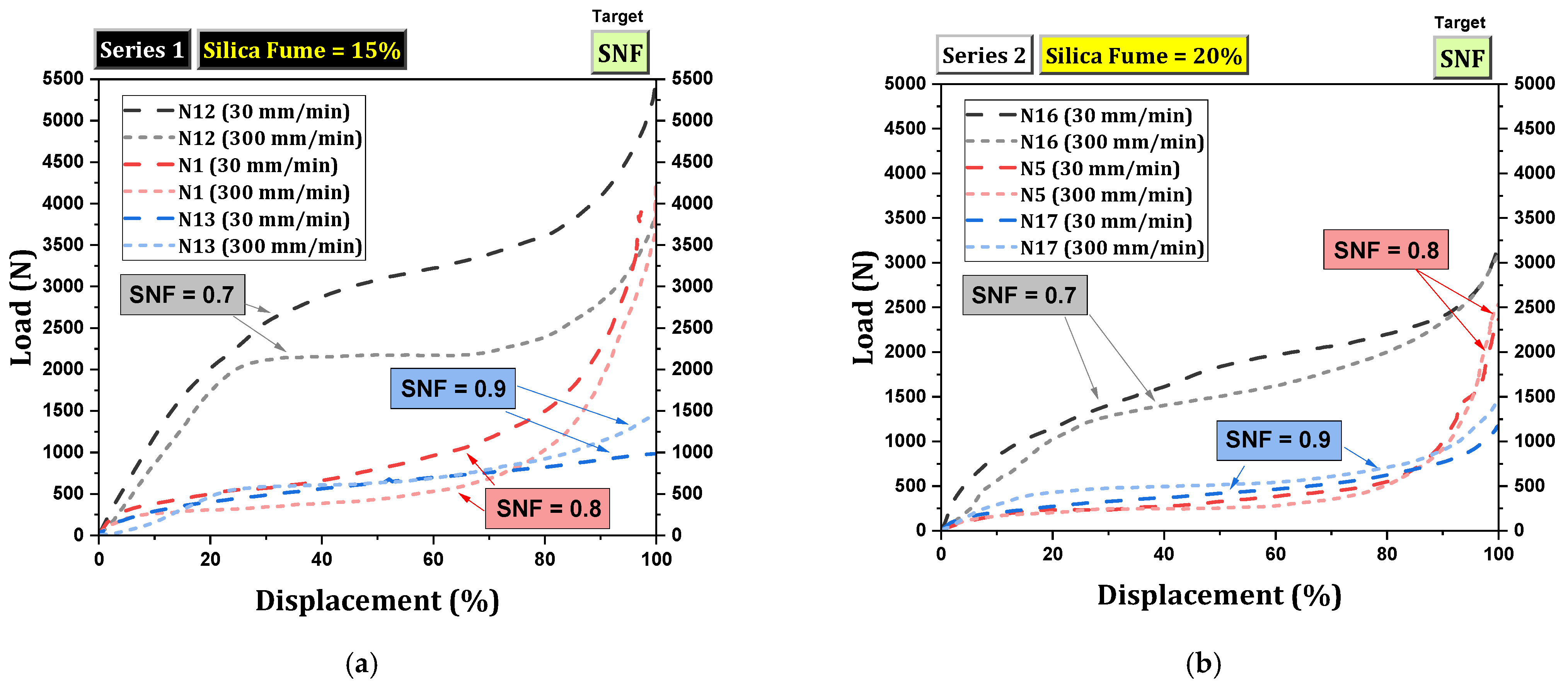

6.1.3. Squeezing Flow Test

Examining the Effect of w/b and SF

Examining the Effect of SNF and SF

6.2. Hardened Tests

6.2.1. Electrical Resistivity

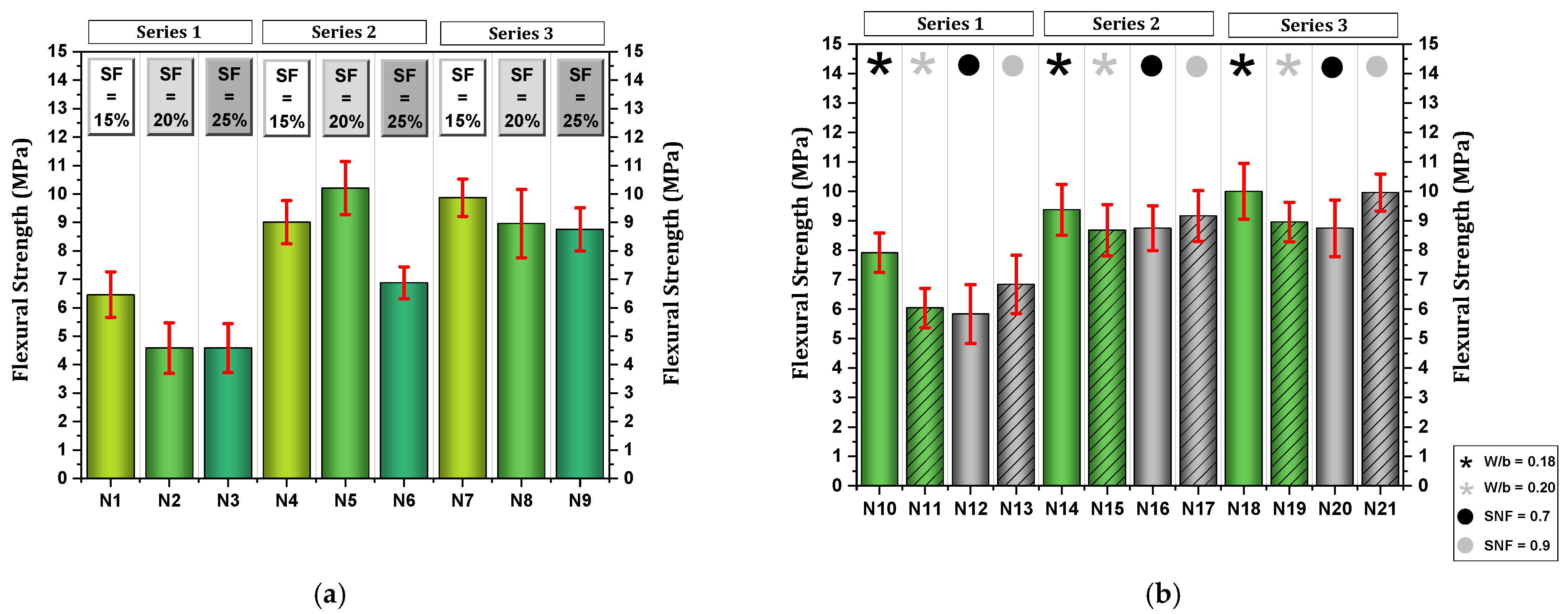

6.2.2. Flexural Strength

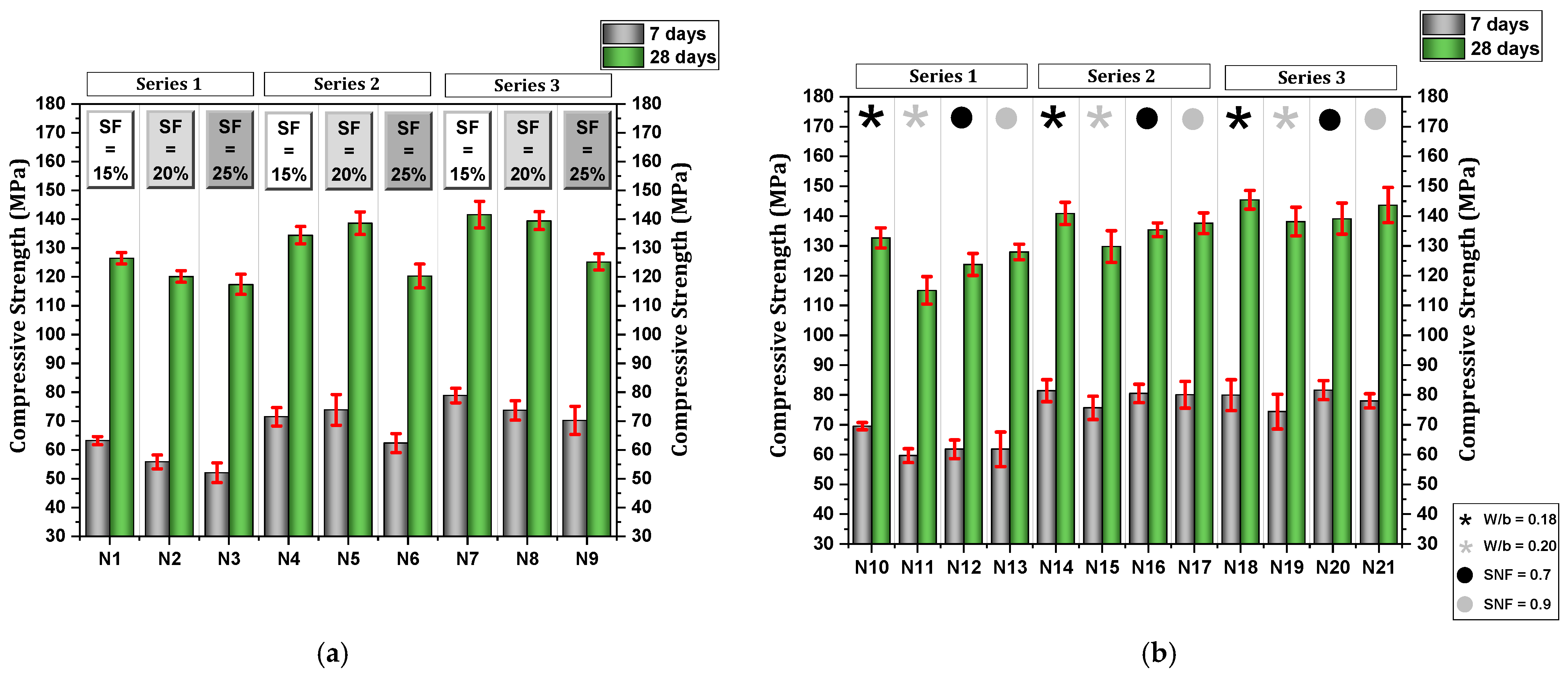

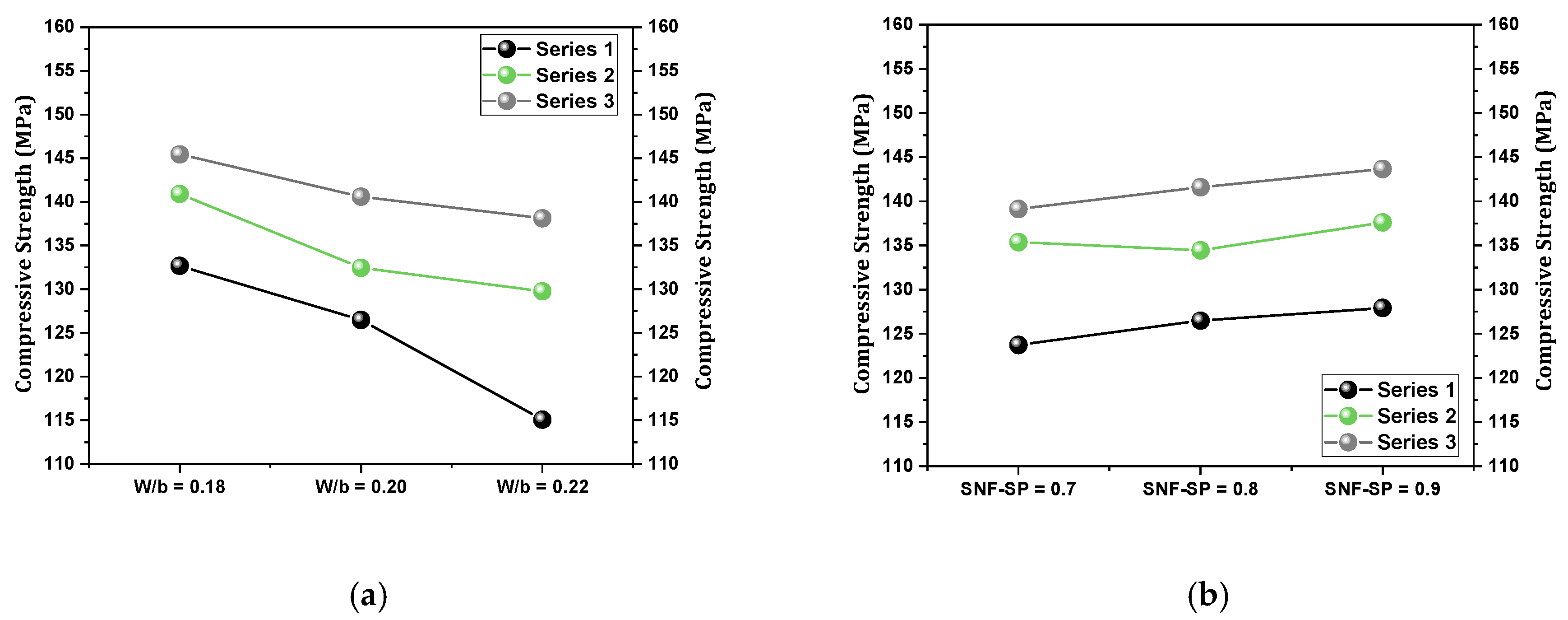

6.2.3. Compressive Strength

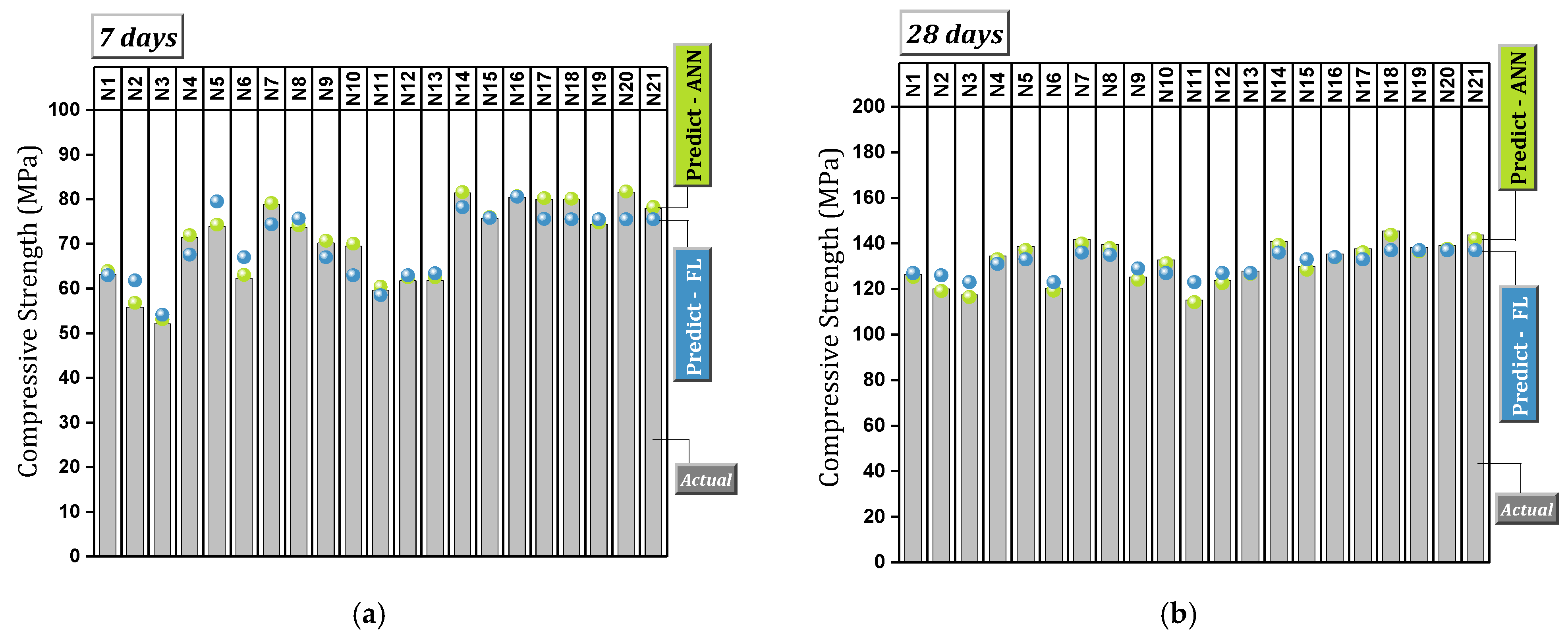

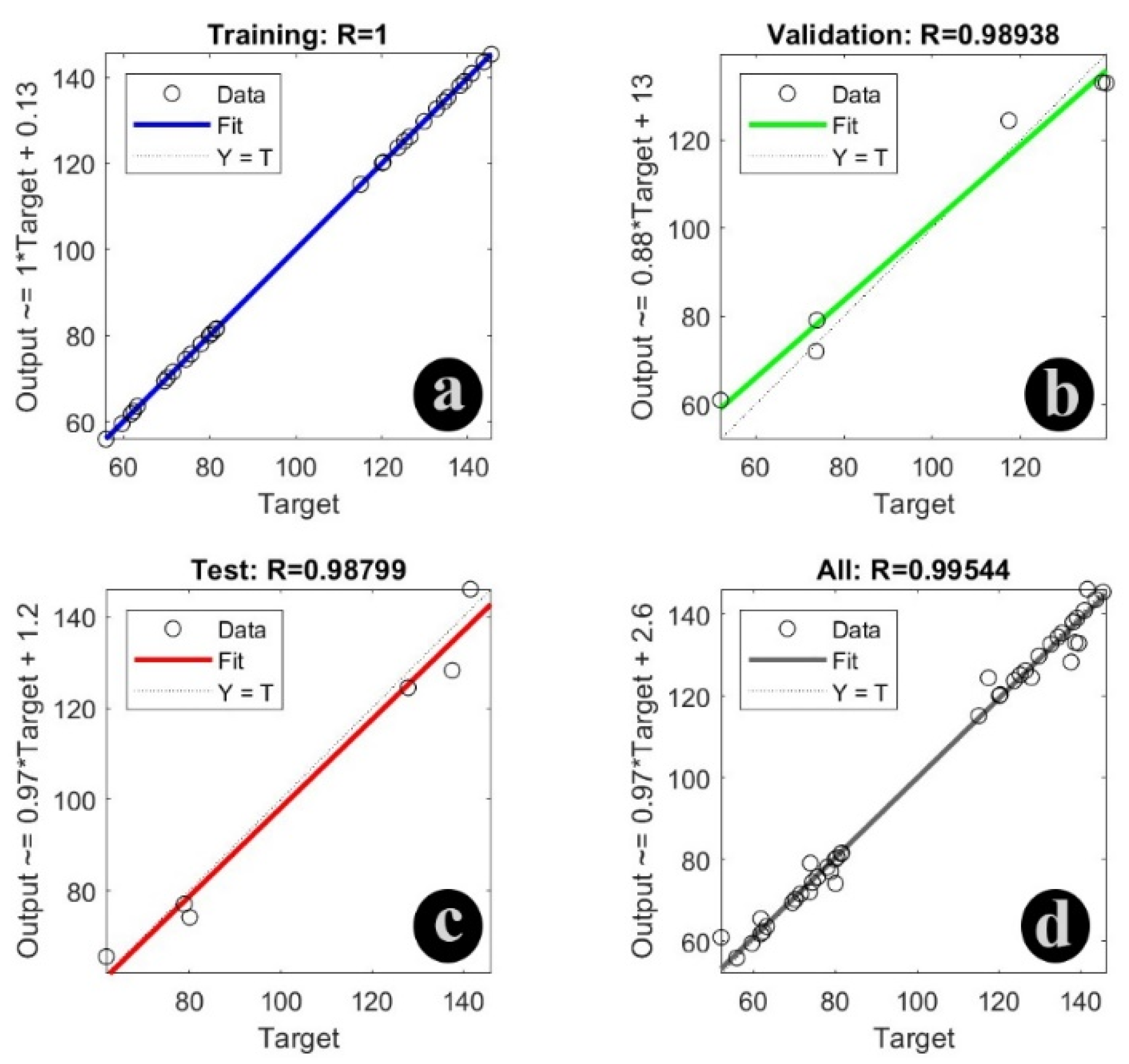

6.3. Analysis and Prediction of the Results with Artificial Neural Network (ANN) and Fuzzy Logic (FL)

7. Conclusions

- Fresh Properties

- •

- Increasing SF content from 15% to 25% led to reduced slump flow and shorter setting times, mainly due to reduced free water and accelerated hydration. Conversely, increasing the w/b ratio improved slump flow and extended setting time by enhancing particle mobility.

- •

- A higher SNF dosage (from 0.7% to 0.9%) significantly improved both slump flow and setting time, demonstrating effective dispersion of cement particles and reduced agglomeration.

- •

- Squeeze flow testing revealed three distinct paste behaviors:

- •

- Low workability mixes with high stiffness and rapid transition to strain hardening;

- •

- Highly flowable mixes exhibiting extended plastic phases and higher dilatancy;

- •

- Transitional mixes highly sensitive to variables like flow rate and composition, affecting displacement trends.

- Mechanical characteristics

- •

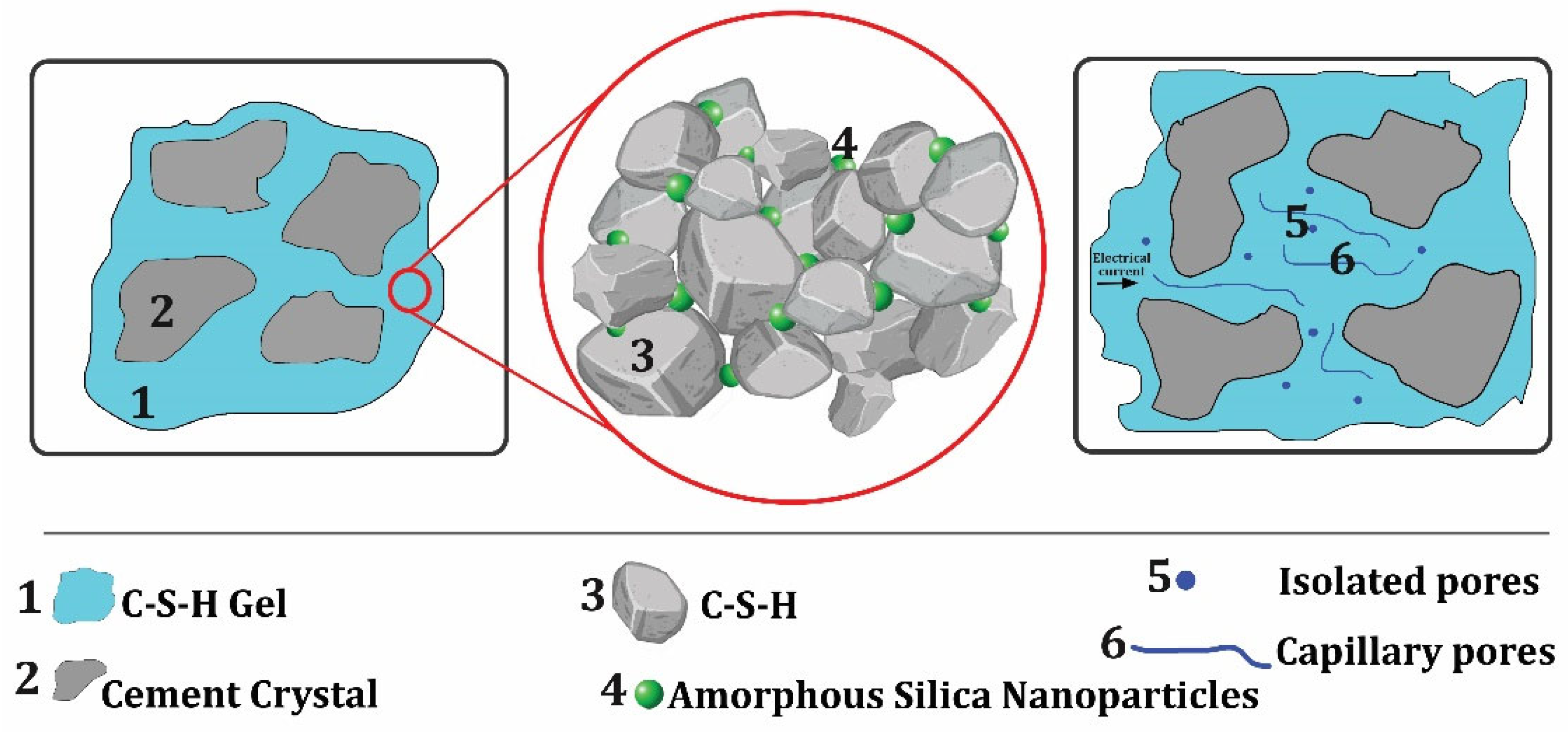

- Increasing the SF dose led to the closure of capillary paths and enhanced density, resulting in higher electrical resistance. The rise in the w/b ratio provided a conducive substrate for ion movement, leading to reduced electrical resistance. Higher SNF substitution enhanced cement particle packing density and raised electrical resistance.

- •

- Increasing SF dosage from 15% to 25% reduced compressive and flexural strength due to uneven cement particle distribution, hydration disruption, and ITZ weakening. A higher w/b ratio also decreased strength by limiting the material for C-S-H gel formation. However, raising the SNF dosage from 0.7% to 0.9% improved UHPC strength by promoting complete hydration and reducing internal friction.

- •

- The ANN model with 4-10-2 architecture presented an acceptable performance, according to the regression coefficient of >0.98. Also, the good performance of the FL model should not be overlooked. The error rate of the fuzzy logic model resulted in a range of 3.18–4.36%, while the error rate recorded for the ANN model was much lower (0.74–1.03%).

- Benefits and Limitations of Second-Generation Superplasticizers

- •

- Naphthalene-based superplasticizers have the potential to improve workability without compromising strength while also improving particle dispersion for a denser, more homogeneous microstructure. However, their limitations include potential slump loss over time due to rapid adsorption on cement particles, reduced effectiveness in low-temperature conditions, and incompatibility with some cement types, which can lead to delayed setting or strength gain issues. Additionally, they may not provide the same level of flow retention as newer polycarboxylate ether (PCE)-based alternatives, making them less ideal for highly complex UHPC applications requiring prolonged workability. Nevertheless, using this type of economic superplasticizer for relatively expensive concrete mixtures like UHPC may present a partial solution for further industrial application of this material.

- Recommended Mix Design

- Among the tested mixes, the most balanced performance was observed for:

- SF20WB20N09: 20% SF, w/b = 0.20, SNF = 0.9%.

- This mixture exhibited high flexural and compressive strength, suitable setting time, and adequate slump flow, making it the recommended formulation for UHPC in practical applications.

- Industrial perspective

- •

- The study focused exclusively on second-generation SNF-based superplasticizers, and the conclusions remain within this scope. The results demonstrate that optimized SNF dosages (0.9%) can produce UHPC mixes with satisfactory fresh behavior and mechanical strength, suggesting the continued viability of SNF in cost-sensitive or prefabrication settings where flowability and early strength are critical. While third-generation superplasticizers offer enhanced performance, SNF is still a cost-effective and functional alternative, especially for applications not requiring extreme workability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of Ultra-High Performance Concrete—A Review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-obeidah, A.; Nassif, H.; Wang, H. New Development of Ultra-High-Performance Concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Mohammad Nezhad Ayandeh, M.H.; Ghodousian, O.; Mohammad Nezhad, H.; Mohtasham Moein, M.; Saradar, A.; Karakouzian, M. Steel Slag and Zeolite as Sustainable Pozzolans for UHPC: An Experimental Study of Binary and Ternary Pozzolan Mixtures under Various Curing Conditions. Innov. Infrastruct. Solut. 2024, 9, 265. [Google Scholar] [CrossRef]

- Shao, Y.; Nguyen, W.; Bandelt, M.J.; Ostertag, C.P.; Billington, S.L. Seismic Performance of High-Performance Fiber-Reinforced Cement-Based Composite Structural Members: A Review. J. Struct. Eng. 2022, 148, 03122004. [Google Scholar] [CrossRef]

- Yang, C.; Okumus, P. Ultrahigh-Performance Concrete for Posttensioned Precast Bridge Piers for Seismic Resilience. J. Struct. Eng. 2017, 143, 03122004. [Google Scholar] [CrossRef]

- Hung, C.-C.; El-Tawil, S.; Chao, S.-H. A Review of Developments and Challenges for UHPC in Structural Engineering: Behavior, Analysis, and Design. J. Struct. Eng. 2021, 147, 03121001. [Google Scholar] [CrossRef]

- Cardoso, F.A.; John, V.M.; Pileggi, R.G.; Banfill, P.F.G. Characterisation of Rendering Mortars by Squeeze-Flow and Rotational Rheometry. Cem. Concr. Res. 2014, 57, 79–87. [Google Scholar] [CrossRef]

- Cardoso, F.A.; Grandes, F.A.; Sakano, V.K.; Rego, A.C.A.; Lofrano, F.C.; John, V.M.; Pileggi, R.G. Experimental Developments of the Squeeze Flow Test for Mortars. In Rheology and Processing of Construction Materials; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 23. [Google Scholar]

- Soltani, A.; Tarighat, A.; Rostami, R.; Tavakoli, D.; Moradi, A. Investigation of Mechanical Properties of Concrete with Clinoptilolite and Silica Fume Using Taguchi Method. Innov. Infrastruct. Solut. 2024, 9, 77. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Heidari, A.; Tavakoli, D. Performance of Ceramic Tile Powder as a Pozzolanic Material in Concrete. Int. J. Adv. Mater. Sci. 2012, 3, 1–11. [Google Scholar]

- Kujawa, W.; Olewnik-Kruszkowska, E.; Nowaczyk, J. Concrete Strengthening by Introducing Polymer-Based Additives into the Cement Matrix-a Mini Review. Materials 2021, 14, 6071. [Google Scholar] [CrossRef] [PubMed]

- Lei, D.; Yu, L.; Wang, S.; Li, Y.; Jia, H.; Wu, Z.; Bao, J.; Liu, J.; Xi, X.; Su, L. A State-of-the-Art on Electromagnetic and Mechanical Properties of Electromagnetic Waves Absorbing Cementitious Composites. Cem. Concr. Compos. 2025, 157, 105889. [Google Scholar] [CrossRef]

- Li, Y.; Dong, C.; Wang, S.; Lei, D.; Yin, B.; Cui, Y.; Wang, Y.; Li, R. Micro-Macro Regulating Heterogeneous Interface Engineering in 3D N-Doped Carbon Fiber/MXene/TiO 2 Nano-Aerogel for Boosting Electromagnetic Wave Absorption. Nano Res. 2025, 18, 94907169. [Google Scholar] [CrossRef]

- Lei, D.; Liu, C.; Wang, S.; Zhang, P.; Li, Y.; Yang, D.; Jin, Y.; Liu, Z.; Dong, C. Multiple Synergistic Effects of Structural Coupling and Dielectric-Magnetic Loss in Promoting Microwave Absorption of Bark-Derived Absorbers. Adv. Compos. Hybrid. Mater. 2025, 8, 158. [Google Scholar] [CrossRef]

- Lei, D.; Jia, H.; Yu, L.; Li, Y.; Wu, Z.; Wang, B.; Zhou, A.; Qin, L.; Sun, J.; Wang, W.; et al. Recent Developments in Low-Carbon Engineered Cementitious Composites (ECC). J. Build. Eng. 2025, 100, 111734. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; Lu, Y.; Yang, M.; Zhang, P.; Lei, D.; Liu, C.; Wang, S.; Dong, C. Surface Energy Induced Microstructural Engineering of Bio-Derived N-Doped Carbon Fibers Anchored by CoNi Nanoparticles for Superior Microwave Absorption. Adv. Compos. Hybrid. Mater. 2025, 8, 176. [Google Scholar] [CrossRef]

- al-Swaidani, A.M.; Khwies, W.T.; al-Baly, M.; Lala, T. Development of Multiple Linear Regression, Artificial Neural Networks and Fuzzy Logic Models to Predict the Efficiency Factor and Durability Indicator of Nano Natural Pozzolana as Cement Additive. J. Build. Eng. 2022, 52, 104475. [Google Scholar] [CrossRef]

- Rostami, J.; Rasekhi Sahneh, A.; Sedighardekani, R.; Latifinowsoud, M.; Rostami, R.; Kaltaei, A.; Sanaei Ataabadi, H.; Bahrami, N.; Mahmoudy, S.A.; Khandel, O. Influence of Phase Change Material and Nano Silica Aerogel Aggregates on the Characteristics of Cementitious Composite: An Experimental and Predictive Study. J. Build. Eng. 2024, 82, 108148. [Google Scholar] [CrossRef]

- Heyran Najafi, M.R.; Saradar, A.; Mohtasham Moein, M.; Karakouzian, M. Investigation Mechanical Characteristics and Permeability of Concrete with Pozzolanic Materials: A Sustainable Approach. Multiscale Multidiscip. Model. Exp. Des. 2024, 7, 5051–5078. [Google Scholar] [CrossRef]

- Moein, M.M.; Moein, A.M.; Saradar, A.; Rigby, S.E.; Tazari, H.; Karakouzian, M. Mechanical Properties of Portland Cement Concrete Mixed with Different Doses of Recycled Brick Powder and Steel Fiber. Heliyon 2025, 11, e41900. [Google Scholar] [CrossRef]

- Tayfur, G.; Erdem, T.K.; Kırca, Ö. Strength Prediction of High-Strength Concrete by Fuzzy Logic and Artificial Neural Networks. J. Mater. Civ. Eng. 2014, 26, 04014079. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, M.; Shang, X.; Xiong, Y.; Zhang, Y. Predicting the Compressive Strength of UHPC with Coarse Aggregates in the Context of Machine Learning. Case Stud. Constr. Mater. 2023, 19, e02627. [Google Scholar] [CrossRef]

- Behforouz, B.; Tavakoli, D.; Gharghani, M.; Ashour, A. Bond Strength of the Interface between Concrete Substrate and Overlay Concrete Containing Fly Ash Exposed to High Temperature. Structures 2023, 49, 183–197. [Google Scholar] [CrossRef]

- Song, H.; Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Maślak, M.; Czarnecki, S.; Aslam, F. Predicting the Compressive Strength of Concrete with Fly Ash Admixture Using Machine Learning Algorithms. Constr. Build. Mater. 2021, 308, 125021. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A. Modeling Compressive Strength of EPS Lightweight Concrete Using Regression, Neural Network and ANFIS. Constr. Build. Mater. 2013, 42, 205–216. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Rahmati, K.; Mohtasham Moein, A.; Saradar, A.; Rigby, S.E.; Akhavan Tabassi, A. Employing Neural Networks, Fuzzy Logic, and Weibull Analysis for the Evaluation of Recycled Brick Powder in Concrete Compositions. Buildings 2024, 14, 4062. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Rahmati, K.; Mohtasham Moein, A.; Rigby, S.E.; Saradar, A.; Karakouzian, M. Utilizing Construction and Demolition Waste in Concrete as a Sustainable Cement Substitute: A Comprehensive Study on Behavior Under Short-Term Dynamic and Static Loads via Laboratory and Numerical Analysis. J. Build. Eng. 2024, 97, 110778. [Google Scholar] [CrossRef]

- Sobhani, J.; Ejtemaei, M.; Sadrmomtazi, A.; Mirgozar, M.A. Modeling flexural strength of EPS lightweight concrete using regression, neural network and ANFIS. Int. J. Optim. Civil Eng. 2019, 9, 313–329. [Google Scholar]

- Wang, S.; Xia, P.; Chen, K.; Gong, F.; Wang, H.; Wang, Q.; Zhao, Y.; Jin, W. Prediction and Optimization Model of Sustainable Concrete Properties Using Machine Learning, Deep Learning and Swarm Intelligence: A Review. J. Build. Eng. 2023, 80, 108065. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Başyigit, C.; Akkurt, I.; Kilincarslan, S.; Beycioglu, A. Prediction of Compressive Strength of Heavyweight Concrete by ANN and FL Models. Neural Comput. Appl. 2010, 19, 507–513. [Google Scholar] [CrossRef]

- Soltanifar, M.; Sharafi, H.; Hosseinzadeh Lotfi, F.; Pedrycz, W.; Allahviranloo, T. Introduction to Fuzzy Logic. In Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2023; Volume 471. [Google Scholar]

- Zadeh, L.A. Is There a Need for Fuzzy Logic? Inf. Sci. 2008, 178, 2751–2779. [Google Scholar] [CrossRef]

- Mirgozar Langaroudi, M.A.; Mohtasham Moein, M.; Saradar, A.; Karakouzian, M. Investigation of the Mechanical Properties and Durability of Fiber-Reinforced Geopolymer Mortars Containing Metakaolin and Glass Powder. Infrastruct. 2025, 10, 25. [Google Scholar] [CrossRef]

- Saridemir, M. Predicting the Compressive Strength of Mortars Containing Metakaolin by Artificial Neural Networks and Fuzzy Logic. Adv. Eng. Softw. 2009, 40, 920–927. [Google Scholar] [CrossRef]

- Topçu, I.B.; Saridemir, M. Prediction of Compressive Strength of Concrete Containing Fly Ash Using Artificial Neural Networks and Fuzzy Logic. Comput. Mater. Sci. 2008, 41, 305–311. [Google Scholar] [CrossRef]

- Zhang, Q.; Shu, X.; Yang, Y.; Wang, X.; Liu, J.; Ran, Q. Preferential Adsorption of Superplasticizer on Cement/Silica Fume and Its Effect on Rheological Properties of UHPC. Constr. Build. Mater. 2022, 359, 129519. [Google Scholar] [CrossRef]

- Li, P.P.; Yu, Q.L.; Brouwers, H.J.H. Effect of PCE-Type Superplasticizer on Early-Age Behaviour of Ultra-High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 153, 740–750. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Huang, H.; Han, G. Influence of Rheological Properties of Cement Mortar on Steel Fiber Distribution in UHPC. Constr. Build. Mater. 2017, 144, 65–73. [Google Scholar] [CrossRef]

- Teng, L.; Jin, M.; Du, J.; Khayat, K.H. Synergetic Effect of Viscosity Modifying Admixtures and Polycarboxylate Ether Superplasticizer on Key Characteristics of Thixotropic UHPC for Bonded Bridge Deck Overlay Rehabilitation. Case Stud. Constr. Mater. 2024, 20, e02739. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of Nano-Silica on the Hydration and Microstructure Development of Ultra-High Performance Concrete (UHPC) with a Low Binder Amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K.; Fraaij, A.L.A.; Bui, D.D. The Study of Using Rice Husk Ash to Produce Ultra High Performance Concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Ahmadi, S.M.; Honarbakhsh, A.; Zhiani, R.; Tavakoli, D. Effects of KCC-1/Ag Nanoparticles on the Mechanical Properties of Concrete. Int. J. Eng. 2022, 35, 1388–1397. [Google Scholar] [CrossRef]

- Heidari, A.; Tavakoli, S.; Tavakoli, D. Reusing Waste Ceramic and Waste Sanitary Ware in Concrete as Pozzolans with Nano-Silica and Metakaolin. Int. J. Sustain. Constr. Eng. Technol. 2019, 10, 55–67. [Google Scholar] [CrossRef]

- Murugesan, A.; Umapathi, N.; Mohamed Ismail, A.A.; Srinivasan, D. Compatibility Matrix of Superplasticizers in Ultra-High-Performance Concrete for Material Sustainability. Innov. Infrastruct. Solut. 2023, 8, 260. [Google Scholar] [CrossRef]

- Ramkumar, K.B.; Kannan Rajkumar, P.R.; Noor Ahmmad, S.; Jegan, M. A Review on Performance of Self-Compacting Concrete—Use of Mineral Admixtures and Steel Fibres with Artificial Neural Network Application. Constr. Build. Mater. 2020, 261, 120215. [Google Scholar] [CrossRef]

- Balf, F.R.; Kordkheili, H.M.; Kordkheili, A.M. A New Method for Predicting the Ingredients of Self-Compacting Concrete (SCC) Including Fly Ash (FA) Using Data Envelopment Analysis (DEA). Arab. J. Sci. Eng. 2021, 46, 4439–4460. [Google Scholar] [CrossRef]

- Ly, H.-B.; Nguyen, T.-A.; Thi Mai, H.-V.; Tran, V.Q. Development of Deep Neural Network Model to Predict the Compressive Strength of Rubber Concrete. Constr. Build. Mater. 2021, 301, 124081. [Google Scholar] [CrossRef]

- Liu, J.C.; Zhang, Z. Neural Network Models to Predict Explosive Spalling of PP Fiber Reinforced Concrete under Heating. J. Build. Eng. 2020, 32, 101472. [Google Scholar] [CrossRef]

- Biswas, R.; Kumar, M.; Singh, R.K.; Alzara, M.; El Sayed, S.B.A.; Abdelmongy, M.; Yosri, A.M.; Yousef, S.E.A.S. A Novel Integrated Approach of RUNge Kutta Optimizer and ANN for Estimating Compressive Strength of Self-Compacting Concrete. Case Stud. Constr. Mater. 2023, 18, e02163. [Google Scholar] [CrossRef]

- Qayyum Khan, A.; Ahmad Awan, H.; Rasul, M.; Ahmad Siddiqi, Z.; Pimanmas, A. Optimized Artificial Neural Network Model for Accurate Prediction of Compressive Strength of Normal and High Strength Concrete. Clean. Mater. 2023, 10, 100211. [Google Scholar] [CrossRef]

- Shafaie, V.; Ghodousian, O.; Ghodousian, A.; Cucuzza, R.; Movahedi Rad, M. Integrating Push-out Test Validation and Fuzzy Logic for Bond Strength Study of Fiber-Reinforced Self-Compacting Concrete. Constr. Build. Mater. 2024, 425, 136062. [Google Scholar] [CrossRef]

- Abbas, Y.M.; Iqbal Khan, M. Prediction of Compressive Stress–Strain Behavior of Hybrid Steel–Polyvinyl-Alcohol Fiber Reinforced Concrete Response by Fuzzy-Logic Approach. Constr. Build. Mater. 2023, 379, 131212. [Google Scholar] [CrossRef]

- Demir, F. A New Way of Prediction Elastic Modulus of Normal and High Strength Concrete-Fuzzy Logic. Cem. Concr. Res. 2005, 35, 1531–1538. [Google Scholar] [CrossRef]

- ASTM C150/C150M-19a; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1240; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C778; Standard Specification for Standard Sand. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C230/230M-21; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C191-08; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: West Conshohocken, PA, USA, 2008.

- Cardoso, F.A.; John, V.M.; Pileggi, R.G. Rheological Behavior of Mortars under Different Squeezing Rates. Cem. Concr. Res. 2009, 39, 748–753. [Google Scholar] [CrossRef]

- ASTM-C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- AASHTO TP 119; Standard Method of Test for Electrical Resistivity of a Concrete Cylinder Tested in a Uniaxial Resistance Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- ASTM C109/C109M-20b; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 Mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021.

- Ali, K.; Qureshi, M.I.; Saleem, S.; Khan, S.U. Effect of Waste Electronic Plastic and Silica Fume on Mechanical Properties and Thermal Performance of Concrete. Constr. Build. Mater. 2021, 285, 122952. [Google Scholar] [CrossRef]

- Sharma, M.; Behera, P.; Saha, S.; Mohanty, T.; Saha, P. Effect of Silica Fume and Red Mud on Mechanical Properties of Ferrochrome Ash Based Concrete. Mater. Today Proc. 2022, 60, 55–61. [Google Scholar] [CrossRef]

- Fidjestol, P. ACI 234R-06: Guide for the Use of Silica Fume in Concrete; American Concrete Institute: Mumbai, MH, USA, 2006; Volume 96. [Google Scholar]

- Saradar, A.; Rezakhani, Y.; Rahmati, K.; Johari Majd, F.; Mohtasham Moein, M.; Karakouzian, M. Investigating the Properties and Microstructure of High-Performance Cement Composites with Nano-Silica, Silica Fume, and Ultra-Fine TiO2. Innov. Infrastruct. Solut. 2024, 9, 84. [Google Scholar] [CrossRef]

- Gleize, P.J.P.; Müller, A.; Roman, H.R. Microstructural Investigation of a Silica Fume-Cement-Lime Mortar. Cem. Concr. Compos. 2003, 25, 171–175. [Google Scholar] [CrossRef]

- Jo, B.W.; Chakraborty, S.; Lee, S.T.; Lee, Y.S. Durability Study of Silica Fume-Mortar Exposed to the Combined Sulfate and Chloride-Rich Solution. KSCE J. Civ. Eng. 2019, 23, 356–366. [Google Scholar] [CrossRef]

- Bahrami, N.; Zohrabi, M.; Mahmoudy, S.A.; Akbari, M. Optimum Recycled Concrete Aggregate and Micro-Silica Content in Self-Compacting Concrete: Rheological, Mechanical and Microstructural Properties. J. Build. Eng. 2020, 31, 101361. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Langeroudi, M.A.M.; Fasihi, A.; Haghi, A.K. An Investigation on Effect of Using PP Fibers and Different Cementitious Materials on Mechanical Properties of EPS Concrete. In Proceedings of the 3rd International Conference on Concrete and Development, Tehrant, Iran, 27–29 April 2009. [Google Scholar]

- Huynh, P.T.; Bui, P.T.; Ogawa, Y.; Kawai, K. Effect of Water-to-Binder Ratio on Cementing Efficiency Factor of Fly Ash Regarding Compressive Strength of Concrete. In ICSCEA 2019: Proceedings of the International Conference on Sustainable Civil Engineering and Architecture; Lecture Notes in Civil Engineering; Springer: Singapore, 2020; Volume 80. [Google Scholar]

- Melo, K.A.; Repette, W.L. Optimization of Superplasticizer Content in Self-Compacting Concrete. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- Kawai, T.; Okada, T. Effect of Superplasticizer and Viscosity-Increasing Admixture on Properties of Lightweight Aggregate Concrete; ACI Special Publication; American Concrete Institute: Farmington Hills, MI, USA, 1989; Volume SP-119. [Google Scholar]

- Zhang, G.; Wang, S.; Wang, B.; Zhao, Y.; Kang, M.; Wang, P. Properties of Pervious Concrete with Steel Slag as Aggregates and Different Mineral Admixtures as Binders. Constr. Build. Mater. 2020, 257, 119543. [Google Scholar] [CrossRef]

- Wang, G.; Kong, Y.; Sun, T.; Shui, Z. Effect of Water-Binder Ratio and Fly Ash on the Homogeneity of Concrete. Constr. Build. Mater. 2013, 38, 1129–1134. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N. Effect of Liquid to Binder Ratio and Curing Temperature on the Engineering Properties of the Geopolymer Concrete. Silicon 2022, 14, 1743–1757. [Google Scholar] [CrossRef]

- Xun, W.; Wu, C.; Leng, X.; Li, J.; Xin, D.; Li, Y. Effect of Functional Superplasticizers on Concrete Strength and Pore Structure. Appl. Sci. 2020, 10, 3496. [Google Scholar] [CrossRef]

- Yousuf, F.; Wei, X.; Tao, J. Evaluation of the Influence of a Superplasticizer on the Hydration of Varying Composition Cements by the Electrical Resistivity Measurement Method. Constr. Build. Mater. 2017, 144, 25–34. [Google Scholar] [CrossRef]

- Ma, B.; Ma, M.; Shen, X.; Li, X.; Wu, X. Compatibility between a Polycarboxylate Superplasticizer and the Belite-Rich Sulfoaluminate Cement: Setting Time and the Hydration Properties. Constr. Build. Mater. 2014, 51, 47–54. [Google Scholar] [CrossRef]

- Min, B.H.; Erwin, L.; Jennings, H.M. Rheological Behaviour of Fresh Cement Paste as Measured by Squeeze Flow. J. Mater. Sci. 1994, 29, 1374–1381. [Google Scholar] [CrossRef]

- Lai, M.H.; Binhowimal, S.A.M.; Hanzic, L.; Wang, Q.; Ho, J.C.M. Dilatancy Mitigation of Cement Powder Paste by Pozzolanic and Inert Fillers. Struct. Concr. 2020, 21, 1164–1180. [Google Scholar] [CrossRef]

- Lai, M.H.; Lao, W.C.; Tang, W.K.; Hanzic, L.; Wang, Q.; Ho, J.C.M. Dilatancy Swerve in Superplasticized Cement Powder Paste. Constr. Build. Mater. 2023, 362, 129524. [Google Scholar] [CrossRef]

- Daukšys, M.; Skripkiunas, G. Investigation of Dilatancy Mechanism of Portland Cement Paste. Constr. Build. Mater. 2015, 83, 53–61. [Google Scholar] [CrossRef]

- Medeiros, R.A.; Lima, M.G. Electrical Resistivity of Unsaturated Concrete Using Different Types of Cement. Constr. Build. Mater. 2016, 107, 11–16. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ahmed, H.U.; Rafiq, S.; Sor, N.H.; Ibrahim, D.F.; Qaidi, S.M.A. Performance of Self-Compacting Mortars Modified with Nanoparticles: A Systematic Review and Modeling. Clean. Mater. 2022, 4, 100086. [Google Scholar] [CrossRef]

- Cosoli, G.; Mobili, A.; Tittarelli, F.; Revel, G.M.; Chiariotti, P. Electrical Resistivity and Electrical Impedance Measurement in Mortar and Concrete Elements: A Systematic Review. Appl. Sci. 2020, 10, 9152. [Google Scholar] [CrossRef]

- Pourahmadi, H.; Arabani, S.; Sadrmomtazi, A.; Langaroudi, M.A.M.; Khoshkbijari, R.K.; Amooie, M. Durability of Self-Compacting Lightweight Aggregate Concretes (LWSCC) as Repair Overlays ARTICLE INFO ABSTRACT. J. Rehabil. Civ. Eng. 2017, 5, 101–113. [Google Scholar]

- Sadrinejad, I.; Madandoust, R.; Ranjbar, M.M. The Mechanical and Durability Properties of Concrete Containing Hybrid Synthetic Fibers. Constr. Build. Mater. 2018, 178, 72–82. [Google Scholar] [CrossRef]

- AlHassan, M.K.; Nasser, M.S.; Onaizi, S.A.; Hussein, I.A.; Hassan, M.K. Production of High-Performance Concrete through the Addition of New Generation of Superplasticizers: A Comprehensive Review on the Electrokinetics and Rheological Behaviors. Emergent Mater. 2023, 7, 403–441. [Google Scholar] [CrossRef]

- Liao, Y.; Wei, X. Penetration Resistance and Electrical Resistivity of Cement Paste with Superplasticizer. Mater. Struct. 2014, 47, 563–570. [Google Scholar] [CrossRef]

- Toutanji, H.A.; El-Korchi, T. The Influence of Silica Fume on the Compressive Strength of Cement Paste and Mortar. Cem. Concr. Res. 1995, 25, 1591–1602. [Google Scholar] [CrossRef]

- Shafieyzadeh, M. Prediction of Flexural Strength of Concretes Containing Silica Fume and Styrene-Butadiene Rubber (SBR) with an Empirical Model. J. Inst. Eng. (India) Ser. A 2015, 96, 349–355. [Google Scholar] [CrossRef]

- Beshkari, M.; Amani, B.; Rahmati, K.; Mohtasham Moein, M.; Saradar, A.; Karakouzian, M. Synergistic Effects of Pozzolan and Carbon Fibers on the Performance of Self-Consolidating Concrete under Plastic Shrinkage and Dynamic Loading. Innov. Infrastruct. Solut. 2024, 9, 160. [Google Scholar] [CrossRef]

- He, T.; Xiang, W.; Zhang, J.; Hu, C.; Zhang, G.; Kou, B. Influence of Water-Binder Ratio on the Mechanical Strength and Microstructure of Arch Shell Interface Transition Zone. Buildings 2022, 12, 491. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, X.; Deng, H.; Yu, P.; Yao, Y. Effects of Water/Binder Ratio on the Properties of Engineered Cementitious Composites. J. Wuhan. Univ. Technol. Mater. Sci. Ed. 2010, 25, 298–302. [Google Scholar] [CrossRef]

- Gagné, R.; Boisvert, A.; Pigeon, M. Effect of Superplasticizer Dosage on Mechanical Properties, Permeability, and Freeze-Thaw Durability of High-Strength Concretes with and without Silica Fume. ACI Mater. J. 1996, 93, 111–120. [Google Scholar] [CrossRef]

- Adebanjo, A.U.; Shafiq, N.; Razak, S.N.A.; Kumar, V.; Farhan, S.A.; Singh, P.; Abubakar, A.S. Design and Modeling the Compressive Strength of High-Performance Concrete with Silica Fume: A Soft Computing Approach. Soft Comput. 2023, 28, 6059–6083. [Google Scholar] [CrossRef]

- Eren, Ö.; Çelik, T. Effect of Silica Fume and Steel Fibers on Some Properties of High-Strength Concrete. Constr. Build. Mater. 1997, 11, 373–382. [Google Scholar] [CrossRef]

- Nabighods, K.; Saradar, A.; Mohtasham Moein, M.; Mirgozar Langaroudi, M.A.; Byzyka, J.; Karakouzian, M. Evaluation of Self-Compacting Concrete Containing Pozzolan (Zeolite, Metakaolin & Silica Fume) and Polypropylene Fiber against Sulfate Attacks with Different PH: An Experimental Study. Innov. Infrastruct. Solut. 2023, 9, 1. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Saradar, A.; Jabbari, M.; Moein, M.M. Evaluation of Fresh and Hardened Properties of Self-Compacting Concrete Containing Different Percentages of Waste Tiles. J. Build. Pathol. Rehabil. 2023, 8, 81. [Google Scholar] [CrossRef]

- Xiaofeng, C.; Shanglong, G.; Darwin, D.; McCabe, S.L. Role of Silica Fume in Compressive Strength of Cement Paste, Mortar, and Concrete. ACI Mater. J. 1992, 89, 375–387. [Google Scholar] [CrossRef][Green Version]

- Yogendran, V.; Langan, B.W.; Haque, M.N.; Ward, M.A. Silica Fume in High-Strength Concrete. ACI Mater. J. 1987, 84, 124–129. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Shoaei, P.; Bahrami, N. Recycled Ceramic Waste High Strength Concrete Containing Wollastonite Particles and Micro-Silica: A Comprehensive Experimental Study. Constr. Build. Mater. 2019, 201, 11–32. [Google Scholar] [CrossRef]

- Burhan, L.; Ghafor, K.; Mohammed, A. Modeling the Effect of Silica Fume on the Compressive, Tensile Strengths and Durability of NSC and HSC in Various Strength Ranges. J. Build. Pathol. Rehabil. 2019, 4, 19. [Google Scholar] [CrossRef]

- Govin, A.; Bartholin, M.C.; Schmidt, W.; Grosseau, P. Combination of Superplasticizers with Hydroxypropyl Guar, Effect on Cement-Paste Properties. Constr. Build. Mater. 2019, 215, 595–604. [Google Scholar] [CrossRef]

- Matias, D.; De Brito, J.; Rosa, A.; Pedro, D. Mechanical Properties of Concrete Produced with Recycled Coarse Aggregates—Influence of the Use of Superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Shi, C.; He, T.S.; Zhang, G.; Wang, X.; Hu, Y. Effects of Superplasticizers on Carbonation Resistance of Concrete. Constr. Build. Mater. 2016, 108, 48–55. [Google Scholar] [CrossRef]

- Malhotra, V.M. Effect of Repeated Dosages of Superplasticizers on Slump, Strength and Freeze-Thaw Resistance of Concrete. Matériaux Constr. 1981, 14, 79–89. [Google Scholar] [CrossRef]

| Chemical Properties | Physical Properties | |||

|---|---|---|---|---|

| SiO2 | 21.27 | Compressive strength (MPa) | 3 days | 20.1 |

| Al2O3 | 1.12 | 7 days | 28.2 | |

| Fe2O3 | 4.03 | 28 days | 40.3 | |

| CaO | 62.95 | Setting time (min) | Initial | 154 |

| MgO | 1.55 | Final | 195 | |

| SO3 | 2.26 | Longitudinal expansion | 1.5 mm-0.08% | |

| Na2O | 0.49 | |||

| K2O | 0.65 | Specific surface (cm2/gr) | 2910 | |

| C3A | 6.30 | |||

| Chemical Properties | Physical Properties | ||

|---|---|---|---|

| SiO2 | 89.26 | Physical state | amorphous |

| Al2O3 | 4.95 | ||

| Fe2O3 | 1.8 | Particle size (typical) | <1 µm |

| CaO | 0.87 | ||

| MgO | 1.1 | Color | Light gray |

| Na2O | 0.5 | ||

| K2O | 0.66 | Specific surface (cm2/gr) | 21,000 |

| Sieve Size | ASTM C778 [58] | This Study | |

|---|---|---|---|

| mm | No. | ||

| 1.18 | 16 | 100 | 100 |

| 0.6 | 30 | 100 | 96–100 |

| 0.425 | 40 | 67.5 | 65–75 |

| 0.3 | 50 | 28 | 20–30 |

| 0.15 | 100 | 3.5 | 0–4 |

| Technical Features | |

|---|---|

| Generation | 2 |

| Physical State | Liquid |

| Color | Brown |

| Specific weight | 1.2 ± 0.02 kg/lit |

| PH | 8 ± 1 |

| Chlorides (PPM) | 500 max |

| Chemical Base | Modified sodium naphthalene sulfonate compounds |

| Mix No. | Group | Design Code | Cement | Silica Fume | Water | w/b | S.P. | Aggregate | Dry Unit Weight (kg/m3) | Final Water Absorption (%Wt.) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | % | ||||||||||

| N1 | A | 1-SF15WB20N08 | 696 | 104 | 15 | 160 | 0.2 | 6.4 | 1479 | 2083 | 3.42 |

| N2 | 1-SF20WB20N08 | 667 | 133 | 20 | 160 | 0.2 | 6.4 | 1463 | 2074 | 3.24 | |

| N3 | 1-SF25WB20N08 | 640 | 160 | 25 | 160 | 0.2 | 6.4 | 1448 | 2064 | 2.99 | |

| N4 | 2-SF15WB20N08 | 783 | 117 | 15 | 180 | 0.2 | 7.2 | 1333 | 2067 | 3.47 | |

| N5 | 2-SF20WB20N08 | 750 | 150 | 20 | 180 | 0.2 | 7.2 | 1315 | 2051 | 3.15 | |

| N6 | 2-SF25WB20N08 | 720 | 180 | 25 | 180 | 0.2 | 7.2 | 1298 | 2042 | 2.82 | |

| N7 | 3-SF15WB20N08 | 870 | 131 | 15 | 200 | 0.2 | 8.0 | 1185 | 2045 | 3.21 | |

| N8 | 3-SF20WB20N08 | 833 | 167 | 20 | 200 | 0.2 | 8.0 | 1166 | 2024 | 3.26 | |

| N9 | 3-SF15WB20N08 | 800 | 200 | 25 | 200 | 0.2 | 8.0 | 1148 | 2015 | 2.88 | |

| N10 | B | 1-SF15WB18N08 | 696 | 104 | 15 | 144 | 0.2 | 6.4 | 1522 | 2114 | 3.02 |

| N11 | 1-SF15WB22N08 | 696 | 104 | 15 | 176 | 0.2 | 6.4 | 1437 | 2065 | 3.64 | |

| N12 | 1-SF15WB20N07 | 696 | 104 | 15 | 160 | 0.2 | 5.6 | 1481 | 2097 | 3.51 | |

| N13 | 1-SF15WB20N09 | 696 | 104 | 15 | 160 | 0.2 | 7.2 | 1477 | 2090 | 3.31 | |

| N14 | 2-SF20WB18N08 | 750 | 150 | 20 | 162 | 0.2 | 7.2 | 1362 | 2081 | 3.03 | |

| N15 | 2-SF20WB22N08 | 750 | 150 | 20 | 198 | 0.2 | 7.2 | 1267 | 2026 | 3.23 | |

| N16 | 2-SF20WB20N07 | 750 | 150 | 20 | 180 | 0.2 | 6.3 | 1317 | 2054 | 3.23 | |

| N17 | 2-SF20WB20N09 | 750 | 150 | 20 | 180 | 0.2 | 8.1 | 1312 | 2051 | 3.1 | |

| N18 | 3-SF15WB18N08 | 870 | 131 | 15 | 180 | 0.2 | 8.0 | 1238 | 2053 | 3.33 | |

| N19 | 3-SF15WB22N08 | 870 | 131 | 15 | 220 | 0.2 | 8.0 | 1132 | 2006 | 3.29 | |

| N20 | 3-SF15WB20N07 | 870 | 131 | 15 | 200 | 0.2 | 7.0 | 1188 | 2028 | 3.37 | |

| N21 | 3-SF15WB20N09 | 870 | 131 | 15 | 200 | 0.2 | 9.0 | 1183 | 2026 | 3.09 | |

| Independent variables (kg/m3) | ||||

| Min. | Max. | Averg. | SD. | |

| Cement (C) | 640 | 870 | 763 | 75.3 |

| Silica fume (SF) | 104 | 200 | 137.24 | 26.58 |

| Water (W) | 144 | 220 | 180 | 19.44 |

| Sulphonated naphthalene formaldehyde (SNF) | 6 | 9 | 7.2 | 0.832 |

| Dependent variables (MPa) | ||||

| Min | Max | Averg. | SD. | |

| Compressive strength—7 days | 52.08 | 81.60 | 70.76 | 29.1 |

| Compressive strength—28 days | 115.07 | 145.44 | 132.05 | 9.13 |

| Input | Fuzzy MF | Range |

| Cement (kg/m3) | “L” (Low) | 635–732 |

| “M” (Medium) | 686–824 | |

| “H” (High) | 778–890 | |

| Silica fume (kg/m3) | “L” (Low) | 140–174 |

| “M” (Medium) | 159–212 | |

| “H” (High) | 193–225 | |

| Water (kg/m3) | “L” (Low) | 140–174 |

| “M” (Medium) | 159–212 | |

| “H” (High) | 193–225 | |

| NSF (kg/m3) | “L” (Low) | 4.5–7.1 |

| “M” (Medium) | 6.6–8.4 | |

| “H” (High) | 7.8–9.5 | |

| Output | Fuzzy MF | Range |

| Compressive strength (MPa)—7 Days | “L” (Low) | 45–60 |

| “M” (Medium) | 57–68 | |

| “H” (High) | 65–77 | |

| “V.H” (Very High) | 74–90 | |

| Compressive strength (MPa)—28 Days | “L” (Low) | 110–123 |

| “M” (Medium) | 120–132 | |

| “H” (High) | 128–141 | |

| “V.H” (Very High) | 136–150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tajasosi, S.; Barandoust, J.; Saradar, A.; Mohtasham Moein, M.; Rigby, S.E.; Karakouzian, M. Investigation of Mechanical and Fresh Properties of Ultra-High-Performance Concrete Incorporating Second-Generation Superplasticizers. Appl. Sci. 2025, 15, 5133. https://doi.org/10.3390/app15095133

Tajasosi S, Barandoust J, Saradar A, Mohtasham Moein M, Rigby SE, Karakouzian M. Investigation of Mechanical and Fresh Properties of Ultra-High-Performance Concrete Incorporating Second-Generation Superplasticizers. Applied Sciences. 2025; 15(9):5133. https://doi.org/10.3390/app15095133

Chicago/Turabian StyleTajasosi, Sama, Jalil Barandoust, Ashkan Saradar, Mohammad Mohtasham Moein, Sam E. Rigby, and Moses Karakouzian. 2025. "Investigation of Mechanical and Fresh Properties of Ultra-High-Performance Concrete Incorporating Second-Generation Superplasticizers" Applied Sciences 15, no. 9: 5133. https://doi.org/10.3390/app15095133

APA StyleTajasosi, S., Barandoust, J., Saradar, A., Mohtasham Moein, M., Rigby, S. E., & Karakouzian, M. (2025). Investigation of Mechanical and Fresh Properties of Ultra-High-Performance Concrete Incorporating Second-Generation Superplasticizers. Applied Sciences, 15(9), 5133. https://doi.org/10.3390/app15095133