Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling

Abstract

1. Introduction

2. Methodology

2.1. Design of Concrete Gravity Dams

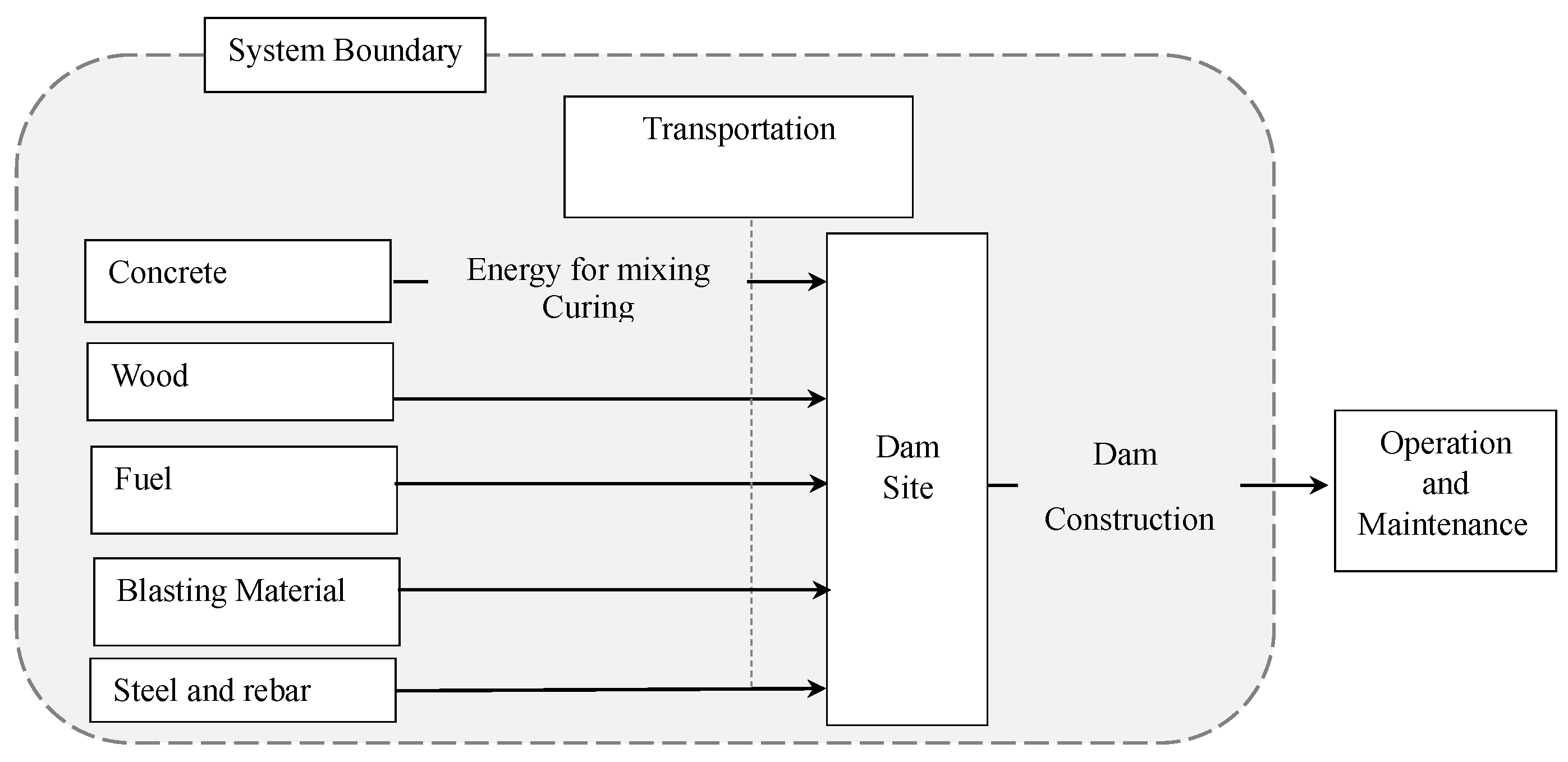

2.2. LCA Method

2.3. CFA Method

2.4. LCC Method

3. Model Description

4. Results and Discussion

4.1. Construction Stage

4.1.1. Environmental Impacts

4.1.2. LCC Results of the Construction Stage

4.2. The Effects of Demolition

4.3. The Effects of Recycling

4.3.1. CFA Results

4.3.2. LCC Results of Recycling

4.4. The Effects of Compressive Strength of the Concrete

5. Conclusions

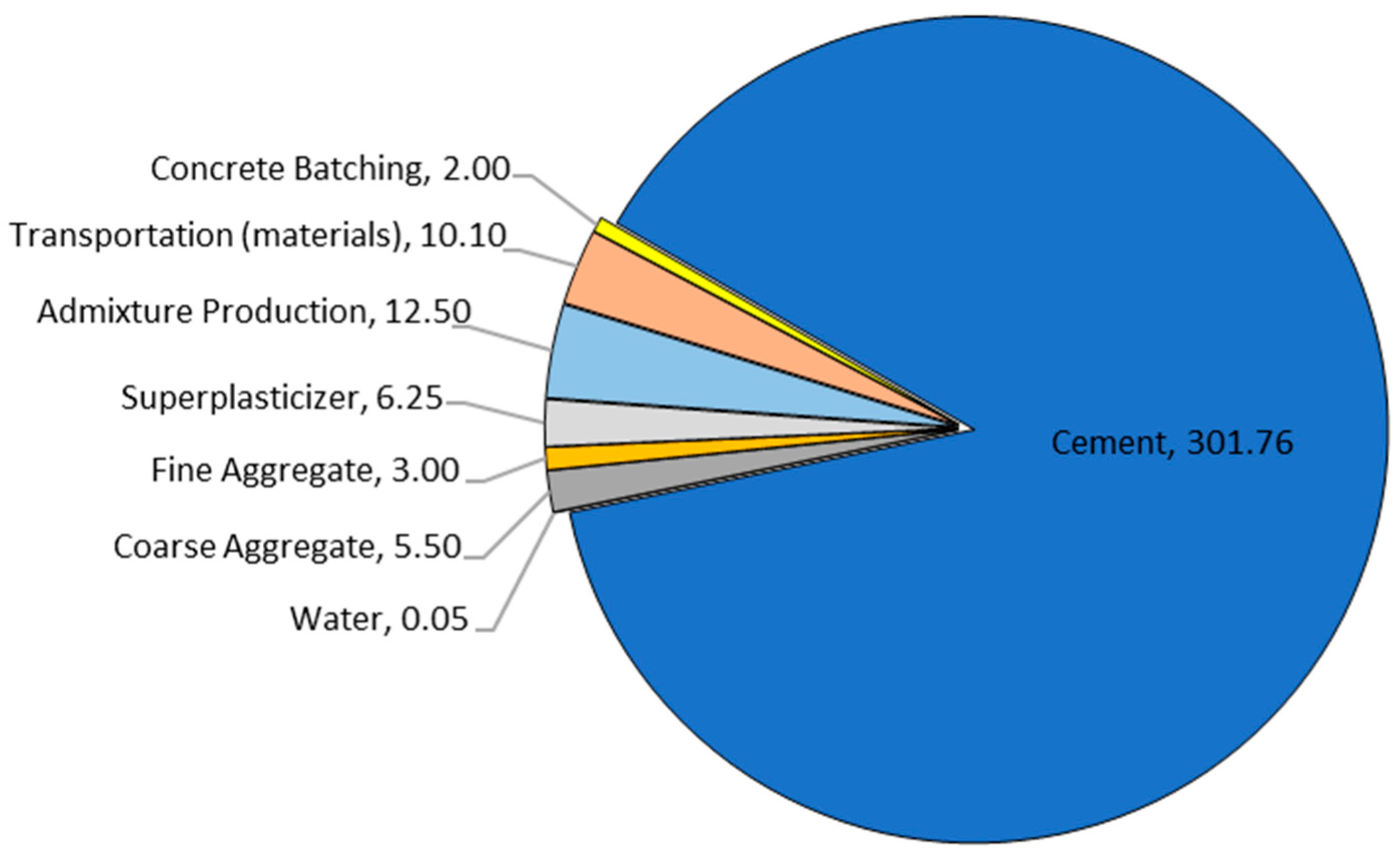

- Cement is the largest contributor to the carbon footprint of concrete due to its energy-intensive production. Aggregates and admixtures contribute smaller but meaningful emissions, while transportation and batching also add to the total footprint.

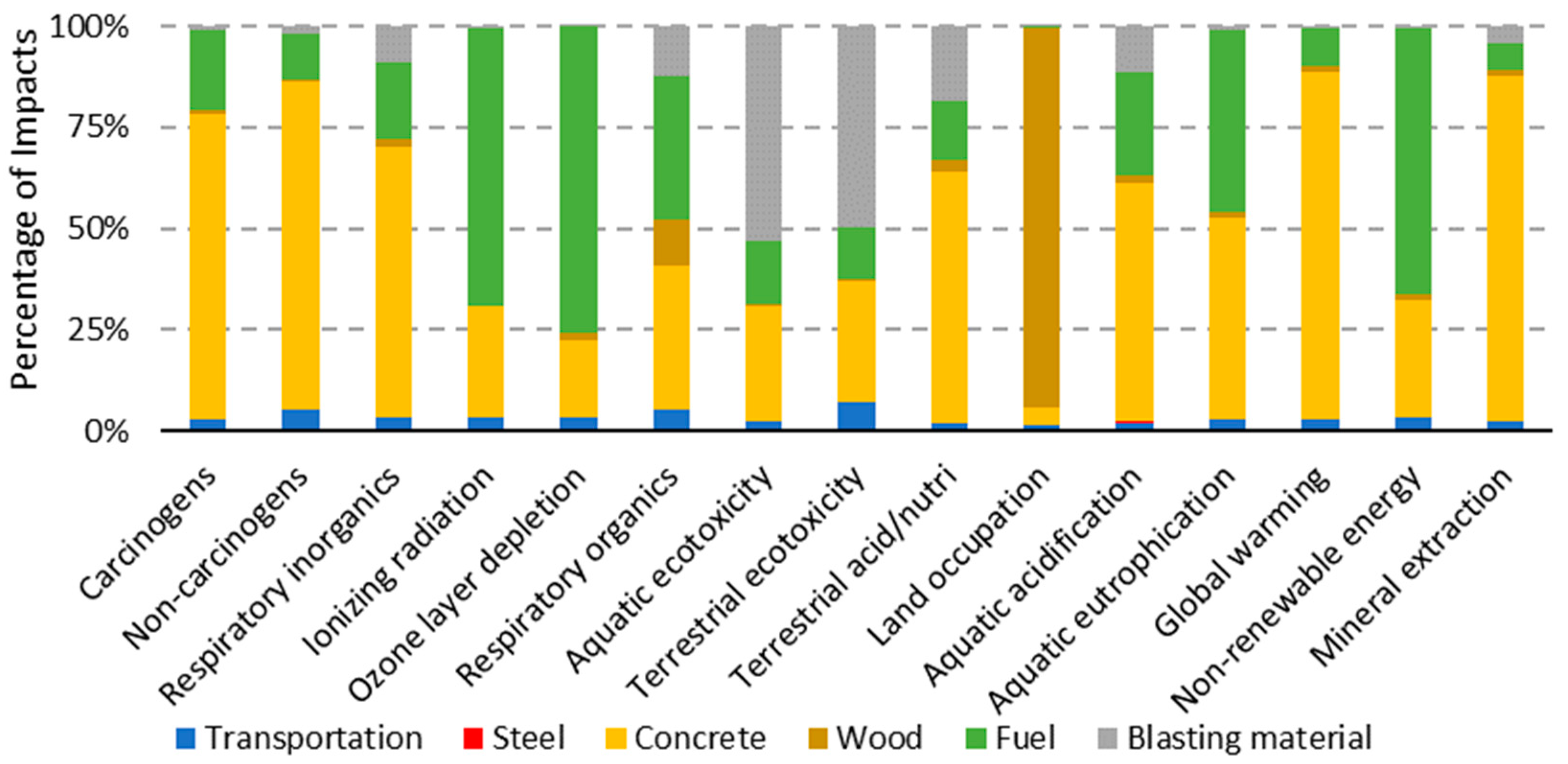

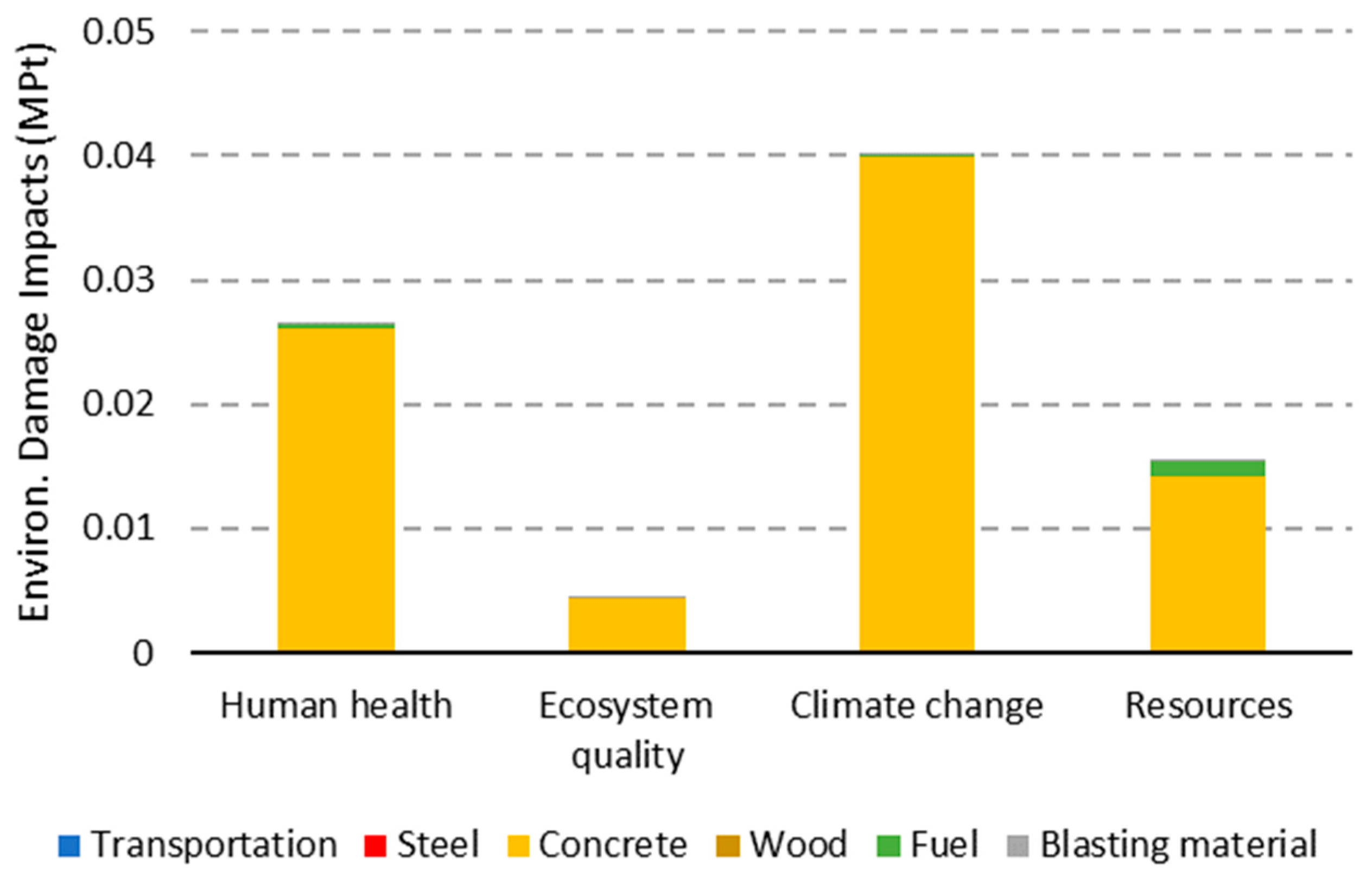

- The findings highlight the significant environmental impact of concrete production and fuel usage, which are the primary contributors to carbon emissions in construction of 1 m width of the dam, with total CO2 eq emissions reaching 355 ton/m. Concrete alone accounts for over 305 ton CO2 eq/m. The project’s non-renewable energy consumption exceeds 5,700,000 MJ/m, largely driven by concrete and fuel.

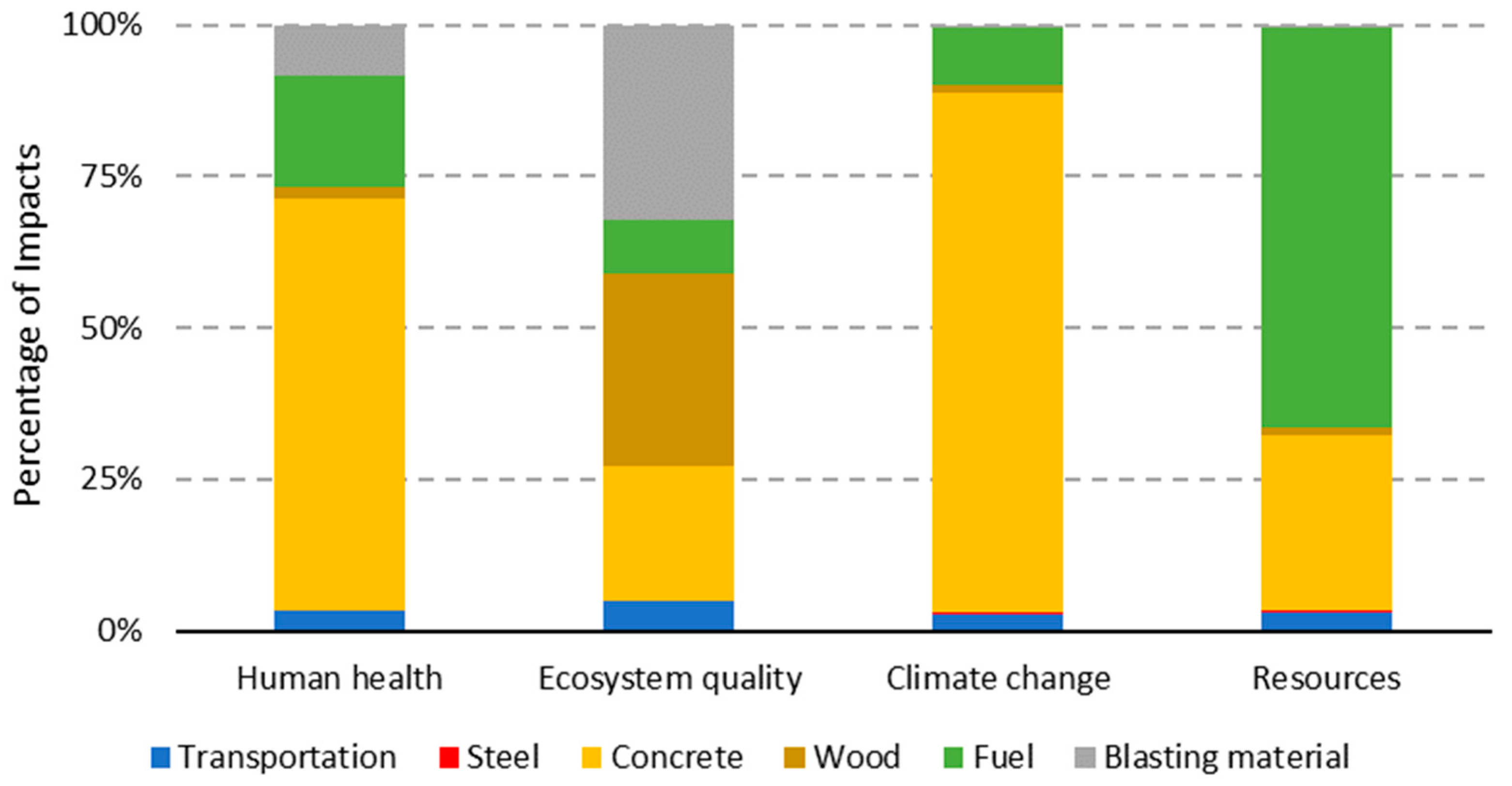

- Climate change and human health rank as the top environmental concerns, with concrete consistently emerging as the dominant factor in these categories. These findings reinforce the importance of addressing material production and energy consumption to mitigate environmental impacts, particularly in large-scale construction projects such as dam construction.

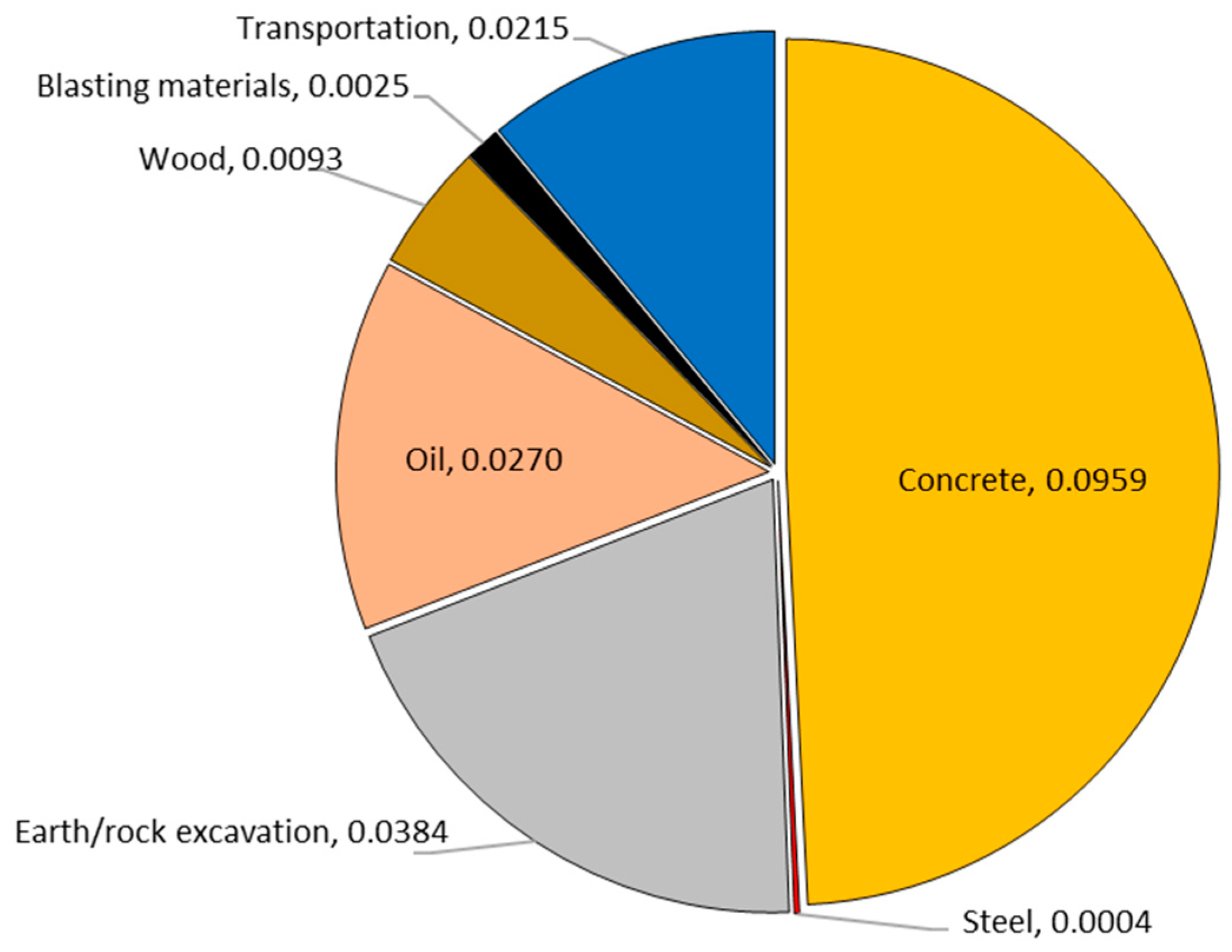

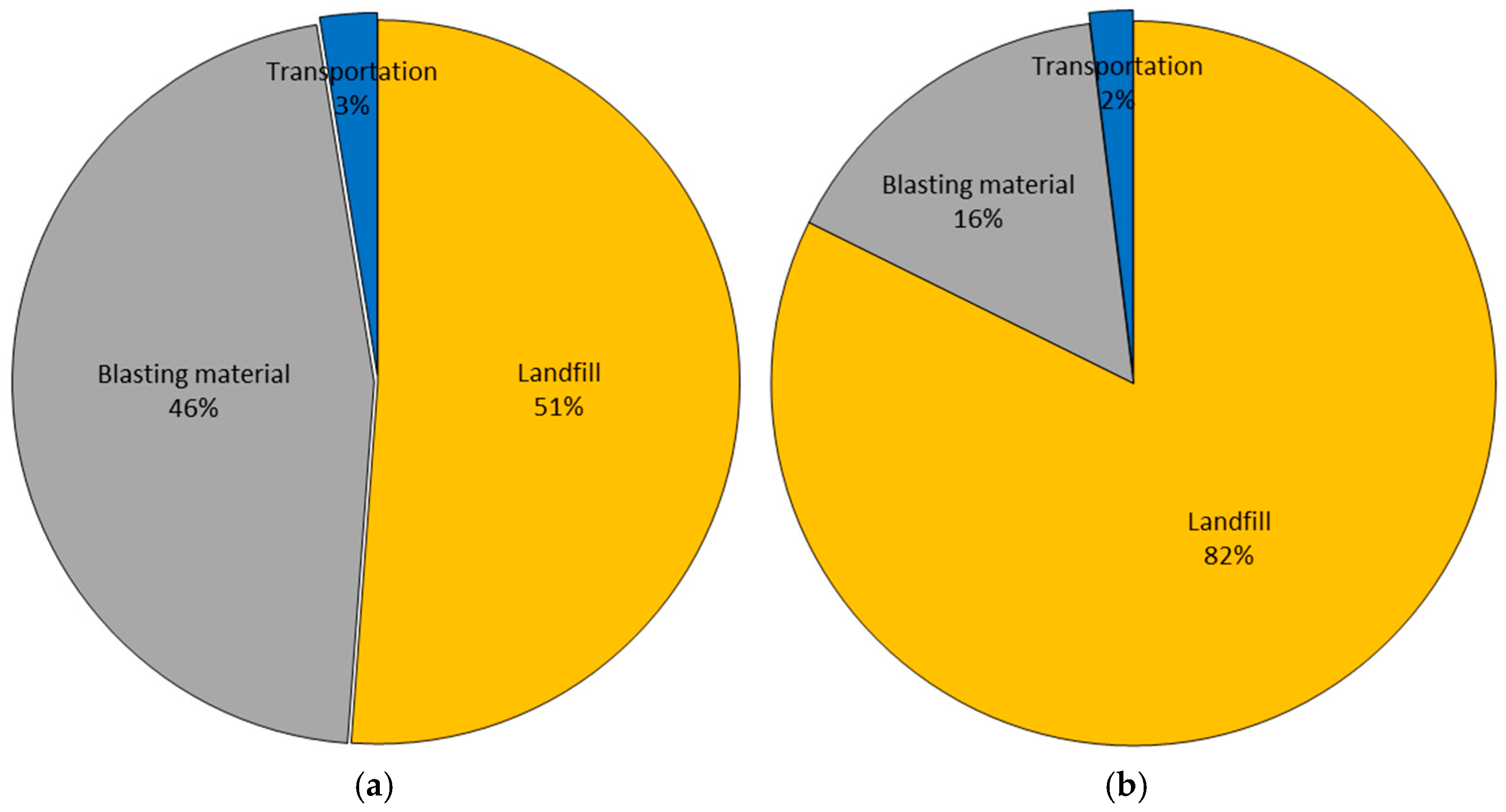

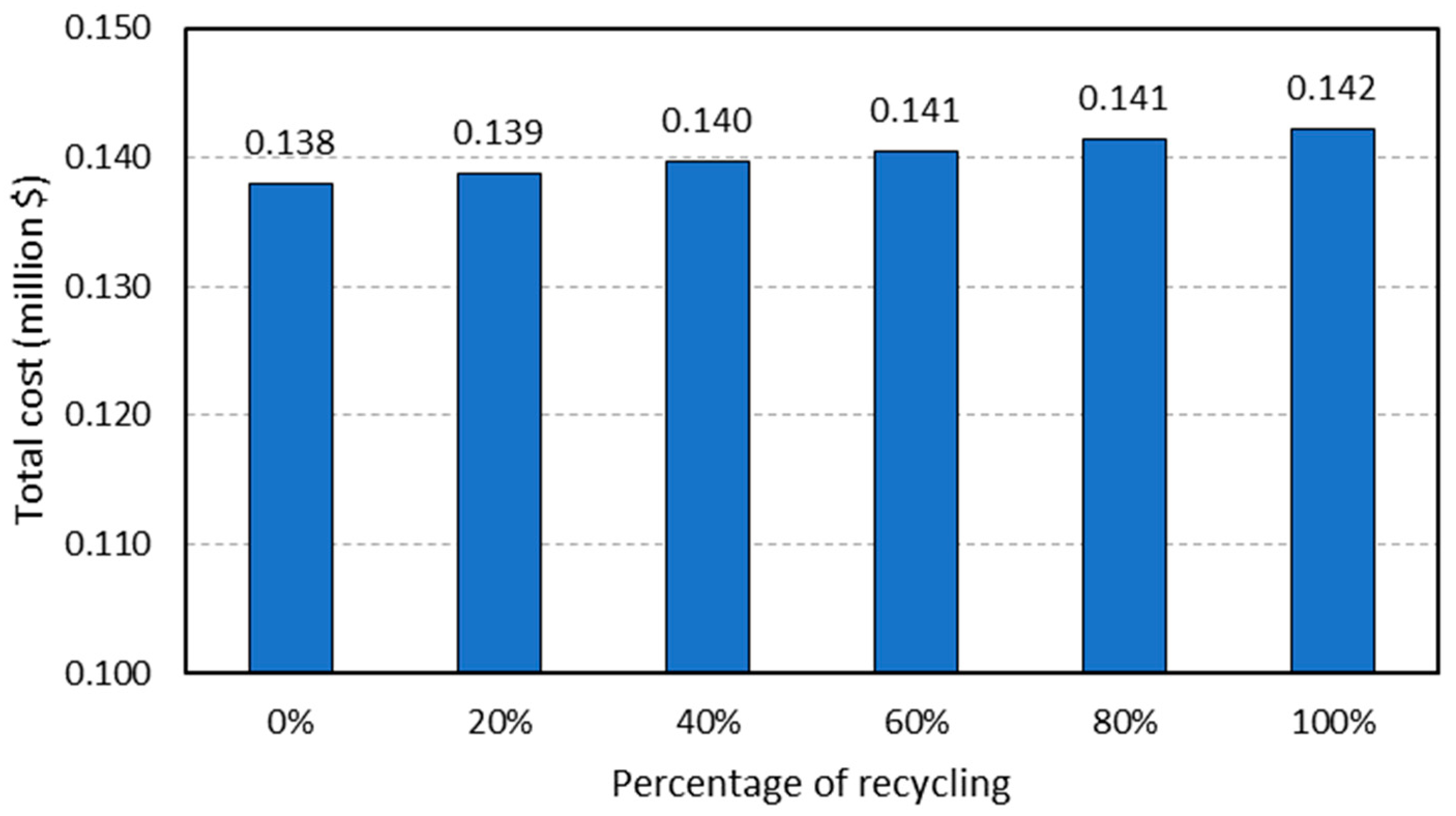

- The total estimated cost for the dam’s construction phase is approximately USD 0.195 million, with concrete being the most significant contributor, accounting for USD 0.0959 million. Excavation is the second-largest cost at USD 0.0384 million, followed by oil usage at USD 0.0270 million. The overall cost for the decommissioning of the dam is estimated at around USD 0.138 million. Integrating the recycling of concrete and steel leads to an augmentation in the overall cost of dam demolition. To illustrate, if all the employed steel and concrete are recycled, the total cost for the dam’s demolition escalates to USD 0.142 million.

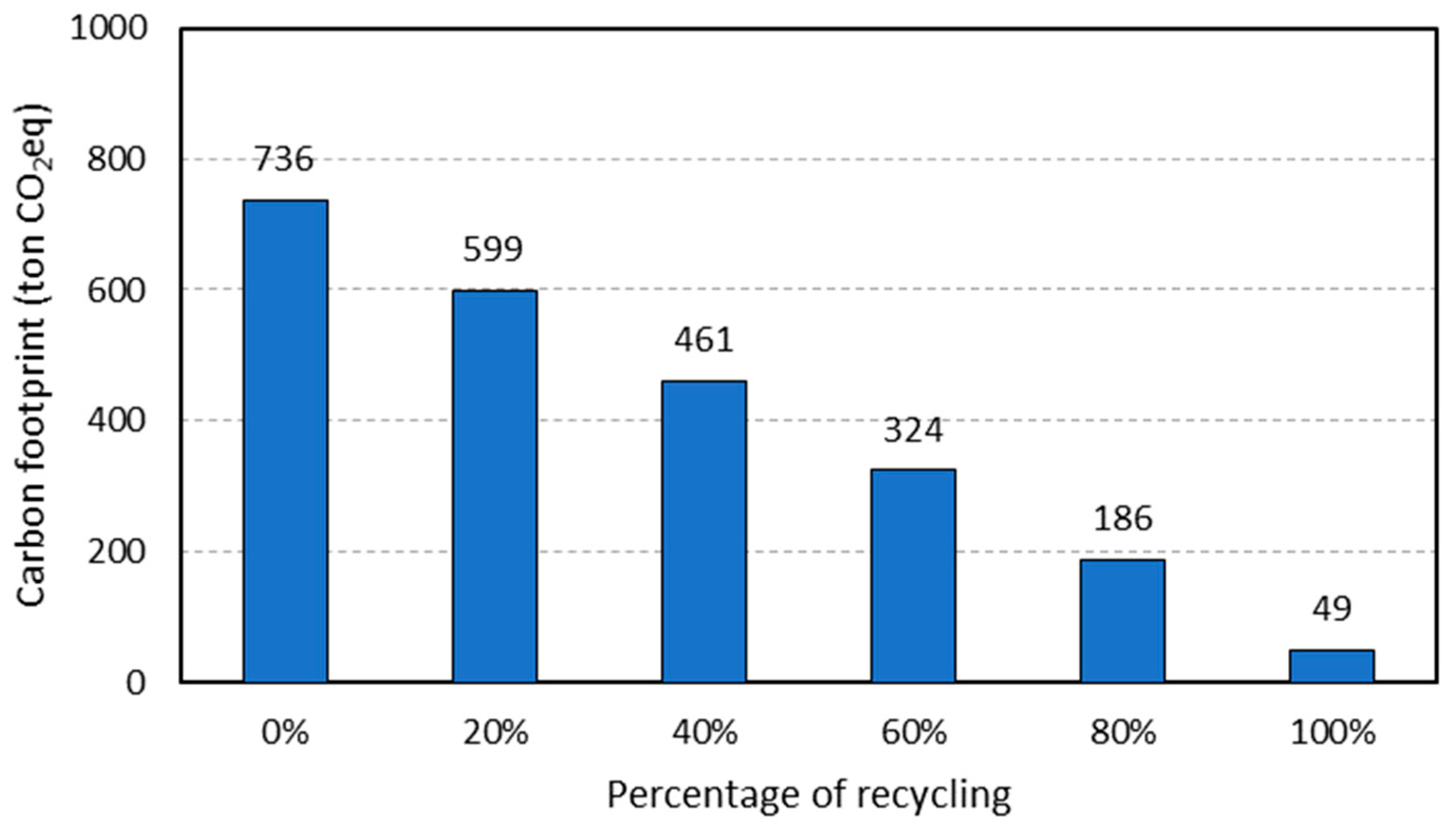

- The carbon footprint resulting from the decommissioning process, excluding recycling, was assessed using CFA and amounted to around 735 ton CO2 eq/m. The outcomes underscore the considerable influence of material recycling on the carbon footprint, demonstrating a notable 95% reduction in greenhouse gas emissions. Recycling concrete as RCA not only reduces waste and conserves natural resources, but also significantly lowers the carbon footprint by decreasing the demand for virgin aggregate extraction. Recycled steel, similarly, can be repurposed in various construction applications, promoting a circular economy approach. These practices contribute to environmental and economic benefits by minimizing landfill usage, reducing greenhouse gas emissions, and aligning with sustainable development goals.

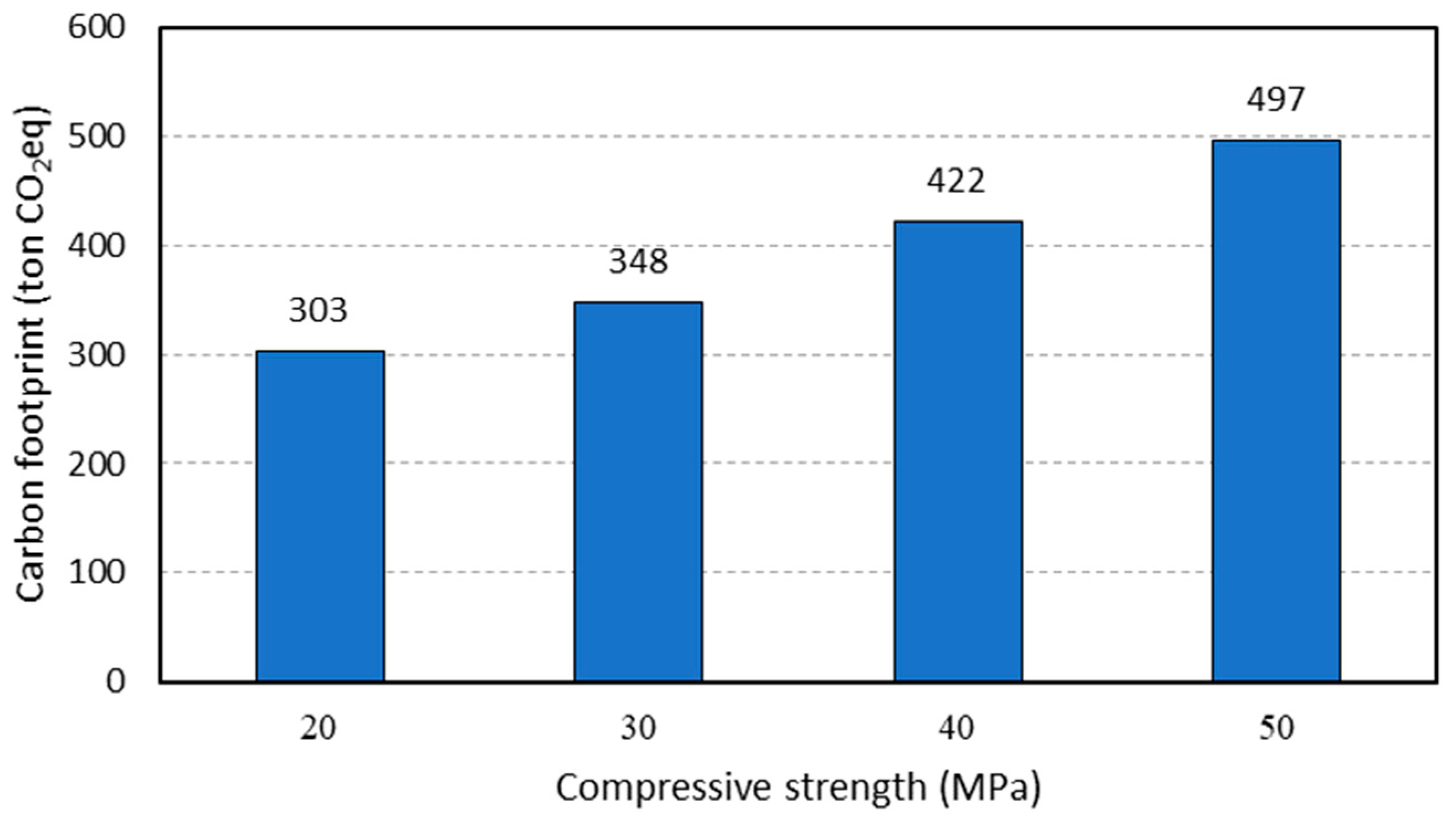

- While lower compressive strength requires more concrete, its total carbon footprint remains lower due to its reduced cement content. Conversely, increasing compressive strength reduces concrete volume, but significantly raises carbon emissions, as cement consumption is the primary contributor to greenhouse gas emissions.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFA | Carbon footprint analysis |

| GHGs | Greenhouse gases |

| LCA | Life cycle assessment |

| LCC | Life cycle costs |

| LCI | Life cycle inventory |

| RCA | Recycled concrete aggregate |

References

- Mostafaei, H. Modal Identification Techniques for Concrete Dams: A Comprehensive Review and Application. Sci 2024, 6, 40. [Google Scholar] [CrossRef]

- Schmitt, R.J.P.; Rosa, L. Dams for hydropower and irrigation: Trends, challenges, and alternatives. Renew. Sustain. Energy Rev. 2024, 199, 114439. [Google Scholar] [CrossRef]

- Angelakis, A.N.; Baba, A.; Valipour, M.; Dietrich, J.; Fallah-Mehdipour, E.; Krasilnikoff, J.; Bilgic, E.; Passchier, C.; Tzanakakis, V.A.; Kumar, R. Water Dams: From ancient to present times and into the future. Water 2024, 16, 1889. [Google Scholar] [CrossRef]

- Mostafaei, H.; Bahmani, H. Sustainable High-Performance Concrete Using Zeolite Powder: Mechanical and Carbon Footprint Analyses. Buildings 2024, 14, 3660. [Google Scholar] [CrossRef]

- Ali, H.O. Advancing integrated water resources management approaches for the sustainability of small dams in arid and semi-arid regions: A case study of the Um Dafoug dam in South Darfur State, Sudan. Int. J. Water Resour. Environ. Eng. 2025, 17, 1–16. [Google Scholar]

- Bahmani, H.; Mostafaei, H.; Santos, P.; Fallah Chamasemani, N. Enhancing the mechanical properties of Ultra-High-Performance Concrete (UHPC) through silica sand replacement with steel slag. Buildings 2024, 14, 3520. [Google Scholar] [CrossRef]

- Udara Willhelm Abeydeera, L.H.; Wadu Mesthrige, J.; Samarasinghalage, T.I. Global research on carbon emissions: A scientometric review. Sustainability 2019, 11, 3972. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of environmental sustainability and circular economy through construction waste management for material reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- Santos, P.; Cervantes, G.C.; Zaragoza-Benzal, A.; Byrne, A.; Karaca, F.; Ferrández, D.; Salles, A.; Bragança, L. Circular Material Usage Strategies and Principles in Buildings: A Review. Buildings 2024, 14, 281. [Google Scholar] [CrossRef]

- Al Omar, S.; Abdelhadi, A. Comparative Life-Cycle Assessment of Steel and GFRP Rebars for Procurement Sustainability in the Construction Industry. Sustainability 2024, 16, 3899. [Google Scholar] [CrossRef]

- Saffari, R.; Habibagahi, G.; Nikooee, E.; Niazi, A. Biological stabilization of a swelling fine-grained soil: The role of microstructural changes in the shear behavior. Iran. J. Sci. Technol. Trans. Civ. Eng. 2017, 41, 405–414. [Google Scholar] [CrossRef]

- Shabani, K.; Bahmani, M.; Fatehi, H.; Chang, I. Improvement of the geotechnical engineering properties of dune sand using a plant-based biopolymer named serish. Geomech. Eng. 2022, 29, 535–548. [Google Scholar]

- Banias, G.F.; Karkanias, C.; Batsioula, M.; Melas, L.D.; Malamakis, A.E.; Geroliolios, D.; Skoutida, S.; Spiliotis, X. Environmental assessment of alternative strategies for the management of construction and demolition waste: A life cycle approach. Sustainability 2022, 14, 9674. [Google Scholar] [CrossRef]

- Zhang, L.W.; Sojobi, A.O.; Kodur, V.K.R.; Liew, K.M. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J. Clean. Prod. 2019, 236, 117600. [Google Scholar] [CrossRef]

- Yu, Y.; Pacheco-Torgal, F.; Zhao, X.-Y.; Wang, X.-L. Cleaner production of the precast concrete industry: Comparative life cycle analysis of concrete using recycled aggregates from crushed precast rejects. Eur. J. Environ. Civ. Eng. 2024, 28, 1014–1038. [Google Scholar] [CrossRef]

- Mostafaei, H.; Rostampour, M.A.; Chamasemani, N.F.; Wu, C. An In-Depth Exploration of Carbon Footprint Analysis in the Construction Sector with Emphasis on the Dam Industry. In Carbon Footprint Assessments: Case Studies & Best Practices; Springer: Berlin/Heidelberg, Germany, 2024; pp. 45–80. [Google Scholar]

- Song, C.; Gardner, K.H.; Klein, S.J.W.; Souza, S.P.; Mo, W. Cradle-to-grave greenhouse gas emissions from dams in the United States of America. Renew. Sustain. Energy Rev. 2018, 90, 945–956. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; van der Meide, M.; Di Maio, F.; Yang, X.; Gao, X.; Li, K.; Zhao, H.; Li, C. Life cycle assessment of material footprint in recycling: A case of concrete recycling. Waste Manag. 2023, 155, 311–319. [Google Scholar] [CrossRef] [PubMed]

- Suwanit, W.; Gheewala, S.H. Life cycle assessment of mini-hydropower plants in Thailand. Int. J. Life Cycle Assess. 2011, 16, 849–858. [Google Scholar] [CrossRef]

- Chhun, B.; Bonnet, S.; Gheewala, S.H. Life cycle assessment of the Kamchay hydropower plant in Cambodia. J. Sustain. Energy Environ. 2021, 12, 23–33. [Google Scholar]

- Pang, M.; Zhang, L.; Wang, C.; Liu, G. Environmental life cycle assessment of a small hydropower plant in China. Int. J. Life Cycle Assess. 2015, 20, 796–806. [Google Scholar] [CrossRef]

- Sadok, R.H.; Belaribi, N.B.; Mazouzi, R.; Sadok, F.H. Life cycle assessment of cementitious materials based on calcined sediments from Chorfa II dam for low carbon binders as sustainable building materials. Sci. Total Environ. 2022, 826, 154077. [Google Scholar] [CrossRef] [PubMed]

- Pacca, S. Impacts from decommissioning of hydroelectric dams: A life cycle perspective. Clim. Change 2007, 84, 281–294. [Google Scholar] [CrossRef]

- Rosa, L.P.; Dos Santos, M.A.; Matvienko, B.; Dos Santos, E.O.; Sikar, E. Greenhouse gas emissions from hydroelectric reservoirs in tropical regions. Clim. Change 2004, 66, 9–21. [Google Scholar] [CrossRef]

- Fearnside, P.M. Greenhouse gas emissions from hydroelectric dams in tropical forests. In Alternative Energy and Shale Gas Encyclopedia; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 426–436. [Google Scholar]

- Zhang, S.; Zhang, S.; Wu, Z.; Wang, X.; Jiang, Z.; Wang, C.; Zhao, G. IFC-enabled LCA for carbon assessment in pumped storage hydropower (PSH) with concrete face rockfill dams. Autom. Constr. 2023, 156, 105121. [Google Scholar] [CrossRef]

- Liu, C.; Ahn, C.R.; An, X.; Lee, S. Life-cycle assessment of concrete dam construction: Comparison of environmental impact of rock-filled and conventional concrete. J. Constr. Eng. Manag. 2013, 139, A4013009. [Google Scholar] [CrossRef]

- Zhang, S.; Pang, B.; Zhang, Z. Carbon footprint analysis of two different types of hydropower schemes: Comparing earth-rockfill dams and concrete gravity dams using hybrid life cycle assessment. J. Clean. Prod. 2015, 103, 854–862. [Google Scholar] [CrossRef]

- IS 6512; Criteria for Design of Solid Gravity Dams (Second Revision). Bureau of Indian Standards (BIS): New Delhi, India, 2019.

- Sharma, S. Fostering Green Product Design and Innovation for a Sustainable Future. In Waste Management and Life Cycle Assessment for Sustainable Business Practice; IGI Global: Hershey, PA, USA, 2024; pp. 86–110. [Google Scholar]

- Sakib, M.N.; Kabir, G.; Ali, S.M. A life cycle analysis approach to evaluate sustainable strategies in the furniture manufacturing industry. Sci. Total Environ. 2024, 907, 167611. [Google Scholar] [CrossRef]

- Akintayo, B.D.; Babatunde, O.M.; Olanrewaju, O.A. Comparative Analysis of Cement Production Methods Using a Life Cycle Assessment and a Multicriteria Decision-Making Approach. Sustainability 2024, 16, 484. [Google Scholar] [CrossRef]

- Yuguda, T.K.; Li, Y.; Xiong, W.; Zhang, W. Life cycle assessment of options for retrofitting an existing dam to generate hydro-electricity. Int. J. Life Cycle Assess. 2020, 25, 57–72. [Google Scholar] [CrossRef]

- Curran, M.A. Life-Cycle Assessment: Principles and Practice; National Risk Management Research Laboratory, Office of Research and Development, U.S. Environmental Protection Agency: Cincinnati, OH, USA, 2006. [Google Scholar]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- Momotaz, H.; Rahman, M.M.; Karim, M.R.; Zhuge, Y.; Ma, X.; Levett, P. Comparative study on properties of kerb concrete made from recycled materials and related carbon footprint. J. Build. Eng. 2023, 72, 106484. [Google Scholar] [CrossRef]

- Wang, C.; Chen, B.; Vo, T.L.; Rezania, M. Mechanical anisotropy, rheology and carbon footprint of 3D printable concrete: A review. J. Build. Eng. 2023, 76, 107309. [Google Scholar] [CrossRef]

- Mostafaei, H.; Kelishadi, M.; Bahmani, H.; Wu, C.; Ghiassi, B. Development of sustainable HPC using rubber powder and waste wire: Carbon footprint analysis, mechanical and microstructural properties. Eur. J. Environ. Civ. Eng. 2025, 29, 399–420. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. Sustainable high-performance concrete with sugar factory lime waste-activated slag and fiber reinforcement: Mechanical properties and environmental impact. Constr. Build. Mater. 2025, 464, 140202. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. A novel development of ultra-high-performance concrete with calcium oxide-activated materials and fibers: Engineering properties and sustainability evaluation. Mag. Concr. Res. 2024, 76, 882–902. [Google Scholar] [CrossRef]

- Cordoba, G.; Irassar, E.F. Carbon footprint of reinforced concrete columns with and without supplementary cementitious materials. Int. J. Life Cycle Assess. 2023, 28, 800–812. [Google Scholar] [CrossRef]

- Hassan, H.F.; Al-Shamsi, K.; Al-Jabri, K. Effect of Steel Slag on the Permanent Deformation and Life Cycle Cost of Asphalt Concrete Pavements. Int. J. Pavement Res. Technol. 2023, 17, 1513–1530. [Google Scholar] [CrossRef]

- Njotea, B.A.; Okonkwo, V.O.; Mezie, E.O.; Nwankwoeke, C.H. Investigation of the Economic and Life Cycle Cost Benefits of Concrete Pavement over Asphalt Pavement: Case Study of Isieke Road, Ebonyi State. Saudi J. Civ. Eng. 2023, 7, 29–39. [Google Scholar]

- Kromoser, B.; Butler, M.; Hunger, M.; Kimm, M.; Kopf, F.; Mechtcherine, V.; Pressmair, N.; Traverso, M. Article of RILEM TC 292-MCC: Life cycle assessment (LCA) of non-metallic reinforcement for reinforcing concrete: Manufacturing, durability, dismantling, recycling and reuse: A review. Mater. Struct. 2023, 56, 126. [Google Scholar] [CrossRef]

- Ellingwood, B.; Tekie, P.B. Fragility analysis of concrete gravity dams. J. Infrastruct. Syst. 2001, 7, 41–48. [Google Scholar] [CrossRef]

- Leclerc, M.; Léger, P.; Tinawi, R. Computer aided stability analysis of gravity dams—CADAM. Adv. Eng. Softw. 2003, 34, 403–420. [Google Scholar] [CrossRef]

- Tekie, P.B.; Ellingwood, B.R. Seismic fragility assessment of concrete gravity dams. Earthq. Eng. Struct. Dyn. 2003, 32, 2221–2240. [Google Scholar] [CrossRef]

- Baghlani, A.; Sattari, M.; Makiabadi, M.H. Application of genetic programming in shape optimization of concrete gravity dams by metaheuristics. Cogent Eng. 2014, 1, 982348. [Google Scholar] [CrossRef]

- Gauthier, D. European Cement Research Academy Technical Report; Report, no. 1001-0742; European Cement Research Academy: Duesseldorf, Germany, 2015. [Google Scholar]

| Material or Operation | Value (ton) | Transportation (km) |

|---|---|---|

| Concrete | 2142 | 30 |

| Steel and rebar | 0.35 | 550 |

| Blasting | 4.14 | 620 |

| Fuel oil | 66.3 | 150 |

| Wood | 27 | 150 |

| Earth and rock excavation | 192 | 25 |

| Construction Material or Operation | Unit Cost ($) |

|---|---|

| Concrete (USD/ton) | 45 |

| Wood (USD/ton) | 345 |

| Fuel oil (USD/ton) | 407 |

| Steel and Rebar (USD/ton) | 1050 |

| Earth and rock excavation (USD/ton) | 200 |

| Transportation (USD/ton.km) | 0.25 |

| Blasting materials (USD/ton) | 599 |

| Landfill (USD/ton) | 23 |

| Recycling concrete (USD/ton) | 55 |

| Impact Category | Total |

|---|---|

| Carcinogens (ton C2H3Cl eq) | 2.405 |

| Non-carcinogens (ton C2H3Cl eq) | 5.059 |

| Respiratory inorganics (ton PM2.5 eq) | 0.269 |

| Ionizing radiation (Bq C-14 eq) | 2,384,000 |

| Ozone layer depletion (ton CFC-11 eq) | 0.00006 |

| Respiratory organics (ton C2H4 eq) | 0.126 |

| Aquatic ecotoxicity (ton TEG water) | 58,727 |

| Terrestrial ecotoxicity (ton TEG soil) | 16,074 |

| Terrestrial acid (ton SO2 eq) | 6.253 |

| Land occupation (m2org.arable) | 62,759 |

| Aquatic acidification (ton SO2 eq) | 1.348 |

| Aquatic eutrophication (ton PO4 P-lim) | 0.042 |

| Global warming (ton CO2 eq) | 355 |

| Non-renewable energy (MJ primary) | 5,700,000 |

| Mineral extraction (MJ surplus) | 5215 |

| Damage Category | Total |

|---|---|

| Human health (DALY) | 0.210 |

| Ecosystem quality (PDF m2 r) | 205,000 |

| Climate change (kg CO2 eq) | 355 |

| Resources (MJ primary) | 5,700,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mostafaei, H.; Chamasemani, N.F.; Mashayekhi, M.; Hamzehkolaei, N.S.; Santos, P. Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling. Appl. Sci. 2025, 15, 2479. https://doi.org/10.3390/app15052479

Mostafaei H, Chamasemani NF, Mashayekhi M, Hamzehkolaei NS, Santos P. Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling. Applied Sciences. 2025; 15(5):2479. https://doi.org/10.3390/app15052479

Chicago/Turabian StyleMostafaei, Hasan, Niyousha Fallah Chamasemani, Mohammadreza Mashayekhi, Naser Safaeian Hamzehkolaei, and Paulo Santos. 2025. "Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling" Applied Sciences 15, no. 5: 2479. https://doi.org/10.3390/app15052479

APA StyleMostafaei, H., Chamasemani, N. F., Mashayekhi, M., Hamzehkolaei, N. S., & Santos, P. (2025). Sustainability Enhancement and Evaluation of a Concrete Dam Using Recycling. Applied Sciences, 15(5), 2479. https://doi.org/10.3390/app15052479