Effect of High Hydrostatic Pressure on the Quality Parameters of Wild Red Deer (Cervus elaphus) Meat

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Pressure Treatment

2.3. pH Determination

2.4. Instrumental Color Measurement

2.5. Microbiological Evaluation

2.6. Instrumental Texture Measurement

2.7. Analysis of Sarcoplasmic and Myofibrillar Proteins by Sodium Dodecyl-Sulfate Polyacrylamide Gel Electrophoresis

2.7.1. Isolation of Sarcoplasmic and Myofibrillar Proteins

2.7.2. SDS-PAGE Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. pH

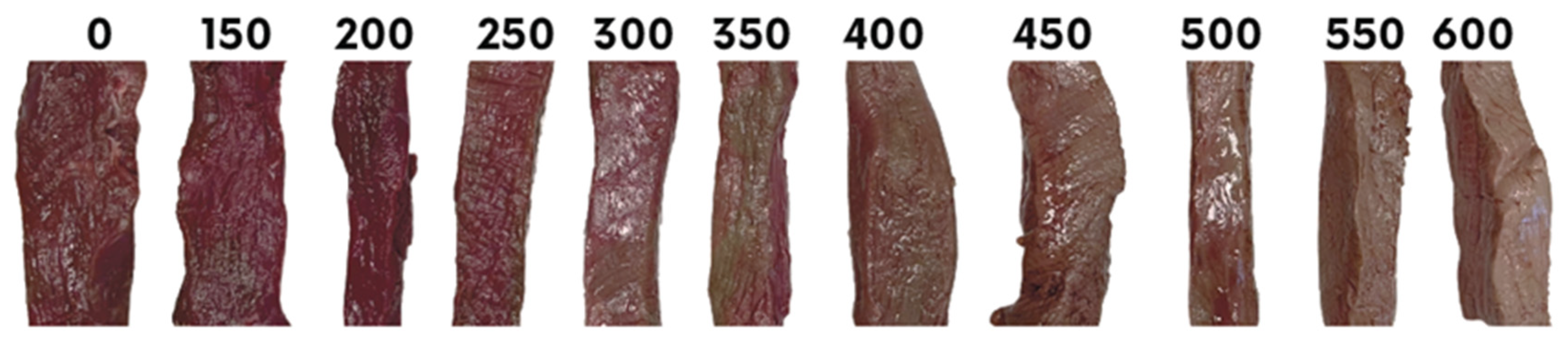

3.2. Surface Color

3.3. Microbiological Evaluation

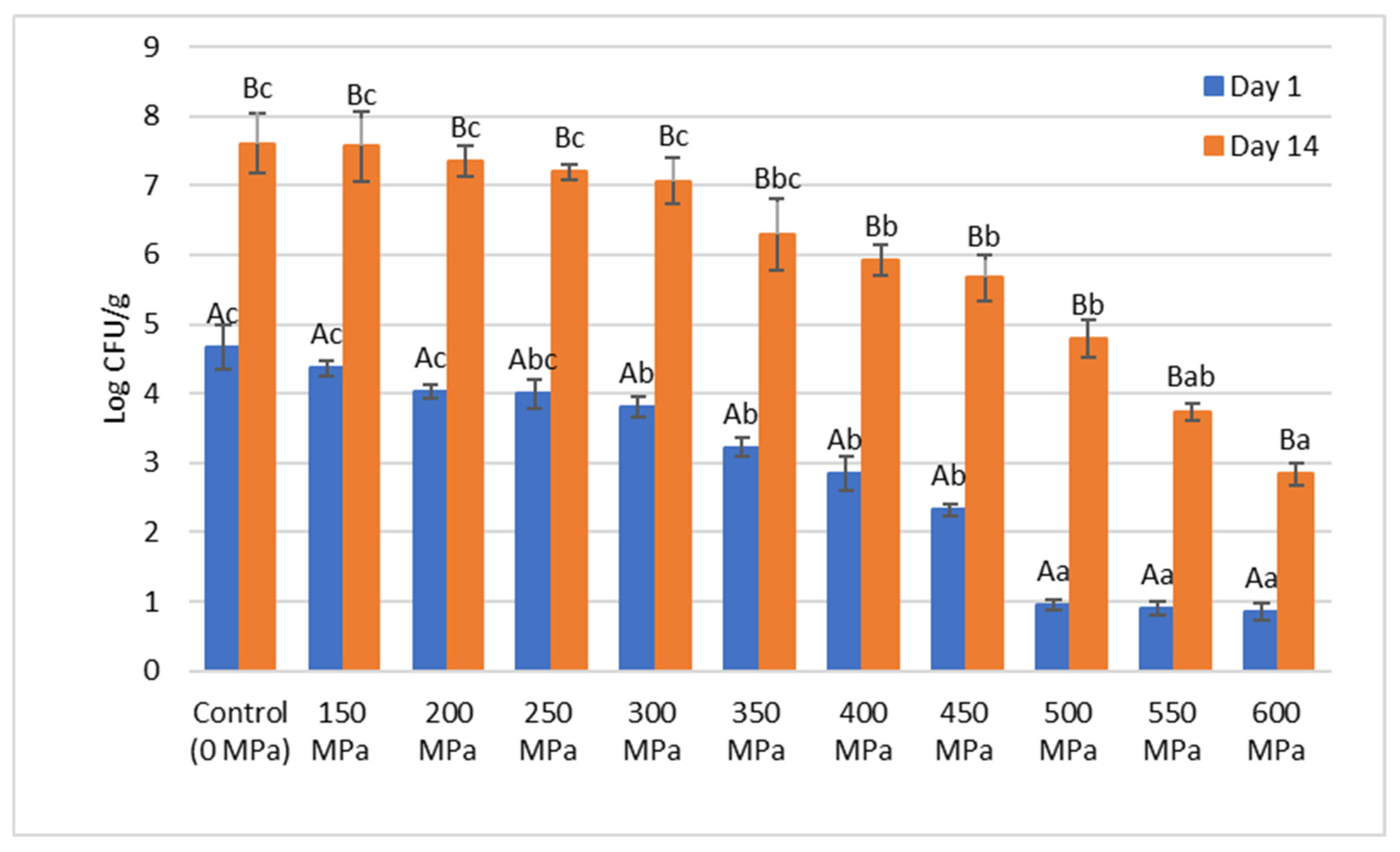

3.4. Texture Analysis

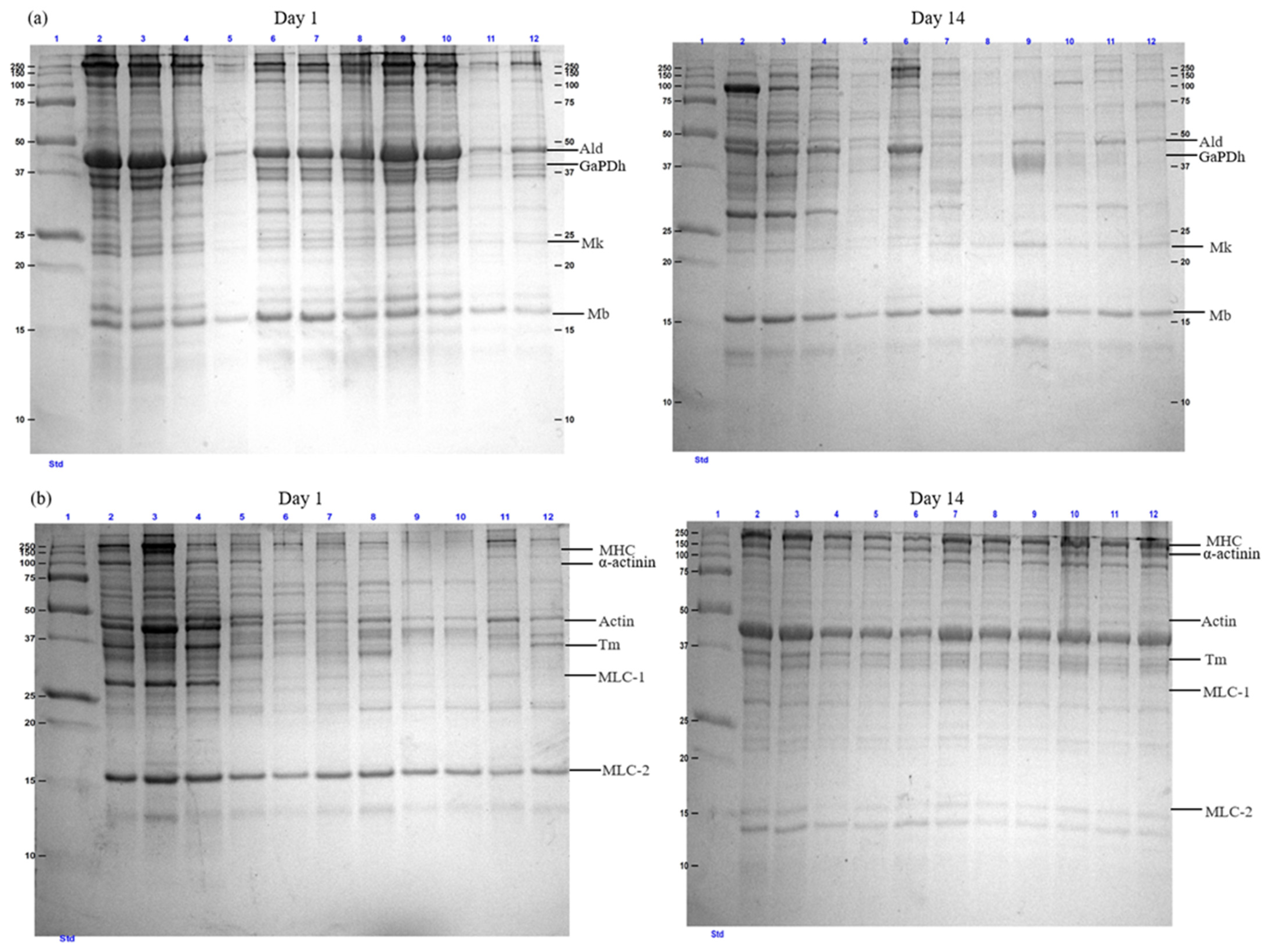

3.5. Protein Profile Analysis Using SDS-PAGE

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milczarek, A.; Janocha, A.; Niedziałek, G.; Zowczak-Romanowicz, M.; Horoszewicz, E.; Piotrowski, S. Health-Promoting Properties of the Wild-Harvested Meat of Roe Deer (Capreolus capreolus L.) and Red Deer (Cervus elaphus L.). Animals 2021, 11, 2108. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Maggiolino, A.; Gallego, L.; Pateiro, M.; Serrano, M.P.; Domínguez, R.; García, A.; Landete-Castillejos, T.; De Palo, P. Effect of Age on Nutritional Properties of Iberian Wild Red Deer Meat. J. Sci. Food Agric. 2019, 99, 1561–1567. [Google Scholar] [CrossRef] [PubMed]

- Kudrnáčová, E.; Bartoň, L.; Bureš, D.; Hoffman, L.C. Carcass and Meat Characteristics from Farm-Raised and Wild Fallow Deer (Dama Dama) and Red Deer (Cervus Elaphus): A Review. Meat Sci. 2018, 141, 9–27. [Google Scholar] [CrossRef]

- de Oliveira, F.A.; Neto, O.C.; dos Santos, L.M.R.; Ferreira, E.H.R.; Rosenthal, A. Effect of High Pressure on Fish Meat Quality–A Review. Trends Food Sci. Technol. 2017, 66, 1–19. [Google Scholar] [CrossRef]

- Bak, K.H.; Lindahl, G.; Karlsson, A.H.; Orlien, V. Effect of High Pressure, Temperature, and Storage on the Color of Porcine Longissimus Dorsi. Meat Sci. 2012, 92, 374–381. [Google Scholar] [CrossRef]

- Morton, J.D.; Pearson, R.G.; Lee, H.Y.-Y.; Smithson, S.; Mason, S.L.; Bickerstaffe, R. High Pressure Processing Improves the Tenderness and Quality of Hot-Boned Beef. Meat Sci. 2017, 133, 69–74. [Google Scholar] [CrossRef]

- Omana, D.A.; Plastow, G.; Betti, M. The Use of β-Glucan as a Partial Salt Replacer in High Pressure Processed Chicken Breast Meat. Food Chem. 2011, 129, 768–776. [Google Scholar] [CrossRef]

- Yang, H.; Khan, M.A.; Yu, X.; Zheng, H.; Han, M.; Xu, X.; Zhou, G. Changes in Protein Structures to Improve the Rheology and Texture of Reduced-Fat Sausages Using High Pressure Processing. Meat Sci. 2016, 121, 79–87. [Google Scholar] [CrossRef]

- Sikes, A.L.; Warner, R. Application of High Hydrostatic Pressure for Meat Tenderization. In Innovative Food Processing Technologies; Elsevier: Amsterdam, The Netherlands, 2016; pp. 259–290. [Google Scholar]

- Marcos, B.; Aymerich, T.; Garriga, M.; Arnau, J. Active Packaging Containing Nisin and High Pressure Processing as Post-Processing Listericidal Treatments for Convenience Fermented Sausages. Food Control 2013, 30, 325–330. [Google Scholar] [CrossRef]

- Han, G.; Chen, Q.; Xia, X.; Liu, Q.; Kong, B.; Wang, H. High Hydrostatic Pressure Combined with Moisture Regulators Improves the Tenderness and Quality of Beef Jerky. Meat Sci. 2021, 181, 108617. [Google Scholar] [CrossRef]

- Duma-Kocan, P.; Rudy, M.; Gil, M.; Żurek, J.; Stanisławczyk, R.; Krajewska, A.; Dziki, D. The Influence of High Hydrostatic Pressure on Selected Quality Features of Cold-Storage Pork Semimembranosus Muscle. Foods 2024, 13, 2089. [Google Scholar] [CrossRef] [PubMed]

- Ros-Polski, V.; Koutchma, T.; Xue, J.; Defelice, C.; Balamurugan, S. Effects of High Hydrostatic Pressure Processing Parameters and NaCl Concentration on the Physical Properties, Texture and Quality of White Chicken Meat. Innov. Food Sci. Emerg. Technol. 2015, 30, 31–42. [Google Scholar] [CrossRef]

- Enkhbold, M.; Lőrincz, A.; Elayan, M.; Friedrich, L.; Barkó, A.; Csurka, T.; Boros, A.; Hitka, G.; Varga-Tóth, A. Effects of Lactic Acid and Ascorbic Acid Mixture on Quality Properties of Wild Red Deer (Cervus Elaphus) Meat. Appl. Sci. 2024, 14, 8915. [Google Scholar] [CrossRef]

- ISO 4833-2:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 2: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization (ISO): Geneva, Switzerland, 2013.

- Csehi, B.; Szerdahelyi, E.; Pásztor-Huszár, K.; Salamon, B.; Tóth, A.; Zeke, I.; Jónás, G.; Friedrich, L. Changes of Protein Profiles in Pork and Beef Meat Caused by High Hydrostatic Pressure Treatment. Acta Aliment. 2016, 45, 565–571. [Google Scholar] [CrossRef]

- Kretzschmar, U. Funktionelle Eigenschaften von Sarcoplasmaproteinen. II: Emulgiereigenschaften. Fleischwirtschaft 1995, 75, 1354–1357. [Google Scholar]

- Laemmli, U.K. Cleavage of Structural Proteins during the Assembly of the Head of Bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

- Darnay, L.; Barkó, A.; Hidas, K.; Pataki, F.A.; Miklós, G.; Surányi, J.; Laczay, P. Comparison of Quality Properties of Powder Milk-based Camel Cheese Depending on Calf Rennet Concentration and Microbial Transglutaminase. Int. J. Dairy Technol. 2024, 77, 532–539. [Google Scholar] [CrossRef]

- Darnay, L.; Tóth, A.; Csehi, B.; Szepessy, A.; Horváth, M.; Pásztor-Huszár, K.; Laczay, P. The Effect of Microbial Transglutaminase on the Viscosity and Protein Network of Kefir Made from Cow, Goat, or Donkey Milk. Fermentation 2021, 7, 214. [Google Scholar] [CrossRef]

- McArdle, R.A.; Marcos, B.; Kerry, J.P.; Mullen, A.M. Influence of HPP Conditions on Selected Beef Quality Attributes and Their Stability during Chilled Storage. Meat Sci. 2011, 87, 274–281. [Google Scholar] [CrossRef]

- Szerman, N.; Barrio, Y.; Schroeder, B.; Martinez, P.; Sancho, A.M.; Sanow, C.; Vaudagna, S.R. Effect of High Hydrostatic Pressure Treatments on Physicochemical Properties, Microbial Quality and Sensory Attributes of Beef Carpaccio. Procedia Food Sci. 2011, 1, 854–861. [Google Scholar] [CrossRef]

- Şayin Sert, T.; Coşkun, F. The Effects of High-Pressure Processing on PH, Thiobarbituric Acid Value, Color and Texture Properties of Frozen and Unfrozen Beef Mince. Molecules 2022, 27, 3974. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.; Ghoul, M.; de Lamballerie-Anton, M. Influence of High Pressure on the Color and Microbial Quality of Beef Meat. LWT-Food Sci. Technol. 2003, 36, 625–631. [Google Scholar] [CrossRef]

- Chmiel, M.; Świder, O.; Roszko, M.; Adamczak, L.; Cegiełka, A.; Pietrzak, D.; Florowski, T.; Bryła, M.; Florowska, A. Effect of High-Pressure Processing and Long-Time Storage on Color, Lipid Oxidation, and Free Amino Acids Profile of Beef. Appl. Sci. 2025, 15, 2382. [Google Scholar] [CrossRef]

- Reesman, C.; Sullivan, G.; Danao, M.-G.; Pfeiffer, M.; More, S.; Mafi, G.; Ramanathan, R.; Mafi, G.G. Use of High-Pressure Processing to Improve the Redness of Dark-Cutting Beef. Meat Muscle Biol. 2023, 7, 15716. [Google Scholar] [CrossRef]

- Martínez Bernié, I.; Mussio, P.; Jorcin, S.; Rajchman, M.; López-Pedemonte, T. Application of High Hydrostatic Pressure for the Reduction of STEC on Raw Ground Beef Patties and Its Impact on Physicochemical Properties: PH and Color. LWT 2021, 151, 112126. [Google Scholar] [CrossRef]

- Garriga, M.; Grebol, N.; Aymerich, M.T.; Monfort, J.M.; Hugas, M. Microbial Inactivation after High-Pressure Processing at 600 MPa in Commercial Meat Products over Its Shelf Life. Innov. Food Sci. Emerg. Technol. 2004, 5, 451–457. [Google Scholar] [CrossRef]

- Wei, P.-C.; Lee, Y.-C.; Kang, C.; Tsai, Y.-H.; Arakawa, O. High-Hydrostatic Pressure on Escolar Meats: Impact on the Microbial, Chemical, and Organoleptic Qualities and Bacterial Community by Using High-Throughput Sequencing. LWT 2025, 215, 117196. [Google Scholar] [CrossRef]

- Kunová, S.; Sendra, E.; Haščík, P.; Vuković, N.L.; Vukić, M.D.; Hsouna, A.B.; Mnif, W.; Kačániová, M. Microbiological Quality of Deer Meat Treated with Essential Oil Litsea Cubeba. Animals 2022, 12, 2315. [Google Scholar] [CrossRef]

- Doulgeraki, A.I.; Ercolini, D.; Villani, F.; Nychas, G.-J.E. Spoilage Microbiota Associated to the Storage of Raw Meat in Different Conditions. Int. J. Food Microbiol. 2012, 157, 130–141. [Google Scholar] [CrossRef]

- Macfarlane, J.J.; McKenzie, I.J.; Turner, R.H.; Jones, P.N. Pressure Treatment of Meat: Effects on Thermal Transitions and Shear Values. Meat Sci. 1981, 5, 307–317. [Google Scholar] [CrossRef]

- Hoffman, L.C.; Wiklund, E. Game and Venison–Meat for the Modern Consumer. Meat Sci. 2006, 74, 197–208. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.D.; Holley, R.A. High Hydrostatic Pressure Effects on the Texture of Meat and Meat Products. J. Food Sci. 2010, 75, R17–R23. [Google Scholar] [CrossRef] [PubMed]

- Marcos, B.; Kerry, J.P.; Mullen, A.M. High Pressure Induced Changes on Sarcoplasmic Protein Fraction and Quality Indicators. Meat Sci. 2010, 85, 115–120. [Google Scholar] [CrossRef] [PubMed]

- Majzinger, K.; Kovács-Bányász, B.; Horváth-Mezőfi, Z.; Pósa, E.; Csehi, B.; Hitka, G.; Alpár, B.; Nyulas-Zeke, I.C. The Effects of High Hydrostatic Pressure Treatment on the Quality Characteristics and the Protein Structure of Vacuum-Packed Fresh Pork and Wild Boar Meats. Appl. Sci. 2025, 15, 1766. [Google Scholar] [CrossRef]

- Bekhit, A.E.-D.A.; Geesink, G.H.; Ilian, M.A.; Morton, J.D.; Sedcole, R.; Bickerstaffe, R. Particulate Metmyoglobin Reducing Activity and Its Relationship with Meat Color. J. Agric. Food Chem. 2003, 51, 6026–6035. [Google Scholar] [CrossRef]

| Pressure (MPa) | Day 1 | Day 14 |

|---|---|---|

| Control | 5.60 ± 0.05 bx | 5.13 ± 0.03 ax |

| 150 | 5.61 ± 0.02 bx | 5.30 ± 0.04 ax |

| 200 | 5.66 ± 0.02 ax | 5.59 ± 0.05 by |

| 250 | 5.67 ± 0.04 bx | 5.55 ± 0.04 ay |

| 300 | 5.69 ± 0.04 ay | 5.68 ± 0.03 ay |

| 350 | 5.82 ± 0.02 ay | 5.80 ± 0.03 az |

| 400 | 5.76 ± 0.03 ay | 5.93 ± 0.02 bz |

| 450 | 5.80 ± 0.03 ay | 5.92 ± 0.02 bz |

| 500 | 5.75 ± 0.05 ay | 5.88 ± 0.02 bz |

| 550 | 5.71 ± 0.03 ay | 5.85 ± 0.01 bz |

| 600 | 5.94 ± 0.03 az | 5.90 ± 0.01 az |

| Pressure (MPa) | Day 1 | Day 14 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | Hue Angle (°) | Chroma | L* | a* | b* | Hue Angle (°) | Chroma | |

| Control | 38.9 ± 1.39 ay | 17.4 ± 0.85 bx | 3.0 ± 0.57 ax | 0.17 ± 0.01 ax | 17.64 ± 0.57 ax | 35.4 ± 3.89 ax | 16.8 ± 2.04 cx | 4.9 ± 0.67 ay | 0.28 ± 0.01 ay | 17.45 ± 0.45 cx |

| 150 | 40.9 ± 1.58 ay | 15.3 ± 1.12 ax | 2.4 ± 0.48 ax | 0.16 ± 0.01 ax | 15.47 ± 0.34 ax | 36.6 ± 3.58 ax | 14.9 ± 2.47 bx | 4.6 ± 1.16 ay | 0.30 ± 0.02 ay | 15.65 ± 0.73 bx |

| 200 | 41.8 ± 0.83 aby | 15.9 ± 1.19 abx | 2.6 ± 0.77 ax | 0.16 ± 0.01 ax | 16.08 ± 0.43 ax | 38.7 ± 1.84 ax | 17.4 ± 1.58 cy | 3.5 ± 1.65 ay | 0.20 ± 0.01 ax | 17.71 ± 0.86 cy |

| 250 | 42.7 ± 2.22 by | 18.2 ± 0.87 cy | 3.8 ± 0.61 ax | 0.20 ± 0.01 ax | 18.58 ± 0.59 by | 39.3 ± 3.57 abx | 15.1 ± 2.28 bx | 5.8 ± 1.48 aby | 0.37 ± 0.02 ay | 16.18 ± 1.23 bx |

| 300 | 43.9 ± 0.99 by | 17.5 ± 0.54 bx | 3.6 ± 0.62 ax | 0.20 ± 0.01 ax | 17.84 ± 0.78 abx | 41.5 ± 1.49 bx | 17.1 ± 2.53 cx | 4.2 ± 1.72 ay | 0.24 ± 0.01 ax | 17.65 ± 0.96 cx |

| 350 | 46.8 ± 2.27 bcy | 18.2 ± 1.16 cy | 5.1 ± 1.27 abx | 0.27 ± 0.01 abx | 18.88 ± 0.92 bcy | 45.7 ± 2.8 bcx | 15.5 ± 1.74 bcx | 7.2 ± 1.27 by | 0.43 ± 0.01 by | 17.06 ± 0.83 cx |

| 400 | 48.6 ± 2.52 cy | 19.1 ± 1.48 cy | 6.5 ± 1.22 bx | 0.33 ± 0.02 bx | 20.19 ± 0.84 cy | 46.9 ± 3.17 cx | 14.2 ± 1.17 bx | 8.6 ± 0.89 by | 0.55 ± 0.02 by | 16.57 ± 1.14 bcx |

| 450 | 51.3 ± 3.12 cx | 15.1 ± 1.44 ay | 10.8 ± 0.90 cx | 0.62 ± 0.04 cx | 18.61 ± 1.12 by | 50.6 ± 5.30 cx | 11.9 ± 0.99 abx | 10.9 ± 0.80 cx | 0.74 ± 0.03 cy | 16.20 ± 0.36 bx |

| 500 | 49.7 ± 4.93 cx | 14.8 ± 2.11 ay | 11.1 ± 1.65 cx | 0.64 ± 0.01 cx | 18.56 ± 1.01 by | 50.5 ± 5.94 cx | 10.4 ± 1.09 ax | 11.6 ± 0.78 cx | 0.84 ± 0.02 cy | 15.54 ± 0.88 bx |

| 550 | 47.7 ± 2.61 bcy | 14.5 ± 1.68 ay | 10.3 ± 0.77 bcx | 0.62 ± 0.02 cx | 17.78 ± 0.97 aby | 45.9 ± 2.59 bcx | 9.3 ± 1.22 ax | 10.1 ± 0.57 cx | 0.83 ± 0.03 cy | 13.78 ± 0.62 ax |

| 600 | 49.6 ± 3.56 cx | 16.6 ± 1.96 by | 12.0 ± 0.87 cx | 0.63 ± 0.01 cx | 20.45 ± 1.16 cy | 49.8 ± 3.51 cx | 10.6 ± 1.91 ax | 11.7 ± 1.36 cx | 0.83 ± 0.01 cy | 15.78 ± 1.46 bx |

| Pressure (MPa) | Day 1 | Day 14 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Shear Force WB (N) | Hardness TPA (N) | Cohesiveness TPA (-) | Springiness TPA (mm) | Chewiness TPA (mJ) | Shear Force WB (N) | Hardness TPA (N) | Cohesiveness TPA (-) | Springiness TPA (mm) | Chewiness TPA (mJ) | |

| Control | 40.32 ± 3.89 ax | 23.90 ± 1.23 cx | 0.24 ± 0.01 ax | 0.87 ± 0.03 cx | 4.80 ± 0.12 bx | 82.19 ± 4.98 by | 21.93 ± 1.99 ax | 0.22 ± 0.01 ax | 0.88 ± 0.05 cx | 4.29 ± 0.44 ax |

| 150 | 56.94 ± 3.11 abx | 9.34 ± 1.64 ax | 0.28 ± 0.02 bx | 0.87 ± 0.04 cx | 2.47 ± 0.21 ax | 80.87 ± 5.11 by | 25.19 ± 1.23 by | 0.25 ± 0.02 bx | 0.89 ± 0.03 cx | 5.50 ± 0.34 aby |

| 200 | 59.09 ± 2.45 bx | 19.75 ± 1.45 bcx | 0.25 ± 0.01 ax | 0.79 ± 0.02 ax | 4.76 ± 0.23 bx | 86.08 ± 4.21 bcy | 26.05 ± 2.02 by | 0.22 ± 0.01 abx | 0.89 ± 0.02 cy | 5.13 ± 0.56 abx |

| 250 | 58.03 ± 4.36 bx | 18.30 ± 1.28 bx | 0.25 ± 0.01 ax | 0.88 ± 0.03 cx | 4.91 ± 0.29 bx | 69.44 ± 3.59 aby | 24.81 ± 1.34 ay | 0.24 ± 0.01 bx | 0.85 ± 0.03 bx | 4.99 ± 0.23 ax |

| 300 | 59.81 ± 2.89 bx | 10.38 ± 1.56 abx | 0.23 ± 0.01 ax | 0.85 ± 0.04 bcx | 2.96 ± 0.17 ax | 56.84 ± 4.36 ax | 17.33 ± 1.12 ay | 0.20 ± 0.01 ax | 0.89 ± 0.05 cx | 3.12 ± 0.29 ax |

| 350 | 75.04 ± 3.49 cx | 4.30 ± 0.34 ax | 0.29 ± 0.01 bx | 0.86 ± 0.04 cy | 1.79 ± 0.13 ax | 80.52 ± 6.15 bx | 11.26 ± 1.06 ay | 0.26 ± 0.02 bcx | 0.73 ± 0.07 ax | 2.10 ± 0.12 ax |

| 400 | 52.42 ± 3.56 abx | 6.54 ± 0.27 ax | 0.26 ± 0.01 ax | 0.79 ± 0.05 ax | 2.32 ± 0.17 ax | 75.17 ± 3.98 by | 14.24 ± 1.11 ay | 0.27 ± 0.01 cx | 0.89 ± 0.07 cy | 3.41 ± 0.21 a |

| 450 | 83.40 ± 6.23 cy | 23.45 ± 1.69 cx | 0.35 ± 0.02 cy | 0.77 ± 0.02 ax | 7.13 ± 0.45 cy | 57.79 ± 4.12 ax | 20.77 ± 1.45 ax | 0.28 ± 0.02 cx | 0.88 ± 0.04 cy | 5.05 ± 0.25 abx |

| 500 | 64.55 ± 3.12 bx | 23.26 ± 1.11 cx | 0.29 ± 0.01 by | 0.84 ± 0.03 bx | 7.88 ± 056 cx | 64.35 ± 3.45 ax | 41.81 ± 3.67 cy | 0.24 ± 0.01 bx | 0.89 ± 0.04 cx | 9.08 ± 0.76 bcy |

| 550 | 87.39 ± 6.48 cx | 24.94 ± 1.98 cx | 0.40 ± 0.03 cy | 0.86 ± 0.04 cx | 8.34 ± 0.76 cy | 100.64 ± 8.88 cy | 31.49 ± 1.23 by | 0.24 ± 0.01 bx | 0.89 ± 0.03 cx | 6.84 ± 0.13 bx |

| 600 | 71.13 ± 7.11 cy | 27.38 ± 1.99 cx | 0.32 ± 0.02 bx | 0.87 ± 0.05 cx | 9.78 ± 0.37 cx | 64.63 ± 4.58 ax | 56.69 ± 3.65 cy | 0.28 ± 0.01 cx | 0.87 ± 0.05 cx | 13.81 ± 0.99 cy |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enkhbold, M.; Lőrincz, A.; Elayan, M.; Friedrich, L.; Barkó, A.; Hidas, K.I.; Varga-Tóth, A. Effect of High Hydrostatic Pressure on the Quality Parameters of Wild Red Deer (Cervus elaphus) Meat. Appl. Sci. 2025, 15, 4336. https://doi.org/10.3390/app15084336

Enkhbold M, Lőrincz A, Elayan M, Friedrich L, Barkó A, Hidas KI, Varga-Tóth A. Effect of High Hydrostatic Pressure on the Quality Parameters of Wild Red Deer (Cervus elaphus) Meat. Applied Sciences. 2025; 15(8):4336. https://doi.org/10.3390/app15084336

Chicago/Turabian StyleEnkhbold, Munkhnasan, Attila Lőrincz, Majd Elayan, László Friedrich, Annamária Barkó, Karina Ilona Hidas, and Adrienn Varga-Tóth. 2025. "Effect of High Hydrostatic Pressure on the Quality Parameters of Wild Red Deer (Cervus elaphus) Meat" Applied Sciences 15, no. 8: 4336. https://doi.org/10.3390/app15084336

APA StyleEnkhbold, M., Lőrincz, A., Elayan, M., Friedrich, L., Barkó, A., Hidas, K. I., & Varga-Tóth, A. (2025). Effect of High Hydrostatic Pressure on the Quality Parameters of Wild Red Deer (Cervus elaphus) Meat. Applied Sciences, 15(8), 4336. https://doi.org/10.3390/app15084336