Abstract

This study presents a multi-user virtual reality (VR) tool designed to enhance hands-on learning in engineering education through real-time sensorized digital twins. The motivation stems from the limitations of traditional laboratory settings, such as time constraints and restricted access to physical equipment, which can hinder practical learning. The developed environment allows multiple students, wearing VR headsets, to interact simultaneously with a real-time synchronized virtual model of an engine, replicating its physical counterpart at the Mechanical Engineering Laboratory of the Pontificia Universidad Católica de Valparaíso, Chile. This novel integration of VR and digital twin technology offers students a unique opportunity to observe engine behavior in operation within a safe, controlled virtual space. By bridging theoretical knowledge with practical experience, this approach deepens understanding of complex mechanical concepts while fostering the development of key technical skills. Additionally, the use of real-time data visualization and digital twins provides a safer, more interactive, and efficient alternative to traditional laboratory practices, overcoming constraints like time limitations and equipment availability. This innovative method introduces students to Industry 4.0 principles, encouraging data-driven analysis and informed decision making.

1. Introduction

Technical training in mechanical engineering requires a practical approach that facilitates effective understanding of the fundamental principles related to the operation and maintenance of mechanical systems. In the university context, there are several laboratories specialized in different areas of mechanical engineering, which allow reinforcement of theoretical knowledge through practical activities that favor their visualization and application.

Among these learning spaces, the motors laboratory stands out as particularly attractive for students due to the possibility of interacting with motors, compressors, fans, burners, and other industrial machinery. This laboratory plays an essential role in the training of future engineers, as it provides direct experience of the equipment and technologies they will encounter in the professional environment, thus strengthening their skills and preparation for the practice of engineering in industrial environments.

1.1. Practical Work in the Engine Laboratory

One of the most significant experiments in the engine laboratory is the “Trailed Engine Test”. This test is fundamental in technical education as it enables the analysis of energy losses and the dynamic behavior of an internal combustion engine under controlled conditions. The test involves driving the engine using an electric motor, eliminating combustion effects to allow a more accurate assessment of mechanical losses, such as frictional power and ventilation system energy consumption [1]. Mastering this experiment is essential for students to develop data interpretation skills and apply thermodynamic principles, as set out in [2].

Traditionally, the entrained engine test is carried out in the laboratory using a traditional methodology that, although functional, has inherent limitations. This process includes measurements performed under three specific conditions:

- Cold oil with the fan disconnected.

- Warm oil with the fan disconnected.

- Warm oil with the fan connected.

During the test, one student manually adjusts the engine revolutions per minute (RPM) using a motor-variator, while another student monitors the temperatures with multichannel equipment, and a third student records the data obtained.

1.2. Digital Twins and Their Interaction in Virtual Reality for Technical Education in the Context of Industry 4.0

The incorporation of technologies such as virtual reality and digital twins in technical education responds to the evolution of industry towards digitalization and automatization, key features of Industry 4.0 as explored in Petruse, R.E.; Grecu, V.; Gakić, M.; Gutierrez, J.M.; Mara, D. “Exploring the Efficacy of Mixed Reality versus Traditional Methods in Higher Education: A Comparative Study”, in which the integration of these technologies was analyzed in the context of engineering education and industrial training [3,4]. Digital twins have been widely adopted in industrial sectors for process simulation and optimization, allowing the creation of virtual replicas of machinery, production plants, and complete systems [5,6,7]. Its application in educational and laboratory environments offers the possibility of replicating real operating conditions without the costs and risks associated with physical experimentation, providing an interactive platform for analysis and decision making in real time [8,9,10,11,12,13]. Virtual reality has emerged as a key tool in human–machine interaction, facilitating immersion in simulated environments where students can manipulate digital models and experiment with complex systems in a controlled environment [14,15,16,17].

The transition to Industry 4.0 requires that technical education evolves in sync with the transformations of the productive sector [18,19,20]. The adoption of digital twins and virtual reality in education not only modernizes learning methods, but also strengthens essential competencies, such as data interpretation, system optimization, and problem solving in digitized environments. These technologies also facilitate real-time process monitoring and forecasting, aspects that are increasingly important in managing and improving industrial systems [21] By providing hands-on experience aligned with the demands of the labor market, these technologies enable students to develop key skills to lead the digital transformation of the industry, ensuring effective adaptation to the challenges and opportunities of the technological era, as demonstrated in Weis, P.; Smetanka, L.; Hrček, S.; Vereš, M. “Interactive Application as a Teaching Aid in Mechanical Engineering”, in which similar methodologies were applied to enhance student engagement and technical proficiency in engineering education [17,21,22,23].

1.3. Research Gaps and Objectives

The teaching of mechanical engineering requires methodologies that not only transmit theoretical knowledge, but also provide practical experiences allied to current technological advances. In this context, engine laboratories play a fundamental role in the training of students, allowing them to interact with high-capacity machinery and understand its operation under real conditions. However, traditional methods have shortcomings in data acquisition and visualization, making it difficult to accurately analyze system variables and limiting the connection with Industry 4.0 concepts.

The trailed engine experience in the engine lab is an essential component in the training of mechanical engineers, but its current methodology requires updating to reflect emerging trends in the industrial sector [24,25,26]. In particular, the manual reading of signals and the lack of integration with digital tools hinder the efficient interpretation of data such as temperatures and RPM, affecting the understanding of the physical phenomena involved.

To address these limitations, this research proposes the integration of virtual reality and real-time sensing technologies for the development of a collaborative, safe, and interactive environment, enhancing the learning experience in engine laboratories [27,28,29]. Using the Unity graphics engine, a digital twin was designed that was synchronized with the physical parameters of the system, allowing it not only to show system behavior in real time, but also to adjust variables such as engine RPM in real time [30].

The implementation of this digital environment not only optimizes data collection and visualization, but also better prepares students to face the future of Industry 4.0, where the convergence of physical and digital systems is key to innovation and efficiency. In this way, this research seeks to reduce the gap between traditional teaching and current technological demands, providing a more dynamic educational model aligned with the evolution of mechanical engineering [31].

2. Materials and Methods

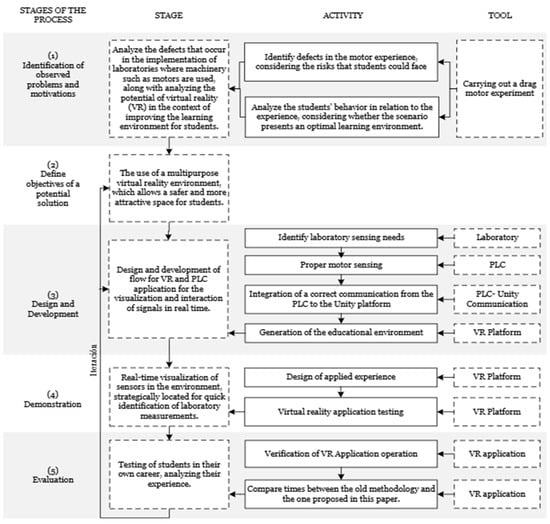

This research addresses and proposes the integration of virtual reality and real-time sensing technologies for the development of a collaborative, safe, and interactive environment, aimed at improving the learning experience of students in work that involves the use of high-capacity engines. To achieve this, the Design Science Research Methodology (DSRM) was used, recognized in the field of design science for its ability to systematically structure the research process. The following stages were considered: (1) Identification of observed problems; (2) Definition of objectives of a potential solution; (3) Design and development; (4) Demonstration; and (5) Evaluation. Figure 1 shows the stages, activities, and tools needed to carry out this research.

Figure 1.

Methodology.

During the first stage of the research, several tests of the trailed engine experiment, considered an essential component in the training of mechanical engineers, were carried out. This experiment is particularly relevant as it allows the study of the behavior of an internal combustion engine in the absence of phenomena associated with combustion and exhaust gases. In this context, the behavior of the students when participating in this experiment was analyzed, evaluating their level of interest and commitment in the laboratory, as well as the safety of the environment in terms of physical risks and possible future damage.

Based on the above analysis, the opportunity to incorporate virtual reality technologies as an innovative solution was identified. Virtual reality not only provides a safer environment for conducting laboratory work but also increases student interest by incorporating modern technological tools [32]. Previous studies suggest that increased interest in the laboratory can translate into more effective learning and, ultimately, into the formation of more competent mechanical engineers better prepared for the challenges of industry.

At this stage, an exhaustive analysis of the signals that are currently monitored in the engine was carried out, to preserve the essence of the experiment and guarantee correct sensorization. A real-time communication system was implemented between the sensors and Unity, the platform used for the development of the virtual environment [32,33,34,35]. This process was divided into three phases: (1) analysis and correct sensorization of the engine; (2) effective real-time communication between the signals and a server; (3) implementation of the real-time signals in a multi-user environment.

The implementation of these phases was essential to establish real-time communication to support the functionality of the proposed system.

With the real-time sensing implemented, a multi-user environment was developed that included a scanned model of the engine used in the laboratory. In this virtual environment, interactive visualizations of the data captured by the PLC sensors were integrated, positioning them in the corresponding locations of the digital model. Subsequently, functional tests were performed to evaluate the accuracy and efficiency of the system.

At this stage, a new laboratory experiment was carried out with students of different academic levels and different Academic Performance Index (IRA) scores. The participants completed both experiments, the traditional and the proposed one, and then answered a satisfaction questionnaire to measure their perception of the new technologies implemented. In addition, the variable of time spent in each modality was externally evaluated to compare the efficiency and effectiveness of both experiences.

3. Workflow for the Development of a New Crawling Engine Experience

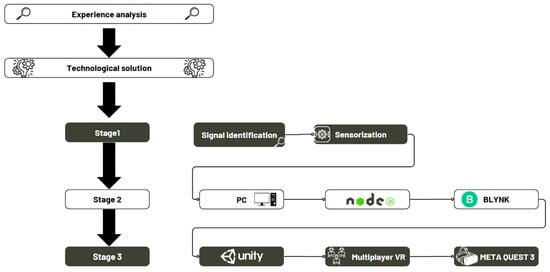

To establish a new methodology for the development of the trailed motor laboratory, a work plan structured in two main stages was designed, as shown in Figure 2.

Figure 2.

Workflow for the development of a new crawling engine experience.

The first stage consisted of a detailed analysis of the laboratory experience, with the objective of identifying its main limitations and understanding the needs of the students. This diagnosis made it possible to detect areas for improvement and define the requirements for optimizing the learning environment, ensuring that students could achieve educational objectives more effectively.

The second stage focused on the development and implementation of a technological solution based on the findings of the previous phase. For this purpose, three key sub-stages were configured: (1) identification of the essential laboratory signals and their sensorization by means of a PLC, (2) establishment of communication between the PLC and a server for real-time data transmission, and (3) integration of the information in a multi-user environment developed in Unity 3D.

This approach not only allows the lab to maintain its technical validity, but also incorporates new capabilities that enrich teaching, providing students with a more immersive, interactive experience aligned with Industry 4.0 technologies.

3.1. Analysis of the Trailed Motor Experience and New Methodology of the Laboratory Experience

Analyzing the behavior of the trainees when performing the trailed motor experiment, some negative aspects of the experiment were noted, such as that the reliance on manual adjustments limits the trainees’ ability to focus on the analysis of the data obtained. Instead of focusing on interpreting key variables and optimizing system performance, much of the time is spent on correcting deviations and ensuring stable operating conditions. This reduces the effectiveness of the experiment as an educational tool and restricts the opportunity to explore more advanced concepts related to automation and process control.

Another critical aspect is temperature monitoring using a multichannel system. Although this tool allows multiple measurement points to be recorded simultaneously, its use presents difficulties in the correct assignment of the values obtained. The lack of an integrated display and the need to manually correlate each reading with its measurement point can lead to confusion and errors in the analysis. This not only affects the accuracy of the results but also hinders the understanding of the thermal distribution patterns within the system being evaluated.

New Methodology for the Realization of the Trailed Motor Experiment

To solve the problems mentioned above, a modernized educational approach is proposed, incorporating the emerging technologies detailed in this work. The proposal aims to transform the educational experience by integrating advanced tools, such as multi-user virtual reality environments and real-time sensing, that enrich both learning and safety in motor education.

This new experience seeks not only to provide a safer environment for students by minimizing the risks associated with traditional practices, but also to introduce key Industry 4.0 concepts and technologies. These tools, such as advanced sensing, remote monitoring, and virtualization, allow students to become familiar with current industry practices, thus fostering more complete training aligned with the demands of the modern job market.

Specifically, this proposal aims to achieve the following: (1) develop an interactive and immersive learning environment where multiple users can simultaneously interact with a real-time synchronized digital twin of an engine; (2) enhance data acquisition and visualization using IoT-based real-time monitoring systems to improve the interpretation of mechanical variables; and (3) optimize safety and accessibility in the learning process by reducing the physical risks associated with traditional laboratory practices.

The experiment was carried out following a structured sequence of tests to evaluate the performance of the trailed motor under different thermal and ventilation conditions. The procedure consists of the following steps:

- Motor start-up: The system is started, and the initial operating conditions are established.

- Data logging with cold oil and without fan: Using the Meta Quest 3 indicators, the engine operating parameters are captured in real time for further analysis.

- Restart with warm oil and no fan: The experiment is repeated once the oil has reached a higher operating temperature, in order to evaluate the impact of warm-up on engine performance.

- Restart with hot oil and fan: A final test is carried out, activating the ventilation system to analyze its influence on the thermal stability and efficiency of the engine.

In each of the stages, the motor started its operation at 600 RPM, increasing in increments of 100 RPM until the desired speed was reached. This adjustment was made by means of the frequency inverter or, failing that, through the virtual environment developed in Unity. All tests were carried out under the supervision of a teacher, ensuring proper use of the motor and safeguarding the integrity of the equipment and the participants.

3.2. Development of the Technological Solution

Since the proposal includes the use of virtual reality and real-time sensing, a development flow of the technological solution used to carry out the new laboratory methodology was implemented. This flow is subdivided into three stages. These stages comprise (1) the identification of essential signals for the laboratory and the sensorization by means of a PLC; (2) the communication of this with a server; and (3), finally, the integration of the data in a multi-user environment developed in Unity 3D.

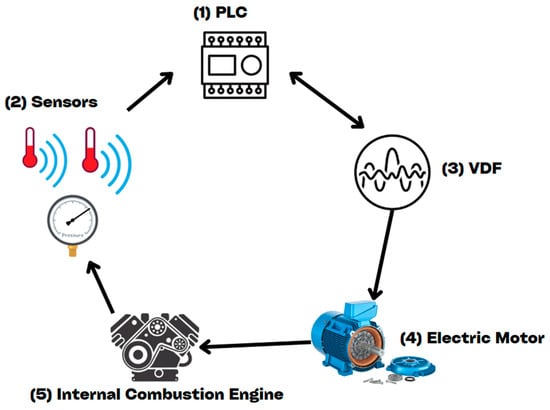

3.2.1. Signal Identification and Sensing

In the first stage, the signals needed to replicate and improve the laboratory experiment were identified. It was decided to extend the monitoring to four key temperatures: intake, exhaust, oil, and ambient, using more accurate thermocouples. Also, a pressure sensor was added to evaluate the conditions of the compression chambers in the absence of combustion, and a sensor to measure the rotational speed of the engine shaft. These additions enriched the analysis and understanding of engine operation.

Then, the monitoring system was improved by implementing Siemens LOGO! 7 PLC, matching the student experience to what is traditionally used in the industry. PT-100 RTD thermocouples were selected, capable of operating in a temperature range from −200 °C to 500 °C, with AM2 RTD extension modules. For safe and efficient integration of the signals, the following configuration was made in the PLC for a correct temperature reading.

To expand the capabilities of the PLC, additional AM2 modules were integrated, allowing the recording of analog signals from 0 to 20 mA or 4 to 20 mA. This allowed the addition of a pressure sensor in the compression chambers, as well as the connection to the frequency inverter to measure the RPM of the motor, eliminating the need for external instruments. In Figure 3, the setup of the sensing system, motors, and VFD is shown, and in Table 1, the list of equipment is provided.

Figure 3.

Sensor mounting.

Table 1.

List of equipment.

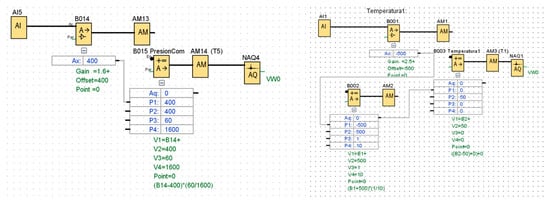

Figure 4 presents the configuration of the program implemented in the PLC, designed to guarantee the correct acquisition and processing of the signals coming from the sensors. First, the operating range within which the recorded analog signals can fluctuate is established, ensuring that the data is interpreted accurately. Subsequently, through a conversion based on simple rules of three, the analog values obtained are transformed to their corresponding scale, allowing the correct visualization and interpretation of them within the system. This procedure is essential to normalize the data and facilitate their integration into the digital environment, ensuring a consistent representation of the physical variables monitored in real time.

Figure 4.

Programming of pressure and temperature signals.

3.2.2. PLC–Server–Unity Communication

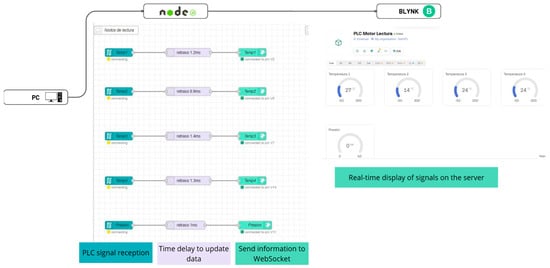

The third stage consisted of establishing a communication system to send the signals acquired by the PLC to a server, to later integrate them into Unity. Node-RED was used as a visual development tool to connect the PLC with an IoT server based on Blynk [36,37,38,39].

Blynk was selected as the IoT platform because of its ability to manage devices remotely and provide real-time communication. Its integration allowed PLC signals to be monitored and stored centrally, facilitating their later use in Unity by converting raw sensor data into structured parameters compatible with the Unity environment for real-time visualization and interaction [34,40,41,42,43].

Figure 5 illustrates the communication scheme between the PC, the Blynk server, and the Node-RED development environment, used to process and visualize in real time the signals acquired from the PLC, ensuring minimal latency and data consistency across platforms.

Figure 5.

Signal flow.

The data flow starts with the reception of the signals coming from the PLC, which are processed in Node-RED. In this environment, the first nodes of the scheme are assigned to each of the signals, allowing their capture directly from the PLC by defining individual processing pipelines for temperature, RPM, and other key variables. Subsequently, through an output node, the converted data are sent to a server via a WebSocket connection which ensures low-latency transmission and seamless data synchronization with Blynk.

This process is repeated for each monitored signal, ensuring its efficient transmission to Blynk, where it is finally visualized within an interactive dashboard capable of displaying real-time trends, historical data analysis, and alert notifications for critical values. In this way, a clear and accessible representation of the variables in real time is achieved, facilitating their analysis and allowing remote supervision of the system while also enabling potential future integration with machine learning models for predictive maintenance.

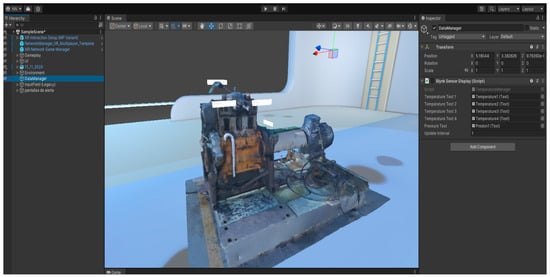

3.2.3. Multi-User Environment

The last stage consisted of the development of a multi-user environment in Unity using Photon, a platform specialized in real-time data synchronization for virtual environments. The laboratory engine was scanned using Polycam, generating a detailed 3D model that was integrated into the virtual environment.

Interactive text boxes were designed within the environment to display engine signals in real time, using code developed to extract information directly from the Blynk server. This environment allows users to visualize relevant data and experiment immersively with the operating conditions of the engine.

With this workflow, it was possible to implement a safer and more interactive educational environment, aligned with the technologies used in today’s industry, as shown in the following images, in which the environment with real-time sensing can be appreciated. In Figure 6, the interface in Unity is shown, displaying its components and the result can be seen in Figure 7.

Figure 6.

Unity interface image.

Figure 7.

Image of the environment.

The implemented code shown in Table 2 facilitates real-time data acquisition, processing, and visualization within the virtual environment. It utilizes API calls to retrieve sensor data stored on the Blynk server, which is then processed in Unity to update the corresponding real-time values in the VR environment. By employing UnityWebRequest, the system periodically fetches sensor readings, formats the data, and dynamically updates UI elements such as temperature, pressure, and RPM indicators. This ensures that users in the multi-user VR space can observe live changes in engine performance, fostering an interactive and immersive learning experience.

Table 2.

Unity Code.

4. Results

4.1. Validation

To evaluate the usefulness of the proposed technologies and students’ perceptions of them, a structured survey was designed and applied. This instrument sought to measure the level of satisfaction and the impact of these technologies on the educational experience. A total of 40 students were surveyed, divided into two groups:

- Group 1: Composed of 25 students in their final years of study, who had previously participated in the traditional engine laboratory.

- Group 2: Composed of 15 students in the first years of the course, who had not yet had previous experience with the moto-res laboratory.

4.1.1. Structure and Flow of the Survey

The survey was divided into four sections: (1) Profile; (2) Experience and satisfaction survey of the traditional experience without VR; (3) Experience and satisfaction survey of the proposed experience with VR; (4) Comparison survey between experiences. This can be seen in Figure 8.

Figure 8.

Workflow with respondents.

The survey was designed to cover four fundamental aspects: to gather information about the participant’s profile, to measure satisfaction with the traditional experience without virtual reality, to evaluate the proposed experience that incorporates virtual reality and real-time sensing, and to analyze both methodologies comparatively. The instrument was applied at three key moments: before the experiences, to record the students’ profiles; after the traditional experience, to capture their immediate perceptions; and at the end of the experience with virtual reality, to evaluate both their satisfaction with the proposal and the perceived differences with respect to the traditional method.

This design allows for a comprehensive analysis, focusing not only on the individual experience of each methodology, but also on the comparison between the two, considering aspects such as interest, safety, learning, and ease of use.

4.1.2. Profile Questions and Answers

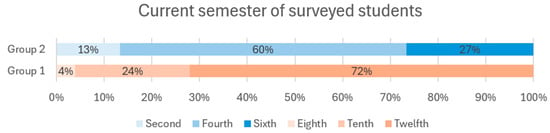

Group 1 is composed of students in higher years, of which 72% (equivalent to 18 students) are in the last semester of their degree program. In contrast, Group 2 is made up mainly of students in the first years, with 60% of its members (equivalent to 9 students) in the fourth semester. This segmentation was carried out with the purpose of analyzing possible differences in perception according to the students’ generation. In addition, 100% of the respondents said that they had no previous experience in the use of Virtual Reality. The distribution of students in the groups is shown in Figure 9.

Figure 9.

Academic levels of students.

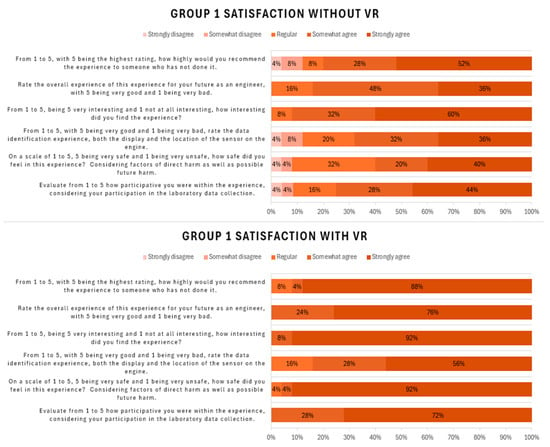

4.1.3. Student Satisfaction Questions and Answers

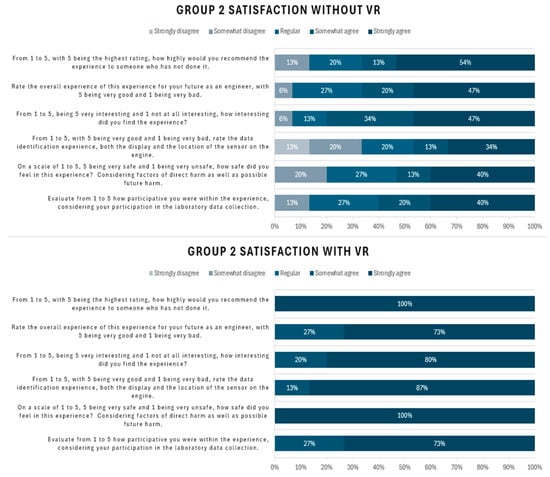

A satisfaction survey was conducted using a Likert scale to better visualize the students’ responses in each of the surveys. the distribution of the responses of both groups is shown in Figure 10 and Figure 11.

Figure 10.

Questions and answers for Group 1.

Figure 11.

Questions and answers for Group 2.

The integration of virtual reality into the laboratory experience significantly enhanced all evaluated aspects, including interest, safety, participation, and perceived educational value. This technology not only deepened participant immersion and engagement but also reduced perceived risk and improved process comprehension. Additionally, it made the experience more engaging and widely recommended. These findings underscore the potential of virtual reality as a powerful tool for teaching technical processes in engineering, fostering both interaction and knowledge retention.

As part of the assessment of student satisfaction with the virtual reality experience, participants were also asked which tool within this multi-user environment they found most beneficial for their engineering education. In both groups, approximately 80% favored real-time data visualization.

Furthermore, students were asked whether this new methodology fostered a more collaborative learning environment. The results were unanimous, with 100% of participants acknowledging an improvement in collaboration.

4.1.4. Questions and Answers for Students Comparing Both Experiences

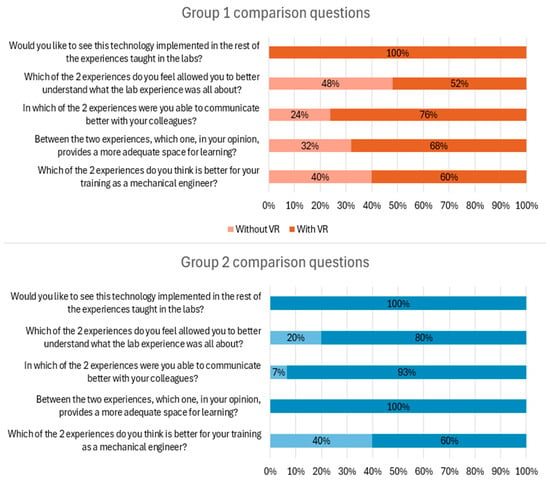

The responses to the section "Questions and Answers for Students Comparing Both Experiences" are presented in Figure 12, where students’ feedback and insights regarding their experiences are analyzed and compared.

Figure 12.

Questions and answers from both groups.

When comparing the two experiences, students in both groups consistently showed a strong preference for virtual reality across all evaluated categories. One of the most significant advantages observed was the improvement in communication among participants, with a clear disparity between the two methods: 76% of students in Group 1 and 93% in Group 2 reported better communication using VR, compared to only 24% and 7%, respectively, in the traditional setting.

Furthermore, virtual reality was widely recognized as providing a more suitable and effective learning environment. In both groups, students acknowledged that VR not only enhanced their ability to engage with the material but also fostered a more interactive and immersive experience. This, in turn, contributed to a deeper understanding of the laboratory process and reinforced its value in engineering education.

Lastly, VR was perceived as a superior tool for mechanical engineering training, with a significant majority favoring it over the conventional approach. These findings underscore the transformative potential of virtual reality in technical education, demonstrating its capacity to improve knowledge retention, collaboration, and overall learning effectiveness.

4.2. Time of Experiment

An important variable nowadays is the time it takes to perform the experiments; over the years, the number of hourly keys has decreased throughout Chile, which presents a great challenge to optimize the laboratories themselves. Therefore, it was measured in both groups how long it took to perform both experiments. Table 3 shows the times of both groups when performing the traditional experience and the VR implementation.

Table 3.

Timetable.

We can observe a variation in the time that the students must dedicate to the realization of the experiment itself. This variable is significantly reduced, which allows the experiment to be carried out in a more optimal and dynamic way within the new time keys provided by the University itself.

5. Discussion

While virtual labs offer accessibility and cost-effectiveness, they can lack essential tactile experiences. On the other hand, remote labs allow interaction with real equipment, although they present challenges in cost and accessibility [12].

In this sense, this work contributes to this discussion by representing a motor in a virtual environment with real-time sensing, which allows users to visualize and analyze its dynamic behavior without the need for direct physical access. This integration facilitates the understanding of mechanical and control phenomena, while offering an accessible alternative for engineering education and experimentation. The future of engineering education lies in exploring these hybrid combinations, ensuring that students not only understand theoretical concepts, but also develop practical skills in accessible, dynamic environments. Continuous evaluation of these approaches will optimize their impact and sustainability in engineering education. This approach contributes significantly to the educational application of digital twins, aligning with previous work that highlights their ability to replicate real operating conditions in virtual environments [5,6,7]. In addition, the possibility of multi-user collaboration in the developed virtual environment strengthens interactive learning, allowing students to work in teams, share observations, and make data-driven decisions in real time [14,15,16,17].

The implementation of 4.0 technologies in engineering education has proven to be a transformative process that goes beyond the simple adoption of new tools, requiring effective pedagogical integration. Previous experience with these technologies plays a key role in their adoption, as does the creation of inclusive environments adapted to different needs. In addition, the preference for technologies such as AI and IoT highlights the importance of leveraging these interests to enhance learning [19]. A key aspect of this proposal is also the reduction of risks associated with experimentation with physical equipment. By moving these practices to a safe virtual environment, hazards are minimized without sacrificing the quality of hands-on learning, an advantage widely recognized in studies of virtual laboratories [10,18,19,20].

In addition to its pedagogical advantages, this implementation faced notable technical challenges, particularly regarding real-time data synchronization and virtual environment optimization. To accurately represent the motor’s dynamic behavior, a combination of edge computing techniques and MQTT-based communication protocols was utilized to enable low-latency data transmission. Additionally, filtering and interpolation algorithms were applied to mitigate potential delays and ensure seamless system response visualization.

As engineering education moves towards Industry 5.0, it will be essential to balance the use of these technologies with a human-centered approach. In this context, the experience developed allows interaction with a mechanical system in a virtual environment, visualizing its behavior in real time and providing a new form of analysis and applied learning. Furthermore, this educational platform not only fulfills a training function, but also prepares students for modern industrial environments. The combination of PLC, Node-RED, Blynk, and Unity replicates configurations used in Industry 4.0, providing key competencies that will be essential in students’ future professional performance [24,25,26].

Immersive technology and gamification have great potential in education, improving student learning, motivation, and engagement by offering interactive experiences adapted to different learning styles [17].

In this context, in our work with the engine there is evidence of greater student interest in interacting with virtual reality experiences compared to traditional methods. This reinforces the importance of immersive technologies in enhancing understanding and engagement in educational environments.

6. Conclusions

The implementation of virtual reality technologies in engineering training experiments has demonstrated a significant positive impact on the learning process. The results obtained reveal that students perceive this tool as a resource that facilitates the creation of better structured learning environments, fosters collaboration, and promotes the acquisition of current and relevant knowledge, such as that related to Industry 4.0, real-time sensing, and remote control of systems. Overall, students felt more engaged and confident in their understanding of complex mechanical systems. In conclusion, the key findings show that virtual reality enhances student engagement, supports collaborative learning, and aids in understanding complex topics, though further investigation is needed to assess its impact on academic performance. However, future research should include objective assessments to verify whether these perceived benefits translate into actual improvements in student knowledge and academic performance. Furthermore, the long-term impact of virtual reality on student retention and conceptual understanding could be explored to assess its effectiveness beyond initial learning outcomes.

Although the model developed in this study is of a basic nature, its application potential is broad. This type of technology is not only useful in the educational field, but also presents promising prospects for industry, serving as a foundation for the development of new digital twins. Future studies could focus on the scalability of these models and their adaptation to specific industries, ensuring that virtual environments are optimized for the complexities and specific needs of various sectors, such as manufacturing, automotive, or energy.

However, certain limitations have been identified that offer opportunities for improvement. Among them, the quality of the virtual environment stands out, specifically in the visual representation of the engine, which could be optimized to achieve greater realism. Future work should investigate the use of more advanced graphical rendering techniques, such as photorealistic modeling or ray tracing, to enhance the visual fidelity of virtual environments. Also, some students reported difficulties with the legibility of the typography used to display the sensorization information and suggested that the functionality and attractiveness of the virtual environment would benefit from the incorporation of motion in the engine. A deeper exploration of user interface design, particularly regarding legibility and clarity of data visualization, could improve the accessibility and user experience for a broader audience, especially for those with varying levels of technical expertise.

In addition, the importance of complementing the use of virtual reality with direct hands-on experiences is emphasized. Although this technology provides valuable support for the interpretation and analysis of signals, it should not be considered a substitute for traditional practices with physical equipment. On the contrary, it should be seen as a complementary tool that enriches training, allowing students to develop a deeper and more complete understanding. Future research could explore hybrid models that combine virtual and augmented reality experiences with physical interaction, aiming to create more immersive and tactile learning environments. This combined approach will contribute significantly to the formation of professionals better prepared to face the challenges of an increasingly digital and intelligent industry. Further investigations could also assess how virtual reality can be integrated into cross-disciplinary training programs, particularly in areas like robotics, mechatronics, and automation, to enhance interdisciplinary collaboration among students from different engineering fields.

Author Contributions

Methodology, J.O. and F.M.-L.R.; Software, N.N., M.C. and E.R. Validation, N.N.; Investigation, N.N.; Writing—original draft, N.N. and E.R. Writing—review & editing, F.M.-L.R. and C.I.G.K.; Supervision, J.O., F.M.-L.R., M.C., J.L.V.R. and C.I.G.K.; Project administration, N.N.; Funding acquisition, J.L.V.R. and C.I.G.K. All authors have read and agreed to the published version of the manuscript.

Funding

We thank the Pontificia Universidad Católica de Valparaíso for funding Proyecto Centenario 2024 No. 39312.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, J.; Guo, S.; Xiong, P.; Li, Y.; Sun, W.; Deng, L. Effects of the Piston Skirt’s Surface Structure on Coating Quality and Friction Functions. Coatings 2024, 14, 1385. [Google Scholar] [CrossRef]

- Pal, R. Teaching Fluid mechanics and thermodynamics simultaneously through pipeline flow experiments. Fluids 2019, 4, 103. [Google Scholar] [CrossRef]

- Petruse, R.E.; Grecu, V.; Gakić, M.; Gutierrez, J.M.; Mara, D. Exploring the Efficacy of Mixed Reality versus Traditional Methods in Higher Education: A Comparative Study. Appl. Sci. 2024, 14, 1050. [Google Scholar] [CrossRef]

- Tokatlidis, C.; Rapti, S.; Tselegkaridis, S.; Sapounidis, T.; Papakostas, D. Virtual Environment in Engineering Education: The Role of Guidance, Knowledge and Skills Development in Electronic Circuits Teaching. Educ. Sci. 2024, 14, 1336. [Google Scholar] [CrossRef]

- Alfaro-Viquez, D.; Zamora-Hernandez, M.; Fernandez-Vega, M.; Garcia-Rodriguez, J.; Azorin-Lopez, J. A Comprehensive Review of AI-Based Digital Twin Applications in Manufacturing: Integration Across Operator, Product, and Process Dimensions. Electronics 2025, 14, 646. [Google Scholar] [CrossRef]

- Aragón, A.; Arquier, M.; Tokdemir, O.B.; Enfedaque, A.; Alberti, M.G.; Lieval, F.; Loscos, E.; Pavón, R.M.; Novischi, D.M.; Legazpi, P.V.; et al. Seeking a Definition of Digital Twins for Construction and Infrastructure Management. Appl. Sci. 2025, 15, 1557. [Google Scholar] [CrossRef]

- Yi, S.; Hyun, D.; Hong, S. The Real-Time Prediction of Cracks and Wrinkles in Sheet Metal Forming According to Changes in Shape and Position of Drawbeads Based on a Digital Twin. Appl. Sci. 2025, 15, 700. [Google Scholar] [CrossRef]

- Wijkmark, C.H.; Metallinou, M.M.; Heldal, I. Remote virtual simulation for incident commanders—Cognitive aspects. Appl. Sci. 2021, 11, 6434. [Google Scholar] [CrossRef]

- Mavrin, I.; Turșie, C.; Matichescu, M.L. Exploring Sustainable Tourism Through Virtual Travel: Generation Z’s Perspectives. Sustainability 2024, 16, 10858. [Google Scholar] [CrossRef]

- Mirauda, D.; Capece, N.; Erra, U. StreamflowVL: A Virtual fieldwork laboratory that supports traditional hydraulics engineering learning. Appl. Sci. 2019, 9, 4972. [Google Scholar] [CrossRef]

- Guerrero-Osuna, H.A.; García-Vázquez, F.; Ibarra-Delgado, S.; Mata-Romero, M.E.; Nava-Pintor, J.A.; Ornelas-Vargas, G.; Castañeda-Miranda, R.; Rodríguez-Abdalá, V.I.; Solís-Sánchez, L.O. Developing a Cloud and IoT-Integrated Remote Laboratory to Enhance Education 4.0: An Approach for FPGA-Based Motor Control. Appl. Sci. 2024, 14, 10115. [Google Scholar] [CrossRef]

- Poo, M.C.-P.; Lau, Y.-Y.; Chen, Q. Are Virtual Laboratories and Remote Laboratories Enhancing the Quality of Sustainability Education? Educ. Sci. 2023, 13, 1110. [Google Scholar] [CrossRef]

- Cotet, G.B.; Carutasu, N.L.; Chiscop, F. Industry 4.0 diagnosis from an imillennial educational perspective. Educ. Sci. 2020, 10, 21. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, J.; Tu, W.; Wang, M.; Yang, Y.; Qian, F.; Xu, Y. The Effectiveness of a Digital Twin Learning System in Assisting Engineering Education Courses: A Case of Landscape Architecture. Appl. Sci. 2024, 14, 6484. [Google Scholar] [CrossRef]

- Verner, I.; Cuperman, D.; Perez-Villalobos, H.; Polishuk, A.; Gamer, S. Augmented and Virtual Reality Experiences for Learning Robotics and Training Integrative Thinking Skills. Robotics 2022, 11, 90. [Google Scholar] [CrossRef]

- Makarova, I.; Mustafina, J.; Boyko, A.; Fatikhova, L.; Parsin, G.; Buyvol, P.; Shepelev, V. A Virtual Reality Lab for Automotive Service Specialists: A Knowledge Transfer System in the Digital Age. Information 2023, 14, 163. [Google Scholar] [CrossRef]

- Mcfettridge, G.; Iqbal, M.Z. CurioCity: Augmented Reality Gamification to Foster Recreational Learning. Virtual Worlds 2024, 3, 586–598. [Google Scholar] [CrossRef]

- Muzata, A.R.; Singh, G.; Stepanov, M.S.; Musonda, I. Immersive Learning: A Systematic Literature Review on Transforming Engineering Education Through Virtual Reality. Virtual Worlds 2024, 3, 480–505. [Google Scholar] [CrossRef]

- Coelho, P.A.; Casanello, F.; Leal, N.; Brintrup, K.; Angulo, L.; Sanhueza, I.; Flores, F.; Reyes, J.; Forcael, E. Challenge-Based Learning and Scrum as Enablers of 4.0 Technologies in Engineering Education. Appl. Sci. 2024, 14, 9746. [Google Scholar] [CrossRef]

- Filipescu, A.; Simion, G.; Ionescu, D.; Filipescu, A. IoT-Cloud, VPN, and Digital Twin-Based Remote Monitoring and Control of a Multifunctional Robotic Cell in the Context of AI, Industry, and Education 4.0 and 5.0. Sensors 2024, 24, 7451. [Google Scholar] [CrossRef]

- Chai, B.X.; Gunaratne, M.; Ravandi, M.; Wang, J.; Dharmawickrema, T.; Di Pietro, A.; Jin, J.; Georgakopoulos, D. Smart Industrial Internet of Things Framework for Composites Manufacturing. Sensors 2024, 24, 4852. [Google Scholar] [CrossRef] [PubMed]

- Weis, P.; Smetanka, L.; Hrček, S.; Vereš, M. Interactive Application as a Teaching Aid in Mechanical Engineering. Computers 2024, 13, 170. [Google Scholar] [CrossRef]

- McCloskey, D.W.; McAllister, E.; Gilbert, R.; O’higgins, C.; Lydon, D.; Lydon, M.; McPolin, D. Embedding Civil Engineering Understanding through the Use of Interactive Virtual Reality. Educ. Sci. 2024, 14, 6. [Google Scholar] [CrossRef]

- Li, X.; Song, S.; Liu, S.; Yin, D.; Wang, R.; Gong, B. Application of Virtual Reality Technology in Enhancing the Teaching Effectiveness of Coal Mine Disaster Prevention. Sustainability 2025, 17, 79. [Google Scholar] [CrossRef]

- Wärmefjord, K.; Söderberg, R.; Schleich, B.; Wang, H. Digital twin for variation management: A general framework and identification of industrial challenges related to the implementation. Appl. Sci. 2020, 10, 3342. [Google Scholar] [CrossRef]

- Gamage, K.A.A.; Ekanayake, S.Y.; Dehideniya, S.C.P. Embedding Sustainability in Learning and Teaching: Lessons Learned and Moving Forward—Approaches in STEM Higher Education Programmes. Educ. Sci. 2022, 12, 225. [Google Scholar] [CrossRef]

- Vailasseri, P.; Long, J.M.; Joordens, M. Embedding bachelor of engineering university education with enhanced work-integrated learning. Educ. Sci. 2021, 11, 756. [Google Scholar] [CrossRef]

- Conesa, J.; Mula, F.J.; Bartlett, K.A.; Naya, F.; Contero, M. The Influence of Immersive and Collaborative Virtual Environments in Improving Spatial Skills. Appl. Sci. 2023, 13, 8426. [Google Scholar] [CrossRef]

- Soliman, M.; Pesyridis, A.; Dalaymani-Zad, D.; Gronfula, M.; Kourmpetis, M. The application of virtual reality in engineering education. Appl. Sci. 2021, 11, 2879. [Google Scholar] [CrossRef]

- Singh, M.; Kapukotuwa, J.; Gouveia, E.L.S.; Fuenmayor, E.; Qiao, Y.; Murray, N.; Devine, D. Comparative Study of Digital Twin Developed in Unity and Gazebo. Electronics 2025, 14, 276. [Google Scholar] [CrossRef]

- Strazzeri, I.; Notebaert, A.; Barros, C.; Quinten, J.; Demarbaix, A. Virtual Reality Integration for Enhanced Engineering Education and Experimentation: A Focus on Active Thermography. Computers 2024, 13, 199. [Google Scholar] [CrossRef]

- Cinar, O.E.; Rafferty, K.; Cutting, D.; Wang, H. AI-Powered VR for Enhanced Learning Compared to Traditional Methods. Electronics 2024, 13, 4787. [Google Scholar] [CrossRef]

- Khalid, W.; Jamil, M.; Khan, A.A.; Awais, Q. Open-Source Internet of Things-Based Supervisory Control and Data Acquisition System for Photovoltaic Monitoring and Control Using HTTP and TCP/IP Protocols. Energies 2024, 17, 4083. [Google Scholar] [CrossRef]

- Waqas, M.; Jamil, M. Smart IoT SCADA System for Hybrid Power Monitoring in Remote Natural Gas Pipeline Control Stations. Electronics 2024, 13, 3235. [Google Scholar] [CrossRef]

- Netinant, P.; Utsanok, T.; Rukhiran, M.; Klongdee, S. Development and Assessment of Internet of Things-Driven Smart Home Security and Automation with Voice Commands. Internet Things 2024, 5, 79–99. [Google Scholar] [CrossRef]

- Taco, J.P.A.; Jácome, O.A.I.; Pico, J.L.A.; Castro, B.A.L. Development of an Industrial Safety System Based on Voice Assistant. Appl. Sci. 2023, 13, 11624. [Google Scholar] [CrossRef]

- Covrig, T.; Ciobotaru, A.; Bejan, P.-A.; Farmathy-Pop, L.; Oltean, S.; Dumitru, C.-D.; Miclea, L.-C. System for the Acquisition and Monitoring of Energy Consumption in the Context of Industry 4.0. Sensors 2024, 24, 6302. [Google Scholar] [CrossRef]

- Kučera, E.; Haffner, O.; Drahoš, P.; Cigánek, J. Educational Case Studies for Pilot Engineer 4.0 Programme: Monitoring and Control of Discrete-Event Systems Using OPC UA and Cloud Applications. Appl. Sci. 2022, 12, 8802. [Google Scholar] [CrossRef]

- Pires, L.M.; Gomes, J. River Water Quality Monitoring Using LoRa-Based IoT. Designs 2024, 8, 127. [Google Scholar] [CrossRef]

- Uddin, R.; Hwang, T.; Koo, I. Worker Presence Monitoring in Complex Workplaces Using BLE Beacon-Assisted Multi-Hop IoT Networks Powered by ESP-NOW. Electronics 2024, 13, 4201. [Google Scholar] [CrossRef]

- Anggraeni, H.E.; Setiawan, A.; Irawan, S. Temperature and Humidity Monitoring System Environmental Cat Incubator Based on the Internet of Things (IoT). Proceedings 2022, 83, 50. [Google Scholar] [CrossRef]

- Pereira, G.P.; Chaari, M.Z.; Daroge, F. IoT-Enabled Smart Drip Irrigation System Using ESP32. Internet Things 2023, 4, 221–243. [Google Scholar] [CrossRef]

- Sankaran, V.; Alagumariappan, P.; Esakki, B.; Choi, J.; Hameed, M.T.K.S.; Pittu, P.S.K.R. Devising an Internet of Things-Based Healthcare Medical Container for the Transportation of Organs and Healthcare Products Using Unmanned Aerial Vehicles. Eng. Proc. 2023, 58, 16. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).