Fundamental Properties of Steam-Cured Cementitious Composites Incorporating Fine Volcanic Glass Powder

Abstract

Featured Application

Abstract

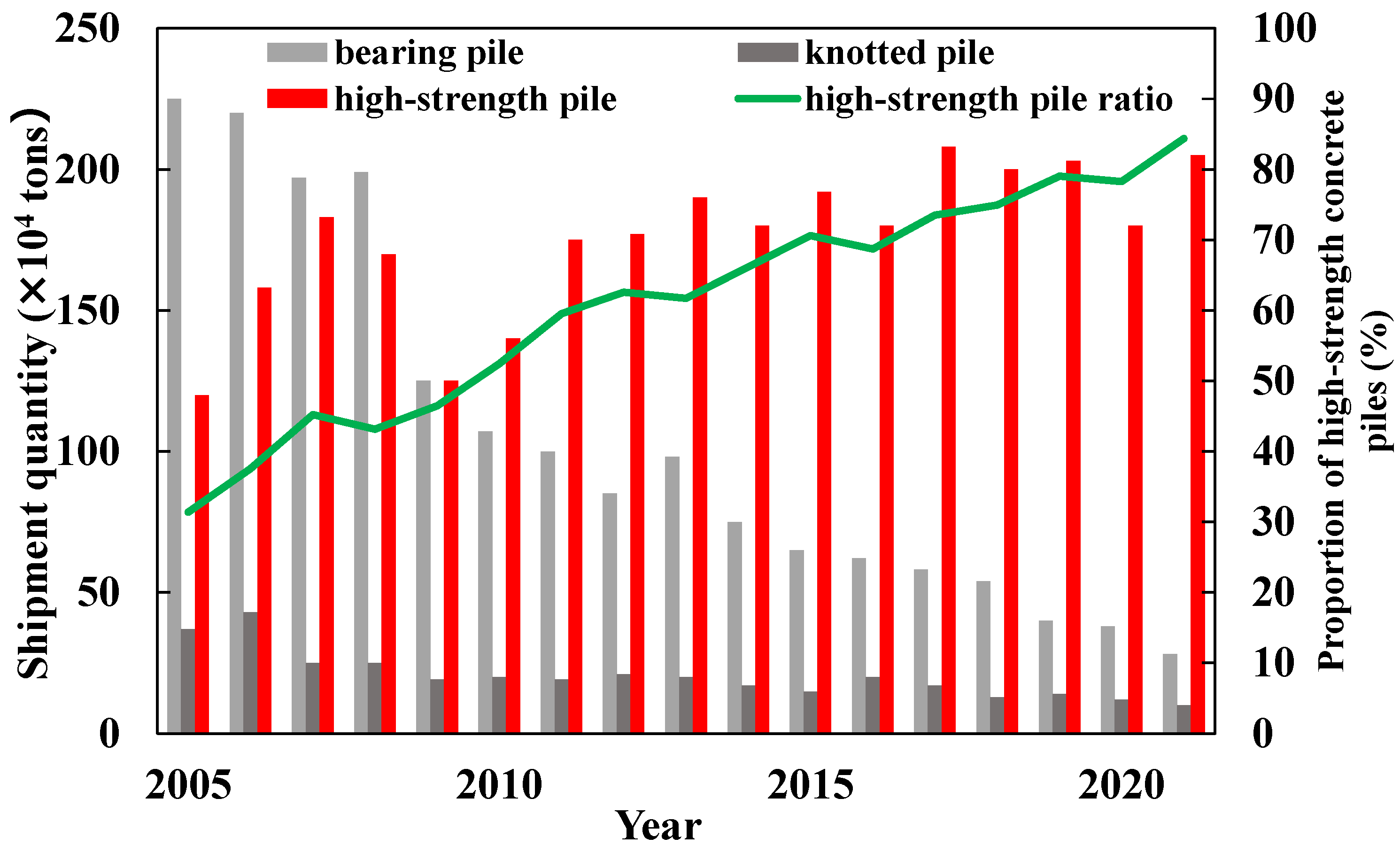

1. Introduction

2. Experiment Study

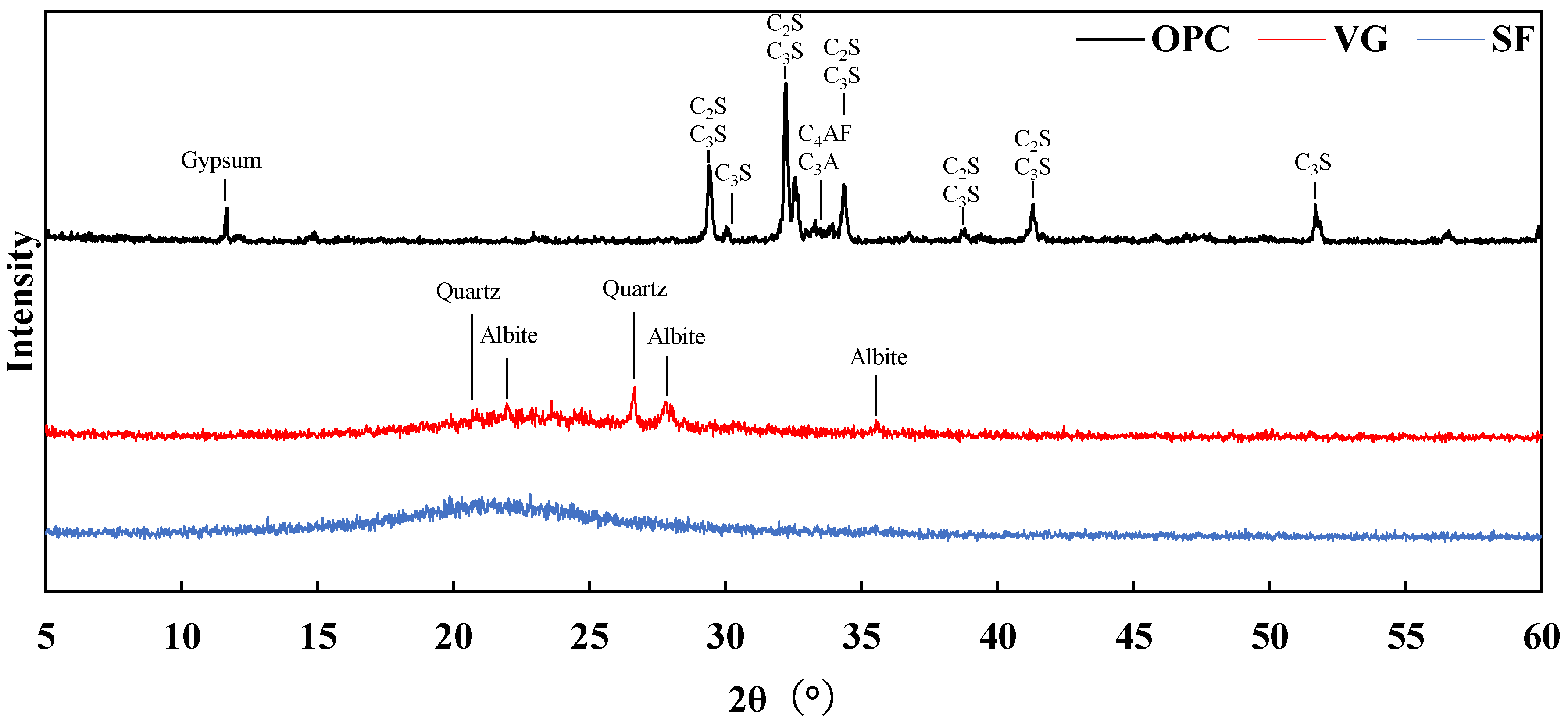

2.1. Materials Used

2.2. Preparation of Mortar and Concrete Specimens

2.2.1. Preparation of Mortar Specimens

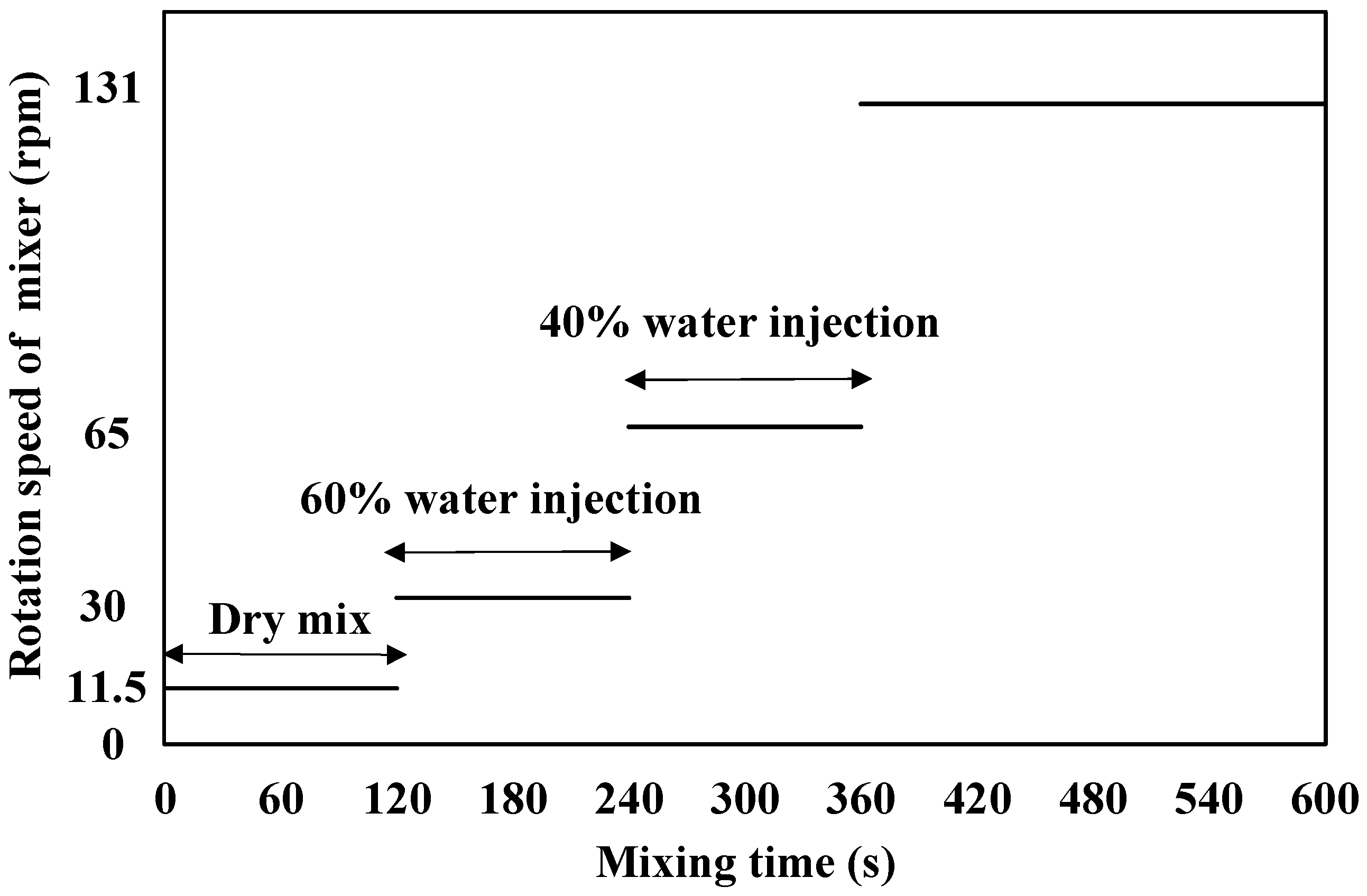

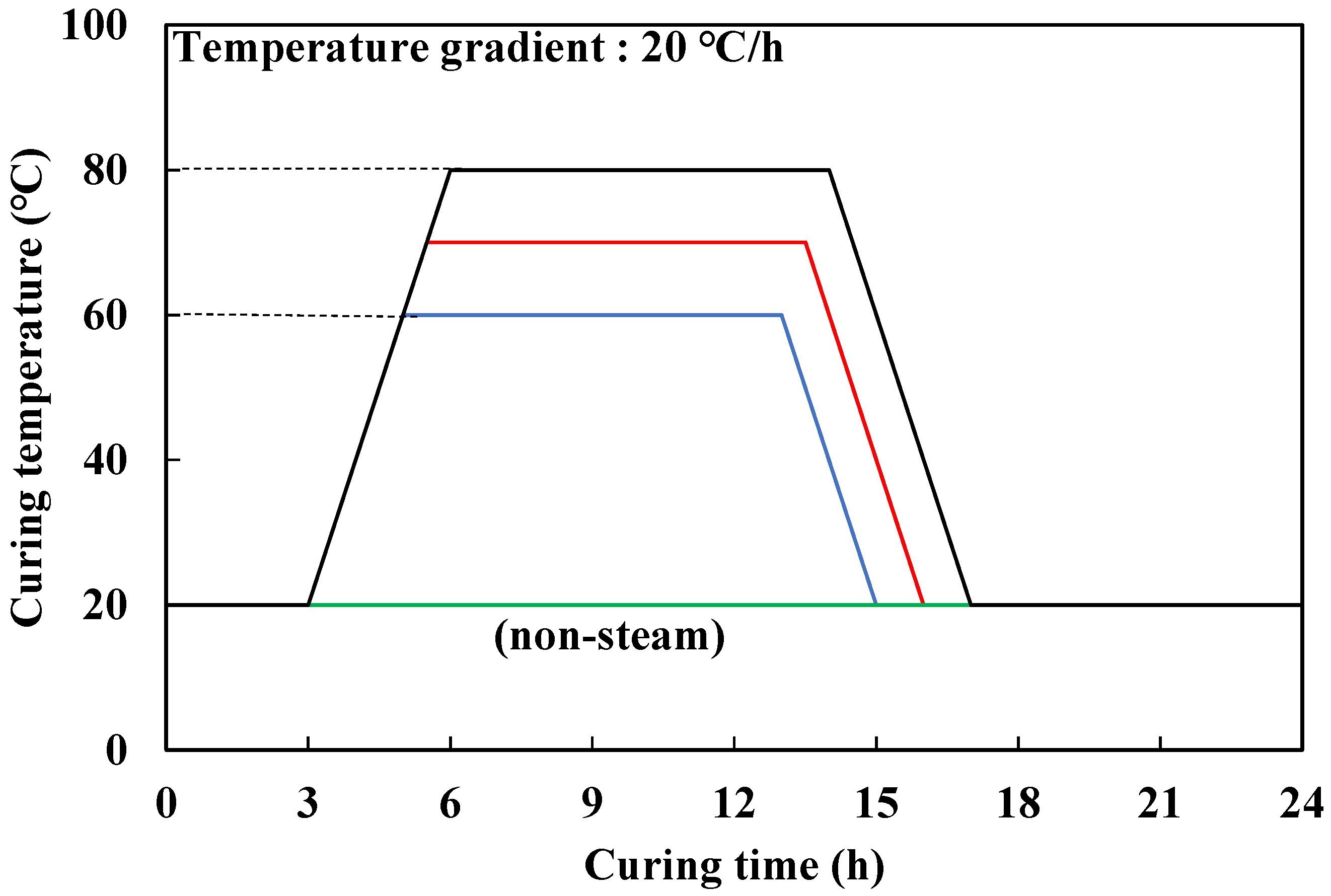

2.2.2. Preparation of Concrete Specimens

2.3. Evaluation Methods

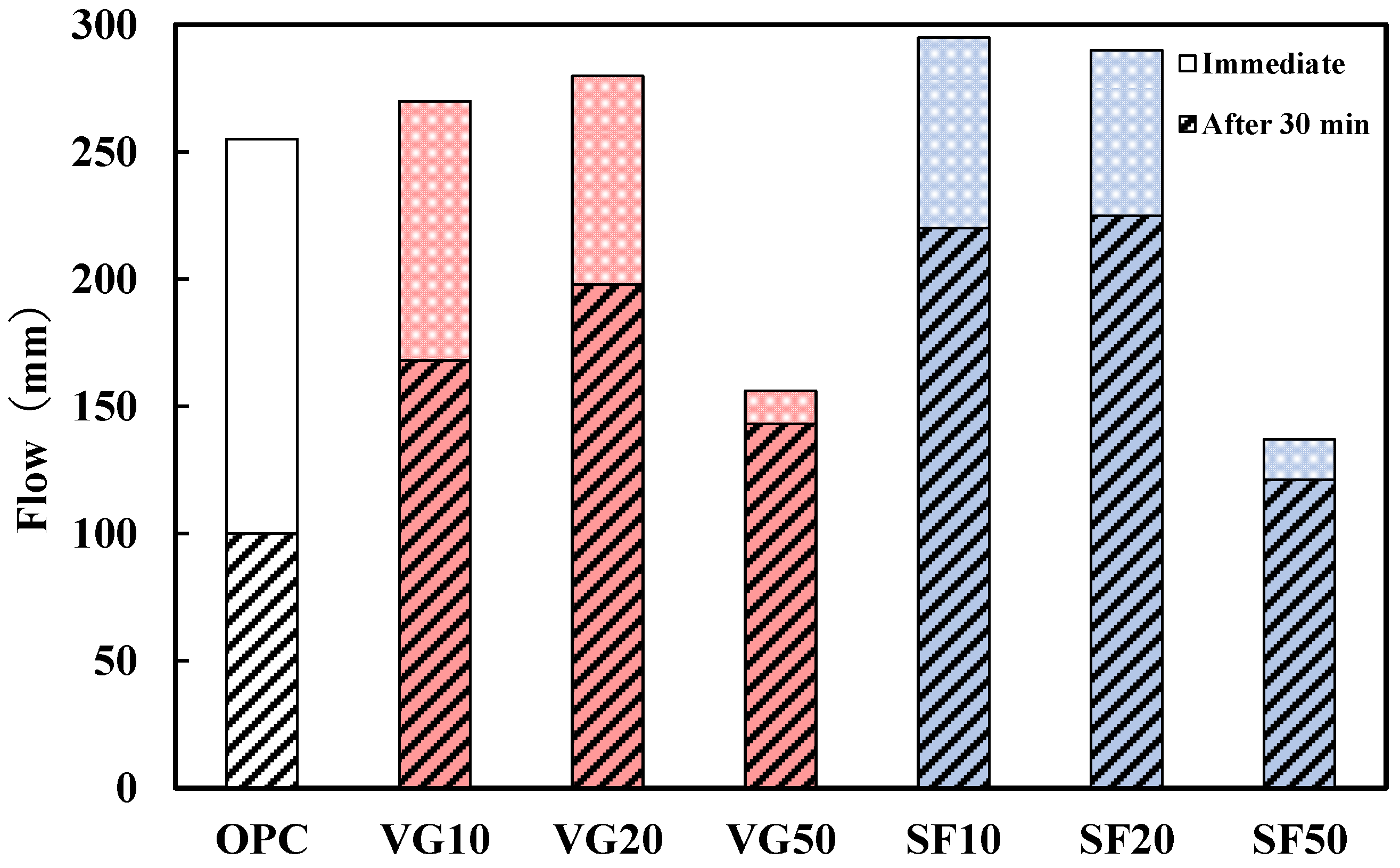

2.3.1. Mortar Flow Value

2.3.2. Compressive Strength and Activity Index of Mortar Specimens

2.3.3. Compressive Strength and Young’s Modulus of Concrete Specimens

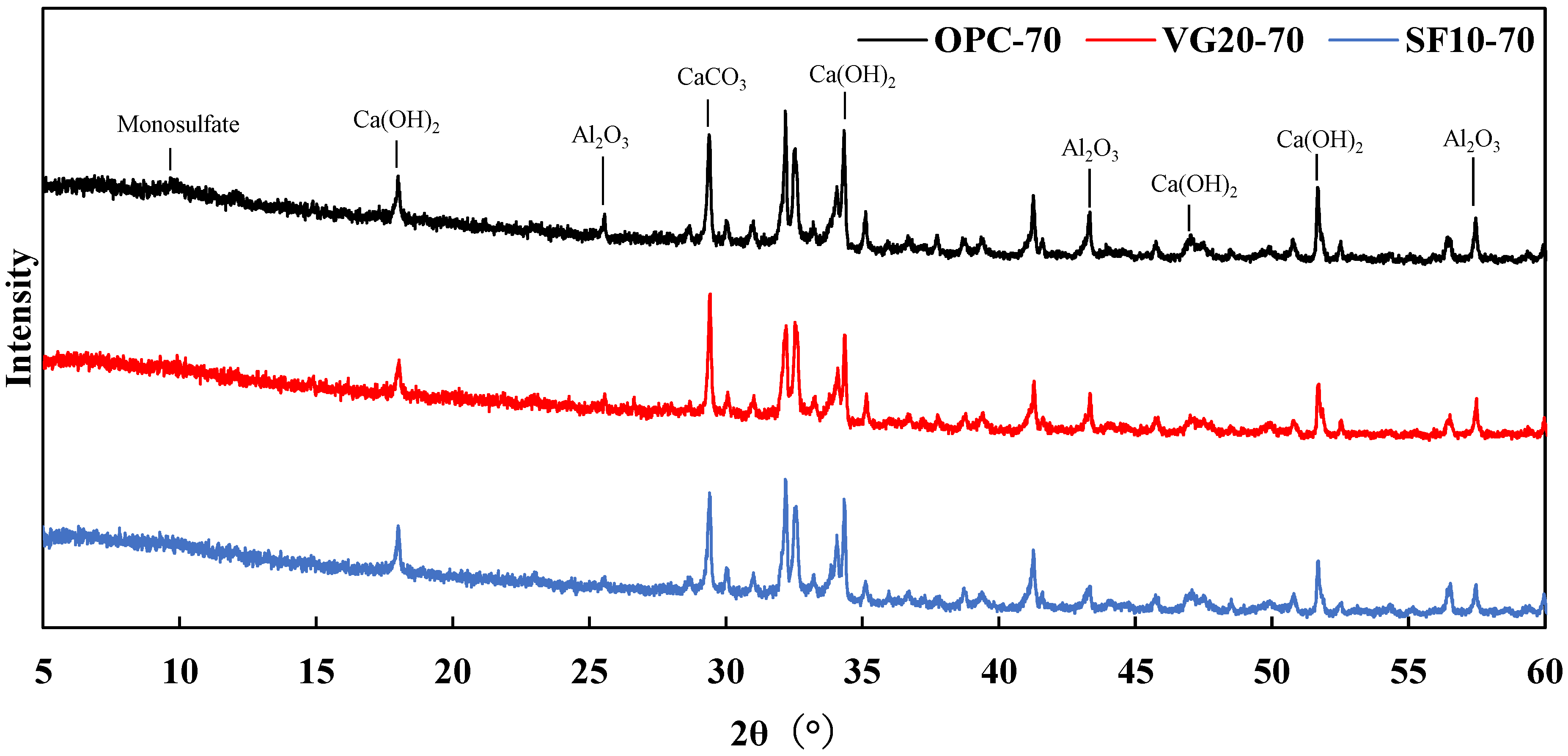

2.3.4. X-Ray Diffractometry of Cement Pastes

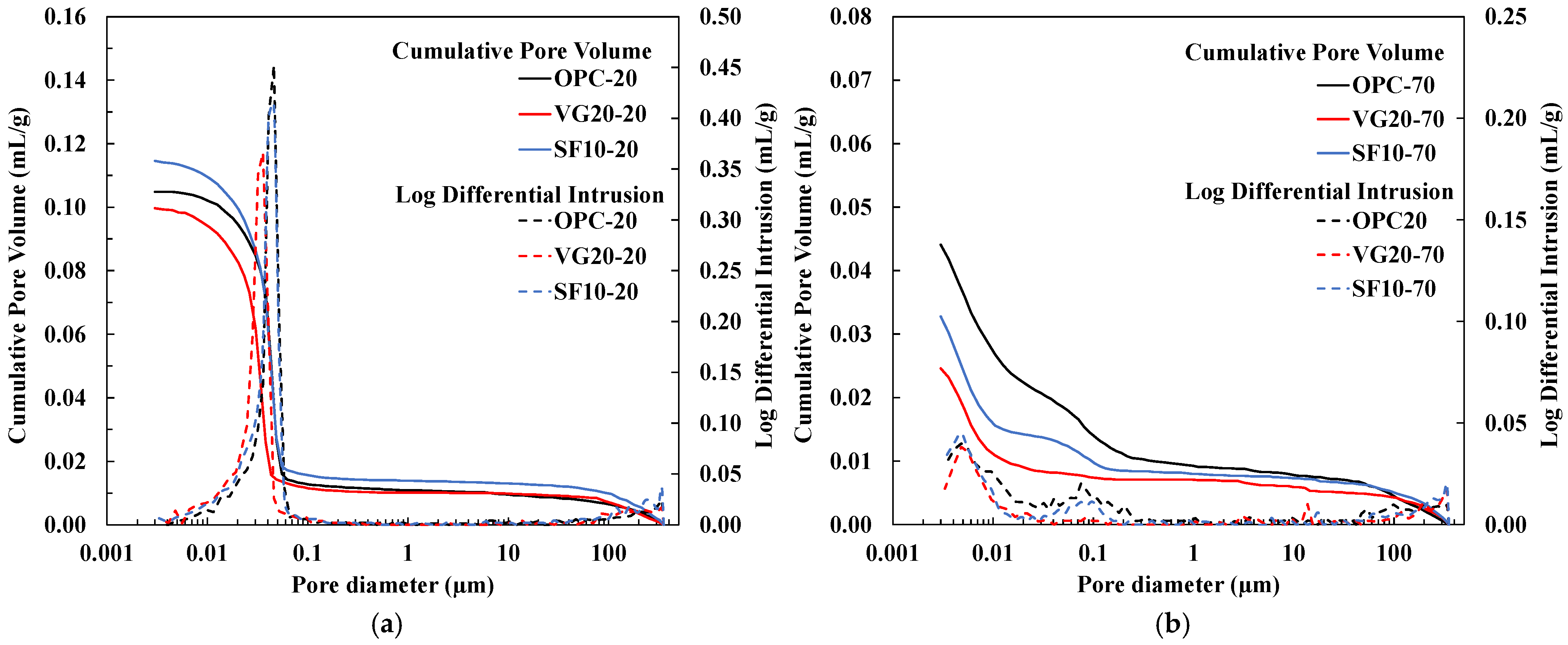

2.3.5. Mercury Injection Test of Cement Pastes

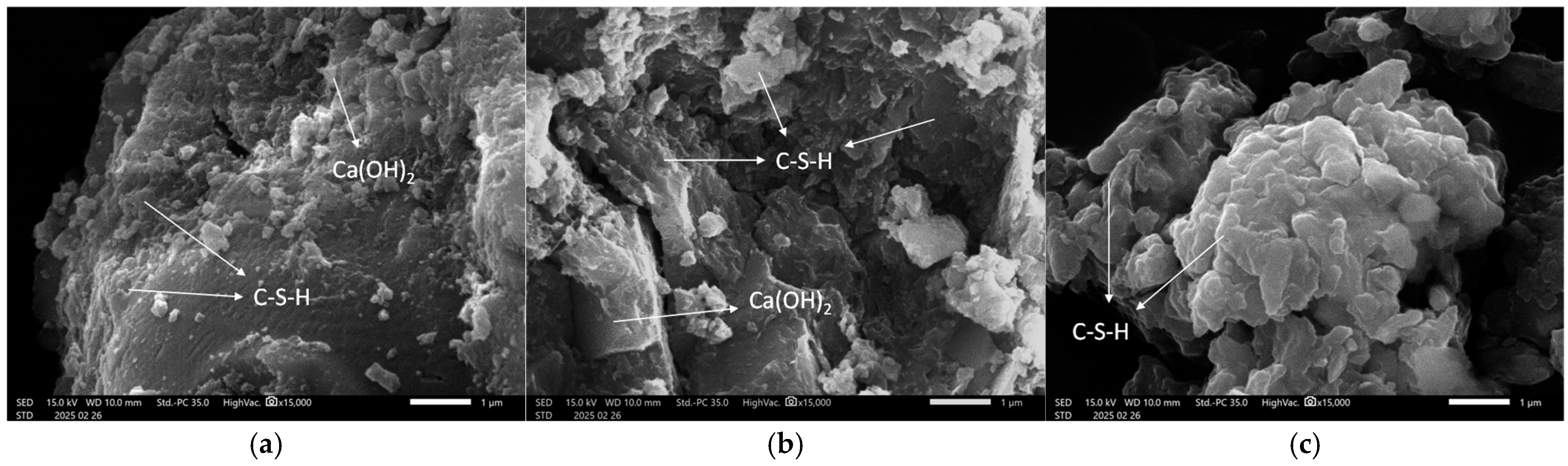

2.3.6. Observation of Crystal Structure of Cement Pastes

3. Experimental Results

4. Conclusions

- VG, like SF, consists of fine particles that enhance mortar fluidity through a ball-bearing effect when mixed with raw materials.

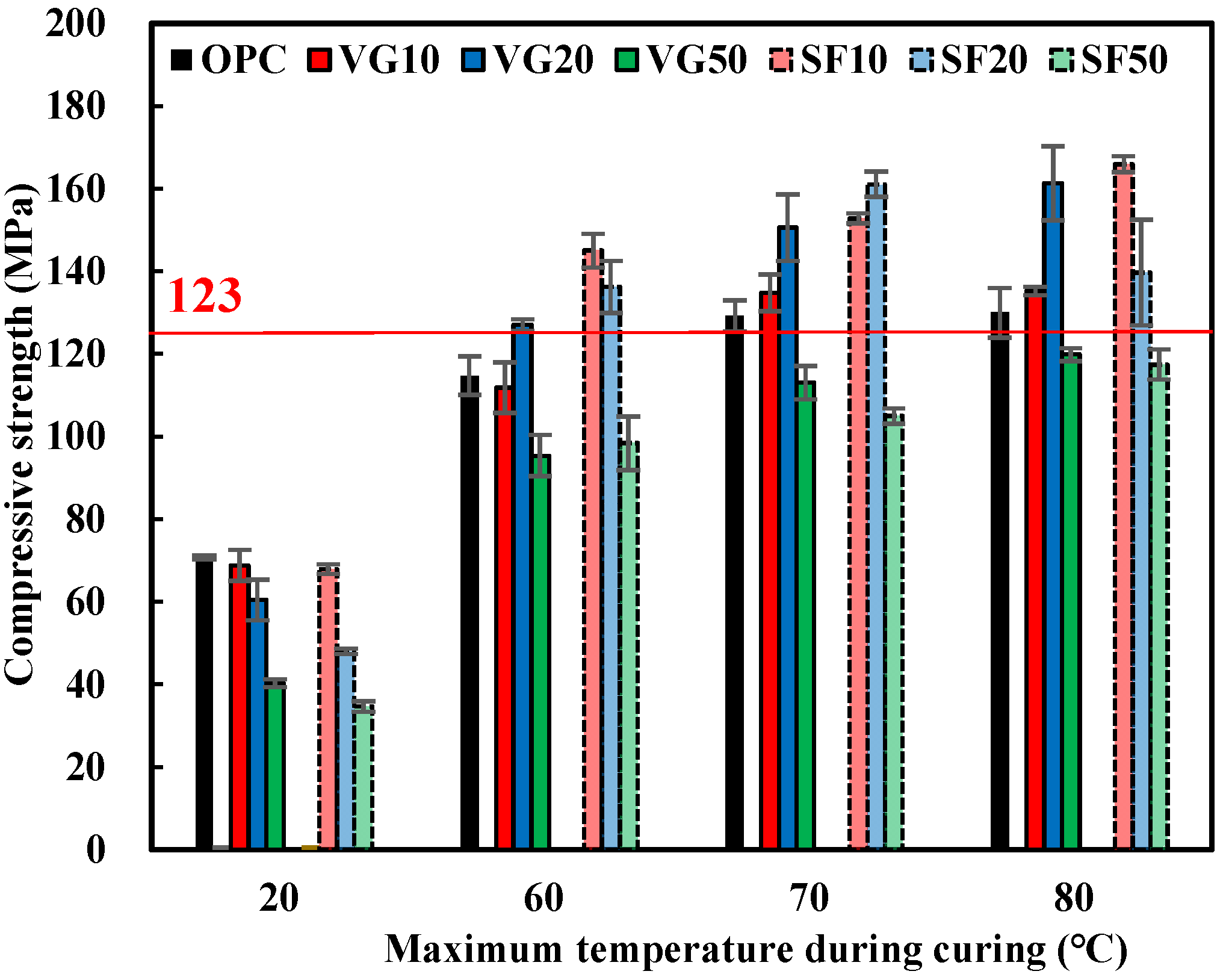

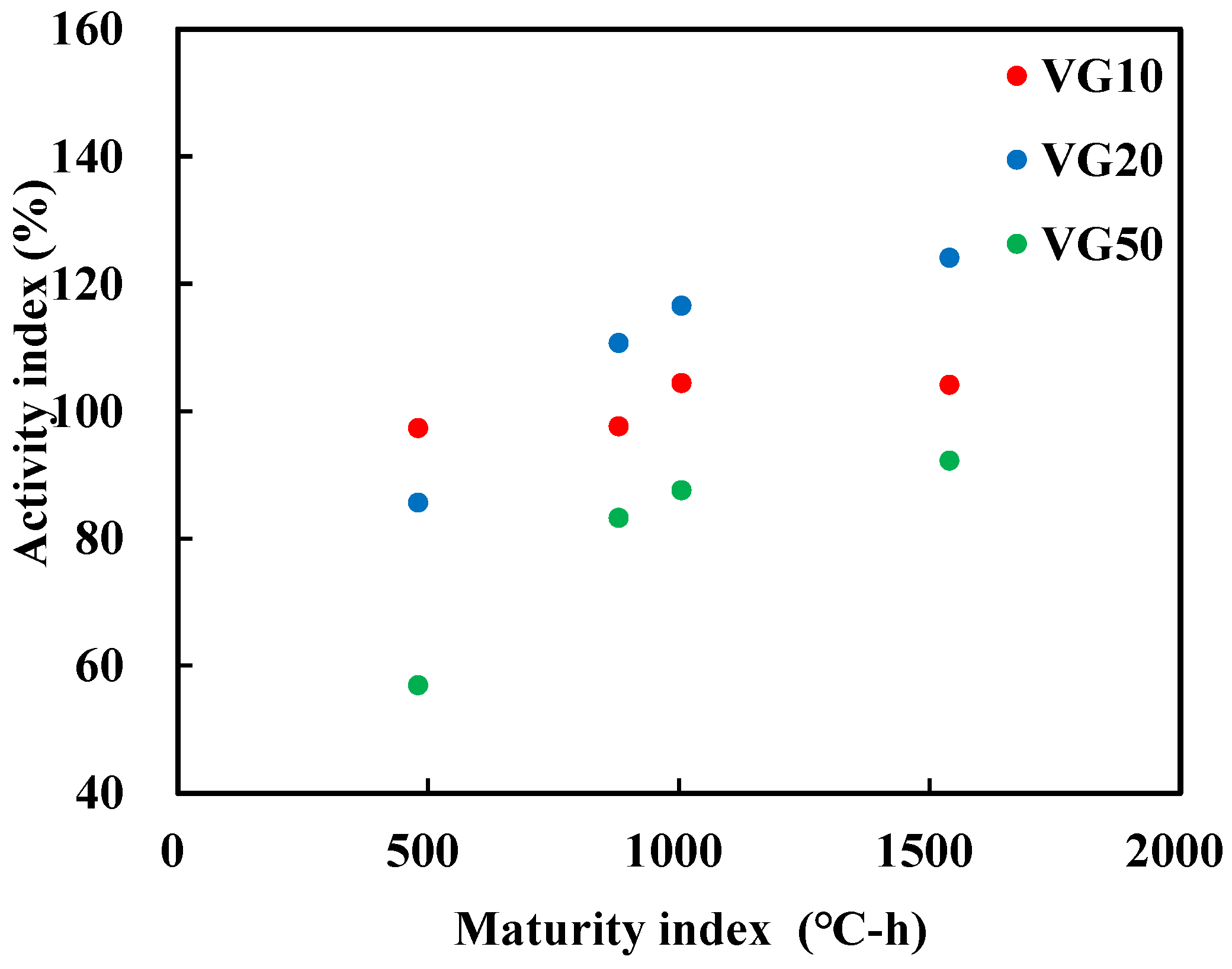

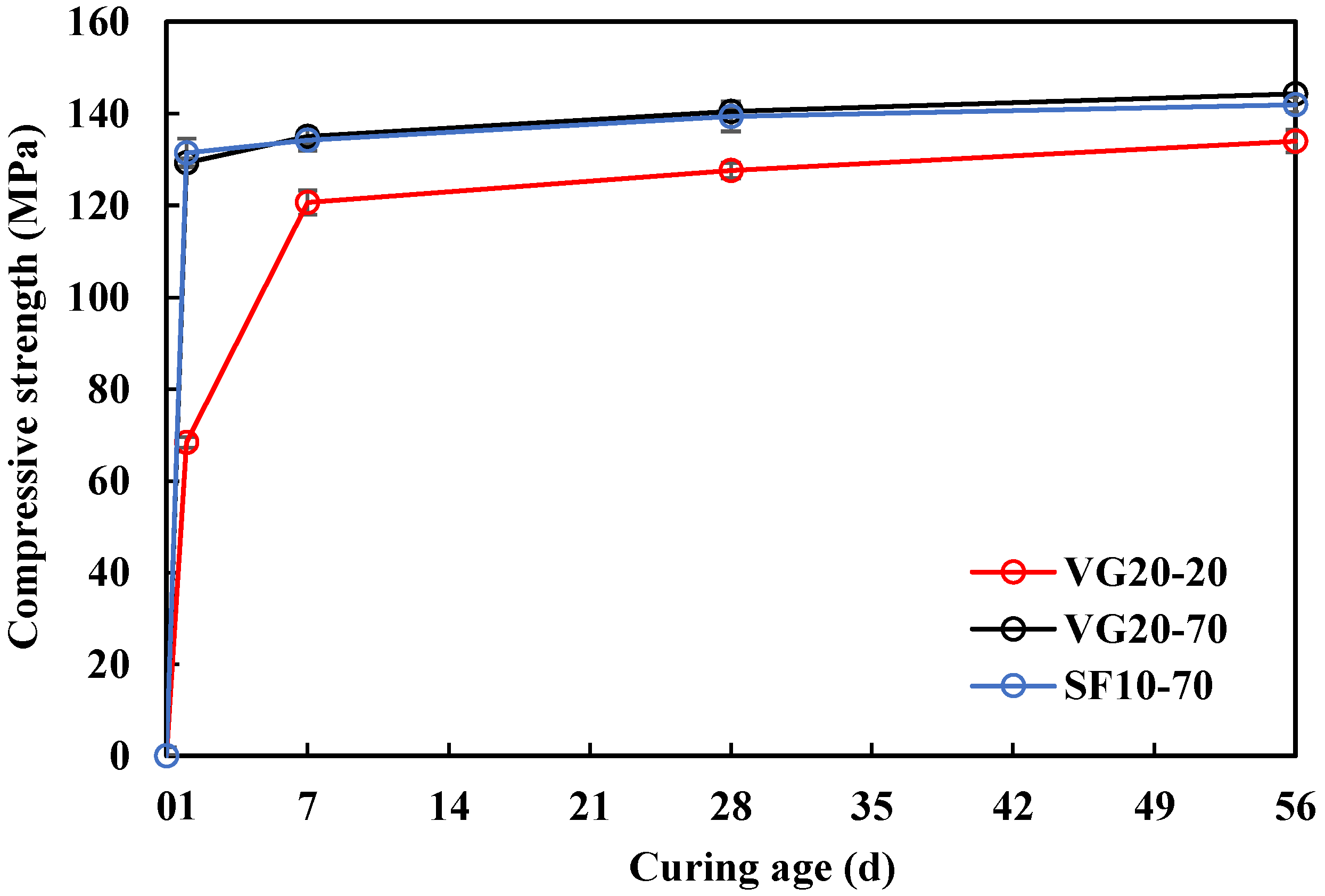

- The activity index of the VG concrete increased when it was steam-cured.

- The compressive strength of VG-mixed concrete was maximized when 20% of the OPC was replaced with VG, achieving a target strength of 123 MPa. The optimal steam curing conditions were maintained at 70 °C for 8 h.

- The Young’s modulus of VG-mixed concrete was slightly lower than that of concrete mixed with OPC alone or SF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAM | Alkali-activated materials |

| ASTM | American Society for Testing and Materials |

| BS | British Standard Methods |

| C-S-H | Calcium silicate hydrate |

| DEF | Delayed ettringite formation |

| JIS | Japanese Industrial Standards |

| OPC | Ordinary Portland cement |

| SEM | Scanning electron microscopy |

| SF | Silica fume |

| VG | Volcanic glass powder |

| XRD | X-ray diffractometry |

References

- Demand Trend Forecasting Committee of Concrete Pile and Pole Industrial Technology Association. Concrete Pile Demand Forecast Report, 2022, 16. Available online: https://www.c-pile.or.jp/library/58d8a24e6a12346753a62666/66137090a66e572383afd44f.pdf (accessed on 4 February 2025). (In Japanese).

- Yang, J.; Fan, J.; Kong, B.; Cai, C.S.; Chen, K. Theory and Application of New Automated Concrete Curing System. J. Build. Eng. 2018, 17, 125–134. [Google Scholar] [CrossRef]

- Liu, B.; Xie, Y.; Zhou, S.; Li, J. Some Factors Affecting Early Compressive Strength of Steam-Curing Concrete with Ultrafine Fly Ash. Cement Concr. Res. 2001, 31, 1455–1458. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Q.; Chen, H. Properties of High-Volume Limestone Powder Concrete under Standard Curing and Steam-Curing Conditions. Powder Technol. 2016, 301, 16–25. [Google Scholar] [CrossRef]

- Gallucci, E.; Zhang, X.; Scrivener, K.L. Effect of Temperature on the Microstructure of Calcium Silicate Hydrate (CSH). Cem. Concr. Res. 2013, 53, 185–195. [Google Scholar] [CrossRef]

- Jinnai, H.; Saeki, T.; Nagataki, S. Silica fume. Concr. J. 2014, 52, 399–404. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Snellings, R.; Mertens, G.; Elsen, J. Supplementary Cementitious Materials. Rev. Mineral. Geochem. 2012, 74, 211–278. [Google Scholar] [CrossRef]

- Becerra-Duitama, J.A.; Rojas-Avellaneda, D. Pozzolans: A review, Eng. Appl. Sci. Res. 2002, 49, 495–504. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; De Wolf, C.; Chin, S.; Ochsendorf, J.; Hajiah, A.E.; Al-Mumin, A.; Buyukozturk, O. Impact of Embodied Energy on Materials/Buildings with Partial Replacement of Ordinary Portland Cement (OPC) by Natural Pozzolanic Volcanic Ash. J. Clean. Prod. 2018, 177, 547–554. [Google Scholar] [CrossRef]

- Tomoyose, A.; Noguchi, T.; Sodeyama, K. Outline of “Development of Volcanic Glass Powder for Use in Concrete”. Nation. Rep. J. Struct. Concr. 2022, 185–186. Available online: https://www.jpci.or.jp/national_report/2022/pdf/49.pdf (accessed on 4 February 2025).

- Tomoyose, A.; Noguchi, T.; Sodeyama, K.; Higashi, K.; Kazuro, H. Origin and Manufacturing of Volcanic Glass Powder. Concr. Eng. 2020, 58, 805–813. (In Japanese) [Google Scholar] [CrossRef]

- Rashad, A.M.; ElNagar, A.M.; El-Nashar, M.H.; Ezzat, M. The Use of Egyptian Volcanic Glass Powder as a Potential Source for Improving the Properties of Alkali-activated Fly Ash Cement. Sustain. Chem. Pharm. 2024, 39, 101597. [Google Scholar] [CrossRef]

- Rashad, A.M.; Abdu, M.F.A.; Ezzat, M. Egyptian Volcanic Glass Powder as a Modifier Agent for Alkali-activated Slag Cement. Constr. Build. Mater. 2023, 408, 133662. [Google Scholar] [CrossRef]

- Wang, W.; Noguchi, T.; Tomoyose, A.; Zhang, Y.; Maruyama, I. Influence of Volcanic Glass Powder on Alkali-silica Reaction Expansion in Alkali-activated Slag Mortars. Cem. Concr. Compos. 2024, 152, 105665. [Google Scholar] [CrossRef]

- Ige, O.E.; Olanrewaju, O.A.; Duffy, K.J.; Obiora, C. A Review of the Effectiveness of Life Cycle Assessment for Gauging Environmental Impacts from Cement Production. J. Clean. Prod. 2021, 324, 129213. [Google Scholar] [CrossRef]

- Yoro, K.O.; Daramola, M.O. CO2 Emission Sources, Greenhouse Gases, and the Global Warming Effect. In Advances in Carbon Capture; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–28. [Google Scholar] [CrossRef]

- Kamath, M.; Prashant, S.; Ralegaonkar, R. Microstructure Properties of Popular Alkali-activated Pastes Cured in Ambient Temperature. Buildings 2023, 13, 858. [Google Scholar] [CrossRef]

- Kaptan, K.; Cunha, S.; Aguiar, J. A Review: Construction and Demolition Waste as a Novel Source for CO2 Reduction in Portland Cement Production for Concrete. Sustainability 2024, 16, 585. [Google Scholar] [CrossRef]

- Elemam, W.E.; Tahwia, A.M.; Abdellatief, M.; Youssf, O.; Kandil, M.A. Durability, Microstructure, and Optimization of High-strength Geopolymer Concrete Incorporating Construction and Demolition Waste. Sustainability 2023, 15, 15832. [Google Scholar] [CrossRef]

- Elemam, W.E.; Agwa, I.S.; Tahwia, A.M. Reusing Ceramic Waste as a Fine Aggregate and Supplemental Cementitious Material in the Manufacture of Sustainable Concrete. Buildings 2023, 13, 2726. [Google Scholar] [CrossRef]

- Mousavinezhad, S.; Garcia, J.M.; Toledo, W.K.; Newtson, C.M. A Locally Available Natural Pozzolan as a Supplementary Cementitious Material in Portland Cement Concrete. Buildings 2023, 13, 2364. [Google Scholar] [CrossRef]

- Tomoyose, A.; Noguchi, T.; Sodeyama, K.; Higashi, K. Research on the Environmental Impact Reduction Effects of Using Volcanic Glass Powder. Proc. Japan Concr. Inst. 2020, 42, 1. Available online: https://data.jci-net.or.jp/data_pdf/42/042-01-1022.pdf (accessed on 4 February 2025). (In Japanese).

- The Japan Cement Association. Summary of Life Cycle Inventory Analysis Data for Cement. 2024, 5. Available online: https://www.jcassoc.or.jp/cement/4pdf/jg1i_01.pdf (accessed on 20 February 2025). (In Japanese).

- Sodeyama, K.; Tomoyose, A.; Noguchi, T.; Kusumoto, K. Investigations on the Resistance of Concrete with Volcanic Glass Powder to Penetration of Corrosion Factors of Reinforcing Steel Bars. Proc. Jpn. Concr. Inst. 2019, 41, 167–172. Available online: https://data.jci-net.or.jp/data_pdf/41/041-01-1023.pdf (accessed on 4 February 2025). (In Japanese).

- Tomoyose, A.; Noguchi, T.; Sodeyama, K.; Higashi, K. Effect of BET Surface Area and Replacement Ratio of Volcanic Glass Powder on Compressive Strength. Cem. Sci. Concr. Technol. 2019, 73, 465–470. (In Japanese) [Google Scholar] [CrossRef]

- Tojo, M.; Sato, M.; Koizumi, K.; Umemura, Y. The Effect of C-S-H and Pore Structure on Compressive Strength of Cement Hardened with Volcanic Glass Powder. Cem. Sci. Concr. Technol. 2022, 76, 427–435. (In Japanese) [Google Scholar] [CrossRef]

- Papadakis, V.G. Experimental investigation and theoretical modeling of silica fume activity in concrete. Cem. Concr. Res. 1999, 29, 79–86. [Google Scholar] [CrossRef]

- Kim, B.-J.; Lee, G.-W.; Choi, Y.-C. Hydration and Mechanical Properties of High-Volume Fly Ash Concrete with Nano-Silica and Silica Fume. Materials 2022, 15, 6599. [Google Scholar] [CrossRef]

- Ueno, A.; Kokubu, K.; Uji, K. A Fundamental Study of Evaluation of Effects of Mineral Powders on Fluidity and Bleeding of Concrete. Jpn. J. JSCE 2003, 725, 213–225. [Google Scholar] [CrossRef][Green Version]

- Miura, N.; Sogo, S. Research on Performance Evaluation Method of Concrete Densify. Proc. Japan Concr. Inst. 2002, 24, 1107–1112. Available online: https://data.jci-net.or.jp/data_pdf/24/024-01-1177.pdf (accessed on 20 February 2025). (In Japanese).

- Sato, M.; Umemura, M.; Koizumi, K. Hydration of Hardened Ultra-High Strength Cement Using Silica Fume and Water Reducing Agent. Cem. Sci. Concr. Technol. 2010, 64, 442–449. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Noguchi, T.; Tomosawa, F. Relationship between Compressive Strength and Modulus of Elasticity of High Strength Concrete. J. Struct. Constr. Eng. 1995, 60, 474. (In Japanese) [Google Scholar] [CrossRef]

- Nagataki, S.; Otsuki, N.; Hisada, M.; Mizuno, K. A Study on the Characterization of Silica Fume and the Evaluation of Properties of Concrete Containing Silica Fume. J. Jpn. Soc. Civ. Eng. 1995, 28, 87–98. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Matsufuji, Y. Effective Use of Resources and Concrete/Concrete with Silica Fume. Concr. J. 1996, 34, 70–75. (In Japanese) [Google Scholar] [CrossRef]

- Mitsui, K.; Yonezawa, T.; Nakashima, M.; Sugimoto, M. Study on Relationship Between Physicochemical Properties of Silica Fume and Properties of High-Strength Concrete. Proc. Jpn. Concr. Inst. 1993, 15, 63–68. Available online: https://data.jci-net.or.jp/data_pdf/15/015-01-1008.pdf (accessed on 4 February 2025). (In Japanese).

- Cai, X.; He, Z.; Tang, S.; Chen, X. Abrasion Erosion Characteristics of Concrete Made with Moderate Heat Portland Cement, Fly Ash, and Silica Fume Using Sandblasting Test. Construct. Build. Mater. 2016, 127, 804–814. [Google Scholar] [CrossRef]

- Yonezawa, T.; Yanagibashi, K.; Ikeo, Y.; Asakura, E. Dispersion of Silica Fume in High Strength Concrete. Proc. Jpn. Concr. Inst. 1993, 15, 69–74. Available online: https://data.jci-net.or.jp/data_pdf/15/015-01-1009.pdf (accessed on 4 February 2025). (In Japanese).

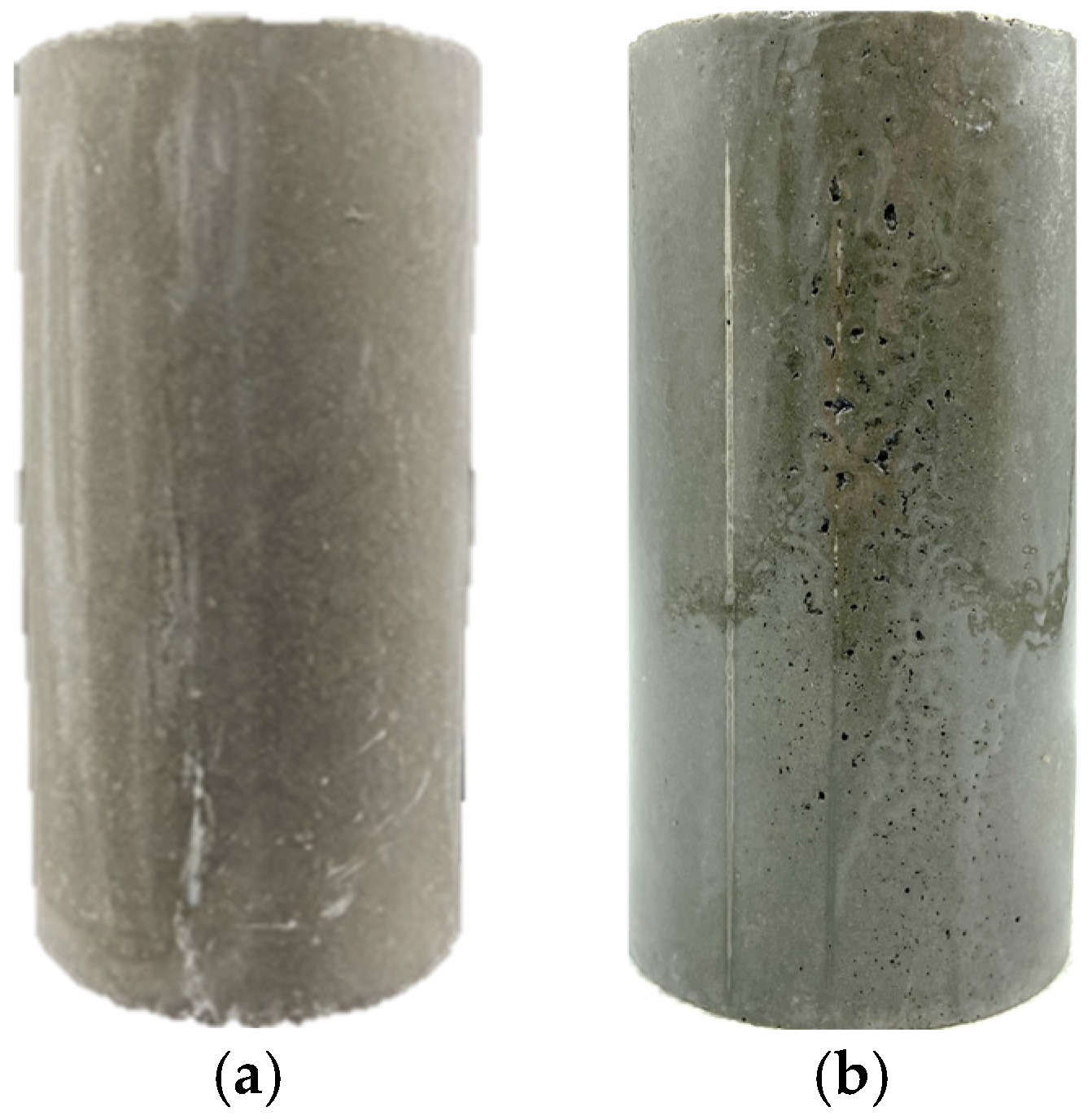

- Ichimiya, K.; Yamasaki, T. Relationship Between Surface Bubble Properties of High Flow Concrete and Steam Curing Methods and Material Permeability. Proc. Japan Concr. Inst. 2010, 32, 1205–1210. Available online: https://data.jci-net.or.jp/data_pdf/32/032-01-1193.pdf (accessed on 4 February 2025). (In Japanese).

- Takahashi, H.; Mori, H.; Komatsu, A. Accelerated Hardening of Concrete by Steam Curing. Rep. Obayashi Corp. Tech. Res. Inst. 1969, 3, 127–137. Available online: https://www.obayashi.co.jp/technology/shoho/003/1969_003_20.pdf (accessed on 4 February 2025). (In Japanese).

- Yan, X.; Jiang, L.; Guo, M.; Chen, Y.; Song, Z.; Bian, R. Evaluation of Sulfate Resistance of Slag Contained Concrete under Steam Curing. Constr. Build. Mater. 2019, 195, 231–237. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical Performances and Microstructures of Metakaolin Contained UHPC Matrix under Steam Curing Conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.; Zhou, F.; Shen, S.; Ding, Y.; Qin, J. Effects of Steam Curing Regimes on the Capillary Water Absorption of Concrete: Prediction Using Multivariable Regression Models. Constr. Build. Mater. 2020, 256, 119426. [Google Scholar] [CrossRef]

- Türkel, S.; Alabas, V. The Effect of Excessive Steam Curing on Portland Composite Cement Concrete. Cem. Concr. Res. 2005, 35, 405–411. [Google Scholar] [CrossRef]

- Erdoğdu, Ş.; Kurbetci, Ş. Influence of Cement Composition on the Early Age Flexural Strength of Heat-Treated Mortar Prisms. Cem. Concr. Compos. 2005, 27, 818–822. [Google Scholar] [CrossRef]

- Ma, W.; Sample, D.; Martin, R.; Brown, P.W. Calorimetric Study of Cement Blends Containing Fly Ash, Silica Fume, and Slag at Elevated Temperatures. Cem. Concr. Aggr. 1994, 16, 93–99. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, K.; Xia, T.; Long, G. Mechanical Property, Sorptivity and Microstructure of Steam-Cured Concrete Incorporated with the Combination of Metakaolin-Limestone. Case Stud. Constr. Mater. 2019, 11, e00267. [Google Scholar] [CrossRef]

- Ho, D.; Chua, C.; Tam, C. Steam-Cured Concrete Incorporating Mineral Admixtures. Cem. Concr. Res. 2023, 33, 595–601. [Google Scholar] [CrossRef]

- Ren, Y.; Maruyama, I.; Tomoyose, A.; Kurihara, R. Effect of Temperature on the Hydration of Ordinary Portland Cement and the Pozzolanic Reaction of Volcanic Glass Powder. Cem. Sci. Concr. Technol. 2021, 75, 166–173. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Influence of Silica Fume Content on Microstructure Development and Bond to Steel Fiber in Ultra-High Strength Cement-Based Materials (UHSC). Cem. Concr. Compos. 2016, 71, 97–109. [Google Scholar] [CrossRef]

- Wang, X.H.; Jacobsen, S.; Lee, S.F.; He, J.Y.; Zhang, Z.L. Effect of Silica Fume, Steel Fiber and ITZ on the Strength and Fracture Behavior of Mortar. Mater. Struct. 2009, 43, 125–139. [Google Scholar] [CrossRef]

- Chan, Y.W.; Chu, S.H. Effect of Silica Fume on Steel Fiber Bond Characteristics in Reactive Powder Concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Chalah, L.; Talah, A.; Ghernouti, Y. Mechanical and Durability Properties of High-Performance Concrete Incorporating Fibers and Algerian Natural Pozzolans in Chloride Attack. Int. J. Eng. Technol. Innov. 2022, 12, 247–259. [Google Scholar] [CrossRef]

- Elshinawy, A.; Yousry Elshikh, M.M.; Kaloop, M.R.; El-Demerdash, W.R.; Elemam, W.E. An Experimental Investigation on Mechanical Characteristics of Steel-fiber-reinforced Volcanic Concrete. Nex. Mater. 2025, 6, 100308. [Google Scholar] [CrossRef]

- Mehedi, M.T.; Sobuz, M.H.R.; Hasan, N.M.S.; Jabin, J.A.; Nijum, N.J.; Miah, M.J. High-strength Fiber Reinforced Concrete Production with Incorporating Volcanic Pumice Powder and Steel Fiber: Sustainability, Strength and Machine Learning Technique. Asian J. Civ. Eng. 2024, 25, 6171–6187. [Google Scholar] [CrossRef]

- Nakai, I.; Izumi, F. Practical Application of Powder X-Ray Analysis, 3rd ed.; Asakura Publishing Co., Ltd.: Tokyo, Japan, 2021. (In Japanese) [Google Scholar]

- Shimoyama, Y. Present State of Agent and Materials for Preventing Sludge Discharge in Centrifugal Casting. Concr. J. 1996, 34, 16–22. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Ba, M.; Qian, C.; Guo, X.; Han, X. Effects of steam curing on strength and porous structure of concrete with low water/binder ratio. Constr. Build. Mater. 2011, 25, 123–128. [Google Scholar] [CrossRef]

| Material | Applicable Standards, Physical Properties (Manufacturing Company, Location) |

|---|---|

| Ordinary Portland cement | JIS R 5210: 2019, density: 3.16 g/cm3, BET surface area: 0.326 m2/g (Tokuyama Corporation, Shunan, Japan) |

| Fine volcanic glass powder | JIS A 6209: 2020, Type I, density: 2.37 g/cm3, BET surface area: 9.5 m2/g (Principle Co., Ltd., Kagoshima, Japan) |

| Silica fume | JIS A 6207: 2016, density: 2.26 g/cm3, BET surface area: 16.5 m2/g (Egyptian Ferroalloys Co., Cairo, Egypt) |

| Water | Tap water |

| Superplasticizer | JIS A 6204: 2011, Type I, Polycarboxylic acid-based, SF500U (Flowric Co., Ltd., Toshima-ku, Japan) |

| Fine aggregate | JIS A 5005: 2020, Crushed sand, density: 2.61 g/cm3, Fineness modulus: 3.02 (Nanshu saiseki Co., Ltd., Hioki, Japan), |

| Coarse aggregate | JIS A 5005: 2020, Crushed stone, density: 2.66 g/cm3, Fineness modulus: 6.64, aggregate crushing value: 9.1% (BS812-110) (Nanshu saiseki Co., Ltd., Hioki, Japan), |

| SiO2 | Al2O3 | CaO | Fe2O3 | Na2O | K2O | MgO | Others | |

|---|---|---|---|---|---|---|---|---|

| OPC | 16.9 | 4.61 | 70.0 | 3.00 | 0.26 | 0.47 | 1.38 | 3.38 |

| VG | 73.7 | 13.8 | 1.94 | 2.37 | 3.51 | 3.95 | 0.32 | 0.41 |

| SF | 95.4 | 0.32 | 0.52 | 1.95 | 0.44 | 0.59 | 0.45 | 0.18 |

| Name | W/B | Unit Content (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|

| W | B | S | G | SP | ||||

| OPC | VG | SF | ||||||

| OPC | 15 | 120 | 800 | 0 | 0 | 701 | 900 | 12 |

| VG10 | 16 | 720 | 60 | 0 | ||||

| VG20 | 640 | 120 | 0 | |||||

| VG50 | 18 | 400 | 300 | 0 | ||||

| SF10 | 16 | 720 | 0 | 57 | ||||

| SF20 | 640 | 0 | 114 | |||||

| SF50 | 18 | 400 | 0 | 286 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsuboguchi, T.; Yasui, K.; Ueyama, S.; Taguchi, T. Fundamental Properties of Steam-Cured Cementitious Composites Incorporating Fine Volcanic Glass Powder. Appl. Sci. 2025, 15, 3644. https://doi.org/10.3390/app15073644

Tsuboguchi T, Yasui K, Ueyama S, Taguchi T. Fundamental Properties of Steam-Cured Cementitious Composites Incorporating Fine Volcanic Glass Powder. Applied Sciences. 2025; 15(7):3644. https://doi.org/10.3390/app15073644

Chicago/Turabian StyleTsuboguchi, Takato, Kentaro Yasui, Sachio Ueyama, and Takumi Taguchi. 2025. "Fundamental Properties of Steam-Cured Cementitious Composites Incorporating Fine Volcanic Glass Powder" Applied Sciences 15, no. 7: 3644. https://doi.org/10.3390/app15073644

APA StyleTsuboguchi, T., Yasui, K., Ueyama, S., & Taguchi, T. (2025). Fundamental Properties of Steam-Cured Cementitious Composites Incorporating Fine Volcanic Glass Powder. Applied Sciences, 15(7), 3644. https://doi.org/10.3390/app15073644