1. Introduction

With the development of space exploration in recent decades, on-orbit space robots are increasingly gaining attention from researchers. Space robots serve as crucial tools for ensuring the safe operation and prolonged lifespan of spacecraft, contributing to tasks such as space station construction, satellite maintenance, and space debris clearance [

1,

2]. However, traditional rigid robots, characterized by limited degrees of freedom and insufficient flexibility, face challenges in efficiently and safely while completing on-orbit tasks within complex and confined environments. Continuum robots, as a new type of biomimetic robotic arm, offer higher flexibility and enhanced interactive safety [

3]. They can perform a variety of tasks in narrow and restricted environments, holding promising applications in the field of space robots.

Continuum robots can achieve continuous bending and motion in complex and confined unstructured environments, leveraging their inherent flexibility. The driving mechanism of continuum manipulators is mostly installed in the base at the bottom. With a relatively small mass and lower stiffness compared to traditional rigid robots, continuum robots exhibit higher safety when in contact with the environment. Currently, continuum robots find widespread applications in areas such as aerospace [

4], medical fields [

5], power systems [

6], exploration [

7], and rescue operations [

8]. However, the use of soft materials and structures can lead to vibrations, creating a strongly coupled nonlinear system. Modeling and controlling such systems both still lack a well-established unified approach. Additionally, the base of space robots is free-floating, introducing complex dynamic coupling between the motion of the manipulator and the satellite base, posing significant challenges in trajectory planning [

9]. Currently, research either focuses solely on the trajectory planning problem of continuum space robots or solely on the dynamic tracking control problem, without effectively integrating the two. Therefore, research on the kinematics and dynamics of continuum space robots is meaningful but also confronts various challenges [

10]. Inaccurate calculation of the robot system’s motion deformation, kinetic energy, and momentum can affect the dynamic coupling of the base, thereby increasing trajectory planning and control errors.

Current commonly used high-precision control methods for robots include adaptive control, fuzzy control, sliding mode control, backstepping control, etc., but most of these systems are asymptotically stable. Dian et al. [

6], addressing the uncertainty compensation issue in a cable-driven continuum robot system, proposed a novel disturbance-resistant control method based on a sliding mode controller and a linear extended state observer. While this method can compensate for the effects of system uncertainty, its sliding mode controller employs exponential reaching law, which cannot guarantee the convergence time of errors. Ayala-Carrillo et al. [

11], addressing robust tracking control issues in pneumatic-driven continuum soft robots, proposed a finite-time sliding mode controller to achieve convergence of tracking errors within a finite time. For the task space tracking control problem of free-floating space robots, Jin et al. [

12] utilized a fixed-time extended state observer to ensure that, even in the presence of external disturbances, the convergence time of tracking errors is bounded and independent of the system’s initial state. Since the relationship between fixed-time controller time and parameters is complex, Sanchez-Torres et al. [

13] introduced the predefined time stability theory, with the upper bound of stability time related to the system, allowing for the pre-definition and simplification of controller design.

The predefined time stability theory ensures system response speed and allows for specification of the convergence time during controller design. Ye et al. [

14] proposed an attitude tracking controller for rigid spacecraft based on predefined time, combining sliding mode control and predefined time theory to achieve high-precision control of spacecraft attitude. Jin et al. [

15], addressing the tracking control problem of free-floating space robots in the task space, introduced a predefined time-based backstepping control method, enabling the end-effector position and attitude of the robot to track the desired trajectory within a predetermined time, even with initial errors. Liu et al. [

16] presented a predefined time-based terminal sliding mode control method, demonstrating through rigorous mathematical formulation the system’s singularity-free and globally predefined time convergence. This method achieves high-precision trajectory tracking control for dual-arm space robots. However, this work did not further investigate the trajectory planning problem considering kinematics. However, predefined-time control methods can guarantee convergence of errors within a given time in any situation, but they lead to the requirement of larger input gains. This is because the predefined-time theory considers convergence time even from infinitely large initial states, leading to overly conservative estimates of convergence time. In trajectory planning, a higher input gain represents larger joint angular velocities, which can lead to increased vibration for continuum space robots. In trajectory tracking control, traditional predefined time inputs that are relatively large can cause actuator saturation and faults.

In engineering applications, it is rare for system states to tend towards infinity; most of the time, they are bounded. For the case where the initial conditions are bounded, Yan et al. [

17] proposed a generalized explicit time stability system with bounded gains, which significantly reduces the initial control input. However, there is currently relatively little research on specific applications based on explicit time stability. The control theory can achieve system convergence within predefined time while initiating smaller initial control inputs to reduce the damage caused by excessive control inputs to the actuators. However, in designing controllers, the mathematical expression forms are complex, especially when applied to sliding mode control, making it difficult to derive. Research on how to design more concise and practical trajectory planning and control algorithms based on explicit time theory is still needed. In summary, this paper proposes a high-precision control scheme for trajectory planning and tracking control of a continuum space robot. By employing explicit time theory in trajectory planning and tracking for continuous space robots, smoother joint trajectories and smaller initial control inputs can be obtained. The main contributions of this paper are as follows:

(1) The model of continuum space robots is established by introducing the arc length parameter. Based on this, the pose feedback kinematic model of continuous space robots is established using quaternions to describe the end effector’s pose of the robotic arm. In the modeling process, the momentum conservation and nonholonomic constraints of the robotic system are taken into account. This modeling approach has more accurate model parameters.

(2) Based on the kinematic model of the continuum space robot, a trajectory planning method utilizing explicit time stability theory is proposed. Compared to other methods, this approach can generate smoother joint trajectories.

(3) Building upon the dynamic model of the continuum space robot, a trajectory tracking control method is devised that integrates explicit time stability theory and sliding mode control. This trajectory tracking control method achieves high-precision tracking of the desired trajectory within explicit time. Compared to other methods, this approach requires lower control inputs.

(4) The proposed trajectory planning and tracking control methods can be combined to further enhance the control performance of continuum space robots. Consequently, this enables high-precision trajectory planning and control for continuum space robots.

(5) Experiments were conducted on a fixed-base, single-end continuum robot, confirming the effectiveness of the explicit-time algorithm on a physical system.

In the subsequent sections,

Section 2 presents the three-dimensional model of the continuum space robot.

Section 3 establishes the theoretical groundwork for the robot’s motion control in later parts of the paper.

Section 4 provides the foundational model.

Section 5 covers the kinematic and dynamic models.

Section 6 introduces trajectory planning and control methods based on explicit time stability.

Section 7 covers the simulation and analysis of the proposed methods.

Section 8 perform experimental validation.

Section 9 presents the conclusion. Finally,

Section 10 presents future recommendations.

2. Notion

Continuum space robots consists of a satellite base and a continuum manipulator.

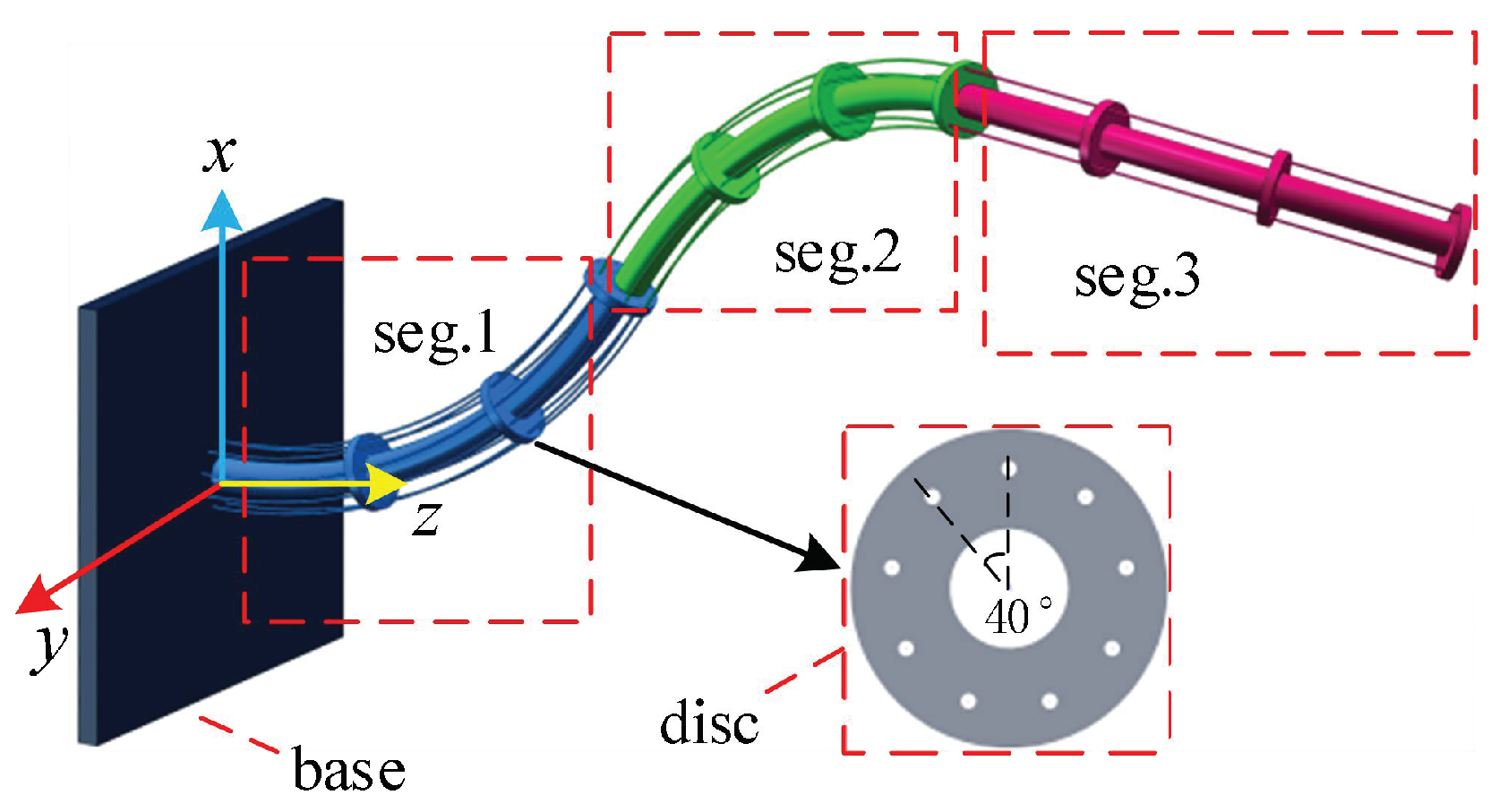

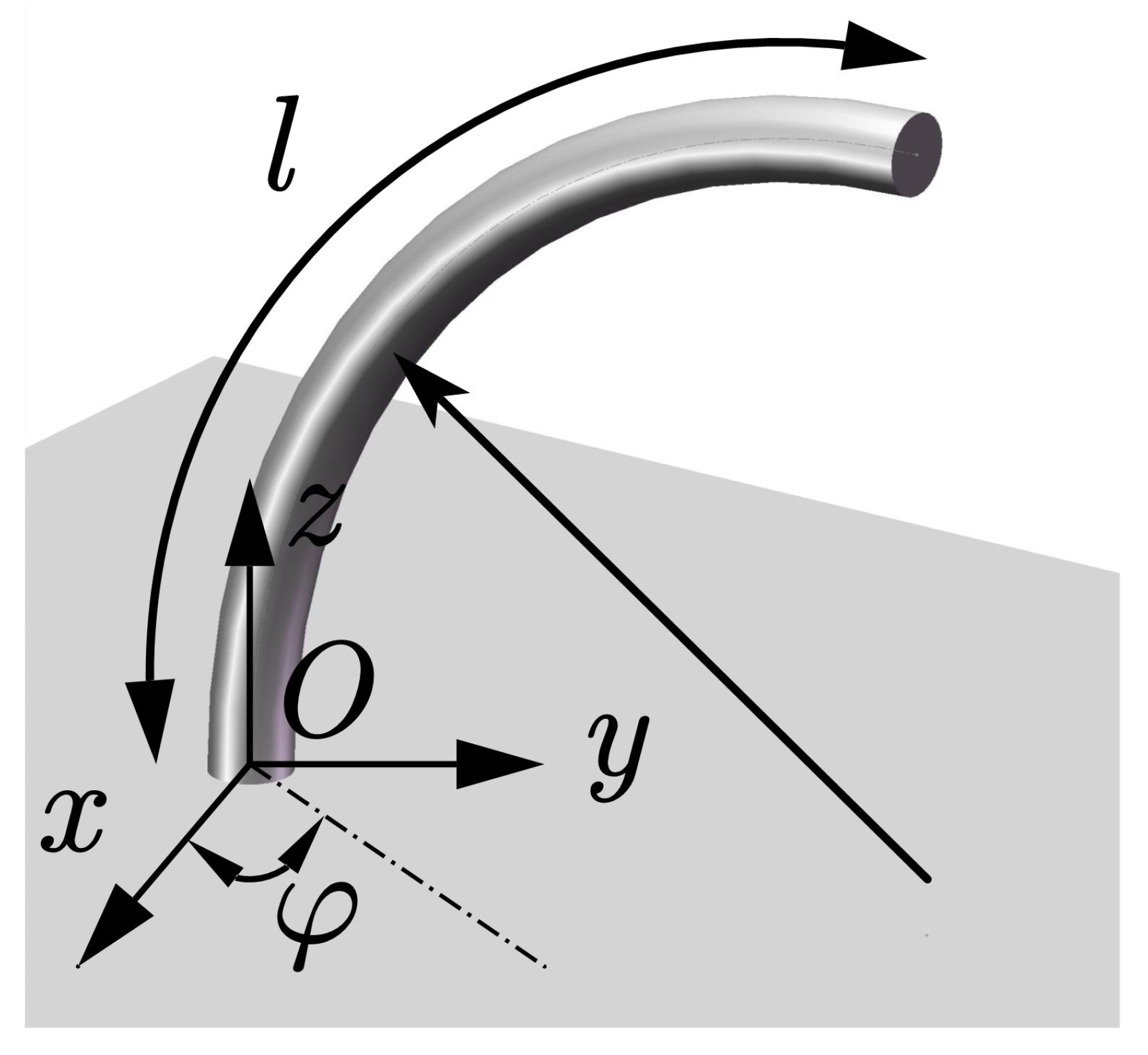

The three-dimensional model of the continuum manipulator is depicted in

Figure 1, comprising a three-segment, cable-driven continuum manipulator. Each segment has a fixed length, with a central axis consisting of an elastic flexible rod controlled by three driving cables, allowing it to bend in any direction, forming an arc. The first segment passes through 9 cables, the second through 6, and the third through 3. Equally spaced support discs are employed to maintain the curvature of the central rod, with the number of perforations on each disc matching the number of cables passing through each segment. Actuated by motors on the base, the cables are pulled to induce bending deformation in the manipulator, facilitating pose control of the robotic system.

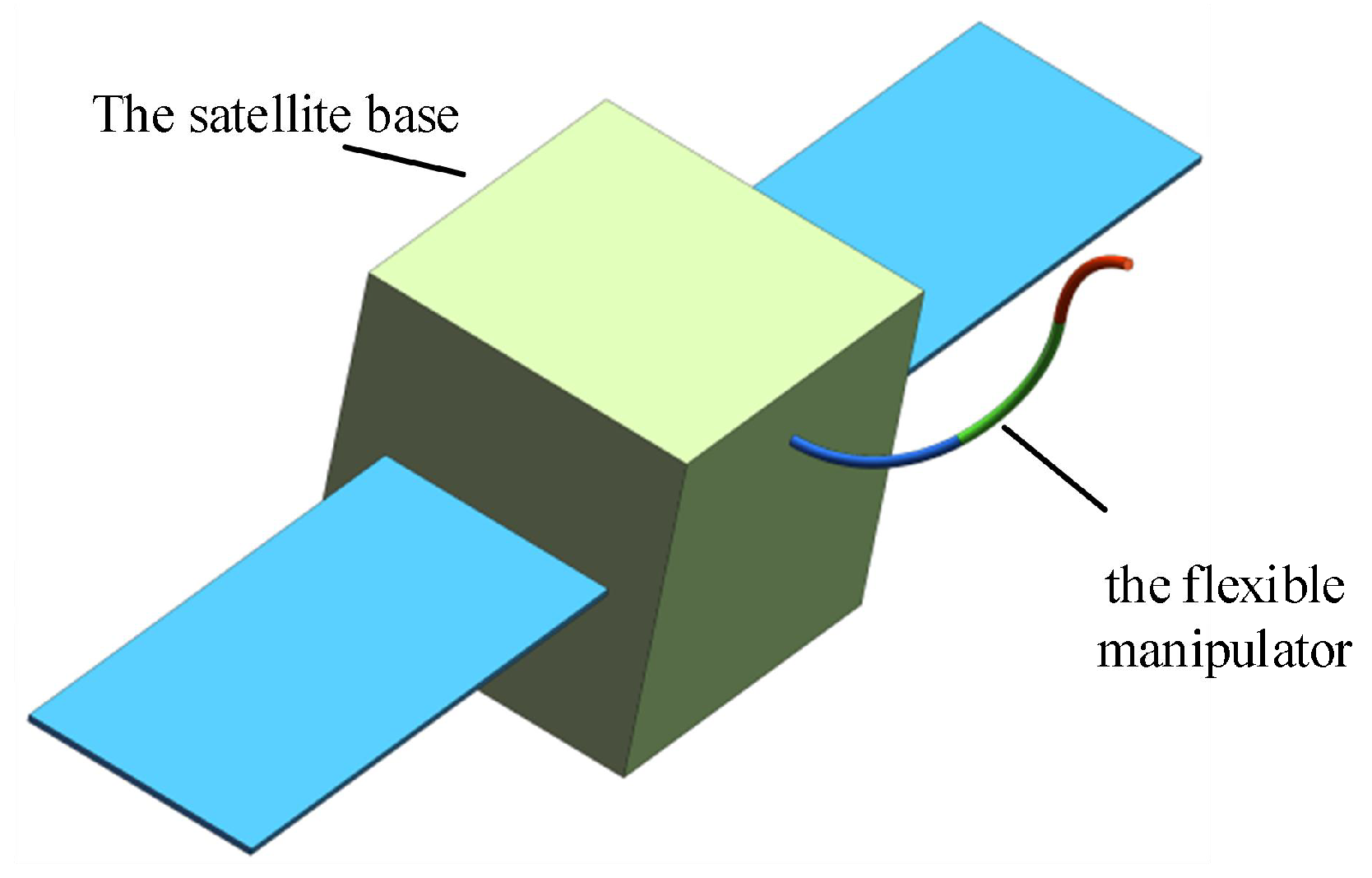

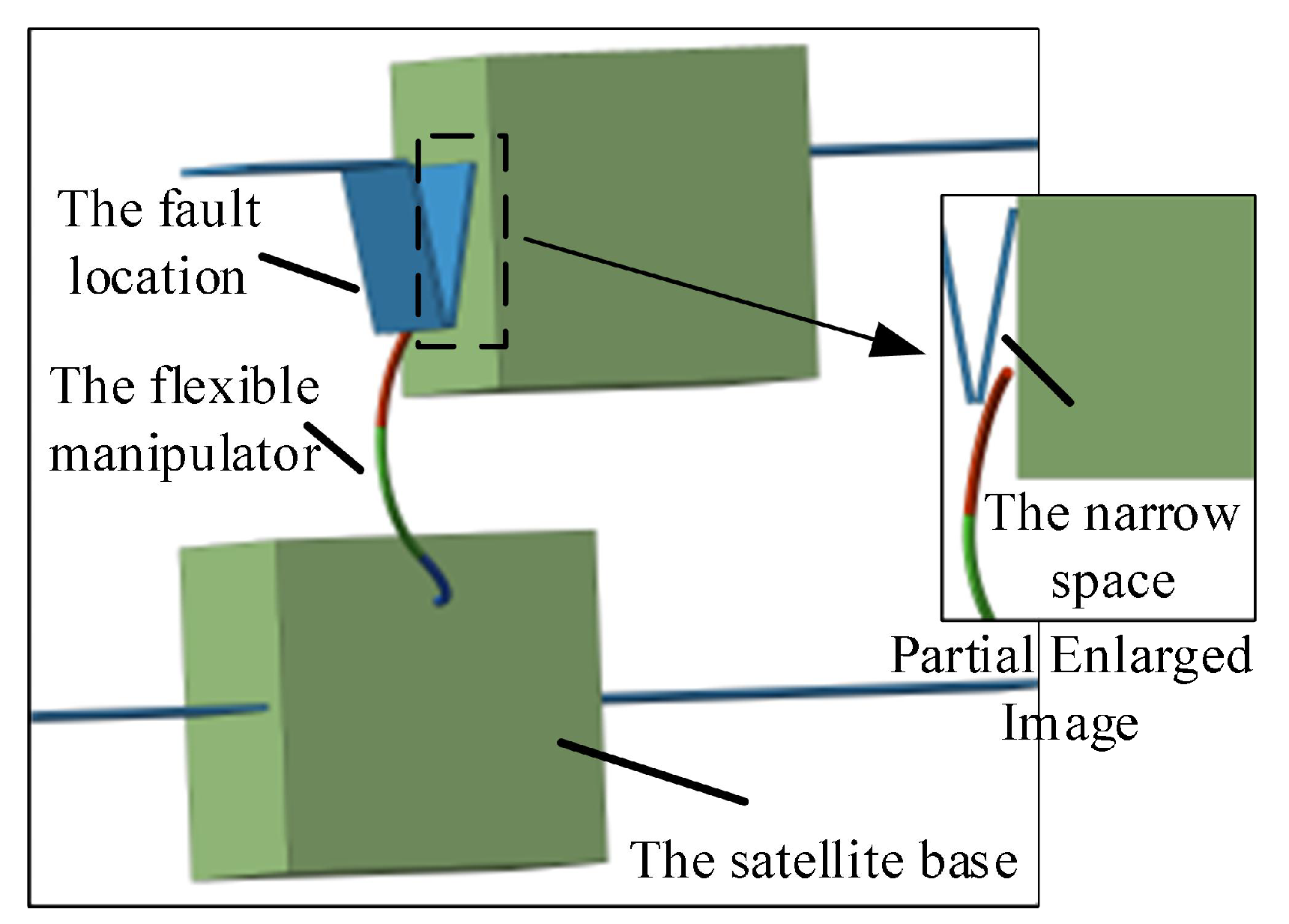

The three-dimensional model of the continuum space robot system is illustrated in

Figure 2. The base is a free-floating satellite, and the manipulator is a continuum manipulator. The advantages of this configuration lie in the flexibility and adaptability of the cable-driven continuum manipulator, making it more suitable for exploration and operations in complex and space-constrained environments, as depicted in

Figure 3.

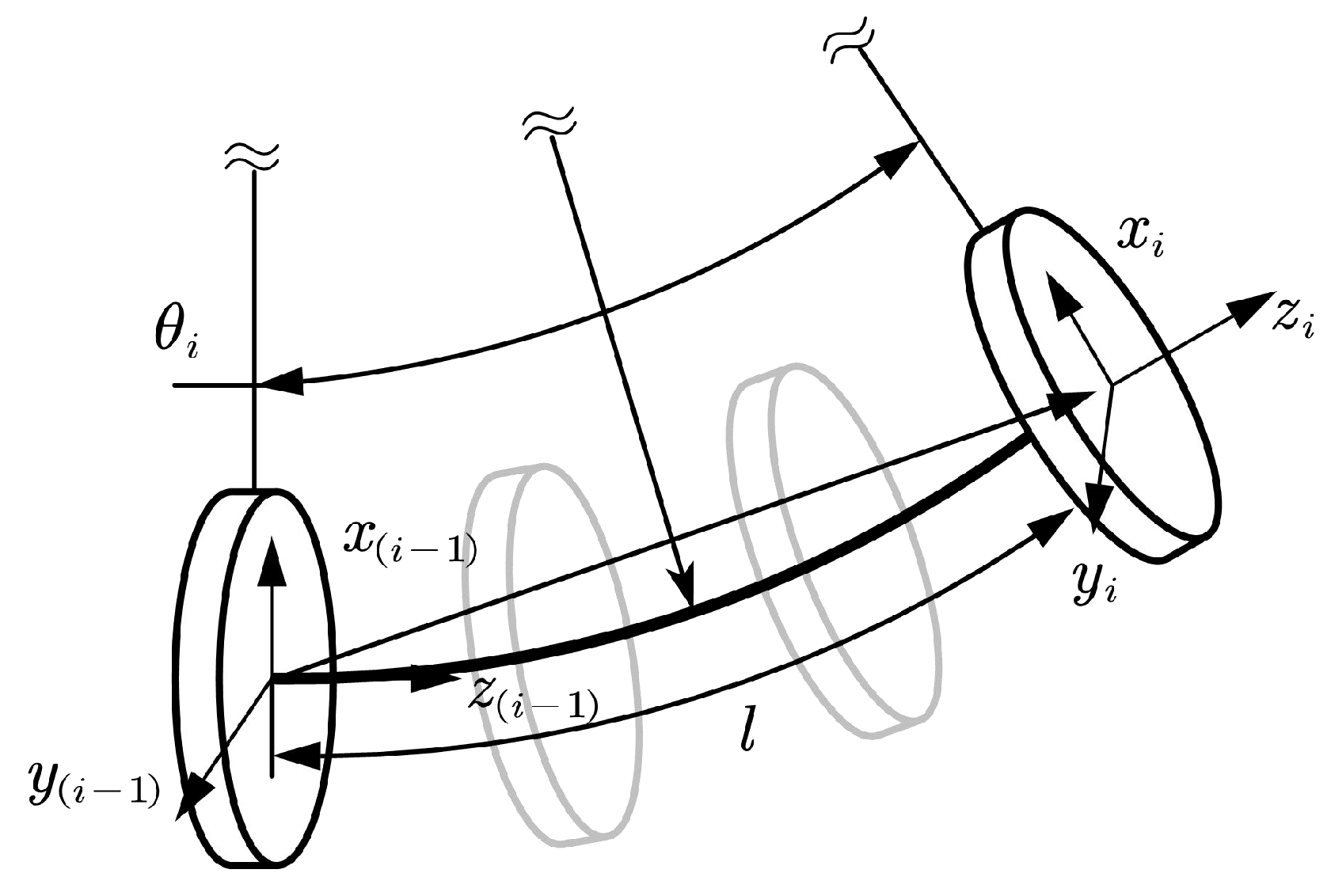

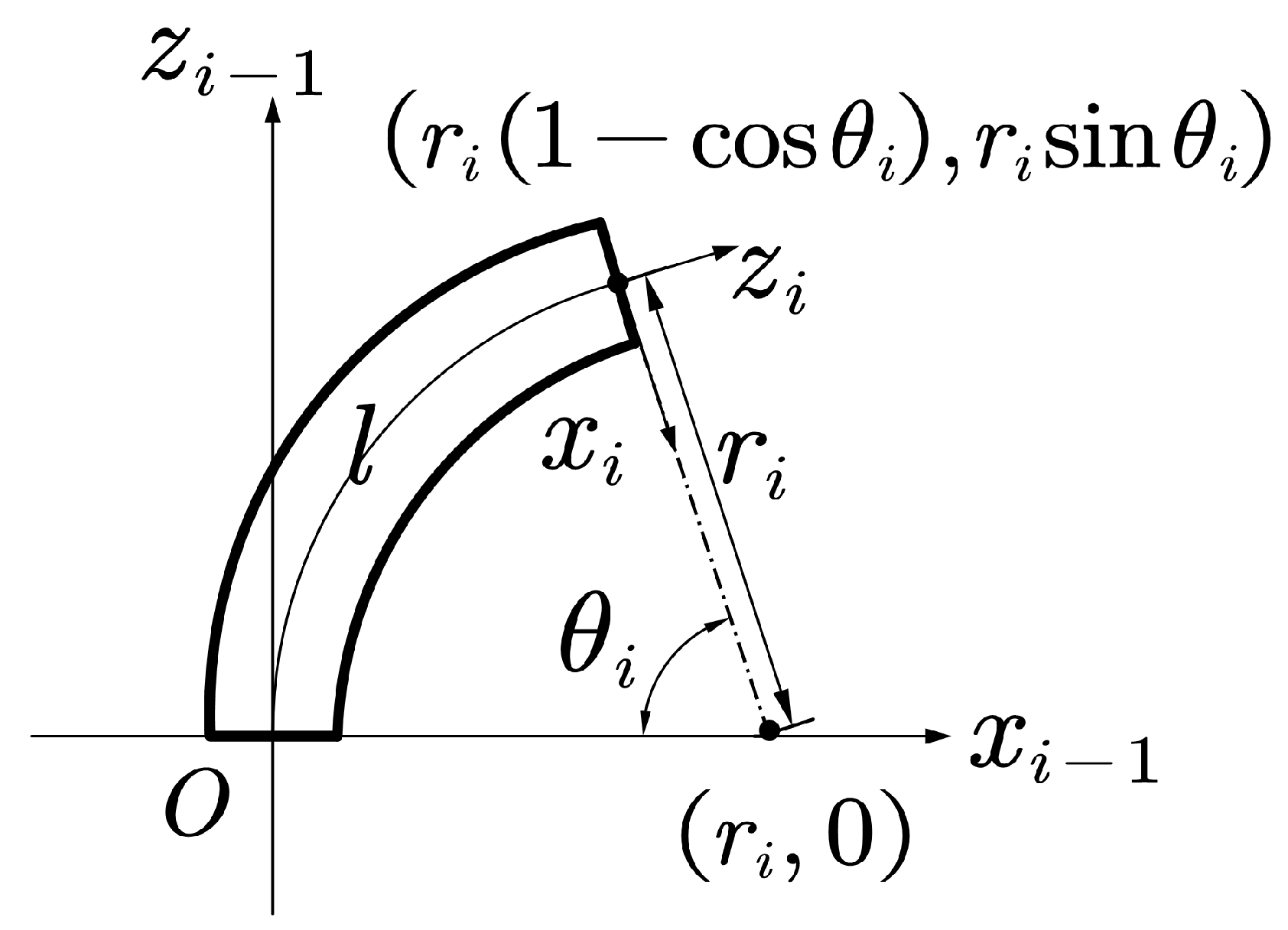

Define the symbols as follows: is the virtual joint variable corresponding to the base, where is the coordinates of the center of mass of the base in the inertial frame and is the Euler angles describing the orientation of the base relative to the inertial frame, using a 3-2-1 sequence. is the velocity of the base. is the joint variable, where and are the bending plane angle and bending angle of the i-th (i = 1, 2, 3) segment of the continuum manipulator. is the joint velocity. is the generalized virtual joint variable. is the generalized virtual joint velocity. and are the linear momentum and angular momentum of the base, respectively. , , , and are the linear momentum and angular momentum of the elastic rod and support disk of the i-th segment of the continuum robot, respectively.

and are the inertia matrices for translation and rotation of the base, respectively. , , , and are the inertia matrices for the translation and rotation of the elastic rod and support disk of the i-th segment of the continuum robot, respectively.

5. Trajectory Planning

The expected response of relative pose error in kinematics can be designed as

where

is the upper bound of the estimated error.

Proposition 1. The system (41) can achieve stability over time under the control of the controller (56).

Proof. Considering a candidate Lyapunov function as

The time derivative of Equation (

57) can be given by

According to (58), the convergence time of the system (56) can be calculated as

Therefore, the relative pose error of continuous space robots is explicit time convergent. The proof is complete. □

Substituting Equation (

56) into (41), the joint velocity of the continuum space robot can be planned as

where

is the desired convergence time. According to Lemma 1, the trajectory planning error can converge to zero, and the upper bound for the convergence time is

.

When the robotic system passes through a singular point (e.g., in an extended state),

becomes irreversible. The singularity avoidance method based on DLS from reference [

25] can be employed. The modified joint velocity planning for the continuum space robot can be expressed as

where

is the singular values of matrix

,

and

are the singular vectors, and

is the damping coefficient. To mitigate errors introduced by the damping coefficient, design a dynamic damping coefficient given by

where

is the maximum damping factor. In robot control, such known and fixed singularity issues can be handled using empirical values

;

is the singular threshold for assessing

.

After the robot exits the singular region, the error caused by the singular point can be eliminated within an explicit time .

6. Trajectory Tracking Control

The goal of trajectory tracking control can be chosen to make the joints track the planed trajectory within an explicit convergence time. The principle can be explained using

Figure 7.

In response to the dynamic model of a continuum space robot proposed in Equation (

55), the objective of the controller design is to ensure that the actual joint angles

track the desired joint angles

. The angle error is defined as

.

Design a terminal sliding mode switching function based on Lemma 1 as follows:

where

is the error boundary.

Design a sliding mode convergence law as

where

is the boundary calculated according to (63).

According (55), (63), and (64), an explicit time terminal sliding mode controller can be designed as

Proposition 2. System (55) can achieve stability over time under the control of the controller (65).

Proof. Considering a candidate Lyapunov function as

The time derivative of Equation (

66) can be given by

According to Lemma 1, the time upper bound of the system in the approaching stage of sliding mode control is .

When the system reaches the sliding surface,

, according to (73), there are

Considering a candidate Lyapunov function as

The time derivative of Equation (

69) can be given by

According to Lemma 1, the time upper bound of the system in the sliding stage of sliding mode control is .

The total upper bound on the stability time of the system is . The proof is complete. □

If considering the uncertainty of the system, system (55) is modified to

In order to improve the robustness of the system, the controller (65) needs to be modified to

where

.

7. Simulation

By designing a 3D model of the continuum robot in SOLIDWORKS(R) Premium 2024 SP0.1 and inputting parameters such as density and material properties, the mass, moment of inertia, area, and other relevant parameters of the base and links can be calculated. The system parameters for the continuum space robot are listed in

Table 1. The following simulations were conducted using MATLAB R2023b, with the fixed time step solver (ode1, Euler), and the fixed time step was set to

s.

7.1. Simulation and Analysis of Trajectory Planning

To validate the kinematic model and trajectory planning method of the continuum space robot, trajectory planning is conducted based on explicit time theory and singularity avoidance methods.

Table 2 presents some initial parameters of the continuum space robot system.

Move the end effector from the initial pose to the final pose, using trapezoidal velocity profiles for both linear and angular velocities [

25].

If one directly attempts to invert the positive kinematic model (33), and given that the momentum of the system is already specified to be zero, the equation for the inverse solution becomes

Due to the occurrence of singular points during the robot’s motion, where the determinant of is close to zero, the planned joint angular velocities are excessively large, which is unrealistic in practical situations.

An improved approach involves directly avoiding singularities by incorporating a damping term to reduce joint velocities at singular points [

25]. Therefore, the joint angular velocities planned based on DLS method are

Its meaning is consistent with Equation (

61).

However, the introduction of singularity avoidance methods can result in pose errors in the robot system, and correction is not achievable. During the operation of the robot system, errors will continue to accumulate.

Therefore, this paper proposes a singularity avoidance trajectory planning method based on pose feedback and improves the precision of the system’s trajectory planning based on explicit time stability theory. The relevant parameter settings for the proposed trajectory planning method (61) are , , .

To validate the proposed trajectory planning method, comparative experiments were conducted. In addition to the singularity avoidance direct inversion used in (74), finite-time algorithms and the commonly used proportional feedback in space robot trajectory planning were also employed.

The joint angular velocities planned based on the finite time [

26] are

where

and

.

The joint angular velocities planned based on the proportional feedback method are

where

is the proportional coefficient matrix; here,

.

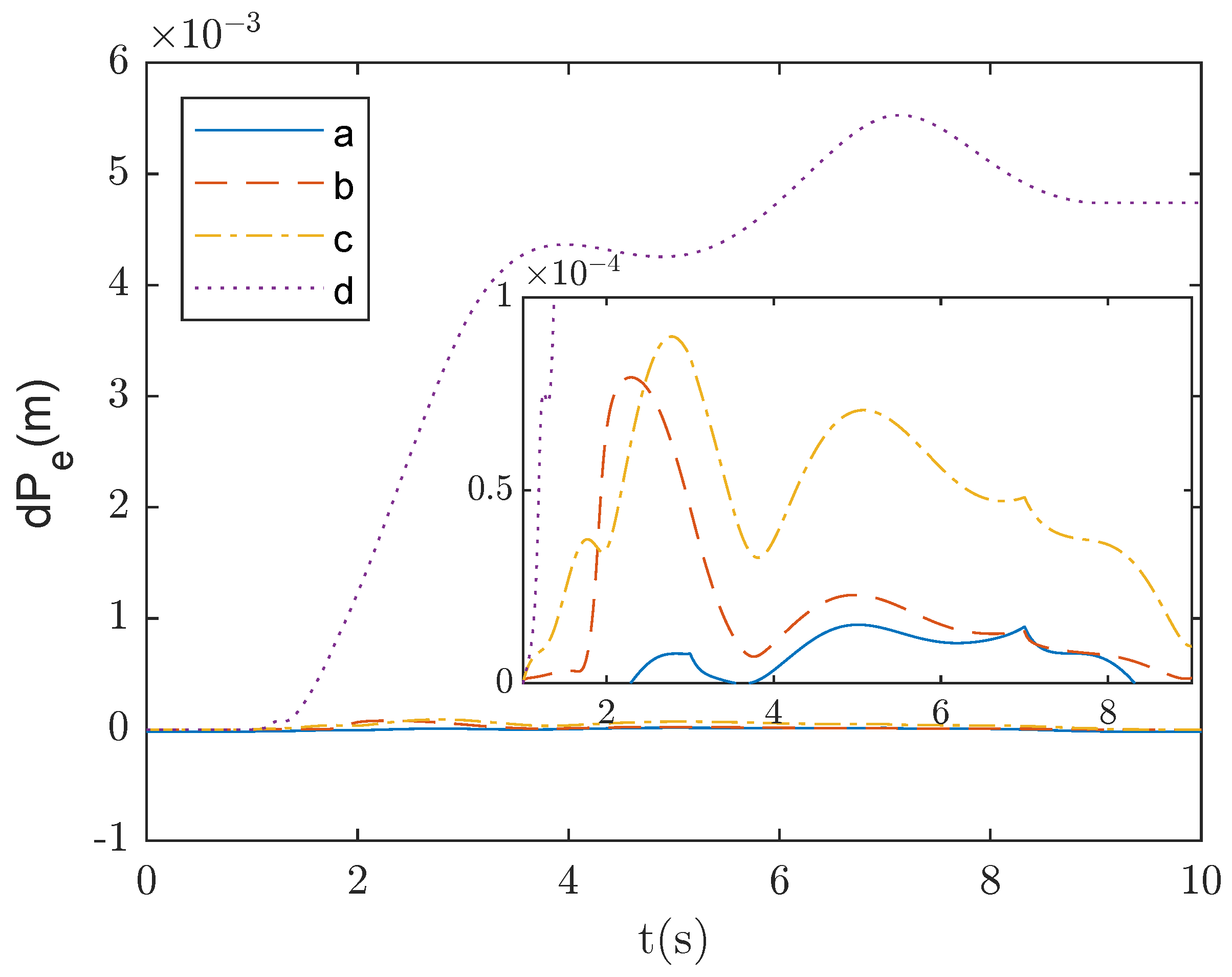

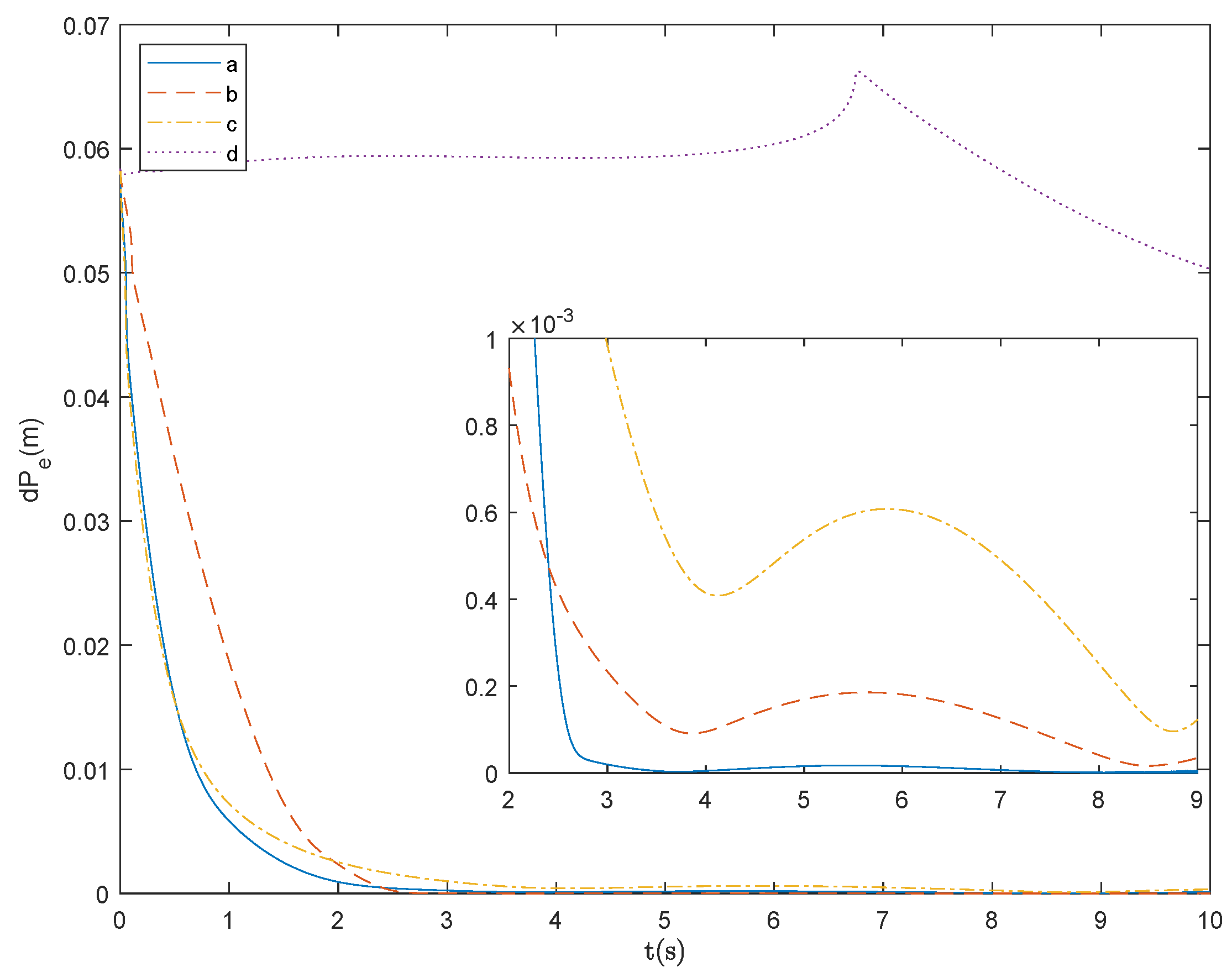

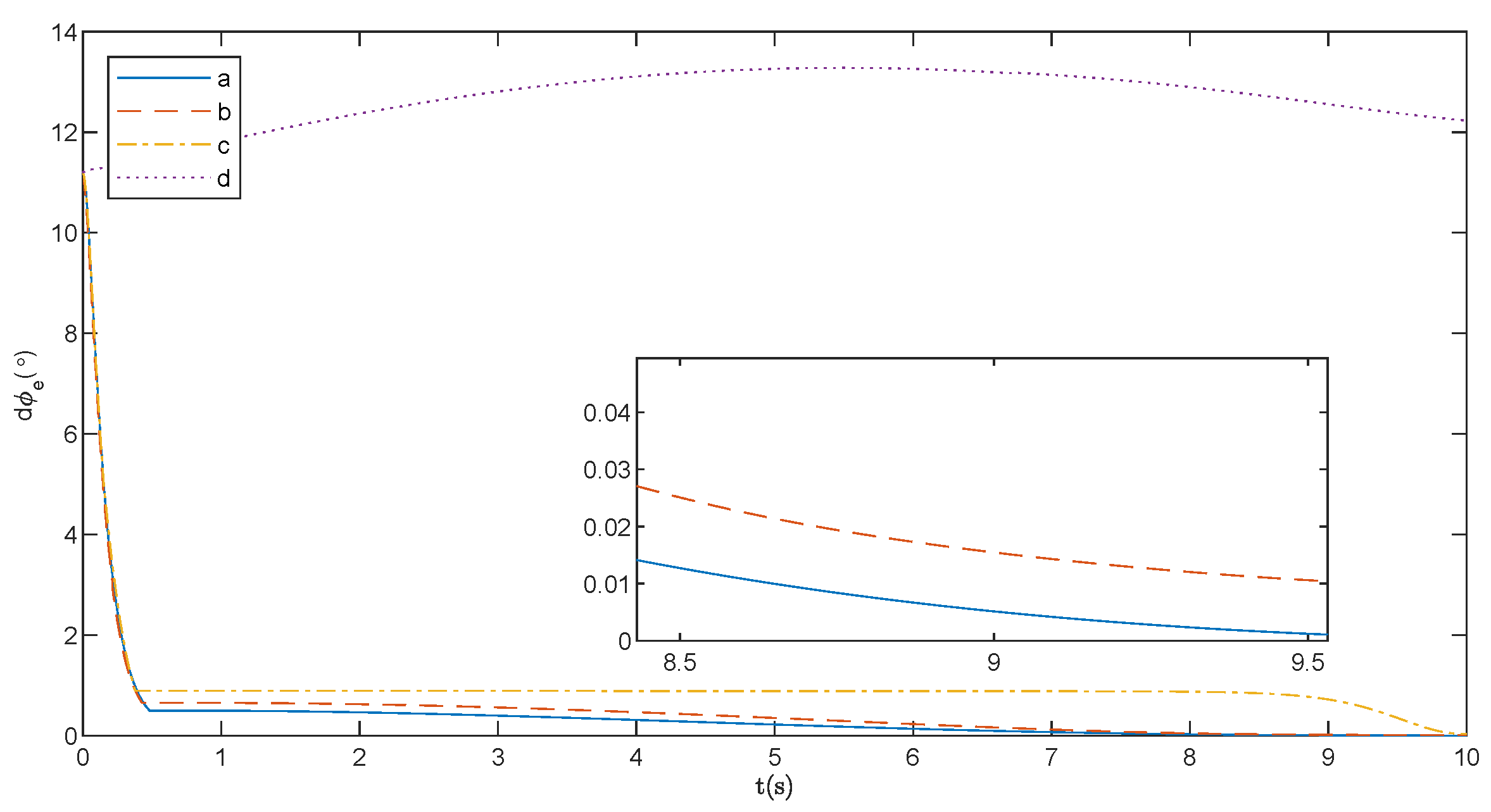

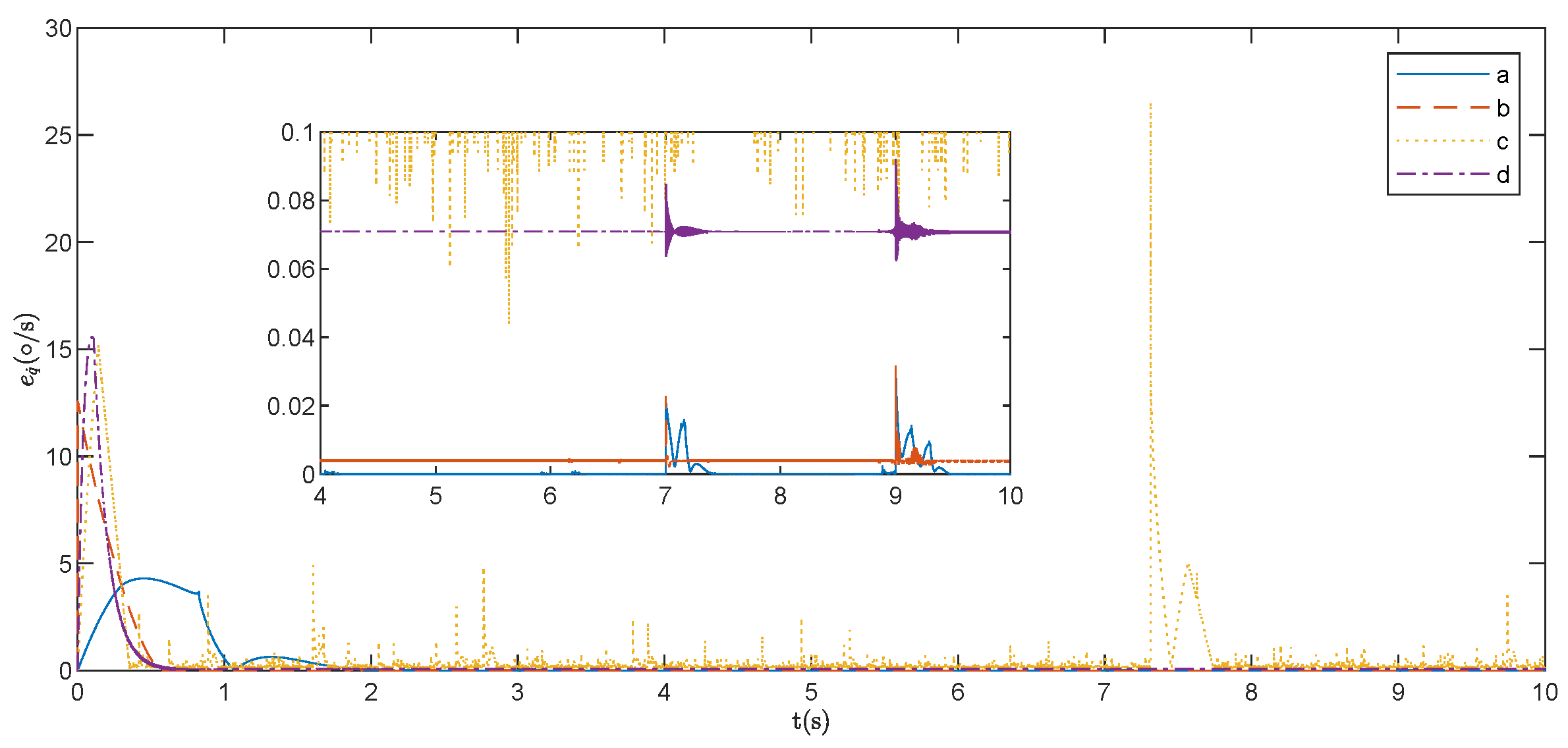

Figure 8 and

Figure 9 illustrate the end effector pose errors of the continuum space robot during the trajectory planning process. Line a represents the proposed explicit-time trajectory planning method, line b is based on the finite-time trajectory planning method, line c is based on proportional feedback for trajectory planning, and line d is based solely on the DLS method without pose feedback. From line d, it can be observed that using only singularity avoidance introduces pose errors, and these errors persist after the completion of the trajectory planning task. On the contrary, trajectory planning methods based on pose error feedback, represented by lines a, b, and c, can converge the errors to zero. Line b shows that the finite-time trajectory planning method, although having a smaller overall error, exhibits noticeable singularity issues at 1.7 s, and the errors cannot be quickly eliminated after the trajectory planning task. Line c, representing the widely used proportional feedback method in space robot trajectory planning, shows no apparent singularity or oscillation issues and can effectively eliminate errors after the trajectory planning task. However, the planning accuracy and error convergence speed are lower than line a. Line a demonstrates that the proposed method can keep the trajectory planning error of the robot consistently at a low level and converge to zero at an earlier stage.

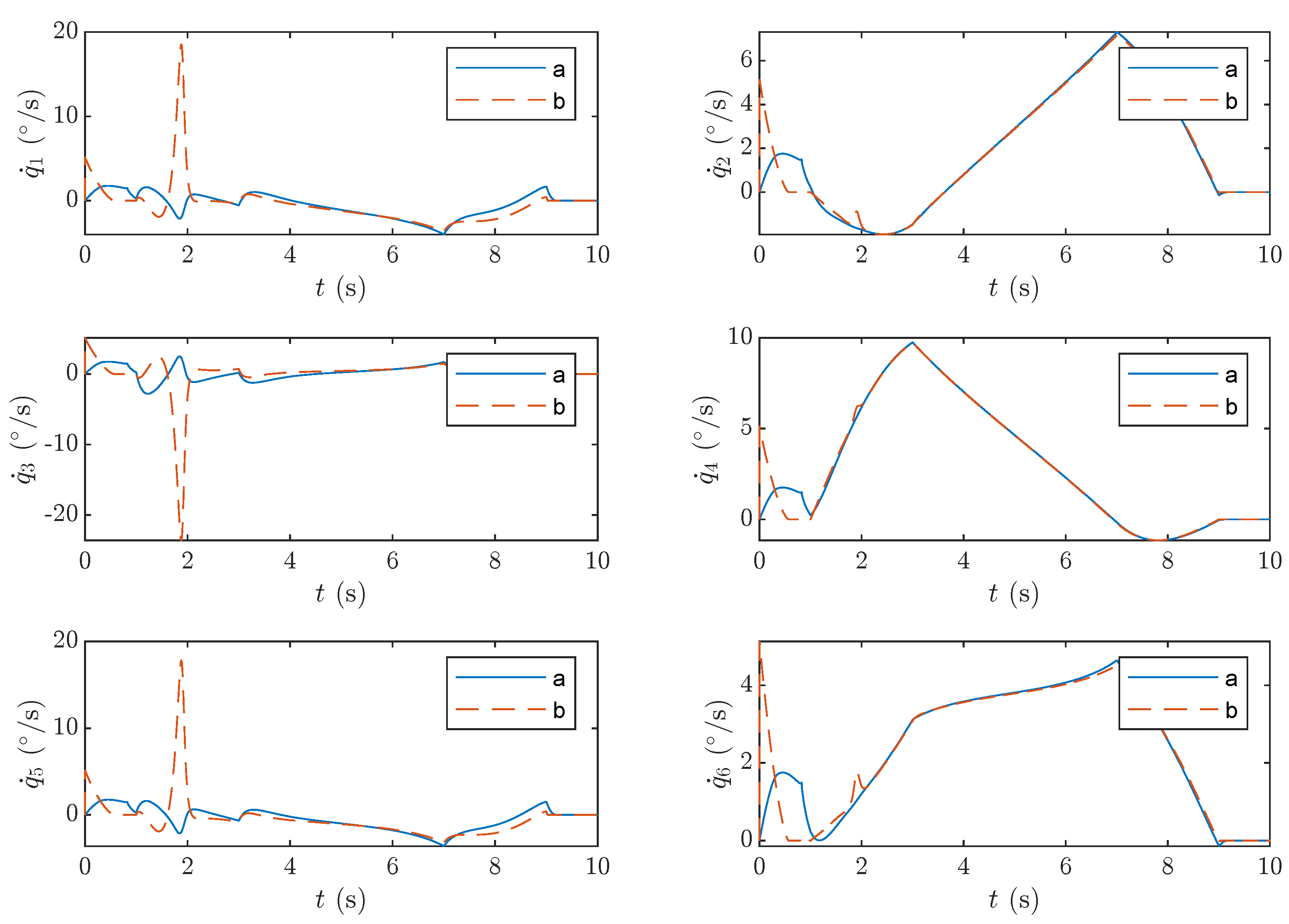

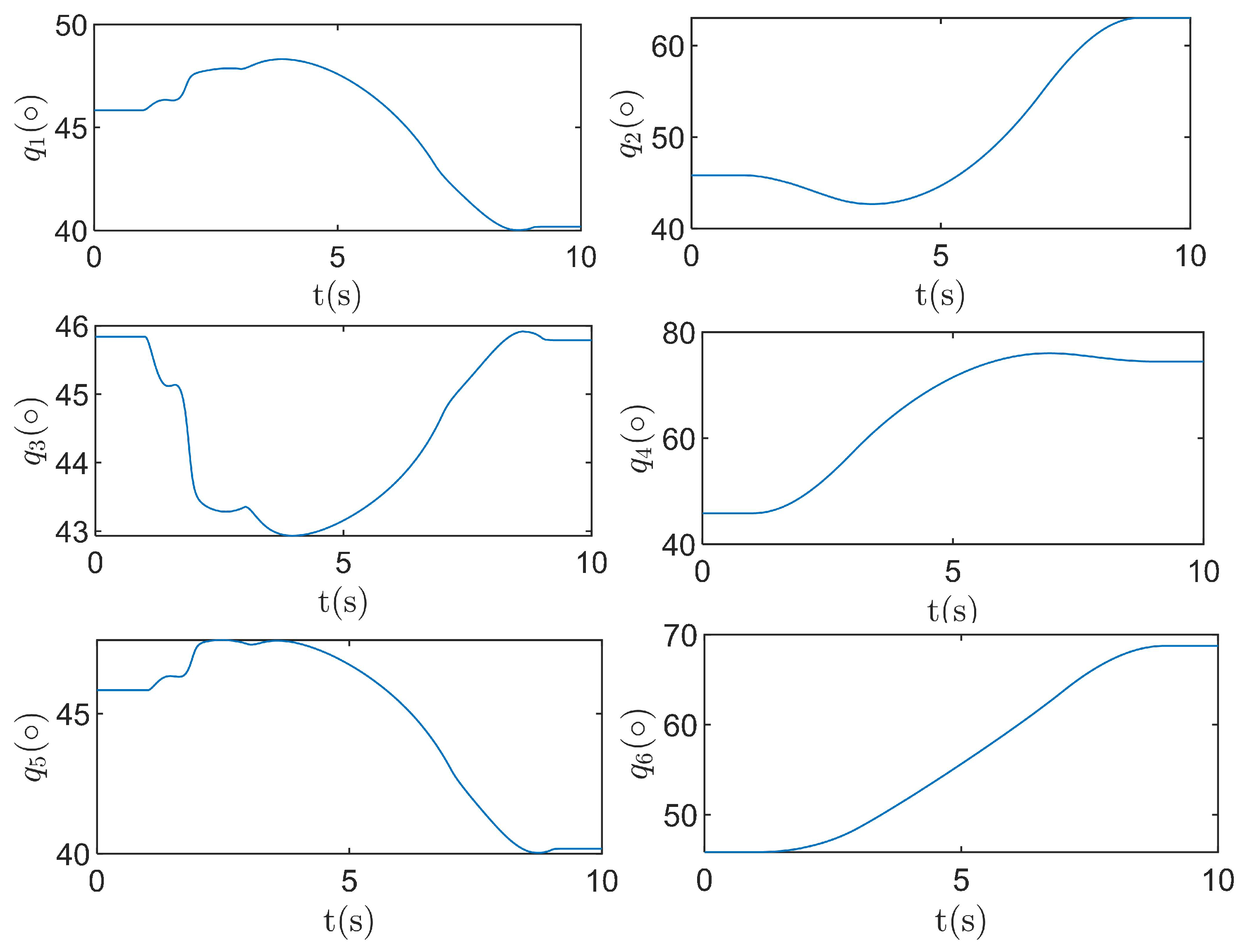

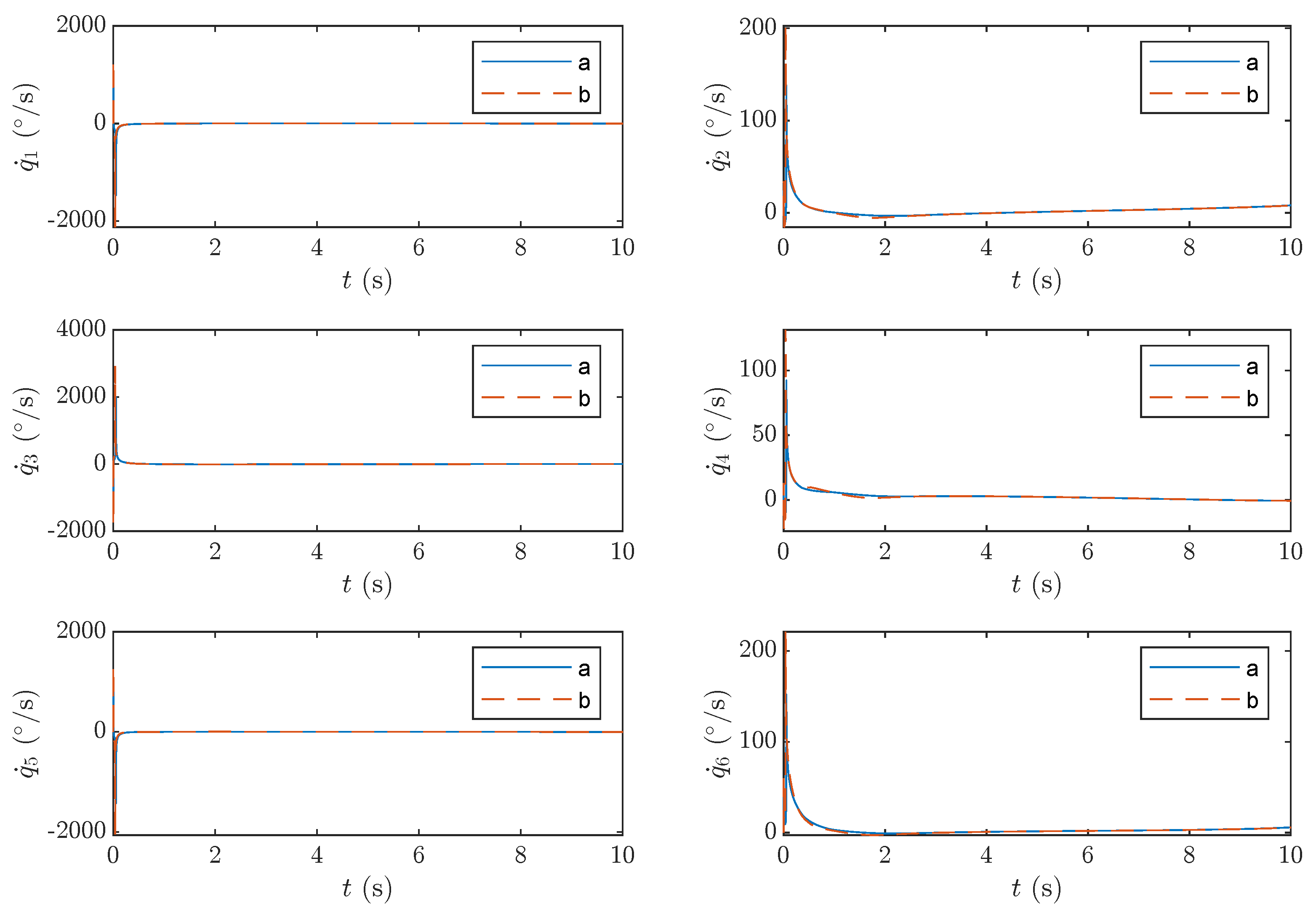

As shown in

Figure 10, line a represents the joint velocity planned by the proposed method and line b represents the joint velocity planned by the predefined time method proposed in reference [

24]. It can be seen that the joint angular velocity obtained by the proposed trajectory planning method is bounded and continuous, and effectively reduces joint velocity. The joint trajectory obtained using the proposed method is shown in

Figure 11.

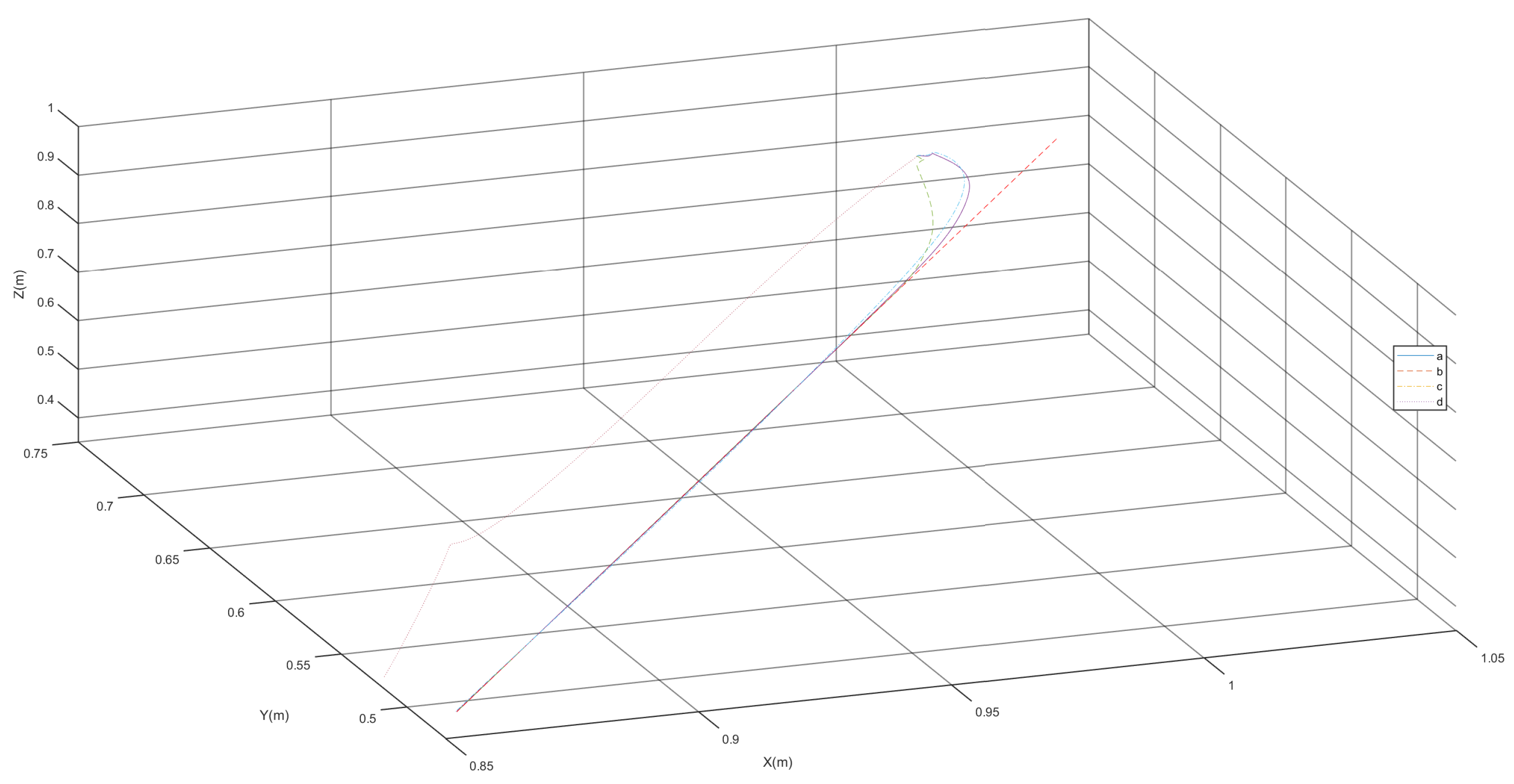

To visually demonstrate the differences in trajectory planning methods, a three-dimensional plot of the end effector’s position trajectory is presented in

Figure 12. Considering a scenario where there is a deviation between the initial position of trajectory planning and the expected initial position, with the expected initial joint angles and end effector pose consistent with

Table 2, the actual initial position is

(m), the initial orientation is

, and the initial joint angles are

(rad). Each line in the figure illustrates the convergence of errors. Line d, which does not use pose feedback, fails to eliminate the existing error. Among the trajectory planning methods based on pose feedback, line a, representing the proposed trajectory planning method, demonstrates the fastest convergence and highest accuracy.

Figure 13 and

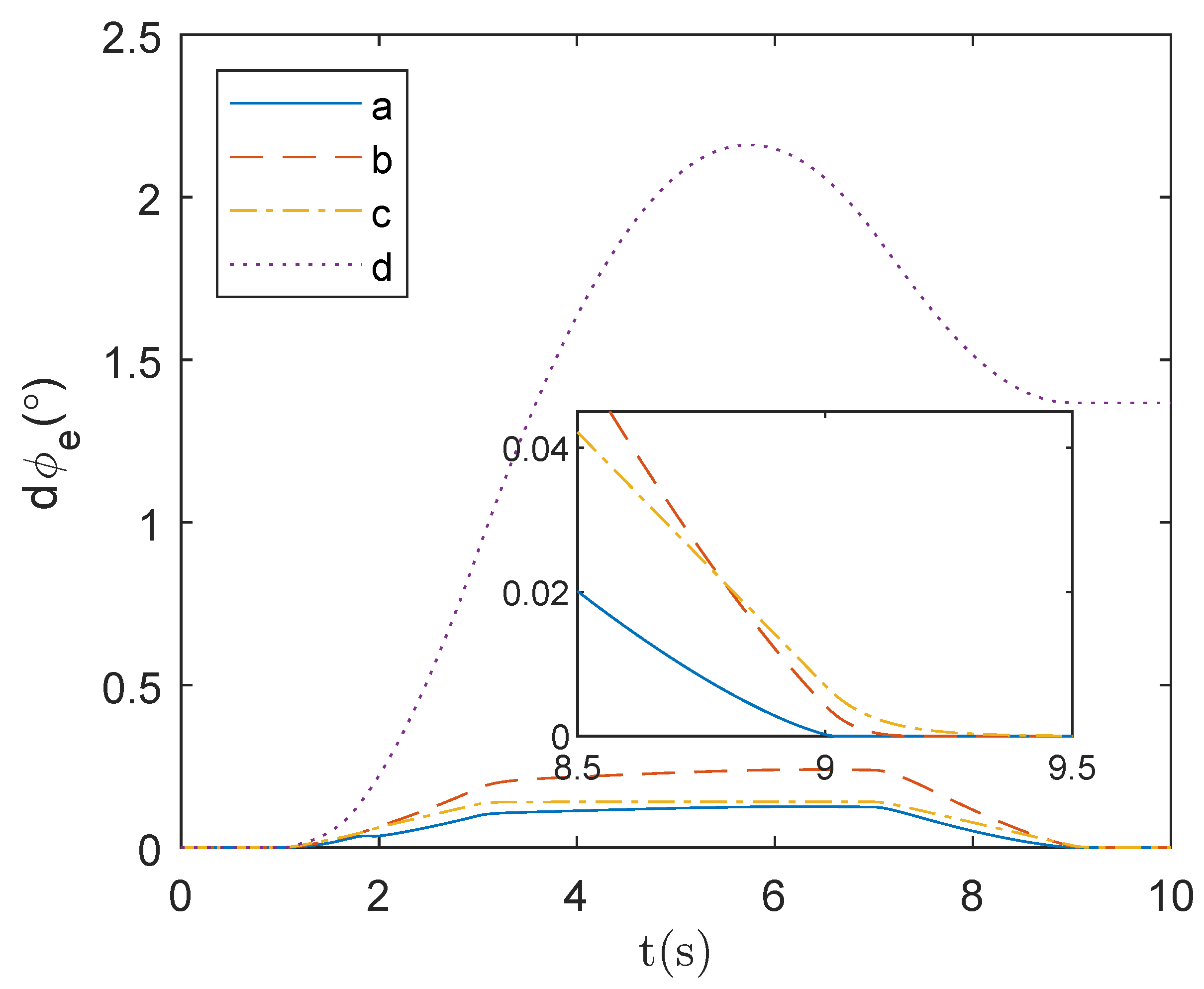

Figure 14 illustrate the end-effector orientation error of the continuum space robot during the trajectory planning process. From curve d, it is evident that relying solely on a singularity avoidance strategy leads to orientation errors, which persist even after the trajectory planning task is completed. In contrast, trajectory planning methods incorporating orientation error feedback (curves a, b, and c) successfully drive the error to zero. Although curve b (finite-time trajectory planning) exhibits relatively low overall error, it struggles to rapidly eliminate residual errors after completing the trajectory planning task. Curve c (the proportional feedback method, widely used in space robot trajectory planning) does not exhibit significant singularity or oscillation issues and effectively eliminates post-task errors. However, its planning accuracy and error convergence rate are lower than those of curve a. Curve a demonstrates that the proposed method consistently maintains a low trajectory planning error and achieves error convergence to zero at an earlier stage.

As shown in

Figure 15, curve a represents the joint velocity planned by the proposed method, while curve b corresponds to the joint velocity planned using the predefined-time method from [

24]. The upper bound of the proposed method in this paper has been marked with a red dashed line. It can be observed that the joint angular velocity obtained through the proposed trajectory planning method is bounded and continuous, effectively reducing joint velocity.

In summary, the trajectory planning method based on explicit time stability theory and pose error feedback can converge errors caused by singular points to zero, enable high-precision tracking of the end effector, and plan appropriate joint angular velocities.

7.2. Simulation and Analysis of Trajectory Tracking

In order to demonstrate the control performance of the explicit-time sliding mode controller proposed in for the continuum space robot, trajectory tracking control simulations were conducted, here considering the bounded uncertainty of the system . The parameters of the proposed controller are , , and , . The convergence time is 5 s.

In the comparative experiments, predefined-time [

22], finite-time [

27], and conventional asymptotic sliding mode controller were selected for comparison.

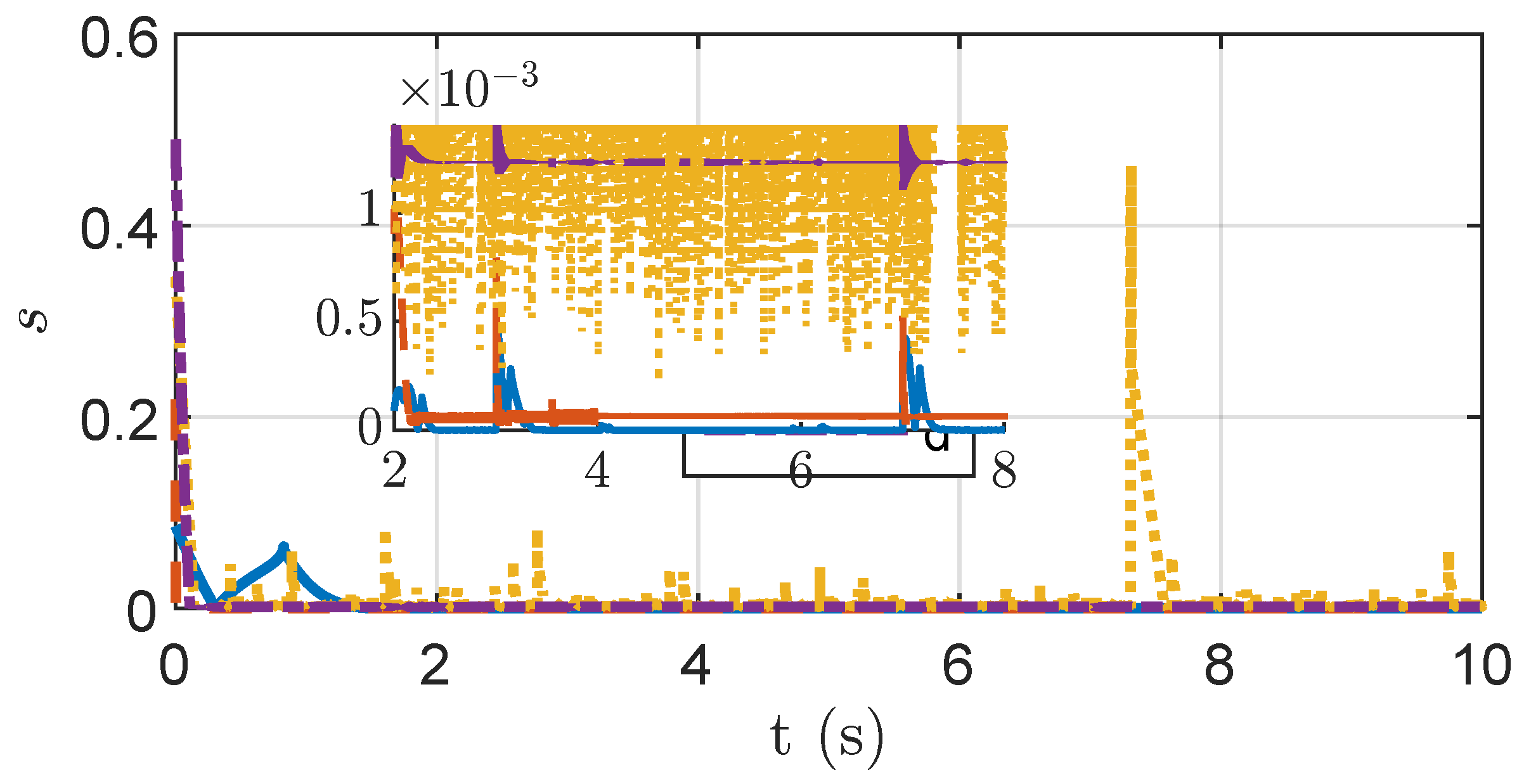

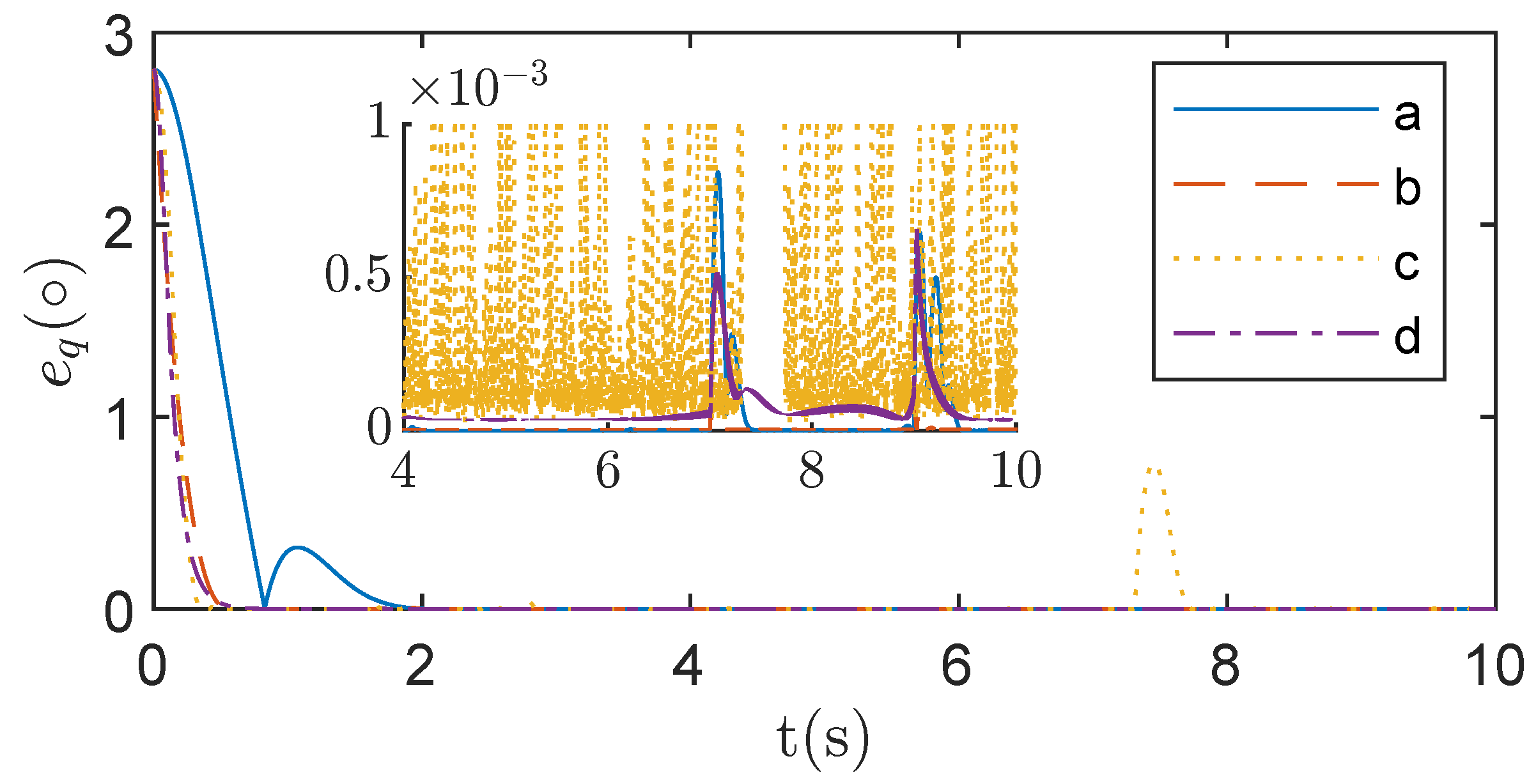

Line a represents the proposed explicit-time controller, line b represents the predefined-time controller, line c represents the finite-time controller, and line d represents the conventional sliding mode controller.

The sliding mode values are depicted in

Figure 16. The proposed method facilitates rapid error convergence to zero, and the convergence time is within the explicit upper bound of time. The convergence time of the predefined time is shorter than the method proposed, but the error is higher than the proposed method. The finite-time method demonstrates quick convergence at the beginning but maintains minor oscillations in the later stages. The error of the conventional sliding mode controller is relatively stable, but due to its asymptotic convergence the error is noticeably higher than that of the proposed method. Corresponding control signals are illustrated in

Figure 17, and their analysis is similar to the sliding mode analysis, showing that the proposed method yields smaller and smoother control signals.

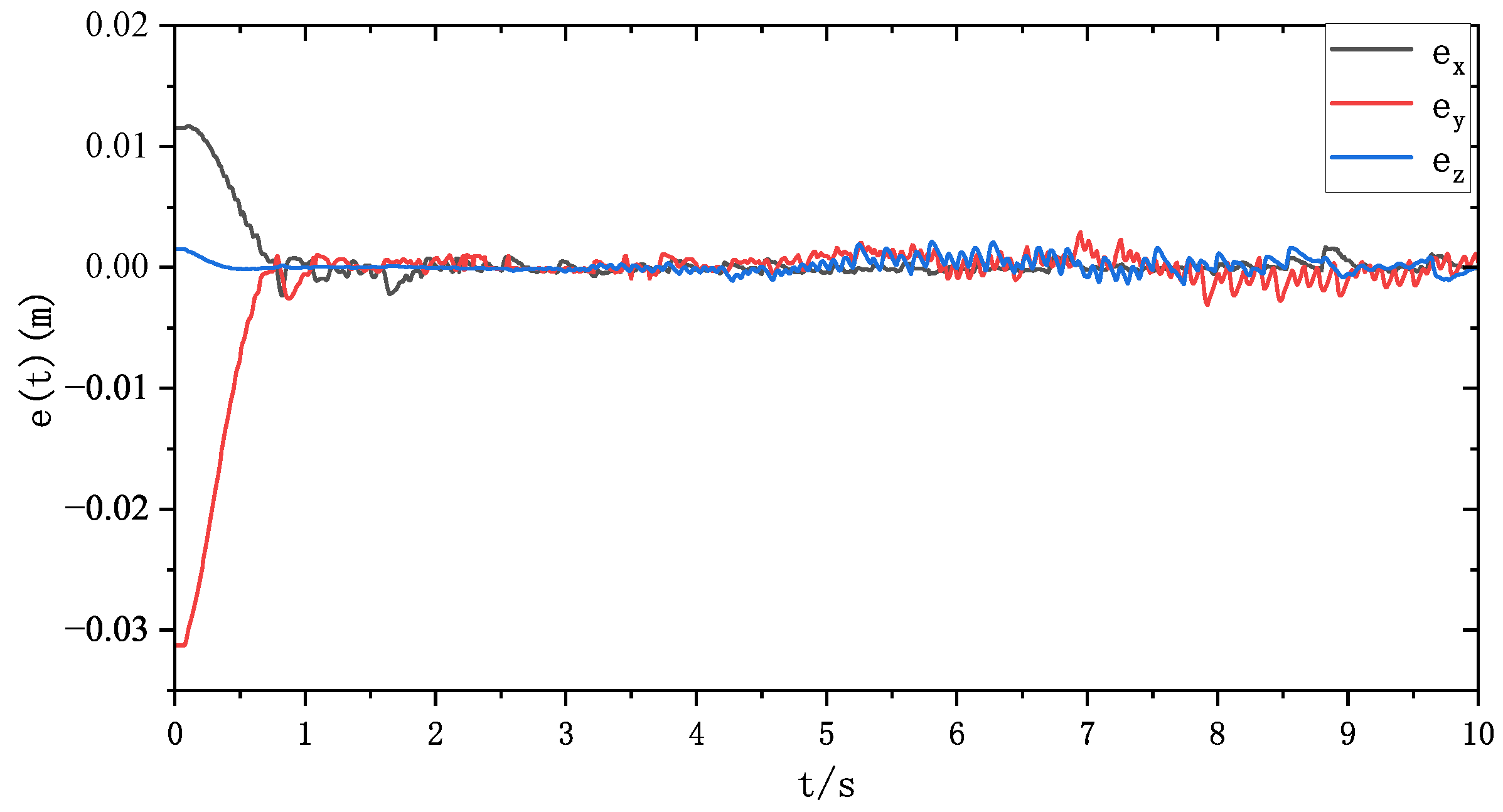

The stability results of the proposed trajectory tracking control are shown in

Figure 18 and

Figure 19, with errors converging to zero within the explicit time.

Both the convergence time of the explicit time and the predefined time are less than the ideal convergence time. Although both can ensure convergence time, the explicit time controller can significantly reduce control inputs, thereby decreasing the damage of the controller to the drive mechanism.

In summary, the proposed trajectory tracking control method demonstrates high accuracy and smoother control inputs.

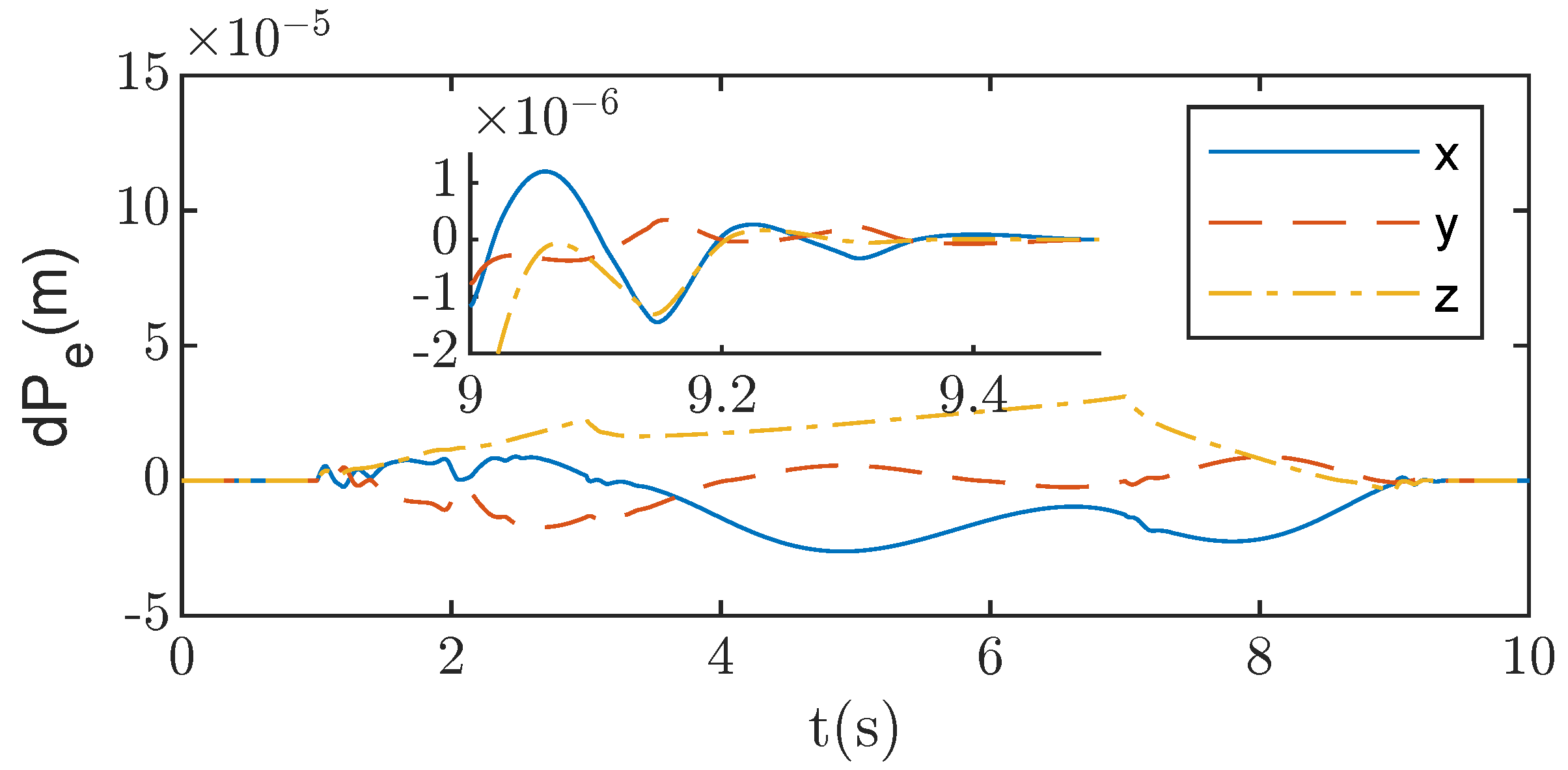

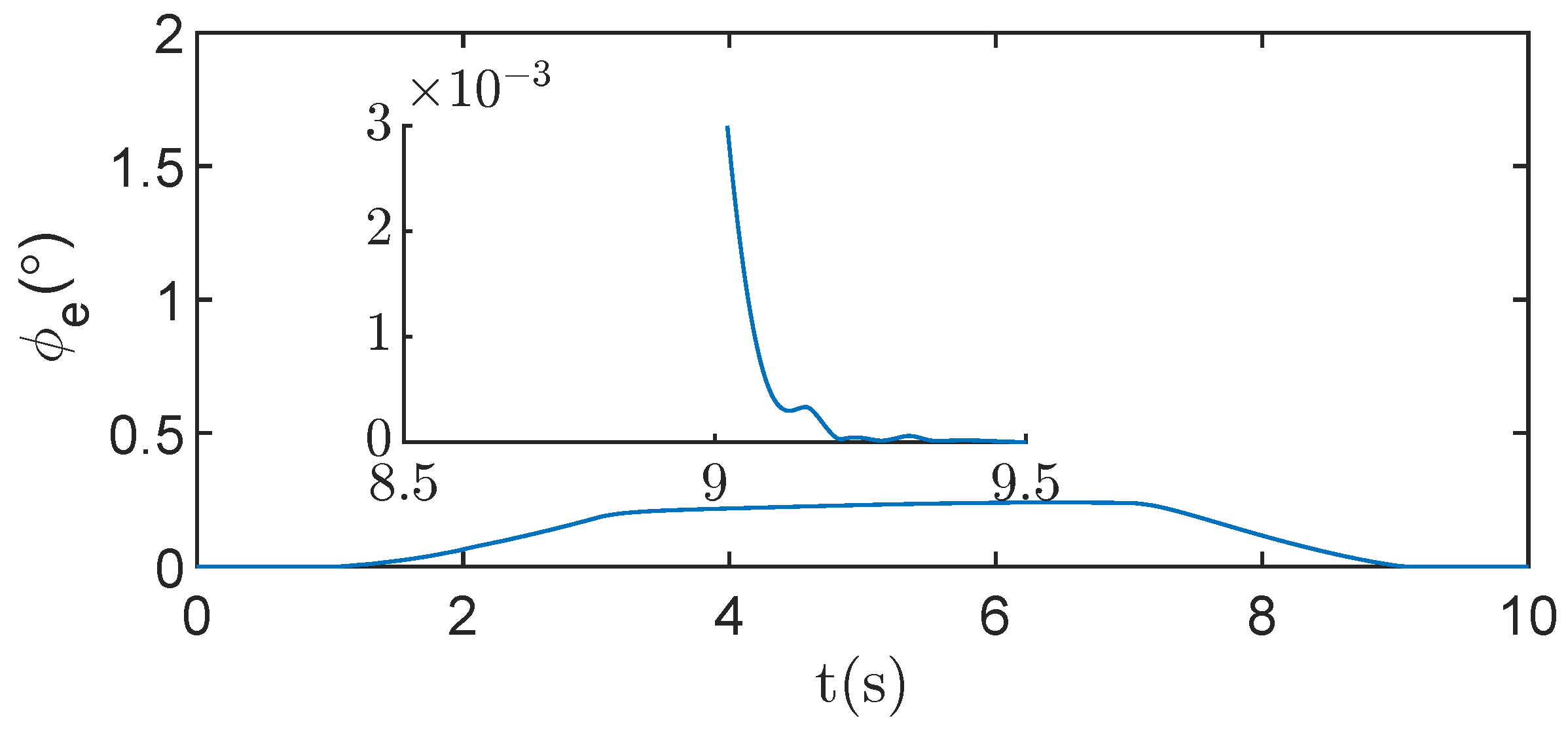

7.3. Simulation and Analysis of Trajectory Planning and Tracking Control

This section presents the co-simulated results of trajectory planning and tracking control for the continuum space robot. As shown in

Figure 20 and

Figure 21, the pose error of the robot remains consistently at a low level throughout the motion. After leaving the singular region, the accumulated pose error of the robot quickly converges to near zero. Ultimately, the position error converges to below

m, and the orientation error converges to below

degrees.

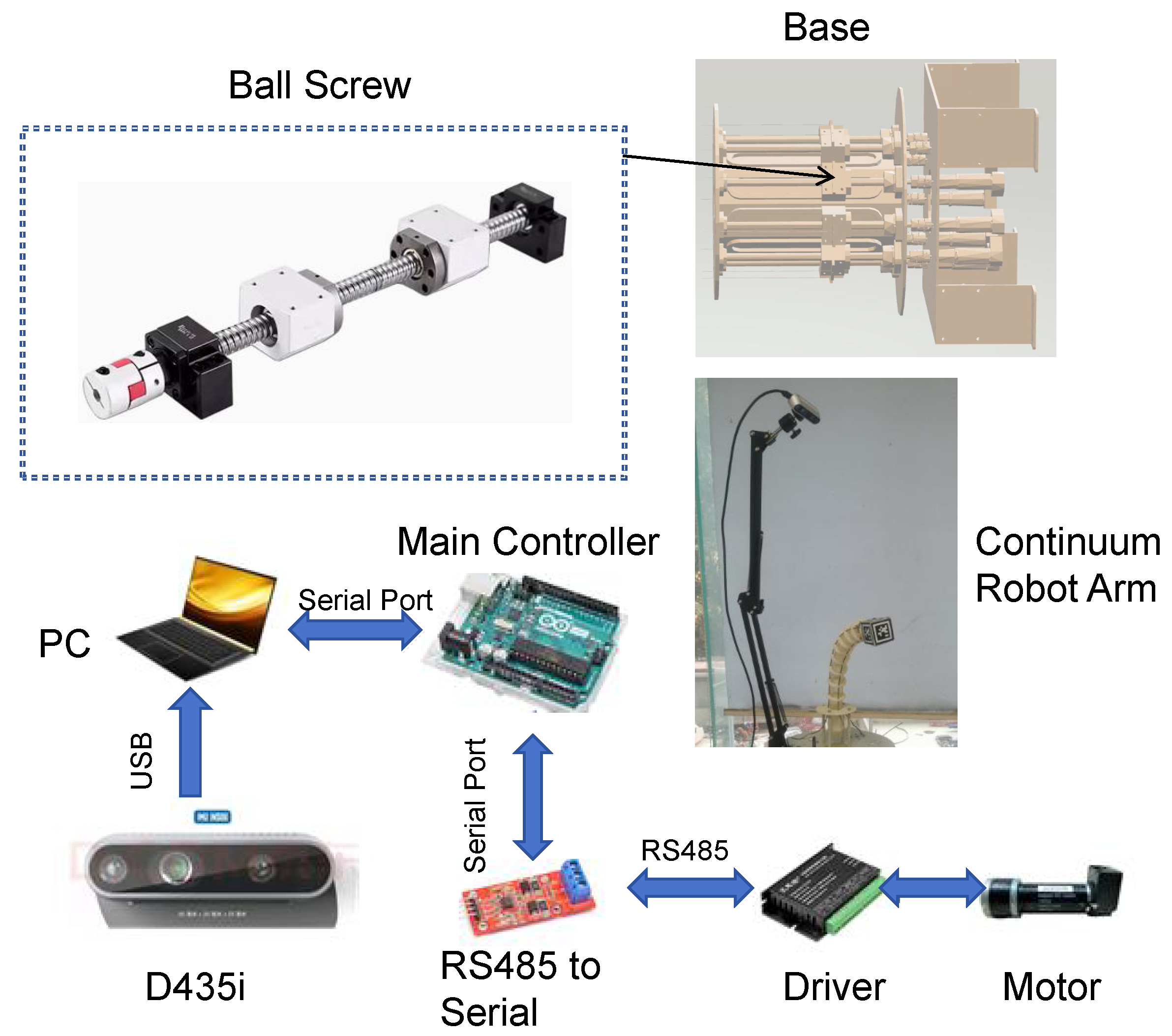

8. Experiment

In this paper, a fixed-base, single-segment continuum robot is used to verify the effectiveness of the explicit time algorithm.

Figure 22 presents the physical prototype of the continuum robot and its experimental platform. The experimental prototype consists of three main components: the continuum body, the motor control system, and the driving mechanism. The body of the continuum robot is made of a polyurethane (PU) rod synthesized from urethane material. During experiments, the length of the central rod remains fixed, and ten support discs are evenly distributed along the main body to better conform to the constant curvature assumption.The host computer runs MATLAB R2023B, responsible for processing robot motion calculations, trajectory planning, sensor data acquisition, and sending motor control commands. The entire control system operates at a sampling rate of 100 Hz (i.e., executing once every 0.01 s). The core of the motor control system is an Arduino development board, which handles the main control tasks and sends control signals to the AQMD6008NS-TBE driver board (Akelc, Chengdu, Sichuan province, China). This driver board regulates the rotational speed of each motor. The motors used are DC motors from the Maxon Motor brand, equipped with an 84:1 gearbox and a 512-pulse ABZ three-phase encoder. The driving mechanism is designed such that the motors drive the movement of sliders via ball screws, which in turn pull the driving cables to achieve the motion of the continuum robot.

During the experiment, an Intel RealSense D435I depth camera (Intel, Santa Clara, CA, USA) was used to acquire data for obtaining the position information of the continuum robot’s end-effector. The camera has a calibration accuracy of 1 mm. Its position relative to the continuum robot follows an “eye-to-hand” configuration. A cubic marker was attached to the end of the continuum robot. By detecting the April Tag on the marker, the position of the robot arm’s end-effector was obtained. The velocity and acceleration of the end-effector were estimated using a low-pass filter. The acquired data were transmitted to the host computer via a USB interface for processing. During the experiment, the host computer continuously transmitted the processed data to the motor control system in real time. Upon receiving the commands, the control system drove the motors, causing the driving cables on the sliders to move linearly. This adjustment of cable length enabled precise control of the continuum robot’s motion.

In the experiment, a point-to-point task in 3D space was used for validation. The same planned trajectory as in the simulation was applied, with a duration set to 10 s, as shown in

Figure 23. During the experiment, the parameters were set to

,

, and

.

Figure 23 shows the tracking error curve of the actual end-effector position of the continuum robot. It can be seen that the proposed method enables the end-effector position tracking error to converge to near zero within

, meeting the predefined convergence time.

Figure 24 is a schematic diagram of the continuum robot motion.

10. Future Recommendation

In future, we should focus on refining the control strategies for continuum space robots by incorporating advanced optimization techniques and machine-learning-based approaches. In particular, reinforcement learning can be explored to develop adaptive control mechanisms that enhance the system’s ability to handle uncertainties and dynamically adjust control parameters in real-time.

Moreover, integrating real-world disturbances, such as space environmental factors and actuator imperfections, into the model will further improve the robustness of trajectory planning and tracking control. Future studies can also investigate the effects of varying payloads and external forces on system performance, optimizing control inputs to ensure stability under different operational conditions.

Additionally, exploring hybrid control strategies that combine explicit-time stability with model predictive control (MPC) or adaptive sliding mode control may enhance the precision and efficiency of trajectory tracking. This approach can help mitigate control input fluctuations while maintaining system stability.

Finally, experimental validation using robotic prototypes in a simulated space environment or under microgravity conditions will be essential to confirm the feasibility and reliability of the proposed methods. By addressing these areas, future research can significantly advance the practical application of continuum space robots in on-orbit servicing, deep-space exploration, and autonomous robotic operations.