The Effect of Nut Oil Cakes on Selected Properties of Enriched Wheat Bread and Their Changes During Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Material

Bread Making and Storage Conditions

2.2. Research Methods

2.2.1. Chemical Composition Analysis of the Bread

2.2.2. Analysis of the Volume and Specific Volume of the Loaves

2.2.3. Analysis of Bread Crumb Color

2.2.4. Analysis of Bread Crumb Texture

2.2.5. Analysis of Total Phenolic Content and Antioxidant Activity

2.2.6. Statistical Analysis

3. Results and Discussions

3.1. Basic Chemical Composition

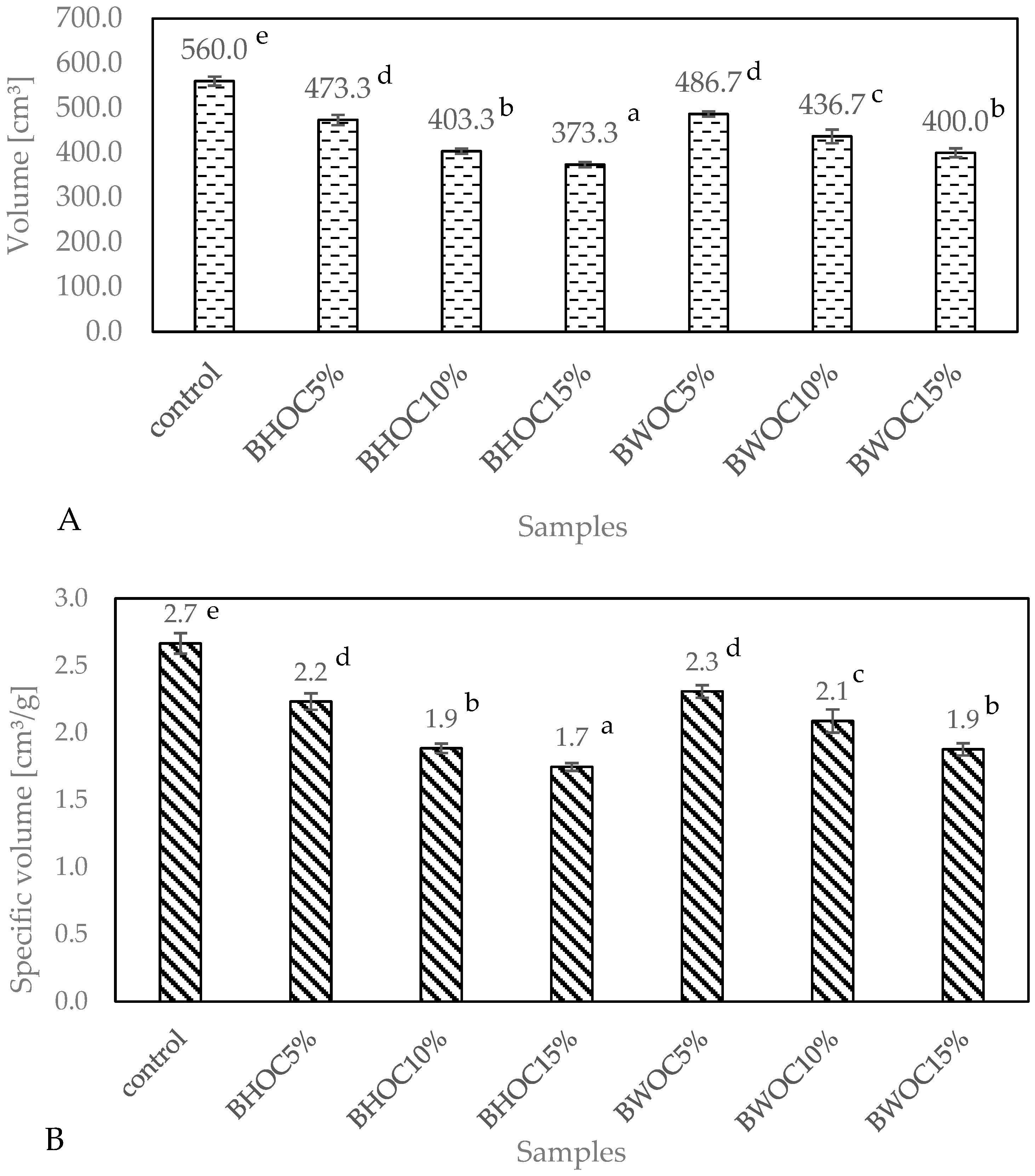

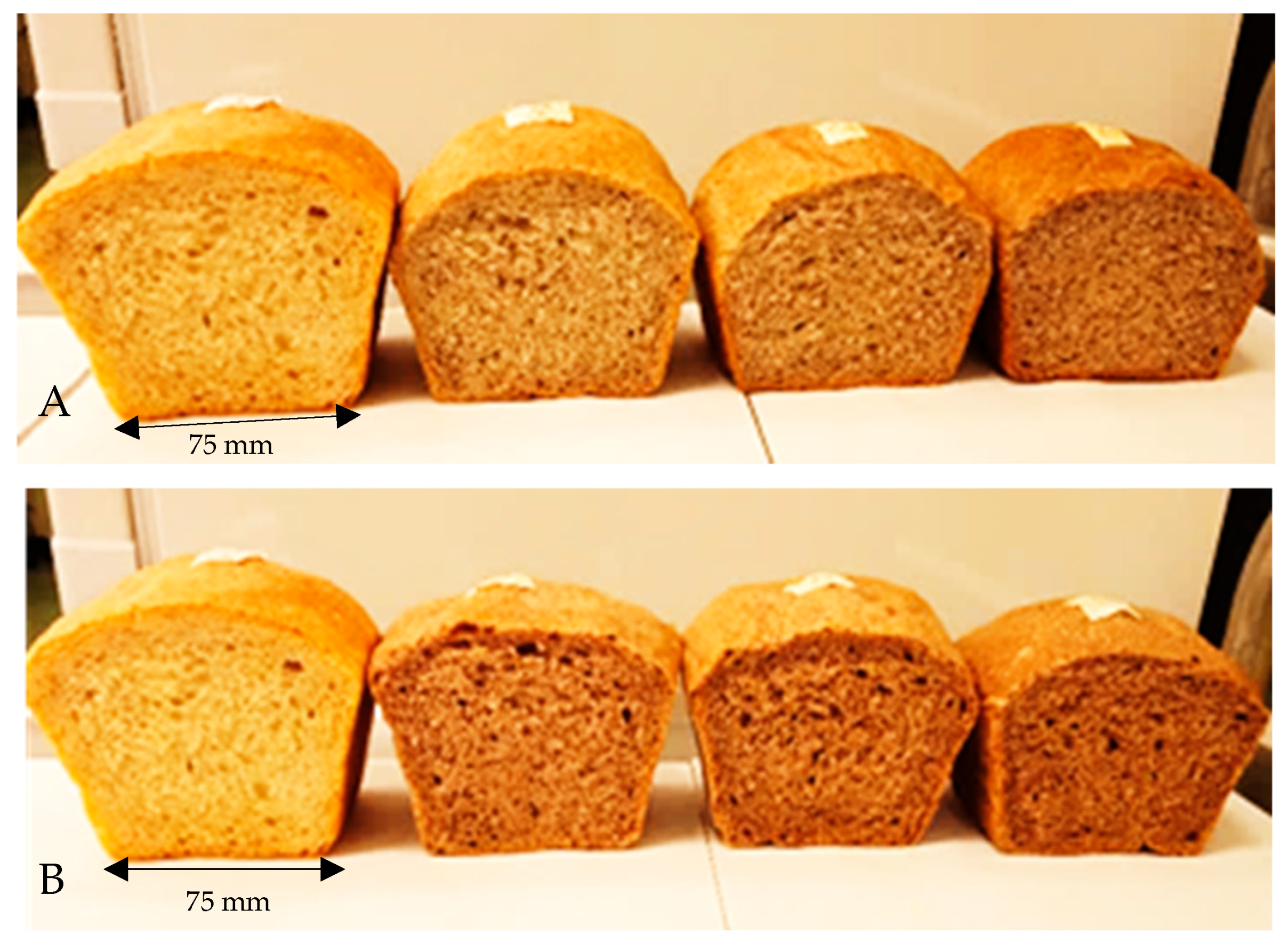

3.2. Volume and Appearance of the Loaves

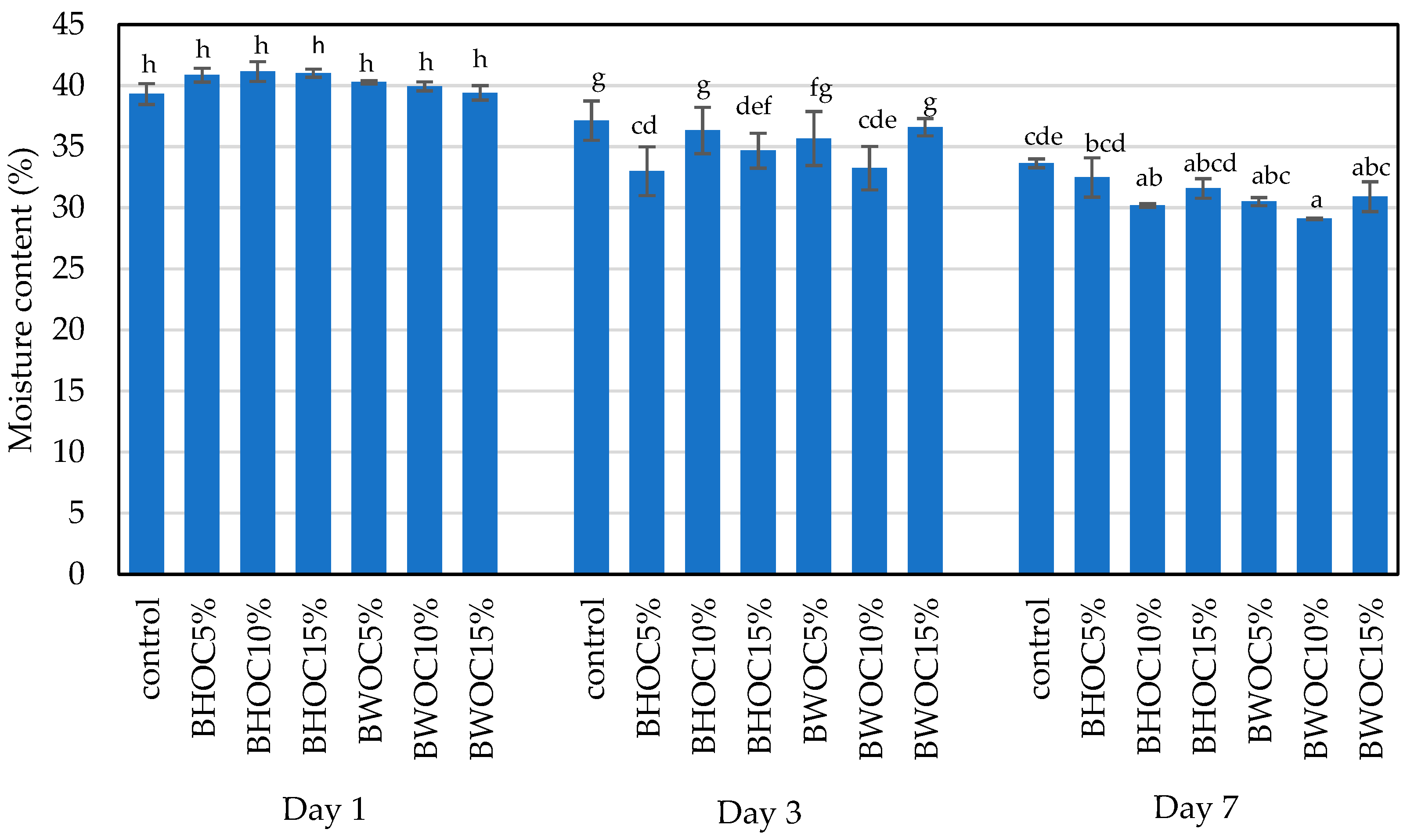

3.3. Color and Moisture of Bread Crumb During Storage

| Samples | L* | a* | b* | ∆E |

|---|---|---|---|---|

| 1 day | ||||

| control | 69.97 ± 0.78 k | 1.83 ± 0.32 b | 20.61 ± 0.75 i | - |

| BHOC5% | 60.98 ± 1.54 jk | 2.87 ± 0.13 c | 13.77 ± 0.16 c | 11.43 ± 1.79 a |

| BHOC10% | 57.82 ± 1.28 fgh | 4.10 ± 0.16 d | 13.14 ± 0.05 b | 14.44 ± 1.08 bc |

| BHOC15% | 56.50 ± 0.33 f | 4.81 ± 0.11 e | 13.23 ± 0.23 b | 15.67 ± 0.44 cd |

| BWOC5% | 52.75 ± 0.60 d | 6.83 ± 0.07 i | 15.67 ± 0.16 e | 18.52 ± 0.38 g |

| BWOC10% | 48.64 ± 1.16 c | 6.60 ± 0.06 hi | 16.51 ± 0.35 f | 21.82 ± 1.27 a |

| BWOC15% | 47.16 ± 0.35 b | 6.67 ± 0.12 i | 17.37 ± 0.24 g | 23.56 ± 0.57 j |

| 3 day | ||||

| control | 71.84 ± 0.23 l | 1.60 ± 0.08 a | 19.59 ± 0.40 h | - |

| BHOC5% | 59.86 ± 0.42 ij | 2.84 ± 0.04 c | 13.43 ± 0.32 bc | 13.52 ± 0.65 b |

| BHOC10% | 58.48 ± 1.19 gh | 3.92 ± 0.08 d | 12.44 ± 0.18 a | 15.33 ± 1.44 cd |

| BHOC15% | 57.17 ± 0.69 fg | 4.67 ± 0.30 e | 12.57 ± 0.32 a | 16.55 ± 0.60 de |

| BWOC5% | 55.00 ± 0.49 e | 6.25 ± 0.15 g | 14.47 ± 0.34 d | 18.21 ± 0.51 fg |

| BWOC10% | 49.04 ± 0.71 c | 6.36 ± 0.23 g | 15.53 ± 0.33 e | 23.64 ± 0.61 j |

| BWOC15% | 49.84 ± 0.71 c | 6.23 ± 0.21 g | 16.99 ± 0.49 g | 22.64 ± 0.57 ij |

| 7 day | ||||

| control | 71.91 ± 0.76 l | 1.86 ± 0.20 b | 19.53 ± 0.95 h | - |

| BHOC5% | 61.74 ± 0.46 k | 3.02 ± 0.06 c | 13.56 ± 0.06 bc | 11.88 ± 0.54 a |

| BHOC10% | 58.74 ± 0.20 hi | 3.92 ± 0.07 d | 12.37 ± 0.10 a | 15.17 ± 0.23 c |

| BHOC15% | 56.72 ± 0.51 f | 4.70 ± 0.05 e | 12.33 ± 0.12 a | 17.08 ± 0.56 fg |

| BWOC5% | 51.49 ± 0.30 d | 6.62 ± 0.05 hi | 14.33 ± 0.22 d | 21.62 ± 0.31 hi |

| BWOC10% | 52.23 ± 0.70 d | 5.96 ± 0.11 f | 15.70 ± 0.05 e | 20.49 ± 0.74 h |

| BWOC15% | 45.81 ± 0.48 a | 6.41 ± 0.19 gh | 16.33 ± 0.08 f | 26.70 ± 0.48 k |

| three-way MANOVA p-values | ||||

| Factor 1 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 |

| Factor 2 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 |

| Factor 3 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 |

| Factor 1 × factor 2 | p = 0.030 | p < 0.001 | p < 0.001 | p < 0.001 |

| Factor 1 × factor 3 | p < 0.001 | p < 0.001 | p = 0.034 | p < 0.001 |

| Factor 2 × factor 3 | p < 0.001 | p < 0.001 | p = 0.127 | p < 0.001 |

| Factor 1 × factor 2 × factor 3 | p < 0.001 | p = 0.070 | p = 0.017 | p < 0.001 |

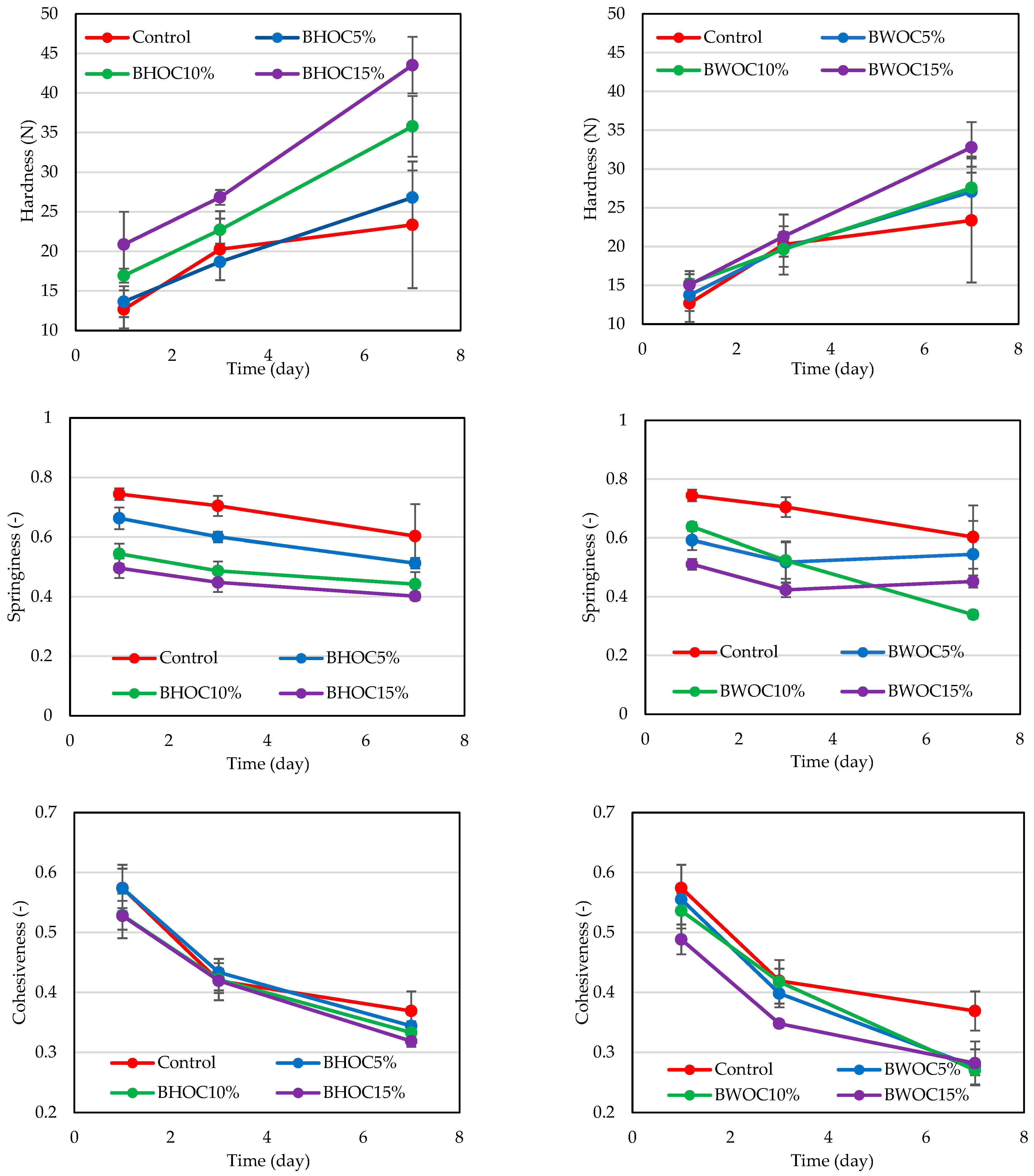

3.4. Bread Texture Results

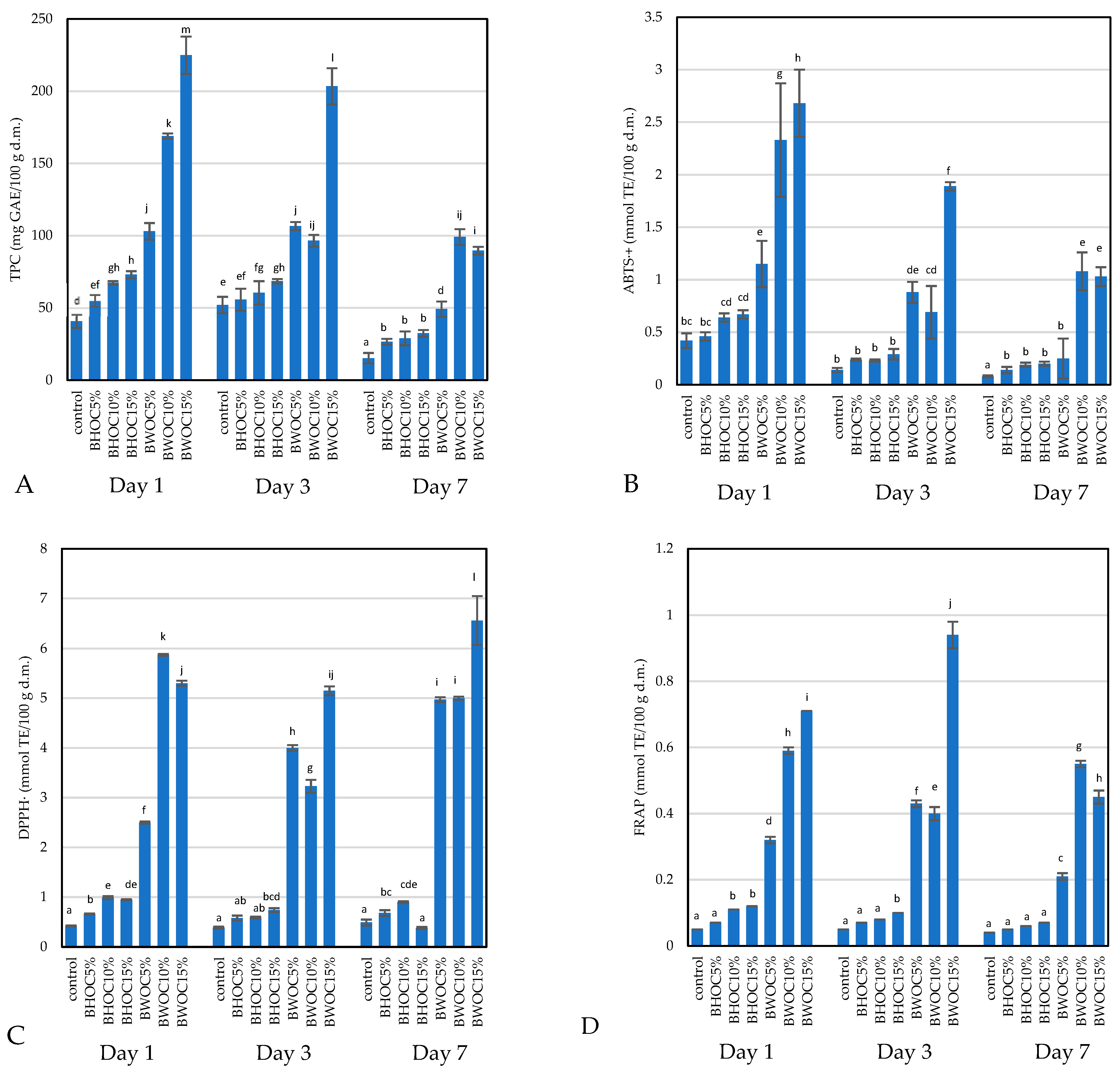

3.5. Total Phenolic Content and Antioxidant Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zarzycki, P.; Wirkijowska, A.; Pankiewicz, U. Functional Bakery Products: Technological, Chemical and Nutritional Modification. Appl. Sci. 2024, 14, 12023. [Google Scholar] [CrossRef]

- Kaim, U.; Goluch, Z.S. Health Benefits of Bread Fortification: A Systematic Review of Clinical Trials according to the PRISMA Statement. Nutrients 2023, 15, 4459. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Wójcik, M.; Krajewska, A. Dandelion Flowers as an Additive to Wheat Bread: Physical Properties of Dough and Bread Quality. Appl. Sci. 2023, 13, 477. [Google Scholar] [CrossRef]

- Vargas, M.C.A.; Simsek, S. Clean label in bread. Foods 2021, 10, 2054. [Google Scholar] [CrossRef]

- Day, D.; Richter, J.; Ek, P.; Gu, B.-J.; Ganjyal, G.M. Utilization of Food Processing By-products in Extrusion Processing: A Review. Front. Sustain. Food Syst. 2021, 4, 603751. [Google Scholar] [CrossRef]

- Jung, J.-M.; Kim, J.Y.; Kim, J.-H.; Kim, S.M.; Jung, S.; Song, H.; Kwon, E.E.; Choi, Y.-E. Zero-waste strategy by means of valorization of bread waste. J. Clean. Prod. 2022, 365, 132795. [Google Scholar] [CrossRef]

- Pop, A.; Păucean, A.; Socaci, S.A.; Alexa, E.; Man, S.M.; Muresan, V.; Chi, S.M.S.; Salantă, L.; Popescu, I.; Berbecea, A.; et al. Quality Characteristics and Volatile Profile of Macarons Modified with Walnut Oilcake By-Product. Molecules 2020, 25, 2214. [Google Scholar] [CrossRef] [PubMed]

- Pycia, K.; Kapusta, I.; Jaworska, G. Walnut oil and oilcake affect selected the physicochemical and antioxidant properties of wheat bread enriched with them. J. Food Process. Preserv. 2020, 44, e14573. [Google Scholar] [CrossRef]

- Anderson, K.J.; Teuber, S.S.; Gobeille, A.; Cremin, P.; Waterhouse, A.L.; Steinberg, F.M. Walnut polyphenolics inhibit in vitro human plasma and LDL oxidation. J. Nutr. 2021, 131, 2837–2842. [Google Scholar] [CrossRef]

- Lin, C.C.; Hsu, Y.F.; Lin, T.C.; Hsu, H.Y. Antioxidant and hepatoprotective effects of punicalagin and punicalin on acetaminophen-induced liver damage in rats. Phytother. Res. 2021, 15, 206–212. [Google Scholar] [CrossRef]

- Martino, V.; Morales, J.; Martinez-Irujo, J.J.; Font, M.; Monge, A.; Coussio, J. Two ellagitannins from the leaves of Terminalia triflora with inhibitory activity on HIV-1 reverse transcriptase. Phytother. Res. 2004, 18, 667–669. [Google Scholar] [CrossRef] [PubMed]

- Bakkalbasi, E.; Meral, R.; Dogan, I.S. Bioactive compounds, physical and sensory properties of cake made with walnut press-cake. J. Food Qual. 2015, 38, 422–430. [Google Scholar] [CrossRef]

- Pycia, K.; Juszczak, L. Rheological Characteristics of Wheat Dough Containing Powdered Hazelnuts or Walnuts Oil Cakes. Foods 2024, 13, 140. [Google Scholar] [CrossRef]

- Ozdemir, M.B.; Kılıçarslan, E.; Demir, H.; Koca, E.; Salum, P.; Berkta¸s, S.; Çam, M.; Erbay, Z.; Aydemir, L.Y. Upgrading the Bioactive Potential of Hazelnut Oil Cake by Aspergillus oryzae under Solid-State Fermentation. Molecules 2024, 29, 4237. [Google Scholar] [CrossRef]

- Acan, B.G.; Toker, O.S.; Palabiyik, I.; Rasouli Pirouzian, H.; Bursa, K.; Kilicli, M.; Yaman, M.; Er, T.; Konar, N. Physicochemical Properties of Chocolate Spread with Hazelnut Cake: Comparative Study and Optimization. LWT-Food Sci. Technol. 2021, 147, 111548. [Google Scholar] [CrossRef]

- Pycia, K.; Kapusta, I.; Jaworska, G. Changes in antioxidant activity, profile, and content of polyphenols and tocopherols in common hazel seed (Corylus avellana L.) depending on variety and harvest date. Molecules 2020, 25, 43. [Google Scholar] [CrossRef]

- Fik, M. Bread staling and methods of prolonging its freshness. Food Sci. Technol. Qual. 2004, 2, 5–22. (In Polish) [Google Scholar]

- Erdogdu-Arnoczky, N.; Czuchajowska, Z.; Pomeranz, Y. Functionality of whey and casein in fermentation and in breadbaking by fixed and optimized procedures. Cereal Chem. 1996, 73, 309–316. [Google Scholar]

- De Lamo, B.; Gómez, M. Bread Enrichment with Oilseeds. A Review. Foods 2018, 7, 191. [Google Scholar] [CrossRef]

- Pycia, K.; Juszczak, L. Influence of hazelnut and walnut oil cakes powder on thermal and rheological properties of wheat flour. Foods 2023, 12, 4060. [Google Scholar] [CrossRef] [PubMed]

- Pycia, K.; Pawłowska, A.M.; Kaszuba, J. Assessment of the Application Possibilities of Dried Walnut Leaves (Juglans regia L.) in the Production of Wheat Bread. Appl. Sci. 2024, 14, 3468. [Google Scholar] [CrossRef]

- AACC. American Association of Cereal Chemistry Approved Methods, 10th ed.; American Association of Cereal Chemists: Saint Paul, MN, USA, 2010; Available online: http://methods.aaccnet.org/toc.aspx (accessed on 10 May 2025).

- AOAC International. Official Methods of Analysis of AOAC International, 20th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Culețu, A.; Susman, I.E.; Mult, E.M.; Cucu, S.E.; Belc, N. Corn Extrudates Enriched with Health-Promoting Ingredients: Physicochemical, Nutritional, and Functional Characteristics. Processes 2023, 11, 1108. [Google Scholar] [CrossRef]

- Wójcik, M.; Dziki, D.; Matwijczuk, A.; Gawlik-Dziki, U. Walnut Flour as an Ingredient for Producing Low-Carbohydrate Bread: Physicochemical, Sensory, and Spectroscopic Characteristics. Foods 2023, 12, 3320. [Google Scholar] [CrossRef]

- Bourekoua, H.; Różyło, R.; Gawlik-Dziki, U.; Benatallah, L.; Zidoune, M.N.; Dziki, D. Evaluation of physical, sensorial, and antioxidant propertiesof gluten-free bread enriched with Moringa Oleifera leaf powder. Eur. Food Res. Technol. 2018, 244, 189–195. [Google Scholar] [CrossRef]

- Gao, X.; Ohlander, M.; Jeppsson, N.; Björk, L.; Trajkovski, V. Changes in antioxidant effects and their relationship to phytonutrients in fruits of sea buckthorn (Hippophae rhamnoides L.) during maturation. J. Agric. Food Chem. 2000, 48, 1485–1490. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef]

- Yen, G.C.; Chen, H. Antioxidant activity of various tea extracts in relation to 434 their antimutagenicity. J. Agr. Food Chem. 1995, 43, 27–32. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Walkowiak, K.; Masewicz, Ł.; Duda, A.; Poliszko, N.; Różańska, M.B.; Jeżowski, P.; Tomkowiak, A.; Mildner-Szkudlarz, S.; Baranowska, H.M. Wheat bread enriched with raspberry and strawberry oilcakes: Effects on proximate composition, texture and water properties. Eur. Food Res. Technol. 2019, 245, 2591–2600. [Google Scholar] [CrossRef]

- Grosu, C. Mineral Composition of Walnut Kernel and Walnut Oil Cake; Academia de Studii Economice a Moldovei: Iasi, Romania, 2017; pp. 225–226. Available online: https://ibn.idsi.md/sites/default/files/imag_file/225-226.pdf (accessed on 10 May 2025).

- Bernardes, E.N.; Flôres, S.H.; Thys, R.C.S. Are Psyllium Fiber and Flaxseed Flour An Exciting Combination of Ingredients in the Development of Gluten-free Vegan Bread? J. Culin. Sci. Technol. 2022, 22, 480–495. [Google Scholar] [CrossRef]

- McKeown, N.M.; Fahey, G.C.; Slavin, J.; Van der Kamp, J.-W. Fibre intake for optimal health: How can healthcare professionalssupport people to reach dietary recommendations? BMJ 2022, 378, e054370. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Available online: http://data.europa.eu/eli/reg/2006/1924/oj (accessed on 3 July 2024).

- Rolls, B.J.; Drewnowski, A.; Ledikwe, J.H. Changing the Energy Density of the Diet as a Strategy for Weight Management. J. Am. Diet. Assoc. 2005, 105, 98–103. [Google Scholar] [CrossRef] [PubMed]

- Chochkov, R.; Chonova, V.; Karadzhov, G.; Nedelcheva, R. The influence of WF quantity on the quality of wheat bread. Int. J. Eng. Res. 2016, 7, 1161–1164. [Google Scholar]

- Hemdane, S.; Jacobs, P.J.; Bosmans, G.M.; Verspreet, J.; Delcour, J.A.; Courtin, C.M. Study on the effects of wheat bran incorporation on water mobility and biopolimer behavior during bread making and storage using time-domain 1H NMR 749 relaxometry. Food Chem. 2017, 236, 76–750. [Google Scholar] [CrossRef]

- Nawrocka, A.; Szymańska-Chargot, M.; Miś, A.; Wilczewska, A.Z.; Markiewicz, K.H. Effect of dietary fibre polysaccharides on structure and thermal properties of 825 gluten proteins–A study on gluten dough with application of FT-Raman spectroscopy, TGA and DSC. Food Hydrocoll. 2017, 69, 410–827. [Google Scholar] [CrossRef]

- Bellary, A.N.; Indiramma, A.R.; Prakash, M.; Baskaran, R.; Rastogi, N.K. Anthocyanin infused watermelon rind and its stability during storage. Innov. Food Sci. Emerg. Technol. 2016, 33, 554–562. [Google Scholar] [CrossRef]

- Romankiewicz, D.; Hassoon, W.H.; Cacak-Pietrzak, G.; Sobczyk, M.; Wirkowska-Wojdy, M.; Ceglińska, A.; Dziki, D. The Effect of Chia Seeds (Salvia hispanica L.) Addition of Quality and Nutritional Value of Wheat Bread. J. Food Qual. 2017, 7352631. [Google Scholar] [CrossRef]

- Pycia, K.; Ivanišová, E. Physicochemical and antioxidant properties of wheat bread enriched with hazelnuts and walnuts. Foods 2020, 9, 1081. [Google Scholar] [CrossRef]

- Nogueira, A.C.; Sehn, G.A.; Rebellato, A.P.; Coutinho, J.P.; Godoy, H.T.; Chang, Y.K.; Clerici, M.T.P. Yellow sweet potato flour: Use in sweet bread processing to increase β-carotene content and improve quality. An. Acad. Bras. Ciências 2018, 90, 283–293. [Google Scholar] [CrossRef]

- Novotni, D.; Ćurić, D.; Galić, K.; Škevin, D.; Neđeral, S.; Kraljić, K.; Gabrić, D.; Ježek, D. Influence of frozen storage and packaging on oxidative stability and texture of bread produced by different processes. LWT—Food Sci. Technol. 2011, 44, 643–649. [Google Scholar] [CrossRef]

- Abdul Aziz, N.A.; Wong, L.M.; Rajeev, B. Nutritional and sensory quality evaluation of sponge cake prepared by incorporation of high dietary fiber containing mango (Mangifera indica var. Chokanan) pulp and peel flours. Int. J. Food Sci. Nutr. 2011, 62, 559–567. [Google Scholar]

- Medina-Rendon, E.A.; Guatemala-Morales, G.M.; Padilla-Camberos, E.; Corona-González, R.I.; Arriola-Guevara, E.; García-Fajardo, J.A. Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties. Processes 2021, 9, 1660. [Google Scholar] [CrossRef]

- Armero, E.; Collar, C. Crumb firming kinetics of wheat breads with antistaling additives. J. Cereal Sci. 1998, 28, 165–174. [Google Scholar] [CrossRef]

- Manonmani, D.; Bhol, S.; Bosco, S.J.D. Effect of Red Kidney Bean (Phaseolus vulgaris L.) Flour on Bread Quality. Open Access Libr. J. 2014, 1, 1–6. [Google Scholar] [CrossRef]

- Alpers, T.; Kerpes, R.; Frioli, M.; Nobis, A.; Hoi, K.I.; Bach, A.; Jekle, M.; Becker, T. Impact of Storing Condition on Staling and Microbial Spoilage Behavior of Bread and Their Contribution to Prevent Food Waste. Foods 2021, 10, 76. [Google Scholar] [CrossRef]

- Ceylan, F.D.; Adrar, N.; Bolling, B.W.; Capanoglu, E. Valorisation of Hazelnut By-Products: Current Applications and Future Potential. Biotechnol. Genet. Eng. Rev. 2022, 39, 586–621. [Google Scholar] [CrossRef]

- Gałkowska, D.; Pycia, K.; Krykhta, A. Fortification of Durum Wheat Pasta with Nut Oil Cake: Effects on Nutritional andTechnological Properties. Molecules 2025, 30, 3411. [Google Scholar] [CrossRef]

- Yalcin, S. Effect of Storage on the Antioxidant, Color and Sensory Properties of Local Bread. AKU J. Sci. Eng. 2024, 24, 341–349. [Google Scholar] [CrossRef]

| Samples | Protein (%) | Fat (%) | Ash (%) | Total Dietary Fiber (%) | Carbohydrates (%) | Energy Value (Kcal/100 g) |

|---|---|---|---|---|---|---|

| control | 13.39 ± 0.03 a | 1.96 ± 0.11 ab | 3.35 ± 0.08 a | 6.14 ± 0.27 a | 75.13 ± 0.10 e | 384.10 ± 0.76 b |

| BHOC5% | 14.51 ± 0.30 b | 1.76 ± 0.02 ab | 3.49 ± 0.11 a | 6.97 ± 1.97 a | 73.44 ± 1.68 d | 380.88 ± 2.84 b |

| BHOC10% | 15.86 ± 0.32 c | 2.60 ± 0.70 bc | 3.79 ± 0.07 b | 9.91 ± 0.78 c | 67.81 ± 0.42 c | 378.03 ± 3.48 abc |

| BHOC15% | 16.65 ± 0.41 d | 3.32 ± 0.76 c | 4.19 ± 0.10 c | 12.71 ± 0.46 d | 63.28 ± 1.50 b | 374.40 ± 2.41 a |

| BWOC5% | 14.82 ± 0.16 b | 1.58 ± 0.81 a | 3.41 ± 0.03 a | 8.24 ± 0.05 b | 71.87 ± 0.66 d | 377.77 ± 2.80 ab |

| BWOC10% | 15.82 ± 0.28 c | 2.16 ± 0.03 ab | 3.68 ± 0.07 b | 9.68 ± 0.61 c | 68.70 ± 0.11 c | 376.74 ± 0.75 ab |

| BWOC15% | 17.93 ± 0.47 e | 4.69 ± 0.92 d | 3.74 ± 0.16 b | 12.85 ± 0.57 d | 60.65 ± 2.20 a | 382.82 ± 2.35 b |

| two-way MANOVA p-values | ||||||

| Factor 1 | p < 0.001 | p = 0.269 | p < 0.001 | p = 0.236 | p = 0.058 | p = 0.292 |

| Factor 2 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p = 0.443 |

| Factor 1 × factor 2 | p < 0.001 | p = 0.010 | p = 0.012 | p = 0.171 | p = 0.040 | p < 0.001 |

| Samples | Hardness (N) | Springiness (-) | Cohesiveness (-) | Chewiness (N) |

|---|---|---|---|---|

| 1 day | ||||

| control | 12.68 ± 2.40 a | 0.74 ± 0.02 j | 0.57 ± 0.04 f | 5.38 ± 0.73 ghi |

| BHOC5% | 13.65 ± 1.95 b | 0.66 ± 0.04 i | 0.57 ± 0.03 f | 5.15 ± 0.51 ghi |

| BHOC10% | 16.94 ± 0.89 bcd | 0.54 ± 0.03 efg | 0.53 ± 0.02 e | 4.86 ± 0.29 defghi |

| BHOC15% | 20.87 ± 4.13 de | 0.50 ± 0.03 cde | 0.53 ± 0.04 e | 5.38 ± 0.33 ghi |

| BWOC5% | 13.74 ± 2.06 b | 0.59 ± 0.03 ghi | 0.56 ± 0.02 ef | 4.50 ± 0.61 cdefgh |

| BWOC10% | 15.22 ± 1.22 bc | 0.64 ± 0.02 i | 0.54 ± 0.03 e | 5.23 ± 0.74 ghi |

| BWOC15% | 15.08 ± 1.75 bc | 0.51 ± 0.02 cdef | 0.49 ± 0.02 d | 3.75 ± 0.37 bcd |

| three-way MANOVA p-values | ||||

| Factor 1 | p < 0.001 | p = 0.640 | p < 0.001 | p < 0.001 |

| Factor 2 | p < 0.001 | p < 0.001 | p < 0.001 | p = 0.875 |

| Factor 3 | p < 0.001 | p < 0.001 | p < 0.001 | p = 0.020 |

| Factor 1 × factor 2 | p < 0.001 | p = 0.169 | p = 0.112 | p = 0.028 |

| Factor 1 × factor 3 | p = 0.024 | p = 0.520 | p = 0.028 | p = 0.025 |

| Factor 2 × factor 3 | p < 0.001 | p = 0.014 | p = 0.046 | p = 0.013 |

| Factor 1 × factor 2 × factor 3 | p = 0.447 | p < 0.001 | p = 0.087 | p < 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pycia, K.; Juszczak, L. The Effect of Nut Oil Cakes on Selected Properties of Enriched Wheat Bread and Their Changes During Storage. Appl. Sci. 2025, 15, 12591. https://doi.org/10.3390/app152312591

Pycia K, Juszczak L. The Effect of Nut Oil Cakes on Selected Properties of Enriched Wheat Bread and Their Changes During Storage. Applied Sciences. 2025; 15(23):12591. https://doi.org/10.3390/app152312591

Chicago/Turabian StylePycia, Karolina, and Lesław Juszczak. 2025. "The Effect of Nut Oil Cakes on Selected Properties of Enriched Wheat Bread and Their Changes During Storage" Applied Sciences 15, no. 23: 12591. https://doi.org/10.3390/app152312591

APA StylePycia, K., & Juszczak, L. (2025). The Effect of Nut Oil Cakes on Selected Properties of Enriched Wheat Bread and Their Changes During Storage. Applied Sciences, 15(23), 12591. https://doi.org/10.3390/app152312591