Chestnut Burr as a Multifunctional Filler for PLA-Based Bio-Composites: Processing, Characterization, and Antioxidant Functionality

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Filler Preparation

2.2. Composite Filament Fabrication

2.3. Three-Dimensional Printing Conditions

2.4. Mechanical Properties

- -

- Frequency sweep, using a 0.1% constant strain (selected within the LVR), in a frequency range from 0.1 Hz to 10 Hz, at 25 °C;

- -

- Temperature sweep, at constant strain and frequency, 0.1% and 1 Hz, respectively, sweeping the temperature from 30 °C to 80 °C, at a heating rate of 10 °C/min.

2.5. Infrared Spectroscopy (ATR FT-IR)

2.6. Thermogravimetric Analysis (TGA)

2.7. Differential Scanning Calorimetry (DSC)

2.8. Scanning Electronic Microscope (SEM)

2.9. Antioxidant Analysis of Composite Filaments Pre- and Post-Printing

2.9.1. Extraction of Antioxidant Compounds

2.9.2. Total Phenolic Content (TPC)

2.9.3. Determination of Reducing Power

2.9.4. DPPH Free-Radical Scavenging Activity

2.9.5. ABTS+ Free-Radical Scavenging Activity

3. Results

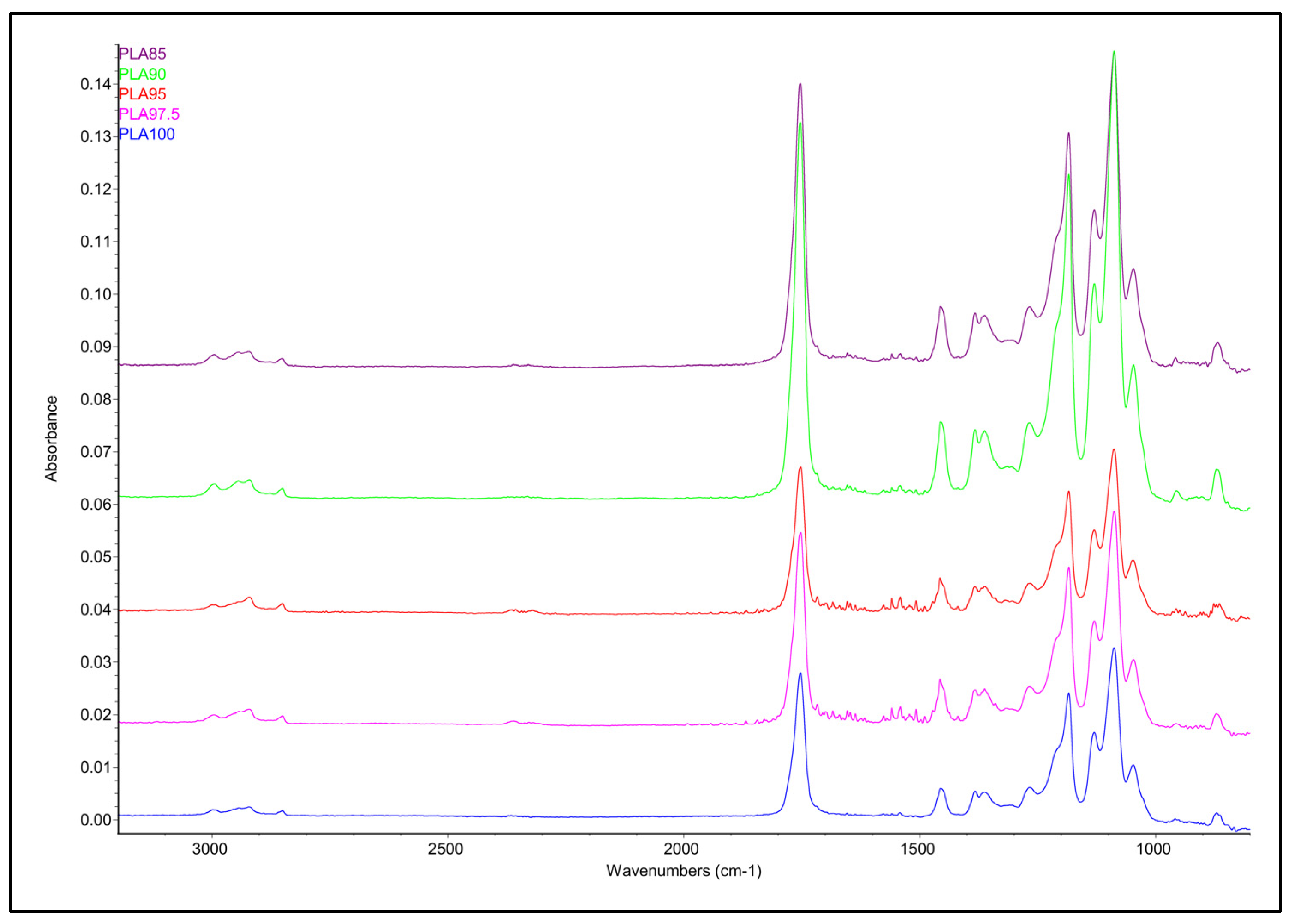

3.1. Infrared Spectroscopy (ATR FT-IR)

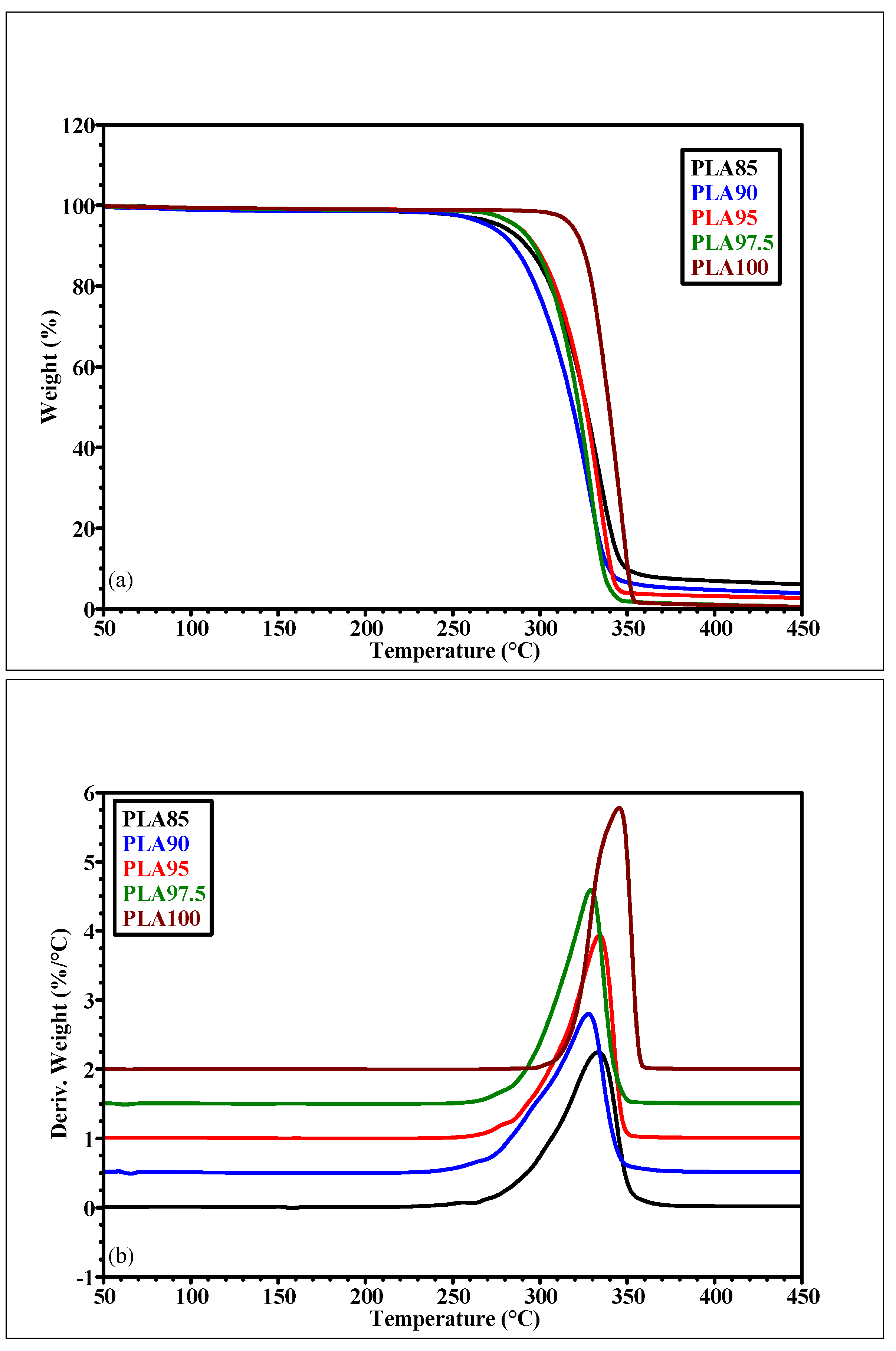

3.2. Thermogravimetric Analysis (TGA)

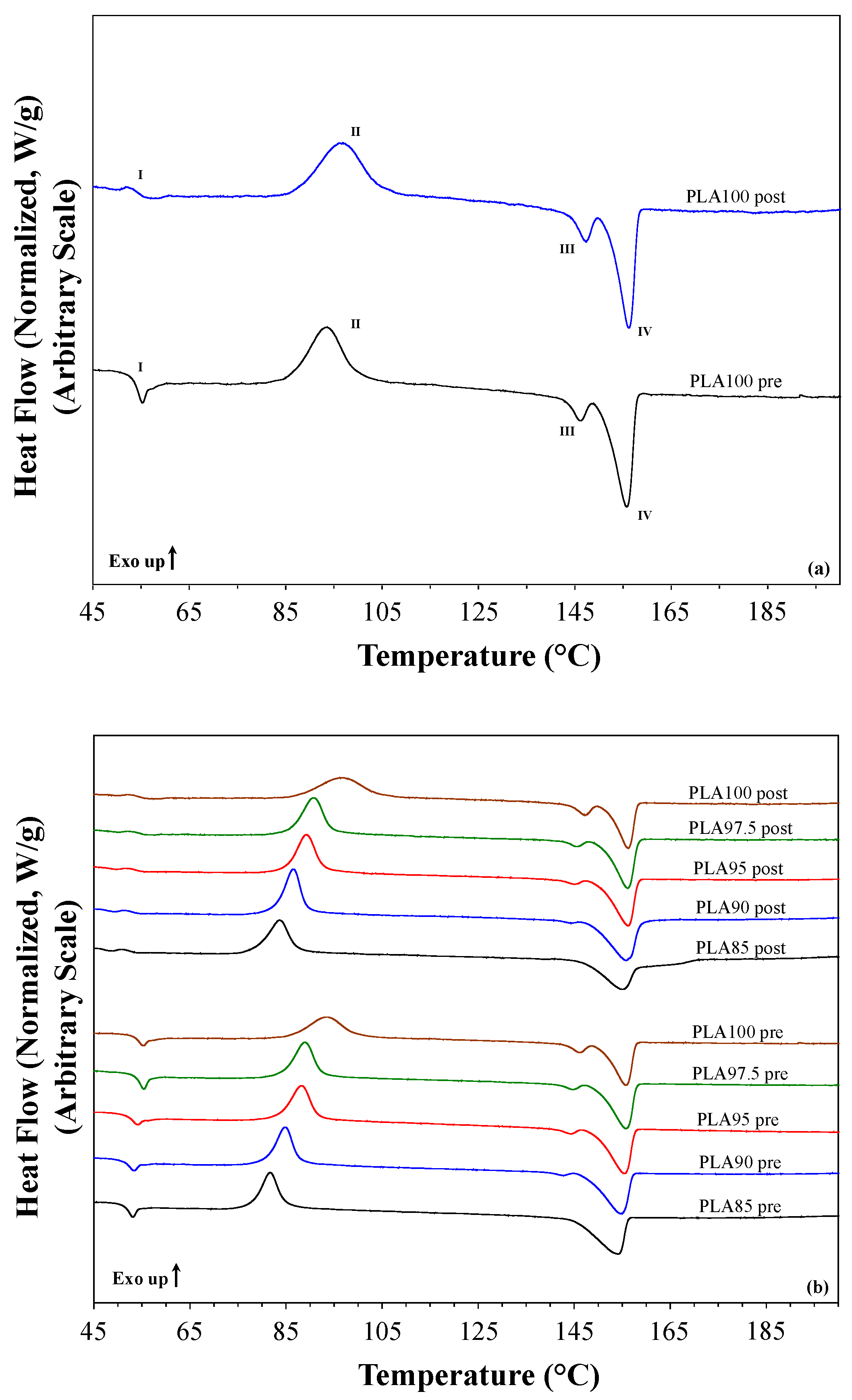

3.3. Differential Scanning Calorimetry (DSC)

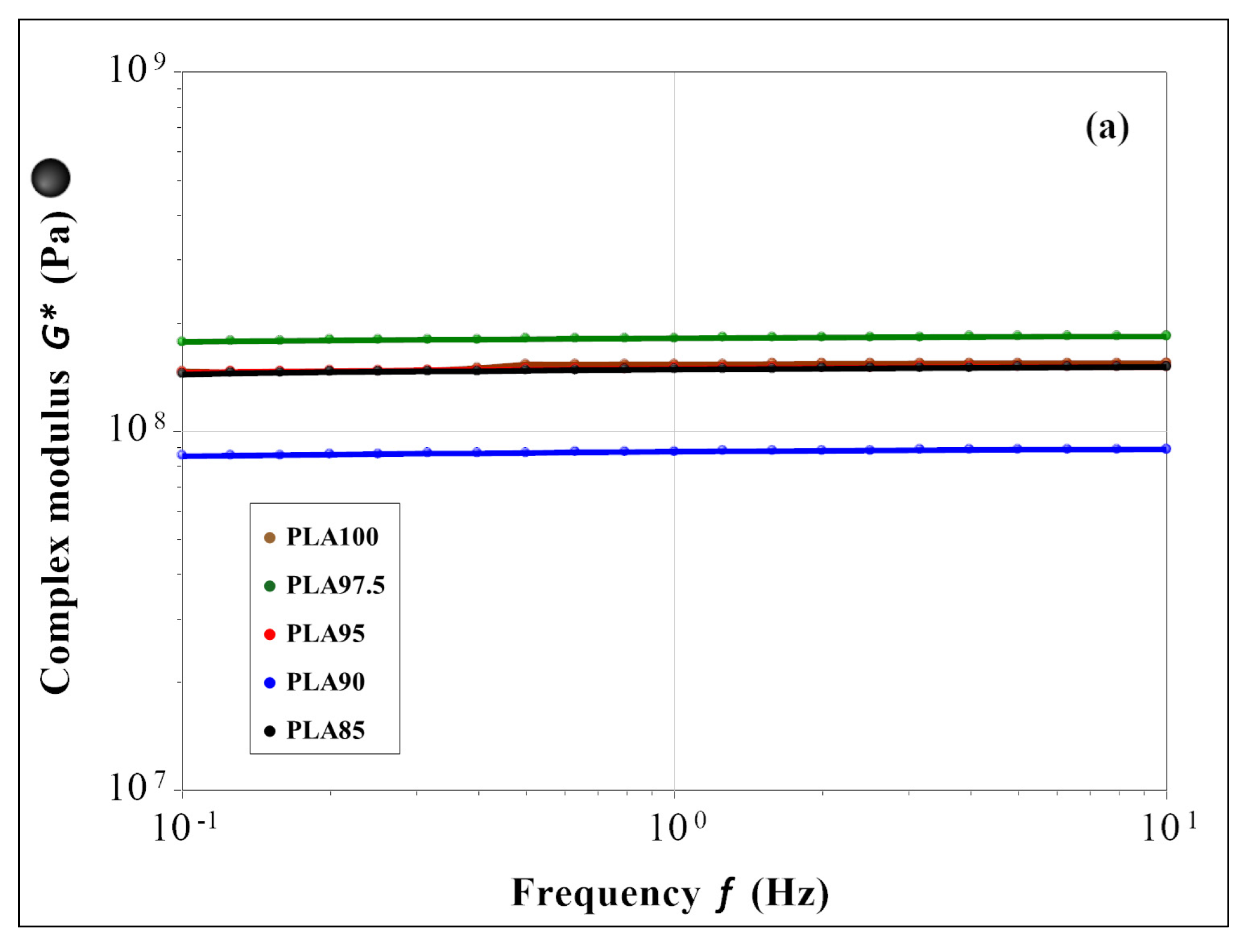

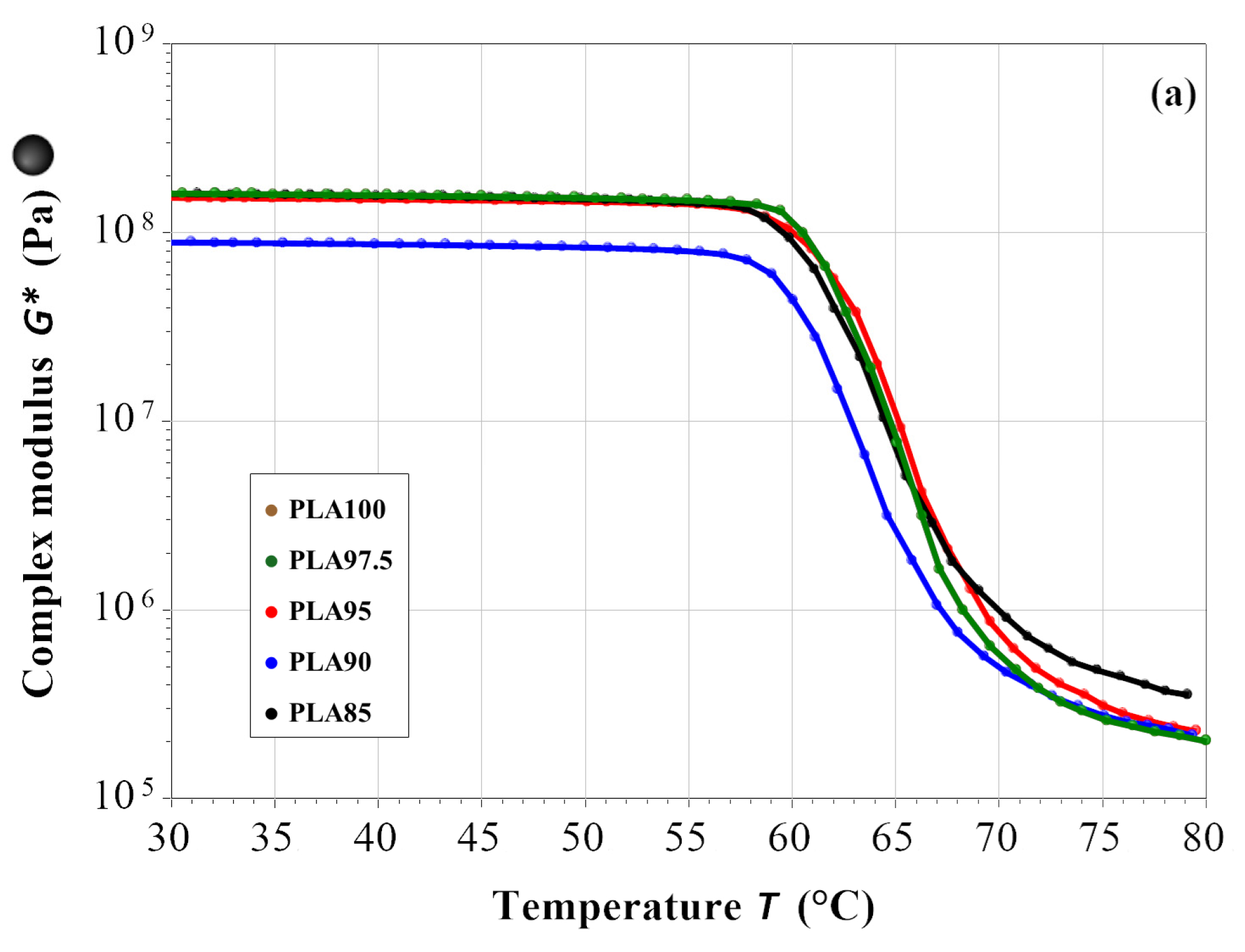

3.4. Mechanical Properties

3.5. Morphological Analysis

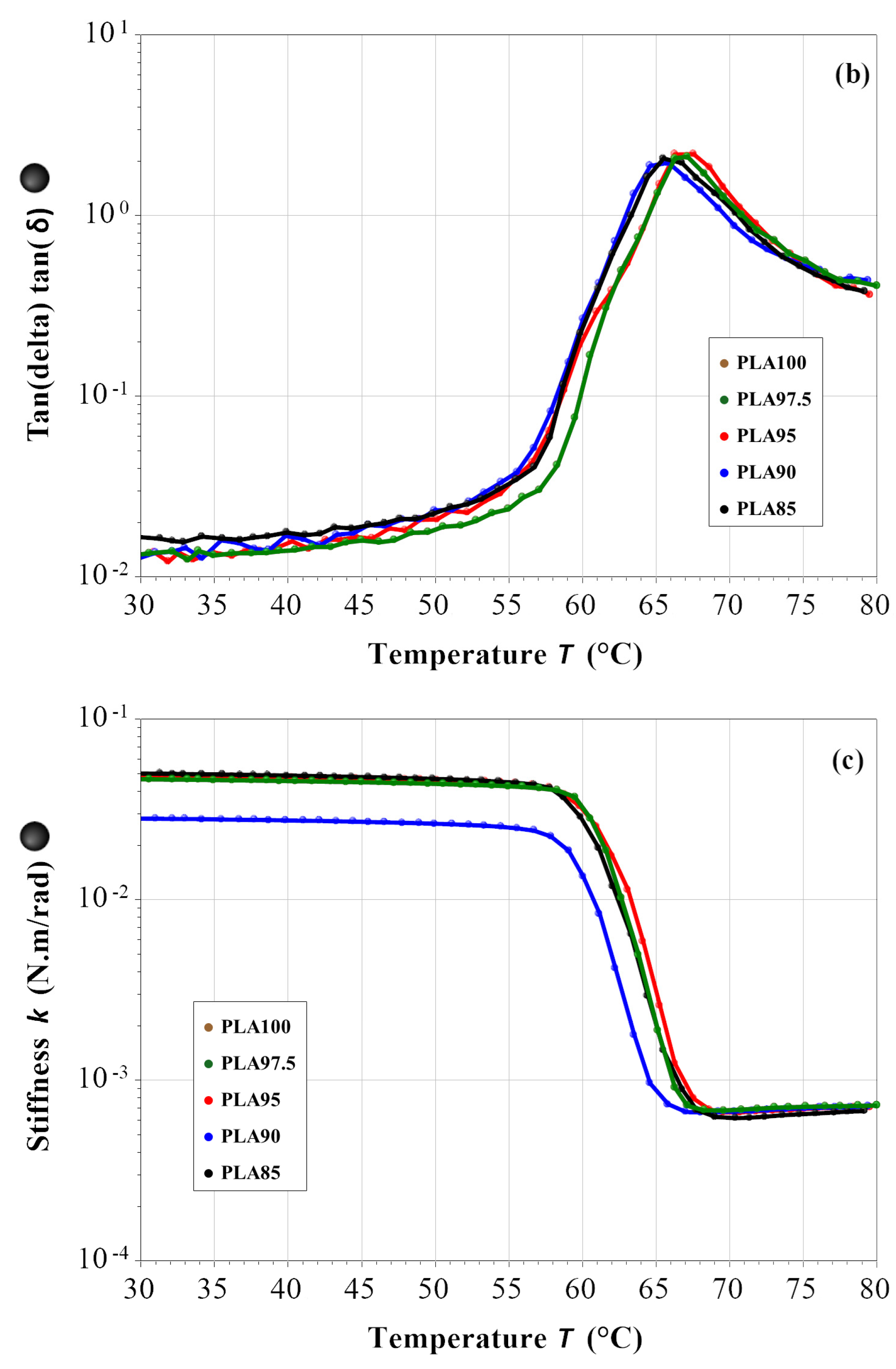

3.5.1. Surface Morphology

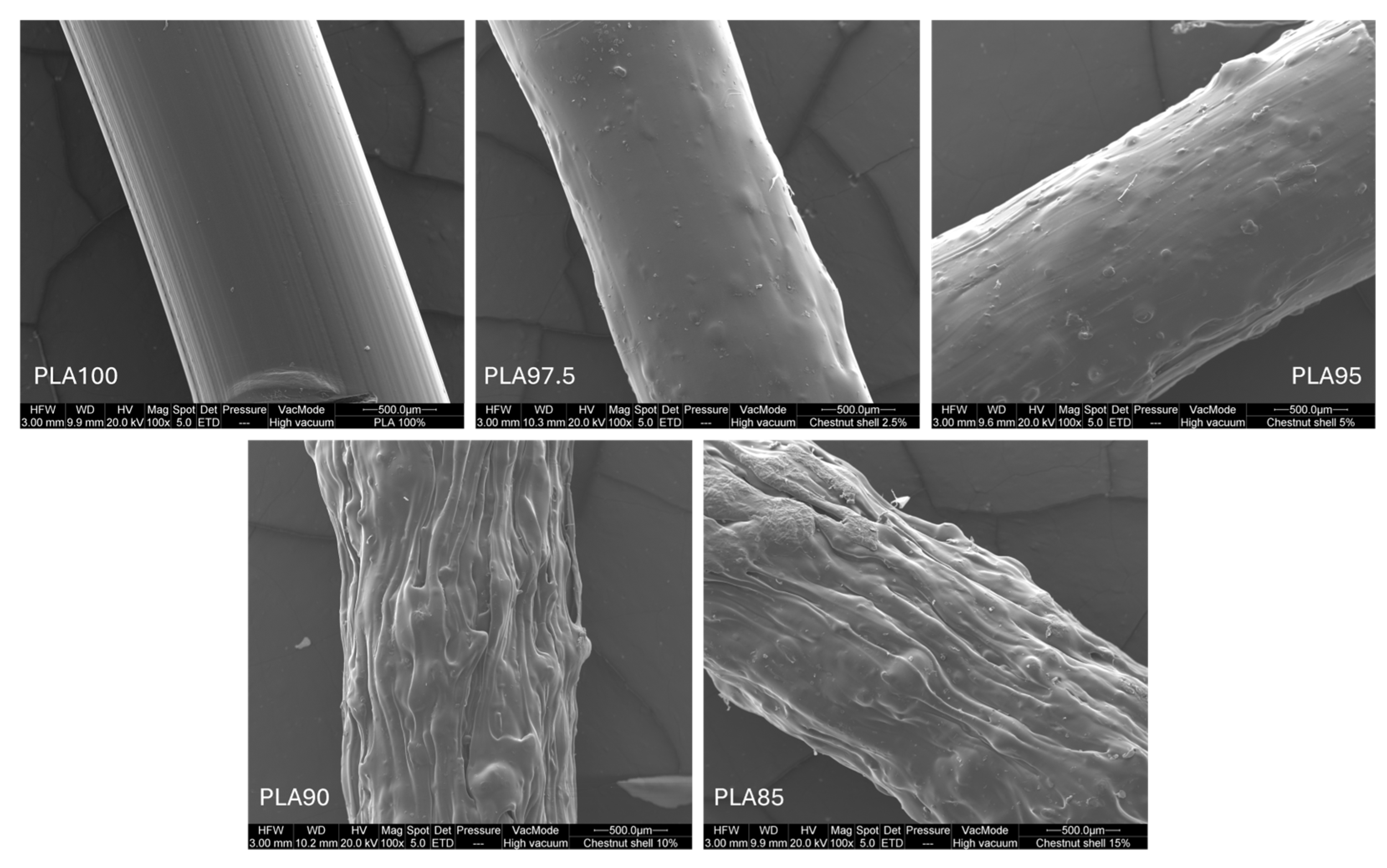

3.5.2. Cross-Sectional Morphology

3.5.3. Functional Implications

3.6. Antioxidant Activity (DPPH, ABTS, FRAP and Folin–Ciocâlteu Assays)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.A.T. Environmental Impact of Bioplastic Use: A Review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef] [PubMed]

- Sangeetha, V.H.; Deka, H.; Varghese, T.O.; Nayak, S.K. State of the Art and Future Prospectives of Poly(Lactic Acid) Based Blends and Composites. Polym. Compos. 2018, 39, 81–101. [Google Scholar] [CrossRef]

- Sherwani, S.F.K.; Zainudin, E.S.; Sapuan, S.M.; Leman, Z.; Khalina, A. Recent Development of Natural Fibers Reinforced Polylactic Acid Composites. J. Res. Nanosci. Nanotechnol. 2022, 5, 103–108. [Google Scholar] [CrossRef]

- Venkatesh, G. Circular Bio-Economy—Paradigm for the Future: Systematic Review of Scientific Journal Publications from 2015 to 2021. Circ. Econ. Sustain. 2022, 2, 231–279. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA Based Biocomposites for Sustainable Products: A Review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Çıtlacıfçı, H.; Kılıç Pekgözlü, A.; Gülsoy, S.K. Characterization of Chestnut Shell. Bartın Univ. Int. J. Nat. Appl. Sci. 2022, 5, 145–150. [Google Scholar] [CrossRef]

- Frusciante, L.; Geminiani, M.; Olmastroni, T.; Mastroeni, P.; Trezza, A.; Salvini, L.; Lamponi, S.; Spiga, O.; Santucci, A. Repurposing Castanea sativa Spiny Burr By-Products Extract as a Potentially Effective Anti-Inflammatory Agent for Novel Future Biotechnological Applications. Life 2024, 14, 763. [Google Scholar] [CrossRef]

- Trezza, A.; Barletta, R.; Geminiani, M.; Frusciante, L.; Olmastroni, T.; Sannio, F.; Docquier, J.D.; Santucci, A. Chestnut Burrs as Natural Source of Antimicrobial Bioactive Compounds: A Valorization of Agri-Food Waste. Appl. Sci. 2024, 14, 6552. [Google Scholar] [CrossRef]

- Łopusiewicz, Ł.; Jędra, F.; Mizielińska, M. New Poly(lactic acid) Active Packaging Composite Films Incorporated with Fungal Melanin. Polymers 2018, 10, 386. [Google Scholar] [CrossRef]

- Papadopoulou, E.L.; Paul, U.C.; Tran, T.N.; Suarato, G.; Ceseracciu, L.; Marras, S.; D’arcy, R.; Athanassiou, A. Sustainable Active Food Packaging from Poly(Lactic Acid) and Cocoa Bean Shells. ACS Appl. Mater. Interfaces 2019, 11, 31317–31327. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agarwal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical Review of FDM 3D Printing of PLA Biocomposites Filled with Biomass Resources, Characterization, Biodegradability, Upcycling and Opportunities for Biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Li, J.; Zhou, X.; Xie, J.; Wang, A. Selective Laser Melting Molding of Individualized Femur Implant: Design, Process, Optimization. J. Bionic. Eng. 2021, 18, 128–137. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Awad, S.; Siakeng, R.; Khalaf, E.M.; Fouad, H.; Abd El-salam, N.M.; Ahmed, F.; Jawaid, M. Fabrication and Characterization of Polylactic Acid/Natural Fiber Extruded Composites. Polym. Eng. Sci. 2023, 63, 1234–1245. [Google Scholar] [CrossRef]

- Lendvai, L. Lignocellulosic Agro-Residue/Polylactic Acid (PLA) Biocomposites: Rapeseed Straw as a Sustainable Filler. Clean. Mater. 2023, 9, 100196. [Google Scholar] [CrossRef]

- Pepi, S.; Talarico, L.; Leone, G.; Bonechi, C.; Consumi, M.; Boldrini, A.; Lauro, A.; Magnani, A.; Rossi, C. Effect of Mild Conditions on PVA-Based Theta Gel Preparation: Thermal and Rheological Characterization. Int. J. Mol. Sci. 2024, 25, 12039. [Google Scholar] [CrossRef]

- Muccilli, V.; Maccarronello, A.E.; Rasoanandrasana, C.; Cardullo, N.; de Luna, M.S.; Pittalà, M.G.G.; Riccobene, P.M.; Carroccio, S.C.; Scamporrino, A.A. Green3: A Green Extraction of Green Additives for Green Plastics. Heliyon 2024, 10, e24469. [Google Scholar] [CrossRef]

- Song, F.L.; Gan, R.Y.; Zhang, Y.; Xiao, Q.; Kuang, L.; Li, H. Bin Total Phenolic Contents and Antioxidant Capacities of Selected Chinese Medicinal Plants. Int. J. Mol. Sci. 2010, 11, 2362–2372. [Google Scholar] [CrossRef]

- Jayaprakasha, G.K.; Singh, R.P.; Sakariah, K.K. Antioxidant Activity of Grape Seed (Vitis vinifera) Extracts on Peroxidation Models in Vitro. Food Chem. 2001, 73, 285–290. [Google Scholar] [CrossRef]

- Frusciante, L.; Geminiani, M.; Shabab, B.; Olmastroni, T.; Scavello, G.; Rossi, M.; Mastroeni, P.; Nyong’a, C.N.; Salvini, L.; Lamponi, S.; et al. Exploring the Antioxidant and Anti-Inflammatory Potential of Saffron (Crocus Sativus) Tepals Extract within the Circular Bioeconomy. Antioxidants 2024, 13, 1082. [Google Scholar] [CrossRef]

- Choksi, N.; Desai, H. Synthesis of Biodegradable Polylactic Acid Polymer By Using Lactic Acid Monomer. Int. J. Appl. Chem. 2017, 13, 377–384. [Google Scholar]

- Narlıoğlu, N.; Salan, T.; Alma, M.H. Properties of 3D-Printed Wood Sawdust-Reinforced PLA Composites. BioResources 2021, 16, 5467–5480. [Google Scholar] [CrossRef]

- Leone, G.; Pepi, S.; Consumi, M.; Lamponi, S.; Fragai, M.; Martinucci, M.; Baldoneschi, V.; Francesconi, O.; Nativi, C.; Magnani, A. Sodium Hyaluronate-g-2-((N-(6-Aminohexyl)-4-Methoxyphenyl)Sulfonamido)-N-Hydroxyacetamide with Enhanced Affinity towards MMP12 Catalytic Domain to Be Used as Visco-Supplement with Increased Degradation Resistance. Carbohydr. Polym. 2021, 271, 118452. [Google Scholar] [CrossRef] [PubMed]

- Patti, A.; Acierno, S.; Cicala, G.; Zarrelli, M.; Acierno, D. The Understanding the Processing Window of Virgin and Recycled Bio-Based Filaments for 3D Printing Applications. Macromol. Symp. 2022, 405, 2100291. [Google Scholar] [CrossRef]

- Tábi, T.; Sajó, I.E.; Szabó, F.; Luyt, A.S.; Kovács, J.G. Crystalline Structure of Annealed Polylactic Acid and Its Relation to Processing. Express Polym. Lett. 2010, 4, 659–668. [Google Scholar] [CrossRef]

- Song, L.; Li, Y.; Meng, X.; Wang, T.; Shi, Y.; Wang, Y.; Shi, S.; Liu, L. Crystallization, Structure and Significantly Improved Mechanical Properties of PLA/PPC Blends Compatibilized with PLA-PPC Copolymers Produced by Reactions Initiated with TBT or TDI. Polymers 2021, 13, 3245. [Google Scholar] [CrossRef]

- Hui, I.; Pasquier, E.; Solberg, A.; Agrenius, K.; Håkansson, J.; Chinga-Carrasco, G. Biocomposites Containing Poly(Lactic Acid) and Chitosan for 3D Printing—Assessment of Mechanical, Antibacterial and in Vitro Biodegradability Properties. J. Mech. Behav. Biomed. Mater. 2023, 147, 106136. [Google Scholar] [CrossRef]

- Camarena-Bononad, P.; Freitas, P.A.V.; González-Martínez, C.; Chiralt, A.; Vargas, M. Influence of the Purification Degree of Cellulose from Posidonia Oceanica on the Properties of Cellulose-PLA Composites. Polysaccharides 2024, 5, 807–822. [Google Scholar] [CrossRef]

- Yang, J.Y.; Kim, D.K.; Han, W.; Park, J.Y.; Kim, K.W.; Kim, B.J. Effect of Nucleating Agents Addition on Thermal and Mechanical Properties of Natural Fiber-Reinforced Polylactic Acid Composites. Polymers 2022, 14, 4263. [Google Scholar] [CrossRef]

- Gupta, A.; Simmons, W.; Schueneman, G.T.; Mintz, E.A. Lignin-Coated Cellulose Nanocrystals as Promising Nucleating Agent for Poly(Lactic Acid). J. Therm. Anal. Calorim. 2016, 126, 1243–1251. [Google Scholar] [CrossRef]

- Thumsorn, S.; Srisawat, N.; On, J.W.; Pivsa-Art, S.; Hamada, H. Crystallization Kinetics and Thermal Resistance of Bamboo Fiber Reinforced Biodegradable Polymer Composites. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2014; Volume 1593, pp. 316–319. [Google Scholar]

- Szczepanik, E.; Szatkowski, P.; Molik, E.; Pielichowska, K. The Effect of Natural Plant and Animal Fibres on PLA Composites Degradation Process. Appl. Sci. 2024, 14, 5600. [Google Scholar] [CrossRef]

- Ventorino, V.; Parillo, R.; Testa, A.; Viscardi, S.; Espresso, F.; Pepe, O. Chestnut Green Waste Composting for Sustainable Forest Management: Microbiota Dynamics and Impact on Plant Disease Control. J. Environ. Manag. 2016, 166, 168–177. [Google Scholar] [CrossRef] [PubMed]

- Ventorino, V.; Parillo, R.; Testa, A.; Aliberti, A.; Pepe, O. Chestnut Biomass Biodegradation for Sustainable Agriculture. BioResources 2013, 8, 4647–4658. [Google Scholar] [CrossRef]

- Costa-Trigo, I.; Otero-Penedo, P.; Outeiriño, D.; Paz, A.; Domínguez, J.M. Valorization of Chestnut (Castanea sativa) Residues: Characterization of Different Materials and Optimization of the Acid-Hydrolysis of Chestnut Burrs for the Elaboration of Culture Broths. Waste Manag. 2019, 87, 472–484. [Google Scholar] [CrossRef]

- Kalita, N.K.; Damare, N.A.; Hazarika, D.; Bhagabati, P.; Kalamdhad, A.; Katiyar, V. Biodegradation and Characterization Study of Compostable PLA Bioplastic Containing Algae Biomass as Potential Degradation Accelerator. Environ. Chall. 2021, 3, 100067. [Google Scholar] [CrossRef]

- Cruz Fabian, D.R.; Durpekova, S.; Dusankova, M.; Cisar, J.; Drohsler, P.; Elich, O.; Borkova, M.; Cechmankova, J.; Sedlarik, V. Renewable Poly(Lactic Acid)Lignocellulose Biocomposites for the Enhancement of the Water Retention Capacity of the Soil. Polymers 2023, 15, 2243. [Google Scholar] [CrossRef]

- ISO 14855-1:2012; Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide-Part 1: General Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- ASTM D5338-15; Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials Under Controlled Composting Conditions. ASTM International: West Conshohocken, PA, USA, 2015.

- Sadeer, N.B.; Montesano, D.; Albrizio, S.; Zengin, G.; Mahomoodally, M.F. The Versatility of Antioxidant Assays in Food Science and Safety-Chemistry, Applications, Strengths, and Limitations. Antioxidants 2020, 9, 709. [Google Scholar] [CrossRef]

- Bianchi, S.; Marchese, P.; Vannini, M.; Sisti, L.; Tassoni, A.; Ferri, M.; Mallegni, N.; Cinelli, P.; Celli, A. Evaluation of the Activity of Natural Phenolic Antioxidants, Extracted from Industrial Coffee Residues, on the Stability of Poly(1,4-Butylene Succinate) Formulations. J. Appl. Polym. Sci. 2023, 140, e53878. [Google Scholar] [CrossRef]

| Sample | Weight Loss at | Residue at 450 °C (% w/w) | DTG Tmax (°C) | |

|---|---|---|---|---|

| 30–200 °C (% w/w) | 200–450 °C (% w/w) | |||

| PLA100 | 1.0% ± 0.1% | 98.5% ± 3.0% | 0.5% ± 0.0% | 345 °C ± 6 °C |

| PLA97.5 | 1.1% ± 0.1% | 98.4% ± 2.0% | 0.5% ± 0.0% | 329 °C ± 2 °C |

| PLA95 | 1.0% ± 0.1% | 96.3% ± 3.9% | 2.7% ± 0.1% | 334 °C ± 4 °C |

| PLA90 | 1.5% ± 0.0% | 94.6% ± 4.7% | 3.9% ± 0.1% | 328 °C ± 4 °C |

| PLA85 | 1.4% ± 0.0% | 92.6% ± 3.7% | 6.1% ± 0.3% | 333 °C ± 3 °C |

| Sample | Tg (T, °C) | ΔHcc (J g−1) | ΔHm (J g−1) | Tcc,max (°C) | Tm,max (°C) | Crystallinity (%) (*) |

|---|---|---|---|---|---|---|

| PLA100 pre | 54.5 | 22.61 | 28.68 | 81.7 | 154.2 | 30.8% |

| PLA97.5 pre | 54.7 | 23.16 | 30.68 | 84.8 | 154.8 | 33.0% |

| PLA95 pre | 53.2 | 23.80 | 30.08 | 88.3 | 155.4 | 32.3% |

| PLA90 pre | 52.6 | 24.19 | 30.84 | 88.9 | 155.8 | 33.2% |

| PLA85 pre | 52.5 | 23.79 | 32.70 | 93.6 | 155.8 | 35.2% |

| PLA100 post | 54.2 | 22.61 | 30.00 | 83.7 | 154.9 | 32.3% |

| PLA97.5 post | 54.9 | 23.16 | 30.45 | 86.5 | 155.8 | 32.7% |

| PLA95 post | 53.7 | 23.80 | 31.73 | 89.2 | 156.3 | 34.1% |

| PLA90 post | 53.1 | 24.19 | 35.39 | 90.8 | 156.1 | 38.1% |

| PLA85 post | 52.5 | 23.79 | 34.58 | 96.8 | 156.3 | 37.2% |

| Sample | DPPH (mgTE/g) | RSA% DPPH | TEAC (μmol TE/g) | RSA% ABTS | TPC (mg GAE/g) | Reducing Power (mg AAE/g) |

|---|---|---|---|---|---|---|

| PLA100 | 0.122 ± 0.012 | 23.78 ± 2.06 | 0.82 ± 0.02 | 42.83 ± 0.96 | 0.350 ± 0.013 | 0.348 ± 0.009 |

| PLA85 | 0.402 ± 0.004 | 71.52 ± 0.69 | 1.81 ± 0.01 | 90.87 ± 0.36 | 0.507 ± 0.017 | 0.703 ± 0.02 |

| PLA85 post-printing | 0.513 ± 0.004 | 90.6 ± 0.61 | 1.8 ± 0.02 | 90.64 ± 0.17 | 0.691 ± 0.07 | 1.128 ± 0.034 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olmastroni, T.; Pepi, S.; Sarwari, M.; Paccagnini, E.; Trezza, A.; Visibelli, A.; Lupetti, P.; Magnani, A.; Travagli, V.; Geminiani, M.; et al. Chestnut Burr as a Multifunctional Filler for PLA-Based Bio-Composites: Processing, Characterization, and Antioxidant Functionality. Appl. Sci. 2025, 15, 11743. https://doi.org/10.3390/app152111743

Olmastroni T, Pepi S, Sarwari M, Paccagnini E, Trezza A, Visibelli A, Lupetti P, Magnani A, Travagli V, Geminiani M, et al. Chestnut Burr as a Multifunctional Filler for PLA-Based Bio-Composites: Processing, Characterization, and Antioxidant Functionality. Applied Sciences. 2025; 15(21):11743. https://doi.org/10.3390/app152111743

Chicago/Turabian StyleOlmastroni, Tommaso, Simone Pepi, Milad Sarwari, Eugenio Paccagnini, Alfonso Trezza, Anna Visibelli, Pietro Lupetti, Agnese Magnani, Valter Travagli, Michela Geminiani, and et al. 2025. "Chestnut Burr as a Multifunctional Filler for PLA-Based Bio-Composites: Processing, Characterization, and Antioxidant Functionality" Applied Sciences 15, no. 21: 11743. https://doi.org/10.3390/app152111743

APA StyleOlmastroni, T., Pepi, S., Sarwari, M., Paccagnini, E., Trezza, A., Visibelli, A., Lupetti, P., Magnani, A., Travagli, V., Geminiani, M., & Santucci, A. (2025). Chestnut Burr as a Multifunctional Filler for PLA-Based Bio-Composites: Processing, Characterization, and Antioxidant Functionality. Applied Sciences, 15(21), 11743. https://doi.org/10.3390/app152111743