Haptic Reproduction of Virtual Textures Based on Ultrasonic Interference Principle

Abstract

1. Introduction

2. Materials and Methods

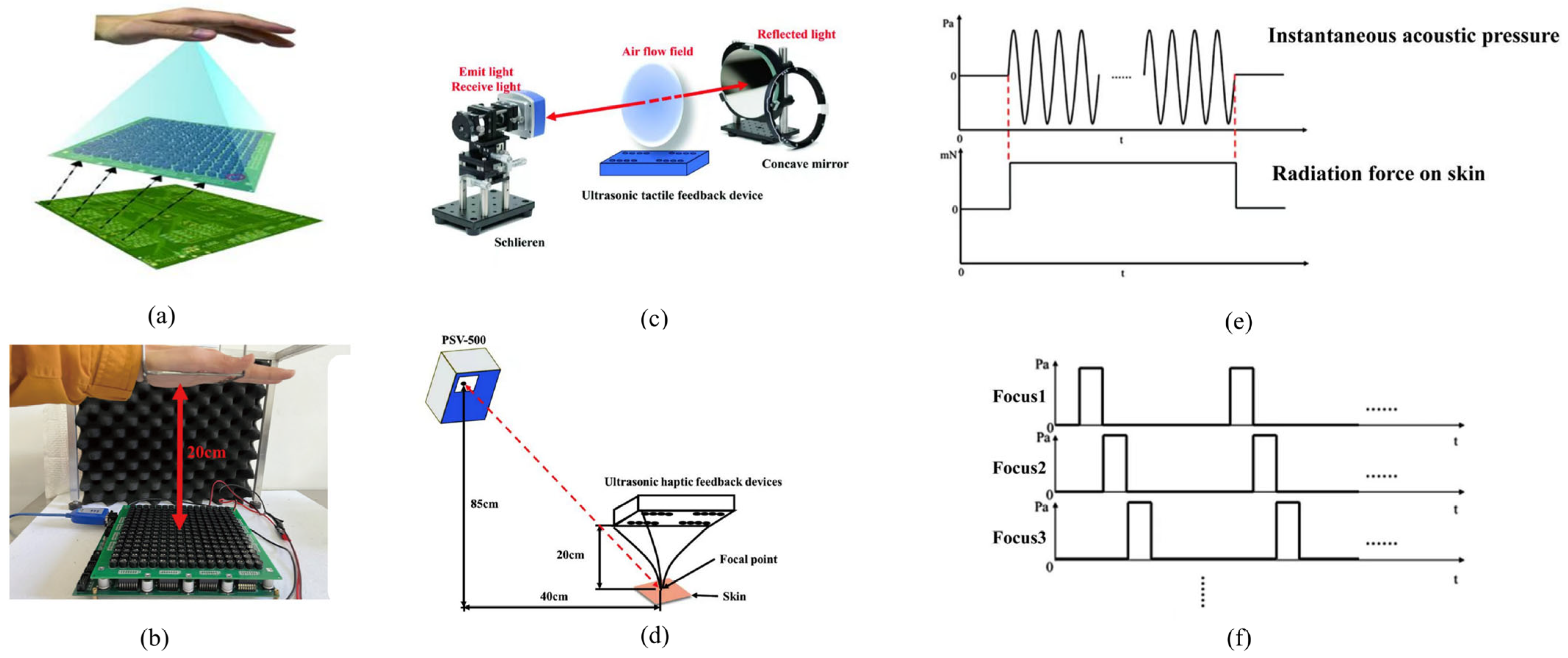

2.1. Ultrasonic Haptic Feedback Technology Focus Size Measurement and Accuracy of Excitation Load Experiments

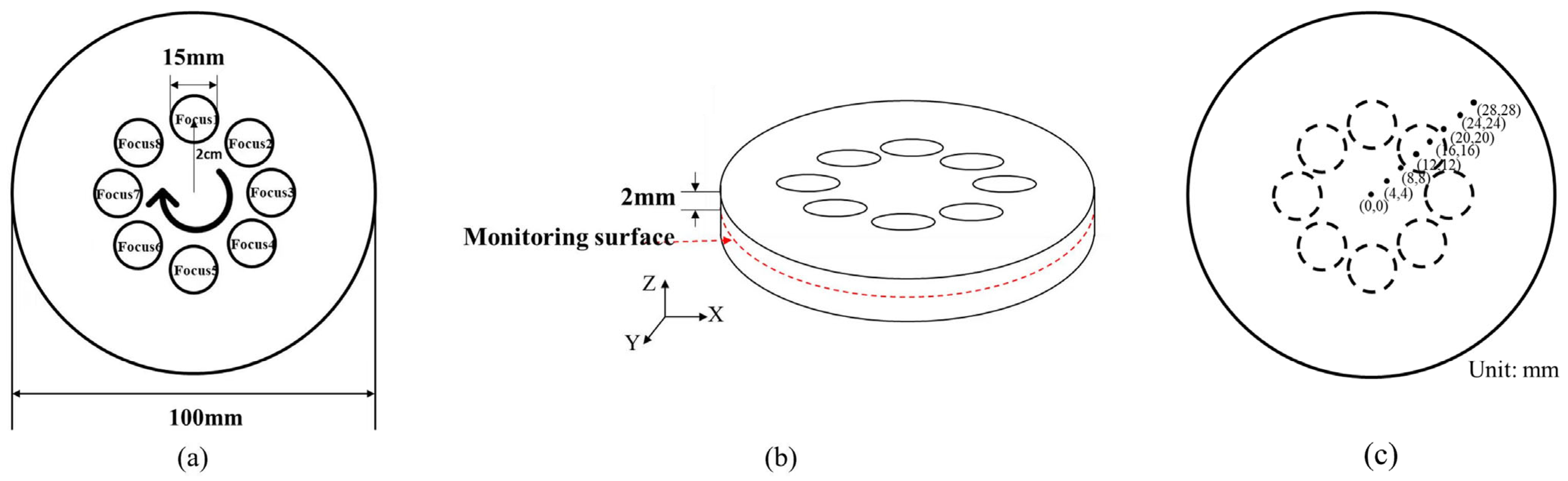

2.2. Setting of Monitoring Point and Monitoring Surface for Skin Texture-Aware Simulation

2.3. Experiment on the Evaluation of Human Realistic Haptics with Ultrasonic Haptic Feedback

3. Results

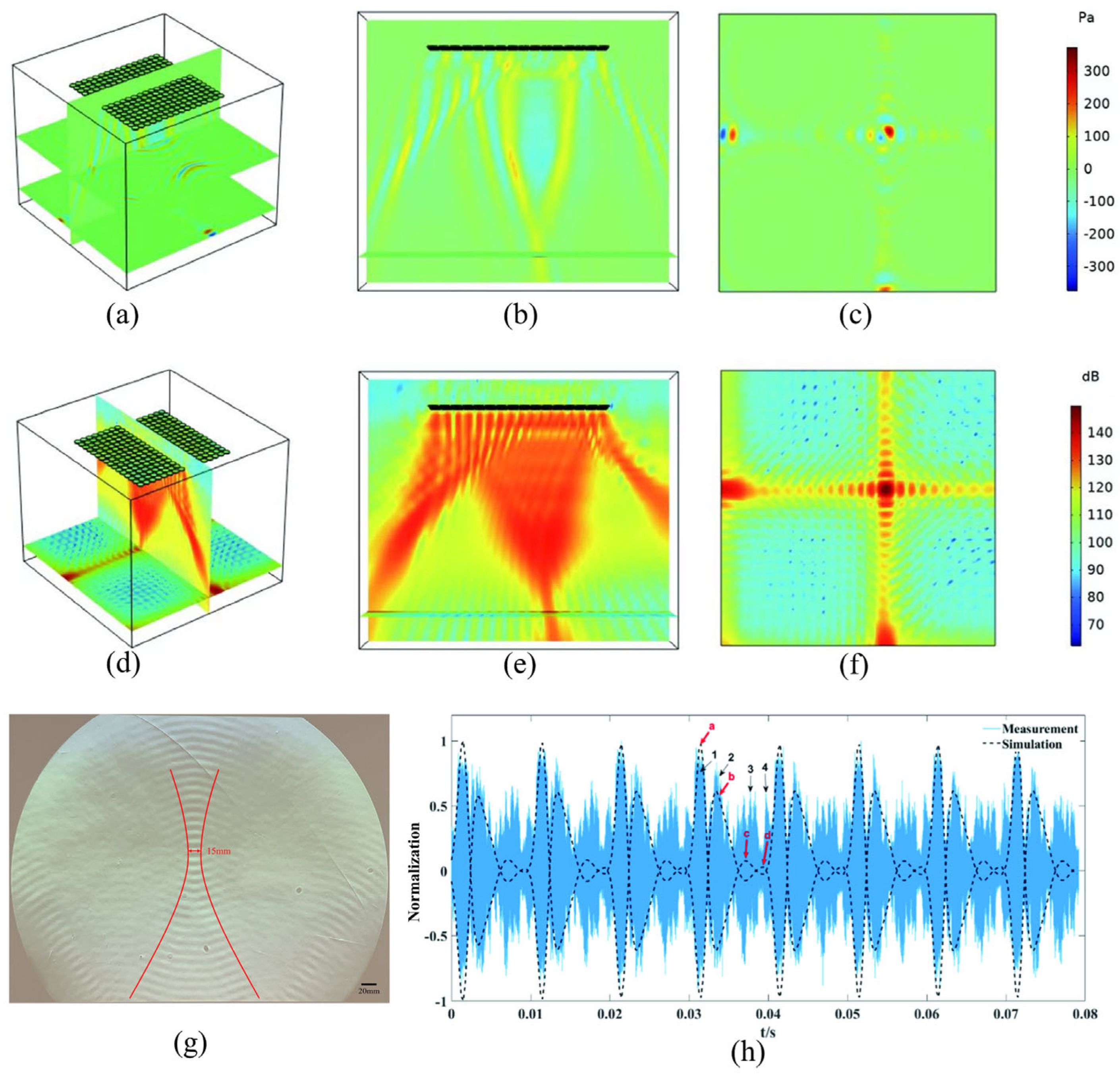

3.1. Tactile Texture Feedback Generated by Ultrasonic

3.2. Simulation of Skin Stress–Strain of Ultrasonic Haptic Feedback

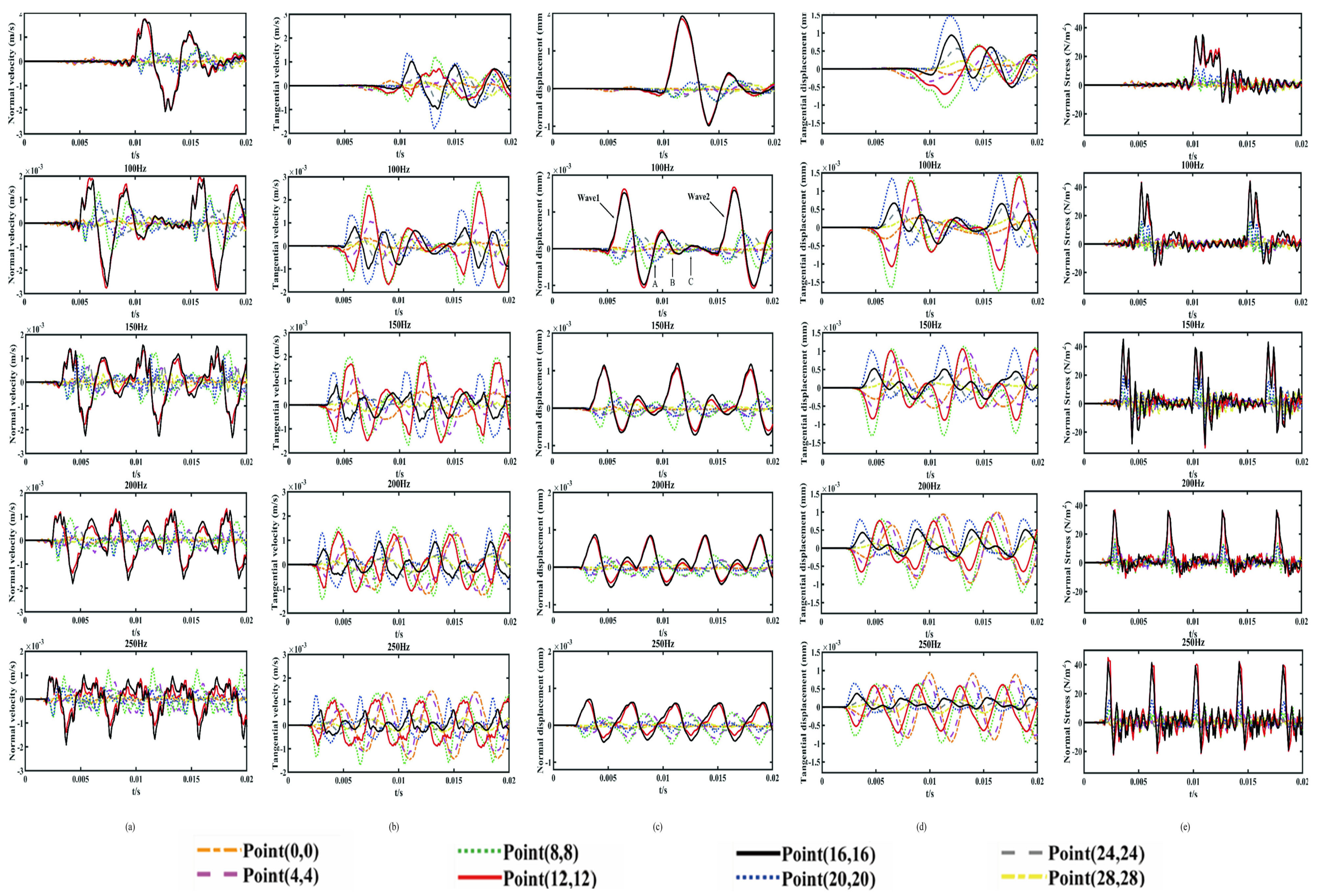

3.3. Stress–Strain Conditions of Monitoring Points

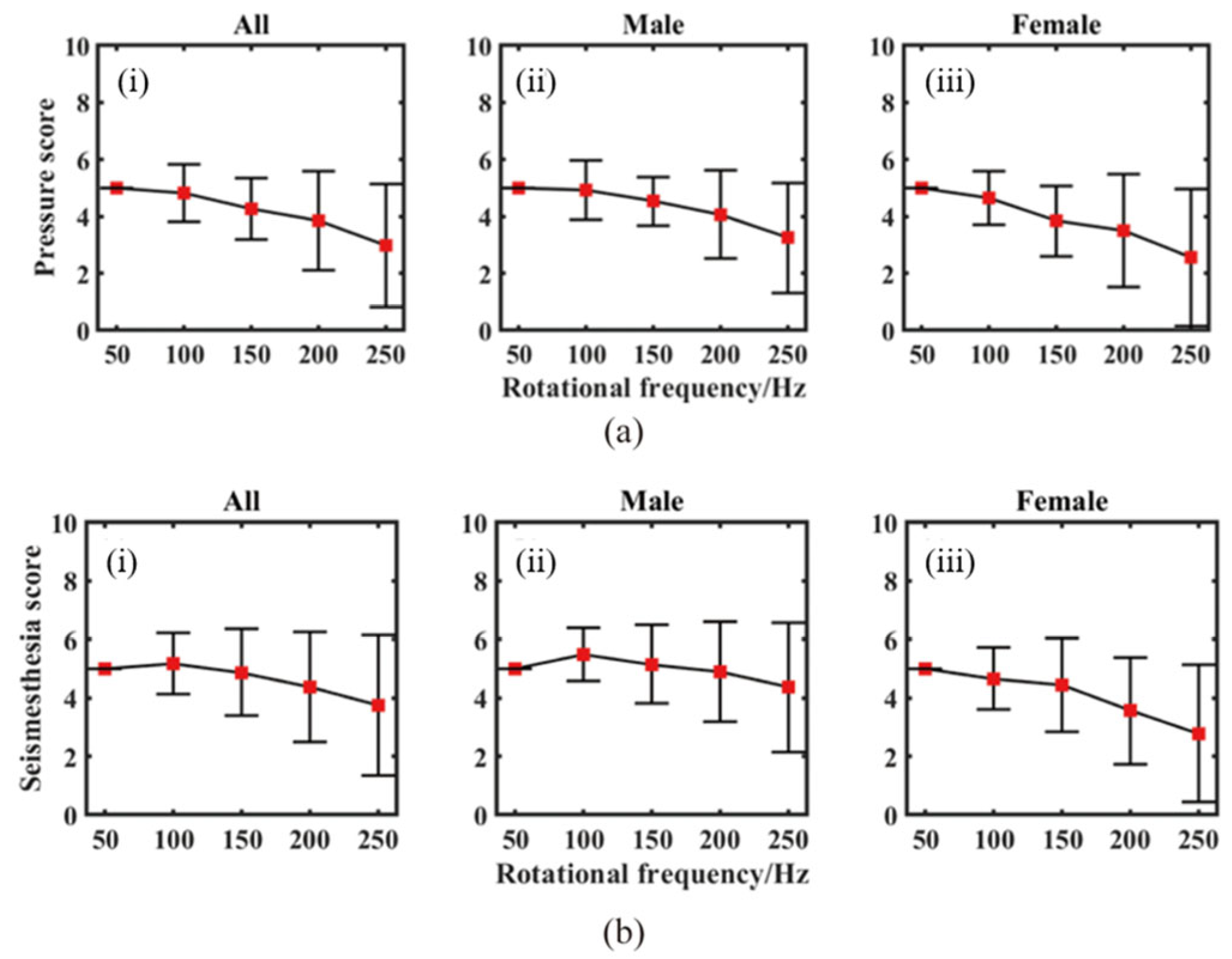

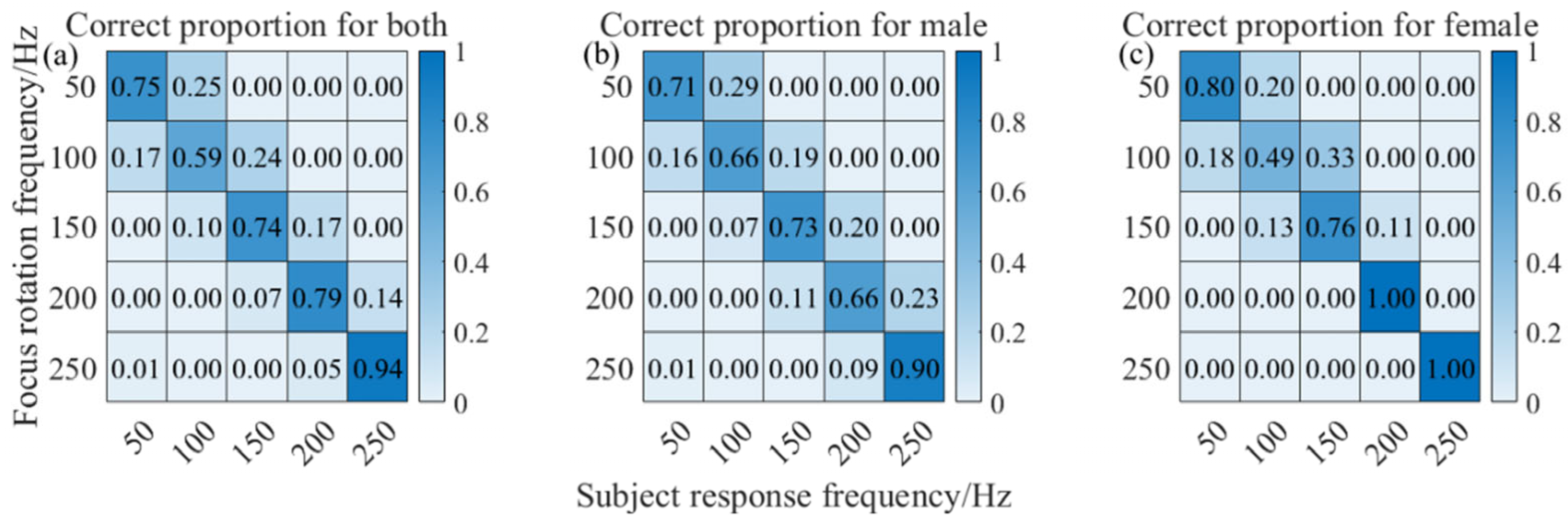

3.4. Evaluation of Human Tactile Perception on Ultrasonic Virtual Texture

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Z.; Zhu, M.; Shan, X.; Lee, C. Augmented tactile-perception and haptic-feedback rings as human-machine interfaces aiming for immersive interactions. Nat. Commun. 2022, 13, 5224. [Google Scholar] [CrossRef] [PubMed]

- Lim, K.; Lee, J.; Kim, S.; Oh, M.; Koh, C.S.; Seo, H.; Hong, Y.-M.; Chung, W.G.; Jang, J.; Lim, J.A.; et al. Interference haptic stimulation and consistent quantitative tactility in transparent electro tactile screen with pressure-sensitive transistors. Nat. Commun. 2024, 15, 7147. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.; Cai, P.; Guo, X.; Wang, M.; Matsuhisa, N.; Yang, L.; Lv, Z.; Luo, Y.; Loh, X.J.; Chen, X. An artificial sensory neuron with visual-haptic fusion. Nat. Commun. 2020, 11, 4602. [Google Scholar] [CrossRef]

- Yu, M.; Cheng, X.; Peng, S.; Cao, Y.; Lu, Y.; Li, B.; Feng, X.; Zhang, Y.; Wang, H.; Jiao, Z.; et al. A self-sensing soft pneumatic actuator with closed-Loop control for haptic feedback wearable devices. Mater. Des. 2022, 223, 111149. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, C.; Lee, Y.J.; DelPreto, J.; Wu, K.; Foshey, M.; Rus, D.; Palacios, T.; Li, Y.; Torralba, A.; et al. Adaptive tactile interaction transfer via digitally embroidered smart gloves. Nat. Commun. 2024, 15, 868. [Google Scholar] [CrossRef]

- Shor, D.; Zaaijer, B.; Ahsmann, L.; Weetzel, M.; Immerzeel, S.; Eikelenboom, D.; Hartcher-O’Brien, J.; Aschenbrenner, D. Designing haptics: Improving a virtual reality glove with respect to realism, performance, and comfort. Int. J. Autom. Technol. 2019, 13, 453–463. [Google Scholar] [CrossRef]

- Kyung, K.-U.; Lee, J.-Y.; Park, J.; Srinivasan, M.A. WUBI-PEN: Sensory feedback stylus interacting with graphical user interface. PRESENCE Virtual Augment. Real. 2012, 21, 142–155. [Google Scholar] [CrossRef]

- Chen, D.; Song, A.; Tian, L.; Fu, L.; Zeng, H. FW-Touch: A finger wearable haptic interface with a MR foam actuator for displaying surface material properties on a touch screen. IEEE Trans. Haptics 2019, 12, 281–294. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, P.; Amoah, A.E.; Wu, W.; Li, P. Control system of a performance test-bed for frost protection wind machines. Int. J. Agric. Biol. Eng. 2016, 9, 36–43. [Google Scholar]

- Kim, W.; Xiong, S. Pseudo-haptics and self-haptics for freehand mid-air text entry in VR. Appl. Ergon. 2022, 104, 103819. [Google Scholar] [CrossRef]

- Hoshi, T.; Takahashi, M.; Iwamoto, T. Noncontact Tactile Display Based on Radiation Pressure of Airborne Ultrasound. IEEE Trans. Haptics 2010, 3, 155–165. [Google Scholar] [CrossRef] [PubMed]

- Sodhi, R.; Poupyrev, I.; Glisson, M.; Israr, A. AIREAL: Interactive tactile experiences in free air. ACM Trans. Graph. 2013, 32, 1–10. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, H.; Xiang, Q.; Chen, C. Comparison of PIV Experiment and Numerical Simulation on the Velocity Distribution of Intermediate Pressure Jets with Different Nozzle Parameters. Irrig. Drain. 2017, 66, 510–519. [Google Scholar] [CrossRef]

- Frueh, C.; Jain, S.; Zakhor, A. Data processing algorithms for generating textured 3D building facade meshes from laser scans and camera images. Int. J. Comput. Vis. 2005, 61, 159–184. [Google Scholar] [CrossRef]

- Almqvist, M.; Holm, A.; Persson, H.W.; Lindström, K. Characterization of air-coupled ultrasound transducers in the frequency range 40 kHz–2 MHz using light diffraction tomography. Ultrasonics 2000, 37, 565–575. [Google Scholar] [CrossRef]

- Li, Z.; He, W.; Huang, X.; Hu, X.; Chen, H.; Zhang, Y.; Shi, J.; Zou, X. Contactless printing of food micro-particles controlled by ultrasound. J. Food Eng. 2025, 388, 112375. [Google Scholar] [CrossRef]

- Gao, J.; Tunio, M.H.; Chen, Y.; He, R. Design and experiment of low-frequency ultrasonic nozzle integrating air-assistant system and acoustic levitation mechanism. Int. J. Agric. Biol. Eng. 2020, 13, 25–33. [Google Scholar] [CrossRef]

- Harvey, G.; Gachagan, A. Noninvasive field measurement of low-frequency ultrasonic transducers operating in sealed vessels. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 1749–1758. [Google Scholar] [CrossRef]

- Young, G.; Milne, H.; Griffiths, D.; Padfield, E.; Blenkinsopp, R.; Georgiou, O. Designing Mid-Air Haptic Gesture Controlled User Interfaces for Cars. Proc. ACM Hum. -Comput. Interact. 2020, 4, 1–23. [Google Scholar] [CrossRef]

- Hu, Y.; Asante, E.A.; Lu, Y.; Mahmood, A.; Buttar, N.A.; Yuan, S. Review of air disturbance technology for plant frost protection. Int. J. Agric. Biol. Eng. 2018, 11, 21–28. [Google Scholar] [CrossRef]

- Chai, X.; Xu, L.; Sun, Y.; Liang, Z.; Lu, E.; Li, Y. Development of a cleaning fan for a rice combine harvester using computational fluid dynamics and response surface methodology to optimise outlet airflow distribution. Biosyst. Eng. 2020, 192, 232–244. [Google Scholar] [CrossRef]

- Mao, H.; Ma, G.; Han, L.; Hu, J.; Gao, F.; Liu, Y. A whole row automatic pick-up device using air force to blow out vegetable plug seedlings. Span. J. Agric. Res. 2020, 18, e211. [Google Scholar] [CrossRef]

- Wu, S.; Liu, J.; Wang, J.; Hao, D.; Wang, R. The Motion of Strawberry Leaves in an Air-Assisted Spray Field and its Influence on Droplet Deposition. Trans. ASABE 2021, 64, 83–93. [Google Scholar] [CrossRef]

- Subramanian, S.; Seah, S.A.; Shinoda, H.; Hoggan, E.; Corenthy, L. Mid-Air Haptics and Displays: Systems for Un-instrumented Mid-air Interactions. In Proceedings of the 2016 CHI Conference Extended Abstracts on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016. [Google Scholar]

- Liu, H.; Zhu, H. Evaluation of a Laser Scanning Sensor in Detection of Complex-Shaped Targets for Variable-Rate Sprayer Development. Trans. ASABE 2016, 59, 1181–1192. [Google Scholar]

- Jun, J.H.; Park, J.R.; Kim, S.P.; Min Bae, Y.; Park, J.Y.; Kim, H.S.; Choi, S.; Jung, S.J.; Park, S.H.; Yeom, D.-I.; et al. Laser-induced thermoelastic effects can evoke tactile sensations. Sci. Rep. 2015, 5, 11016. [Google Scholar] [CrossRef]

- Grammatikopoulos, L.; Kalisperakis, I.; Karras, G. Automatic multi-image photo-texturing of 3d surface models obtained with laser scanning. In Proceedings of the CIPA International Workshop on “Vision Techniques Applied to the Rehabilitation of City Centers”, Torino, Italy, 26 September–1 October 2005. [Google Scholar]

- Bermejo, C.; Hui, P. A survey on haptic technologies for mobile augmented reality. ACM Comput. Surv. 2022, 54, 1–35. [Google Scholar] [CrossRef]

- Wee, C.; Yap, K.M.; Lim, W.N. Haptic interfaces for virtual reality: Challenges and research directions. IEEE ACCESS 2021, 9, 112145–112162. [Google Scholar] [CrossRef]

- Yang, T.H.; Kim, J.R.; Jin, H.; Gil, H.; Koo, J.H.; Kim, H.J. Recent Advances and Opportunities of Active Materials for Haptic Technologies in Virtual and Augmented Reality. Adv. Funct. Mater. 2021, 31, 2008831. [Google Scholar] [CrossRef]

- Pelivanov, I.; Buma, T.; Xia, J.; Wei, C.-W.; O’Donnell, M. A new fiber-optic non-contact compact laser-ultrasound scanner for fast non-destructive testing and evaluation of aircraft composites. J. Appl. Phys. 2014, 115, 113105. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Liu, X.; Wang, G.; Gao, J. Experimental study of ultrasonic atomizer effects on values of EC and pH of nutrient solution. Int. J. Agric. Biol. Eng. 2018, 11, 59–64. [Google Scholar] [CrossRef]

- Iwamoto, T.; Tatezono, M.; Shinoda, H. Non-contact method for producing tactile perception using airborne ultrasound. Lect. Notes Comput. Sci. 2008, 5024, 504–513. [Google Scholar]

- Korres, G.; Eid, M. Haptogram: Ultrasonic point-cloud tactile stimulation. IEEE Access 2016, 4, 7758–7769. [Google Scholar] [CrossRef]

- Wilson, G.; Carter, T.; Subramanian, S.; Brewster, S.A. Perception of ultrasonic haptic feedback on the hand: Localisation and apparent motion. In Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, New York, NY, USA, 22–27 April 2006. [Google Scholar]

- Howard, T.; Marchal, M.; Pacchierotti, C. Ultrasound Mid-Air Haptics for Touchless Interfaces; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 147–183. [Google Scholar]

- Zhang, L.; Hu, Y.; Wang, B.; Xu, X.; Yagoub, A.E.A.; Fakayode, O.A.; Ma, H.; Zhou, C. Effect of ultrasonic pretreatment monitored by real-time online technologies on dried preparation time and yield during extraction process of okra pectin. J. Sci. Food Agric. 2021, 101, 4361–4372. [Google Scholar] [CrossRef] [PubMed]

- Vidal, F.P.; John, N.W.; Healey, A.E.; Gould, D.A. Simulation of ultrasound guided needle puncture using patient specific data with 3D textures and volume haptics. Comput. Animat. Virtual Worlds 2008, 19, 111–127. [Google Scholar] [CrossRef]

- Park, C.; Lee, Y.; Yoon, S.H. UltraBoard: Always-available Wearable Ultrasonic Mid-air Haptic Interface for Responsive and Robust VR Inputs. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2025, 9, 1–31. [Google Scholar] [CrossRef]

- Freeman, E. Enhancing Ultrasound Haptics with Parametric Audio Effects. In Proceedings of the 2021 International Conference on Multimodal Interaction, Montreal, QC, Canada, 18–22 October 2021. [Google Scholar]

- Basdogan, C.; Giraud, F.; Levesque, V.; Choi, S. A Review of Surface Haptics: Enabling Tactile Effects on Touch Surfaces. IEEE Trans. Haptics 2020, 13, 450–470. [Google Scholar] [CrossRef]

- Montano-Murillo, R.; Pittera, D.; Frier, W.; Georgiou, O.; Obrist, M.; Cornelio, P. It sounds cool: Exploring sonification of mid-air haptic textures exploration on texture judgments, body perception, and motor behaviour. IEEE Trans. Haptics 2024, 17, 237–248. [Google Scholar] [CrossRef]

- Takahashi, R.; Hasegawa, K.; Shinoda, H. Tactile stimulation by repetitive lateral movement of midair ultrasound focus. IEEE Trans. Haptics 2020, 13, 334–342. [Google Scholar] [CrossRef]

- Frier, W.; Ablart, D.; Chilles, J.; Long, B.; Giordano, M.; Obrist, M.; Subramanian, S. Using spatiotemporal modulation to draw tactile patterns in mid-air. Lect. Notes Comput. Sci. 2018, 10893, 270–281. [Google Scholar]

- Shen, Z.; Morgan, Z.; Vasudevan, M.K.; Obrist, M.; Plasencia, D.M. Controlled-STM: A two-stage model to predict user’s perceived intensity for multi-point spatiotemporal modulation in ultrasonic mid-air haptics. In Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems, New York, NY, USA, 11–16 May 2024. [Google Scholar]

- Ablart, D.; Frier, W.; Limerick, H.; Georgiou, O.; Obrist, M. Using ultrasonic mid-air haptic patterns in multi-modal user experiences. In Proceedings of the 2019 IEEE International Symposium on Haptic, Audio and Visual Environments and Games (HAVE), Subang Jaya, Malaysia, 3–4 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Reardon, G.; Dandu, B.; Shao, Y.; Visell, Y. Shear shock waves mediate haptic holography via focused ultrasound. Sci. Adv. 2023, 9, eadf2037. [Google Scholar] [CrossRef]

- Sakaguchi, S.; Konyo, M. Skin viscoelasticity effects on the periodic mechanical stimuli propagation between skin layers. J. Mech. Behav. Biomed. Mater. 2024, 152, 106416. [Google Scholar] [CrossRef] [PubMed]

- Wong, W.L.E.; Joyce, T.J.; Goh, K.L. Resolving the viscoelasticity and anisotropy dependence of the mechanical properties of skin from a porcine model. Biomech. Model. Mechanobiol. 2016, 15, 433–446. [Google Scholar] [CrossRef] [PubMed]

- Chilles, J.; Frier, W.; Abdouni, A.; Giordano, M.; Georgiou, O. Laser doppler vibrometry and fem simulations of ultrasonic mid-air haptics. In Proceedings of the IEEE World Haptics Conference, Tokyo, Japan, 9–12 July 2019. [Google Scholar]

- Zhang, R.; Abbott, J.J. Vibrotactile display of patterned surface textures with kinesthetic haptic devices using balanced impulses. IEEE Trans. Haptics 2021, 14, 776–791. [Google Scholar] [CrossRef]

- Saleem, M.K.; Yilmaz, C.; Basdogan, C. Tactile perception of virtual edges and gratings displayed by friction modulation via ultrasonic actuation. IEEE Trans. Haptics 2020, 13, 368–379. [Google Scholar] [CrossRef]

- Zhou, W.; Sarpong, F.; Zhou, C. Use of Ultrasonic Cleaning Technology in the Whole Process of Fruit and Vegetable Processing. Foods 2022, 11, 2874. [Google Scholar] [CrossRef]

- Chu, S.; Tu, H. Understanding the effects of tactile grating patterns on perceived roughness over ultrasonic friction modulation surfaces. Hum. Factors 2022, 65, 1718–1739. [Google Scholar] [CrossRef]

- Skedung, L.; Danerlöv, K.; Olofsson, U.; Johannesson, C.M.; Aikala, M.; Kettle, J.; Arvidsson, M.; Berglund, B.; Rutland, M.W. Tactile perception: Finger friction, surface roughness and perceived coarseness. Tribol. Int. 2011, 44, 505–512. [Google Scholar] [CrossRef]

- Hendriks, C.P.; Franklin, S.E. Influence of surface roughness, material and climate conditions on the friction of human skin. Tribol. Lett. 2009, 37, 361–373. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, X.; Li, J.; Yang, W. The effect of dynamic friction with wet fabrics on skin wetness perception. Int. J. Occup. Saf. Ergon. 2020, 26, 370–383. [Google Scholar] [CrossRef]

- Lieber, J.D.; Bensmaia, S.J. High-dimensional representation of texture in somatosensory cortex of primates. Proc. Natl. Acad. Sci. USA 2019, 116, 3268–3277. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Hu, Y.; Gao, X.; Xu, X.; Zhang, H.; Yagoub, A.E.A.; Ma, H.; Zhou, C. Influence of sweeping frequency ultrasonic pretreatment on pulsed vacuum drying characteristics and microstructure of okra based on real-time monitoring. J. Food Process. Eng. 2021, 44, e13622. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Y.; Okonkwo, C.E.; Chen, L.; Zhou, C. Multimode ultrasonic-assisted decontamination of fruits and vegetables: A review. Food Chem. 2024, 450, 139356. [Google Scholar] [CrossRef]

- Gao, J.; Xu, K.; He, R.; Chen, X.; Tunio, M.H. Development and experiments of low frequency ultrasonic electrostatic atomizing nozzle with double resonators. Int. J. Agric. Biol. Eng. 2022, 15, 39–48. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Wang, L.; Xu, W.; He, Y.; Li, Y.; He, S.; Ma, H. Improvement of skin condition by oral administration of collagen hydrolysates in chronologically aged mice. J. Sci. Food Agric. 2017, 97, 2721–2726. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhu, H.; Liu, H.; Chen, Y.; Ozkan, E. Development of a laser-guided, embedded-computercontrolled, air-assisted precision sprayer. Trans. ASABE 2017, 60, 1827–1838. [Google Scholar] [CrossRef]

- Liang, Q.; Ren, X.; Ma, H.; Li, S.; Xu, K.; Oladejo, A.O. Effect of Low-Frequency Ultrasonic-Assisted Enzymolysis on the Physicochemical and Antioxidant Properties of Corn Protein Hydrolysates. J. Food Qual. 2017, 2017, 2784146. [Google Scholar] [CrossRef]

- Johansson, R.S.; Vallbo, Å.B. Tactile sensory coding in the glabrous skin of the human hand. Trends Neurosci. 1983, 6, 27–32. [Google Scholar] [CrossRef]

- Abraira, V.E.; Ginty, D.D. The sensory neurons of touch. Neuron 2013, 79, 618–639. [Google Scholar] [CrossRef]

- The Third Joint Eurohaptics Conference and Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems. Robot. Autom. Mag. 2008, 15, 5. [CrossRef][Green Version]

- Handler, A.; Ginty, D.D. The mechanosensory neurons of touch and their mechanisms of activation. Nat. Rev. Neurosci. 2021, 22, 521–537. [Google Scholar] [CrossRef] [PubMed]

- Abdouni, A.; Djaghloul, M.; Thieulin, C.; Vargiolu, R.; Pailler-Mattei, C.; Zahouani, H. Biophysical properties of the human finger for touch comprehension: Influences of ageing and gender. R. Soc. Open Sci. 2017, 4, 170321. [Google Scholar] [CrossRef] [PubMed]

| Rotation Frequency (Hz) | Movement Speed (m/s) | Rotation Frequency (Hz) | Movement Speed (m/s) |

|---|---|---|---|

| 50 | 6.28 | 200 | 25.12 |

| 100 | 12.56 | 250 | 31.4 |

| 150 | 18.83 |

| Groups | Num.1 | Num.2 | First | Second | Third | Forth | Fifth |

|---|---|---|---|---|---|---|---|

| Gro.1 | 50 Hz | 100 Hz | 50 Hz | 100 Hz | 50 Hz | 50 Hz | 100 Hz |

| Gro.2 | 100 Hz | 150 Hz | 100 Hz | 100 Hz | 150 Hz | 100 Hz | 150 Hz |

| Gro.3 | 150 Hz | 200 Hz | 150 Hz | 150 Hz | 200 Hz | 150 Hz | 200 Hz |

| Gro.4 | 200 Hz | 250 Hz | 200 Hz | 250 Hz | 200 Hz | 200 Hz | 250 Hz |

| Gro.5 | 250 Hz | 50 Hz | 250 Hz | 250 Hz | 50 Hz | 250 Hz | 50 Hz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Feng, W.; Liu, A.; Wang, Y.; Li, K.; Ru, W.; Feng, K.; Zhang, S.; Yang, N. Haptic Reproduction of Virtual Textures Based on Ultrasonic Interference Principle. Appl. Sci. 2025, 15, 11742. https://doi.org/10.3390/app152111742

Chen S, Feng W, Liu A, Wang Y, Li K, Ru W, Feng K, Zhang S, Yang N. Haptic Reproduction of Virtual Textures Based on Ultrasonic Interference Principle. Applied Sciences. 2025; 15(21):11742. https://doi.org/10.3390/app152111742

Chicago/Turabian StyleChen, Si, Weijie Feng, Aijia Liu, Yansong Wang, Kuo Li, Weimin Ru, Kan Feng, Sai Zhang, and Ning Yang. 2025. "Haptic Reproduction of Virtual Textures Based on Ultrasonic Interference Principle" Applied Sciences 15, no. 21: 11742. https://doi.org/10.3390/app152111742

APA StyleChen, S., Feng, W., Liu, A., Wang, Y., Li, K., Ru, W., Feng, K., Zhang, S., & Yang, N. (2025). Haptic Reproduction of Virtual Textures Based on Ultrasonic Interference Principle. Applied Sciences, 15(21), 11742. https://doi.org/10.3390/app152111742