Abstract

Peru is one of the most diverse countries from a geographical and climatic point of view, where there are three large ecosystem regions called coast, Sierra, and jungle. These characteristics result in the country having many hydrographic basins, with rivers of significant dimensions in terms of the width and length of the channel. In this sense, there is a permanent need to provide connectivity and promote trade between communities through road bridge infrastructure. Thus, Peru historically developed a road network and bridges during the Inca Empire in the Tawantinsuyu region, building a cobblestone road network and suspension bridges with rope cables made of plant fibers from vegetation called Coya-Ichu. This is how bridges in Peru have evolved to meet contemporary vehicular demands and provide structural stability and functionality throughout their useful life. This article presents the following sections: (a) an introduction to the evolution of bridges, (b) the current typology and inventory of bridges, (c) the characterization of the largest bridges, (d) a discussion on the architecture, engineering, construction, and structural health monitoring (AECSHM) of bridges in the face of climate change, earthquakes, and material degradation, and (e) conclusions. Finally, this article presents opportunities and challenges in terms of Peru’s architecture, engineering, construction, and structural health monitoring of road bridges. Special emphasis is given to the use of technologies from the era of Industry 4.0 to promote the digital construction and structural health monitoring of these infrastructures. Finally, it is concluded that the integration of technologies of sensors, the IoT (Internet of Things), AI (artificial intelligence), UAVs (Unmanned Aerial Vehicles), remote sensing, BIM (Building Information Modeling), and DfMA (Design for Manufacturing and Assembly), among others, will allow for more safe, reliable, durable, productive, cost-effective, sustainable, and resilient bridge infrastructures in Peru in the face of climate change.

1. Introduction

1.1. Watersheds, Demographics, and Geographical Diversity of Peru’s Territory

Peru is one of the most diverse countries on the planet, and its geography allows it to have 70% of the planet’s ecosystems. This is how this country, in simple terms, has three geographic units: coast, Sierra, and jungle [1]. The coast corresponds to the entire geographic area near the Pacific Ocean, which is mainly a dry climate and desert territory, which goes from north to south. Then there is the Sierra, which corresponds to the Andean zone where the Andes Mountain range is located, an area full of valleys and high mountains from the north to south of the country. Finally, there is the jungle zone, which corresponds to the Amazon territory, full of vegetation covered by forests and large plains, where high rainfall is recorded throughout the year [2].

In these three main geographic areas, there are a large number of hydrographic basins, where the orography of these territories allows for the development of the water cycle or hydrological cycle, allowing water to transform into its three basic phases: gaseous in the ocean, rivers, and lakes, snow on the summit of the Andes, and liquid in the beds of springs, ravines, streams, lakes, wetlands, and rivers. This is how there are a significant number of riverbeds throughout the territory that connect these coastal, mountain, and jungle areas. Some of the main rivers in the coastal area that we can highlight are the Rímac River, the Chillón River, and the Cañete River, among others. On the other hand, some of the main rivers in the Sierra area are the Huallaga River, the Apurímac River, and the Vilcanota River, among others. Finally, in the jungle area, the main rivers are the Amazon River, the Ucayali River, and the Madre de Dios River, among others [3,4].

The territory of Peru was populated by indigenous peoples who built their first human settlements in strategic places to cope with the impacts of climate change such as floods, droughts, and frosts, as well as the effects of earthquakes. Some of the indigenous peoples who inhabited Peru in its beginnings include the (i) Caral Culture (the oldest in South America), (ii) Moche Culture, (iii) Chimú Culture, (iv) Tía Huanaco Culture, (v) Nazca Culture, and (vi) Inca Culture, among others [3,4]. The arrival of the Spanish in Peru brought about many changes in the original human settlements, where mainly new towns and larger cities were built near the banks of rivers for the purpose of exploiting minerals and metals such as gold and silver and not placing emphasis on avoiding damage from the impact of extreme hydrometeorological events. This is how many of the contemporary towns and cities of Peru are in the coast, Sierra, and jungle areas, where to reach them, provide for the transportation of people and goods/merchandise, and promote services, connectivity is achieved by a network of roads and bridges that allow for crossing the channels of the main rivers (see Figure 1). Some of the main cities in the coast area in Peru include (i) Lima, (ii) Trujillo, and (iii) Chiclayo, among others. Some of the main cities in the Sierra area include (i) Huaraz, (ii) Arequipa, and (iii) Cusco, among others. Some of the main cities in the jungle area include (i) Iquitos, (ii) Pucallpa, and (iii) Puerto Maldonado.

Figure 1.

Typical landscape of watershed in Peru.

1.2. The History of the Inca Trail and the Bridges in the Territory of Peru

As mentioned above, many of the ancient cultures that inhabited the territory of Peru in its beginnings learned to live in harmony with the ecosystem, where a broad and comprehensive learning of the territory was evident [5,6]. This is how, for example, the Inca culture learned from the Andean territory by making use of its natural resources without the purpose of exploiting them but rather by making harmonious and sustainable use of them, as well as avoiding the risks of disasters due to extreme hydrometeorological events. In this way, construction in areas with high levels of exposure was avoided, thus reducing the vulnerability of human settlement systems to climatic threats. It is also worth noting that housing structures were designed and built to resist the effects of large earthquakes, thus avoiding their collapse [7].

It was in this context that the Inca Empire sought to expand into the Andean region, where, through an extensive network of roads, it managed to reach as far north as the current southern territory of Colombia, the city of Quito in Ecuador, Peru, Bolivia, Jujuy in Argentina, and as far south as the El Maule region in Chile. The roads built by the Incas were based on earthworks and cobblestone structures, which allowed people called Chasquis to travel through various territories, connect different communities, and move in different types of climates, given the ecological diversity of the Inca Empire. This road allowed people to connect where there were important rivers, and thus, the Incas learned to build bridge structures.

The Inca trail, also called Qhapaq Ñan (Qhapaq meaning big and Ñan meaning road in the Quechua language), was built without the use of metal or iron, the wheel, or draft animals and covered 40,000 km throughout the Tawantinsuyu (Inca Empire) [8]. Sophisticated constructions could be seen on the Inca trail: flat and stepped cobblestone roads, reservoirs, food and supply depots, as well as watchtowers and fortifications. The road network allowed the Inca to supervise and administer a large Andean territory, crossing one of the most extreme physical geographies on the planet, from mountains with snow-covered peaks of 6768 m above sea level (Huascaran Mountain), passing through jungles, grasslands, and deserts [9]. Inca engineers understood the hydraulic and hydrological behavior of water flow, the action of gravity, and wind erosion, thus optimizing road design for human and animal pedestrian traffic with camelids. An estimated 6% of the Inca trail network is still visible, and existing roads are still used and maintained by Andean indigenous communities today.

Currently, these roads are being studied to understand Inca engineering techniques and their application to contemporary projects. Monumental architecture, terraced agriculture, sophisticated water management infrastructure, food storage, the domestication of high Andean camelids, and the domestication of thousands of potatoes and hundreds of varieties of quinoa and corn are some of the other amazing achievements of the Inca culture. Today, Andean indigenous communities are proud of their heritage and still live sustainably and in balance with the natural environment [3].

Among the technical solutions used to overcome a landscape as rugged as the Andes Mountain range, one of the most interesting is bridges, which were used to cross water courses or to climb ravines and thus shorten journeys. These were built with various engineering techniques and made of various materials such as stone, wood, and plant fiber [10,11,12]. The Incas designed them from an architectural and engineering point of view and then built three types of bridge systems according to the shape of the structure: (i) beam type bridges, where the riverbed was not very wide and where mainly tree trunks were used as beams (Kaspichaka: Kaspi is wooden sticks and Chaka is bridge in the Quechua language), (ii) stone bridges, where on both banks of the river, they had rocks and a flat stone tile as support (Rumichaka: Rumi is stone and Chaka is bridge in the Quechua language); the Incas did not use arches, whereas semicircular arches with stones existed in Europe, but in Europe and in Spain at that time, there were no suspension bridges such as there were in South America, (iii) huaro-type bridges consisting of a cable and basket, (iv) floating bridges, consisting of totora rafts, Coya-Ichu ropes and a wooden log board, a bridge currently known as pontoon type, and (v) suspension-type bridges, where the Incas used to build bridges where the riverbeds were very wide, and ropes made from an Andean plant called Coya-Ichu and other plant fibers were used [13].

The Spanish conquistadors admired the variety of bridges along the Qhapaq Ñan. Europeans had never seen a suspension bridge and were surprised to find hundreds of them along the Inca Trail system. The Q’eswachaka (Q’eswa is rope and Chaka is bridge in Quechua language), the last Inca grass (Coya-Ichu) suspension bridge, spans a high ravine above the Apurímac River in Peru and has been in continuous use for 500 years [13]. The bridge is 30 m in span length and is suspended 15 m above the river. It is made of grass fibers and other organic materials. Each year, 1000 villagers from four neighboring Quechua communities gather, twist, and hand-braid native grass Coya-Ichu to make 16 km of rope and then work continuously for four days to rebuild the bridge [13]. Asking permission from the Apus (sacred mountains in the Quechua language) and making offerings to Pachamama (Mother Earth in the Quechua language) are important activities that take place in conjunction with the reconstruction of the bridge. The community also holds a festival to celebrate the new bridge [8]. The Q’eswachaka is a key component of the Qhapaq Ñan and a masterpiece of Inca engineering; its main features are presented in Table 1. It also serves as an important example of sustainable engineering, a living expression of knowledge, practices, and traditions that have been passed down through generations of the Quechua people in the Andes [14] (see Figure 2).

Table 1.

Main characteristics of the Q’eswachaka bridge.

Figure 2.

Different panoramic views of the Q’eswachaka bridge. Adapted from [13,14].

The Q’eswachaka bridge is built from strong, locally harvested, and fully biodegradable materials, and it is a concept of sustainable architecture, engineering, and construction. The Incas used a variety of fibrous materials such as grass, cotton, and wool from llamas and other camelids. So, it was only natural that the Incas would find an engineering solution using abundant, locally grown grass fiber that could be woven into rope. Individual grass fibers can easily break and tear, but twisting and braiding them together results in a stronger, more flexible material. This is because the strength of the material increases with the more elements there are to share the load, or forces, acting on them [15].

2. The Current State of Bridges in Peru

2.1. Typology of the Main Bridges in Peru According to the Main Structural System

Each type of bridge has its advantages and disadvantages, and design decisions respond to the specific geographic, climatic, and economic challenges of Peru, showing how engineers optimize safety, durability, and functionality by choosing the right structure for each environment. The bridges presented below correspond to road transport with cars, motorcycles, motorcycle taxis, vans, buses, and heavy-load vehicles such as semi-trailers and trailers. The bridges are classified according to the main structural system in the following three major categories: beam-type bridges, arch-type bridges, and suspension bridges.

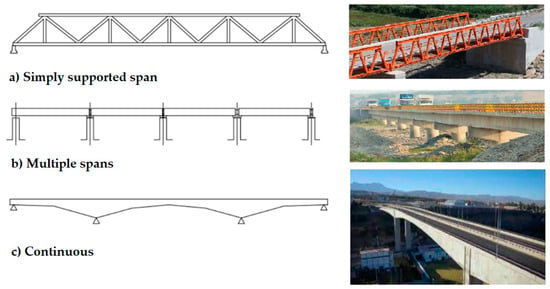

2.1.1. Beam-Type Bridges

These can be bridges with simply supported spans, isostatic Gerber or cantilever-type spans, and hyperstatic or continuous spans. In beam-type bridges, the main load-bearing element is mainly subjected to bending and shear forces (see Figure 3). The main advantage of this type of bridge is that it is economical and easy to build, is ideal for short and multiple spans, and has lower maintenance costs. However, one disadvantage is that it has limitations for covering large spans, since it requires several intermediate supports on the riverbed to remain stable.

Figure 3.

Examples of beam-type bridges built in Peru. (a) Photo in Cajamarca region, (b) photo in Ica region, and (c) photo in Arequipa region.

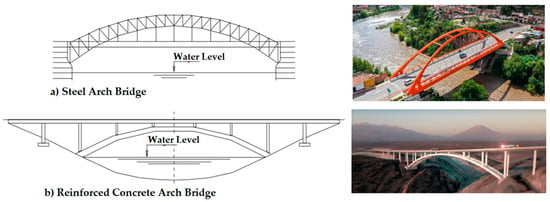

2.1.2. Arch-Type Bridges

These can be bridges of very different shapes, with an upper deck, an intermediate deck, and a lower deck, with a light spandrel or a filled spandrel or a vaulted type. Portal bridges can be considered a particular case of arch bridges and exist with vertical columns and inclined columns (See Figure 4). One of the main advantages of this type of bridge is that they are suitable for uneven terrain, as they efficiently distribute loads and support high weights. Their aesthetics blend well into various landscapes, although one of the main disadvantages is that their construction is more complex and expensive, especially when it comes to their foundations on rough terrain with unfavorable access characteristics.

Figure 4.

Examples of arch-type bridges built in Peru. (a) Photo in Junín region, and (b) photo in Arequipa region.

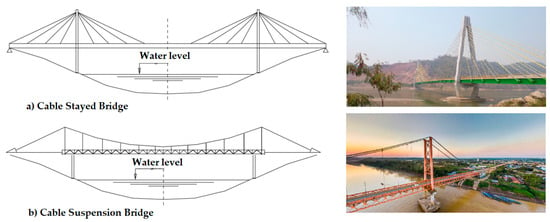

2.1.3. Suspension-Type Bridges

These are bridges that cover large spans and can be hanging, cable-stayed, or a combination of both systems, for example (see Figure 5). The main advantage of this type of bridge is that they are ideal for large spans. These bridges can cover long distances without intermediate support and are visually striking. However, one of the main disadvantages is that their construction and maintenance are expensive and require resistant materials, in addition to requiring a robust structural design to withstand extreme weather conditions.

Figure 5.

Examples of suspension-type bridges built in Peru. (a) Photo in San Martin region, and (b) photo in Madre de Dios region.

2.2. Current Inventory of Bridges in Peru—Year 2024

Bridges constitute a strategic connectivity infrastructure, the intervention of which must be programmed to respond to the new demands of growth and development of the country, increase in loads, safe transit of vehicles and pedestrians (especially in areas surrounding cities or populated centers), adequate visibility distances in terms of accesses and structure, among others [16,17]. Peru has approximately 2300 bridge structures on the roads of the national road network (approximately 25,000 km) [18], which are indicated in Table 2:

Table 2.

Current inventory of bridges in Peru—year 2024.

The different concessions manage 560 bridge structures, which represent 24% of the total, and they are in good condition. Of these, 300 are new, with a load design of 48 tons (in accordance with current traffic requirements), and the rest with previous design loads are being monitored. As for the non-concessioned national road network, most of these bridges were built in the 70s and 80s, with a total of 1740 bridges under the management of Provias Nacional, located on the paved network (1010 bridges with a load design of less than 48 tons, for example, Bailey-type modular mechanical bridges) and asphalted network (730 bridges with a load design of 48 tons) [18]. Bridges in Peru have been severely affected in recent years by the effects and impacts of climate change [1,2]. The negative effects of climate change on bridge infrastructure have impacted agricultural, fishing, and tourism activities, harming many communities in urban and rural areas.

3. The Most Modern and Largest Bridges in Peru Today—10 Case Studies

The selection criteria for the case studies presented below consider the largest and most modern bridges in Peru. These bridges are strategically located in the country, where road communication and transportation are essential. In this sense, modern bridges with different designs/construction processes and with a large span, located in different places in Peru, are considered.

Below are 10 case studies on bridges, corresponding to the largest structures currently existing in the territory of Peru in the year 2024.

3.1. Punta Arenas Bridge

The Punta Arenas bridge is a suspension bridge with a span of 271 m that allows for crossing the Huallaga River. This bridge provides connectivity to the inhabitants of the area, avoiding road closures in the event of river flooding due to extreme hydrological events. Table 3 summarizes the main technical characteristics of this bridge, and Figure 6 shows a panoramic view of the bridge structure described.

Table 3.

Main characteristics of the Punta Arenas bridge.

Figure 6.

Different panoramic views of the Punta Arenas bridge.

The Punta Arenas bridge is in the jungle of Peru, where there is rainfall throughout the year, causing high levels of runoff or depths of the Huallaga River, which sometimes causes the river to overflow and flood. The bridge was designed and built to prevent hydraulic erosion of the base of its pylon due to the presence of fine soils on the riverbank.

3.2. Comuneros Bridge

The Comuneros bridge is a cable-stayed bridge with a span of 300 m that allows for crossing the Mantaro River. This bridge provides connectivity to the inhabitants of the area, avoiding road closures in the event of river flooding due to extreme hydrological events. Table 4 summarizes the main technical characteristics of this bridge, and Figure 7 shows a panoramic view of the bridge structure described.

Table 4.

Main characteristics of the Comuneros bridge.

Figure 7.

Different panoramic views of the Comuneros bridge.

The Comuneros bridge is in the geographical area of the Sierra del Perú, where there is rainfall during the summer months (December to February), causing high runoff heights or depths of the Mantaro River, which sometimes causes the river to overflow and corresponding floods. The bridge was designed and built to provide aesthetic beauty considering the architectural aspects of its structure. This bridge, located in an extremely seismic zone, has been designed and built to withstand and not collapse in the event of earthquakes of a magnitude of over 8.0, considering return periods over 500 years.

3.3. Bellavista Bridge

The Bellavista bridge is a cable-stayed bridge with a span of 320 m that allows for crossing the Huallaga River. This bridge provides year-round connectivity to the inhabitants of the area, avoiding road closures due to river flooding due to extreme hydrological events. Table 5 summarizes the main technical characteristics of this bridge, and Figure 8 shows a panoramic view of the bridge structure described.

Table 5.

Main characteristics of the Bellavista bridge.

Figure 8.

Different panoramic views of the Bellavista bridge.

The Bellavista bridge is in the geographic area of the Peruvian jungle, where there is rainfall throughout the year, causing high runoff heights or depths of the Huallaga River, which sometimes causes the river to overflow and corresponding floods. The bridge was designed and built to provide pedestrian and vehicular connectivity in the communities of the sector.

3.4. Pachitea Bridge

The Pachitea bridge is a special cable-stayed bridge with hybrid pylons (structural steel and reinforced concrete) and steel structural cables with a span of 356 m that allows for crossing the Huánuco River. This bridge provides year-round connectivity to the inhabitants of the area, avoiding road closures due to river flooding due to extreme hydrological events. Table 6 summarizes the main technical characteristics of this bridge, and Figure 9 shows a panoramic view of the bridge structure described.

Table 6.

Main characteristics of the Pachitea bridge.

Figure 9.

Different panoramic views of the Pachitea bridge.

The Pachitea bridge is in the geographic area of the Peruvian jungle, where there is rainfall throughout the year, causing high runoff heights or depths of the Huánuco River, which sometimes causes the river to overflow and corresponding floods. The bridge was designed and built with hybrid steel and reinforced concrete pylons, with orange-colored steel on the upper part and reinforced concrete on the lower part in contact with the water level of the river.

3.5. La Joya Virgen de Chapi Bridge

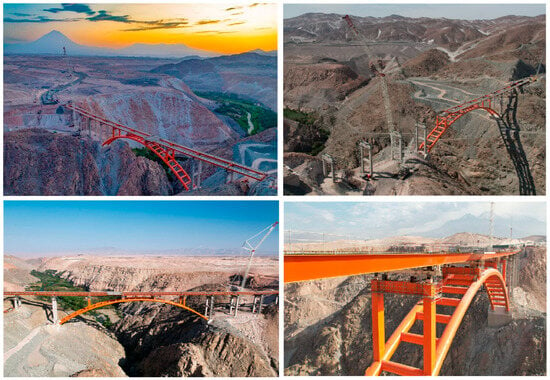

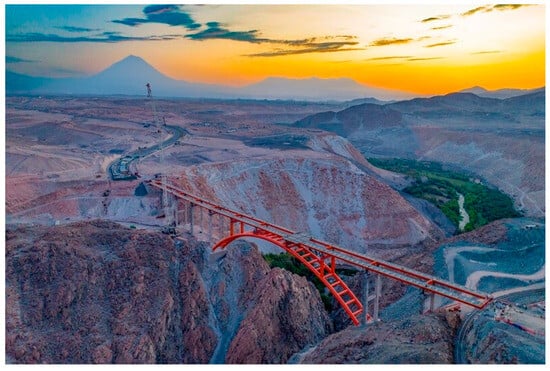

The La Joya Virgen de Chapi bridge is an arch bridge with structural steel and an upper deck, with a span of 371 m that allows for crossing the Chili River. This bridge provides year-round connectivity to the inhabitants of the area, overcoming the important topographic canyon that defines the riverbed. Table 7 summarizes the main technical characteristics of this bridge, and Figure 10 shows a panoramic view of the bridge structure described.

Table 7.

Main characteristics of the La Joya Virgen de Chapi bridge.

Figure 10.

Different panoramic views of the La Joya Virgen de Chapi bridge.

The La Joya bridge is in the geographical area of the Sierra del Perú, where, due to being a dry desert climate zone, there is no rainfall throughout the year, but the extreme topographic conditions demand a stable and safe structure that provides connectivity even in seismic conditions. The bridge was also designed and built to provide aspects of aesthetic beauty in the sector considering its architectural aspects. This bridge, located in an extremely seismic zone, has been designed and built to withstand and not collapse in the event of earthquakes of a magnitude of over 8.0, considering return periods over 500 years.

3.6. Huallaga Bridge

The Huallaga bridge is a cable-stayed bridge with a span of 407 m that allows for crossing the Huallaga River. This bridge provides year-round connectivity to the inhabitants of the area, avoiding road closures due to river flooding due to extreme hydrological events. Table 8 summarizes the main technical characteristics of this bridge, and Figure 11 shows a panoramic view of the bridge structure described.

Table 8.

Main characteristics of the Huallaga bridge.

Figure 11.

Different panoramic views of the Huallaga bridge.

The Huallaga bridge is in the geographic area of the Peruvian jungle, where there is rainfall throughout the year, causing high runoff heights or depths of the Huallaga River, which sometimes causes the river to overflow and corresponding floods. The bridge was designed and built to provide pedestrian and vehicular connectivity in the communities of the sector.

3.7. Chilina Bridge

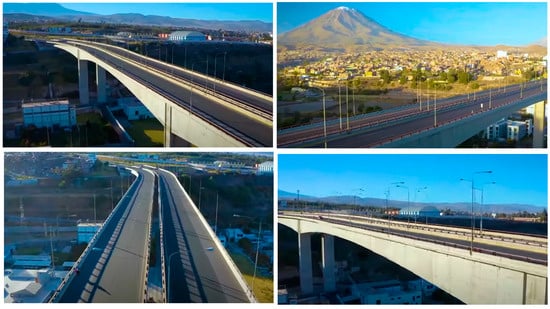

The Chilina bridge is a continuous type of bridge with segments, with a span of 562 m that allows for crossing the Chili River. This bridge provides connectivity to the inhabitants of the urban sector of the city of Arequipa, overcoming the important topographic canyon that defines the riverbed. Table 9 summarizes the main technical characteristics of this bridge, and Figure 12 shows a panoramic view of the bridge structure described.

Table 9.

Main characteristics of the Chilina bridge.

Figure 12.

Different panoramic views of the Chilina bridge.

The Chilina bridge is located in the geographical area of the Andean region of Peru, where, due to being a dry desert climate zone, there is no rainfall throughout the year, but the extreme topographic conditions demand a stable and safe structure that provides connectivity even in seismic conditions. The bridge was designed and built to provide high standards for a four-lane urban highway and thus relieve congestion in the center of the urban area of the city of Arequipa. This bridge, located in an extremely seismic zone, has been designed and built to withstand and not collapse in the event of earthquakes of a magnitude of over 8.0, considering return periods over 500 years.

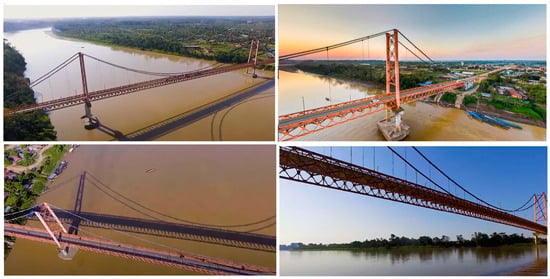

3.8. Continental Bridge

The Continental bridge, also known as President Guillermo Billinghurst, is a suspension bridge with a span of 722 m that allows for crossing the Madre de Dios River. This bridge provides connectivity to the inhabitants of the urban sector in the jungle area of Peru, avoiding negative effects due to rainfall and possible flooding. Table 10 summarizes the main technical characteristics of this bridge, and Figure 13 shows a panoramic view of the bridge structure described.

Table 10.

Main characteristics of the Continental bridge.

Figure 13.

Different panoramic views of the Continental bridge.

The Continental bridge is in the geographic area of the Peruvian jungle, where rainfall occurs throughout the year, causing river overflows and flooding. The bridge was designed and built to provide structural stability and functionality to ensure pedestrian and vehicular traffic.

3.9. Aguaytía Bridge

The Aguaytía bridge is a suspension bridge with a span of 800 m that allows for crossing the Aguaytía River. This bridge provides connectivity to the inhabitants of the urban sector in the jungle area of Peru, avoiding negative effects due to rainfall and possible flooding. Table 11 summarizes the main technical characteristics of this bridge, and Figure 14 shows a panoramic view of the bridge structure described.

Table 11.

Main characteristics of the Aguaytía bridge.

Figure 14.

Different panoramic views of the Aguaytía bridge.

The Aguaytía bridge is in the geographic area of the Peruvian jungle, where rainfall occurs throughout the year, causing river overflows and flooding. The bridge was designed and built to provide structural stability and functionality to ensure pedestrian and vehicular traffic.

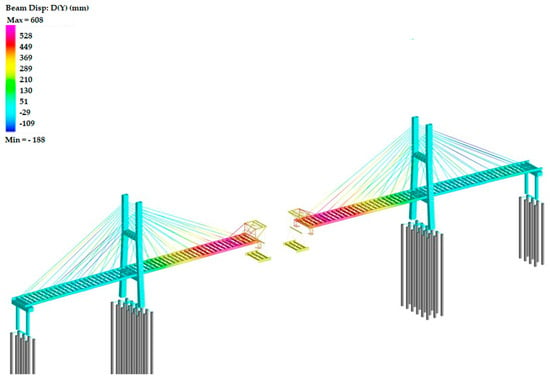

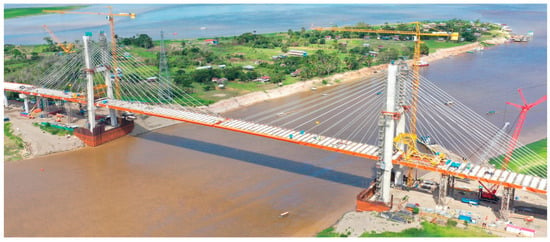

3.10. Nanay Bridge

The Nanay bridge is a cable-stayed bridge with a span of 2157 m that allows for crossing the Nanay River. This bridge provides year-round connectivity to the inhabitants of the area, avoiding road closures in the event of river flooding due to extreme hydrological events. Table 12 summarizes the main technical characteristics of this bridge, and Figure 15 shows a panoramic view of the bridge structure described.

Table 12.

Main characteristics of the Nanay bridge.

Figure 15.

Different panoramic views of the Nanay bridge.

The Nanay bridge is located in the geographic area of the Peruvian jungle, where there is rainfall throughout the year, causing high runoff heights or depths of the Nanay River, which sometimes causes the river to overflow and flood. The bridge was designed and built to provide aesthetic beauty considering the architectural aspects of its structure. Peru is a country located in the Pacific Rim with a high hazard of seismic events. Even though the city of Iquitos is not the city with the highest seismicity in the country, the local fine soil conditions have the effect of amplifying the seismic demands to significant levels. Therefore, earthquake-resistant design considerations were applied in the architecture, engineering, and construction of the cable-stayed bridge.

4. Discussion—Challenges and Opportunities for the Bridges of Peru

Challenges for construction processes and opportunities that must be permanently monitored to ensure the adequate building, correct operation, and adequate level of safety of these structures are discussed and analyzed in this section. Also, climate threats, extreme geological events such as earthquakes, and the deterioration of bridge materials due to high use affect bridge structural stability and functionality. Finally, some aspects of architecture, engineering, construction, and structural health monitoring (AECSHM) of bridges are discussed.

4.1. Challenges in New Digital Technology Tools to Support Bridge Construction

Currently, a series of digital tools are being implemented in Peru to improve aspects of efficiency and precision in bridge infrastructure construction activities. Thus, in many projects, the installation of prefabricated or modular structural elements in both concrete and steel is being implemented. In the case of concrete, prestressed concrete beams or slabs and post-tensioned concrete, which allows for longer-span beams reaching 40 m, are used.

Regarding steel elements, some sections or segments are part of the deck of cable-stayed bridges or suspension bridges, where 10 m long units can be assembled and mounted as modular pieces. On the other hand, there is the use of BIM (Building Information Modeling), which consists of a 5D virtual model of the bridge infrastructure to be built, studying the progress of the project both on the spatial scale and on the temporal scale. A virtual three-dimensional model is generated with all the structural elements and their environment, also coupling a fourth 1D dimension with the construction processes and programming over time, and finally adding a fifth 1D dimension by adding construction costs and expenses to the model [19,20,21].

Finally, it is important to mention the use of UAVs or drones to support the construction aspects of bridge projects, where it is possible to (i) make topographic surveys of the study sector using LiDAR systems, (ii) take photographs of the construction process and analyze its evolution over time, generating a 3D model using photogrammetry, and (iii) generate heat maps of the built infrastructure and identify areas of failure or weakness of sensitive or vulnerable structural elements through the use of thermal cameras. The use of UAVs allows for significant time savings in generating 3D models and avoids the risk of personnel accidents when accessing complex construction conditions [22,23,24,25,26].

The first example is the Nanay Cable-Stayed Bridge Project, where the BIM (Building Information Modeling) and DfMA (Design for Manufacturing and Assembly) methodologies were implemented. The application of these methodologies in this project was a cutting-edge milestone in Peru, since it was the first time that a large-scale infrastructure project had implemented this new construction concept in the country. The lack of significant sources of aggregates for concrete in the project location (jungle of Peru) was an important factor in selecting composite “steel–concrete” solutions, allowing the designer to minimize the use of concrete. In this sense, a composite cable-stayed bridge was the concept with a competitive edge solution [27,28].

The Nanay cable-stayed bridge was designed to be built using successive cantilevers with 10 m segments, symmetrically, on each side of each of the pylons. The project considered that the assembly of the steel structure was carried out using mobile lifting systems. Each steel structure module is made up of two main lateral plate girder beams of 1.5 m height and an interior central beam of 0.3 m height, transverse beams spaced every 3.5 m, stiffeners, bolts and shear connectors. On the other hand, the deck slab was designed to be made from reinforced concrete, which is made up of prefabricated panels that are monolithically joined together by means of concrete joining strips built in situ. In addition, the substructure of the Nanay bridge is made up of an abutment and a pylon on each side of the Nanay River. The foundation is deep, using piles dug 60 m deep and with a diameter of 2 m. Finally, the bridge accesses, both on the left and right banks, are of a frame type with reinforced concrete columns and a crossbeam.

For the execution of the piles, an operations platform was previously prepared, which had to be 2 m above the water table or the maximum water level for the construction period. The construction of the piles was not carried out within the Nanay River. To achieve this, the span and total length of the bridge were increased. Thus, the piles were located outside the width of the river’s water surface in order to carry out the construction work during the dry season of the Nanay River (May–October). The piles were built with benthic mud support and materialized with reinforced concrete.

On the other hand, after the piles were built, the construction of the pylons considered the following phases: (i) construction of the deep foundations, (ii) construction of columns below the level of the lower crossbeam, (iii) construction of the lower crossbeam, (iv) construction of the column base above the level of the lower crossbeam, (v) construction of columns above the level of the lower crossbeam, (vi) construction of the upper crossbeam, and (vii) construction of columns above the level of the upper crossbeam.

The bridge deck was then built using successive 10 m segmental cantilevers. The segments are composite sections, with plate girder steel beams and concrete slabs joined by shear connectors. The elements of the metal structure were manufactured in the city of Lima, where they were then transported to the project area. The concrete slabs were prefabricated in the civil works area, and after assembly, they were joined by concrete strips built on-site. This is how the segment assembly used mobile lifting systems (see Figure 16).

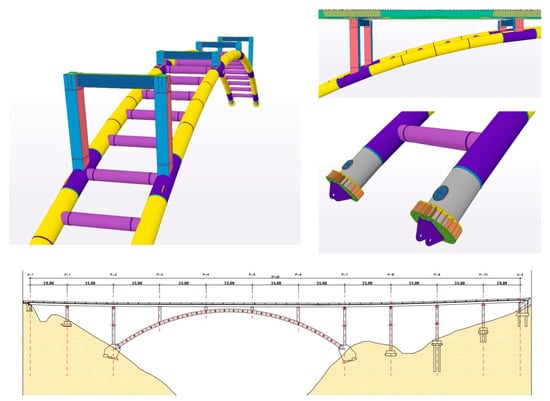

Figure 16.

BIM of Nanay bridge. Adapted from [29].

In the above, the sequence of assembly of the segments was as follows: (i) The elements of the metal structure that are in the river raft were lifted by means of cables by the mobile lifting systems up to the level of the bridge deck work area. (ii) The metal elements were assembled by joining the lifted elements to the previous segment by means of connection bolts by the assembly operators. (iii) Once the assembly of the metal segment was finished, the metal segment was connected to the respective stay or cable, which was anchored in the pylon. (iv) The prefabricated slab panels were then lifted from the raft, and the concrete panels were placed on the template of the metal segment already assembled and supported by the stay cables of the bridge. (v) Four mobile lifting systems were used, two for each pylon, and each system was provided at its front with two hydraulic lifting jacks. (vi) The union between concrete panels was made by means of concrete strips that were placed on-site, where the stay cables were then tensioned, inducing significant pre-compression in the concrete slab. The construction process described above was supported by two high-lift cranes located on the side of each of the bridge pylons (see Figure 17).

Figure 17.

Panoramic view of the construction process of the Nanay bridge. Adapted from [29].

Finally, the aerodynamic stability of the bridge was analyzed. In this sense, at the location of the Nanay bridge, the Peruvian Design Code establishes a design wind speed of 95 km/h at 10 m above the ground for a return period of 50 years. Despite the use of a torsional weak open section, the use of an H-pylon configuration with two planes of cables allowed the bridge to achieve a ratio that is within the limits to prevent flutter instability. Wind tunnel testing was conducted to further ensure the stability of the bridge during construction and operation.

A second example corresponds to the La Joya Virgen de Chapi Bridge Project, where the bridge is of a structural steel arch type, where the BIM (Building Information Modeling) methodology was implemented together with the DfMA (Design for Manufacturing and Assembly) concept with the following purposes: (i) carry out the collaborative work of the different project actors, (ii) reduce errors, deviations, and uncertainties as much as possible in the engineering, construction, and project management stages, and (iii) control the risks of the construction process, considering the industrial manufacturing of components (avoiding on-site work if possible), transportation, and assembly of different elements of the bridge infrastructure, among others.

First, through BIM, which involved a virtual model of the La Joya Virgen de Chapi bridge, it was possible to properly coordinate the activities of the different actors, such as designers, construction contractors, supervisor or inspectors of civil works, and clients. This is how the entire technical file of the project, such as calculation reports, engineering drawings, technical specifications, and manuals, was properly managed using BIM, reducing interference and optimizing the time of professionals from different disciplines such as architecture, civil engineering, hydraulic engineering, hydrology, geotechnical engineering, structural engineering, road engineering, and topography, among others (see Figure 18).

Figure 18.

BIM of the La Joya Virgen de Chapi bridge.

Second, through BIM, it was possible to reduce a large number of possible errors, deviations, and uncertainties in (i) the project’s engineering documents and drawings, (ii) the construction processes of the infrastructure on site, adequately coordinating the scheduling of the construction times of each civil works activity within reasonable time frames, and (iii) the adequate control of the expenses and costs of the work through effective management of human resources, machinery resources, material resources, and financial resources [30].

Also, third, by integrating the BIM methodology with the DfMA (Design for Manufacturing and Assembly) concept, a modular construction process for the arch structure was implemented, where the arch was built using steel metal parts manufactured in a factory in Italy under controlled quality conditions. Once the different pieces of the arch were made, they were transported by ship to Peru, where they were then transported by truck from the port of Callao to the project area. Once the pieces were at the project site, assembly activities were carried out using cranes, materializing the construction of the arch in two parts. In addition, assembly was carried out to ensure the proper connection between each of the pieces. Finally, once the assembly of the arch on site was finished, the installation of the bridge deck was carried out by launching the section of said structure from one abutment to another abutment using cables and hydraulic jacks.

The implementation of the BIM and DfMA methodologies has allowed for substantial improvements in the performance of bridge design/construction projects in Peru. For example, it is possible to mention that reductions in construction times of around 20% have been achieved; in addition, a decrease in construction costs of 15% has been recorded, and the amount of waste on site has also been reduced by 10% (See Figure 19).

Figure 19.

Some images of the construction process of the La Joya Virgen de Chapi bridge.

Finally, this article presents an incipient and promising paradigm shift, from building to DfMA, in bridge infrastructure projects in Peru, fostering the displacement of workers from on-site to off-site activity, and the expansion of interdisciplinary architecture, engineering, construction, and structural health monitoring (AECSHM) collaboration [31,32,33].

Lean construction is a project management approach for bridge construction that is being applied in South America, specifically in Peru, which helps in the design of construction systems in a dynamic environment [30]. The objective is to maximize value for the client through a permanent effort focused on eliminating and reducing waste, a term that is complex to visualize but that, once materialized and applied, helps in exponentially improving construction processes.

In both South America and Peru, lean construction has been applied effectively, paying attention to the principles of this work methodology [34,35]:

- Eliminate everything that does not add value: The main basis of this work methodology refers to the elimination of the steps from the workflow that do not add any type of value to the product (building, housing, road, highway, bridge, civil work, industrial work, etc.).

- Add value to construction: Before starting the project itself, it is essential to have a clear understanding of the client’s needs. All designers involved in the work must participate in alignment meetings and have an in-depth knowledge of the profile of the audience for each project. In this way, it is possible to develop competitive advantages and deliver works that really make sense for the end consumer.

- Reduce variability: Standardized processes are essential for lean construction. Although each project has its peculiarities and it is almost impossible to escape unforeseen events, it is always possible (and ideal) to adopt work patterns that reduce variation between one project and another. In this way, the project becomes uniform and consistent, with more satisfied clients upon delivery of the work.

- Just in time: A lack of planning over time can lead to losses and delays. Therefore, one of the principles of lean construction is the optimization of work cycles, i.e., the time needed to perform tasks. With good planning, it is possible to deliver work in a shorter time, have employees focused on specific tasks, and have a more accurate estimate of work steps.

- Make processes transparent: Transparent construction management makes it easier to identify points of error, as all the necessary information is always available to the people who need it. To have more transparent processes and ensure continuous improvement, it is essential to be simple, reduce friction, eliminate visual obstacles on the construction site, have an open communication flow, and ensure a comfortable work environment.

4.2. Opportunities for Structural Health Monitoring of Bridges in the Face of Flooding Because of Climate Change

Climate change threatens the structural stability and normal functionality of bridges because it is generated by extreme hydrometeorological events linked to ENSO, which shows the following effects: rainfalls, floods, avalanches, and landslides. These events can cause damage to bridges, such as the hydraulic erosion and undermining of pillars and the partial destruction or total dragging of decks, among others. In this sense, digital technological tools are being implemented to improve bridge monitoring and thus issue warning signals against the effects of climate change. Sensors linked to meteorological stations are being used to measure precipitation levels, temperatures, wind direction and speed, and moisture content, among others [36]. These sensors work wirelessly, where the IoT (Internet of Things) allows for digital connectivity at a wide range and with adequate data transfer speed using different systems such as WiFi, LoRa, and Zigbee, among others [37]. Finally, the use of UAVs or drones allows for access to images of the places where the bridges are located and for the timely identifying of areas of vulnerability and at risk of slope collapse or damage to structural elements and for making preventive decisions against the dangers of climate change [22,24,25].

4.3. Opportunities for Structural Health Monitoring of Bridges Against Vibration Damage Due to Vehicle Loads and Earthquakes

The tools provided by Industry 4.0 are allowing for the better study of the performance of bridge infrastructure in the face of extreme seismic events such as earthquakes. For example, by installing sensors such as strain gauges and inclinometers, it is possible to measure deformations, rotations, and displacements in the structural elements of bridges when earthquakes or vibrations are recorded [38,39,40]. By knowing the deformations and displacements induced by earthquakes or vibrations in the structural elements, it is possible to compare them with the threshold levels and define whether they are within the ranges of admissibility and safety or, on the contrary, within the range of the implementation of corrective measures for post-earthquake or post-vibration conservation. These sensors are complemented with sensors that measure seismic accelerations and also the level of vibrations, called accelerometers, which measure seismic accelerations and vibration levels by the induction of loads in different directions in structural elements, both horizontal and vertical, thus indicating a trend in the level of damage that an earthquake can develop in the bridge infrastructure [40,41]. Currently, there are studies where low-cost inclinometer and accelerometer-type sensors are combined with Arduino or Raspberry Pi controller boards alongside the IoT and artificial intelligence to improve the accuracy in vibration level measurements [40]. Finally, the use of UAVs or drones allows for inspecting structural elements of bridges that are difficult to access after an earthquake, thus allowing for assessing the level of damage, including cracks, explosions of elements, and landslides, among others. This allows for the identification of critical structural elements that require the application of conservation measures and thus guarantees the structural stability of the bridge. The use of UAVs avoids traffic disruptions on bridge infrastructures both day and night, as well as significant time savings for the engineering team in charge of repairing the bridge. In addition, the use of images obtained with UAVs avoids falling into biases or subjective criteria for the identification and level of failures in the bridge infrastructure. Finally, it is possible to combine the use of UAVs with artificial intelligence tools to manage aerial images and thus, through CNNs, analyze, process, and study large volumes of data more quickly and accurately, automating the inspection process in bridge infrastructure [24,25,26].

4.4. Opportunities for Structural Health Monitoring of Bridges Against Deterioration Due to Use of Materials

An important issue that must be monitored through continuous monitoring over time is the effect of the deterioration of materials due to environmental conditions in the bridge infrastructure project. Cycles of night and day temperature changes, cycles of temperature changes from winter to summer, moisture content, liquid and solid precipitation, among others, cause internal changes and alterations in the construction materials used in bridges, such as wood, concrete, and steel. These environmental conditions induce deformations, displacement, rotations, sulfation, and corrosion, among others, in bridge infrastructure [38,42,43]. By combining wireless sensors with the use of the IoT and artificial intelligence, it is possible to measure different parameters and monitor changes in the key properties of structural elements in bridges in real time [42,44]. The use of UAVs or drones that have thermal cameras allows for obtaining heat maps of the structural elements of bridges and identifying areas of cracking and fracture in reinforced concrete structures and excessive corrosion in steel structures. The use of UAVs allows the bridge to continue providing normal operation to the public without traffic interruptions day or night [22,23]. Nevertheless, creep and shrinkage effects have to be considered in terms of long-term behavior for the structural health monitoring of bridge infrastructures. In this sense, precast deck systems also have several advantages from a construction point of view, such as superior concrete quality, the possibility of implementing a modular construction scheme, and the fact that there are fewer weather constraints, since the volumes of cast-in-place concrete are significantly reduced. For example, for the Nanay bridge, pre-cast slab panels with dimensions of 3.20 m × 7.30 m, cured at least 60 days before their installation on the bridge, were used to minimize creep and shrinkage effects.

Structural health monitoring for bridge structures generally refers to the process of designing, developing, and implementing a damage detection or characterization strategy for the real-time assessment of structural conditions.

A typical structural health monitoring system includes four main components:(i) A sensor network, (ii) data processing system (including data acquisition, transmission, and storage), (iii) a health assessment system to support decision-making, and (iv) manual inspection by engineers and risk-reduction specialists.

The structural health monitoring process generally involves monitoring a structure over a certain period of time, either short- or long-term, using an appropriate set of sensors and devices.

Likewise, manual monitoring must be complemented with online digital monitoring. It is important that engineers and specialists also carry out on-site inspections, observing possible damage to the structure, to define levels of deterioration/vulnerabilities and make better decisions.

5. Conclusions

The bridges that were built throughout the territory of Tawantinsuyu were part of an extensive network of roads that connected the different towns and villages of the Andes. They saved time and effort for travelers who needed to cross rivers and other obstacles in the rugged geography or, in certain circumstances, became control points for the entrances and exits of towns that acquired some strategic value. However, these were not the only characteristics that made them special; the knowledge and collective work that allowed them to be built and maintained were also factors. As a fruit of Andean cultural and social growth, they were, above all, a symbol of the triumph of man over nature and of the achievements that a community could reach when united in its efforts around an objective. There are some cases in which these bridges are even still being built, and not for reasons of necessity, since there are already modern alternatives to cross rivers, but rather for symbolic, cultural reasons and for the affirmation of collective identity.

Although Peru has more than 2500 bridges in its territory, highlighting the modern aesthetic appeal of important cable-stayed and suspension bridges, there is still a lack of this type of infrastructure in remote places, where greater private and public investment will soon allow for a higher level of connectivity for the entire community.

The integrated implementation of the lean construction, BIM, and DfMA methodologies has demonstrated, considering the experience in some projects in Peru, that it allows for a coordinated, efficient, and effective process of (i) the different stages of a bridge infrastructure project, such as architecture, engineering, construction, and monitoring, and that it also (ii) considers collaborative work of all actors in the bridge infrastructure project such as, topography, architecture, civil engineering, hydraulic engineering, hydrology, road engineering, geotechnical engineering, and structural engineering, among others.

It is important to mention that some measures should be considered to encourage the adoption of new technologies in the design/construction of bridges. These measures relate to creating regulatory standards and economic support for engineering and construction companies in implementing the lean construction, BIM, and DfMA methodologies. This will benefit decision-makers and industry stakeholders, allowing for a broad framework of action on the path to the digitalization of the bridge construction industry.

Future modern bridge infrastructures in Peru may evolve hand-in-hand with digital technological development with the presence of new tools from Industry 4.0, such as sensors, the IoT, the use of drones, artificial intelligence, and the use of BIM. All these aspects can help in the faster and more precise execution of bridge infrastructure projects, avoiding interference in the execution process, providing greater structural stability, helping the functionality of the infrastructure, and providing greater security to users.

In this sense, it is recommended to integrate digital technologies from Industry 4.0 with the design, construction, and monitoring of bridges to face the threats that climate change implies in the structural stability and functionality of this type of infrastructure.

Author Contributions

Conceptualization, C.C.; methodology, C.C.; software, C.C.; validation, C.C., E.M. and A.S.; formal analysis, C.C. and E.M.; investigation, C.C.; resources, E.M.; data curation, E.M.; writing—original draft preparation, C.C.; writing—review and editing, C.C., E.M. and A.S.; visualization, C.C.; supervision, A.S.; project administration, C.C.; funding acquisition, C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research Department of the Catholic University of Temuco, Chile.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| AECSHM | Architecture, engineering, construction, structural health monitoring |

| AI | Artificial intelligence |

| IoT | Internet of Things |

| UAVs | Unmanned Aerial Vehicles |

| BIM | Building Information Modeling |

| DfMA | Design for Manufacturing and Assembly |

| ENSO | El Niño Southern Oscillation |

| MTC | Minister of Transport of Communications of Peru |

| m | Meters |

| MPa | Megapascals |

| masl | Meters Above Sea Level |

References

- Cacciuttolo, C.; Guardia, X.; Villicaña, E. Implementation of Renewable Energy from Solar Photovoltaic (PV) Facilities in Peru: A Promising Sustainable Future. Sustainability 2024, 16, 4388. [Google Scholar] [CrossRef]

- Tafur Anzualdo, V.I.; Aguirre Chavez, F.; Vega-Guevara, M.; Esenarro, D.; Vilchez Cairo, J. Causes and Effects of Climate Change 2001 to 2021, Peru. Sustainability 2024, 16, 2863. [Google Scholar] [CrossRef]

- Wright, K.R. The masterful water engineers of machu picchu. Water 2021, 13, 3049. [Google Scholar] [CrossRef]

- Lane, K. Engineering resilience to water stress in the late prehispanic north-central andean highlands (~600–1200 bp). Water 2021, 13, 3544. [Google Scholar] [CrossRef]

- Davidson, R.; Fehren-Schmitz, L.; Llamas, B. A multidisciplinary review of the inka imperial resettlement policy and implications for future investigations. Genes 2021, 12, 215. [Google Scholar] [CrossRef] [PubMed]

- Huamantupa-Chuquimaco, I.; Martinez Trujillo, Y.L.; Orosco Ucamayta, E. Valuation of the Diversity of Native Plants and the Cultural-Archaeological Richness as an Integrative Approach for a Potential Use in Ecotourism in the Inter-Andean Valley of Cusco, Southern Peru. Diversity 2023, 15, 760. [Google Scholar] [CrossRef]

- Ortloff, C.R. Caral, South America’s Oldest City (2600–1600 BC): ENSO Environmental Changes Influencing the Late Archaic Period Site on the North Central Coast of Peru. Water 2022, 14, 1403. [Google Scholar] [CrossRef]

- Garrido, F. Rethinking imperial infrastructure: A bottom-up perspective on the Inca Road. J. Anthropol. Archaeol. 2016, 43, 94–109. [Google Scholar] [CrossRef]

- Palacios-Prado, N.; Corominas-Sustach, F.; Pérez, A.; Verdugo, D.; Podobnikar, T. Encoded Landscapes: A Link between Inka Wall Orientations and Andean Geomorphology. Land 2024, 13, 463. [Google Scholar] [CrossRef]

- Huarca Pulcha, A.; Espinoza Vigil, A.J.; Booker, J. Prioritizing Riverine Bridge Interventions: A Hydrological and Multidimensional Approach. Designs 2023, 7, 117. [Google Scholar] [CrossRef]

- Espinoza Vigil, A.J.; Booker, J. Hydrological Vulnerability Assessment of Riverine Bridges: The Bajo Grau Bridge Case Study. Water 2023, 15, 846. [Google Scholar] [CrossRef]

- Ccanccapa Puma, J.; Hidalgo Valdivia, A.V.; Espinoza Vigil, A.J.; Booker, J. Preserving Heritage Riverine Bridges: A Hydrological Approach to the Case Study of the Grau Bridge in Peru. Heritage 2024, 7, 3350–3371. [Google Scholar] [CrossRef]

- Proyecto Qhapaq Ñan (Perú) Ministerio de Cultura. Q’eswachaka Ingeniería y Tradición Andina. 2014. Available online: http://repositorio.cultura.gob.pe/handle/CULTURA/1539 (accessed on 20 November 2024).

- National Museum of the American Indian. Q’eswachaka Inca Suspension Bridge [Internet]. 2016. Available online: https://americanindian.si.edu/nk360/resources/Qeswachaka-A-Living-Legacy-of-Inka-Engineering (accessed on 20 November 2024).

- Valdez, L.M.; Vivanco, C. Tinkuqchaka: A suspension bridge over the upper pampas river, ayacucho, peru. J. Anthropol. Res. 2021, 77, 208–233. [Google Scholar] [CrossRef]

- Cisneros-Herrera, D.; Lara-Galera, A.; Alcaraz Carrillo de Albornoz, V.; Muñoz-Medina, B. Driving Peru’s Road Infrastructure: An Analysis of Public–Private Partnerships, Challenges, and Critical Success Factors. Buildings 2024, 14, 230. [Google Scholar] [CrossRef]

- Olaya Reyes, M.R.; Soto Abanto, S.E.; García Zare, E.J.; Zavaleta Pesantes, H.W. Post-Investment Cost in Roads and Economic Development in a Peruvian Region. Sustainability 2023, 15, 16588. [Google Scholar] [CrossRef]

- Ministerio de Transporte y Telecomunicaciones. Inventario de Puentes en el Perú; Ministerio de Transporte y Telecomunicaciones: Lima, Peru, 2023.

- Byun, N.; Han, W.S.; Kwon, Y.W.; Kang, Y.J. Development of bim-based bridge maintenance system considering maintenance data schema and information system. Sustainability 2021, 13, 4858. [Google Scholar] [CrossRef]

- Cavieres-Lagos, S.; Muñoz La Rivera, F.; Atencio, E.; Herrera, R.F. Integration of BIM Tools for the Facility Management of Railway Bridges. Appl. Sci. 2024, 14, 6209. [Google Scholar] [CrossRef]

- Ahmad, D.M.; Gáspár, L.; Bencze, Z.; Maya, R.A. The Role of BIM in Managing Risks in Sustainability of Bridge Projects: A Systematic Review with Meta-Analysis. Sustainability 2024, 16, 1242. [Google Scholar] [CrossRef]

- Ameli, Z.; Aremanda, Y.; Friess, W.A.; Landis, E.N. Impact of UAV Hardware Options on Bridge Inspection Mission Capabilities. Drones 2022, 6, 64. [Google Scholar] [CrossRef]

- Feroz, S.; Dabous, S.A. Uav-based remote sensing applications for bridge condition assessment. Remote Sens. 2021, 13, 1809. [Google Scholar] [CrossRef]

- Jacob-Loyola, N.; Muñoz-La Rivera, F.; Herrera, R.F.; Atencio, E. Unmanned aerial vehicles (Uavs) for physical progress monitoring of construction. Sensors 2021, 21, 4227. [Google Scholar] [CrossRef]

- Choi, H.W.; Kim, H.J.; Kim, S.K.; Na, W.S. An Overview of Drone Applications in the Construction Industry. Drones 2023, 7, 515. [Google Scholar] [CrossRef]

- Molina, A.A.; Huang, Y.; Jiang, Y. A Review of Unmanned Aerial Vehicle Applications in Construction Management: 2016–2021. Standards 2023, 3, 95–109. [Google Scholar] [CrossRef]

- Montazeri, S.; Lei, Z.; Odo, N. Design for Manufacturing and Assembly (DfMA) in Construction: A Holistic Review of Current Trends and Future Directions. Buildings 2024, 14, 285. [Google Scholar] [CrossRef]

- Razak, M.I.A.; Khoiry, M.A.; Badaruzzaman, W.H.W.; Hussain, A.H. DfMA for a Better Industrialised Building System. Buildings 2022, 12, 794. [Google Scholar] [CrossRef]

- Lopez Jara, J.; Lopez Acuña, J. Design of the Nanay Bridge Iquitos-Peru. In Proceedings of the International Symposium on Steel Bridges [Internet], Iquitos, Peru, 2016; Available online: https://www.researchgate.net/publication/304628602 (accessed on 10 November 2024).

- Pronesti, B.; Sammartano, G.; Catanzano, A. e-Mosty—La Joya Bridge Peru. Issue 04 December [Internet]. 2023. Available online: www.e-mosty.cz (accessed on 12 November 2024).

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13, 429. [Google Scholar] [CrossRef]

- Langston, C.; Zhang, W. DfMA: Towards an integrated strategy for a more productive and sustainable construction industry in Australia. Sustainability 2021, 13, 9219. [Google Scholar] [CrossRef]

- Roxas, C.L.C.; Bautista, C.R.; Dela Cruz, O.G.; Dela Cruz, R.L.C.; De Pedro, J.P.Q.; Dungca, J.R.; Lejano, B.A.; Ongpeng, J.M.C. Design for Manufacturing and Assembly (DfMA) and Design for Deconstruction (DfD) in the Construction Industry: Challenges, Trends and Developments. Buildings 2023, 13, 1164. [Google Scholar] [CrossRef]

- Dlouhy, J.; Ricalde, M.; Cossio, B.; Januncio, C. Large scale project using takt planning and Takt control-creating and sustaining multitasking flow. In IGLC 2018—Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 18–22 July 2018; The International Group for Lean Construction: Auckland, New Zealand, 2018; pp. 1334–1343. [Google Scholar]

- Castiblanco, F.M.; Castiblanco, I.A.; Cruz, J.P. Qualitative analysis of lean tools in the construction sector in Colombia. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC, Dublin, Ireland, 1–7 July 2019; The International Group for Lean Construction: Auckland, New Zealand, 2019; pp. 1023–1036. [Google Scholar]

- Komarizadehasl, S.; Mobaraki, B.; Ma, H.; Lozano-Galant, J.A.; Turmo, J. Low-Cost Sensors Accuracy Study and Enhancement Strategy. Appl. Sci. 2022, 12, 3186. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Lozano, F.; Lozano-Galant, J.A.; Ramos, G.; Turmo, J. Low-Cost Wireless Structural Health Monitoring of Bridges. Sensors 2022, 22, 5725. [Google Scholar] [CrossRef] [PubMed]

- Emadi, S.; Ma, H.; Lozano-Galant, J.A.; Turmo, J. Simplified Calculation of Shear Rotations for First-Order Shear Deformation Theory in Deep Bridge Beams. Appl. Sci. 2023, 13, 3362. [Google Scholar] [CrossRef]

- Lei, J.; Lozano-Galant, J.A.; Xu, D.; Zhang, F.L.; Turmo, J. Robust static structural system identification using rotations. Appl. Sci. 2021, 11, 9695. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Huguenet, P.; Lozano, F.; Lozano-Galant, J.A.; Turmo, J. Operational and Analytical Modal Analysis of a Bridge Using Low-Cost Wireless Arduino-Based Accelerometers. Sensors 2022, 22, 9808. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Mobaraki, B.; Ma, H.; Lozano-Galant, J.A.; Turmo, J. Development of a low-cost system for the accurate measurement of structural vibrations. Sensors 2021, 21, 6191. [Google Scholar] [CrossRef]

- Lozano, F.; Emadi, S.; Komarizadehasl, S.; Arteaga, J.G.; Xia, Y. Enhancing the Accuracy of Low-Cost Inclinometers with Artificial Intelligence. Buildings 2024, 14, 519. [Google Scholar] [CrossRef]

- Komary, M.; Komarizadehasl, S.; Tošić, N.; Segura, I.; Lozano-Galant, J.A.; Turmo, J. Low-Cost Technologies Used in Corrosion Monitoring. Sensors 2023, 23, 1309. [Google Scholar] [CrossRef]

- Komarizadehasl, S.; Komary, M.; Alahmad, A.; Lozano-Galant, J.A.; Ramos, G.; Turmo, J. A Novel Wireless Low-Cost Inclinometer Made from Combining the Measurements of Multiple MEMS Gyroscopes and Accelerometers. Sensors 2022, 22, 5605. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).