Investigation of Grout Anisotropic Propagation at Fracture Intersections Under Flowing Water

Abstract

1. Introduction

2. Materials and Methods

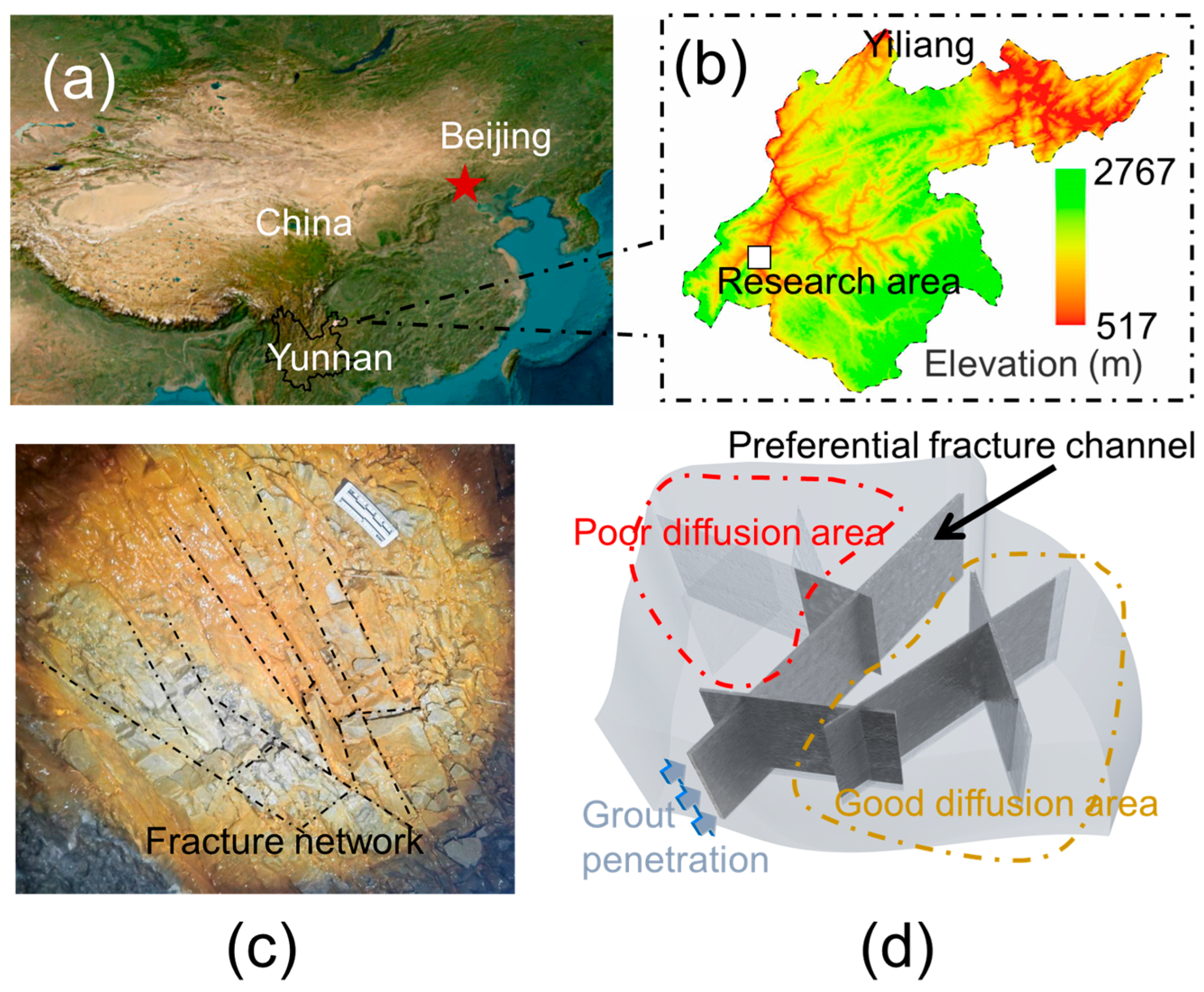

2.1. Background

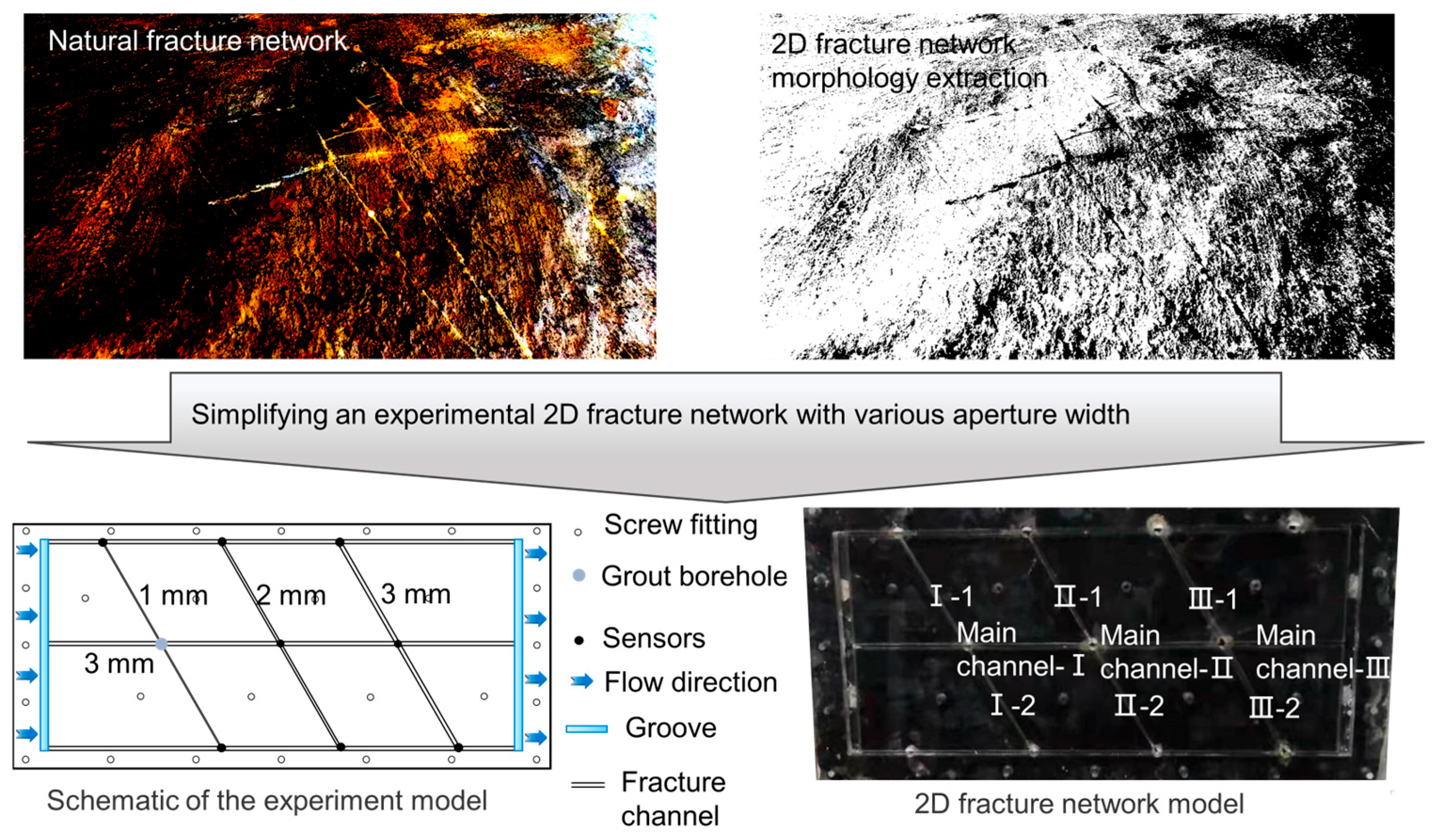

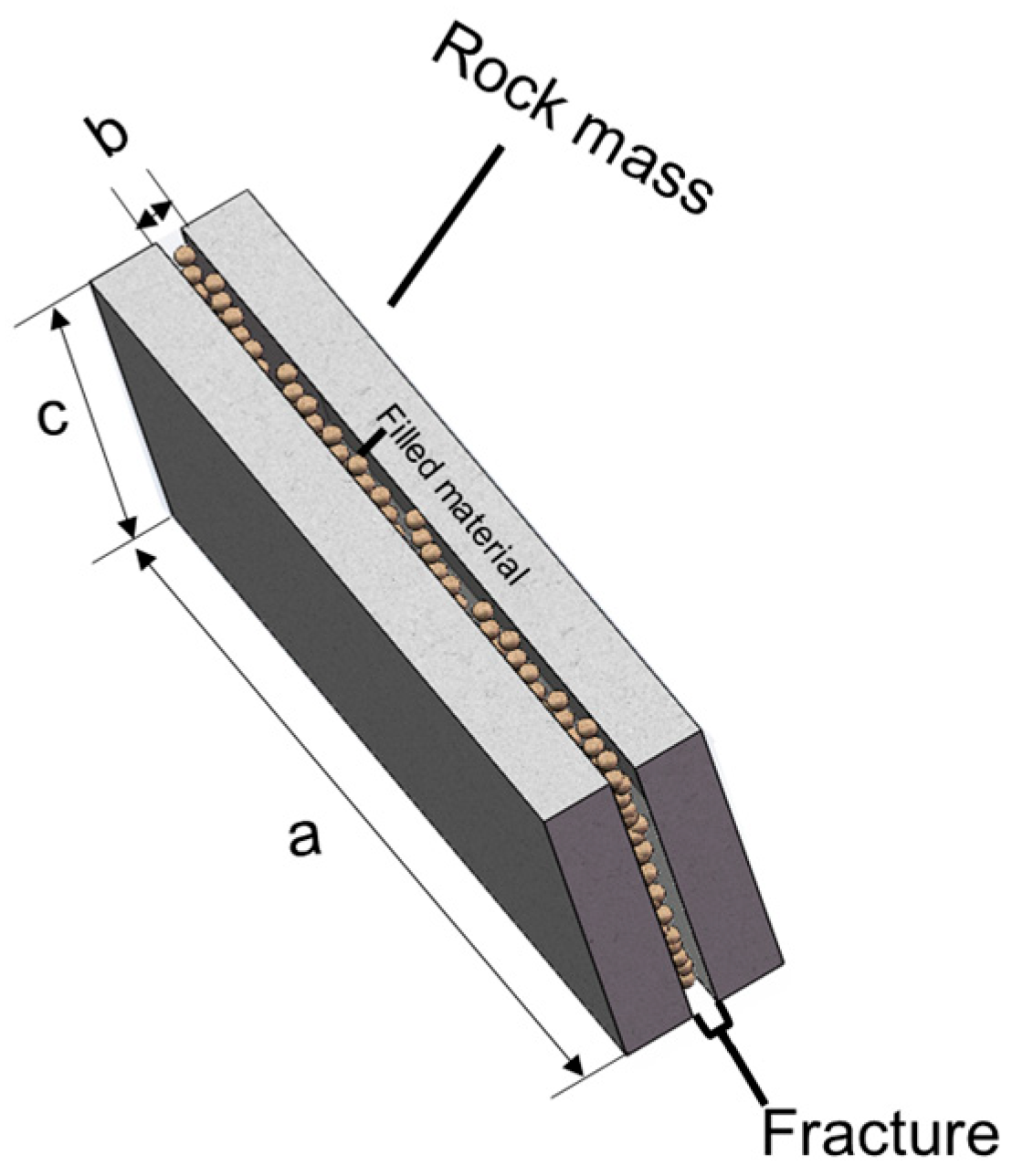

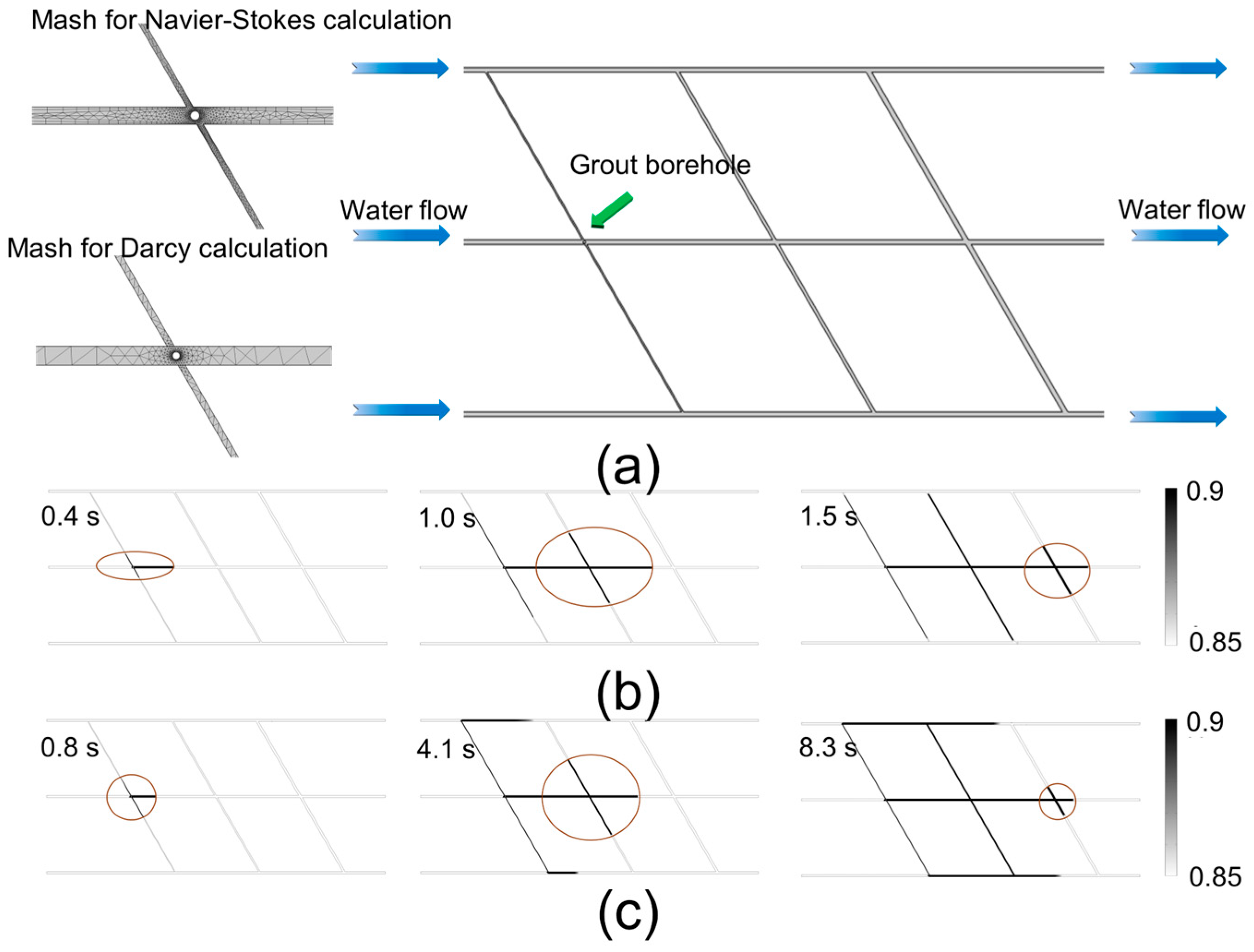

2.2. Fracture Network Model

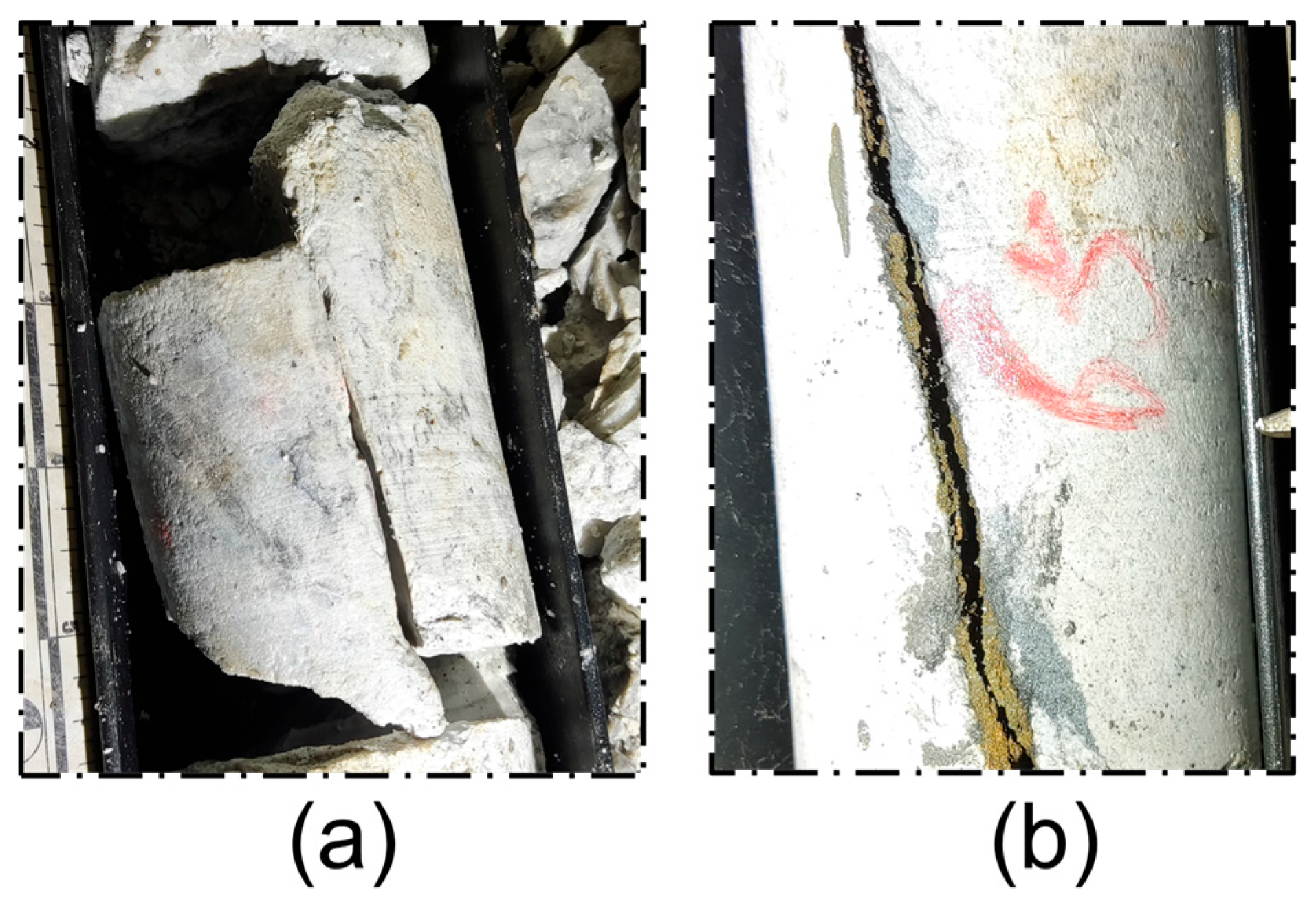

2.3. Filling Material

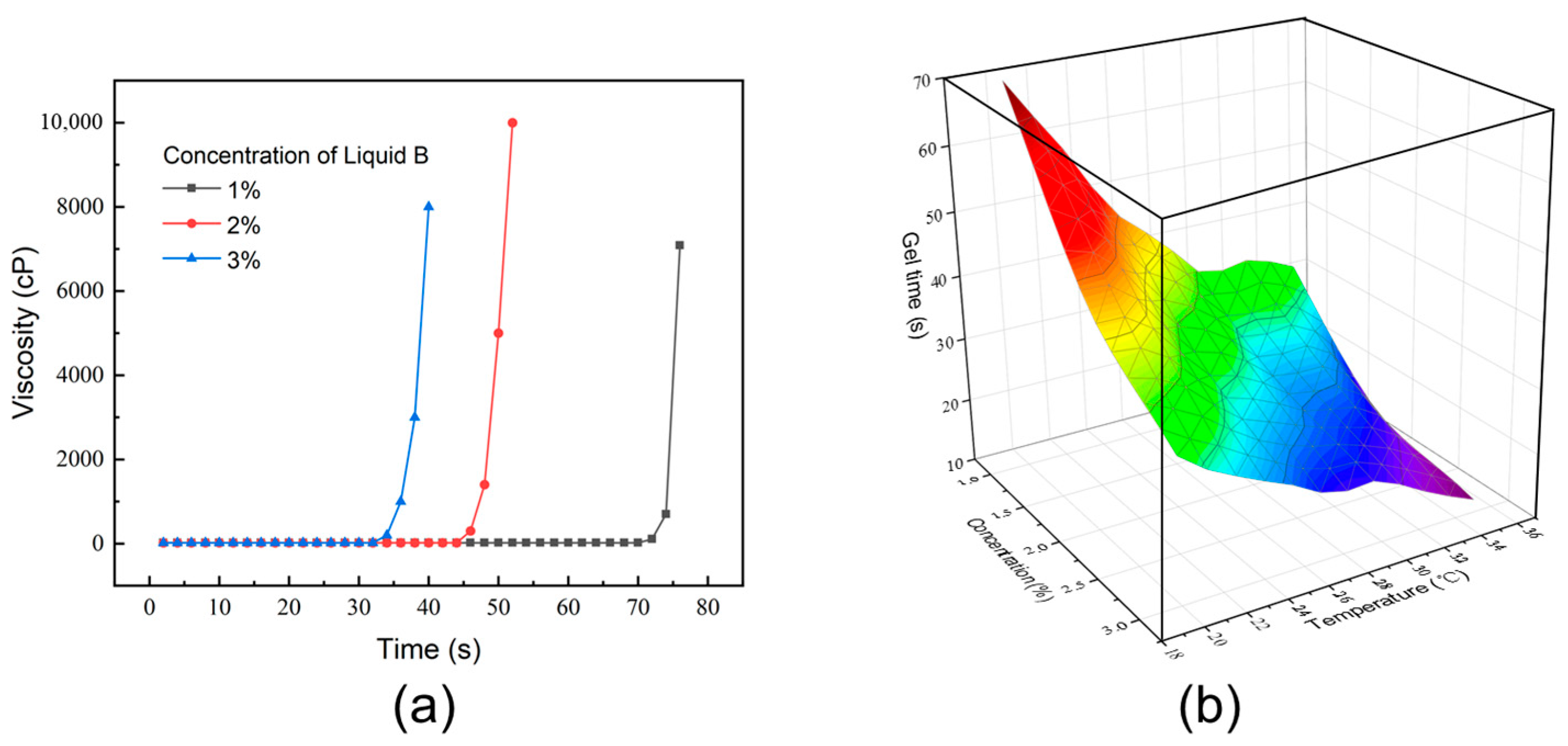

2.4. Grout Material

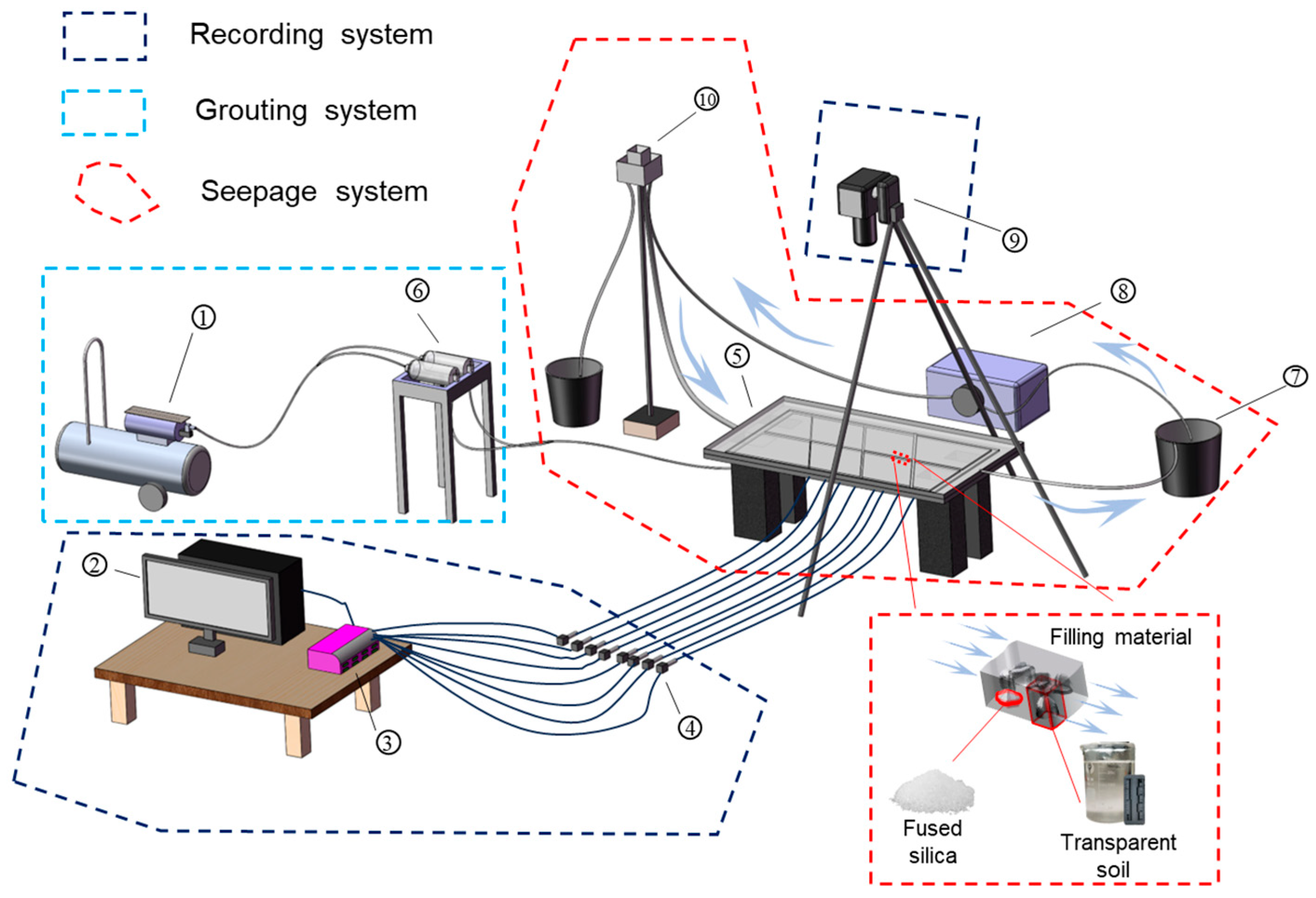

2.5. Experimental Setup

3. Results

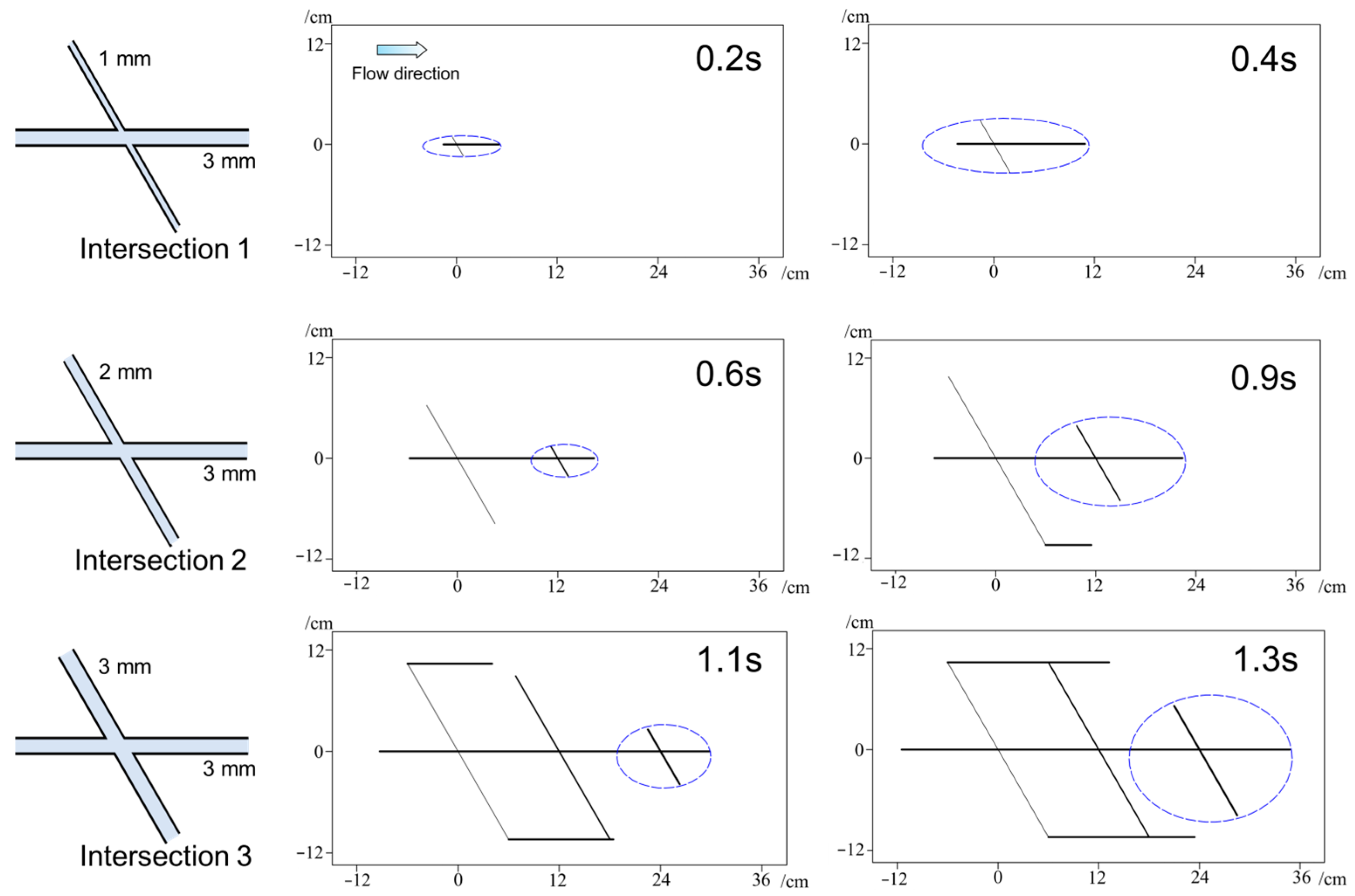

3.1. Subsection

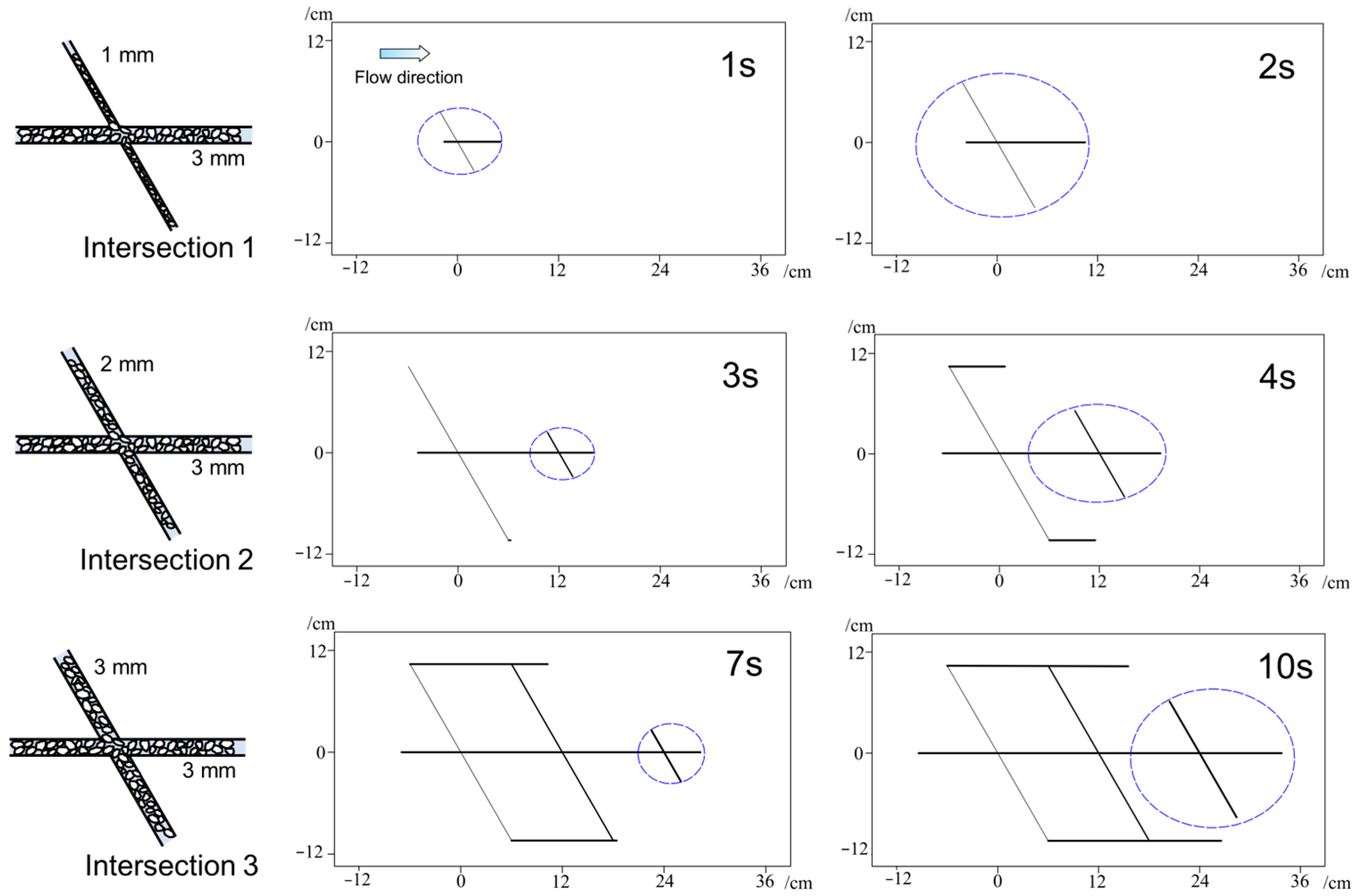

3.2. Grout Propagation in the Filled Fractures

4. Discussion

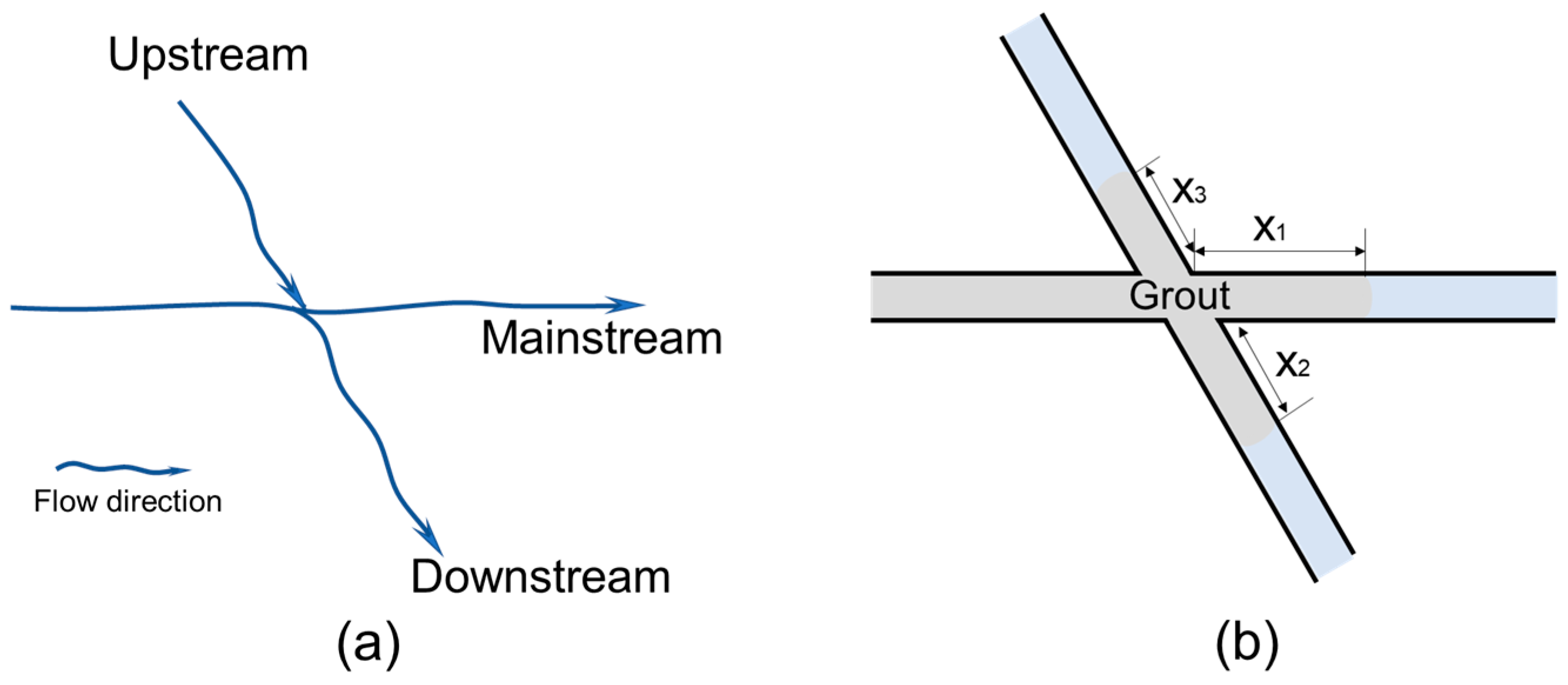

4.1. Grout Propagation in the Unfilled Fractures

4.2. Grout Propagation in the Filled Fractures

4.3. Numerical Simulation

4.4. Ratio of Grout Penetration Length in Branch and Main Pathway

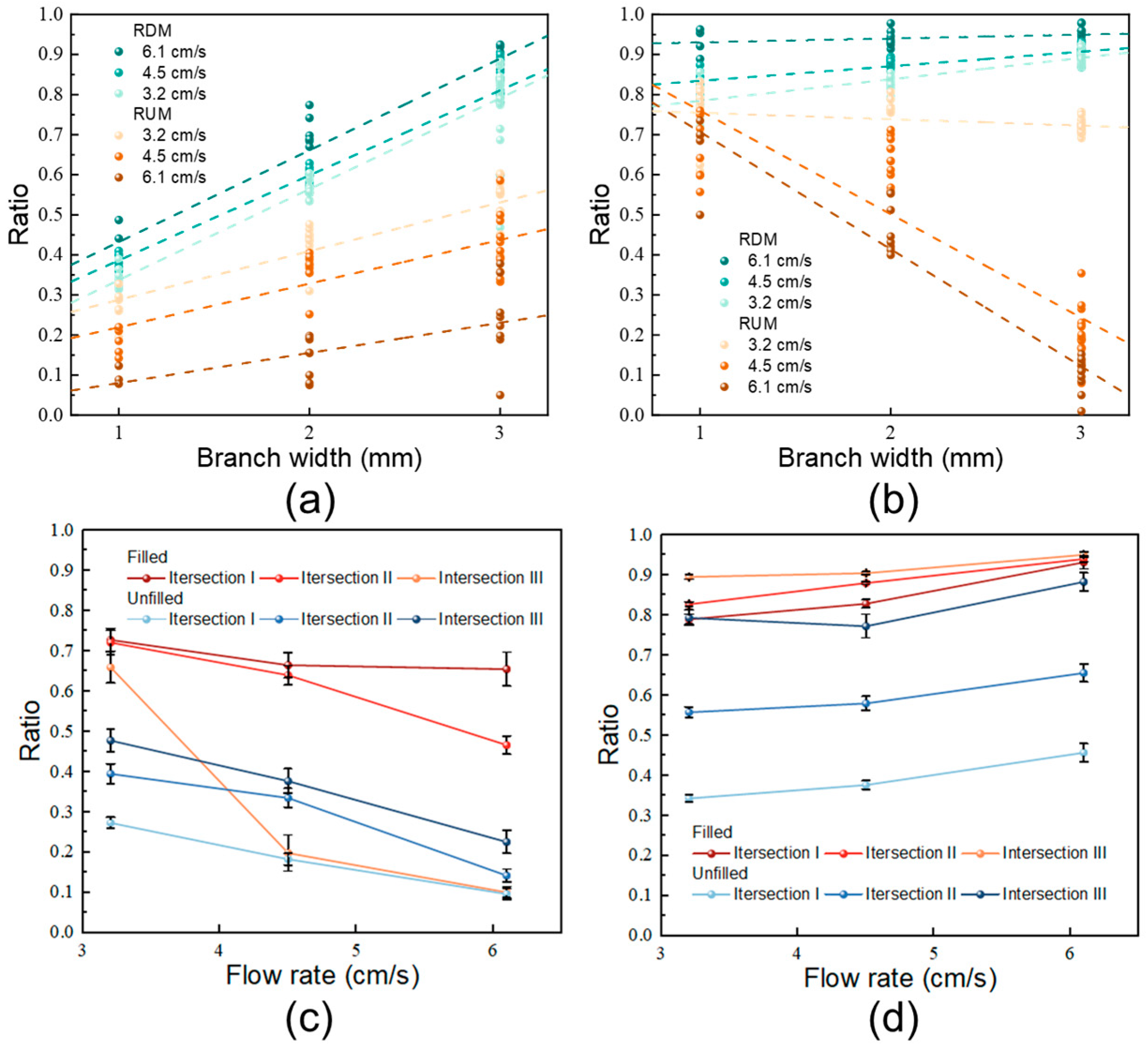

4.5. Effect of Fluid Velocity

4.6. Limitation

5. Conclusions

- (1)

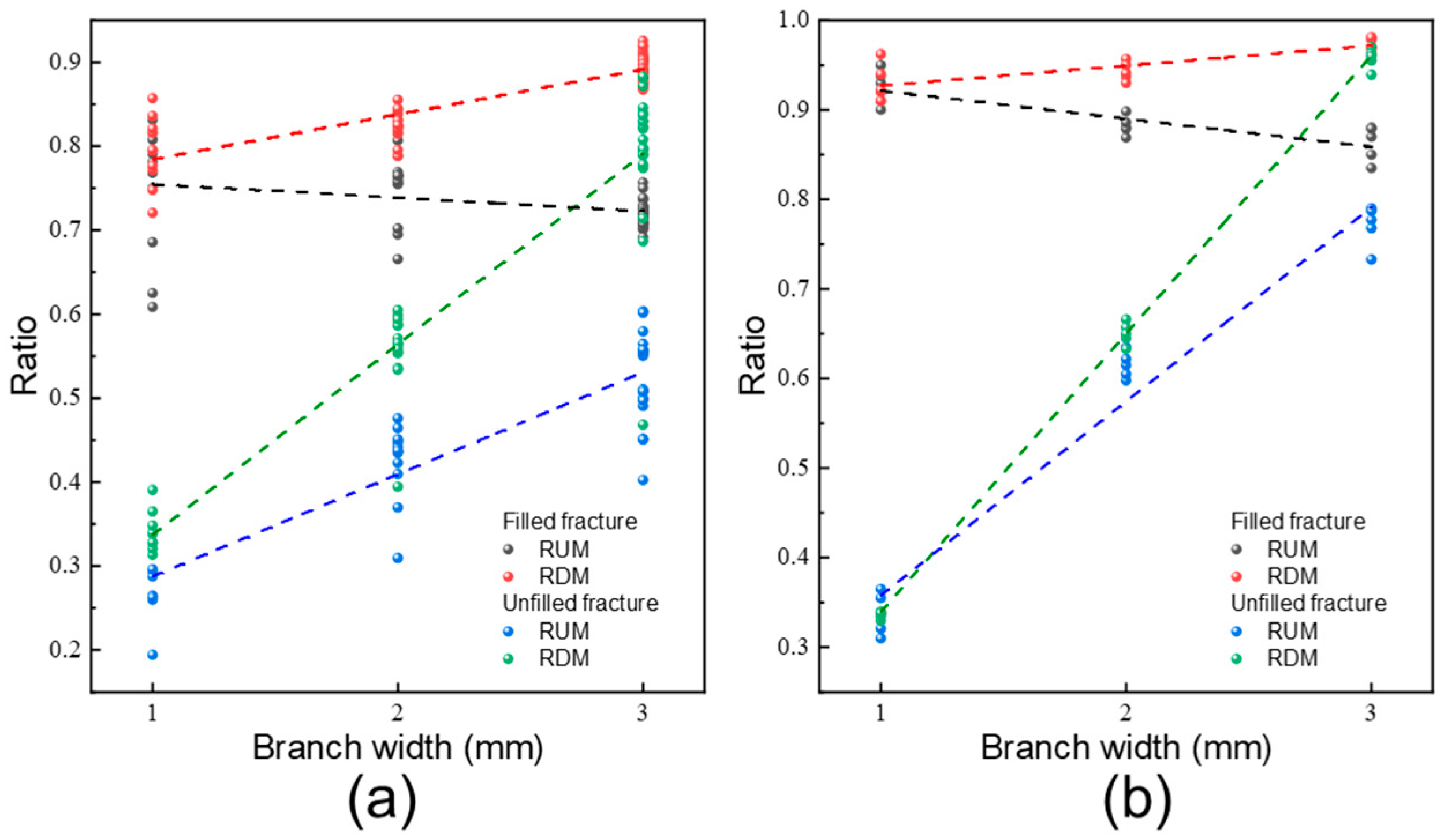

- In the unfilled fracture network, the diffusion ratio between branch and main fractures increased progressively from 0.35–0.44 at intersection I to 0.71–0.88 at intersection III, indicating a gradual weakening of anisotropy and a more balanced flow distribution. After filling, the ratios became more stable, ranging from 0.71 to 0.86 across all intersections, which suggests that fracture filling further reduces anisotropy and promotes more uniform grout propagation between main and branch fractures.

- (2)

- RDM was positively correlated with branch width. This trend was especially evident in unfilled fractures, while in filled fractures the increase in RDM was much less pronounced.

- (3)

- RUM was consistently lower than RDM. In unfilled fractures, RUM increased with branch width, whereas in filled fractures it decreased. Fluid velocity further amplified these anisotropic propagation behaviors.

- (4)

- The presence of porous filling material reduced the permeability differences between fractures with different apertures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, D.; Zhao, Z.; Li, B.; Chen, Y.; Ding, W. Permeability evolution of grout infilled fractures subjected to triaxial compression with low confining pressure. Tunn. Undergr. Space Technol. 2020, 104, 103539. [Google Scholar] [CrossRef]

- Boschi, K.; Giulio di Prisco, C.; Grassi, D.; Modoni, G.; Salvatore, E. Nanosilica grout permeation in sand: Experimental investigation and modeling. J. Geotech. Geoenviron. Eng. 2024, 150, 04023129. [Google Scholar] [CrossRef]

- Meng, X.; Sui, W.; Zhou, C.; Xie, B. Unraveling the Dynamic Failure-Stress Feedback Mechanism in Mining Overburden Through the PIV-DEM Synergistic Analysis. Int. J. Numer. Anal. Methods 2025. [Google Scholar] [CrossRef]

- Cao, N.; Huo, Z.; Liang, Y.; Zhang, L.; Yao, H. Research on slurry seepage law and in-situ test based on the 3-D of goaf porosity in CFD modeling. Fuel 2024, 361, 130701. [Google Scholar] [CrossRef]

- Jin, Y.; Han, L.; Xu, C.; Meng, Q.; Zong, Y. Cement grout nonlinear flow behavior through the rough-walled fractures: An experimental study. Geofluids 2020, 2020, 9514691. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, P.; Li, Z.; Wu, S.; Zhao, Z. Experimental-numerical investigation on grout diffusion and washout in rough rock fractures under flowing water. Comput. Geotech. 2020, 126, 103717. [Google Scholar] [CrossRef]

- Hao, M.; Song, T.; Li, X.; Zou, L.; Zhong, Y.; Zhang, B.; Wang, L. Propagation analysis of polymer grout in vertical fractures: An experimental and numerical study. KSCE J. Civ. Eng. 2024, 28, 1217–1226. [Google Scholar] [CrossRef]

- Yan, C.; Tong, Y.; Luo, Z.; Ke, W.; Wang, G. A two-dimensional grouting model considering hydromechanical coupling and fracturing for fractured rock mass. Eng. Anal. Bound. Elem. 2021, 133, 385–397. [Google Scholar] [CrossRef]

- Ding, W.; Lei, B.; Duan, C.; Zhang, Q. Numerical simulation of grout diffusion in rough rock fractures considering multiple influencing factors. Rock Mech. Rock Eng. 2024, 58, 355–377. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, D.; Shao, Y.; Ma, G. A model of cement grout flow in a fracture network system. Comput. Geotech. 2024, 175, 106698. [Google Scholar] [CrossRef]

- Xiong, F.; Wei, W.; Xu, C.; Jiang, Q. Experimental and numerical investigation on nonlinear flow behavior through three-dimensional fracture intersections and fracture networks. Comput. Geotech. 2020, 121, 103446. [Google Scholar] [CrossRef]

- Tian, K. The hydraulic properties of crossing-flow in an intersected fracture. Acta Geol. Sin. 1986, 60, 202–214. [Google Scholar]

- Jiang, X.; Zheng, G.; Sui, W.; Chen, J.; Zhang, J. Anisotropic propagation of chemical grouting in fracture network with flowing water. ACS Omega 2021, 6, 4672–4679. [Google Scholar] [CrossRef]

- Zheng, G.; Sui, W.; Zhang, G.; Chen, J.; Zhang, D. Propagation and sealing efficiency of chemical grouting in a two-dimensional fracture network with flowing water. Int. J. Rock Mech. Min. 2023, 33, 903–917. [Google Scholar] [CrossRef]

- Feng, L.; Huang, F.; Wang, G.; Huang, T.; Qian, Z. Experimental investigation on pneumatic pre-fracturing grouting in low-permeability soil. Tunn. Undergr. Space Technol. 2023, 131, 104798. [Google Scholar] [CrossRef]

- Shao, J.; Zhang, Q.; Wu, X.; Lei, Y.; Wu, X.; Wang, Z. Investigation on the water flow evolution in a filled fracture under seepage-induced erosion. Water 2020, 12, 3188. [Google Scholar] [CrossRef]

- Zhuo, Z.; Li, R. Theoretical and experimental study on one-dimensional fracture grouting in soil medium. Sadhana-Acad. P. Eng. S. 2020, 45, 117. [Google Scholar] [CrossRef]

- Wang, Z.; Li, C.; Ding, X. Application of transparent soil model tests to study the soil-rock interfacial sliding mechanism. J. Mt. Sci.-Engl. 2019, 16, 935–943. [Google Scholar] [CrossRef]

- Iskander, M.; Bathurst, R.J.; Omidvar, M. Past, present, and future of transparent soils. Geotech. Test. J. 2015, 38, 557–573. [Google Scholar] [CrossRef]

- Huang, B.; Guo, C.; Tang, Y.; Guo, J.; Cao, L. Experimental study on the permeability characteristic of fused quartz sand and mixed oil as a transparent soil. Water 2019, 11, 2514. [Google Scholar] [CrossRef]

- Iskander, M. Modeling with Transparent Soils: Visualizing Soil Structure Interaction and Multi-Phase Flow, Non-Intrusively; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Yuan, B.; Xiong, L.; Zhai, L.; Zhou, Y.; Chen, G.; Gong, X.; Zhang, W. Transparent synthetic soil and its application in modeling of soil-structure interaction using optical system. Front. Earth Sci. 2019, 7, 276. [Google Scholar] [CrossRef]

- Kong, G.; Li, H.; Yang, G.; Cao, Z. Investigation on shear modulus and damping ratio of transparent soils with different pore fluids. Granul. Matter 2018, 20, 8. [Google Scholar] [CrossRef]

- Wang, J.; Long, Y.; Gao, F.; Wang, H.; Shi, Y.; Yang, T.; Liu, X.; Huang, X.; Xu, N. Transparent soil test evaluation of vertical-horizontal mixed curtain during dewatering. Acta Geotech. 2022, 17, 3293–3313. [Google Scholar] [CrossRef]

- Xiao, Y.; Yin, F.; Liu, H.; Chu, J.; Zhang, W. Model tests on soil movement during the installation of piles in transparent granular soil. Int. J. Geomech. 2017, 17, 06016027. [Google Scholar] [CrossRef]

- Bieniawski, Z.; Hawkes, I. International Society for Rock Mechanics Commission on standardization of laboratory and field tests: Suggested methods for the quantitative description of discontinuities in rock masses. Int. J. Rock Mech. Min. Sci. 1978, 15, 319–368. [Google Scholar]

- Sui, W.; Qu, H.; Gao, Y. Modeling of grout propagation in transparent replica of rock fractures. Geotech. Test. J. 2015, 38, 765–773. [Google Scholar] [CrossRef]

- Su, B.; Zhan, M. Experimental research of seepage characteristic for filled fracture. Rock Soil Mech. 1994, 15, 46–52. [Google Scholar]

- Miyazaki, T. Water Flow in Soils; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Mohajerani, S.; Baghbanan, A.; Wang, G.; Forouhandeh, S. An efficient algorithm for simulating grout propagation in 2D discrete fracture networks. Int. J. Rock Mech. Min. 2017, 98, 67–77. [Google Scholar] [CrossRef]

- Yue, P.; Feng, J.; Liu, C.; Shen, J. A diffuse-interface method for simulating two-phase flows of complex fluids. J. Fluid Mech. 2004, 515, 293–317. [Google Scholar] [CrossRef]

- Chen, Z.; Huan, G.; Ma, Y. Computational Methods for Multiphase Flows in Porous Media; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2006. [Google Scholar]

| Density (g/cm3) | Kinematic Viscosity (mPa·s) | Refractive Index | |

|---|---|---|---|

| Mineral Oil A | 0.812 | 5~6 | 1.4663 |

| Mineral Oil B | 0.844 | 10 | 1.4397 |

| Mixed Oil | 0.823 | 8.5 | 1.4585 |

| Specific Density, Gs | Maximum Void Ratio, emax | Minimum Void Ratio, emin | Hydraulic Conductivity, K (10−3 cm/s) | |

|---|---|---|---|---|

| Chinese standard sand | 2.65 | 0.76 | 0.51 | 6.52~7.00 |

| Fused silica | 2.21 | 0.8 | 0.51 | 6.39~8.32 |

| Fracture Width b (cm) | Average Diameter of Filling d (cm) | Particle Shape Factors α | Porosity e | Permeability k (cm2) |

|---|---|---|---|---|

| 1 | 0.05 | 1.5 | 0.3 | 3.18 × 10−7 |

| 2 | 0.05 | 1.5 | 0.3 | 3.26 × 10−7 |

| 3 | 0.05 | 1.5 | 0.3 | 3.28 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, B.; Li, D.; Liu, X.; Hu, Q.; Li, X.; Meng, X.; Sui, W. Investigation of Grout Anisotropic Propagation at Fracture Intersections Under Flowing Water. Appl. Sci. 2025, 15, 9787. https://doi.org/10.3390/app15179787

Sun B, Li D, Liu X, Hu Q, Li X, Meng X, Sui W. Investigation of Grout Anisotropic Propagation at Fracture Intersections Under Flowing Water. Applied Sciences. 2025; 15(17):9787. https://doi.org/10.3390/app15179787

Chicago/Turabian StyleSun, Bangtao, Dongli Li, Xuebin Liu, Qiquan Hu, Xiaoxiong Li, Xiangdong Meng, and Wanghua Sui. 2025. "Investigation of Grout Anisotropic Propagation at Fracture Intersections Under Flowing Water" Applied Sciences 15, no. 17: 9787. https://doi.org/10.3390/app15179787

APA StyleSun, B., Li, D., Liu, X., Hu, Q., Li, X., Meng, X., & Sui, W. (2025). Investigation of Grout Anisotropic Propagation at Fracture Intersections Under Flowing Water. Applied Sciences, 15(17), 9787. https://doi.org/10.3390/app15179787