Simulation-Based Optimization of Material Supply in Automotive Production Using RTLS Data

Abstract

1. Introduction

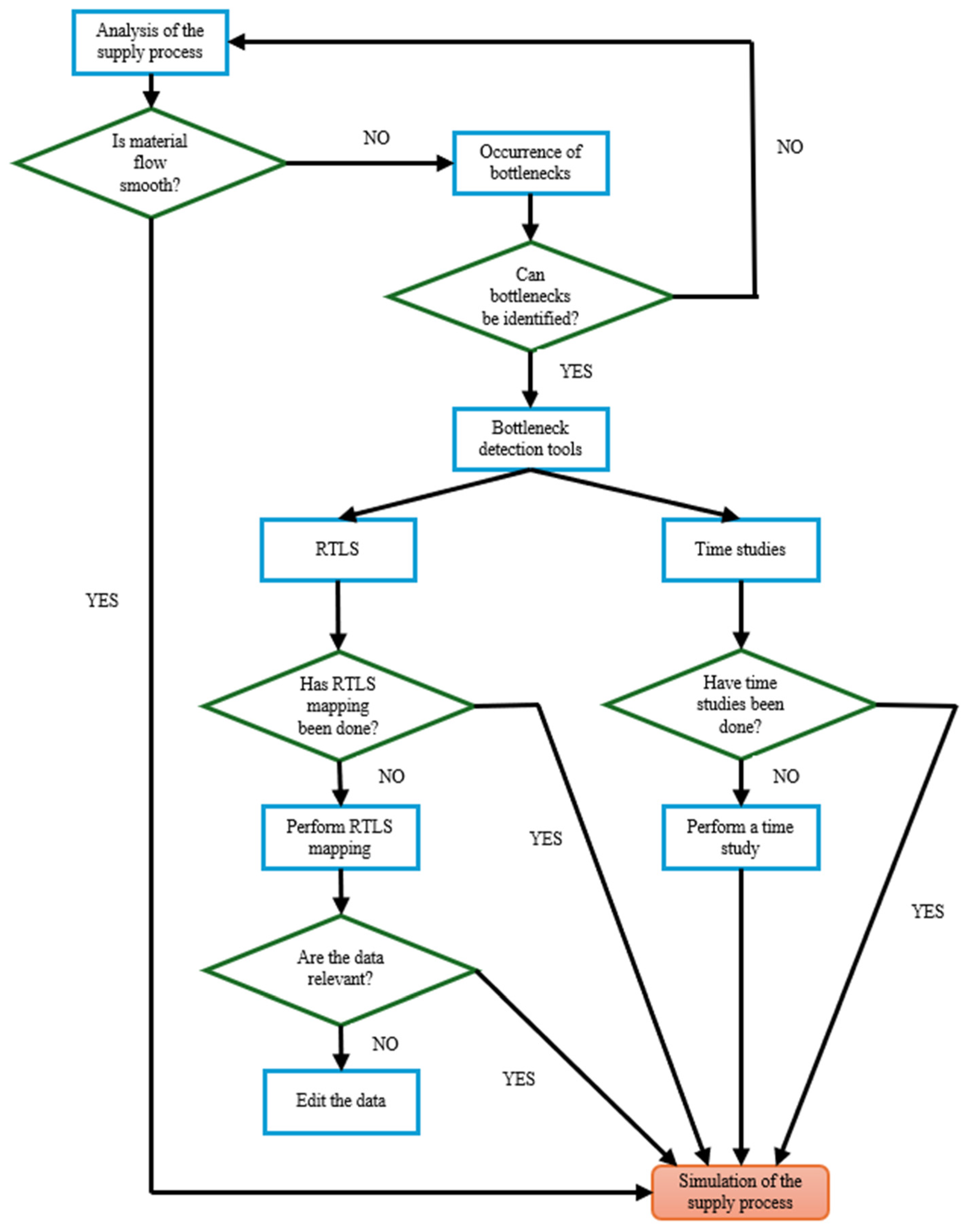

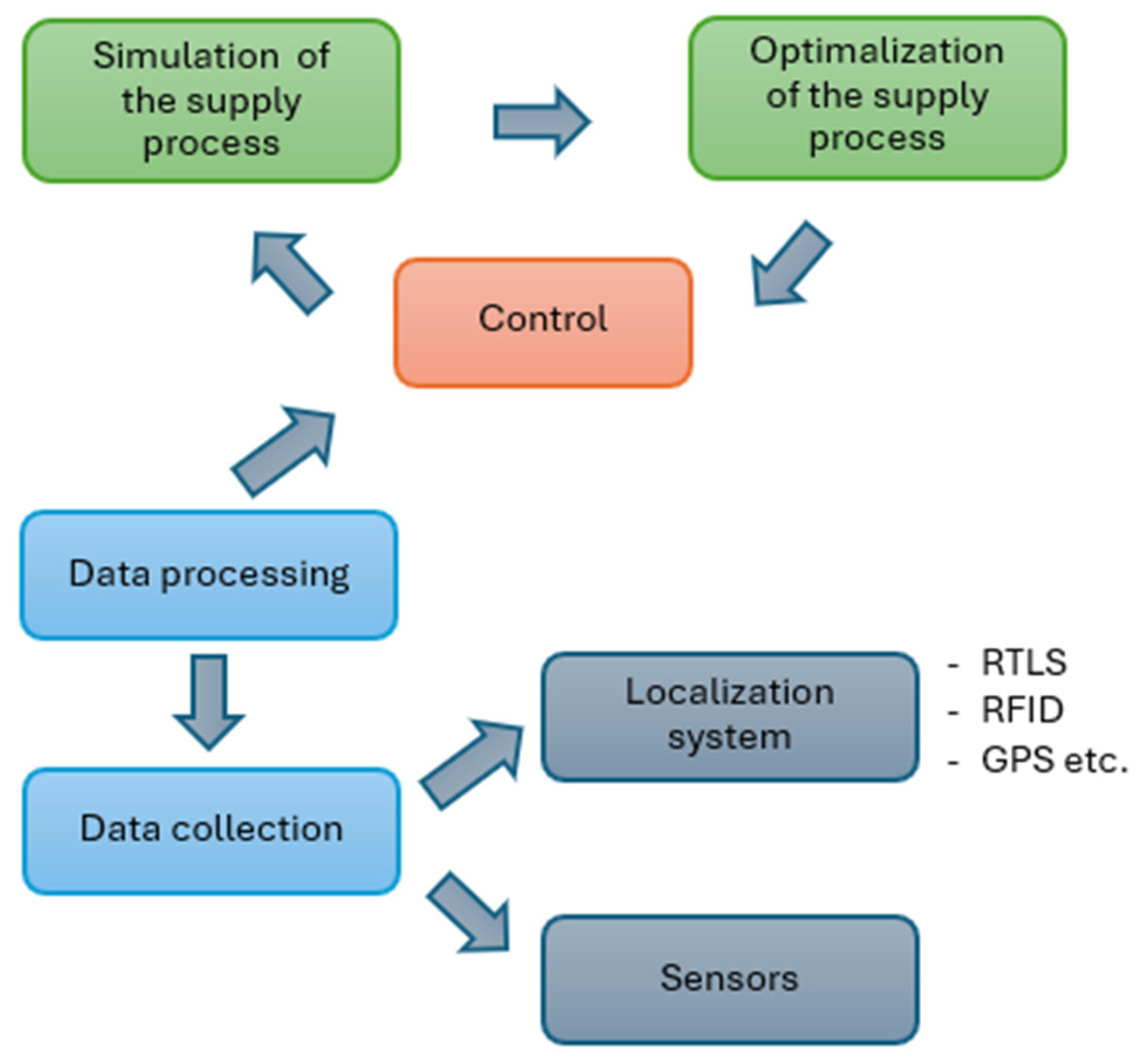

2. Materials and Methods

2.1. RTLS Monitoring Technology

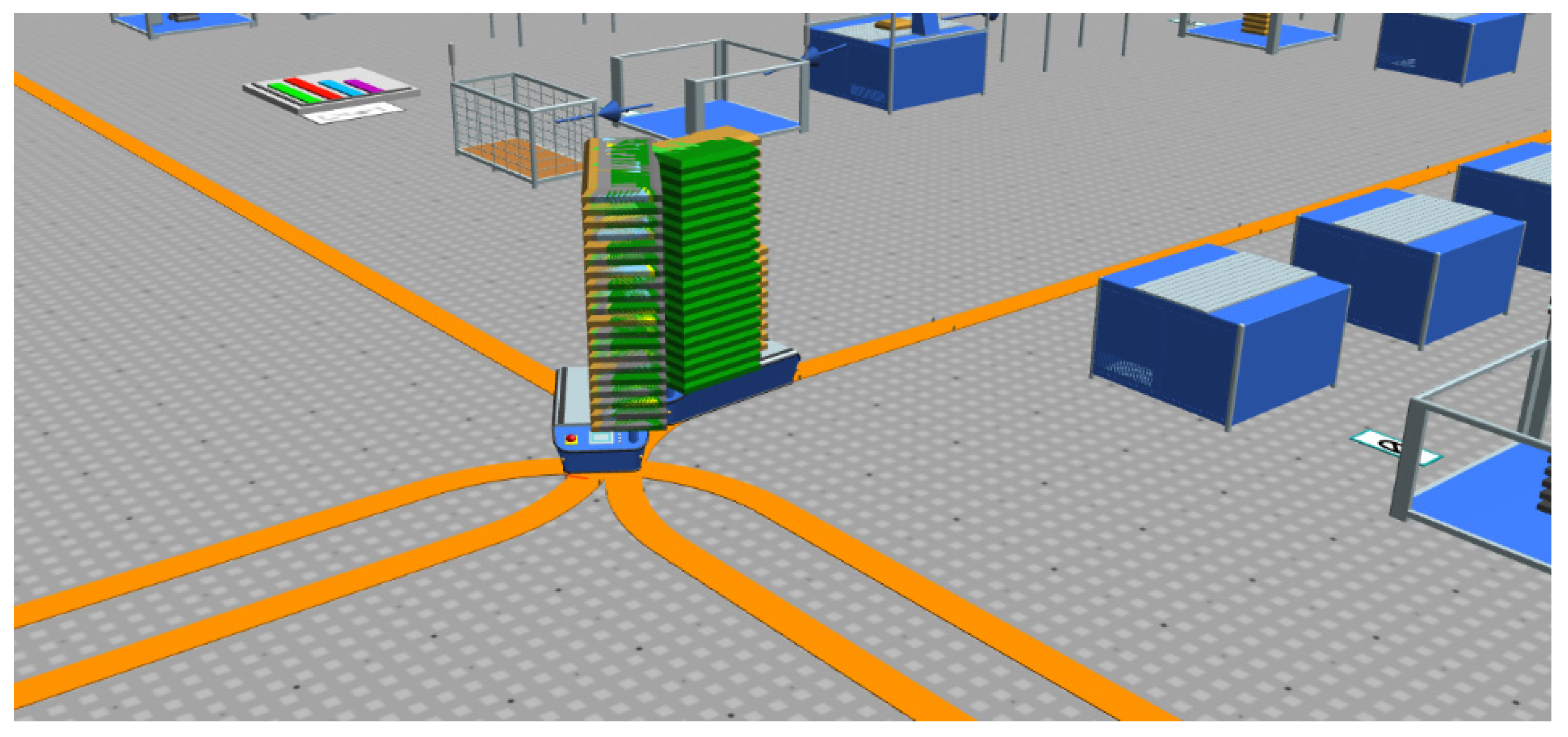

2.2. Simulation

3. Results and Discussion

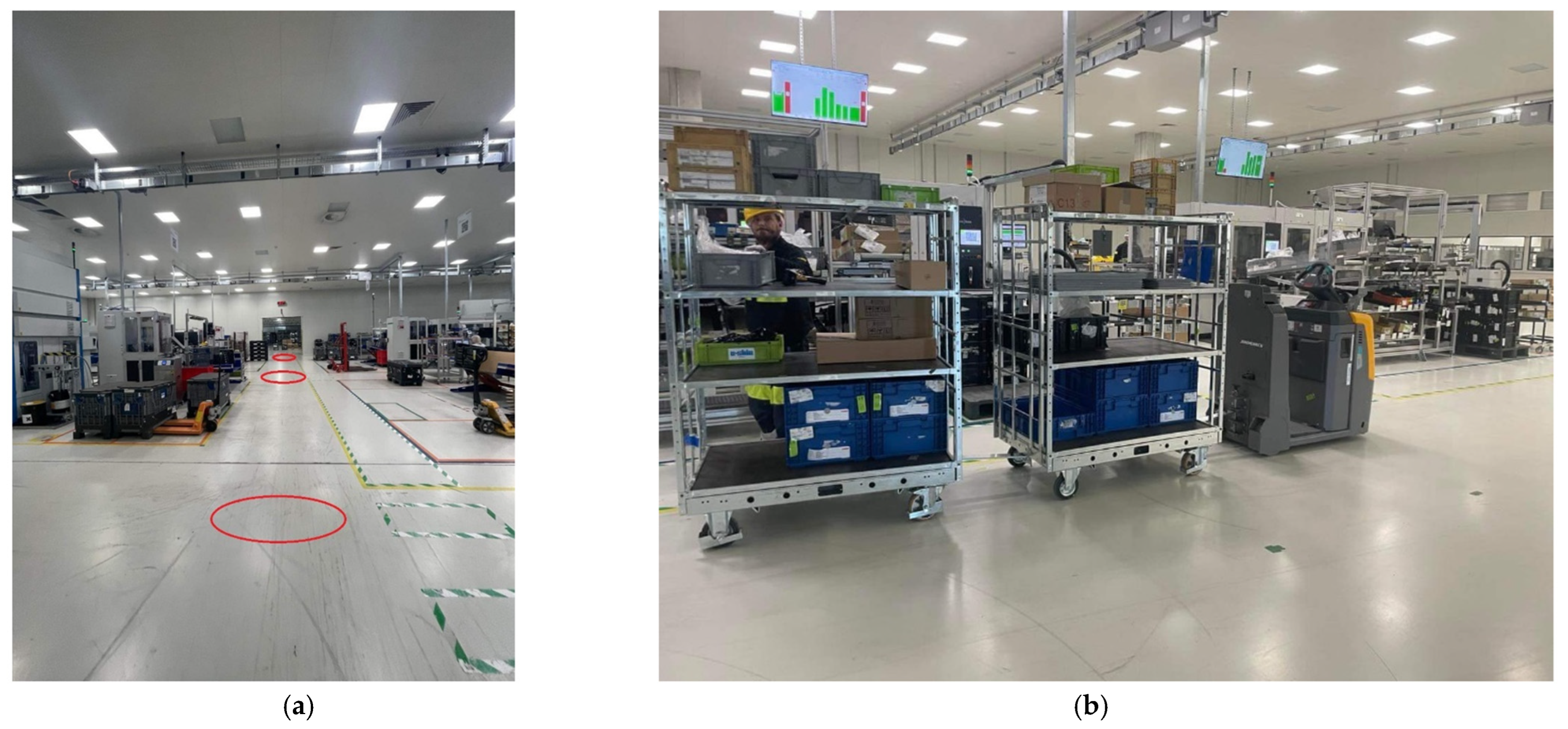

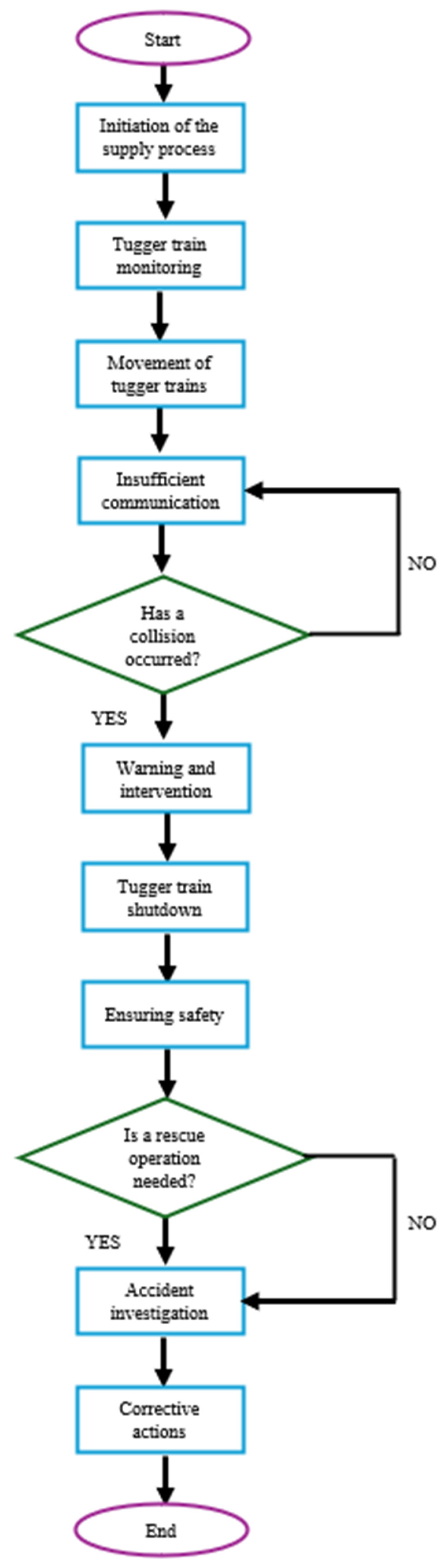

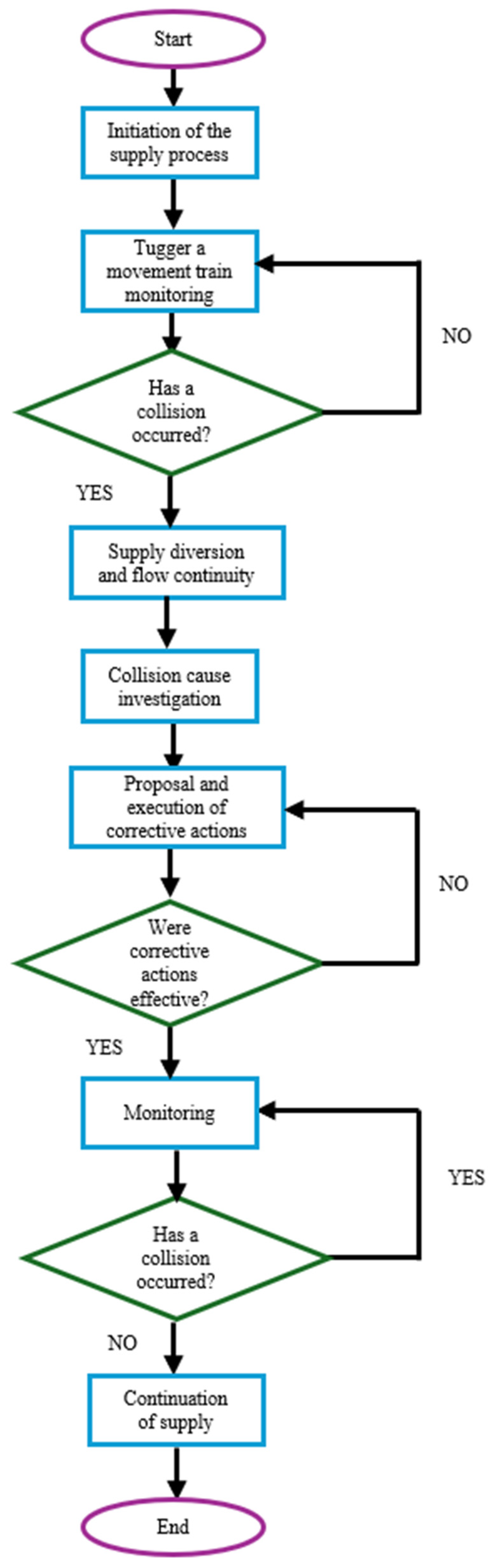

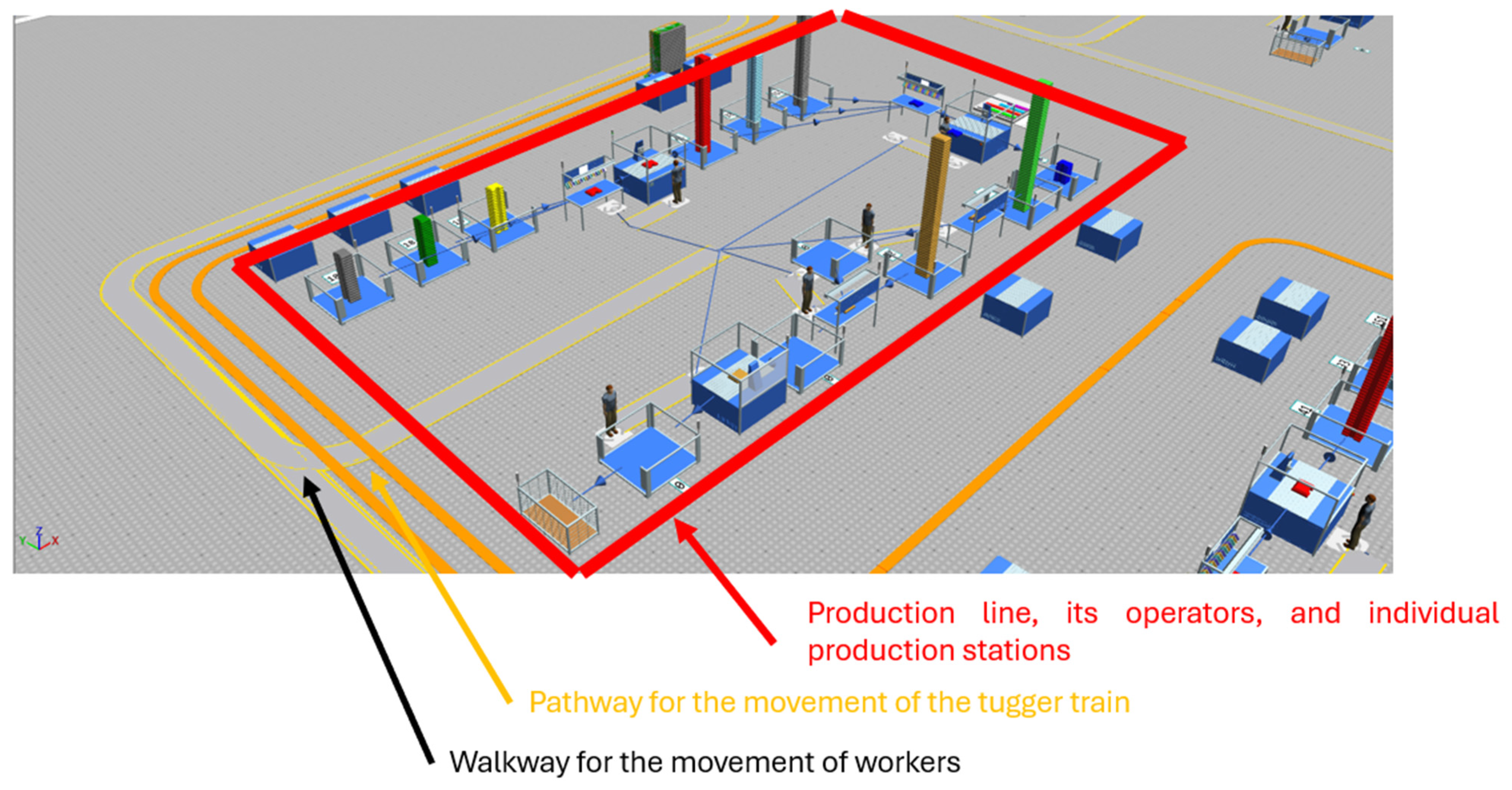

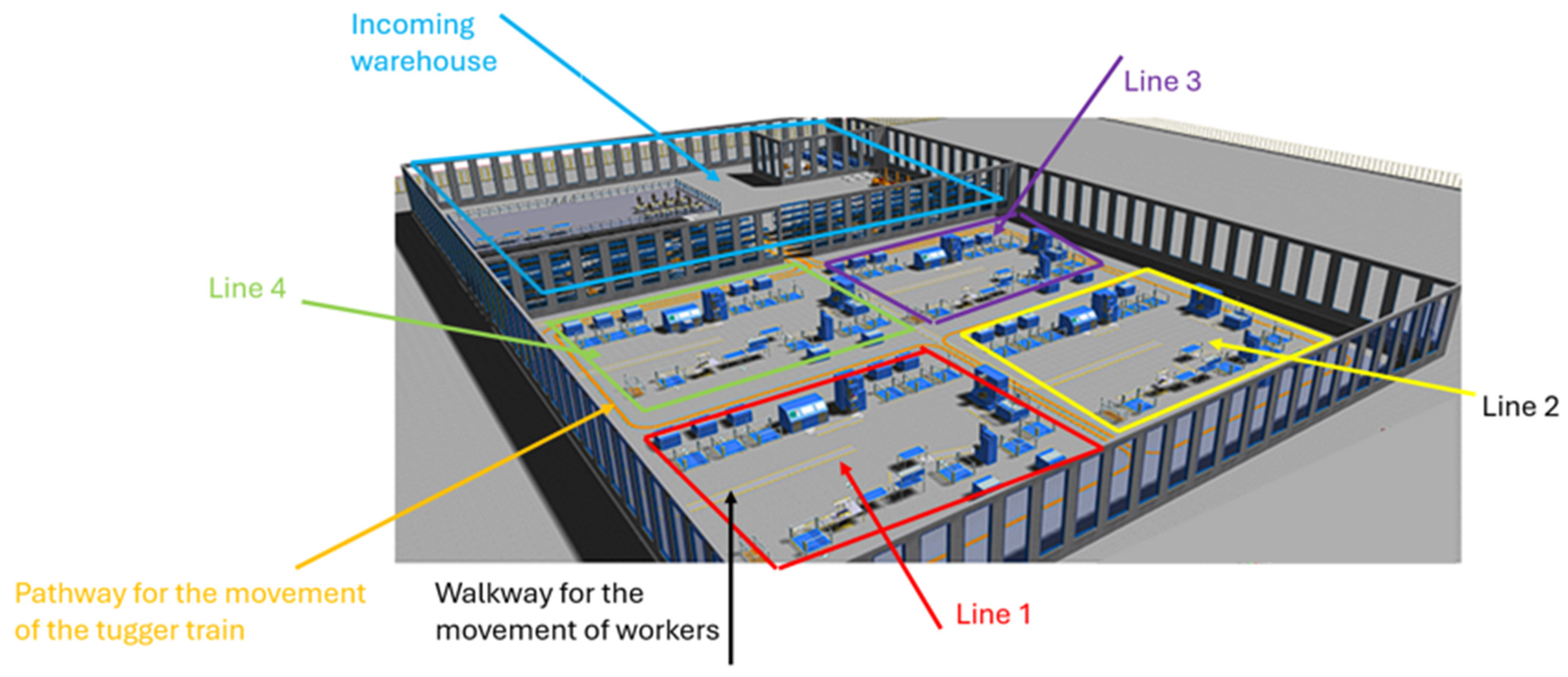

3.1. Case Study Description

- Tugger train operators—2 employees;

- Production operators—20 employees;

- Line supervisors—4 employees;

- Maintenance service—2 employees;

- Security personnel—1 employee;

- Production and technical staff—3 employees;

- Data analysts—2 employees;

- Process engineers—3 employees;

- Shift supervisor—1 employee.

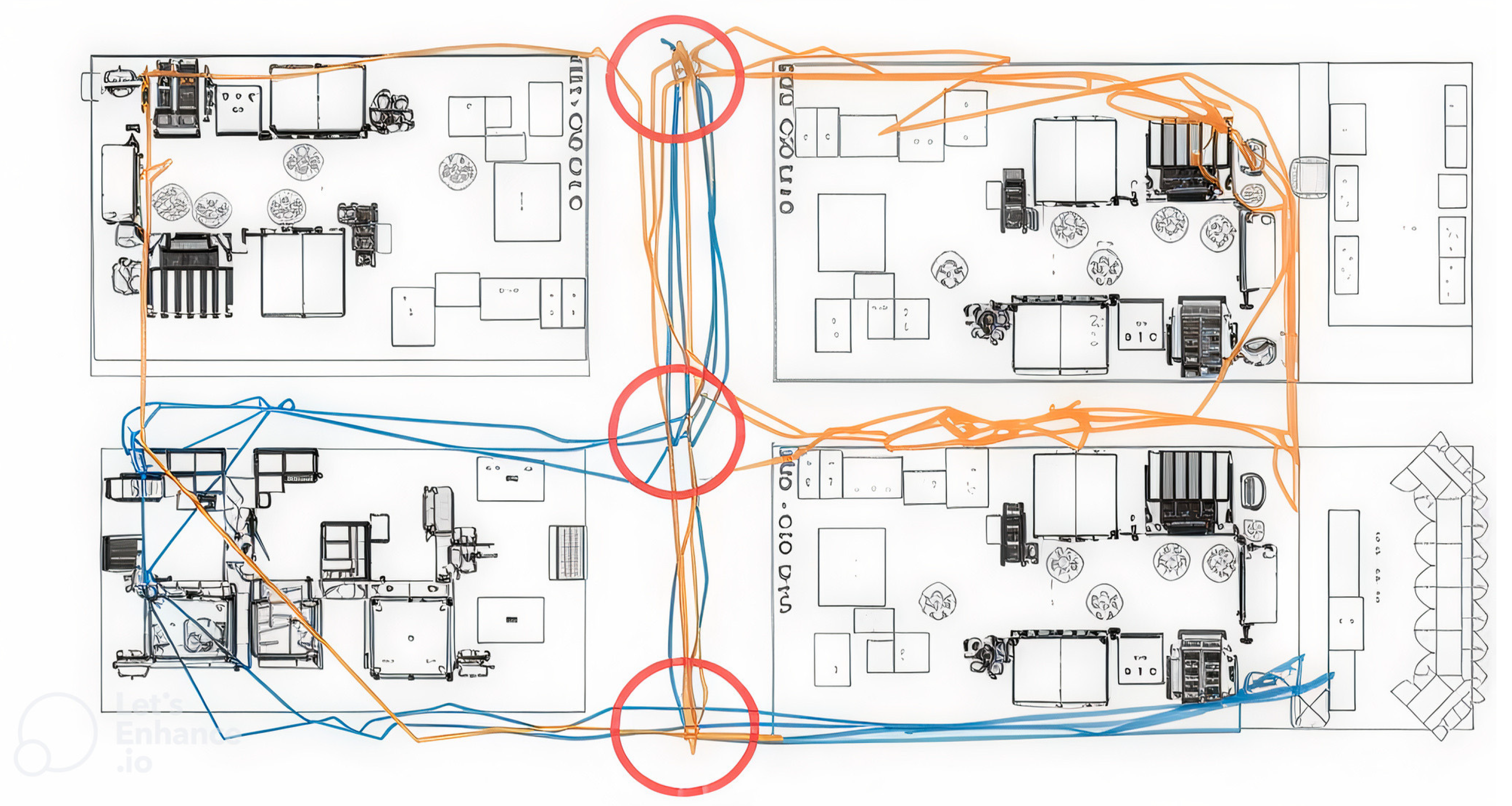

3.2. Data Collection and Input Parameters

3.3. Results and Comparison

3.4. Discussion and Implications

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ojstersek, R.; Javernik, A.; Buchmeister, B. The impact of the collaborative workplace on the production system capacity: Simulation modelling vs. real-world application approach. Adv. Prod. Eng. Manag. 2021, 16, 431–442. [Google Scholar] [CrossRef]

- Glova, J.; Sabol, T.; Vajda, V. Business Models for the Internet of Things Environment. Emerg. Mark. Queries Financ. Bus. 2013, 15, 1122–1129. [Google Scholar] [CrossRef]

- Krajcovic, M.; Gabajová, G.; Matys, M.; Grznár, P.; Dulina, L.; Kohár, R. 3D Interactive Learning Environment as a Tool for Knowledge Transfer and Retention. Sustainability 2021, 13, 7916. [Google Scholar] [CrossRef]

- Marschall, M.; Gregor, M.; Durica, L.; Vavrík, V.; Bielik, T.; Grznár, P.; Mozol, Š. Defining the Number of Mobile Robotic Systems Needed for Reconfiguration of Modular Manufacturing Systems via Simulation. Machines 2022, 10, 316. [Google Scholar] [CrossRef]

- Gola, A.; Plinta, D.; Grznar, P. Modelling and simulation of reconfigurable manufacturing system for machining of casing-class parts. In Proceedings of the 20th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021; pp. 1563–1568. [Google Scholar] [CrossRef]

- Wicher, P.; Stas, D.; Karkula, M.; Lenort, R.; Besta, P. A Computer Simulation-Based Analysis of Supply Chains Resilience in Industrial Environment. Metalurgija 2015, 54, 703–706, ISSN 0543-5846, eISSN 1334-2576. [Google Scholar]

- Tsai, J.F.; Wang, P.C.; Tsai, W.L. Competence Set Expansion for Production Process Planning. NTU Manag. Rev. 2013, 23, 263–296. [Google Scholar] [CrossRef]

- Holtewert, P.; Bauernhansl, T. Interchangeable Product Designs for the Increase of Capacity Flexibility in Production Systems. 26th Cirp Des. Conf. 2016, 50, 252–257. [Google Scholar] [CrossRef]

- Sarjono, H.; Kusuma, V.; Hamali, S.; Mulyono. Planning Production Capacity Optimisation with Rough Cut Capacity Planning. Pertanika J. Soc. Sci. Humanit. 2016, 24, 33–45, ISSN 0128-7702, eISSN 2231-8534. [Google Scholar]

- Huang, D.; Lin, Z.K.; Wei, W. Optimal production planning with capacity reservation and convex capacity costs. Adv. Prod. Eng. Manag. 2018, 13, 31–43. [Google Scholar] [CrossRef]

- Schwarz, J.A.; Tan, B. Optimal sales and production rollover strategies under capacity constraints. Eur. J. Oper. Res. 2021, 294, 507–524. [Google Scholar] [CrossRef]

- Creutznacher, T.; Berger, U.; Lepratti, R.; Lamparter, S. The Transformable Factory: Adapting Automotive Production Capacities, Research and Innovation in Manufacturing: Key Enabling Technologies for the Factories of the Future. In Proceedings of the 48th Cirp Conference on Manufacturing Systems, Ischia, Italy, 24–26 June 2015; Volume 41, pp. 171–176. [Google Scholar] [CrossRef]

- Saderova, J.; Poplawski, L.M.B., Jr.; Michalkova, S.; Cvoliga, M. Layout Design Options for Warehouse Management. Pol. J. Manag. Stud. 2020, 22, 443–455. [Google Scholar] [CrossRef]

- Paska, M.; Malkus, T.; Rosova, A.; Trebuna, P.; Kacmary, P.; Behun, M. International Commercial Terms and Their Necessity for the Logistics. In Proceedings of the 8th Carpathian Logistics Congress 2018, Prague, Czech Republic, 3–5 December 2018; pp. 688–696, ISBN 978-80-87294-88-8. [Google Scholar]

- Balzer, R.; Užík, M.; Glova, J. Managing Growth Opportunities in The Digital Era—An Empiric Perspective of Value Creation. Pol. J. Manag. Stud. 2020, 21, 87–100. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Straka, M. Identification of Social and Economic Expectations: Contextual Reasons for the Transformation Process of Industry 4.0 into the Industry 5.0 Concept. Sustainability 2022, 14, 1391. [Google Scholar] [CrossRef]

- Matisková, D.; Balog, M.; Husár, J. Criteria for the Optimization of Production Processes in Machining of Metallic Materials. Manag. Syst. Prod. Eng. 2018, 26, 227–230. [Google Scholar] [CrossRef]

- Sujova, A.; Marcinekova, K.; Hittmar, S. Sustainable Optimization of Manufacturing Process Effectiveness in Furniture Production. Sustainability 2017, 9, 923. [Google Scholar] [CrossRef]

- Laciak, M.; Raskayova, D.; Flegner, P.; Kacur, J.; Durdan, M. Automated system for optimizing input parameters of the UCG process. In Proceedings of the 20th International Carpathian Control Conference, Krakow-Wieliczka, Poland, 26–29 May 2019; pp. 311–315. [Google Scholar] [CrossRef]

- Chu, J.F.; Xu, F.; Zhu, Q.Y.; Fukuyama, H. Production scale expansion and congestion in two-stage network systems. Comput. Ind. Eng. 2024, 193, 110317. [Google Scholar] [CrossRef]

- Lin, M.H.; Tsai, J.F.; Wang, P.C.; Ho, Y.T. A coordinated production planning model with capacity expansion for supply chain networks. Eur. J. Ind. Eng. 2019, 13, 435–460. [Google Scholar] [CrossRef]

- Min, Z.; Nie, G.H.; Ming, Z.; Lihm, H. Capacity improvement of an LCM production line. In Proceedings of the 3rd International Conference on Innovation & Management, Vols 1 and 2, Wuhan, China, 2–3 December 2006; pp. 1028–1031, ISBN 978-7-5629-2471-5. [Google Scholar]

- Radatz, H.; Kühne, K.; Bramsiepe, C.; Schembecker, G. Comparison of capacity expansion strategies for chemical production plants. Chem. Eng. Res. Des. 2019, 143, 56–78. [Google Scholar] [CrossRef]

- West, N.; Schwenken, J.; Deuse, J. Data-Driven Approach for Diagnostic Analysis of Dynamic Bottlenecks in Serial Manufacturing Systems. arXiv 2023, arXiv:2306.16120. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, E.; Luo, Z. Bottleneck Detection for Discrete Manufacturing System Based on Object-Oriented Colored Petri Nets and Cloud Simulation. ITM Web Conf. 2022, 45, 01015. [Google Scholar] [CrossRef]

- Pekarciková, M.; Trebuna, P.; Kliment, M.; Edl, M.; Rosocha, L. Transformation the Logistics to Digital Logistics: Theoretical Approach. Acta Logist. 2020, 7, 217–223. [Google Scholar] [CrossRef]

- Kábele, P.; Edl, M. Increasing the Efficiency of the Production Process Due to Using Methods of Industrial Engineering. In Advances in Design, Simulation and Manufacturing II, Proceedings of the 2nd International Conference on Design, Simulation, Manufacturing II 2019, Lutsk, Ukraine, 11–14 June 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 126–137. [Google Scholar] [CrossRef]

- Sasiadek, M.; Kielec, R.; Wozniak, W. The Application of the Dependency Structure Matrix in the Planning of Production Processes, Vision 2025: Education Excellence and Management of Innovations Through Sustainable Economic Competitive Advantage. In Proceedings of the 36th IBIMA Conference, Madrid, Spain, 13–14 November 2019; pp. 6148–6155, ISBN 978-0-9998551-3-3. [Google Scholar]

- Manlig, F.; Slaichova, E.; Koblasa, F.; Vavruska, J. Innovation of business processes by means of computer-aided simulation. Nov. Trends Prod. Devices Syst. 2014, 474, 67–72. [Google Scholar] [CrossRef]

| Observed Issue | Frequency (Per Month) |

|---|---|

| Collisions of tugger trains | 9 |

| Unauthorized employee interventions | 17 |

| Incorrect barcode scanning by operators | 11 |

| Planned Ideal State | |

|---|---|

| Number of collisions per month | 0 |

| Production capacity (units/production line) | 1200 |

| Loading time of the tugger trains | 90 min |

| Tugger train time in the production hall | <30 min |

| Kanban replenishment time | <3 min |

| State Proposed and Verified Through Simulation | Actual State During Data Collection | |

|---|---|---|

| Number of collisions per month | 0 | 9 |

| Production capacity (units/production line) | 950 | 825 |

| Loading time of the tugger trains | <105 min | <120 min |

| Tugger train time in the production hall | <20 min | <44 min |

| Kanban replenishment time | <2 min | <1.32 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pekarčíková, M.; Kliment, M.; Kronová, J.; Trebuňa, P.; Hovana, A. Simulation-Based Optimization of Material Supply in Automotive Production Using RTLS Data. Appl. Sci. 2025, 15, 9102. https://doi.org/10.3390/app15169102

Pekarčíková M, Kliment M, Kronová J, Trebuňa P, Hovana A. Simulation-Based Optimization of Material Supply in Automotive Production Using RTLS Data. Applied Sciences. 2025; 15(16):9102. https://doi.org/10.3390/app15169102

Chicago/Turabian StylePekarčíková, Miriam, Marek Kliment, Jana Kronová, Peter Trebuňa, and Anton Hovana. 2025. "Simulation-Based Optimization of Material Supply in Automotive Production Using RTLS Data" Applied Sciences 15, no. 16: 9102. https://doi.org/10.3390/app15169102

APA StylePekarčíková, M., Kliment, M., Kronová, J., Trebuňa, P., & Hovana, A. (2025). Simulation-Based Optimization of Material Supply in Automotive Production Using RTLS Data. Applied Sciences, 15(16), 9102. https://doi.org/10.3390/app15169102