2.1. Sensor Technologies and Foodborne Illness Monitoring

Foodborne illnesses are a major yet preventable public health issue, responsible for about 48 million illnesses and 3000 deaths worldwide each year. They are caused by consuming food contaminated with harmful microorganisms like bacteria, viruses, or parasites. Since symptoms often resemble the flu—such as nausea, vomiting, diarrhoea, and fever—many cases go unrecognised or are misattributed.

Traditional methods of detecting and reporting foodborne outbreaks are often slow and inefficient. In response, modern technologies such as wireless sensors, intelligent monitoring systems, and data analytics (including infodemiology and infoveillance) are now being used to detect potential outbreaks in real-time. These tools improve the speed, accuracy, and effectiveness of food safety monitoring compared to conventional systems [

6,

7].

Food traceability and monitoring is the ability to track the movement of food products throughout the supply chain, from farm to shelf. It allows the identification of the origin, processing, distribution, and sale of perishable products. Food traceability is essential in the food industry, as it helps ensure food safety and quality, prevent foodborne illness outbreaks, and reduce the impact of food recalls. Several studies [

6,

7] utilised various monitoring tools to assess food temperature throughout the cold chain and detected temperature abuse at all stages of the chain [

8]. Therefore, food distribution is a complex process that considers the effect of environmental conditions on the food temperature throughout the cold chain [

9].

The cold supply chain comprises several key stages to ensure that temperature-sensitive products, such as food, remain at the proper temperature to preserve their quality and safety. It begins with production or harvesting, where products are quickly cooled or frozen to prevent spoilage. Next, they are packaged in materials that help maintain the required temperature, often using insulation or temperature-controlled containers. Once packaged, the products are transported in refrigerated trucks, containers, or via air cargo, where temperature is closely monitored to prevent disruptions. Upon reaching storage facilities, products are kept in climate-controlled environments, such as refrigerators or freezers, until they are ready for further distribution. These products are then distributed to retail outlets, healthcare facilities, or directly to consumers, still under temperature control. At retail, temperature-sensitive products are displayed in refrigerated or frozen units, which must be handled carefully to prevent temperature abuse. Finally, at the consumer or end-use stage, the consumer must store the products correctly, such as in refrigeration, to maintain their integrity until they are consumed or used. Each stage in the cold supply chain requires careful monitoring and handling to ensure that products remain safe, effective, and of high quality. So, transportation, storage, and retail stages demonstrated the highest temperature abuse rate [

9,

10].

The ongoing monitoring and regulation of food storage temperatures throughout all phases of the cold chain are essential components of ensuring food safety. Any disruption at any point in this chain can result in significant food waste, elevate the risk of foodborne illnesses, and lead to non-compliance with established safety regulations. Fortunately, advances in LoRaWAN technology have greatly enhanced the capabilities of wireless sensors, enabling them to effectively meet the stringent performance demands in the challenging environments of food service organisations. This includes a wide range of settings such as commercial restaurants, large warehouses, transport vehicles, and every other critical stage involved in maintaining the integrity of the food cold chain. This transformation not only enhances the efficiency of temperature monitoring but also reinforces the overall safety and quality of food products, ensuring they remain safe for consumption from production to the consumer’s plate [

10].

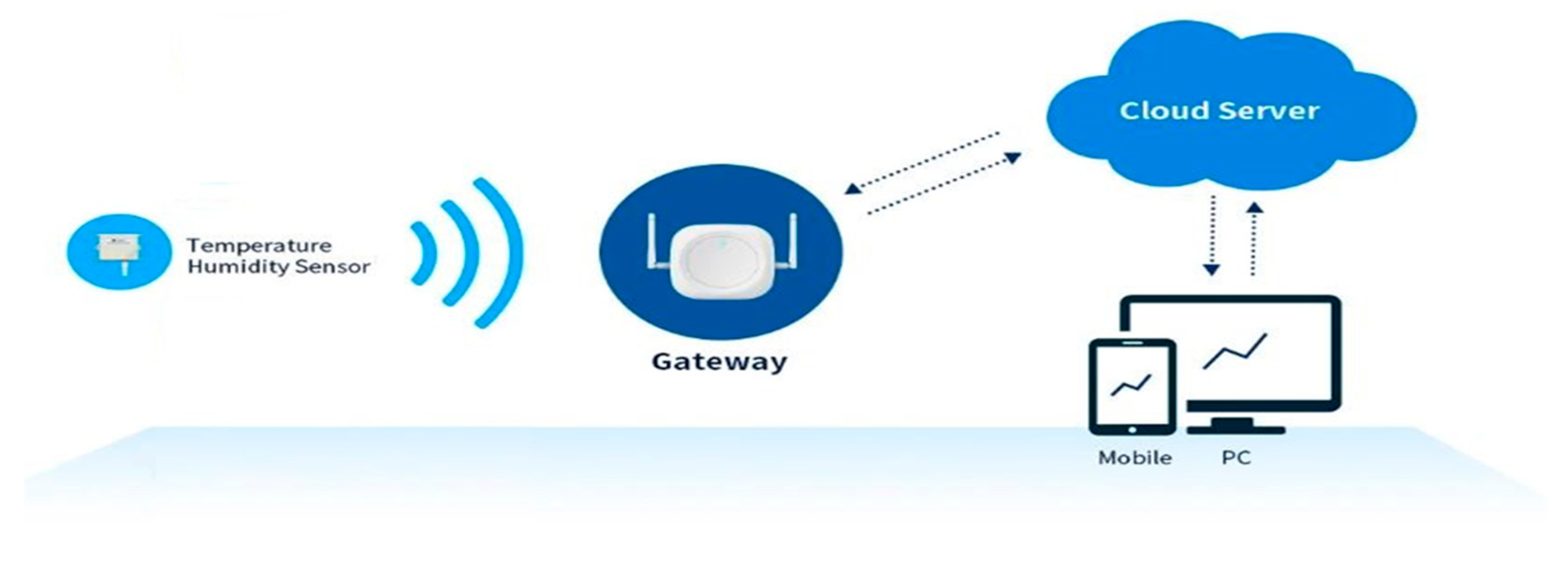

In recent years, advancements in wireless sensor networks have revolutionised how temperature monitoring is conducted, particularly in the food industry. This innovative approach enables the automated, real-time monitoring, measurement, and recording of temperature. By employing such an automatic system, organisations can significantly enhance food safety protocols, such as HACCP and FSMS, ensuring a continuous and reliable stream of temperature data is available around the clock—24 h a day, 7 days a week, and throughout the year. With immediate access to temperature data, companies can take swift action in the event of any temperature-related concerns. This proactive approach facilitates quicker problem resolutions and is crucial in minimising the risk of food spoilage and waste. Ultimately, implementing automated wireless temperature and humidity monitoring systems represents a significant step in maintaining high food safety standards and operational efficiency in the agrifood supply chain. Collecting temperature data is systematic and efficient, as it can be stored securely in the cloud. This cloud-based storage solution offers the convenience of accessing temperature records from any device connected to the internet, regardless of location.

2.2. Temperature and Humidity Control in Cold Chain Logistics

Monitoring temperature conditions during transport gained popularity in the business sector during the mid-2000s. This shift was marked by the widespread adoption of sophisticated data loggers and monitoring devices, which were integrated into shipments to mitigate risks associated with temperature variations. These technological advancements help ensure compliance with agreed-upon temperature ranges and provide a comprehensive history of temperature conditions throughout transit. The driving forces behind the evolution of temperature monitoring practices included a growing awareness of the potential risks associated with improper temperature management, increased regulatory requirements, and the demand for higher quality assurance standards. As a result, organisations have increasingly recognised the importance of implementing robust temperature monitoring systems to protect their valuable temperature-sensitive products during transportation [

4].

The primary rationale for utilising temperature and humidity monitoring devices is the critical need for continuous and real-time tracking of these environmental conditions. This vigilance is vital for determining whether the integrity and quality of temperature-sensitive products are at risk due to exposure to unfavourable or undesirable environmental factors. When selecting a monitoring device, it is essential to consider the user’s specific needs, which will determine whether an active or passive system is suitable. Based on the unique requirements of the product in question, the selected device (or sensors) can play a significant role in either approving or rejecting shipments. The nature of the information gathered by these sensors can vary significantly, as it is greatly influenced by the specific application for which the sensors are designed and the particular technology used in their operation. This nuanced selection process ensures that the monitoring systems are tailored to meet the specific operational demands and quality assurance standards necessary for efficiently handling sensitive products [

11].

It is imperative to maintain a specific low-temperature range and appropriate relative humidity to preserve the quality and integrity of perishable goods. Additionally, some products require even more extreme conditions, often referred to as ultralow temperature storage or deep freeze environments, to ensure their viability and safety. If the appropriate temperature is not consistently upheld throughout the storage and transportation processes, it can result in significant product degradation. This compromise affects the quality of the goods and can lead to substantial financial repercussions for businesses, as spoilt products may have to be discarded or result in customer dissatisfaction. Therefore, strict adherence to temperature and humidity control protocols is crucial in handling perishable items to avoid adverse outcomes [

12].

The temperature standards applicable to cold chain logistics can differ significantly based on the specific type of product being transported or stored. Regulatory authorities and industry organisations have developed comprehensive guidelines for managing temperature and humidity to ensure the quality and safety of products that are sensitive to temperature fluctuations. These standards ensure that such products remain safe for consumption and retain their intended quality throughout the supply chain. Overall, implementing these temperature standards is vital for effectively managing cold chain logistics, as they play a key role in ensuring that temperature-sensitive products reach their destination in optimal condition and are ready for consumption. Similarly, products like meat, dairy, and seafood must be maintained at temperatures between 0 °C and 5 °C during storage and transportation. This temperature control is vital for inhibiting bacterial growth, which can compromise food safety and lead to health risks if the products are not kept within the appropriate temperature range [

13]. For instance, when it comes to fresh produce, which includes a vast array of fruits and vegetables, the recommended temperature range for storage and transportation is typically between 0 °C and 5 °C. This specific temperature range is crucial for maintaining the freshness of the produce and preventing spoilage, which can occur rapidly if temperatures exceed this threshold. For frozen food items, including frozen meals and vegetables, strict temperature requirements mandate that these products be stored and transported at temperatures below −18 °C. Adhering to this standard is crucial to prevent spoilage and ensure that the quality of frozen products is maintained throughout the cold chain process [

14].

2.3. Advanced IoT Architectures and Smart Sensor Technologies

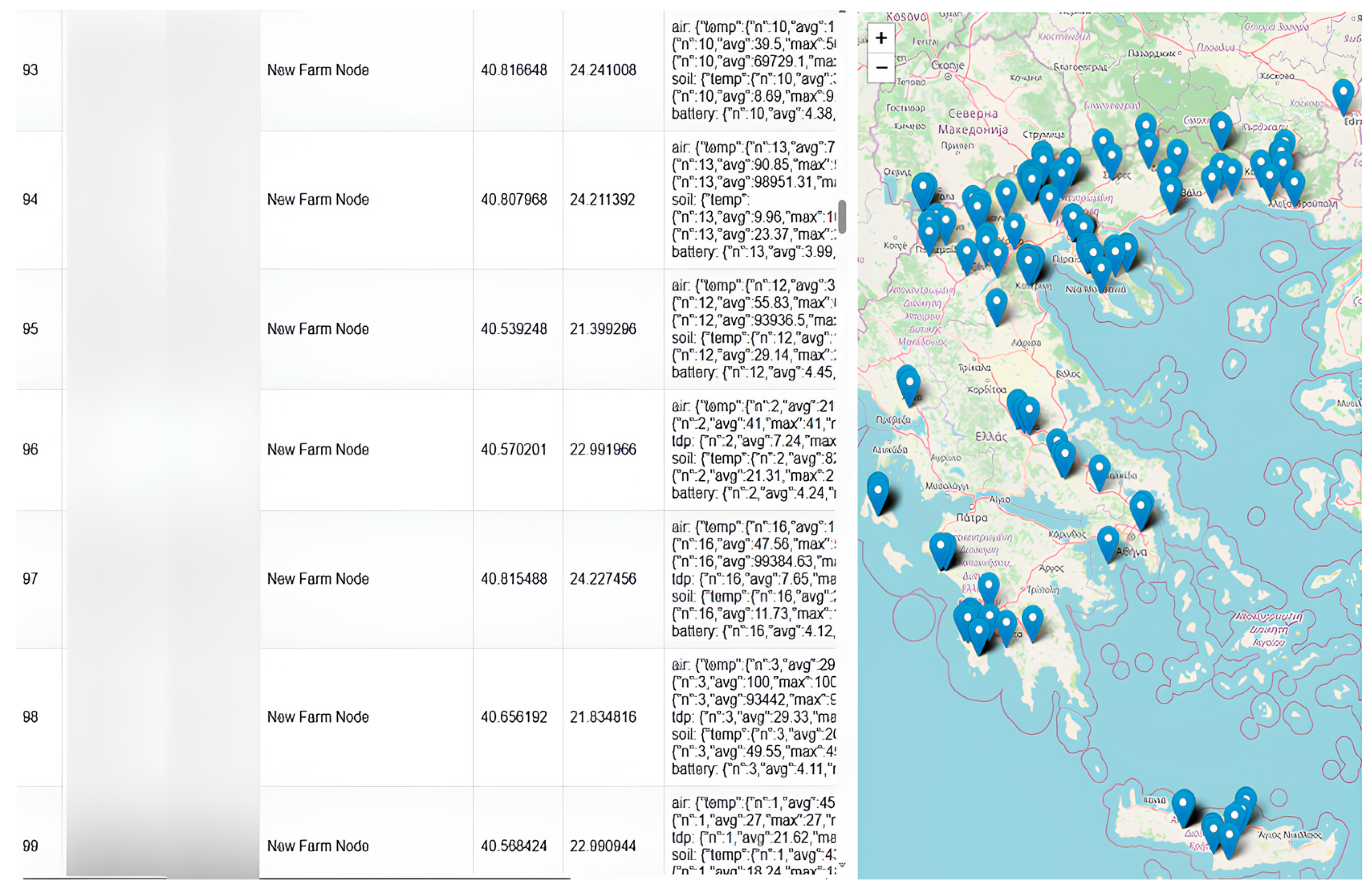

The utilisation of new IoT-based real-time monitoring technologies is a promising new field in agrifood supply chains, with applications in precision, traceability, visibility, and controllability. IoT is rapidly expanding and has the potential to become a massive source of data for agrifood supply chains. Although these new technologies are expected to lead to more efficient and sustainable food chains in the near future, limited attention has been given to their potential applications in the food sector. As a result, this study contributes to addressing the research gap in the lack of awareness about the applicability of real-time monitoring technologies based on IoT devices in the food sector, as well as the prevalent behaviours related to these technologies [

15].

However, significant literature reviews have successfully implemented IoT-based food quality monitoring using low-cost sensors. An innovative IoT-based food quality monitoring approach using low-cost sensors was initially implemented, where the system consisted of gas, temperature, and humidity sensors that provided the necessary information for assessing the quality of the packaged product [

16]. A real-time tracking system for estimating the shelf life of fruits and vegetables was subsequently implemented [

17]. A Blockchain-based Cold Chain Logistics Traceability System for fresh agricultural products was also developed. Finally, a systematic review of real-time food tracking technologies highlighted key elements of agrifood supply chains and IoT technologies [

18].

The continuous monitoring of specific quality characteristics of products during transport and storage throughout production and logistics processes is considered a cornerstone for ensuring product quality. In addition, often, even a slight deviation from the predetermined values, e.g., regarding the colour or smell of the product, results in the rejection of the product. Thus, integrating innovative sensors, combined with advances in food safety, has yielded promising results leading to the development of Intelligent Packaging (IP). During the monitoring of products at the package level, the sensors commonly used are passive and visual indicators of freshness due to their relatively low price. They are also valuable for the consumer, as they eliminate the possibility of unmonitored food deterioration in the event of mishandling during the transfer from the packaging to the fork. At the same time, sensors at the package level can be used to continuously validate the product’s expiration date, as the expiration date assumes retaining specific environmental conditions at all stages. Therefore, tracking at the product package level downstream in the cold supply chain is particularly important and can now be fully customised according to the product and the specific features of the supply chain.

Various innovative sensor device technologies are now available to collect information on packaged food products, e.g., external and internal sensors. First, external sensors are attached to the outside of the package. Examples of these devices are temperature and physical vibration sensors. The second type is placed inside the package, in the upper space, or attached to the lid, for example, biosensors and indicators of biological growth. The sensors could share the measurements by communicating with data collection and utilisation centres, using a 5-layer architecture, and operating in a cloud computing environment [

19].

Certain Internet of Things (IoT) applications, particularly those focused on monitoring the quality of agrifood products, have a distinct set of requirements that must be considered for effective implementation. These applications often require long-range communication capabilities to ensure data can be transmitted over significant distances without losing integrity or reliability. Additionally, they typically operate with low bit rates, meaning that the amount of data transmitted at any given time is minimal. This is particularly crucial for applications where bandwidth is limited or costly. Furthermore, low power consumption is crucial, as many IoT devices are deployed in environments where access to power sources is limited or nonexistent. This combination of requirements underscores the specialised nature of food quality monitoring applications within the broader IoΤ landscape, underscoring the need for tailored solutions to address these challenges effectively. Dominant technologies include LoRa/LoRaWAN, WiMAX, LTE-M, SigFox, and Narrowband IoT, characterised as medium- to long-range technologies, which possess many technological features that enable the reliable transmission of necessary data. At the same time, the required low energy is another significant feature.

Briefly comparing IoT technologies, short-range and narrowband technologies differ primarily in their coverage, frequency, and use cases. Short-range technologies, such as Wi-Fi, Bluetooth, and Near Field Communication (NFC), operate within limited distances, typically ranging from tens to hundreds of meters. They are designed for high-speed data transfer and are widely used in applications such as wireless connectivity, smart home devices, and wearable technology. These technologies operate at relatively high frequencies and are ideal for densely populated areas where rapid communication between devices is essential. On the other hand, narrowband-range technologies, like NB-IoT (Narrowband Internet of Things) and LoRa (Long Range), prioritise extended reach and power efficiency over high data rates. They are optimised for devices that communicate over longer distances, often spanning several kilometres, while consuming minimal energy. This makes them suitable for environmental monitoring, smart agriculture, and urban infrastructure management applications. While short-range technologies excel in local and immediate data exchange, narrowband technologies focus on low-power, long-distance communication, which is essential for IoT ecosystems. Concentrating on the LPWAN standards that match these requirements reveals that NB-IoT depends on previously established 3GPP networks and high-cost network deployments. It also has a narrower range than SigFox and LoRa. In terms of technological specifications, SigFox and LoRa are comparable. However, LoRa, among other things, has the advantage of being an open protocol that allows the creation of a low-cost network, unlike other corresponding wireless standards. As can be seen from the technical specifications review that follows, LoRa/LoRaWAN is considered the ideal protocol for developing the project, based on our requirements [

20].

LoRa, Wi-Fi, ZigBee, SigFox, and NB-IoT are wireless technologies commonly used in IoT applications, each with distinct characteristics. LoRa (Long Range) is designed for long-range, low-power communication, offering ranges of up to 15 km in rural areas and data rates between 0.3 and 27 kbps, making it ideal for IoT devices that require infrequent data transmission over large distances. Wi-Fi is a high-speed, short- to medium-range technology (up to 100 m) operating at 2.4 GHz and 5 GHz, with speeds reaching up to 9.6 Gbps, and is widely used for broadband internet and local area networks. ZigBee is a low-power, low-data-rate technology primarily used in home automation and sensor networks, supporting mesh networking for enhanced coverage. It typically operates in the 2.4 GHz range, with speeds of up to 250 kbps and a range of 10–100 m. SigFox operates in the unlicensed ISM bands and is optimised for ultra-low-power, low-data-rate communication, with a range of up to 50 km in rural areas and a data rate of around 100 bps, making it suitable for applications like asset tracking and environmental monitoring. NB-IoT (Narrowband IoT) is a cellular-based technology that offers deep coverage and low power consumption, operating in licensed spectrum and providing speeds of up to 250 kbps with a range that extends to underground or remote areas, making it ideal for innovative city applications, utilities, and agricultural monitoring. Each technology offers a trade-off between range, speed, and power consumption to meet specific use-case requirements.

The diversity of sensors available is contingent upon the underlying network architecture and connectivity protocols, each exhibiting distinct characteristics suitable for various applications. An initial categorisation of these sensors includes the following: a. Passive and Active, b. Analogue and Digital, as well as Scalar and Vector types. It is evident that each category possesses unique attributes; however, collectively, they encompass a wide array of static and dynamic characteristics. Active sensors function as detecting devices that necessitate an external power source; conversely, passive sensors solely detect and respond to specific inputs from the physical environment. Both active and passive sensing technologies play crucial roles in remote sensing applications, enabling observations and measurements at distances or scales that exceed human visual capacity. Furthermore, sensors are particularly valuable in extreme conditions and inaccessible areas where human presence may be impractical or impossible.