Comprehensive Study of the Mechanical and Tribological Properties of NiCr-Al Detonation Coatings

Abstract

1. Introduction

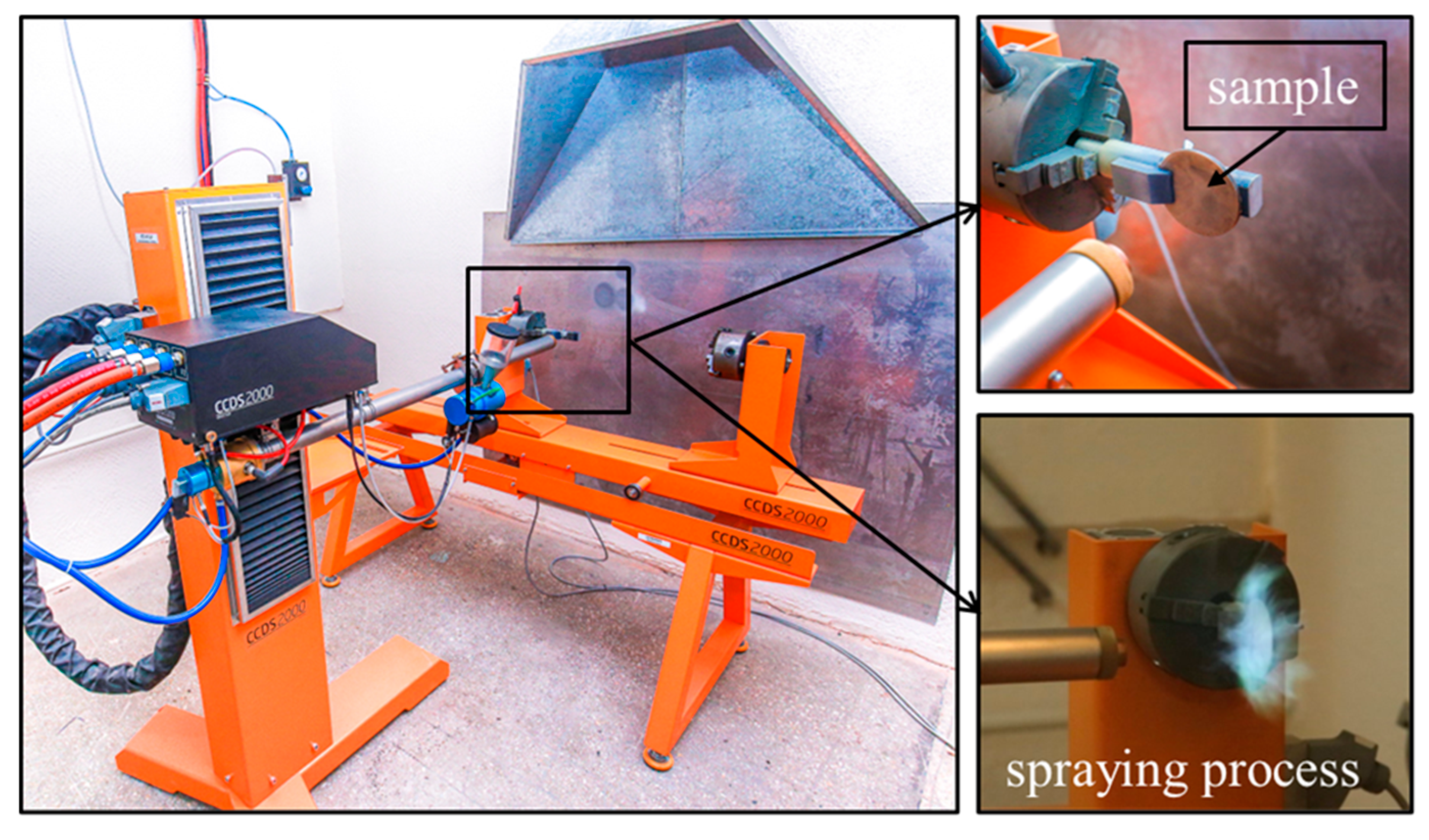

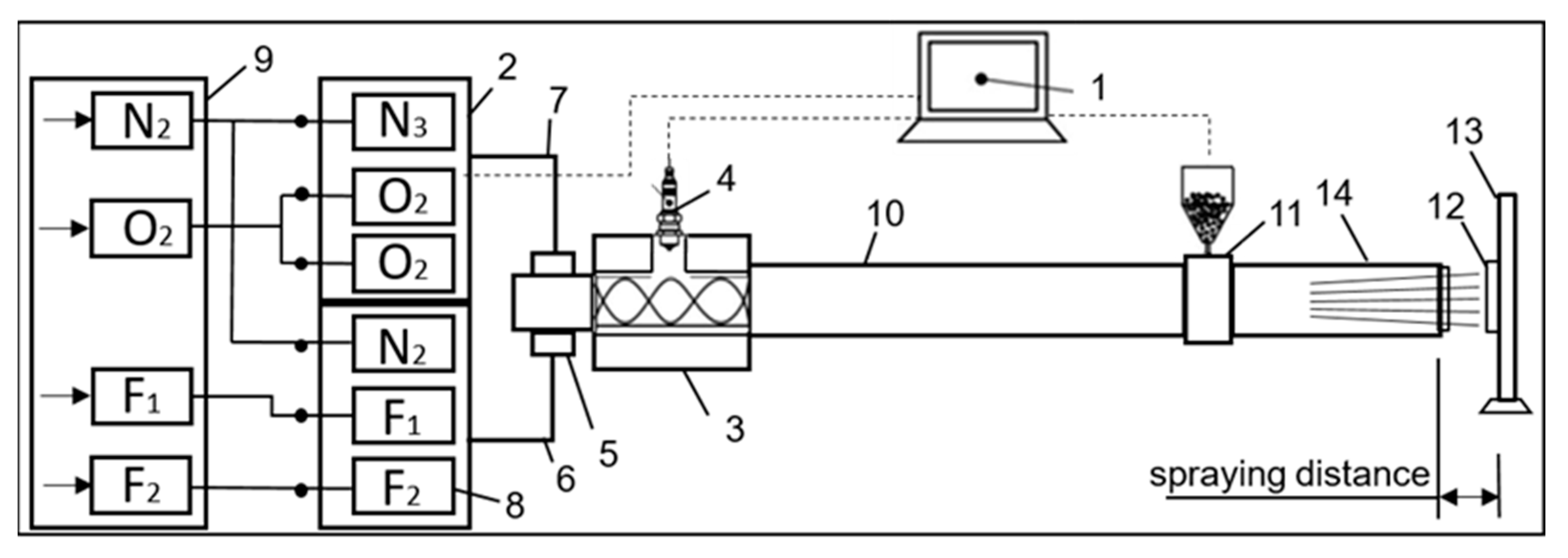

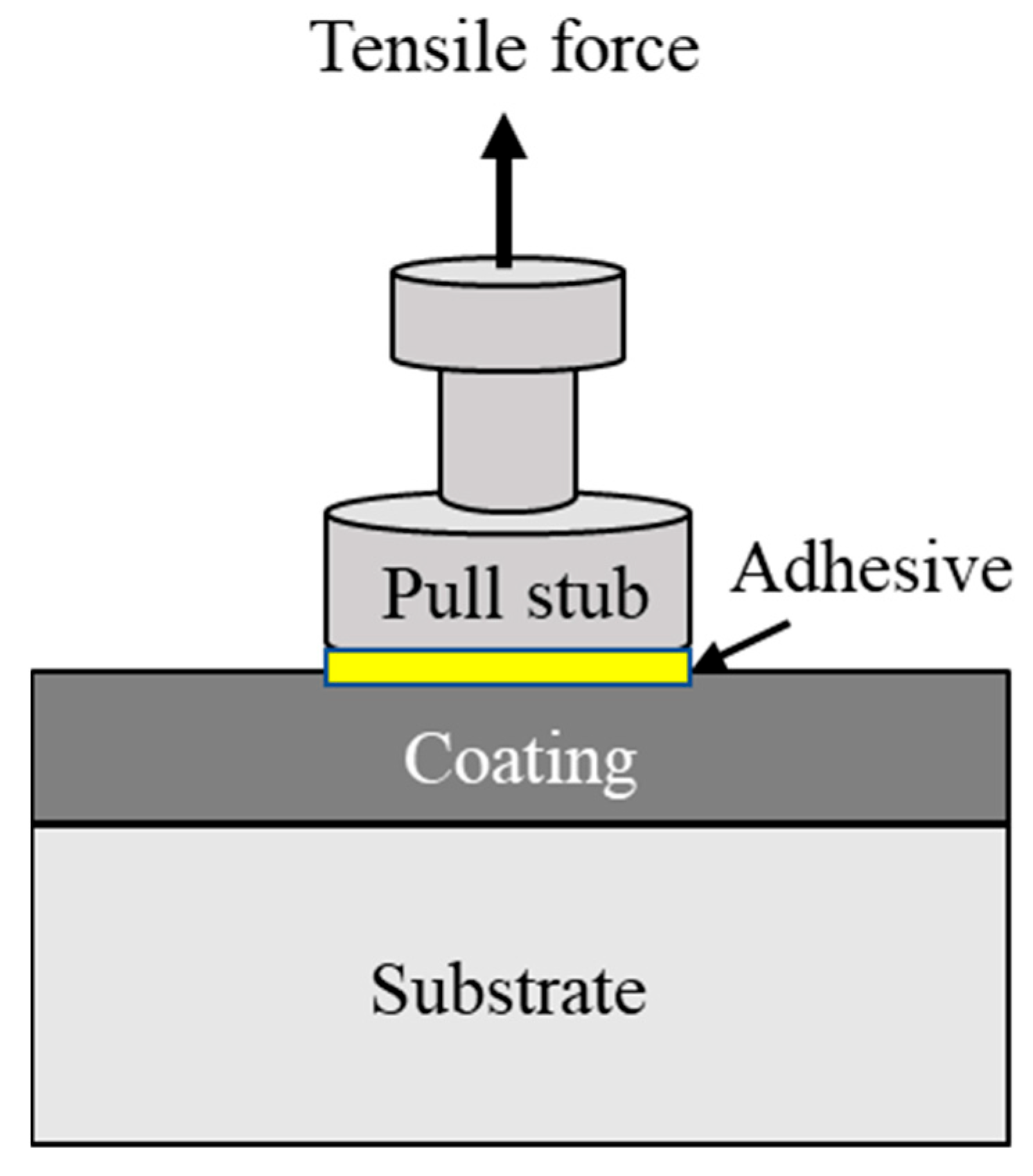

2. Materials and Methods

3. Results and Discussion

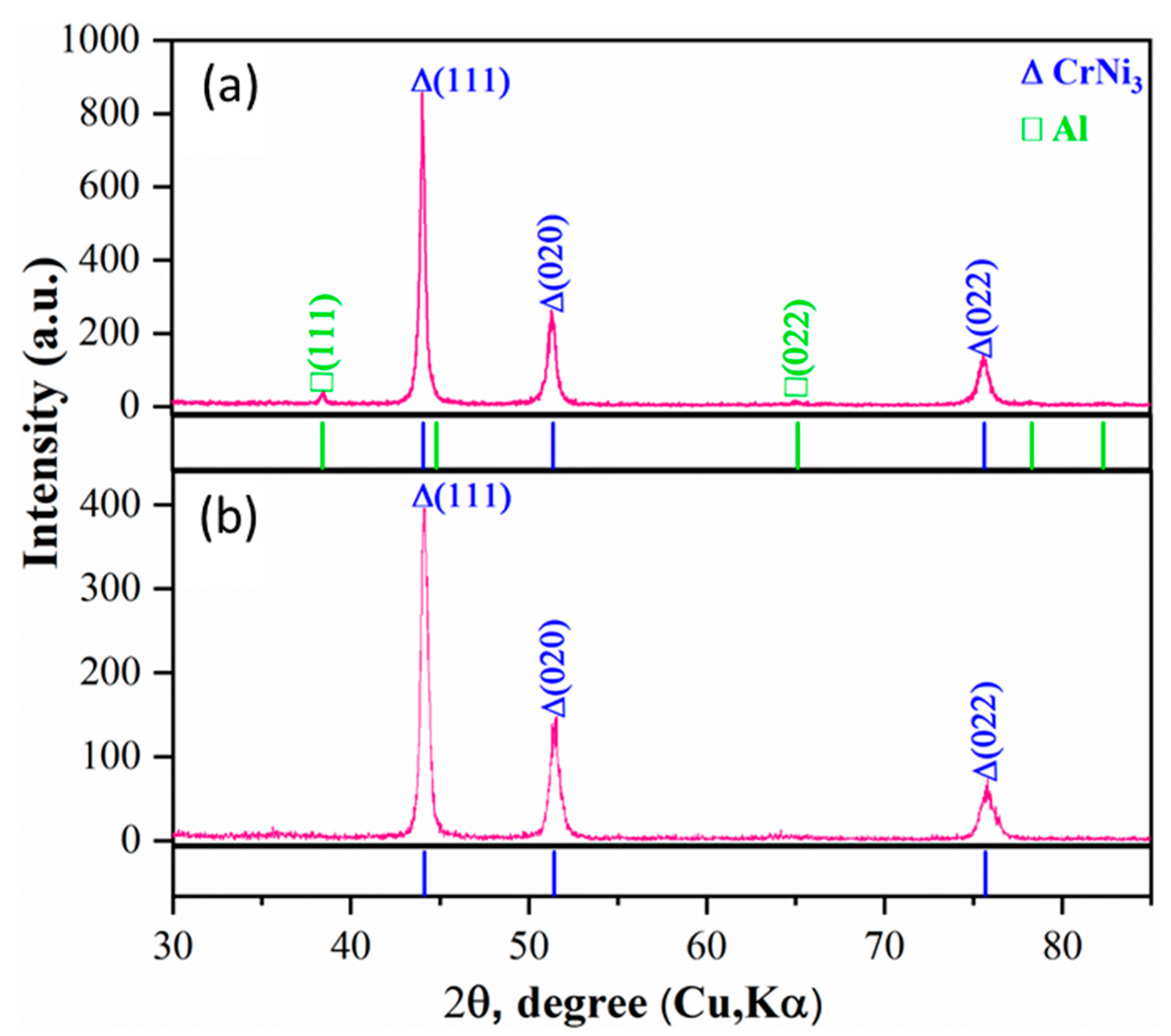

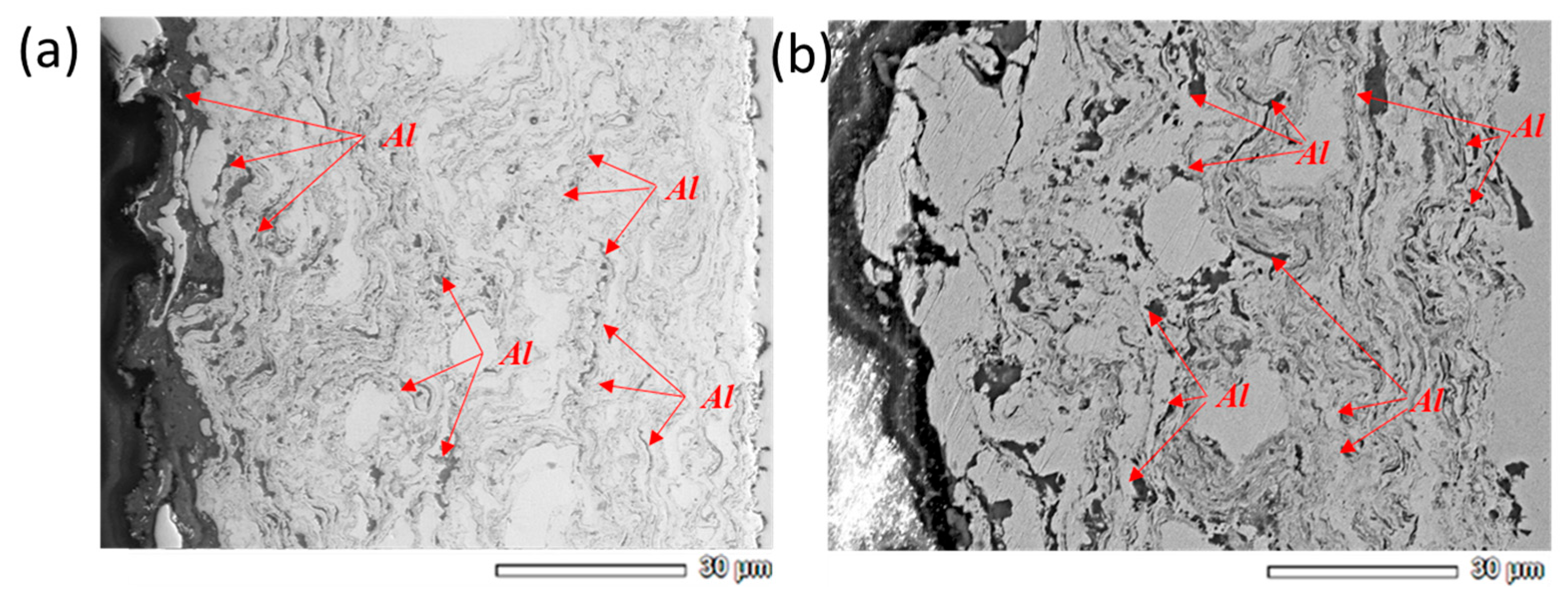

3.1. Microstructure and Phase Analysis

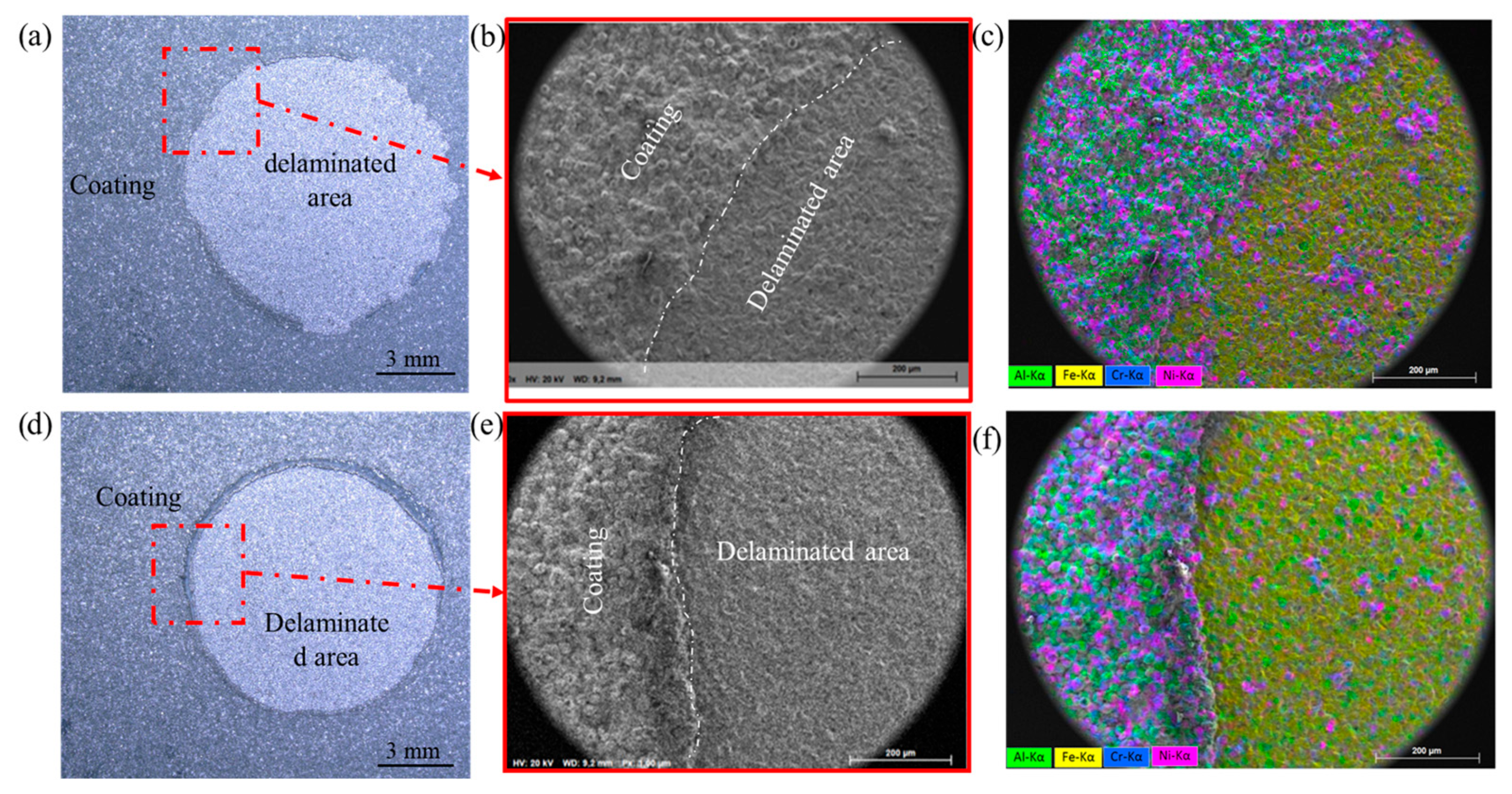

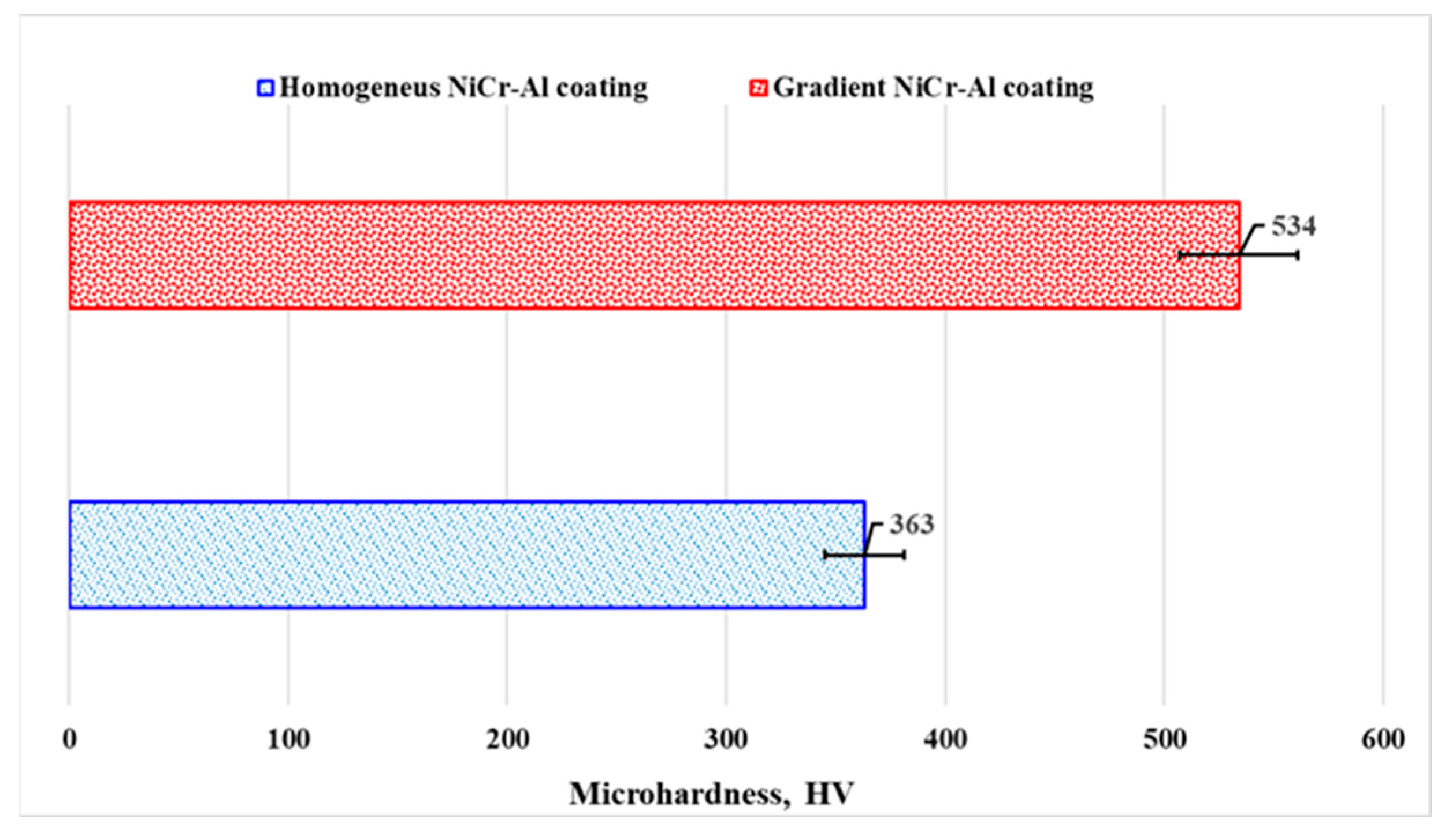

3.2. Mechanical Properties

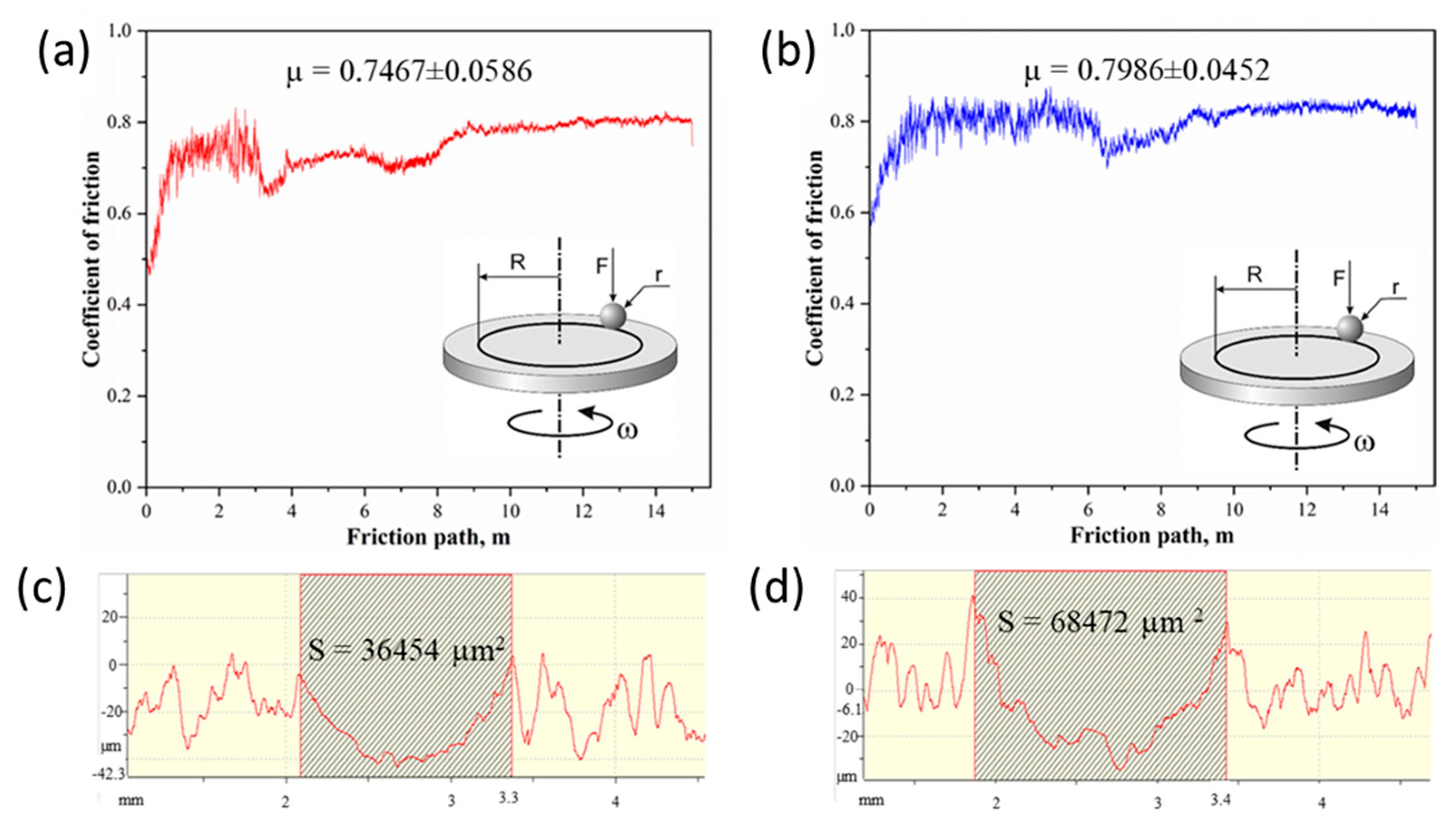

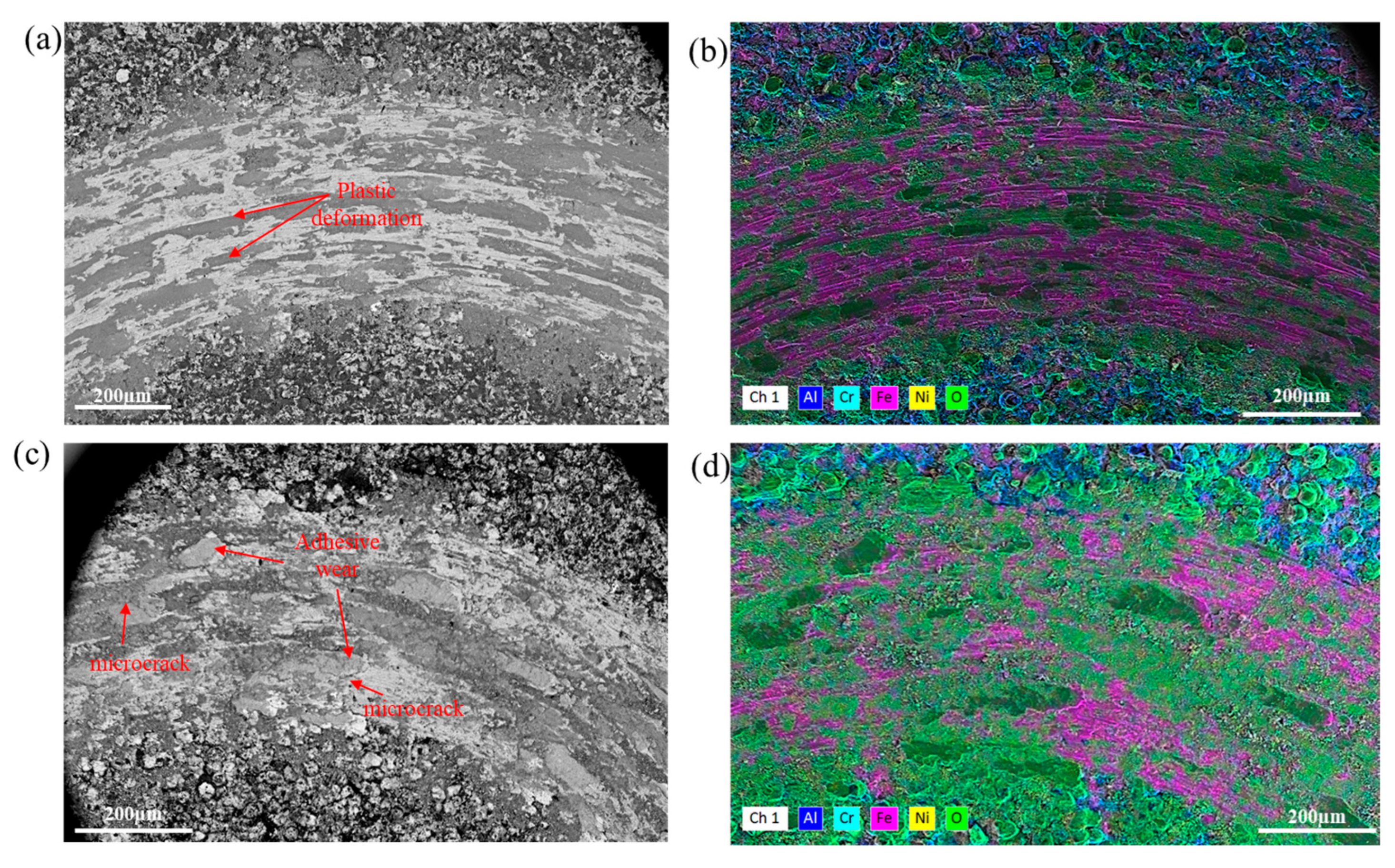

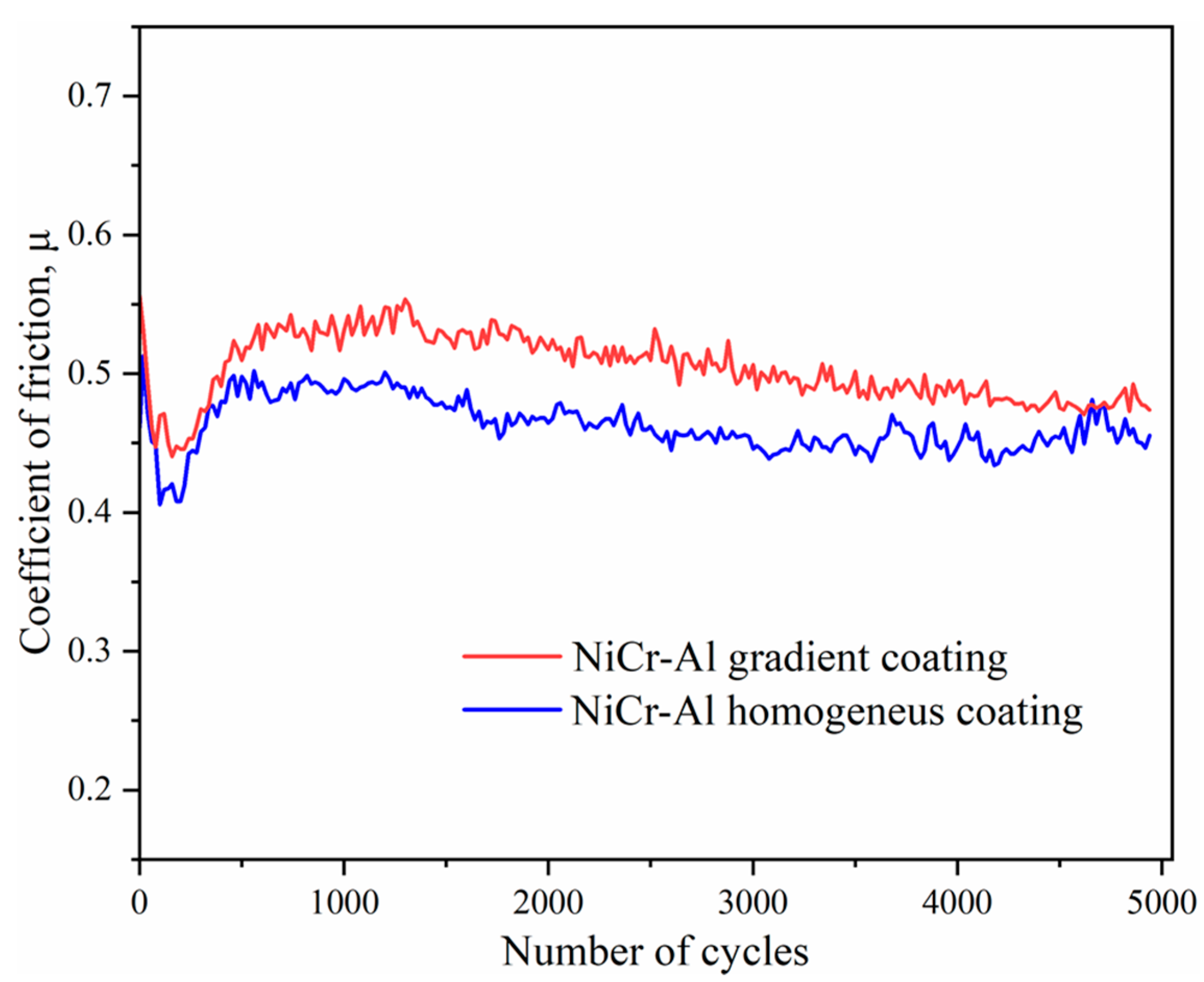

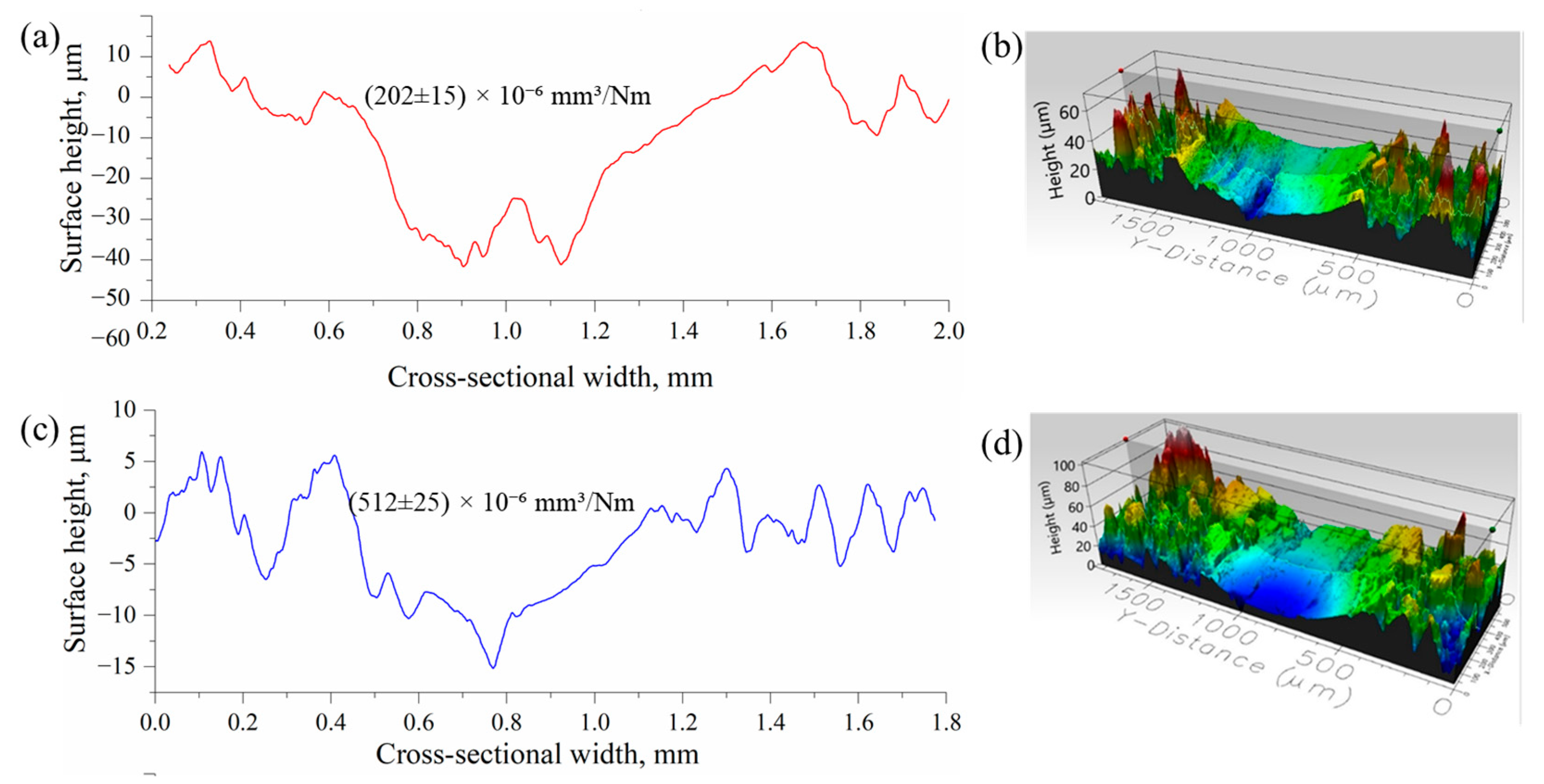

3.3. Wear Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Seraffon, M.; Simms, N.J.; Sumner, J.; Nicholls, J.R. Oxidation Behaviour of NiCrAl and NiCoCrAl Bond Coatings Under Industrial Gas Turbine Conditions. Oxid. Met. 2013, 81, 203–215. [Google Scholar] [CrossRef]

- Seraffon, M.; Simms, N.J.; Sumner, J.; Nicholls, J.R. The Development of New Bond Coat Compositions for Thermal Barrier Coating Systems Operating Under Industrial Gas Turbine Conditions. Surf. Coat. Technol. 2011, 206, 1529–1537. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, M.; Zhang, G.; Chang, M. Analysis of Superalloy Turbine Blade Tip Cracking During Service. Eng. Fail. Anal. 2006, 13, 1429–1436. [Google Scholar] [CrossRef]

- Poblano-Salas, C.A.; Cabral-Miramontes, J.A.; Gallegos-Melgar, A.; Ruiz-Luna, H.; Aguilar-Escobar, J.D.; Espinosa Arbelaez, D.G.; Espinoza-Beltran, F.; Trapaga Martinez, G.; Munoz-Saldana, J. Effects of VC additions on the mechanical properties of bimodal WC-Co HVOF thermal sprayed coatings measured by nanoindentation. Int. J. Refract. Met. Hard Mater. 2015, 48, 167–178. [Google Scholar] [CrossRef]

- Cabral-Miramontes, J.A.; Gaona-Tiburcio, C.; Almeraya-Calderon, F.; Estupinan-Lopez, F.H.; Pedraza-Basulto, G.K.; Poblano-Salas, C.A. Parameter Studies on High-Velocity Oxy-Fuel Spraying of CoNiCrAlY Coatings Used in the Aeronautical Industry. Int. J. Corros. 2014, 2014, 703806. [Google Scholar] [CrossRef]

- Gaona-Tiburcio, C.; Aguilar, L.M.R.; Zambrano Robledo, P.; Estupinan Lopez, F.; Cabral Miramontes, J.A.; Nieves-Mendoza, D.; Castillo-Gonzalez, E.; Almeraya-Calderon, F. Electrochemical Noise Analysis of Nickel Based Superalloys in Acid Solutions. Int. J. Electrochem. Sci. 2014, 9, 523–533. [Google Scholar] [CrossRef]

- Liang, G.Y.; Su, J.Y. The Microstructure and Tribological Characteristics of Laser-Clad Ni–Cr–Al Coatings on Aluminium Alloy. Mater. Sci. Eng. A 2000, 290, 207–212. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, Y.; Zhao, M.; Liu, P.; Qi, H.; Yang, Y. Impact of Al Nanoparticles upon the Microstructure and Wear Properties of Ni-Cr-Al Nanocomposite Coatings. J. Indian Chem. Soc. 2023, 100, 100822. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, T.; Fu, B.; Li, G.; Liu, Q.; Li, Y. Microstructure and Properties of Cold Sprayed NiCrAl Coating on AZ91D Magnesium Alloy. Coatings 2023, 11, 193. [Google Scholar] [CrossRef]

- Zhen, H.; Peng, X. A New Approach to Manufacture Oxidation-Resistant NiCrAl Overlay Coatings by Electrodeposition. Corros. Sci. 2019, 150, 121–126. [Google Scholar] [CrossRef]

- Peng, X.; Zhen, H.; Tian, L.; Wang, X.; Wang, K.; Xie, Y. A Novel Strategy to Apply Metallic Nanoparticles to Manufacture NiCrAl Composite Coatings Smartly Growing Chromia and Alumina. Compos. Part B Eng. 2022, 234, 109721. [Google Scholar] [CrossRef]

- Zhen, H.; Xie, Y.; Tian, L.; Peng, X. Discontinuous Oxidation in Wet Air of T91 with a Novel Al2O3-Forming NiCrAl Nanocomposite Coating in As-Deposited and Pre-Oxidized States. Surf. Coat. Technol. 2022, 449, 128937. [Google Scholar] [CrossRef]

- Mahesh, R.A.; Jayaganthan, R.; Prakash, S. Evaluation of Hot Corrosion Behaviour of HVOF Sprayed NiCrAl Coating on Superalloys at 900 °C. Mater. Chem. Phys. 2008, 111, 524–533. [Google Scholar] [CrossRef]

- Mahesh, R.A.; Rengaswamy, J.; Prakash, S. High Temperature Oxidation Studies on HVOF Sprayed NiCrAl Coatings on Superalloys. Surf. Eng. 2011, 27, 332–339. [Google Scholar] [CrossRef]

- Mahesh, R.A.; Rengaswamy, J.; Prakash, S. Evaluation of Hot Corrosion Behaviour of HVOF Sprayed Ni–5Al and NiCrAl Coatings in Coal Fired Boiler Environment. Surf. Eng. 2010, 26, 413–421. [Google Scholar] [CrossRef]

- Aristu, D.; Carlos, B.-L.; Alberro, M.; Rández, X.; Fernández, A.G. A Comprehensive Study on Hot Corrosion Resistance of NiCoCrAlYTa and NiCrAl Thermal-Sprayed Coatings for CSP Applications. J. Energy Storage 2023, 74, 109346. [Google Scholar] [CrossRef]

- Celik, E.; Ozdemir, I.; Avci, E.; Tsunekawa, Y. Corrosion Behaviour of Plasma Sprayed Coatings. Surf. Coat. Technol. 2005, 193, 297–302. [Google Scholar] [CrossRef]

- Stathopoulos, V.; Sadykov, V.; Pavlova, S.; Bespalko, Y.; Fedorova, Y.; Bobrova, L.; Salanov, A.; Ishchenko, A.; Stoyanovsky, V.; Larina, T.; et al. Design of Functionally Graded Multilayer Thermal Barrier Coatings for Gas Turbine Application. Surf. Coat. Technol. 2016, 295, 20–28. [Google Scholar] [CrossRef]

- Ghadami, F.; Sabor Rouh Aghdam, A.; Ghadami, S. Microstructural Characteristics and Oxidation Behavior of the Modified MCrAlX Coatings: A Critical Review. Vacuum 2021, 185, 109980. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Saleh, B. A Critical Review on Functionally Graded Coatings: Methods, Properties, and Challenges. Compos. Part B Eng. 2021, 225, 109278. [Google Scholar] [CrossRef]

- Latka, L.; Pawlowski, L.; Winnicki, M.; Sokolowski, P.; Malachowska, A.; Kozerski, S. Review of Functionally Graded Thermal Sprayed Coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Fethi, R.; Wei, H.; Saleh, B.; Radhika, N.; Jiang, J.; Ma, A.; Ahmed, M.H.; Li, Q.; Ostrikov, K.K. Past and Present of Functionally Graded Coatings: Advancements and Future Challenges. Appl. Mater. Today 2022, 26, 101373. [Google Scholar] [CrossRef]

- Kumar, A.; Patnaik, P.C.; Chen, K. Damage Assessment and Fracture Resistance of Functionally Graded Advanced Thermal Barrier Coating Systems: Experimental and Analytical Modeling Approach. Coatings 2020, 10, 474. [Google Scholar] [CrossRef]

- EL-Galy, I.M.; Bassiouny, B.I.; Ahmed, M.H. Empirical Model for Dry Sliding Wear Behavior of Centrifugally Cast Functionally Graded Composite Based on Pure Al/SiCp. IOP Conf. Ser. Mater. Sci. Eng. 2018, 786, 276–285. [Google Scholar] [CrossRef]

- Su, Y.; Chen, B.; Tan, C.; Song, X.; Feng, J. Influence of Composition Gradient Variation on the Microstructure and Mechanical Properties of 316L/Inconel718 Functionally Graded Material Fabricated by Laser Additive Manufacturing. J. Mater. Process. Technol. 2020, 283, 116702. [Google Scholar] [CrossRef]

- Uysal, M.U. Numerical Modeling of Functional Graded TiB Coating in Nanoindentation on Determination of Mechanical Properties. Mater. Today Proc. 2015, 2, 217–223. [Google Scholar] [CrossRef]

- Saleh, B.; Ahmed, M. Wear Characteristics of Functionally Graded Tubes Reinforced with Silicon Carbide and Alumina: A Comparative Study. Trans. Nanjing Univ. Aeronaut. Astronaut. 2021, 38, 76–83. [Google Scholar]

- Lv, B.; Fan, X.; Li, D.; Wang, T.J. Towards Enhanced Sintering Resistance: Air-Plasma-Sprayed Thermal Barrier Coating System with Porosity Gradient. J. Eur. Ceram. Soc. 2018, 38, 1946–1956. [Google Scholar] [CrossRef]

- Vaßen, R.; Rauwald, K.H.; Guillon, O.; Aktaa, J.; Weber, T.; Back, H.C.; Qu, D.; Gibmeier, J. Vacuum Plasma Spraying of Functionally Graded Tungsten/EUROFER97 Coatings for Fusion Applications. Fusion Eng. Des. 2018, 133, 148–156. [Google Scholar] [CrossRef]

- Kumar, S.; Reddy, K.; Kumar, A.; Devi, G. Development and Characterization of Polymer–Ceramic Continuous Fiber Reinforced Functionally Graded Composites for Aerospace Application. Aerosp. Sci. Technol. 2013, 26, 185–191. [Google Scholar] [CrossRef]

- Pasupuleti, K.T.; Dsouza, S.; Thejaraju, R.; Venkataraman, S.; Ramaswamy, P.; Murty, N. Performance and Steady State Heat Transfer Analysis of Functionally Graded Thermal Barrier Coatings Systems. Mater. Today Proc. 2018, 5, 27936–27945. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.; Zou, J.; Lin, X.; Liu, Z.; Yu, Y.; Wang, Z.; Zeng, Q.; Chen, W.; Tian, L.; et al. In-Situ Fabrication of Gradient Titanium Oxide Ceramic Coating on Laser Surface Textured Ti6Al4V Alloy with Improved Mechanical Property and Wear Performance. Vacuum 2020, 176, 109327. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, M.C.; Park, C.G. Evaluation of Functionally Graded Thermal Barrier Coatings Fabricated by Detonation Gun Spray Technique. Surf. Coat. Technol. 2003, 168, 275–280. [Google Scholar] [CrossRef]

- Kumar, R.R.; Maruno, S. Functionally Graded Coatings of HA-G-Ti Composites and Their In Vivo Studies. Mater. Sci. Eng. A 2002, 334, 156–162. [Google Scholar] [CrossRef]

- Anil Kumar, R.; Radhika, N. Enhancement of Mechanical and Wear Properties of Tungsten Carbide Coated AA 6063 Alloy Using Detonation Gun Technique. Trans. Inst. Met. Finish. 2018, 96, 212–219. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Buitkenov, D.; Sagdoldina, Z.; Idrisheva, Z.; Zhamanbayeva, M.; Kakimzhanov, D. Preparation and Characterization of NiCr/NiCr-Al2O3/Al2O3 Multilayer Gradient Coatings by Gas Detonation Spraying. Coatings 2021, 11, 1524. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kakimzhanov, D.N.; Buitkenov, D.B.; Kozhanova, R.S.; Zhurerova, L.G.; Sagdoldina, Z.B. Tribological and Mechanical Properties of Gradient Coating on Al2O3-Based Coating Produced by Detonation Spraying Methods. Hindawi Adv. Tribol. 2023, 2023, 1520135. [Google Scholar] [CrossRef]

- Kakimzhanov, D.; Rakhadilov, B.; Sulyubayeva, L.; Dautbekov, M. Influence of Pulse-Plasma Treatment Distance on Structure and Properties of Cr3C2-NiCr-Based Detonation Coatings. Coatings 2023, 13, 1824. [Google Scholar] [CrossRef]

- Buitkenov, D.; Nabioldina, A.; Raisov, N. Development of Method for Applying Multilayer Gradient Thermal Protective Coatings Using Detonation Spraying. Coatings 2024, 14, 899. [Google Scholar] [CrossRef]

- Buitkenov, D.; Rakhadilov, B.K.; Nabioldina, A.; Mukazhanov, Y.; Adilkanova, M.; Raisov, N. Investigation of Structural Phase, Mechanical, and Tribological Characteristics of Layer Gradient Heat-Protective Coatings Obtained by the Detonation Spraying Method. Materials 2024, 17, 5253. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Maulet, M.; Abilev, M.; Sagdoldina, Z.; Kozhanova, R. Structure and Tribological Properties of Ni-Cr-Al Based Gradient Coating Prepared by Detonation Spraying. Coatings 2021, 11, 218. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Sagdoldina, Z.; Maulet, M.; Buitkenov, D.; Sulubayeva, L. Method of Obtaining Functionally Gradient Coating. Patent for Utility Model. No. 8922, Republic of Kazakhstan, 7 March 2024. [Google Scholar]

- Rakhadilov, B.; Sulyubayeva, L.; Maulet, M.; Sagdoldina, Z.; Buitkenov, D.; Issova, A. Investigation of High-Temperature Oxidation of Homogeneous and Gradient Ni-Cr-Al Coatings Obtained by Detonation Spraying. Coatings 2024, 14, 11. [Google Scholar] [CrossRef]

- ISO 4955; Heat-Resistant Steels. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- Nikolaev, Y.A.; Vasiliev, A.A.; Ulianitsky, V.Y. Gas detonation and its application in engineering and technologies (Review). Combust. Explos. Shock Waves 2003, 39, 382–410. [Google Scholar] [CrossRef]

- ISO 14916; Thermal Spraying — Determination of Tensile Adhesive Strength. International Organization for Standardization (ISO): Geneva, Switzerland, 2017.

- GOST R ISO 6507-1-2007; Metallic Materials — Vickers Hardness Test — Part 1: Test Method. Standartinform (Federal Agency on Technical Regulating and Metrology): Moscow, Russia, 2008.

- GOST R 8.748-2011; State System for Ensuring the Uniformity of Measurements. Metallic Materials. Instrumented Indentation Test for Hardness and Materials Parameters. Part 1: Test Method. Standartinform (Federal Agency for Technical Regulation and Metrology): Moscow, Russia, 2013.

- ASTM G 99; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

- ISO 20808:2016; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics) — Determination of Friction and Wear Characteristics of Monolithic Ceramics by Ball-on-Disc Method. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- ISO 13565-1:1996; Geometrical Product Specifications (GPS) — Surface Texture: Profile Method — Surfaces Having Stratified Functional Properties — Part 1: Filtering and General Measurement Conditions. International Organization for Standardization (ISO): Geneva, Switzerland, 1996.

- Sundararajan, T.; Kuroda, S.; Abe, F. Steam oxidation resistance of two-layered Ni–Cr and Al APS coating for USC boiler applications. Corros. Sci. 2005, 47, 1129–1147. [Google Scholar] [CrossRef]

- Makesh, R.A.; Jayaganthan, R.; Prakash, S. Microstructural characteristics and mechanical properties of HVOFsprayed NiCrAl coating on superalloys. J. Alloys Compd. 2009, 468, 392–405. [Google Scholar]

- Vaz, R.F.; Sucharski, G.B.; Chicoski, A.; Siqueira, I.B.; Tristante, R.; Pukasiewicz, A.G. Comparison of FeMnCrSi Cavitation Resistance Coatings Deposited by Twin-Wire Electric Arc and High-Velocity Oxy-Fuel Processes. J. Therm. Spray Technololgy 2021, 30, 754–771. [Google Scholar] [CrossRef]

- Vaz, R.F.; Silvello, A.; Sanchez, J.; Albaladejo, V.; Cano, I.G. The Influence of the Powder Characteristics on 316L Stainless Steel Coatings Sprayed by Cold Gas Spray. Coatings 2021, 11, 168. [Google Scholar] [CrossRef]

| Coating Structure | O2/C2H2 | Spraying Distance, mm | Barrel Filling Volume, % | Number of Shots |

|---|---|---|---|---|

| Homogeneous | 1.856 | 150 | 50 | 40 |

| Gradient | 1.856 | 150 | 50 | 10 |

| 40 | 10 | |||

| 30 | 10 | |||

| 25 | 10 |

| Coating Structure | Phase Composition | Adhesion, MPa | Microhardness, HV | Tribometer TRB3 | Tribometer T-21 | ||

|---|---|---|---|---|---|---|---|

| µ | Wv, mm3/N × m | µ | mm3/N × m | ||||

| Homogeneous | CrNi3 | 25.4 ± 3.1 | 363 ± 10 | 0.80 ± 0.04 | (5.73 ± 0.30) × 10−3 | 0.50 ± 0.03 | (512 ± 25) × 10−6 |

| Gradient | CrNi3, Al | 38.7 ± 6.9 | 534 ± 12 | 0.74 ± 0.05 | (3.13 ± 0.20) × 10−3 | 0.46 ± 0.02 | (202 ± 15) × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagdoldina, Z.; Rakhadilov, B.; Maulet, M.; Sulyubayeva, L.; Drenda, C.; Bolatov, S. Comprehensive Study of the Mechanical and Tribological Properties of NiCr-Al Detonation Coatings. Appl. Sci. 2025, 15, 7513. https://doi.org/10.3390/app15137513

Sagdoldina Z, Rakhadilov B, Maulet M, Sulyubayeva L, Drenda C, Bolatov S. Comprehensive Study of the Mechanical and Tribological Properties of NiCr-Al Detonation Coatings. Applied Sciences. 2025; 15(13):7513. https://doi.org/10.3390/app15137513

Chicago/Turabian StyleSagdoldina, Zhuldyz, Bauyrzhan Rakhadilov, Meruyert Maulet, Laila Sulyubayeva, Cezary Drenda, and Sanzhar Bolatov. 2025. "Comprehensive Study of the Mechanical and Tribological Properties of NiCr-Al Detonation Coatings" Applied Sciences 15, no. 13: 7513. https://doi.org/10.3390/app15137513

APA StyleSagdoldina, Z., Rakhadilov, B., Maulet, M., Sulyubayeva, L., Drenda, C., & Bolatov, S. (2025). Comprehensive Study of the Mechanical and Tribological Properties of NiCr-Al Detonation Coatings. Applied Sciences, 15(13), 7513. https://doi.org/10.3390/app15137513