Waste as a Source of Fuel and Developments in Hydrogen Storage: Applied Cases in Spain and Their Future Potential

Abstract

1. Introduction

2. Materials and Methods

2.1. Potential for Replication

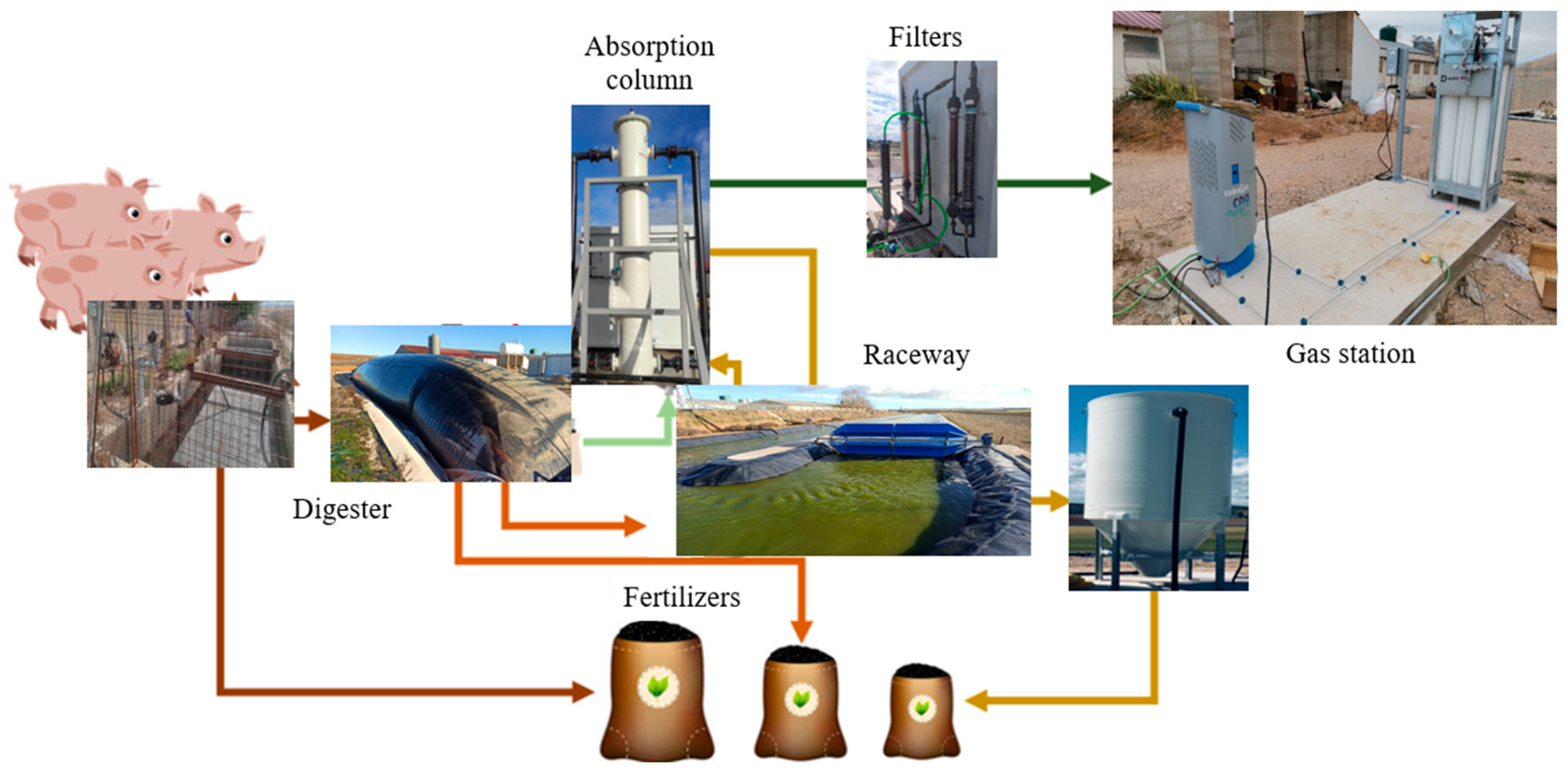

2.1.1. Biomethane Production from Pig Manure

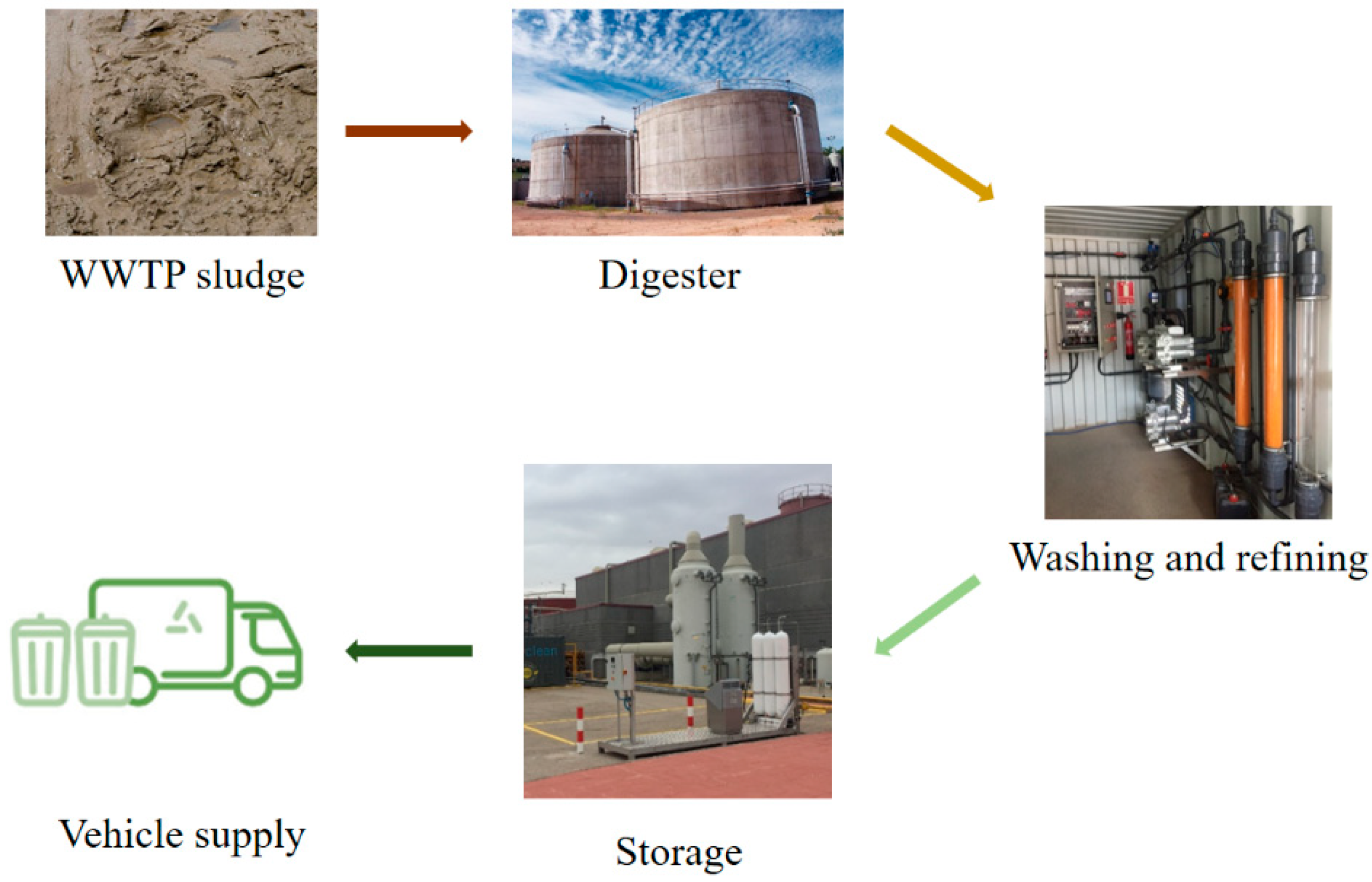

2.1.2. Biomethane Production from WWTP

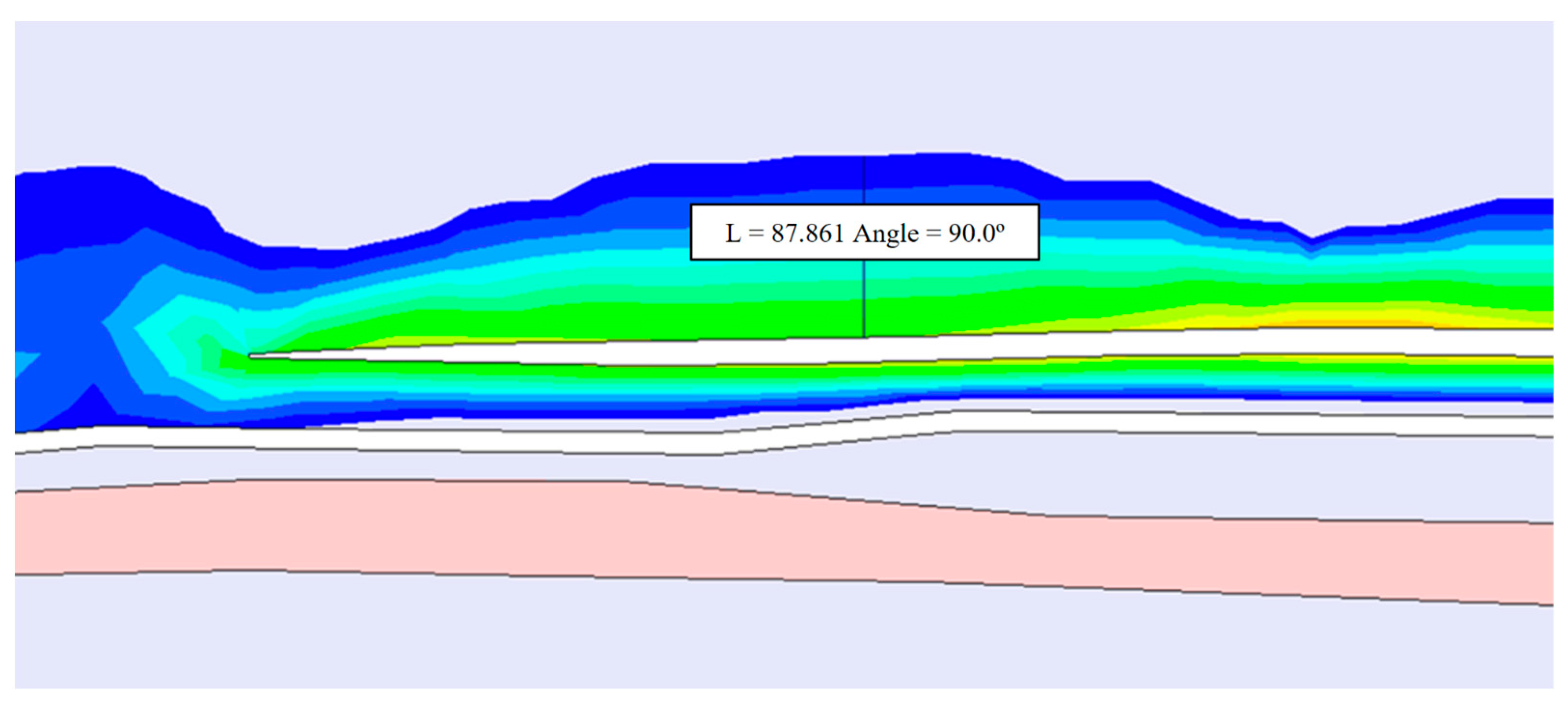

2.1.3. Hydrogen Storage

- For depleted hydrocarbon deposits and aquifers, the density of hydrogen is considered at the lithostatic pressure. The lithostatic pressure is dependent on the depth, as 10 MPa/km [37]. According to data obtained for different storages, the density of hydrogen for depleted hydrocarbon deposits is 16 kg/m3 (considering an average depth of 2.2 km), and for aquifers, it is 6.56 kg/m3 (considering an average depth of 800 m). The low heating value (LHV) for hydrogen is 120 MJ/kg [38].

- For salt caverns formed in diapirs, the energy density is considered to be 280 kWh/m3 [39], and for caves of 500,000 m3 [39]. In Appendix A, there is a detailed table of caverns considered.

- The potential of hydrogen would represent only the operational volume of the storage, not the total volume. The operation volume is considered as 60% of the total volume [40].

3. Results and Discussion

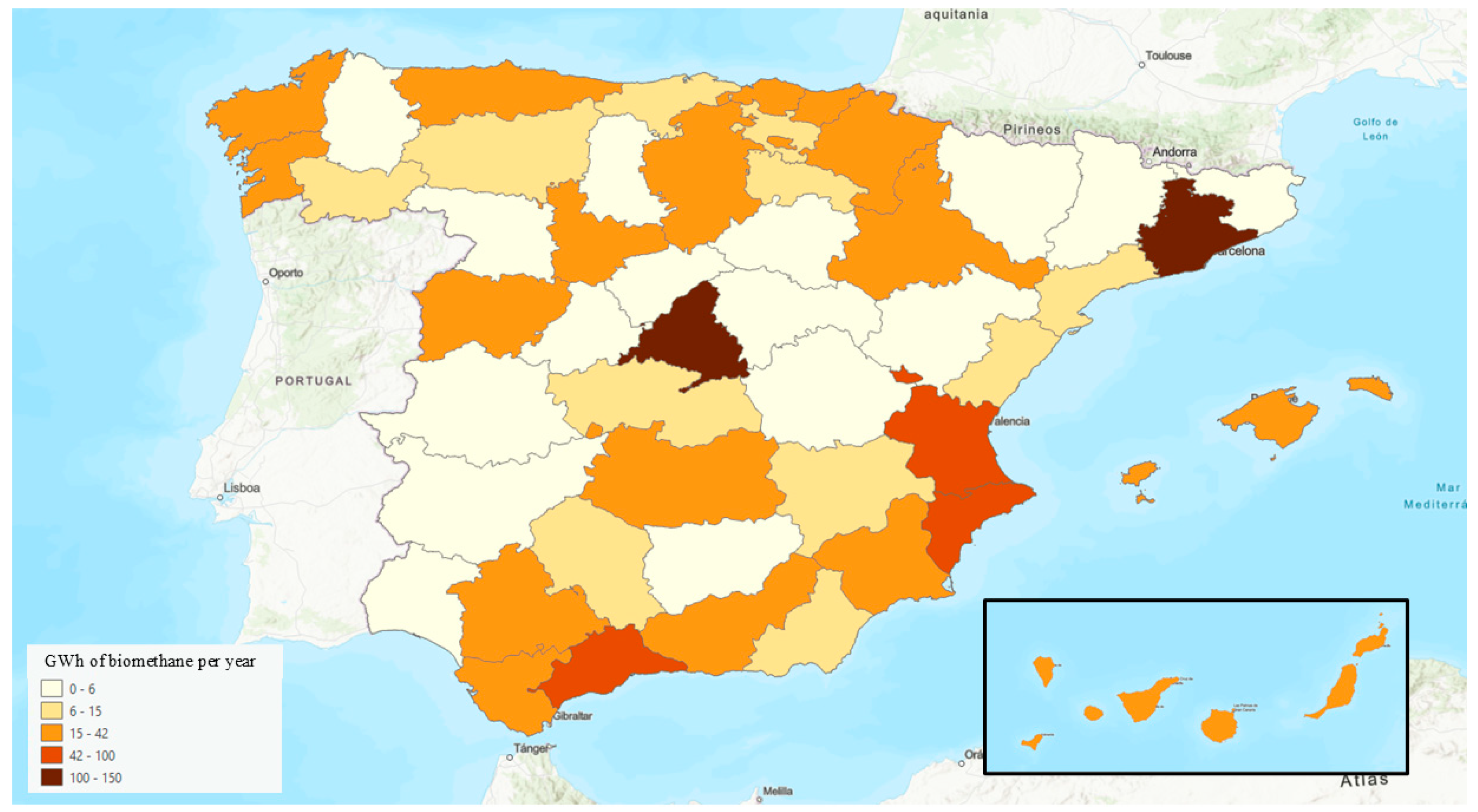

3.1. Potential Replication of Biomethane Production from Pig Manure

3.2. Potential Replication of Biomethane Production from WWTP

3.3. Potential Replication of Hydrogen Storage

3.4. End-Use Applications for Biomethane and Hydrogen

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GHG | Greenhouse gas |

| UHS | Underground Hydrogen Storage |

| LHV | Low Heating Value |

| VS | Volatile Solids |

| WWTPs | Wastewater treatment plants |

Appendix A

| Name | Province | Volume (m3) |

|---|---|---|

| Poza de la Sal | Burgos | 500,000 |

| Lorca | Navarra | 500,000 |

| Arteta | Navarra | 500,000 |

| Salinas de Oro y falla de Etxauri | Navarra | 500,000 |

| Estella | Navarra | 500,000 |

| Madax | Albacete | 500,000 |

| Contacto mecánico entre el diapiro triásico y la serie miocena en El Cenajo. | Albacete | 500,000 |

| Rosa | Murcia | 500,000 |

| Morrón | Murcia | 500,000 |

| Pinoso | Alicante | 500,000 |

Appendix B

Appendix B.1

| Province | Swine Heads [26] | Outdoor Temperature (°C) [57] | Boiler Percentage | m3 of Biomethane per Year | GWh of Biomethane per Year |

|---|---|---|---|---|---|

| Almería | 463,375 | 21 | 28% | 6,193,771 | 83.02 |

| Cádiz | 80,288 | 20 | 28% | 1,067,335 | 14.31 |

| Córdoba | 293,195 | 20 | 29% | 3,865,661 | 51.81 |

| Granada | 271,841 | 17 | 34% | 3,316,890 | 44.46 |

| Huelva | 232,467 | 20 | 29% | 3,056,522 | 40.97 |

| Jaén | 126,982 | 19 | 31% | 1,627,976 | 21.82 |

| Málaga | 398,280 | 21 | 27% | 5,352,670 | 71.74 |

| Sevilla | 680,281 | 19 | 30% | 8,795,862 | 117.89 |

| Huesca | 1,858,293 | 16 | 37% | 21,523,942 | 288.49 |

| Teruel | 609,917 | 14 | 41% | 6,620,329 | 88.73 |

| Zaragoza | 1,648,848 | 17 | 35% | 19,818,397 | 265.63 |

| Asturias | 7319 | 14 | 40% | 81,309 | 1.09 |

| Illes Balears | 85,739 | 19 | 31% | 1,092,976 | 14.65 |

| Las Palmas | 15,265 | 23 | 23% | 217,380 | 2.91 |

| Santa Cruz de Tenerife | 22,666 | 23 | 23% | 321,949 | 4.32 |

| Cantabria | 2082 | 16 | 37% | 24,267 | 0.33 |

| Ávila | 246,374 | 12 | 44% | 2,557,650 | 34.28 |

| Burgos | 509,874 | 13 | 43% | 5,330,215 | 71.44 |

| León | 139,299 | 13 | 42% | 1,496,803 | 20.06 |

| Palencia | 136,224 | 14 | 41% | 1,488,560 | 19.95 |

| Salamanca | 662,676 | 14 | 40% | 7,289,508 | 97.70 |

| Segovia | 1,281,574 | 14 | 41% | 13,864,154 | 185.82 |

| Soria | 558,476 | 13 | 43% | 5,858,633 | 78.52 |

| Valladolid | 409,284 | 13 | 42% | 4,397,859 | 58.94 |

| Zamora | 481,234 | 14 | 40% | 5,346,189 | 71.65 |

| Albacete | 407,159 | 15 | 38% | 4,686,329 | 62.81 |

| Ciudad Real | 79,243 | 16 | 36% | 938,039 | 12.57 |

| Cuenca | 395,132 | 14 | 41% | 4,288,951 | 57.48 |

| Guadalajara | 19,015 | 16 | 37% | 221,629 | 2.97 |

| Toledo | 1,884,257 | 17 | 35% | 22,716,508 | 304.47 |

| Barcelona | 1,922,673 | 19 | 32% | 24,299,669 | 325.69 |

| Girona | 1,006,341 | 17 | 35% | 12,169,036 | 163.10 |

| Lleida | 4,665,626 | 17 | 34% | 56,588,287 | 758.45 |

| Tarragona | 598,156 | 18 | 33% | 7,429,117 | 99.57 |

| Alacant/Alicante | 58,029 | 20 | 28% | 767,202 | 10.28 |

| Castelló/Castellón | 758,160 | 19 | 30% | 9,775,215 | 131.02 |

| València/Valencia | 565,594 | 19 | 31% | 7,210,027 | 96.64 |

| Badajoz | 1,478,735 | 19 | 31% | 18,904,319 | 253.37 |

| Cáceres | 203,350 | 18 | 32% | 2,555,228 | 34.25 |

| A Coruña | 316,384 | 16 | 37% | 3,699,120 | 49.58 |

| Lugo | 254,777 | 14 | 40% | 2,802,575 | 37.56 |

| Ourense | 434,943 | 16 | 37% | 5,069,460 | 67.95 |

| Pontevedra | 402,713 | 17 | 35% | 4,811,101 | 64.48 |

| Madrid | 19,290 | 16 | 37% | 223,429 | 2.99 |

| Murcia | 2,366,928 | 19 | 30% | 30,603,784 | 410.18 |

| Navarra | 827,530 | 14 | 40% | 9,193,307 | 123.22 |

| Araba/Álava | 20,822 | 14 | 41% | 226,770 | 3.04 |

| Bizkaia | 2984 | 15 | 38% | 34,345 | 0.46 |

| Gipuzkoa | 5858 | 15 | 38% | 67,211 | 0.90 |

| La Rioja | 175,662 | 15 | 38% | 2,015,443 | 27.01 |

Appendix B.2

| Province | WWTP Equivalent Habitants [29] | m3 of Biomethane per Year | GWh of Biomethane per Year |

|---|---|---|---|

| Las Palmas | 1,502,729 | 2,597,512 | 34.81 |

| Santa Cruz de Tenerife | 1,111,264 | 1,920,853 | 25.75 |

| Araba/Álava | 467,864 | 808,717 | 10.84 |

| Albacete | 673,989 | 1,165,010 | 15.61 |

| Alacant/Alicante | 3,904,614 | 6,749,242 | 90.46 |

| Almería | 702,817 | 1,214,840 | 16.28 |

| Ávila | 505,487 | 873,749 | 11.71 |

| Badajoz | 1,015,101 | 1,754,632 | 23.52 |

| Illes Balears | 2,001,382 | 3,459,449 | 46.37 |

| Barcelona | 7,019,380 | 12,133,208 | 162.62 |

| Burgos | 1,034,129 | 1,787,523 | 23.96 |

| Cáceres | 589,442 | 1,018,868 | 13.66 |

| Cádiz | 2,744,829 | 1,587,956 | 36.79 |

| Castelló/Castellón | 990,326 | 1,711,808 | 22.94 |

| Ciudad Real | 1,217,763 | 2,104,940 | 28.21 |

| Córdoba | 947,162 | 1,637,198 | 21.94 |

| A Coruña | 1,431,609 | 2,474,579 | 33.17 |

| Cuenca | 308,873 | 533,896 | 7.16 |

| Girona | 750,521 | 1,297,298 | 17.39 |

| Granada | 947,394 | 1,637,599 | 21.95 |

| Guadalajara | 291,376 | 503,652 | 6.75 |

| Gipuzkoa | 1,129,153 | 1,951,775 | 26.16 |

| Huelva | 719,937 | 1,244,433 | 16.68 |

| Huesca | 355,530 | 614,544 | 8.24 |

| Jaén | 573,795 | 991,822 | 13.29 |

| León | 672,440 | 1,162,333 | 15.58 |

| Lleida | 311,168 | 537,863 | 7.21 |

| La Rioja | 456,492 | 789,060 | 10.58 |

| Lugo | 296,730 | 512,907 | 6.87 |

| Madrid | 6,883,568 | 11,898,453 | 159.47 |

| Málaga | 2,206,214 | 3,813,507 | 51.11 |

| Murcia | 2,435,998 | 4,210,695 | 56.44 |

| Navarra | 1,264,919 | 2,186,450 | 29.30 |

| Ourense | 494,431 | 854,639 | 11.45 |

| Asturias | 1,377,194 | 2,380,521 | 31.91 |

| Palencia | 336,645 | 581,901 | 7.80 |

| Pontevedra | 1,607,471 | 2,778,562 | 37.24 |

| Salamanca | 818,980 | 1,415,631 | 18.97 |

| Cantabria | 656,348 | 1,134,517 | 15.21 |

| Segovia | 261,660 | 452,287 | 6.06 |

| Sevilla | 2,424,413 | 4,190,670 | 56.17 |

| Soria | 167,044 | 288,741 | 3.87 |

| Tarragona | 734,179 | 1,269,050 | 17.01 |

| Teruel | 190,909 | 329,992 | 4.42 |

| Toledo | 1,251,219 | 2,162,769 | 28.99 |

| València/Valencia | 5,280,824 | 9,128,062 | 122.34 |

| Valladolid | 1,009,007 | 1,744,099 | 23.38 |

| Bizkaia | 1,570,292 | 2,714,297 | 36.38 |

| Zamora | 205,368 | 354,985 | 4.76 |

| Zaragoza | 1,771,939 | 3,062,849 | 41.05 |

| Ceuta | 114,595 | 198,081 | 2.65 |

| Melilla | 100,000 | 172,853 | 2.32 |

Appendix C

| Aquifers (GWh) | Depleted Gas Deposits (GWh) | Salt Caverns (GWh) | |

|---|---|---|---|

| A Coruña | 0 | 0 | 0 |

| Alacant/Alicante | 97,088 | 0 | 0 |

| Albacete | 5248 | 0 | 168 |

| Almería | 0 | 0 | 0 |

| Araba/Álava | 0 | 0 | 0 |

| Asturias | 0 | 0 | 0 |

| Ávila | 0 | 0 | 0 |

| Badajoz | 0 | 0 | 0 |

| Barcelona | 0 | 0 | 0 |

| Bizkaia | 0 | 857,920 | 0 |

| Burgos | 31,488 | 0 | 84 |

| Cáceres | 0 | 0 | 0 |

| Cádiz | 1312 | 0 | 0 |

| Cantabria | 39,360 | 0 | 0 |

| Castelló/Castellón | 1312 | 0 | 0 |

| Ceuta | 0 | 0 | 0 |

| Ciudad Real | 0 | 0 | 0 |

| Córdoba | 3936 | 0 | 0 |

| Cuenca | 255,840 | 0 | 0 |

| Gipuzkoa | 0 | 0 | 0 |

| Girona | 0 | 0 | 0 |

| Granada | 7872 | 0 | 0 |

| Guadalajara | 53,792 | 640,000 | 0 |

| Huelva | 11,808 | 47,040 | 0 |

| Huesca | 37,248 | 320,000 | 0 |

| Illes Balears | 0 | 0 | 0 |

| Jaén | 38,048 | 0 | 0 |

| La Rioja | 23,616 | 0 | 0 |

| Las Palmas | 0 | 0 | 0 |

| León | 11,808 | 0 | 0 |

| Lleida | 31,488 | 0 | 0 |

| Lugo | 0 | 0 | 0 |

| Madrid | 31,488 | 0 | 0 |

| Málaga | 0 | 0 | 0 |

| Melilla | 0 | 0 | 0 |

| Murcia | 47,232 | 0 | 168 |

| Navarra | 52,480 | 0 | 336 |

| Ourense | 0 | 0 | 0 |

| Palencia | 0 | 0 | 0 |

| Pontevedra | 0 | 0 | 0 |

| Salamanca | 0 | 0 | 0 |

| Santa Cruz de Tenerife | 0 | 0 | 0 |

| Segovia | 0 | 0 | 0 |

| Sevilla | 0 | 0 | 0 |

| Soria | 11,808 | 0 | 0 |

| Tarragona | 10,496 | 0 | 0 |

| Teruel | 57,728 | 0 | 0 |

| Toledo | 66,912 | 0 | 0 |

| València/Valencia | 0 | 0 | 0 |

| Valladolid | 49,856 | 0 | 0 |

| Zamora | 0 | 0 | 0 |

| Zaragoza | 19,680 | 0 | 0 |

References

- Red Eléctrica de España. Evolution of Renewable and Non-Renewable Generation (%), Electricity System; Red Eléctrica de España: Madrid, Spain, 2025. [Google Scholar]

- Gobierno de España. Spain’s Integrated National Energy and Climate Plan 2021–2030; Climate Change Laws of the World: London, UK, 2023.

- Gobierno de España. Energy Balance of Spain; Ministerio para la Transición Ecológica y el Reto Demográfico: Madrid, Spain, 2023.

- European Parliament, European Council. Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652; Official Journal of the European Union: Luxemburg, 2023. [Google Scholar]

- Gobierno de España. Biogas Roadmap; Ministerio para la Transición Ecológica y el Reto Demográfico: Madrid, Spain, 2022.

- García Álvaro, A.; Martínez-Hernando, M.-P.; García-Martínez, M.-J.; Ruiz Palomar, C.; Suárez Rodríguez, M.d.C.; Hermosilla, D.; Ortega, M.F.; de Godos Crespo, I. Life cycle assessment of swine manure management: A comparison of different management systems with Montecarlo simulation. J. Clean Prod. 2025, 502, 145368. [Google Scholar] [CrossRef]

- Ankathi, S.K.; Chaudhari, U.S.; Handler, R.M.; Shonnard, D.R. Sustainability of Biogas Production from Anaerobic Digestion of Food Waste and Animal Manure. Appl. Microbiol. 2024, 4, 418–438. [Google Scholar] [CrossRef]

- de Jong, W.; van Ommen, J.R. Biomass as a Sustainable Energy Source for the Future: Fundamentals of Conversion Processes; Wiley: Hoboken, NJ, USA, 2014; Available online: https://books.google.es/books?hl=en&lr=&id=wZWwBAAAQBAJ&oi=fnd&pg=PR13&dq=delft+biomass+wiebren+de+jong+book&ots=ioVSmYSqxD&sig=TUOn-fwY5g1HUi17QjFBr-Jeh1o&redir_esc=y#v=onepage&q=delft%20biomass%20wiebren%20de%20jong%20book&f=false (accessed on 11 February 2025).

- Oh, S.T.; Martin, A.D. Thermodynamic equilibrium model in anaerobic digestion process. Biochem. Eng. J. 2007, 34, 256–266. [Google Scholar] [CrossRef]

- Vu, H.P.; Nguyen, L.N.; Wang, Q.; Ngo, H.H.; Liu, Q.; Zhang, X.; Nghiem, L.D. Hydrogen sulphide management in anaerobic digestion: A critical review on input control, process regulation, and post-treatment. Bioresour. Technol. 2022, 346, 126634. [Google Scholar] [CrossRef]

- Eisted, R.; Larsen, A.W.; Christensen, T.H. Collection, transfer and transport of waste: Accounting of greenhouse gases and global warming contribution. Waste Manag. Res. 2009, 27, 738–745. [Google Scholar] [CrossRef]

- Ferdeș, M.; Paraschiv, G.; Ionescu, M.; Dincă, M.N.; Moiceanu, G.; Zăbavă, B.Ș. Anaerobic Co-Digestion: A Way to Potentiate the Synergistic Effect of Multiple Substrates and Microbial Diversity. Energies 2023, 16, 2116. [Google Scholar] [CrossRef]

- Blumenstein, B.; Siegmeier, T.; Bruckhaus, C.; Anspach, V.; Möller, D. Integrated Bioenergy and Food Production—A German Survey on Structure and Developments of Anaerobic Digestion in Organic Farming Systems. Sustainability 2015, 7, 10709–10732. [Google Scholar] [CrossRef]

- Mudhoo, A.; Kumar, S. Effects of heavy metals as stress factors on anaerobic digestion processes and biogas production from biomass. Int. J. Environ. Sci. Technol. 2013, 10, 1383–1398. [Google Scholar] [CrossRef]

- Peces, M.; Astals, S.; Mata-Alvarez, J. Assessing total and volatile solids in municipal solid waste samples. Environ. Technol. 2014, 35, 3041–3046. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Hu, S. Underground hydrogen storage in depleted gas fields: Progress, challenges, and outlook. J. Energy Storage 2024, 102, 113842. [Google Scholar] [CrossRef]

- Ozarslan, A. Large-scale hydrogen energy storage in salt caverns. Int. J. Hydrogen Energy 2012, 37, 14265–14277. [Google Scholar] [CrossRef]

- LIFE Smart Agromobility. 2019. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE19-CCM-ES-001206/processing-of-livestock-waste-for-the-production-of-biomethane-for-use-in-agricultural-vehicles-and-biofertilizers (accessed on 8 April 2025).

- Ayuntamiento de Guadalajara. I+D+i de protección Ambiental—Smart-Met-Value; Ayuntamiento de Guadalajara: Guadalajara, Spain, 2018.

- Underground Energy. UNDERGY Project. 2024. Available online: https://undergy.eu/en/project-summary-english-version (accessed on 8 April 2025).

- Ruiz Palomar, C.; García Álvaro, A.; Muñoz, R.; Repáraz, C.; Ortega, M.F.; de Godos, I. Pre-Commercial Demonstration of a Photosynthetic Upgrading Plant: Investment and Operating Cost Analysis. Processes 2024, 12, 2794. [Google Scholar] [CrossRef]

- Petersen, S.O.; Olsen, A.B.; Elsgaard, L.; Triolo, J.M.; Sommer, S.G. Estimation of methane emissions from slurry pits below pig and cattle confinements. PLoS ONE 2016, 11, e0160968. [Google Scholar] [CrossRef]

- Sedigas. A Study of the Capacity for Biomethane Production in Spain; Sedigas: Barcelona, Spain, 2023. [Google Scholar]

- García Álvaro, A.; Ruiz Palomar, C.; Valenzuela, E.I.; Hermosilla Redondo, D.; Muñoz Torre, R.; de Godos Crespo, I. Microbial analysis of anaerobic digester reveals prevalence of manure microbiota. J. Water Process Eng. 2024, 60, 105162. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística. Censo Agrario 2020. 2020. Available online: https://www.ine.es/jaxi/Datos.htm?tpx=51176 (accessed on 27 May 2024).

- Instituto Geográfico Nacional. Recintos Provinciales. 2024. Available online: https://centrodedescargas.cnig.es/CentroDescargas/catalogo.do?Serie=CAANE (accessed on 18 May 2025).

- Chiaramonti, D.; Testa, L. Deploying EU biomethane potential for transports: Centralized/decentralized biogasrefinery schemes to SAF and maritime fuels. Appl. Energy 2024, 366, 123306. [Google Scholar] [CrossRef]

- Ministerio para la Transición Ecológica y el Reto Demográfico. Aglomeraciones Urbanas y Estaciones Depuradoras de Aguas Residuales. 2021. Available online: https://www.miteco.gob.es/es/cartografia-y-sig/ide/descargas/agua/situacion-q2021.html (accessed on 6 February 2025).

- Kraviarová, D.; Janošovský, J.; Variny, M. The feasibility study of alternative fuels production following National Hydrogen Strategy in Slovakia. Int. J. Hydrog. Energy 2024, 86, 1386–1400. [Google Scholar] [CrossRef]

- Freire Ordóñez, D.; Ganzer, C.; Halfdanarson, T.; González Garay, A.; Patrizio, P.; Bardow, A.; Guillén-Gosálbez, G.; Shah, N.; MacDowell, N. Quantifying global costs of reliable green hydrogen. Energy Adv. 2023, 2, 2042–2054. [Google Scholar] [CrossRef]

- Niroula, S.; Kafle, N.; Chitrakar, S.; Thapa, B.S. Green hydrogen production from surplus hydroelectric power: A case study in Nepal. Int. J. Hydrogen Energy 2024, 92, 527–534. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, J.; Yang, X.; Lv, R.; Li, J.; Yu, B.; Yan, D.; Zhang, H.; Guo, W.; Hao, R.; et al. Study on the synergistic failure of hydrogen embrittlement and corrosion in high-pressure hydrogen-blended natural gas pipelines. J. Mater. Res. Technol. 2025, 36, 6099–6112. [Google Scholar] [CrossRef]

- Enagás. Folleto Almacenamientos Subterráneos; Enagás: Madrid, Spain, 2024. [Google Scholar]

- Hystories. Hydrogen Storage in European Subsurface. 2024. Available online: https://bgs.maps.arcgis.com/apps/dashboards/630ec7b3cbd54e39b4111e397315ae99 (accessed on 17 February 2025).

- IGME. Base de Datos del Inventario Español de Lugares de Interés Geológico. 2007. Available online: https://info.igme.es/ielig/default.aspx (accessed on 27 March 2025).

- Martínez, R.; Suárez, I.; Zapatero, M.A.; Saftic, B.; Kolenkovic, I.; Car, M.; Persoglia, S.; Donda, F. The EU Geocapacity Project—Saline aquifers storage capacity in Group South countries. Energy Procedia 2009, 1, 2733–2740. [Google Scholar] [CrossRef]

- MITECO. Annex 7. CO2 Emission Factors and Lower Heating Value (LHV) of Fuels; MITECO: Madrid, Spain, 2023.

- Caglayan, D.G.; Weber, N.; Heinrichs, H.U.; Linßen, J.; Robinius, M.; Kukla, P.A.; Stolten, D. Technical potential of salt caverns for hydrogen storage in Europe. Int. J. Hydrogen Energy 2020, 45, 6793–6805. [Google Scholar] [CrossRef]

- Valle-Falcones, L.M.; Grima-Olmedo, C.; Mazadiego-Martínez, L.F.; Hurtado-Bezos, A.; Eguilior-Díaz, S.; Rodríguez-Pons, R. Green Hydrogen Storage in an Underground Cavern: A Case Study in Salt Diapir of Spain. Appl. Sci. 2022, 12, 6081. [Google Scholar] [CrossRef]

- Repsol. Aprende Como Calcular el Consumo de Tu Coche. 2024. Available online: https://www.repsol.es/particulares/asesoramiento-consumo/calcular-consumo-coche/ (accessed on 6 August 2024).

- Sobrino, F.H.; Monroy, C.R.; Pérez, J.L.H. Critical analysis on hydrogen as an alternative to fossil fuels and biofuels for vehicles in Europe. Renew. Sustain. Energy Rev. 2010, 14, 772–780. [Google Scholar] [CrossRef]

- Dirección General de Tráfico. Kilómetros Anualizados Recorridos Por El Parque Móvil Español; Dirección General de Tráfico: Madrid, Spain, 2022. [Google Scholar]

- Dirección General de Tráfico. Anuario Estadístico General 2022; Dirección General de Tráfico: Madrid, Spain, 2022. [Google Scholar]

- Martínez-Hernando, M.-P.; Ruiz Palomar, C.; García Álvaro, A.; Suárez Rodríguez, M.C.; Bolonio, D.; García-Martínez, M.-J.; de Godos Crespo, I.; Ortega, M.F. Life Cycle Assessment of LIFE Smart Agromobility Project. 2024. Available online: https://www.researchgate.net/publication/381301959_Life_Cycle_Assessment_of_LIFE_Smart_Agromobility_project (accessed on 18 May 2025).

- European Commission. Commission Recommendation (EU) 2021/2279 of 15 December 2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations. 2021. Available online: https://www.consilium.europa.eu/media/40928/st12791-en19.pdf (accessed on 21 June 2025).

- European Parliament. Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015; European Parliament: Luxembourg, 2015. [Google Scholar]

- European Commission. Commission Delegated Regulation (EU) 2023/1185 of 10 February 2023; European Commission: Luxembourg, 2023. [Google Scholar]

- Scarlat, N.; Fahl, F.; Dallemand, J.F.; Monforti, F.; Motola, V. A spatial analysis of biogas potential from manure in Europe. Renew. Sustain. Energy Rev. 2018, 94, 915–930. [Google Scholar] [CrossRef]

- Ministerio para la Transición Ecológica. Resolución de 8 de Octubre de 2018, de la Dirección General de Política Energética y Minas, por la que se Modifican las Normas de Gestión Técnica del Sistema NGTS-06, NGTS-07 y los Protocolos de Detalle PD-01 y PD-02; Ministerio para la Transición Ecológica: Madrid, Spain, 2018.

- UNE-EN_16723-2:2018; Gas Natural y Biometano para uso en Transporte y Biometano para Inyección en la red de Gas Natural—Parte 2: Especificaciones del Combustible para Automoción. Asociación Española de Normalización: Madrid, Spain, 2018.

- Tangöz, S.; Kahraman, N.; Akansu, S.O. The effect of hydrogen on the performance and emissions of an SI engine having a high compression ratio fuelled by compressed natural gas. Int. J. Hydrogen Energy 2017, 42, 25766–25780. [Google Scholar] [CrossRef]

- Ortenzi, F.; Chiesa, M.; Scarcelli, R.; Pede, G. Experimental tests of blends of hydrogen and natural gas in light-duty vehicles. Int. J. Hydrogen Energy 2008, 33, 3225–3229. [Google Scholar] [CrossRef]

- Koç, Y.; Yağlı, H.; Görgülü, A.; Koç, A. Analysing the performance, fuel cost and emission parameters of the 50 MW simple and recuperative gas turbine cycles using natural gas and hydrogen as fuel. Int. J. Hydrogen Energy 2020, 45, 22138–22147. [Google Scholar] [CrossRef]

- Nam, J.; Lee, Y.; Joo, S.; Yoon, Y.; Yoh, J.J. Numerical analysis of the effect of the hydrogen composition on a partially premixed gas turbine combustor. Int. J. Hydrogen Energy 2019, 44, 6278–6286. [Google Scholar] [CrossRef]

- di Gaeta, A.; Reale, F.; Chiariello, F.; Massoli, P. A dynamic model of a 100 kW micro gas turbine fuelled with natural gas and hydrogen blends and its application in a hybrid energy grid. Energy 2017, 129, 299–320. [Google Scholar] [CrossRef]

- Suelo Solar. Temperaturas Ambiente Medias en Horas de Sol en las Provincias de España. 2025. Available online: https://suelosolar.com/guiasolares/acs/temproves.asp (accessed on 15 May 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pous de la Flor, J.; Martínez-Hernando, M.-P.; Paredes, R.; Garcia-Franco, E.; Cabello, J.P.; Ortega, M.F. Waste as a Source of Fuel and Developments in Hydrogen Storage: Applied Cases in Spain and Their Future Potential. Appl. Sci. 2025, 15, 7514. https://doi.org/10.3390/app15137514

Pous de la Flor J, Martínez-Hernando M-P, Paredes R, Garcia-Franco E, Cabello JP, Ortega MF. Waste as a Source of Fuel and Developments in Hydrogen Storage: Applied Cases in Spain and Their Future Potential. Applied Sciences. 2025; 15(13):7514. https://doi.org/10.3390/app15137514

Chicago/Turabian StylePous de la Flor, Juan, María-Pilar Martínez-Hernando, Roberto Paredes, Enrique Garcia-Franco, Juan Pous Cabello, and Marcelo F. Ortega. 2025. "Waste as a Source of Fuel and Developments in Hydrogen Storage: Applied Cases in Spain and Their Future Potential" Applied Sciences 15, no. 13: 7514. https://doi.org/10.3390/app15137514

APA StylePous de la Flor, J., Martínez-Hernando, M.-P., Paredes, R., Garcia-Franco, E., Cabello, J. P., & Ortega, M. F. (2025). Waste as a Source of Fuel and Developments in Hydrogen Storage: Applied Cases in Spain and Their Future Potential. Applied Sciences, 15(13), 7514. https://doi.org/10.3390/app15137514