Strength Parameters and Failure Criterion of Granite After High-Temperature and Water-Cooling Treatment

Abstract

1. Introduction

2. Mohr-Coulomb Strength Parameters of Granite Samples After High-Temperature and Water-Cooling Treatment

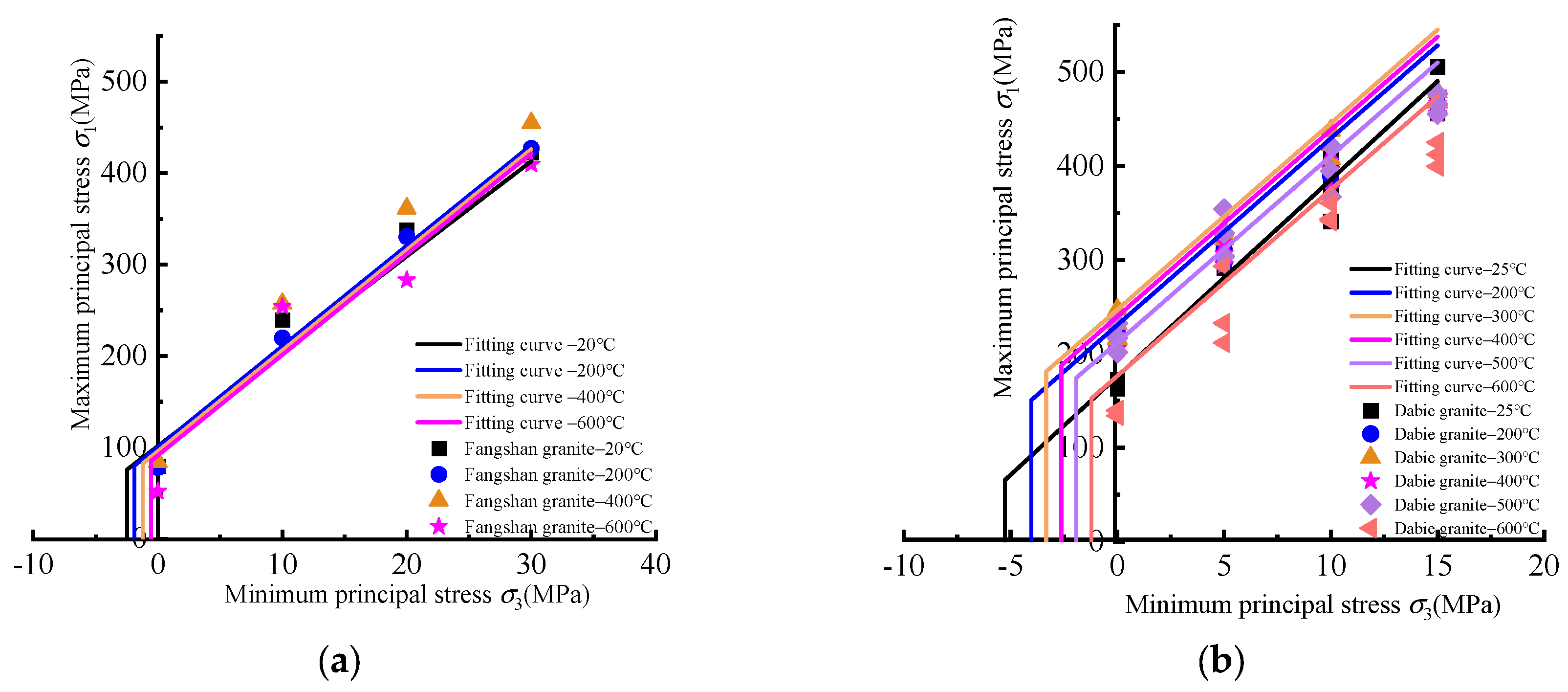

2.1. Laboratory Experiments on Fangshan Granite Samples

2.1.1. Granite Samples and Experimental Methods

2.1.2. Experimental Results

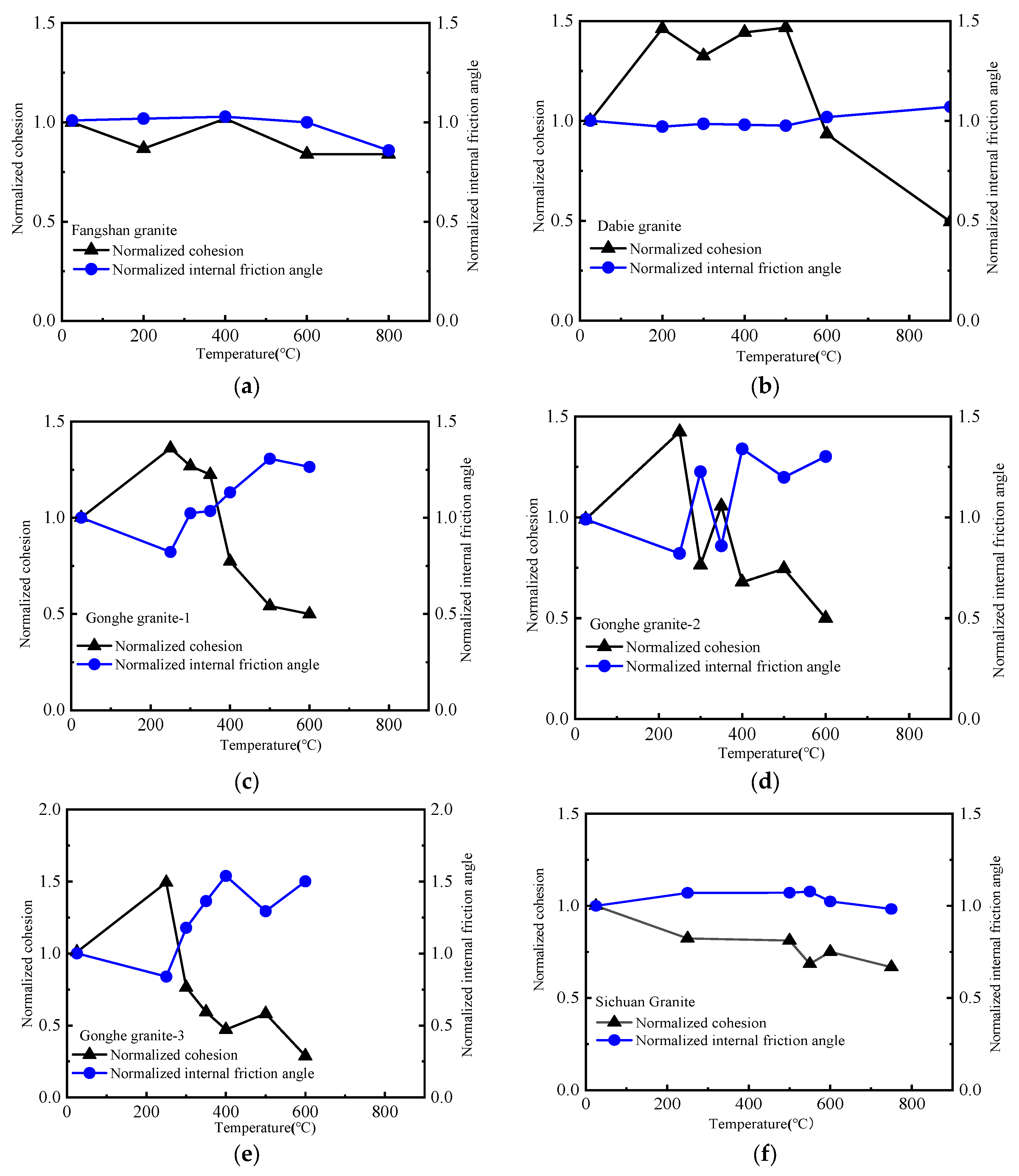

2.2. Evolution Behaviors of Mohr-Coulomb Strength Parameters

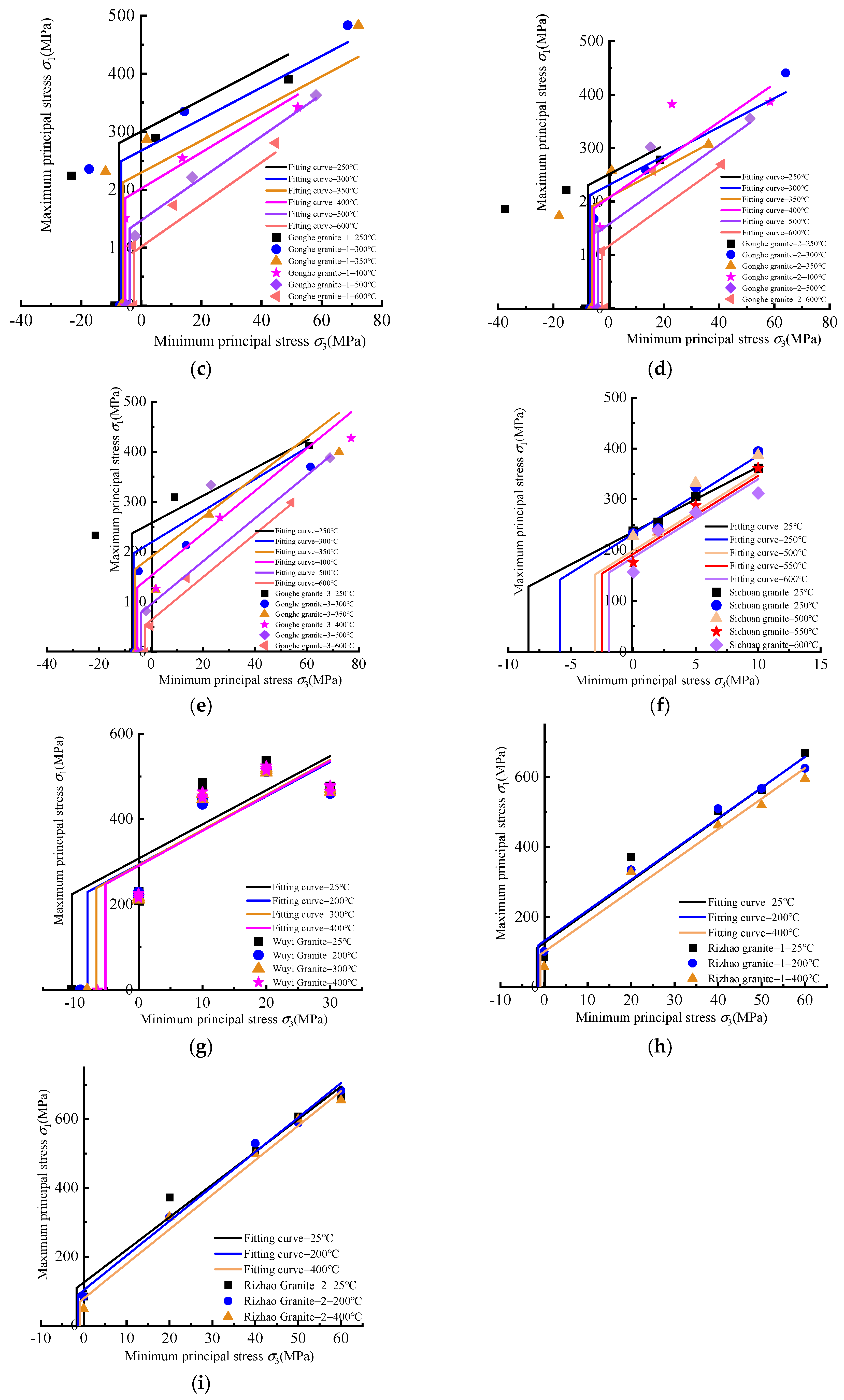

2.2.1. Extended Data from Different Granite Samples

- (1)

- Type I: Cohesion keeps decreasing with the growing treatment temperature. For example, Fangshan granite, Sichuan granite, Wuyi granite, and Rizhao granite—2 samples.

- (2)

- Type II: Cohesion goes up to a peak value before going down with the growing treatment temperature. For example, Dabie granite, Gonghe granite, and Rizhao granite—1 samples.

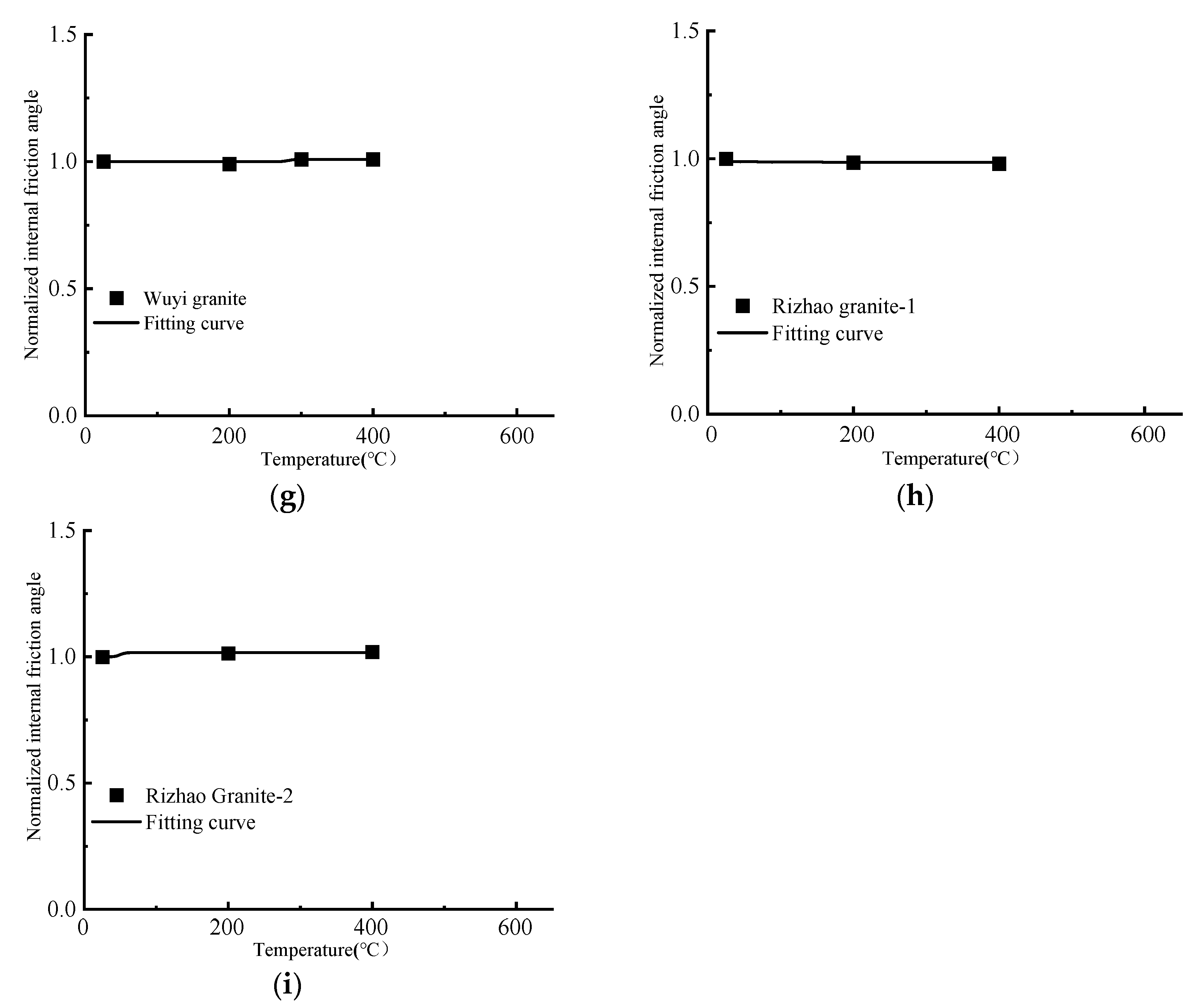

- (1)

- Type I: Internal friction angle remains almost constant under different treatment temperatures. For example, Fangshan granite, Dabie granite, Sichuan granite, Wuyi granite, and Rizhao granite—1 & 2 samples.

- (2)

- Type II: Internal friction angle increases with the increasing treatment temperature. For example, Gonghe granite samples.

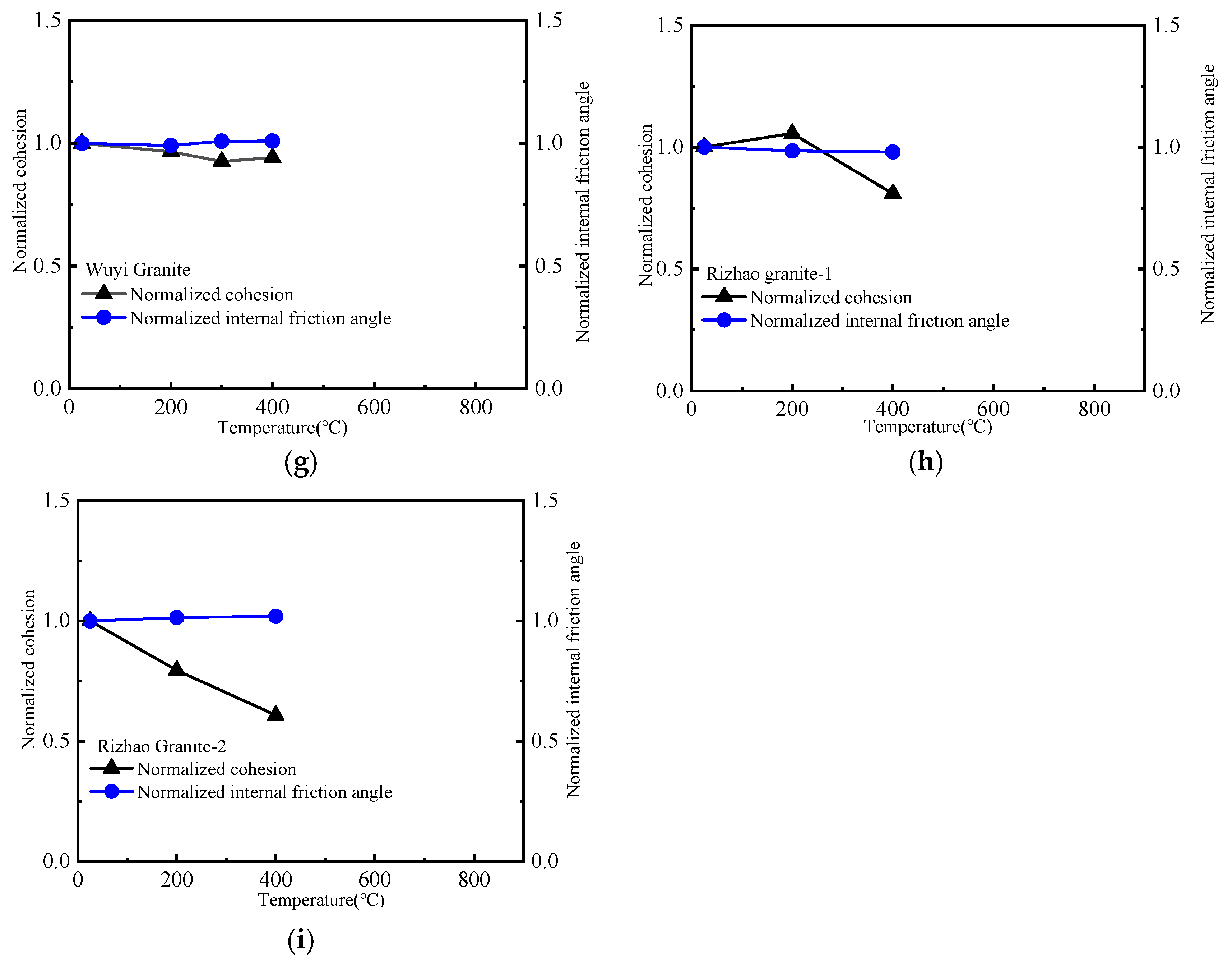

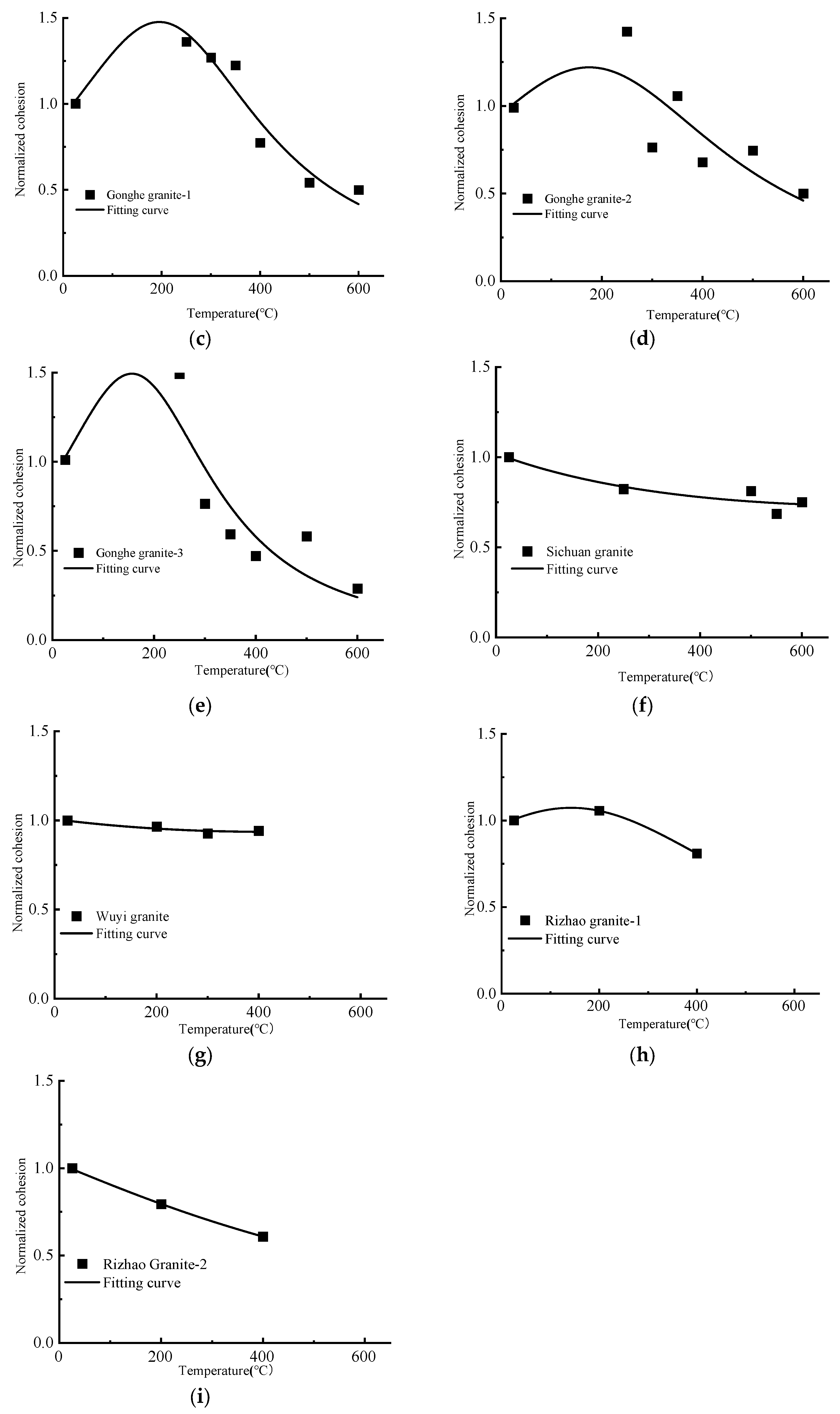

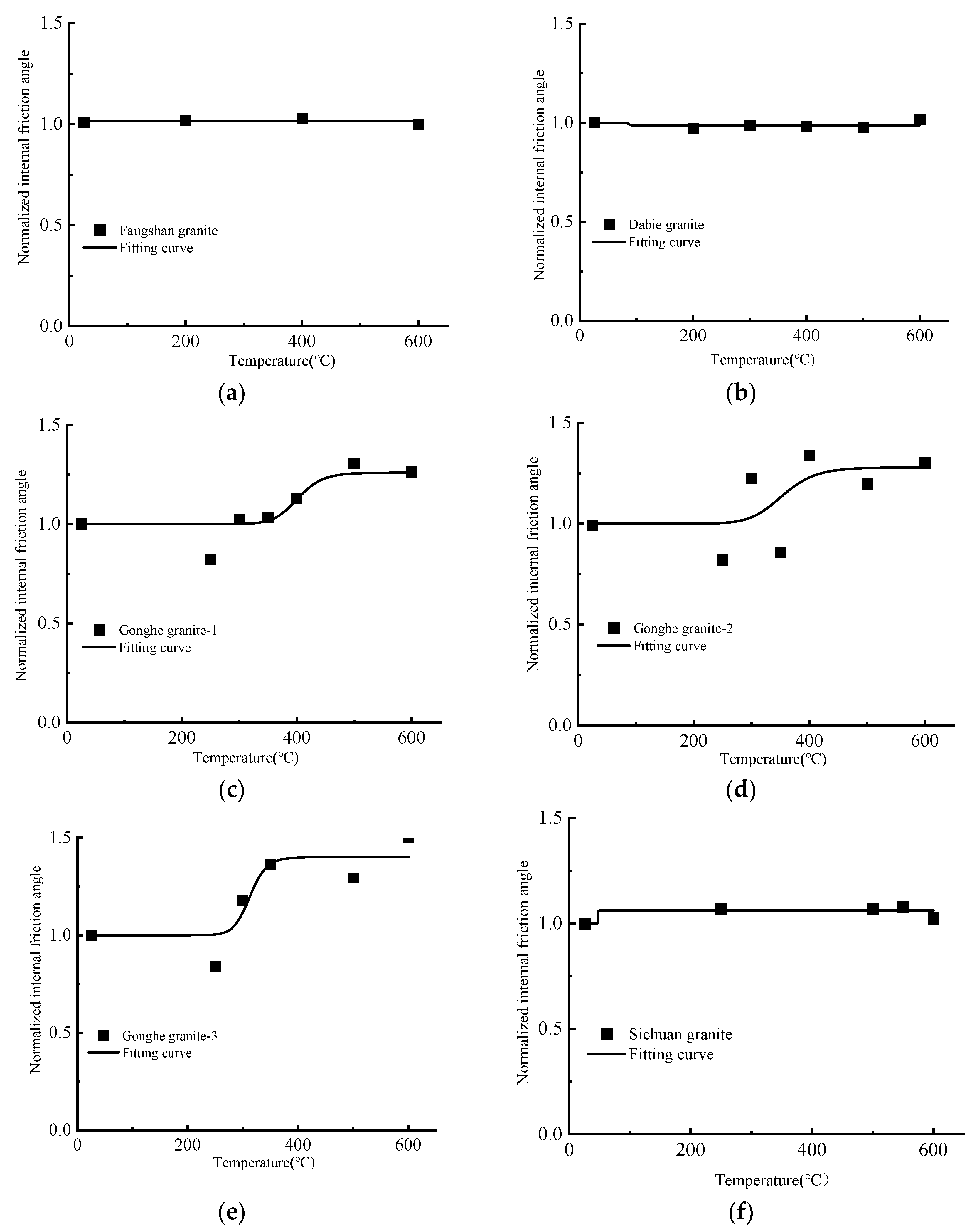

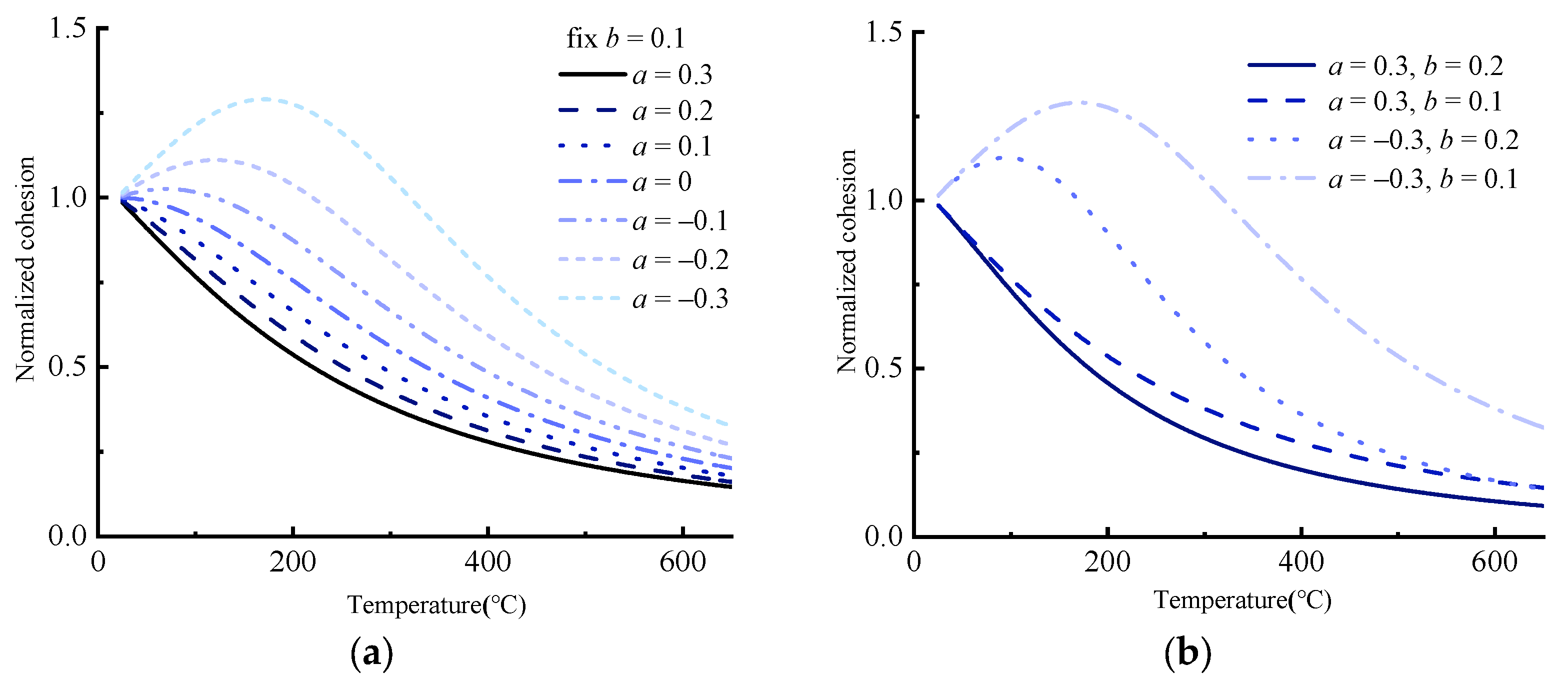

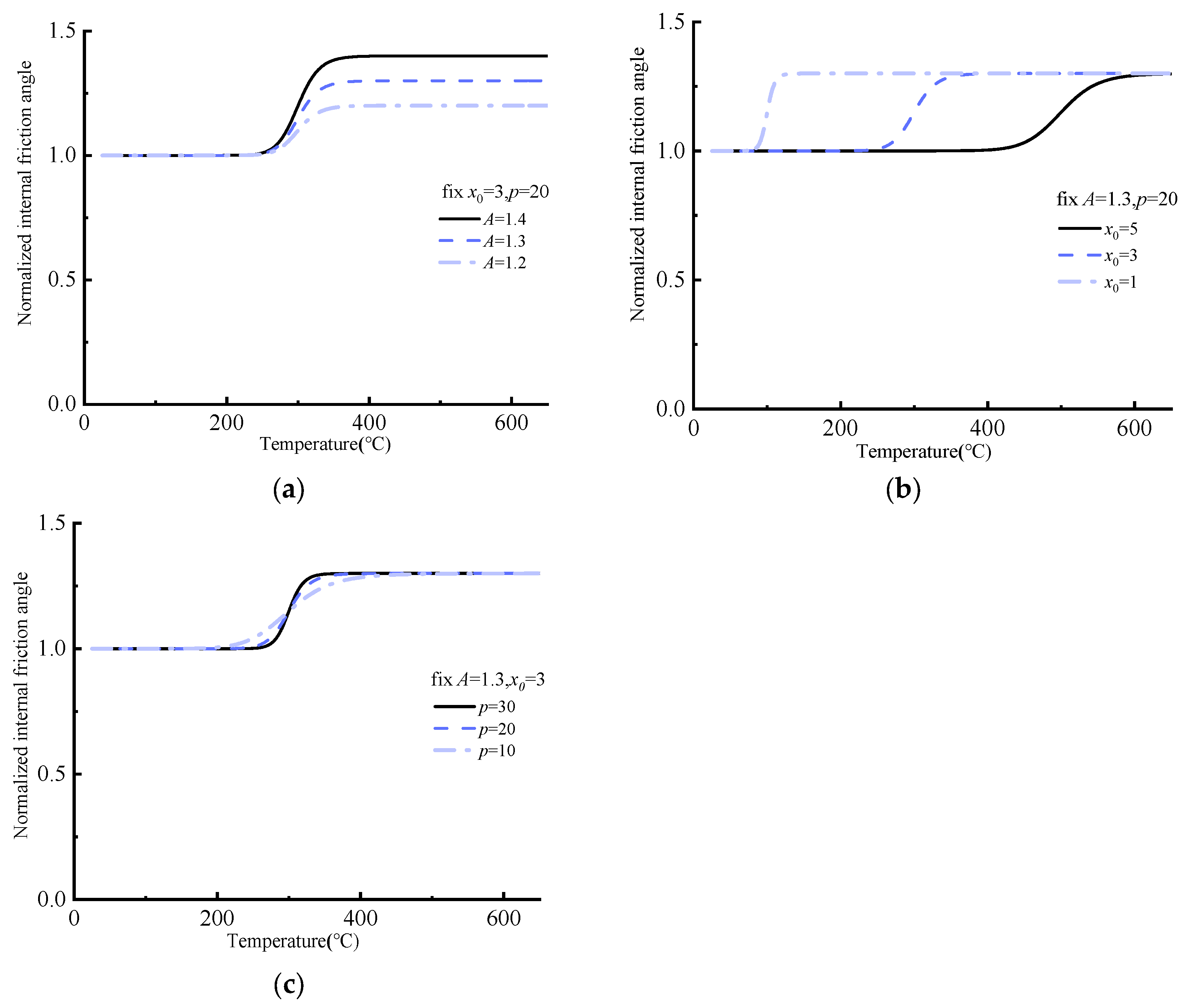

2.2.2. Empirical Formula for Cohesion and the Internal Friction Angle

3. Tensile Strength of Granite Samples After High-Temperature and Water-Cooling Treatment

4. Failure Criterion of Granite Samples After High-Temperature and Water-Cooling Treatment

5. Discussion

6. Conclusions

- (1)

- It is found that there are two types of variation behaviors of cohesion and the internal friction angle for the granite samples after heating and cooling treatment.

- (2)

- Unified empirical equations have been provided to describe the different types of variation behaviors of cohesion and the internal friction angle for the granite samples after heating and cooling treatment. The sensitivity analyses show that the fitting coefficients have quite clear physical meanings.

- (3)

- The tensile strength decreases in a similar way for the different granite samples with the increasing treatment temperature. A linear empirical equation has been given to describe this behavior.

- (4)

- A modified Mohr-Coulomb failure criterion with a “tension cut-off” has been established for the granite samples considering the effects of high-temperature and water-cooling treatment. The criterion has been validated by well describing the different types of granite behaviors after heating and cooling treatment.

- (5)

- A discussion has been supplied on the mechanism of the different granite behaviors. It should be closely related to the damage and cracking process during the heating and cooling treatment on the granite samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Regelous, A.; Scharfenberg, L.; De Wall, H. Origin of S-, A- and I-Type Granites: Petrogenetic Evidence from Whole Rock Th/U Ratio Variations. Minerals 2021, 11, 672. [Google Scholar] [CrossRef]

- Lutgens, F.K.; Tarbuck, E.J.; Tasa, D.G. Essentials of Geology, 13th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2018. [Google Scholar]

- Wang, K.; Liu, Z.; Zeng, T.; Wang, F.; Shen, W.; Shao, J. Performance of enhanced geothermal system with varying injection-production parameters and reservoir properties. Appl. Therm. Eng. 2022, 207, 118160. [Google Scholar] [CrossRef]

- Zeng, Y. Technical Progress and Thinking for Development of Hot Dry Rock (HDR) Geothermal Resources. Pet. Drill. Tech. 2015, 43, 1–7. [Google Scholar]

- Tran, N.H.; Rahman, S.S. Development of hot dry rocks by hydraulic stimulation: Natural fracture network simulation. Theor. Appl. Fract. Mech. 2007, 47, 77–85. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, T.; Qu, Z.; Wang, Z. Research of fracture initiation and propagation in HDR fracturing under thermal stress from meso-damage perspective. Energy 2019, 178, 508–521. [Google Scholar] [CrossRef]

- He, C.; Mishra, B.; Yuan, W.; Wang, X.; Shi, Q. Investigation of the dynamic behavior and fracturing mechanism of granite. Fuel 2024, 360, 130579. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, S.; Zheng, W.; Tannant, D.D. Coupled thermal-hydraulic simulations of fracturing in granite under high temperature and high pressure treatment via peridynamic. Int. J. Rock Mech. Min. Sci. 2022, 160, 105247. [Google Scholar] [CrossRef]

- Dimitri, R.; Rinaldi, M.; Trullo, M.; Tornabene, F. Theoretical and computational investigation of the fracturing behavior of anisotropic geomaterials. Contin. Mech. Thermodyn. 2023, 35, 1417–1432. [Google Scholar] [CrossRef]

- Dimitri, R.; Rinaldi, M.; Trullo, M.; Tornabene, F.; Fidelibus, C. FEM/XFEM modeling of the 3D fracturing process in transversely isotropic geomaterials. Compos. Struct. 2021, 276, 114502. [Google Scholar] [CrossRef]

- Abé, H.; Niitsuma, H.; Baria, R. Special issue: Hot dry rock/hot wet rock: Academic review: Preface. Geothermics 1999, 28, 451–454. [Google Scholar]

- Huang, Y.; Zheng, M.; Zhang, Q.; Lu, D.; Wang, X.; Hans Jörg, K.; Wolfgang, S. Long Term Temperature and Humidity Evolution Forecast in Near Field of Nuclear Waste Container. Inst. Oceanol. 2018, 5, 109–113. [Google Scholar]

- Lee, Y.H. A Comparative Study on the High-Level Nuclear Waste Management in Sweden and Finland. J. Korean Soc. Trend Perspect. 2022, 114, 189–226. [Google Scholar]

- Hasan, S.E. International practice in high-level nuclear waste management. Concepts Appl. Environ. Geochem. 2007, 5, 57–77. [Google Scholar]

- Zhang, F.; Zhao, J.; Hu, D.; Skoczylas, F.; Shao, J. Laboratory Investigation on Physical and Mechanical Properties of Granite After Heating and Water-Cooling Treatment. Rock Mech. Rock Eng. 2018, 51, 677–694. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Dong, N.; Dou, B.; Chen, J.; Zhang, Y.; Wang, B.H. Experimental study of physico-mechanical properties of heat-treated granite by water cooling. Rock Soil Mech. 2018, 39, 169–176. [Google Scholar]

- Cui, H.; Tang, J.; Jiang, X. Experimental Study on Mechanical and Acoustic Characteristics of High-temperature Granite after Natural Cooling and Water Cooling. Chin. J. Solid Mech. 2019, 40, 571–582. [Google Scholar]

- Wang, P.; Chen, Y.; Zhou, X.; Gao, S.; Zhao, H. Impact of rapid cooling in water on residual mechanical properties of granite under high temperature. J. Water Resour. Water Eng. 2013, 24, 54–57. [Google Scholar]

- Zhu, Y.; Yu, J.; Gao, H.; Li, G.; Zhou, X.; Zheng, X. Effect of water cooling on microscopic damage and dynamic properties of high-temperature granite. Explos. Shock. Waves 2019, 39, 083104. [Google Scholar]

- Xie, Y.; Xu, N.; Qin, Y.; Chen, Y. Experimental study on the influence of rapid water cooling and natural cooling on the physical properties of high temperature granite. Geotech. Investig. Surv. 2019, 4, 471–475+23. [Google Scholar]

- Ram, B.K.; Gupta, V. Physico-mechanical characterization of Higher Himalayan granite under the thermal treatments of different heating-cooling conditions. Acta Geotech. 2024, 19, 2841–2854. [Google Scholar] [CrossRef]

- Yin, T.; Li, Q.; Li, X. Experimental investigation on mode I fracture characteristics of granite after cyclic heating and cooling treatments. Eng. Fract. Mech. 2019, 222, 106740. [Google Scholar] [CrossRef]

- Jin, P.; Hu, Y.; Shao, J.; Zhao, G.; Zhu, X.; Li, C. Experimental study on physico-mechanical and transport properties of granite subjected to rapid cooling. Chin. J. Rock Mech. Eng. 2018, 37, 2556–2564. [Google Scholar]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Xi, B.; Zhao, Y. Experimental research on mechanical properties of water-cooled granite under high temperatures within 600 °C. Chin. J. Rock Mech. Eng. 2010, 29, 892–898. [Google Scholar]

- Xi, B.; Wu, Y.; Zhao, Y.; Wang, L.; Zhang, B.; Niu, X. Experimental investigations of compressive strength and thermal damage capacity characterization of granite under different cooling modes. Chin. J. Rock Mech. Eng. 2020, 39, 286–300. [Google Scholar]

- Shao, S.; Wasantha, P.; Ranjith, P.; Chen, B. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K. Experimental investigation of quenching effect on mechanical, microstructural and flow characteristics of reservoir rocks: Thermal stimulation method for geothermal energy extraction. J. Pet. Sci. Eng. 2018, 162, 419–433. [Google Scholar] [CrossRef]

- Qin, Y.; Tian, H.; Xu, N.; Chen, Y. Physical and Mechanical Properties of Granite After High-Temperature Treatment. Rock Mech. Rock Eng. 2020, 53, 305–322. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.; Yu, Y.; Hu, D.; Shao, J. Influence of cooling rate on thermal degradation of physical and mechanical properties of granite. Int. J. Rock Mech. Min. Sci. 2020, 129, 104285. [Google Scholar] [CrossRef]

- Xi, B.; Wu, Y.; Wang, S.; Xiong, G.; Zhao, Y. Evolution of mechanical properties of granite under thermal shock in water with different cooling temperatures. Rock Soil Mech. 2020, 41 (Suppl. S1), 83–94. [Google Scholar]

- Jin, Y.; He, C.; Yao, C.; Sun, Z.; Wang, J.; Zhang, X.; Yang, J.; Jiang, Q.; Zhou, C. Experimental and numerical simulation study on the evolution of mechanical properties of granite after thermal treatment. Comput. Geotech. 2024, 172, 106464. [Google Scholar] [CrossRef]

- Guo, P. Study on Physical and Mechanical Properties and Damage Characteristics of Heat-Treated Granite. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2023. [Google Scholar]

- Zhou, C. Damage Characteristics and Fracturing Mechanism of High-Temperature Granite Induced by Liquid Nitrogen. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2023. [Google Scholar]

- Zhou, C.; Gao, F.; Cai, C.; Su, S.; Zheng, W.; Huo, L. Variations in Stress Thresholds for Heated Granite Subjected to Rapid Cooling under Different Confining Pressures. Nat. Resour. Res. 2022, 31, 2653–2671. [Google Scholar] [CrossRef]

- Brady, B.H.G.; Brown, E. Rock Mechanics For Underground Mining; Chapman and Hall: London, UK, 2006. [Google Scholar]

- Cui, H. Effects of High Temperature Cooling Conditions on Mechanical—Acoustic-Thermal Performance and Roughness of Granite After Thermal Cracking. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2021. [Google Scholar]

- Zhao, Y.; Feng, Z.; Xi, B.; Wan, Z.; Yang, D.; Liang, W. Deformation and instability failure of borehole at high temperature and high pressure in Hot Dry Rock exploitation. Renew. Energy 2015, 77, 159–165. [Google Scholar] [CrossRef]

- Espinoza, W.F.; Pereira, J.-M.; Kneafsey, T.; Dai, S. Mechanical and creep properties of granitic minerals of albite, biotite, and quartz at elevated temperature. Geomech. Energy Environ. 2023, 34, 100465. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Rutqvist, J.; Hu, M.; Wang, Z.; Tang, X. Thermally Induced Microcracks in Granite and Their Effect on the Macroscale Mechanical Behavior. J. Geophys. Res.-Solid Earth 2023, 128, e2022JB024920. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Zhang, H.; Zhang, J.; Qiu, M.; Li, G.; Ma, F.; Guo, J. Numerical study of the fluid fracturing mechanism of granite at the mineral grain scale. Front. Earth Sci. 2023, 11, 1289662. [Google Scholar] [CrossRef]

- Ganneau, F.; Constantinides, G.; Ulm, F.-J. Dual-indentation technique for the assessment of strength properties of cohesive-frictional materials. Int. J. Solids Struct. 2006, 43, 1727–1745. [Google Scholar] [CrossRef]

- Hajiabdolmajid, V.; Kaiser, P.K.; Martin, C.D. Modelling brittle failure of rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 731–741. [Google Scholar] [CrossRef]

- Dwivedi, R.D.; Goel, R.K.; Prasad, V.V.R.; Sinha, A. Thermo-mechanical properties of Indian and other granites. Int. J. Rock Mech. Min. Sci. 2008, 45, 303–315. [Google Scholar] [CrossRef]

- Cheng, C.; Li, X.; Li, S.; Zheng, B. Geomechanical Studies on Granite Intrusions in Alxa Area for High-Level Radioactive Waste Disposal. Sustainability 2016, 8, 1329. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Mechanism of brittle fracture of rock, parts I, II and III. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 395–430. [Google Scholar] [CrossRef]

- Tham, L.G.; Liu, H.; Tang, C.A.; Lee, P.K.K.; Tsui, Y. On Tension Failure of 2-D Rock Specimens and Associated Acoustic Emission. Rock Mech. Rock Eng. 2005, 38, 1–19. [Google Scholar] [CrossRef]

- Cai, M. Practical Estimates of Tensile Strength and Hoek–Brown Strength Parameter mi of Brittle Rocks. Rock Mech. Rock Eng. 2010, 43, 167–184. [Google Scholar] [CrossRef]

| Confining Pressure (MPa) | Peak Deviatoric Stress (σ1–σ3) (MPa) | ||||

|---|---|---|---|---|---|

| 20 °C 1 | 200 °C | 400 °C | 600 °C | 800 °C | |

| 0 | 79.9 | 77.8 | 84.3 | 51.9 | 31.0 |

| 10 | 229.3 | 209.7 | 247.3 | 244.0 | 161.0 |

| 20 | 317.7 | 310.7 | 341.7 | 263.0 | 246.7 |

| 30 | 392.7 | 397.0 | 425.0 | 379.7 | 219.0 |

| Heating Temperature (°C) | c (MPa) | φ (°) | R2 |

|---|---|---|---|

| 20 | 15.7 | 55.3 | 0.97 |

| 200 | 13.8 | 55.8 | 0.99 |

| 400 | 16.0 | 56.7 | 0.97 |

| 600 | 13.3 | 54.9 | 0.91 |

| 800 | 13.1 | 47.2 | 0.77 |

| Samples | Sample Size (mm) | Mineral Contents 1 | Heating Rate | Cooling Temprature 2 | References |

|---|---|---|---|---|---|

| Fangshan granite | φ25 × 50 | Qz (38%), Pl (47%), Mc (11%), and Mi (4%) | 3 °C/min | 20 °C | This study |

| Dabie granite | φ37 × 74 | Qz (8.9%), Pf (45.1%), Ab (21.1%), Mi (23.2%) | 5 °C/min | RM | [30] |

| Gonghe granite-1 | 50 × 50 × 50 | Pl (40%~50%), Qz (20%~25%), Bt (5%~10%) | 3~5 °C/h | 20 °C | [31] |

| Gonghe granite-2 | 60 °C | ||||

| Gonghe granite-3 | 100 °C | ||||

| Sichuan granite | φ50 × 100 | Fs (54.1%), Qz (40.2%), Bt (5.7%) | 5 °C/min | RM | [32] |

| Wuyi granite | φ40 × 80 | Qz (16%), Mc (51%), Bt (32%), Am (1%) | 5 °C/min | 25 °C | [33] |

| Rizhao granite-1 | φ50 × 100 | Qz (25%), Pl (39%), Pf (22%), Bt (14%) | 2~4 °C/min | RM | [34] |

| Rizhao granite-2 | [35] |

| Samples | Parameters in Equation (4) for Cohesion | R2 | Parameters in Equation (5) for the Internal Friction Angle | R2 | |||

|---|---|---|---|---|---|---|---|

| a | b | A | x0 | p | |||

| Fangshan granite | 0.0198 | 0.0008 | 0.19 | 1.02 | 0.24 | 8.92 | 0.07 |

| Dabie granite | −0.2104 | 0.0351 | 0.61 | 0.99 | 0.87 | 54.19 | 0.11 |

| Gonghe granite-1 | −0.3681 | 0.1069 | 0.93 | 1.26 | 4.02 | 20.00 | 0.69 |

| Gonghe granite-2 | −0.2326 | 0.0750 | 0.52 | 1.28 | 3.79 | 35.00 | 0.43 |

| Gonghe granite-3 | −0.4848 | 0.1818 | 0.80 | 1.40 | 3.13 | 15.00 | 0.74 |

| Sichuan granite | 0.1012 | −0.0069 | 0.87 | 1.06 | 0.47 | 198.90 | 0.62 |

| Wuyi granite | 0.0350 | −0.0040 | 0.88 | 1.01 | 2.83 | 63.37 | 0.65 |

| Rizhao granite-1 | −0.1120 | 0.0460 | 0.99 | 0.99 | 0.10 | 0.65 | 0.38 |

| Rizhao granite-2 | 0.1190 | 0.0130 | 0.99 | 1.02 | 0.50 | 13.57 | 0.93 |

| Samples | Sample Size (mm) | Mineral Contents 1 | Heating Rate | Cooling Water 2 | References |

|---|---|---|---|---|---|

| Gonghe granite-1 | φ50 × 25 | Pl (40%~50%), Qz (20%~25%), Bt (5%~10%) | 3~5 °C/h | 20 °C | [31] |

| Gonghe granite-2 | 60 °C | ||||

| Gonghe granite-3 | 100 °C | ||||

| Songliao granite | φ50 × 25 | Qz (26.1%), Mi (8.9%), PF (36%), Pl (25.2%) | 30 °C/h | 20 °C | [17,37] |

| Rizhao granite | φ50 × 25 | Pl (35%), PF (40–45%), Qz (20–25%), Bt (3–5%) | 3 °C/h | RM | [23] |

| Pingyi granite | φ50 × 25 | Il (25%), Qz (28%), Fs (43%) | N/A | RM | [25,38] |

| Samples | (MPa) | (°) | (MPa) |

|---|---|---|---|

| Fangshan granite | 15.74 | 55.34 | 2.46 1 |

| Dabie granite | 19.03 | 65.35 | 5.30 1 |

| Gonghe granite | 65.50 | 27.50 | 10.68 |

| Sichuan granite | 32.97 | 58.71 | 8.44 1 |

| Wuyi granite | 54.43 | 51.08 | 10.5 |

| Rizhao granite-1 | 20.93 | 53.44 | 1.73 1 |

| Rizhao granite-2 | 20.29 | 54.06 | 1.67 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Cheng, C.; Xie, Y.; Chen, P. Strength Parameters and Failure Criterion of Granite After High-Temperature and Water-Cooling Treatment. Appl. Sci. 2025, 15, 7481. https://doi.org/10.3390/app15137481

Yu J, Cheng C, Xie Y, Chen P. Strength Parameters and Failure Criterion of Granite After High-Temperature and Water-Cooling Treatment. Applied Sciences. 2025; 15(13):7481. https://doi.org/10.3390/app15137481

Chicago/Turabian StyleYu, Jincai, Cheng Cheng, Yuan Xie, and Peng Chen. 2025. "Strength Parameters and Failure Criterion of Granite After High-Temperature and Water-Cooling Treatment" Applied Sciences 15, no. 13: 7481. https://doi.org/10.3390/app15137481

APA StyleYu, J., Cheng, C., Xie, Y., & Chen, P. (2025). Strength Parameters and Failure Criterion of Granite After High-Temperature and Water-Cooling Treatment. Applied Sciences, 15(13), 7481. https://doi.org/10.3390/app15137481