Abstract

The plasma reactor and cylindrical-type electrostatic precipitator (PRESP), combined operation in one device, made in the metallic chimney of low-thermal power boilers (up to 50 kW) that burn wood, can be used in home applications. The discharge electrode is stretched and supported by two groups of medium-voltage insulators. The sensitive elements of PRESP are medium-voltage insulators. This article analyses the design, use, and effect of dirty gases on the medium-voltage insulators that support the discharge electrode under real operating conditions for a PRESP installed in a 20 kW thermal power boiler that burns wood (there are no studies on the performance of PRESP). The electrical properties of the medium-voltage insulators (isolation resistance, dielectric absorption ratio, and polarisation index) and the chemical analysis of the dust layer deposited on the medium-voltage insulators are analysed. Of the two types of insulators analysed, a longer length of the electrical insulators determines a safer and better operation of PRESP. After a period of operation of the PRESP, the insulation resistance decreases by more than 10 times. The polarisation index (values greater than 1.1–1.2) provides better information (compared to the dielectric absorption ratio) on the insulation quality.

1. Introduction

Numerous international studies have been conducted on plasma reactors (PRs) and electrostatic precipitators (ESPs), both of which utilise the corona phenomenon. Their operation is based on the application of a medium voltage (DC or pulse voltage, tens of kV) between the discharge and collection electrodes to obtain the corona effect [1,2,3,4,5,6,7,8].

Many studies on plasma reactors refer to the reduction of volatile organic compounds, CO2, NO, and NOx concentrations performed under laboratory conditions (laboratory models) used for various applications, such as diesel engines, kitchens, or in strict laboratory conditions [1,2,3,4]. There are studies on ESP used for low-power boilers (kW of thermal power) and some ESPs used for low-power boilers that have small ionisation zones, with direct implications for operation [5,6,8,9,10,11,12]. Most research on ESPs has been conducted using small laboratory models [13,14,15,16,17].

When burning wood on stoves, comparative studies were carried out with separate or combined operations with ESP (with DC medium-voltage) and platinum/palladium catalysts [18,19]. The use of a larger number of collector tubes leads to a slight increase in collection efficiency, but maintenance is much more difficult [20]. Some studies have been conducted on the use of cylindrical-type ESPs (CESPs) with several tubes mounted in cylindrical or rectangular enclosures between the boiler and chimney [21,22,23,24]. It has been found that ESPs with one section have a simple design because they are supplied from a single DC medium voltage (usually up to 30 kV). Different configurations (simpler or more complex) of electrical insulators have been used and experimented under the conditions under which they work in difficult conditions (high temperature and humidity, dirty gases), because their resistance decreases with time, and the voltage applied between the electrodes is lower (the Corona is less intense) [19,20,25].

Research was conducted on the placement of medium-voltage insulators. By placing the medium-voltage insulators outside the gas flow (oblique to the vertical chimney or near the chimney), a decrease in the rapid deposition of dirt on the surface of the medium-voltage insulators was observed. The disadvantages of these methods include the use of small discharge electrodes (reduced corona effect), major deficiencies in the centring of the discharge electrode in the collection electrode (the applied voltage is lower and the corona is much reduced), and small dust collection (30–40%) [18,25].

The smoke resulting from wood combustion consists of particulate matter (PM), NOx, CO, CO2, formaldehyde, volatile organic compounds, CH4, H2, and so on. Smoke from burning wood is composed of a complex mixture of gases and fine particles (PM 10, PM 2.5, PM 1) [5,7,26,27,28,29]. These components are harmful to human health, as to well as the environment [30,31].

PRESPs can encounter several problems during operation, such as the cleaning of medium-voltage insulators and collector electrodes, re-entrainment of particles from collector electrodes, and long-term stability of medium-voltage insulators [5,7,9,10,11]. Some problems occur when moisture is condensed in the gas on the surface of the insulators, and short currents occur [5,6,8,19,20,25].

This article presents an analysis of medium-voltage electric insulators for a cylindrical-type plasma reactor and electrostatic precipitator made directly in the chimney (stainless steel). In this way, the PRESP footprint on the ground is missing, which solves a real problem.

This article analyses the modification of the electrical properties of the medium-voltage insulators used at PRESP and does not focus on the performance of the plasma reactor and the collection of the cylindrical-type electrostatic precipitator. The article has the following structure: introduction, materials and method, results, discussions, and the last section, conclusions.

2. Materials and Method

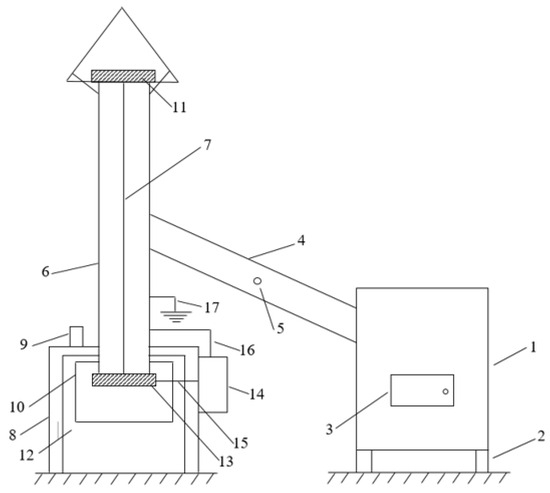

The experiments were conducted using a low-power boiler 1 that burned wood with a thermal power of 20 kW (Figure 1). The boiler has support 2 and the wood supply door 3. The boiler smoke outlet had an outer diameter of 125 mm. A connection tube (stainless steel tube) 4 (1.45 m long) between chimney 6 (stainless steel tube, PRESP) and boiler 3 has an access area 5 for measuring the smoke and gases after the boiler. The chimney has a height of 4.5 m, an inner diameter of 125 mm, and an outer diameter of 129 mm. Inside the chimney is a thin wire (discharge electrode, with a constant cross-section) 7 with a diameter of 0.75 mm, stretched on the central axis of the chimney through an electrical medium-voltage insulator 11 in the upper part of the chimney and an electrical medium-voltage insulator 13 in the lower part. The discharge electrode 7 is stretched, and there is a weight at the bottom. A metal conical cover is placed at the upper end of the chimney to prevent water from entering the chimney during rain. The chimney is supported by the support with legs 8, on which is an electromagnet 9 used for shaking, a collection device 10, a medium-voltage source 14 with conductor 15 supplying the discharge electrode 7 (negative polarity of the medium-voltage source), and conductor 16 (positive polarity of the medium-voltage source; it is also connected to the ground) that connects to the chimney 6 (the collection electrode).

Figure 1.

Principle experimental scheme with a real PRESP connected to a low-power boiler.

Chimney 6 is connected by two bridges, and metallic support 8 is connected by one bridge to an earth socket consisting of four electrodes inserted into the ground. The electric resistance is 3.5 Ω (must be less than 4 Ω; measured with 8PK-ST1520, Pro’sKit (Hsinchu, Taiwan)—device for measuring the earth socket with a resolution of 0.1 Ω).

PRESP can work in combination using two electrodes (one discharge electrode and another collection electrode, by applying a DC medium-voltage): a plasma reactor, with the possibility of reducing chemical compounds (CO, NOx), and an electrostatic precipitator to reduce the concentration of dust (PM) at the output of the chimney.

During the operation of the PRESP, dirt is deposited on the medium-voltage electrical insulators. The electrical properties of medium-voltage electrical insulators are influenced by dust and gases resulting from combustion.

To analyse the PRESP, it is compared with other CESP. Some characteristics of the domestic CESP connected to low-power boilers are as follows: radius of the collection tube r = 8 cm; active length of the precipitator L = 0.5 m; number of collection tubes n = 6; lateral surface for a tube Sl = 0.19 m2; total lateral surface: Slt = 1.13 m2; diameter of the discharge electrode with constant cross-section Φc = 1 mm; switching voltage source with medium voltage up to 30 kV, DC; and can be connected to a boiler with a maximum power of 50 kW [23].

The main features of the PRESP (Figure 1) connected to a 20 kW boiler are as follows:

- -

- Radius of the collection stainless steel tube: r = 62.5 mm (diameter D = 125 mm);

- -

- Active length of the precipitator: h = 4.5 m;

- -

- The number of collection tubes: n = 1;

- -

- Discharge electrode diameter (with a constant cross-section): Φc = 0.75 mm;

- -

- The maximum DC medium-voltage power supply (with short-circuit protection, max. 10 mA): U = 30 kV.

The gas flow at the input of the domestic precipitator is Q = 40–65 m3/h (0.0111–0.018 m3/s) [5,6,9,13,23,28]. The cross-section of the cylindrical precipitator is:

St = 0.012272 m2.

The average speed in the cross-section of the domestic precipitator can be computed as follows:

For Q = 40 m3/h, vavg = 0.904 m/s was obtained, and for Q = 65 m3/h, vavg = 1.469 m/s was obtained. The average time spent by the particles in the electric field was calculated as follows:

After calculation, for Q = 40 m3/h, tavg = 4.978 s, and for Q = 65 m3/h, 3.063 s are obtained.

A lower gas flow rate ensures a longer gas passage time near the discharge electrode, which ensures better treatment of gases and dust collection. The time (approximately) to electrostatic charge of small particles (<1 μm) is [7]:

- -

- through an electric field of 0.1 s (in 90% of the cases);

- -

- through diffusion 2.3 ÷ 5 s.

A lower gas velocity results in better loading of dust particles and a long enough time for the plasma reactor to operate. The average electric strength in a cylindrical-type domestic electrostatic precipitator can be calculated as [32]:

where U is the supply voltage, and r is the radius of the cylinder.

For U = 10 kV, Eavg = 1.6 kV/cm, and U = 30 kV, Eavg = 4.8 kV/cm. Taking into account the distance between the electrodes, the maximum voltage is 30 kV.

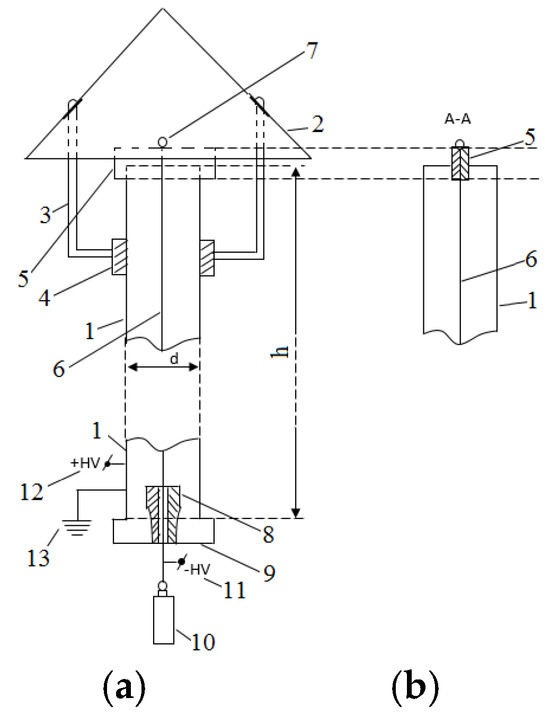

During many experiments (conducted over 4 years), it was found that the upper-side insulator was the most demanding (due to the high temperatures above 250 °C and the gas content affecting the medium-voltage electrical insulators supporting the discharge electrode) from a thermal, mechanical, and, in particular, electrical point of view (Figure 2 and Figure 3).

Figure 2.

(a) The longitudinal cross-section from the chimney; (b) side view of the 90°-degree rotation of the chimney.

Figure 3.

(a) The chimney made with upper-side electrical insulator type 2 in the top part—side view; (b) top view.

In Figure 2: 1—the stainless steel tube of the chimney; 2—the upper metal cover from the top part of the chimney; 3—metal supports for attaching the metal upper cover to the tube of the chimney; 4—metal collar for fastening on the chimney tube; 5—the upper-side electrical insulator, type 1, with dimmensions of 250 × 60 × 20 mm, mounted in the top part to connect the discharge electrode; 6—discharge electrode; 7—metallic terminal element for supporting the discharge electrode on the upper-side electrical insulator; 8—ceramic support mounted in the lower part of the chimney for centring the discharge electrode; 9—textolite electro-insulating support (lower side electrical insulator) for supporting and centring the discharge electrode; 10—weight for stretching the discharge electrode; 11—the negative potential of the medium-voltage source mounted at the discharge electrode; 12—the positive potential of the medium-voltage source mounted on the stainless steel chimney (collecting electrode); 13—grounding the chimney (through an earth socket).

The purpose of the upper and lower side electrical insulators that support the discharge electrode connected to the medium-voltage source is to ensure a high electrical resistance between the discharge electrode and the chimney (which is the collecting electrode) under conditions of dust, chemical compounds, humidity, and high temperature.

Over time, two types (type 1 and type 2) of upper-side electrical insulators have been tested: a simpler rectangular porcelain insulator with a metal rain protection cover (5, type 1, Figure 2; ensures a small distance between two electrodes, equal to D/2) and a more complex one with porcelain insulators and a porcelain cover (2, 5, type 2, Figure 3; ensures a much greater distance, more than 2.5 times compared to type 1, Figure 2).

The material used for the medium-voltage insulators was porcelain, which has very good properties as an electrical insulator at high temperatures, humidity, and under dirty conditions (dust deposits). Electrical insulation on the lower side is much less stressed: temperatures below 100 °C, and it is not directly in the gas flow; instead, the dust falling on the insulator can change its properties). The electrical insulator supporting and centring the discharge electrode consists of a ceramic support (8) and a cylindrical textile support (9), as shown in Figure 2.

In Figure 3a, there are three electrical insulators (5) offset by 120°. In Figure 3: 1—the stainless steel tube of the chimney; 2—the upper porcelain cover from the top part of the chimney (diameter 240 mm; height 110 mm); 3—metal supports to connect the components; 4—cylindrical collars to attach metal supports to the chimney; 5—3 × 18 kV medium-voltage porcelain electrical insulator (three elements connected in series); 6—discharge electrode; 7—metallic terminal element to support the discharge electrode on the upper porcelain cover; 8—electrical insulation against moisture with 40 mm diameter; 9—metal supports to hold the upper ceramic cover; 10—component mounting holes. Medium-voltage insulators (5, Figure 3) are three insulators connected in series (to operate at a higher voltage); a simple insulator has the following characteristics: voltage 18 kV, outer diameter 40 mm, four striations (striation thickness 5 mm, distance between two successive striations 5 mm), height 40 mm, and mechanical connection M8. For configuration type 2, (5, Figure 3), three medium-voltage insulators connected in series (3 × 18 kV) are distributed in three arms.

3. Results

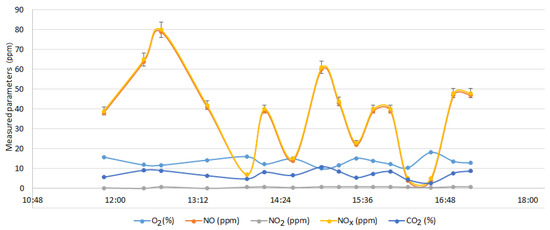

To exemplify the concentration of some compounds during the combustion of wood, O2, NO, NO2, NOx, CO2, CO, and H2 were measured with the TESTO 350XL analyser (Lenzkirch, Germany) (specialised analyser for measuring combustion gases according to sensors on chemical compounds; sensors were used for detection O2, NO, NO2, NOx, CO2, CO, and H2; also, measure the ambient air temperature and gas temperatures) without using the medium-voltage source to supply PRESP (Figure 4). The measurements were performed at the exit of the chimney. At the same time, the gas temperature at the chimney output and the ambient temperature were measured (Figure 5). Dry wood (less than 10% humidity) was burned in the stove (about 2.3–2.8 kg per load, from time to time).

Figure 4.

Evolution of some measured quantities (O2, NO, NO2, NOx, and CO2 measured with TESTO 350XL) during the combustion of wood in the 20 kW power plant.

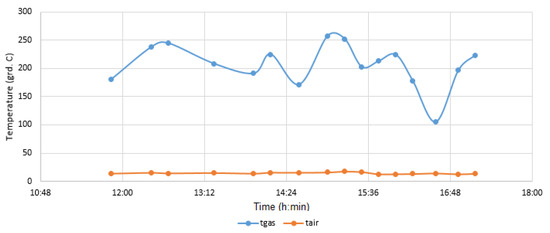

Figure 5.

Evolution of the ambient temperature (tair) and gases in the chimney output (tgas), measured with TESTO 350XL during the burning of wood in the 20 kW power plant.

In Figure 4 and Figure 5, the error bars for the measured values have been passed. For O2 and CO2 (Figure 4), the errors are below 0.8%, and for the temperature (Figure 5), the errors are below 1% (for this reason, the error bars are not visible on the graphs).

During the supply of wood to the boiler, NO and NOx increase to high values (at the beginning of the operation to 80 ppm, after a few hours to 40–60 ppm), as well as the temperature of the gases at the output of the chimney. After a period of operation (2–3 h), the operating temperature decreases, as do the concentrations of NO and NOx. During the beginning of wood burning, the concentration of O2 decreases and CO2 increases, and after the wood has burned, the evolution is reversed for O2 and CO2.

Other quantities were also measured: CO, which had values above 5000 ppm (the device can measure up to 5000 ppm; lower values after burning the wood 3500–4500 ppm; in this stage, evaluations were also made on the operation of the plasma reactor); and H2, which had values above 2000 ppm (the device can measure up to 2000 ppm; lower values after burning the wood 1000–1700 ppm).

The metallic chimney, together with the central electrode, forms a cylindrical capacitor, whose electrical capacitance is calculated as [32]

After performing the calculations using the PRESP data, C = 48.867 pF. The measured electrical capacitance (consisting of the stainless steel chimney and the central discharge electrode) with air (εr = 1), when the boiler is not working, is 50 pF. During boiler operation (with smoke at high temperatures and humidity), as the temperature increases, the electrical capacitance increases (εr > 1): 67 pF at 198 °C, 68 pF at 202 °C, and 71 pF at 244 °C.

Some factors in computing and evaluating insulation quality are the dielectric absorption ratio (Dar) and the polarisation index (Pi) [32].

The values of Dar and Pi are used to estimate the quality of the electric insulation (in principle, values above unity indicate better quality of insulation). This is achieved by plotting the insulation resistance with respect to time and calculating the Dar and Pi values. For a medium-quality insulation material, the resistance should increase when a measuring voltage is applied [32].

When measuring the electrical parameters that characterise the electrical insulators of PRESP (5, 8, 9 Figure 2; 2, 3 Figure 3), the UNILAP ISO 5kV megohmmeter (test voltages up to 5 kV) and LEM were used, which can apply DC test voltages of 0.5, 1, 2.5, and 5 kV.

Table 1 shows the experimental measurements (before and after cleaning; Riso—isolation resistance) on the lower side of the electrical insulator (9, Figure 2a), which must be cleaned periodically. The experiments were carried out for three hours during which a fire was started in the boiler with dry wood (humidity < 10%).

Table 1.

Measurements before and after cleaning the lower side insulator (textolite, round plate) from the PRESP.

For type 1 upper-side electrical insulator (5, Figure 2), measurements were performed before using the gas flow from the boiler. The measurements are presented in Table 2 and Table 3, where the insulation resistances are very high (of the order of GΩ when the electrical insulator is clean) and decrease after it has been used.

Table 2.

Measurements taken on the new type 1 upper-side medium-voltage insulator when fitted on the PRESP.

Table 3.

Measurements made on the used type 1 upper-side medium-voltage insulator after approximately 14 days of operation.

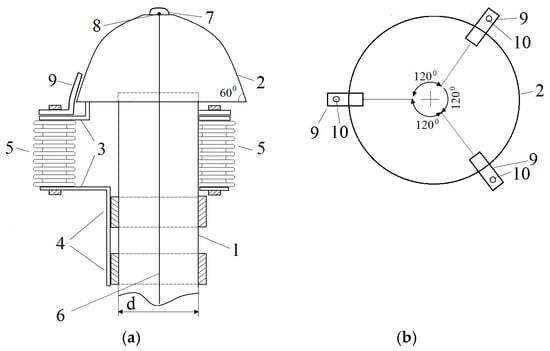

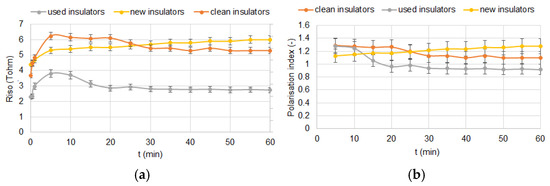

For the upper-side type 2 configuration (5, 9, Figure 3a), three groups of single insulators connected in series were used for safety in operation and to increase the operation. As shown in Figure 6, experiments were carried out on insulators connected in series (3 × 18 kV). Each graph was created for a time of 60 min. Error bars have been added to the graphs.

Figure 6.

Three insulators connected in series, new insulators (Dar = 1.04), used (approximately 2 months; Dar = 1.1), and cleaned (Dar = 1.08), 5 kV test voltage: (a) insulation resistance; (b) polarisation index.

For the upper type 2 electrical insulator with the configuration shown in Figure 3a. The insulation resistance and dielectric absorption ratio were measured at different test voltages (1 kV and 2.5 kV), and the results are listed in Table 4.

Table 4.

Measurements taken on the new type 2 upper-side medium-voltage insulator when mounted on the chimney.

For the chemical analysis of dust, measurements were made with a spectrometer (sequential X-ray fluorescence spectrometer, Thermo Scientific ARL X900 XRF spectrometer, UniQuant Software, Thermo Fischer, Waltham, MA, USA) on the dust deposited on the electro-insulating supports of the chimney [33,34]. The results are presented in Appendix A Table A1, Table A2 and Table A3. The chemical compounds deposited on the electrical insulators determine the modification of the electrical properties (especially the insulation resistance) of the electrical insulators (the most sensitive are the upper-side medium-voltage insulators, type 2, Figure 3) for PRESP. The surface electrical resistance between the metal ends of the electrical insulators (5, 9, Figure 3) changes.

4. Discussions

The lower side insulator must be cleaned often (at least every 2 days) because the insulation resistance drops significantly (to tens of MΩ). In the future, the lower side insulator should be replaced with a porcelain insulator (it has better dielectric qualities and can work at high temperatures). After cleaning, the resistance of the lower side insulator increasesby tens of times (when testing with 2.5 or 5 kV).

The design of medium-voltage electrical insulators is crucial, particularly for the high reliability and optimal operation of the PRESP. A longer length of the electrical isolation route (longer length in type 2, Figure 3, compared to type 1, Figure 2) ensures better operation (possibility of applying a higher average voltage over long periods of time because the insulation resistance has high values).

The use of the three support arms of the upper-side medium-voltage insulator (porcelain) cover (2, Figure 3) leads to a reduction in the insulation resistance. In future research, another two-arm clamping system should be designed. The explanation is as follows: by using three identical electrical resistances connected in parallel (Riso/3), the equivalent electrical resistance is lower than that obtained by using two electrical resistances connected in parallel (Riso/2). The insulation resistance values of the insulation resistances are high (>2 TΩ) for the configuration with three insulators connected in series (Figure 6). It was observed that the insulation resistance increases with time, which indicates a good quality.

In the configuration with three insulators connected in series (Figure 6), the insulation resistance is high (over 4.3 TΩ) over time. If the insulators have been used for a period of time, it is observed that the insulation resistance drops to almost half (compared to the situation when they were clean), and the evolution of the resistance is no longer increasing (which indicates that the electrical properties of the insulation are affected). After cleaning the electrical insulators, the electric resistance increases by 0.5–0.7 TΩ, but the evolution over time decreases. The same evolutions can be found in the polarisation index: for clean insulators, the evolution of the polarisation index is increasing (values above 1.1), and in the other two situations, the evolutions of the polarisation index are decreasing.

Carbon (which is in high concentration in the layer deposited on the insulators over 23%; Appendix A Table A1, Table A2 and Table A3) has a low electrical resistivity. For some chemical elements and compounds (K2O, CaO, Cl, Fe2O3, and ZnO), the electrical resistivity decreases with increasing temperature. All these elements or chemical compounds that were found in high concentrations in the electrical insulators (relative mass greater than 2.7%, Appendix A Table A1, Table A2 and Table A3) change the insulation resistance of the electrical insulators. Some chemical compounds can create acids that directly act on PRESP elements.

In order not to decrease the insulation resistance, the following measures can be taken:

- -

- The use of wood as dry as possible (humidity below 10%), preferably hardwood;

- -

- Avoid frequent start-ups of the boiler, the performance of the PRESP being greatly reduced during the start-up of the boiler, which can last 1.5–2 h, and when wood is introduced into the boiler;

- -

- Boiler operation at the nominal regime for as long periods of time as possible;

- -

- The use of electrical insulation with as large isolation routes as possible;

- -

- Periodic cleaning of the electrical insulator from deposits that change the insulation resistance;

- -

- Periodic replacement of the discharge electrode because, at some point, it can break and put the PRESP out of action;

- -

- During the operation of PRESP, the insulation resistance of electrical insulators can decrease by 10 times compared to the situation when they are new;

- -

- By cleaning electrical insulators, the insulation resistance increases, but not to the initial values (when the insulator is new);

- -

- To indicate the quality of the electrical insulator, the polarisation index is more useful (values above 1.1–1.2 are for good quality of the insulation) compared to the dielectric absorption ratio (which can have high values, 1.3–1.5 when the insulator is dirty).

In the following, a cost analysis is made of implementing a PRESP under the conditions in which the investments in the boiler, the stainless steel chimney, and the stainless steel have been made:

- -

- medium-voltage switched mode power supply (max. 30 kV, DC) with overcurrent protection (max. 10 mA) and short circuit: Euro 250;

- -

- medium-voltage insulator from the upper-side of the chimney (type 2, Figure 3): Euro 200;

- -

- medium-voltage insulator from the lower side of the chimney (Figure 2): Euro 50;

- -

- earth socket (for connecting the chimney) consisting of galvanised stakes, galvanised connection plate, and copper conductor: Euro 125.

5. Conclusions

Through the passage of gases and dust (which can have low electrical resistivity at high temperatures) through the medium-voltage insulators, they are deposited on the surface of the electrical insulators, and the insulation resistance can decrease hundreds or even thousands of times, which leads to a limitation of the voltage applied between the electrodes. Medium-voltage insulators from the upper side are the most requested (operation at high temperatures and humidity in gas with dust that creates deposits on the insulator). An electrical insulator with a longer path ensures a long operation of the PRESP. Of the two configurations tested, the type 2 configuration (consisting of the upper porcelain cover and medium-voltage porcelain electrical insulators; three branches of three insulators each connected in series) of upper-side medium-voltage electric insulators ensures a better operation over a longer period of time. To indicate the quality of electrical insulation, the polarisation index is more useful (good insulation quality value 1.1–1.2) than the electrical absorption ratio. Cleaning electric insulation increases insulation resistance but not initial value.

In the future, research will be carried out on the performance of PRESP when supplied with DC medium-voltage and pulsed medium-voltage to establish its performance (over long periods of time) and to be as reliable as possible (from the point of view of the power source and the discharge electrode).

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The author wishes to thank Iosif Popa for valuable and interesting discussions about the topic of this research. The author thanks the beautiful collaboration with Iosif Popa, who passed away in 2023. Also, the author is grateful for collaboration and interesting discussions with Marcel Modiga.

Conflicts of Interest

The author declares no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PRESP | Plasma reactor and cylindrical-type electrostatic precipitator |

| PR | Plasma reactor |

| ESP | Electrostatic precipitator |

| DC | Direct current |

| CESP | Cylindrical-type electrostatic precipitator |

| PM | Particulate matter |

| r | Radius of a collection stainless steel tube |

| D | Diameter of a collection stainless steel tube |

| h | Active length of the precipitator |

| n | Number of collection tubes |

| Φc | Discharge electrode diameter (with constant cross-section) |

| U | DC medium-voltage |

| Q | Gas flow at the input |

| St | Cross-section of cylindrical precipitator |

| vavg | Average speed in the cross-section |

| tavg | Average time spent by the particles in the electric field |

| Eavg | Average electric strength in a cylindrical-type electrostatic precipitator |

| Riso | Isolation resistance |

| Dar | Dielectric absorption ratio |

| Pi | Polarisation index |

Appendix A

In Table A1, Table A2 and Table A3, the weight is the relative weight of the compound or element, and StdErr is the standard error in weight % for the compound or element calculated with [33,34]:

where k = 0.05–0.15 depending on the compound or element and the physical nature of the sample, and C is the compound.

Table A1.

Analysis of the dust that falls into the chimney without the operation of the PRESP.

Table A1.

Analysis of the dust that falls into the chimney without the operation of the PRESP.

| Compound | Relative Weight (%) | StdErr (−) | Element | Relative Weight (%) | StdErr (−) |

|---|---|---|---|---|---|

| Fe2O3 | 21.93 | 0.21 | Fe | 15.33 | 0.14 |

| CaO | 15.42 | 0.18 | Ca | 11.02 | 0.13 |

| SiO2 | 9.98 | 0.15 | Si | 4.67 | 0.07 |

| K2O | 7.07 | 0.13 | K | 5.87 | 0.11 |

| Cl | 4.58 | 0.1 | Cl | 4.58 | 0.1 |

| MgO | 3.94 | 0.1 | Mg | 2.38 | 0.06 |

| SO3 | 3.45 | 0.09 | Sx | 1.38 | 0.04 |

| Al2O3 | 3.25 | 0.09 | Al | 1.72 | 0.05 |

| Na2O | 2.74 | 0.08 | Na | 2.04 | 0.06 |

| P2O5 | 1.57 | 0.06 | Px | 0.684 | 0.027 |

| ZnO | 0.349 | 0.042 | Zn | 0.682 | 0.034 |

| MnO | 0.607 | 0.03 | Mn | 0.47 | 0.023 |

| TiO2 | 0.364 | 0.018 | Ti | 0.219 | 0.011 |

| BaO | 0.282 | 0.021 | Ba | 0.253 | 0.019 |

| CuO | 0.247 | 0.012 | Cu | 0.197 | 0.01 |

| Cr2O3 | 0.181 | 0.009 | Cr | 0.124 | 0.006 |

| PbO | 0.0908 | 0.0045 | Pb | 0.0843 | 0.0042 |

| SrO | 0.0558 | 0.0020 | Sr | 0.0472 | 0.0024 |

| NiO | 0.48 | 0.0118 | Ni | 0.0374 | 0.0085 |

| ZrO2 | 0.0183 | 0.0022 | Zr | 0.0135 | 0.0016 |

| Rb2O | 0.0102 | 0.0014 | Rb | 0.0093 | 0.0013 |

| SnO2 | 0.0092 | 0.0041 | Sn | 0.0072 | 0.0032 |

| MoO3 | 0.0059 | 0.0013 | Mo | 0.0039 | 0.0008 |

| Br | 0.0024 | 0.0012 | Br | 0.0024 | 0.0012 |

Carbon 23.3%.

Table A2.

Analysis of the dust that falls into the chimney during the operation of the PRESP.

Table A2.

Analysis of the dust that falls into the chimney during the operation of the PRESP.

| Compound | Relative Weight (%) | StdErr (−) | Element | Relative Weight (%) | StdErr (−) |

|---|---|---|---|---|---|

| CaO | 18.1 | 0.19 | Ca | 12.94 | 0.14 |

| SiO2 | 16.02 | 0.18 | Si | 7.51 | 0.09 |

| K2O | 11.04 | 0.16 | K | 9.16 | 0.3 |

| SO3 | 7.79 | 0.13 | Sx | 3.12 | 0.05 |

| Cl | 4.45 | 0.1 | Cl | 4.45 | 0.1 |

| Fe2O3 | 4.3 | 0.1 | Fe | 3.01 | 0.07 |

| Al2O3 | 3.41 | 0.09 | Al | 1.8 | 0.05 |

| MgO | 2.44 | 0.08 | Mg | 1.47 | 0.05 |

| Na2O | 1.97 | 0.07 | Na | 1.46 | 0.05 |

| P2O5 | 1.84 | 0.07 | Px | 0.802 | 0.029 |

| ZnO | 1.4 | 0.06 | Zn | 1.07 | 0.05 |

| TiO2 | 0.57 | 0.028 | Ti | 0.334 | 0.017 |

| MnO | 0.5 | 0.017 | Mn | 0.271 | 0.014 |

| PbO | 0.099 | 0.01 | Pb | 0.185 | 0.09 |

| BaO | 0.08 | 0.0075 | Ba | 0.717 | 0.0067 |

| SrO | 0.057 | 0.0028 | Sr | 0.0482 | 0.0024 |

| CuO | 0.0547 | 0.0027 | Cu | 0.0437 | 0.0022 |

| ZrO2 | 0.0337 | 0.0017 | Zr | 0.0249 | 0.0012 |

| Br | 0.0299 | 0.0015 | Br | 0.0299 | 0.0015 |

| CdO | 0.0277 | 0.0014 | Cd | 0.0242 | 0.0012 |

| Rb2O | 0.0271 | 0.0014 | Rb | 0.0248 | 0.0012 |

| Cr2O3 | 0.0188 | 0.0011 | Cr | 0.0129 | 0.0007 |

| SnO2 | 0.0044 | 0.0018 | Sn | 0.0035 | 0.0014 |

| MoO3 | 0.0025 | 0.0007 | Mo | 0.0017 | 0.0005 |

| Ca3O4 | 0.0023 | 0.0008 | Co | 0.0017 | 0.0006 |

| SeO2 | 0.0019 | 0.0008 | Se | 0.0014 | 0.0006 |

Carbon 25.8%.

Table A3.

Analysis of the dust deposited on the upper-side medium-voltage insulators.

Table A3.

Analysis of the dust deposited on the upper-side medium-voltage insulators.

| Compound | Relative Weight (%) | StdErr (−) | Element | Relative Weight (%) | StdErr (−) |

|---|---|---|---|---|---|

| K2O | 15.4 | 0.18 | K | 12.79 | 0.15 |

| CaO | 13.1 | 0.17 | Ca | 9.94 | 0.12 |

| Cl | 9.28 | 0.15 | Cl | 9.28 | 0.15 |

| SO3 | 9.03 | 0.14 | Sx | 3.61 | 0.06 |

| SiO2 | 8.95 | 0.14 | Si | 4.18 | 0.07 |

| Fe2O3 | 5.9 | 0.11 | Fe | 3.56 | 0.08 |

| Na2O | 2.2 | 0.08 | Na | 2.09 | 0.06 |

| ZnO | 2.7 | 0.08 | Zn | 2.15 | 0.06 |

| Al2O3 | 2.5 | 0.07 | Al | 1.09 | 0.04 |

| MgO | 1.7 | 0.06 | Mg | 0.886 | 0.036 |

| P2O5 | 0.73 | 0.036 | Px | 0.318 | 0.016 |

| BaO | 0.386 | 0.019 | Ba | 0.346 | 0.017 |

| TiO2 | 0.333 | 0.017 | Ti | 0.2 | 0.01 |

| PbO | 0.323 | 0.016 | Pb | 0.3 | 0.015 |

| MnO | 0.316 | 0.016 | Mn | 0.245 | 0.012 |

| Br | 0.717 | 0.0036 | Br | 0.0717 | 0.0036 |

| SrO | 0.66 | 0.0033 | Sr | 0.0558 | 0.0028 |

| CuO | 0.571 | 0.0029 | Cu | 0.0456 | 0.0023 |

| Rb2O | 0.378 | 0.0019 | Rb | 0.0346 | 0.0017 |

| ZrO2 | 0.295 | 0.0026 | Zr | 0.0218 | 0.0019 |

| Ar | 0.232 | 0.0017 | Ar | 0.0232 | 0.0017 |

| Cr2O3 | 0.196 | 0.0014 | Cr | 0.0134 | 0.001 |

| SnO2 | 0.163 | 0.0035 | Sn | 0.0128 | 0.0028 |

| As2O3 | 0.162 | 0.0078 | As | 0.0123 | 0.0059 |

| CdO | 0.093 | 0.0024 | Cd | 0.0081 | 0.0021 |

| SeO2 | 0.0061 | 0.0016 | Se | 0.0043 | 0.0011 |

Carbon 26.9%.

References

- Veerapandian, S.K.P.; Leys, C.; De Geyter, N.; Morent, R. Abatement of VOCs Using Packed Bed Non-Thermal, Plasma Reactors: A Review. Catalysts 2017, 7, 113. [Google Scholar] [CrossRef]

- Talebizadeh, P.; Rahimzadeh, H.; Babaie, M.; Anaghizi, S.J.; Ghomi, H.; Ahmadi, G.; Brown, R. Evaluation of Residence Time on Nitrogen Oxides Removal in Non-Thermal Plasma Reactor. PLoS ONE 2015, 10, e0140897. [Google Scholar] [CrossRef] [PubMed]

- Sasujit, K.; Dussadee, N.; Tippayawong, N. Development of a Non-Thermal Gliding-Arc Discharge Reactor for Biomass Tar Treatment. Eng. Appl. Sci. Res. 2019, 46, 176–182. [Google Scholar]

- Colozza, A.J.; Gray, T.G.; Steinetz, B.M.; Edwards, L.G.; Jakupca, I.J.; Castle, C.; Johnson, D.; Daniels, C.C. Plasma Reactor Summary; NASA/TM—2020-220344; Glenn Research Center: Cleveland, OH, USA, August 2020. [Google Scholar]

- Bologa, A.; Paur, H.R.; Ulbricht, T.; Woletz, K. Particle Discharges from Small Scale Wood Combustion Devices and their Control by Electrostatic Precipitation. Chem. Eng. Trans. 2010, 22, 119–124. [Google Scholar]

- Bologa, A.; Paur, H.R.; Woletz, K. Development and Study of an Electrostatic Precipitator for Small Scale Wood Combustion. Choice 2011, 2, 7. [Google Scholar]

- Parker, K.R. Applied Electrostatic Precipitation; Chapman and Hall: London, UK, 1997. [Google Scholar]

- Bologa, A.; Paur, H.R.; Seifert, H.; Woletz, K. Particle Collection by an Electrostatic Precipitator from the Exhaust Gas of a Wood Combustion Stove. In Proceedings of the European Combustion Meeting, Vienna, Austria, 14–17 April 2009; pp. 1–6. [Google Scholar]

- Hartmann, H.; Turowski, P.; Kiener, S. Electrostatic Precipitators for Small-Scale Combustion Systems—Results from Lab- and Field Tests. In Proceedings of the Central European Biomass Conference, Graz, Austria, 26–28 January 2011. [Google Scholar]

- Hartmann, H.; Turowski, P.; Kiener, S. Electrostatic precipitators for small scale wood furnances. Environ. Eng. 2010, 5, 342–345. [Google Scholar]

- Bäfver, L.; Yngvesson, J.; Niklasson, F. Residential Electrostatic Precipitator—Performance at Efficient and Poor Combustion Conditions. Eneriteknik 2012, 42, 1–25. [Google Scholar]

- Levy, J.I.; Biton, L.; Hopke, P.K.; Zhang, K.M.; Rector, L.A. A Cost-Benefit Analysis of a Pellet Boiler with Electrostatic Precipitator Versus Conventional Biomass Technology: A Case Study of an Institutional Boiler in Syracuse, New York. Environ. Res. 2017, 156, 312–319. [Google Scholar] [CrossRef] [PubMed]

- Wilton, E. Evaluation of the Effectiveness of the Oeko Tube ESP in the Management of PM10 in Reefton; Prepared for West Coast Regional Council; Environet Ltd.: Christchurch, New Zealand, 28 February 2014. [Google Scholar]

- Yang, S.; Ford, P.; Subramanian, S.; Singleton, D.; Sanders, J.; Cronin, S.B. Transient Pasma-Enhanced Remediation of Nanoscale Particulatematter in Restaurant Smoke Discharges via Electrostatic Precipitation. Particuology 2021, 55, 43–47. [Google Scholar] [CrossRef]

- Popa, G.N.; Dăscălescu, L. Variable Cross-Section Cylinder-Type Corona and Combined Corona-Dielectric Barrier Discharge Precipitators for Fly-Ash Particles. Part. Sci. Technol. Int. J. 2014, 32, 445–450. [Google Scholar] [CrossRef]

- Ruttanachot, C.; Tirawanichakul, Y.; Tekasakul, P. Application of Electrostatic Precipitator in Collection of Smoke Aerosol Particles from Wood Combustion. Aerosol Air Qual. Res. 2011, 11, 90–98. [Google Scholar] [CrossRef]

- Popa, G.N.; Dăscălescu, L. Pulsed-High-Voltage-Supplied Variable Cross-Section Cylindrical Electrostatic Precipitators for Fly-Ash Particles. Part. Sci. Technol. Int. J. 2018, 36, 1029–1036. [Google Scholar] [CrossRef]

- Vicente, E.D.; Duarte, M.A.; Tarelho, L.A.C.; Alves, C.A. Efficiency of Emission Reduction Technologies for Residential Biomass Combustion Appliances: Electrostatic Precipitator and Catalyst. Energies 2022, 15, 4066. [Google Scholar] [CrossRef]

- Afshari, A.; Ekberg, L.; Forejt, L.; Mo, J.; Rahimi, S.; Siegel, J.; Chen, W.; Wargocki, P.; Zurami, S.; Zhang, J. Electrostatic Precipitators as an Indoor Air Cleaner—A Literature Review. Sustainability 2020, 12, 8774. [Google Scholar] [CrossRef]

- Trnka, J.; Jandačka, J.; Holubčík, M. Improvement of the Standard Chimney Electrostatic Precipitator by Dividing the Flue Gas Streaminto a Larger Number of Pipes. Appl. Sci. 2022, 12, 2659. [Google Scholar] [CrossRef]

- Popa, G.N. Dry Plate-Type Electrostatic Precipitator with Parallelepiped Housing. Patent No. 132976, 30 April 2024. [Google Scholar]

- Popa, G.N.; Diniș, C.M.; Iagăr, A.; Deaconu, S.I. An Analysis of the High Voltage Sources Used for Small Cylindrical Type Electrostatic Precipitators. In Proceedings of the ATEE 2021, Bucharest, Romania, 25–27 March 2021; 6p. [Google Scholar]

- Fischer, T.; Grass, N.; Zouzou, N.; Dăscălescu, L.; Greil, R.; Hopf, N. Smart Home Precipitator for Biomass Furnaces: Design Considerations on a Small-Scale Electrostatic Precipitator. IEEE Trans. Ind. Appl. 2014, 50, 2219–2224. [Google Scholar] [CrossRef]

- Popa, G.N. Cylindrical-Type Electrostatic Precipitator for Dedusting from Wood-Fired Power Plants; 1st Prize in the Ideas Category; E.ON Energy Globe Award Romania: Bucharest, Romania, 2018. [Google Scholar]

- Cid, N.; Rico, J.J.; Pérez-Orozco, R.; Larrañaga, A. Experimental Study of the Performance of a Laboratory-Scale ESP with Biomass Combustion: Discharge Electrode Disposition, Dynamic Control Unit and Aging Effect. Sustainability 2021, 13, 10344. [Google Scholar] [CrossRef]

- Hasler, P.; Nussbaumer, T. Particle Size Distribution of the Fly Ash from Biomass Combustion, Biomass for Energy and Industry. In Proceedings of the 10th European Conference and Technology Exhibition, Würzburg, Germany, 8–11 June 1998; 4p. [Google Scholar]

- Nussbaumer, N. Feinstaubminderung und Stromerzeugung im Rahmen der zukünftigen Energieversorgung. In Proceedings of the Holzenergie-Symposium, Zürich, Switzerland, 20 October 2006. [Google Scholar]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2008. [Google Scholar]

- Directive 2008/50/EC of the European Parliamanet and of the Council on Ambient Air Quality and Cleaner air for Europe; 2008.50/CE; European Union: Brussels, Belgium, 21 May 2008.

- Naeher, L.P.; Lipsett, M.; Zelikoff, J.T.; Simpson, C.D.; Koenig, J.Q.; Smith, K.R. Woodsmoke Health Effects: A Review. Inhal. Toxicol. 2007, 19, 67–106. [Google Scholar] [CrossRef] [PubMed]

- Riddervold, I.S.; Riddervold, I.S.; Bønløkke, J.H.; Olin, A.C.; Grønborg, T.K.; Schlünssen, V.; Skogstrand, K.; Hougaard, D.; Massling, A.; Sigsgaard, T. Effects of Wood Smoke Particles from Wood-Burning Stoves on the Respiratory Health of Atopic Humans. Part. Fibre Toxicol. 2012, 9, 12. [Google Scholar] [CrossRef] [PubMed]

- Ryan, H.M. High-Voltage Engineering and Testing, 3rd ed, Power and Energy Series. IET: Stevenage, UK, 2013.

- Sequential X-Ray Fluorescence Spectrometer; Thermo Fischer Scientific: Waltham, MA, USA, 2021.

- Thermo Scientific UniQuant Software; Thermo Fischer Scientific: Waltham, MA, USA, 2021.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).