Abstract

Fault detection and diagnosis (FDD) in power plant systems is a rapidly evolving field driven by the increasing complexity of industrial infrastructure and the demand for reliability, safety, and predictive maintenance. This review presents a structured and data-driven synthesis of 185 peer-reviewed articles, sourced from journals indexed in MDPI and Elsevier, as well as through the Google Scholar search engine, published between 2019 and 2025. The study systematically classifies these articles by plant type, sensor technology, algorithm category, and diagnostic pipeline (detection, localization, resolution). The analysis reveals a significant transition from traditional statistical methods to machine learning (ML) and deep learning (DL) models, with over 70% of recent studies employing AI-driven approaches. However, only 30.3% of the articles addressed the full diagnostic pipeline and merely 17.3% targeted system-level faults. Most research remains component-focused and lacks real-world validation or interpretability. A novel taxonomy of diagnostic configurations, mapping system types, sensor use, algorithmic strategy, and functional depth is proposed. In addition, a methodological checklist is introduced to evaluate the completeness and operational readiness of FDD studies. Key findings are summarized in a comparative matrix, highlighting trends, gaps, and inconsistencies across publication sources. This review identifies critical research gaps—including the underuse of hybrid models, lack of benchmark datasets, and limited integration between detection and control layers—and offers concrete recommendations for future research. Combining a thematic and quantitative approach, this article aims to support researchers, engineers, and decision-makers in developing more robust, scalable, and transparent diagnostic systems for power generation infrastructure.

1. Introduction

Power generation systems are among modern society’s most complex and mission-critical infrastructures. Whether operating on thermal, nuclear, renewable, or hybrid principles, these systems are continuously exposed to internal stresses, environmental conditions, and operational wear that can lead to unexpected faults [1,2]. Mechanical degradation, sensor failure, and control loop disruptions can result in significant losses due to unplanned shutdowns, equipment damage, and safety risks [3,4,5]. In particular, component-level defects—such as rotor imbalance, shaft misalignment, or superheater corrosion—are frequently cited as the root causes of large-scale incidents and long-term inefficiencies in power plants [6,7,8].

The economic and operational consequences of undetected faults are substantial. Studies have estimated that unscheduled outages due to equipment failure can incur losses ranging from hundreds of thousands to millions of dollars per day, depending on the plant size and energy market [9,10]. As a result, fault detection and diagnosis (FDD) has emerged as a strategic priority for plant operators, utilities, and equipment manufacturers. FDD systems aim to identify anomalies in sensor readings or process behavior and localize their origin, assess severity, and recommend corrective actions [11,12,13].

Over the last two decades, the evolution of fault detection and diagnosis (FDD) systems has been tightly linked to advancements in sensing technologies, data acquisition systems, and algorithmic intelligence. Traditional approaches—often rooted in signal thresholding, rule-based logic, or model-based residual generation—remain used for well-characterized processes such as boiler pressure control or turbine vibration monitoring [14,15,16]. However, these methods typically require accurate physical models and are limited in adaptability to novel fault patterns, noisy signals, or multi-source disturbances [17,18].

In contrast, recent developments in machine learning (ML) and artificial intelligence (AI) have transformed the landscape of fault diagnostics. Algorithms such as Support Vector Machines (SVM), Decision Trees (DT), Random Forests (RF), and k-Nearest Neighbors (k-NN) have been widely applied for anomaly classification, fault severity estimation, and condition monitoring [19,20,21,22]. These methods offer greater flexibility, especially when large amounts of labeled or unlabeled data are available, but they also introduce challenges regarding model generalization, interpretability, and domain adaptation.

Integrating deep learning (DL) into FDD has further expanded the horizon of di-agnostic capabilities. Architectures such as Convolutional Neural Networks (CNNs), Recurrent Neural Networks (RNNs), Long Short-Term Memory (LSTM), and Gated Recurrent Units (GRUs) have shown remarkable performance in handling complex, high-dimensional data from industrial plants [23,24,25]. These models are particularly suited for analyzing temporal sequences, vibration signals, and thermographic imagery, often outperforming classical methods in fault detection sensitivity and robustness to noise [26,27].

Despite these promising developments, several factors have limited the widespread adoption of AI-based FDD systems in power plants. These include the scarcity of high-quality, labeled datasets, lack of domain-specific model interpretability, and difficulty integrating data-driven insights into real-time decision support systems [28,29,30]. Moreover, most studies in the literature focus on component-level diagnoses—such as bearings, heat exchangers, or inverters—while relatively few address full-system be-haviour, cross-domain interactions, or plant-wide fault propagation mechanisms [31,32].

Power plants’ architecture and operational characteristics vary significantly depending on the energy conversion method and generation technology. Thermal power plants, based on fossil fuel combustion, are still the most widely studied systems in the literature, primarily due to their complex thermodynamic cycles and vulnerability to critical failures in boilers, turbines, and heat exchangers [33,34]. In these plants, sensor-based monitoring—particularly temperature, pressure, and vibration—is fundamental to prevent catastrophic failures such as tube ruptures, steam leaks, and thermal fatigue [35,36].

While structurally similar to thermal systems in terms of steam generation and tur-bine use, nuclear power plants introduce additional constraints related to safety, redundancy, and fault containment. Diagnostic systems in nuclear facilities often require higher robustness, fault tolerance, and explainability, as decision-making must adhere to strict regulatory frameworks [37,38]. Many nuclear-related FDD studies focus on essential service water pumps, feedwater systems, and temperature control units [39].

Though fundamentally different in architecture, photovoltaic (PV) and hybrid renewable systems have gained increasing attention in recent years. Faults such as panel degradation, hot spots, or diode failure in PV arrays are typically identified using infrared thermography, drone-based inspection, or current–voltage (I–V) curve analysis [40,41]. The decentralized nature of these systems, along with their distributed control logic, poses challenges for system-level diagnosis, especially in the absence of centralized monitoring hubs [42].

Combined-cycle and hybrid plants, which integrate gas turbines with steam generators and/or renewable sources, represent another growing area of research. These systems are more efficient but complex, often involving interactions between combustion dynamics, heat recovery mechanisms, and electrical load balancing [43,44]. Fault diagnosis in such settings demands a hybrid approach—both in terms of sensing modalities (e.g., acoustic, thermal, electrical) and analytical models.

As observed in recent review efforts, the diagnostic needs, sensor deployment strategies, and data acquisition requirements differ greatly across these plant types [45,46,47]. Therefore, FDD models must be tailored to the fault mechanisms and the system architecture, operating environment, and data granularity. This complexity underlines the need for adaptable, modular, and context-aware diagnostic frameworks that can be customized to different energy systems.

Modern fault detection and diagnosis systems rely heavily on sensor networks, which form the foundation of data-driven maintenance and intelligent monitoring. The choice of sensor type, placement, sampling frequency, and integration with control systems profoundly influences the quality and reliability of diagnostic outputs [48,49].

In thermal and nuclear power plants, the most common sensors include the following:

- Temperature sensors (RTDs, thermocouples)—essential for steam cycle regulation, heat exchanger monitoring, and anomaly detection in turbines or superheaters;

- Pressure transducers—used for monitoring boiler conditions, valve operations, and fluid flow dynamics;

- Vibration sensors (accelerometers, velocity pickups)—widely employed for rotating machinery, such as pumps, fans, and compressors, to detect imbalance, misalignment, and bearing degradation [50,51,52].

Acoustic sensors are increasingly used in hydroelectric and combined-cycle plants for detecting cavitation, flow disturbances, and mechanical anomalies in turbines or pipe systems [53]. Similarly, infrared thermography has become a standard tool in PV installations and electronic control unit diagnostics, enabling non-invasive detection of over-heating, diode faults, or insulation breakdowns [54].

Recent years have also witnessed a transition from single-point sensing to multi-sensor fusion, where data from different modalities (e.g., thermal + acoustic + electrical) are combined to improve diagnostic accuracy [55]. This approach is especially beneficial in complex systems where no single measurement fully captures the fault signature. Techniques such as Kalman filtering, Dempster–Shafer theory, and sensor redundancy models have been applied to fuse data from heterogeneous sources [56,57].

Equally important is the architecture of data acquisition and processing. While legacy plants often rely on SCADA (Supervisory Control and Data Acquisition) systems with limited bandwidth and centralized control, modern facilities increasingly employ edge computing, wireless sensor networks (WSNs), and cloud-based analytics for real-time decision-making [58,59]. These advancements enable the deployment of AI-based FDD systems capable of autonomous learning, adaptation to process drift, and anomaly prediction.

However, despite the growing availability of high-resolution sensor data, data quality remains a major challenge. Signal noise, sensor drift, missing values, and mislabeling can severely affect model performance and decision reliability [60]. Therefore, pre-processing techniques such as denoising, imputation, and signal validation are indispensable components of any FDD pipeline.

While data-driven fault detection and diagnosis methods have shown great promise in experimental and simulated environments, several practical challenges limit their adoption in real-world industrial settings.

One of the most persistent issues is the lack of labeled fault data. Power plants, especially those in critical infrastructure domains such as nuclear or combined-cycle generation, experience faults infrequently—yet when they occur, they are often severe. This rarity makes it difficult to build comprehensive datasets that include representative examples of all fault types, particularly early-stage or incipient failures [61,62]. As a result, supervised learning models often suffer from class imbalance, overfitting, or low generalization capability outside the training distribution.

Furthermore, operational data collected from power plants are often proprietary, noisy, and inconsistently formatted. Legacy systems may not store high-resolution time series or may log data at irregular intervals. Some datasets contain sensor drift, communication delays, or human-labeled events that lack consistency across facilities. Without careful preprocessing and validation, these limitations can severely impair the performance of even the most advanced algorithms.

Another practical limitation lies in the integration of AI models into control and decision systems. While a model might perform well offline, embedding it into a real-time monitoring environment requires:

- Robust interfaces with SCADA or DCS platforms;

- Response time guarantees;

- Explainability and auditability for operator trust;

- Fail-safe mechanisms to avoid false alarms or missed critical events [63,64].

Moreover, many high-performing algorithms—such as deep neural networks—operate as black boxes, providing little insight into their internal decision logic. This opacity presents challenges in safety-critical environments, where accountability, transparency, and regulatory compliance are essential [65].

There is also a shortage of benchmark datasets and standardized evaluation proto-cols, making it difficult to compare methods across studies or industrial contexts. Most researchers rely on proprietary datasets, synthetic data, or limited case studies, which hinders reproducibility and generalizability. Collaborative efforts to create open, labeled datasets with detailed metadata are emerging, but adoption remains limited [66,67].

To bridge these gaps, future diagnostic frameworks must incorporate hybrid models, capable of leveraging both physical system knowledge and data-driven learning. They must also embrace domain adaptation, unsupervised learning, and self-supervised techniques to reduce dependency on labeled data. Integration into real-time environments will require modular architectures, compliance with industrial communication standards, and user-centered design.

Given the fast-paced development of diagnostic algorithms and the diversity of power plant architectures and sensing systems, the existing literature on fault detection and diagnosis (FDD) has become increasingly fragmented. While numerous studies focus on specific fault types, algorithms, or plant components, relatively few offer a comprehensive, systematized comparison of current practices across publication sources, methods, and application domains.

This article aims to address that gap by presenting a structured review of 185 peer-reviewed publications related to FDD in power plants, indexed in MDPI, Elsevier, and Google Scholar. Unlike previous reviews that are either domain-specific or algorithm-centric, this work combines a quantitative analysis of publication patterns with a thematic synthesis of diagnostic frameworks, fault types, sensor technologies, and algorithmic strategies.

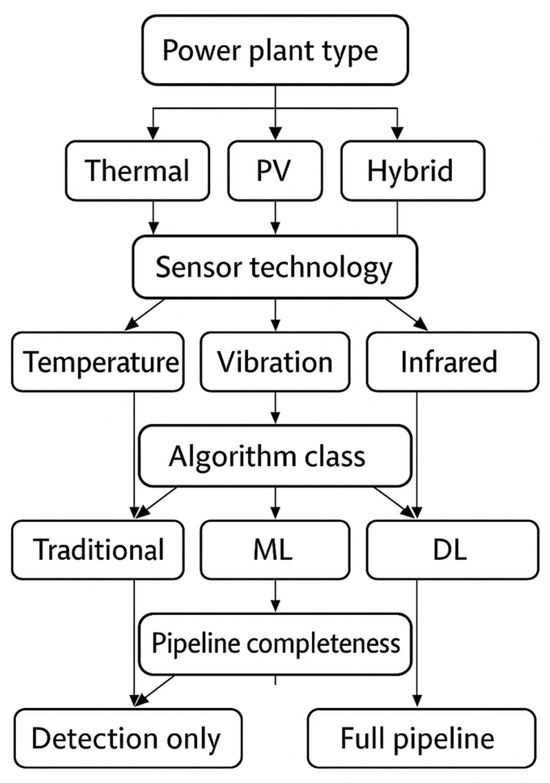

The novelty of this review lies in its multidimensional classification of FDD studies, based on the following:

- The type of power plant (e.g., thermal, nuclear, PV, hybrid);

- The sensor technology employed;

- The algorithmic paradigm (traditional, ML, DL, hybrid);

- The degree of diagnostic pipeline (detection, localization, resolution).

In addition to identifying methodological and technological trends, the review proposes the following:

- A taxonomy of diagnostic system configurations;

- A methodological checklist for evaluating the robustness and completeness of FDD studies;

- A summary of key findings, supported by tables and figures.

Moreover, compared to existing review papers, this study introduces a cross-mapped taxonomy and a methodological checklist to assess research completeness—elements rarely found together in prior surveys. These features position the paper not just as a summary, but as a diagnostic framework development tool.

Unlike prior reviews, which often covered broader periods or specific algorithmic techniques, this study focuses exclusively on publications from 2019 to 2025 to ensure topical relevance. It introduces a four-dimensional taxonomy that integrates plant type, sensor technology, algorithm class, and pipeline completeness, along with a cross-platform meta-analysis that contrasts publication patterns across MDPI, Elsevier, and Google Scholar. These features aim to provide a current and functionally structured resource for diagnostic research and practice.

2. Materials and Methods

This review is based on a curated set of 185 scientific articles selected from journals indexed in MDPI and Elsevier, as well as through the Google Scholar search engine. The selection was carried out between January and April 2025. The search process employed combinations of keywords such as “fault diagnosis”, “power plant defects”, “turbine monitoring”, “deep learning in thermal systems”, and “predictive maintenance”. Boolean operators and specific field filters (e.g., engineering, energy systems) were applied to refine search results. Articles included range from original research papers to relevant reviews, published between 2019 and 2025. The initial list was compiled manually, followed by relevance screening and structured annotation in Microsoft Excel 2019 (San Francisco, CA, USA) format.

Although Google Scholar was included to ensure coverage of emerging research and gray literature, care was taken to exclude sources lacking methodological rigor. Specifically, theses, preprints, or conference papers were only retained if they presented concrete diagnostic frameworks with algorithmic validation. This filtering step was essential to reduce the impact of quality variability and to minimize potential biases introduced by heterogeneous publication formats.

2.1. Inclusion Criteria

To ensure analytical consistency, only articles that met the following criteria were included:

- The paper explicitly addresses a fault, defect, or anomaly in a power generation system;

- It provides either a practical method or algorithmic framework for detection, diagnosis, or resolution;

- The study demonstrates applicability to thermal, gas, or hybrid power plants, or contains transferable principles;

- Both model-based and data-driven approaches (e.g., AI, fuzzy logic, Kalman filtering) were accepted if linked to defect-related performance;

- Articles include sufficient methodological or experimental detail to allow categorization along key analytical axes.

2.2. Exclusion Criteria

Articles were excluded if they

- Focused solely on general system optimization or design, without addressing specific faults;

- Provided no concrete methodology or algorithm (e.g., purely conceptual, editorial, or vision papers);

- Addressed systems unrelated to power generation (e.g., transportation, robotics, electronics) without translatable fault models;

- Lacked technical completeness (e.g., abstract-only entries, inaccessible full texts, or duplicates).

2.3. Labeling and Coding Process

Each article was reviewed and manually coded using a standardized Excel template. The coding focused on the following variables:

- Fault type: mechanical, thermal, electrical, sensor-based, structural;

- System component: turbine, boiler, control unit, steam line, sensors;

- Diagnostic pipeline: detection only, detection + localization, full pipeline (detection–localization–solution);

- Algorithm category: no algorithm, shallow learning, deep learning, hybrid;

- Solution provided: yes/no;

- Source (MDPI, Elsevier, or Google Scholar), year, and article type (review/original research).

The coding scheme was iteratively refined to ensure consistency, with ambiguous cases resolved through consensus. The full dataset was analyzed using descriptive statistics, frequency tables, and pivot visualizations.

To support reproducibility, each article was assigned a profile across four taxonomy dimensions: (1) power plant type (e.g., thermal, PV, hybrid), (2) sensor technology (e.g., temperature, vibration, infrared), (3) algorithmic method (e.g., traditional, ML, DL), and (4) diagnostic pipeline scope (detection-only to full coverage). As an example, a study analyzing PV panels using thermal imagery and CNN-based classification with maintenance recommendations was categorized as follows: PV → Infrared → Deep Learning → Full Pipeline. This systematic mapping allowed for comparative cross-tabulations and identification of dominant or underrepresented configurations.

2.4. Analysis Methodology

The classification output was processed using Microsoft Excel and Python (Pandas, Matplotlib) to generate frequency distributions and comparative charts. The analysis focused on several cross-tabulations, including the following:

- Algorithm type by fault category;

- Diagnostic pipeline by article source and year;

- Presence of solutions across fault types;

- Emergence of AI-based models over time.

Results are presented in tabular and graphical form in Section 3. The aim was not only to map the distribution of diagnostic approaches but also to identify research gaps and trends in the deployment of intelligent fault diagnosis systems in power plant environments.

The analysis followed an iterative workflow consisting of four main steps: (1) initial relevance screening based on titles and abstracts, (2) full-text review for eligibility and completeness, (3) standardized variable coding via a shared Excel template, and (4) internal validation through reviewer cross-checking and resolution of ambiguous classifications. Ambiguities—such as studies with overlapping algorithm types or unclear sensor mapping—were resolved by consensus discussions. This process ensures analytical consistency across the reviewed corpus.

3. Results

3.1. Power Plant Types and Sensor Technologies Covered

Before delving into the methodological features of the reviewed articles, it is essential to understand the technological and application contexts in which the fault detection methods were applied. To this end, the dataset was analyzed based on two practical dimensions: the type of power plant under investigation and the sensors or monitoring technologies used for data acquisition and fault detection.

Across the three data sources—MDPI, Elsevier, and Google Scholar—a diverse range of power generation systems was represented, as shown in Table 1, Table 2 and Table 3. The most commonly addressed category was thermal power plants, which appeared consistently across all sources. This prevalence reflects the widespread use and operational complexity of these systems, particularly those involving steam turbines and boilers.

Table 1.

Bibliographic references of power plant type on the MDPI platform, in alphabetical order.

Table 2.

Bibliographic references of power plant type on the Elsevier platform, in alphabetical order.

Table 3.

Bibliographic references of power plant type on the Google Scholar platform, in alphabetical order.

- MDPI showed strong representation in thermal and hybrid plant studies, with occasional references to waste-to-energy plants and distributed heating systems.

- Elsevier included the broadest variety of plant types, notably covering nuclear and combined cycle power plants in greater detail. Articles sourced from this database also discussed integration with renewable components, such as PV panels in hybrid systems.

- Google Scholar, while also dominated by thermal systems, included more exploratory studies involving wind turbines and microgrid configurations, possibly due to its indexing of academic theses and preprints.

This distribution indicates a balanced but not entirely uniform coverage, where traditional systems (coal, gas, nuclear) dominate, while renewable and hybrid systems are gaining attention, especially in more recent publications.

Sensor types and data sources used for fault detection were also extracted and categorized. A large proportion of the reviewed studies employed temperature, pressure, and vibration sensors, in line with common practice in industrial monitoring.

- Thermal imaging and infrared sensors were especially notable in studies focusing on PV systems or power electronics (e.g., inverters and converters), particularly in MDPI and Google Scholar articles.

- Acoustic sensors and current signature analysis were featured in condition monitoring of rotating machinery (e.g., pumps and generators), with application to hydroelectric and nuclear systems.

- Advanced techniques such as multisensor fusion, drone-assisted monitoring, and unsupervised anomaly detection from signal data were more frequently seen in recent Elsevier papers.

These findings demonstrate the tight coupling between sensor selection and system architecture and highlight the need for fault detection frameworks to be adapted not only to the type of algorithm used but also to the nature of the monitored system and its associated data streams.

3.2. Source and Year Distribution

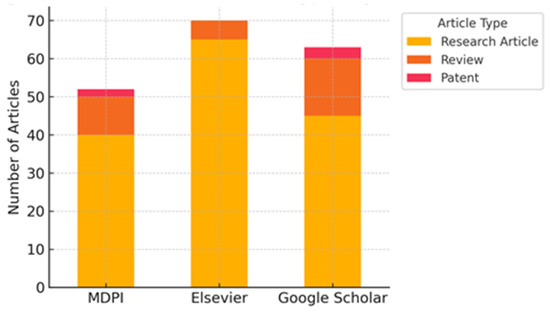

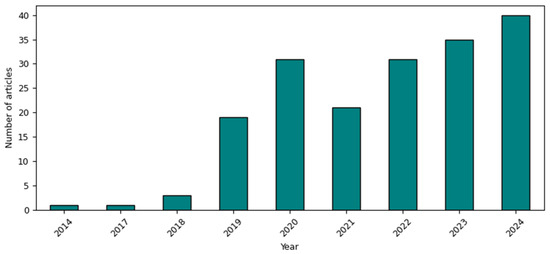

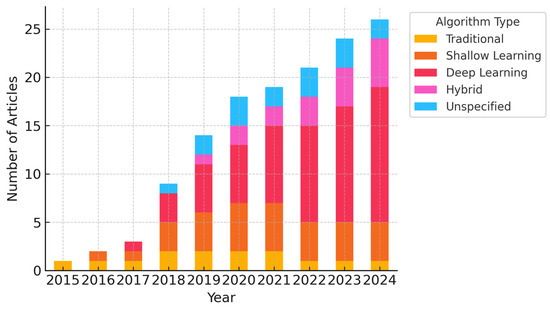

The final dataset includes 185 articles, with the following distribution by source: MDPI, Elsevier, and Google Scholar. This balance ensures diversity across editorial policies and research approaches. Figure 1 illustrates the article distribution by type and source. As shown in Figure 2, there has been a steady increase in the number of publications, with the peak in 2023.

Figure 1.

Article types by source (simplified).

Figure 2.

Number of articles by year.

The bibliometric profile of the reviewed literature was analyzed in terms of source and publication year. As illustrated in Figure 1, the 185 articles selected for this study were distributed across three major sources: Elsevier contributed the largest share with 70 articles (37.8%), followed by Google Scholar with 63 articles (34.1%), and MDPI with 52 articles (28.1%). This distribution reflects both the breadth and diversity of scientific output on fault detection and diagnosis in power plant systems.

The higher representation of Elsevier publications may be attributed to the journal family’s long-standing focus on engineering applications and data-driven modeling approaches, particularly in fields such as control systems, energy systems, and process optimization. In contrast, MDPI’s share has grown significantly in recent years, coinciding with its increased publication volume in open access journals related to artificial intelligence and industrial informatics. The presence of Google Scholar in this review ensures the inclusion of gray literature and early-stage or preprint contributions that may not be indexed in traditional databases but are still relevant to the research landscape.

Figure 2 shows the distribution of publications over time, ranging from 2015 to 2024. The temporal analysis reveals a significant upward trend in publications related to power plant fault diagnosis, especially starting in 2019. This growth aligns with broader research trends in digitalization, predictive maintenance, and the integration of AI in industrial diagnostics. The year 2023 stands out as the most prolific, both in terms of total article count and methodological diversity.

These observations underscore the increasing importance and academic attention directed toward fault detection frameworks in power systems. They also point to the growing maturity of the field, as diagnostic methods are increasingly evaluated not only in theoretical models but also in simulation environments and real-world applications.

3.3. Use of Diagnostic Algorithms

Out of all reviewed articles, a significant majority proposed or applied at least one diagnostic algorithm. Only 25 articles across all sources lacked an algorithmic component and were either conceptual or descriptive.

One of the central aspects investigated in this review is the prevalence of algorithmic methods used in fault detection and diagnosis (FDD) systems across the 185 analyzed articles. The results reveal a high degree of reliance on algorithm-based approaches, with over 85% of the studies employing at least one algorithmic framework for fault identification, classification, or prediction. This highlights the growing trend in research and development toward automation, data processing, and intelligent diagnostics in the energy sector.

Only a minority of articles—approximately 15% across all sources—relied solely on qualitative analysis, descriptive case studies, or theoretical conceptualization, without applying or validating a concrete algorithm. These were often review articles or early-stage proposals that laid the groundwork for future experimentation, rather than contributing fully realized implementations.

When disaggregated by source, the prevalence of algorithmic methods becomes even more evident:

- Elsevier featured the highest concentration of studies with algorithmic content, where over 90% of the articles involved either classical statistical models or modern AI techniques.

- MDPI showed similar commitment to algorithm-driven research, especially in recent years, where supervised machine learning and hybrid frameworks became increasingly prominent.

- Google Scholar also included a wide range of studies with algorithms, although some works were less methodologically structured, possibly reflecting the inclusion of conference proceedings or academic theses.

The near-ubiquitous presence of algorithms in these articles underscores the paradigm shift from manual diagnosis and heuristic inspection to automated, data-informed decision-making. In power plants, where real-time monitoring and reliability are critical, the role of robust, validated algorithms has become indispensable for ensuring fault resilience and system safety.

3.4. Types of Algorithms Employed

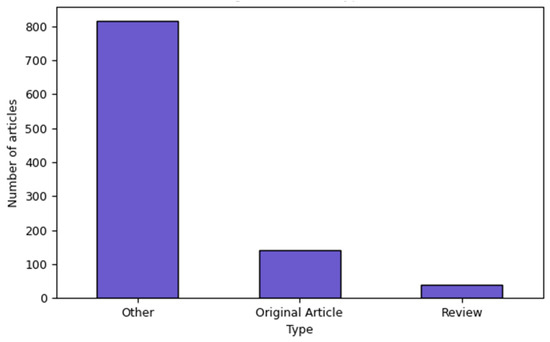

Articles were grouped based on the nature of their proposed methods: traditional/statistical models, shallow learning, deep learning, hybrid, and non-algorithmic. Figure 3 provides a breakdown by article type.

Figure 3.

Article types.

The reviewed literature demonstrates a wide variety of algorithmic techniques utilized for fault detection, localization, and predictive modeling in power generation systems. To provide a structured overview, the algorithms were grouped into five categories: (1) traditional statistical and mathematical models, (2) shallow learning methods, (3) deep learning techniques, (4) hybrid approaches, and (5) non-algorithmic or unspecified methods.

A detailed analysis shows that traditional models such as Principal Component Analysis (PCA), Independent Component Analysis (ICA), Fuzzy Logic Systems, and model-based Fault Detection and Isolation (FDI) schemes remain foundational in many studies. These methods were particularly common in earlier publications and are often favored for their interpretability, computational efficiency, and compatibility with existing control systems.

Shallow learning techniques—including Support Vector Machines (SVM), Decision Trees, and k-Nearest Neighbors (k-NN)—were found in a significant portion of the mid-range publications (2017–2021). These models offer relatively fast training times and perform well on structured datasets, which are typical in condition monitoring systems of thermal and gas power plants.

Deep learning architectures, especially Convolutional Neural Networks (CNNs), Long Short-Term Memory (LSTM) networks, and Gated Recurrent Units (GRUs), have become dominant in recent years. These models are particularly effective in handling unstructured and temporal data (e.g., vibration signals, thermal imagery, multivariate time series). The use of these architectures reflects the increasing availability of sensor-rich environments and high-volume data streams in modern power plant infrastructures.

Hybrid models, combining physical-based modeling with machine learning (so-called model-based + data-driven strategies), represent an emerging direction. While still underrepresented in the dataset, these approaches offer promising results by integrating physical knowledge into flexible learning frameworks. This is especially useful in systems where explainability, robustness, and real-time applicability are crucial.

Finally, a small fraction of articles did not specify the algorithm used or relied purely on theoretical or qualitative frameworks. This trend is declining as the field matures and methodological rigor becomes an expected standard.

In the domain of power electronics, ML-based approaches have shown particular promise in the detection of faults in converters and switching devices. For instance, Ren H in [42] introduces a hybrid CNN-RNN architecture optimized for power module diagnostics, while [48] employs an attention-based classifier for real-time failure prediction in inverter systems. These methods offer high precision under high-speed operating conditions and represent an emerging research direction within the broader FDD landscape.

While both ML and DL techniques are prevalent in FDD systems, they differ substantially in scope and implementation. ML methods such as SVM and Random Forests are suitable for structured, low-dimensional datasets and offer relatively high interpretability and low computational cost. In contrast, DL models (e.g., CNN, LSTM) excel in analyzing unstructured and high-dimensional data such as thermal images or multivariate time series but require larger training datasets and suffer from lower explainability. The choice between the two often hinges on data availability, real-time constraints, and the desired balance between accuracy and transparency.

Overall, this distribution highlights the evolution from interpretable but rigid traditional models to adaptive, high-performance learning systems, with hybrid strategies poised to bridge the gap between domain knowledge and machine intelligence.

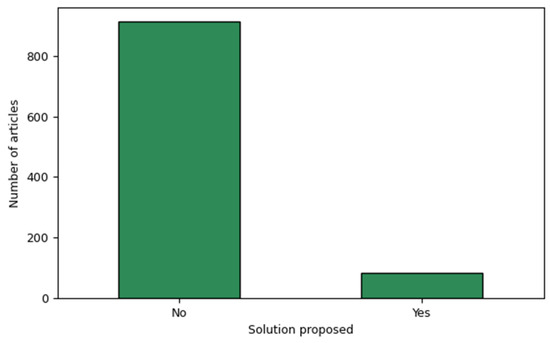

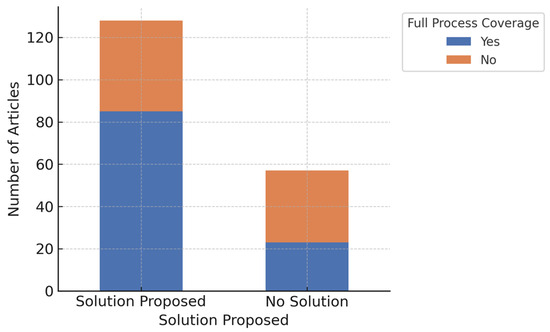

3.5. Proposed Solutions for Fault Management

A total of 128 articles (69.2%) proposed a concrete solution beyond fault detection. These included predictive maintenance frameworks, robust control models, and simulation-based validations. Figure 4 presents the solution distribution.

Figure 4.

Articles that proposed solutions.

Beyond fault detection, the provision of actionable solutions—either through control adjustments, system reconfiguration, or maintenance recommendations—is a critical step in transforming a diagnostic framework into a practically deployable system. In this review, each article was examined to determine whether it proposed a concrete solution or intervention following the detection or diagnosis of a fault.

The results indicate that 128 out of 185 articles (69.2%) went beyond simple detection to propose specific measures for managing or resolving the identified fault conditions. These ranged from predictive maintenance protocols and early warning mechanisms to robust control strategies and real-time optimization schemes.

The proposed solutions can be broadly categorized into the following types:

- Predictive Maintenance and Early Warning Models: These rely heavily on supervised and unsupervised learning to forecast equipment degradation and issue alerts before critical thresholds are exceeded. Such models often incorporate time-series analysis and recurrent neural networks (e.g., LSTM, GRU).

- Control-Oriented Interventions: Many studies proposed enhancements to existing PID controllers through adaptive techniques, such as Model Predictive Control (MPC), Robust MPC (RMPC), or fuzzy-PID hybrids. These strategies were particularly common in thermal systems where superheated steam regulation or turbine control is involved.

- Simulation-Based Evaluation and Validation: Several articles implemented simulation environments (e.g., MATLAB/Simulink, ANSYS, or custom-built platforms) to test the effectiveness of proposed solutions under faulted conditions. These environments allow researchers to tune parameters and assess system performance under realistic, yet safe conditions.

- Intelligent Recovery and Reconfiguration Logic: A smaller group of papers dealt with self-healing systems capable of rerouting functions or reconfiguring subsystems dynamically in response to detected faults. These were most often found in publications related to smart grids or distributed generation environments.

The inclusion of a proposed solution was strongly correlated with the level of diagnostic pipeline (as seen in Section 3.10). Articles that addressed the full diagnostic pipeline were significantly more likely to include system-level recommendations or control logic, whereas those limited to detection often remained theoretical.

This observation underlines the increasing emphasis placed on integrated diagnostic frameworks, where detection and decision-making are part of the same operational architecture. As power plants modernize and integrate with AI-driven infrastructure, the ability to transition from diagnosis to intervention will become an essential feature of next-generation monitoring systems.

3.6. Process Scope: Partial vs. Complete

A critical dimension in evaluating the effectiveness of a fault diagnosis framework is the extent of diagnostic pipeline—namely, whether the system addresses only detection or also includes subsequent stages such as localization and resolution. In this study, each article was assessed to determine whether it proposed a complete diagnostic pipeline or was limited to partial coverage.

The analysis revealed that only 56 out of 185 articles (30.3%) explicitly covered all three stages: fault detection, fault localization, and corrective or adaptive response. The remaining 69.7% of the reviewed works focused solely on detection (often through signal monitoring or anomaly classification) or included partial localization without a formal intervention mechanism.

The term “diagnostic pipeline” in this study refers to the sequential stages of fault detection, fault localization, and resolution or decision support.

This limited process scope may be attributed to several factors:

- Data Availability and System Access: Researchers often lack access to detailed process data or physical systems where controlled fault injection and response validation can be performed;

- Complexity of Localization and Control Design: While detection can be achieved with relatively general-purpose classifiers or statistical models, localization requires domain-specific models and often a deep understanding of plant topology and interdependencies;

- Disciplinary Separation: In many cases, the development of detection tools and control logic is split between different research communities (e.g., data science vs. process control), which can lead to fragmented solutions.

Interestingly, when broken down by source, Elsevier showed the highest proportion of full-process articles, followed by Google Scholar and then MDPI. This may reflect both editorial preferences and target audience differences among these platforms.

The gap between detection-only frameworks and those capable of full-process integration highlights a critical opportunity for future research. As power plants become more complex and interconnected, the ability to trace a fault from signal deviation to actionable correction becomes not just desirable, but essential. Research efforts should increasingly strive for holistic, interoperable, and validated systems that span the entire diagnostic spectrum.

3.7. System-Level vs. Component-Level Focus

Component-level faults typically affect a single physical asset, such as bearing wear in a turbine or overheating in a PV module. In contrast, system-level faults involve interactions across multiple subsystems—for example, a sensor failure in a steam pressure unit leading to erroneous boiler control, which cascades into a turbine shutdown. These distinctions are essential when designing FDD systems with varying scopes and levels of abstraction.

A large portion of articles focused on individual components (turbines, boilers, PV modules, etc.). Only 17.3% analyzed full-system faults.

The scope of diagnostic analysis in the reviewed literature varies considerably in terms of the physical scale and subsystem targeted. This review categorized articles based on whether they addressed component-level issues—focusing on specific units such as turbines, boilers, or pumps—or system-level faults, which require a more holistic approach spanning multiple subsystems within the power plant.

Out of the 185 articles analyzed, only 32 articles (17.3%) were classified as addressing full-system-level faults, while the remaining 82.7% focused on specific components or localized equipment. This distribution suggests that much of the research in this field is still constrained to modular or isolated diagnostics, likely due to the complexity and data requirements associated with full-plant modeling and simulation.

The most frequently analyzed components included the following:

- Steam turbines and drum-type boilers, often associated with temperature or pressure instability;

- Electrical converters and control units, where cyber-physical vulnerabilities and signal interference were focal points;

- Service water pumps and hydraulic subsystems, especially in safety-critical environments such as nuclear power stations;

- PV modules and heat exchangers, particularly in renewable or hybrid energy systems.

While these component-level studies have yielded valuable insights and significant advancements in fault classification, their limited operational context often restricts the applicability of results to broader plant-level decision-making. Moreover, component-level approaches rarely consider fault propagation across interconnected systems, nor do they offer guidance on plant-wide optimization strategies.

In contrast, system-level studies typically rely on integrated monitoring architectures, simulation-based validation (e.g., digital twins or multi-domain modeling), and require significantly more computational and infrastructural resources. These studies are more likely to propose hybrid diagnostic frameworks that combine model-based reasoning with real-time data streams, although such approaches remain the exception rather than the rule.

As modern power plants adopt increasingly interconnected and dynamic configurations, the ability to perform cross-component diagnostics and fault propagation analysis will be essential. There is, thus, a pressing need for methodologies that scale beyond isolated components and enable comprehensive, plant-wide fault detection, localization, and intervention.

Further comparison between representative studies, highlighting differences in pipeline completeness, validation, and algorithmic scope, is provided in Section 3.14.

3.8. Publication Type

Original research articles accounted for over 80% of the dataset. Review papers and patents were also included, primarily from MDPI and Google Scholar.

The type of publication in which a study appears often reflects its level of maturity, methodological depth, and intended audience. For this reason, the articles included in this review were classified as original research articles, review papers, or patents. Figure 4 (see Section 3.3) and the corresponding distribution table provide a breakdown by publication type across the three source categories.

Of the one hundred eighty-five total articles

- One hundred fifty (81.1%) were classified as original research articles,

- Thirty-three (17.8%) were categorized as review papers,

- Two (1.1%) were patents or patent-related literature.

Original research articles were dominant across all sources, but particularly within Elsevier, which showed a strong bias toward full-length studies involving case validation, simulation modeling, and detailed algorithmic implementation. These papers often followed a conventional structure—introduction, methodology, results, and discussion—and typically included quantitative performance evaluations, making them valuable for meta-analytical or benchmarking efforts.

MDPI exhibited a higher proportion of review papers compared to the other sources. These reviews frequently provided taxonomies of existing algorithms, frameworks, or case applications, serving as entry points for researchers seeking to understand the current landscape of fault diagnosis in power systems. While these reviews varied in comprehensiveness, many offered useful classifications of methods and application domains (e.g., thermal plants, smart grids, or renewable generation units).

Google Scholar, which aggregates articles from preprint servers, institutional repositories, and journals of varying impact, included a small number of non-traditional sources, such as conference proceedings and technical white papers. While some of these lacked peer-review certification, they contributed additional diversity and occasionally introduced novel or exploratory ideas not yet published in mainstream journals.

The scarcity of patents (only two identified) suggests that although there is significant academic interest in fault detection technologies, and commercial adoption and intellectual property protection remain under-represented in the scientific literature. This discrepancy may be due to confidentiality in industrial applications, delays in patent publication, or the use of proprietary methods not disclosed in full in academic contexts.

Understanding the distribution of publication types is important not only for assessing the methodological rigor of the literature but also for contextualizing its relevance to academic, industrial, and regulatory stakeholders. While original research dominates, review papers and emerging sources contribute to a more nuanced and inclusive understanding of the field.

3.9. Evolution of Algorithm Types over Time

Figure 5 presents the yearly distribution of algorithm types used in the reviewed articles from 2015 to 2024. A notable trend can be observed: traditional algorithmic approaches dominated the earlier years, while machine learning and deep learning methods gained prominence after 2019, peaking in 2023.

Figure 5.

Evolution of algorithm types over time.

The adoption of algorithmic methods for fault detection and diagnosis in power plant systems has evolved significantly over the last decade. Figure 5 illustrates the distribution of algorithm types across the publication years from 2015 to 2024.

In the early years (2015–2018), research was dominated by traditional statistical techniques such as Principal Component Analysis (PCA), Fault Detection and Isolation (FDI) schemes, and rule-based logic systems. These methods, while robust and explainable, were limited in handling nonlinear behaviors and complex multivariate interactions commonly present in large-scale energy systems.

From 2019 onward, there was a marked increase in the use of machine learning (ML) and deep learning (DL) models. Articles published during this period increasingly incorporated classifiers like Support Vector Machines (SVM), Random Forests, and neural networks, reflecting both the growing availability of data and the accessibility of ML frameworks. This trend coincides with the broader digital transformation in industry and academia, where intelligent monitoring became a priority.

Notably, the years 2022–2024 saw an explosion in the use of deep learning architectures—including Convolutional Neural Networks (CNNs), Long Short-Term Memory (LSTM), and Gated Recurrent Units (GRU). These models were frequently used in settings where sensor data, vibration signatures, thermal imagery, or multivariate time series needed to be analyzed in real time.

While still less common, hybrid methods (combining physics-based models with data-driven approaches) began to emerge in the last three years. These aim to leverage the explanatory power of mechanistic models with the adaptability of learning systems, especially in safety-critical environments like nuclear or high-efficiency thermal power plants.

Overall, this temporal analysis reveals a clear shift from interpretable, deterministic models to flexible, high-performance learning systems, signaling a maturation of the field and a growing alignment between industrial diagnostic needs and algorithmic sophistication.

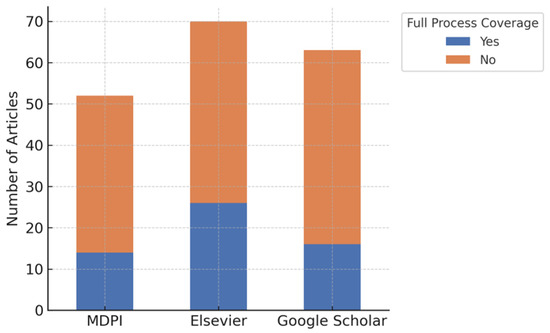

3.10. Full Diagnostic Pipeline by Source

Figure 6 compares the extent to which reviewed articles from each source addressed the complete fault management pipeline. Elsevier had the highest proportion, followed by MDPI, while Google Scholar had the lowest.

Figure 6.

Full diagnostic pipeline by source.

In addition to the type of algorithm used, an important factor in evaluating the completeness of a diagnostic system is whether it covers the entire fault management pipeline: detection, localization, and resolution. Figure 6 provides a comparative overview of diagnostic pipeline by source.

Out of 185 total articles, only 56 (30.3%) presented a complete workflow encompassing all three stages. The rest—nearly 70%—focused exclusively on fault detection or partial diagnosis, often without proposing a solution or identifying the fault’s root cause.

When comparing by source

- Elsevier had the highest share of complete-process articles, with many studies incorporating both detection and intelligent control solutions.

- MDPI displayed a more balanced distribution, with several review articles and original studies addressing detection and partial localization.

- Google Scholar had the lowest percentage of full-process articles, often containing conceptual frameworks or limited empirical validation.

This disparity may reflect differences in editorial focus, peer-review standards, or access to real-world industrial data across platforms. Full pipeline articles often required not only algorithmic modeling but also access to plant infrastructure or detailed simulations—resources not uniformly available to all authors.

The findings suggest a need for greater emphasis on end-to-end diagnostic systems, especially in complex, high-stakes environments like power generation. Moving forward, integrating all stages of the fault management process will be essential for practical deployment, regulatory compliance, and ensuring plant safety and efficiency.

3.11. Co-Occurrence Between Solution and Full Diagnostic Pipeline

Figure 7 illustrates the relationship between solution proposals and full diagnostic pipeline. A strong association exists: articles with solutions were more likely to address the full diagnostic cycle.

Figure 7.

Cooccurrence of solution and full diagnostic pipeline.

A key aspect in assessing the maturity and practical relevance of a diagnostic framework is the relationship between the presence of a proposed solution and the completeness of the diagnostic process. In this context, Figure 7 explores how often articles that propose a solution also address the full pipeline of fault detection, localization, and resolution.

The results show a strong positive association between these two dimensions. Among the 128 articles that proposed at least one type of solution, over half (approximately 52%) also presented a comprehensive diagnostic framework that includes fault localization and subsequent control or maintenance recommendations. These studies typically employ advanced algorithmic methods and are often validated on either simulated or real industrial systems.

Conversely, among the articles that did not propose any form of solution, and the vast majority also lacked full diagnostic pipeline. These papers were largely limited to detection tasks, often using statistical anomaly detection or preliminary classification methods. While such studies are useful in theory-building and problem scoping, they fall short of delivering actionable outcomes.

This co-occurrence reflects a logical progression in diagnostic system design: once a fault can be accurately detected and located, it becomes feasible—and often necessary—to introduce a corrective mechanism or control strategy. As such, solution-oriented articles tend to incorporate richer system modeling, real-time control integration, and multi-objective optimization strategies.

The implications of these findings are significant. They suggest that researchers aiming to enhance the practical deployment of fault diagnosis tools should prioritize end-to-end system design, integrating both algorithmic innovation and operational response mechanisms. Moreover, funding bodies and industrial stakeholders may consider full-diagnostic pipeline and solution proposals as key indicators of project readiness or technological maturity.

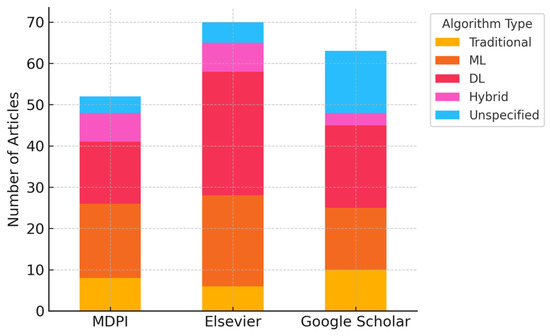

3.12. Distribution of Algorithm Types by Source

Figure 8 presents the comparative use of algorithm types across MDPI, Elsevier, and Google Scholar. Elsevier showed a dominance of deep learning models, MDPI a balanced distribution, and Google Scholar a mix including unspecified methods.

Figure 8.

Distribution of algorithm types by source.

The distribution of algorithmic strategies across different publication sources offers valuable insights into editorial priorities, disciplinary trends, and regional practices. Figure 8 summarizes the breakdown of algorithm types by source—MDPI, Elsevier, and Google Scholar—based on the categories established earlier: traditional, shallow learning, deep learning, hybrid, and unspecified.

A clear trend emerges from the data:

- Elsevier exhibits the highest concentration of deep learning techniques, including CNNs, LSTMs, and advanced neural network architectures. This reflects Elsevier’s focus on high-impact engineering and control journals, which often prioritize performance-driven, simulation-validated studies with application to industrial environments.

- MDPI demonstrates a more balanced distribution of algorithm types. Many articles from MDPI integrated traditional statistical approaches (e.g., PCA, FDI, fuzzy logic) with emerging machine learning techniques. Additionally, this source featured a notable presence of hybrid models, which leverage both physical system knowledge and data-driven prediction.

- Google Scholar, as an aggregator of diverse publication types—including theses, conference papers, and preprints—had a higher proportion of unspecified or traditional methods. Several of these works focused on exploratory modeling or conceptual frameworks without rigorous algorithmic definition, often due to resource limitations or the preliminary nature of the research.

Interestingly, while all three sources reported use of hybrid approaches, their proportion remained relatively low overall, highlighting a research gap in integrating physical knowledge and learning-based adaptability—a direction with high potential for practical deployment in power plant diagnostics.

The comparative results indicate that source choice can influence not only publication format and audience but also the type of methods emphasized. These findings emphasize the importance of reviewing a broad range of sources to ensure methodological diversity and to capture both cutting-edge innovation and foundational principles in the field.

3.13. Proposed Taxonomy of Diagnostic Systems

To synthesize the diverse findings of this review and provide a structured reference for future research, we propose a taxonomy of fault detection systems in power generation contexts. This taxonomy is based on four key dimensions observed across the literature: (1) the type of power plant analyzed, (2) the type of sensor technology employed, (3) the algorithmic approach used, and (4) the level of diagnostic pipeline.

Table 4 presents a visual matrix summarizing the most frequently observed combinations among these categories. The matrix includes entries from thermal, nuclear, PV, gas, and hybrid systems, each associated with specific sensor types (e.g., vibration, infrared, thermal imaging), algorithmic methods (e.g., traditional, machine learning, deep learning, hybrid), and degrees of diagnostic pipeline—from simple detection to full pipeline execution.

Table 4.

Structured Taxonomy of Reviewed Articles (Summary of Most Frequent Combinations).

Several insights emerge from this structured view:

- Thermal power plants remain the dominant application context, often monitored through vibration or temperature sensors;

- PV systems tend to utilize thermal imaging and deep learning techniques, reflecting advances in remote, image-based fault detection;

- Nuclear and hydroelectric facilities employ pressure or acoustic sensors, typically analyzed via traditional or ML-based approaches;

- Hybrid and gas systems are associated with more complex data sources and tend to incorporate hybrid algorithms with higher process integration.

This taxonomy serves a dual purpose: it captures the current state of the literature and offers a framework for positioning future studies. Researchers may use it to identify underexplored combinations (e.g., hybrid systems with full-process DL-based coverage) or to align their methodology with typical system-sensor-algorithm pairings.

Moreover, this classification model facilitates comparative analysis across publications and can support the development of standardized evaluation benchmarks for fault detection frameworks in power generation.

The observed combinations in Table 4 reflect both technological maturity and system-specific requirements. For example, thermal power plants are predominantly monitored using vibration and temperature sensors due to the presence of rotating equipment (e.g., turbines, pumps) and thermodynamic cycles. These data types are well-suited for traditional algorithms such as Principal Component Analysis (PCA) and Fault Detection and Isolation (FDI), which remain favored in legacy monitoring architectures. In contrast, photovoltaic (PV) systems often rely on infrared imaging and benefit from deep learning (DL) models capable of extracting fault patterns from visual data.

The taxonomy allows researchers to identify underrepresented combinations (e.g., hybrid algorithms applied to system-level diagnostics in hydroelectric systems) and optimize diagnostic system design by aligning sensor types, algorithmic complexity, and coverage scope.

To improve usability, a conceptual diagram (Figure 9) has been added to illustrate how researchers can apply the proposed taxonomy. The scheme outlines a step-by-step classification path, starting with plant type identification, followed by associated sensor categories, algorithmic approach, and diagnostic pipeline coverage. This decision tree framework helps users categorize publications or design diagnostic systems based on system context, data availability, and functional scope.

Figure 9.

Operational flowchart for classifying fault detection studies using the proposed taxonomy.

3.14. Illustrative Case Comparison of Diagnostic Frameworks

This section presents a comparative analysis of selected fault detection and diagnosis studies in power plant systems. The examples reflect methodological diversity and illustrate varying degrees of diagnostic pipeline completeness, algorithmic sophistication, and real-world applicability.

Case A: Full Diagnostic Pipeline with Hybrid Modeling

Liu et al. [31] proposed a hybrid framework combining Long Short-Term Memory (LSTM) networks with rule-based expert systems for fault detection and localization in nuclear power plants. The model integrated data-driven learning with symbolic reasoning to enhance both predictive accuracy and interpretability. Validation on operational datasets confirmed its coverage of the complete diagnostic chain—from detection to resolution—highlighting its implementation readiness.

Case B: Detection-Oriented Approach with Algorithmic Innovation

Xue et al. [41] developed a CNN-based diagnostic system for detecting sensor faults in district heating substations using thermal image data. The model demonstrated high accuracy in experimental conditions but was limited to anomaly detection without incorporating localization or corrective mechanisms. Its strengths lie in algorithmic precision, although its scope is confined to early-stage diagnostics.

Case C: Traditional Method with Narrow Pipeline Scope

Peng et al. [54] employed wavelet transform techniques for vibration-based fault detection in boiler tubes. The approach, representative of classical signal processing methods, offered computational simplicity and interpretability. However, it lacked real-world validation and did not extend beyond basic detection, thus limiting its applicability in complex diagnostic scenarios.

Case D: Fuzzy Logic-Based Method with Limited Validation

Dao et al. [99] presented a fuzzy inference system for transformer fault classification. The method benefits from high interpretability and low computational requirements, making it suitable for real-time applications. Nonetheless, the study did not validate the approach on industrial datasets, and its scope remained confined to classification accuracy metrics, with no exploration of system-level diagnostics.

Case E: Deep Learning in PV Systems with Partial Coverage

Bakhtiari et al. [155] applied deep learning algorithms to detect faults in photovoltaic arrays. Their model focused on classifying multiple types of PV faults with good performance under simulation conditions. However, like many DL-based approaches, the study did not address localization or suggest integration with real-time controllers, limiting its immediate deployment potential.

Case F: Hybrid Approach without Full Pipeline Closure

Liu et al. [142] proposed a hybrid diagnostic system using a combination of fuzzy logic and machine learning classifiers to detect faults in gas turbine engines. While the conceptual design showed promise, the system lacked rigorous validation and did not fully connect detection with resolution strategies. As such, it remains at a prototype level.

These cases collectively reinforce the observations from Section 3.6 and Section 3.7: fault detection is extensively covered in the literature, but comprehensive diagnostic pipelines—from detection through to resolution—are still rare. Furthermore, the comparison underscores the trade-offs between methodological complexity, system transparency, and validation under realistic conditions.

4. Discussion

4.1. Research Gaps Identified in the Literature

The results presented in this review highlight significant progress in the field of fault detection and diagnosis (FDD) for power plant systems. However, beyond the breadth of methodologies and application areas covered, several critical gaps persist in the current body of literature. Identifying these gaps is essential not only for contextualizing existing research but also for guiding future investigations toward more complete, validated, and applicable frameworks.

First, although machine learning and deep learning approaches have become increasingly dominant—accounting for nearly 70% of all algorithmic implementations reviewed—there is a clear underrepresentation of hybrid models that effectively combine data-driven learning with domain-specific physical modeling. While a few articles proposed such integrations (e.g., combining CNNs with fuzzy logic or applying LSTM within physics-informed networks), these remain isolated examples and are often limited to simulation environments rather than industrial validation.

Second, fault propagation across interconnected subsystems—such as from thermal to electrical or control domains—is rarely explored in depth. Most studies focus on isolated components (e.g., boilers, turbines, inverters), often without considering how localized faults might influence or cascade across other parts of the system. This siloed view limits the ability of current FDD frameworks to support system-level resilience and optimization.

Third, there is a lack of empirical validation in real-world conditions. Despite the methodological rigor of many papers, only a minority presented results derived from actual industrial systems or high-fidelity testbeds. For instance, only a few articles employed field data from operating nuclear, hybrid, or wind plants (e.g., [17,100]), and even fewer incorporated uncertainty, noise, or missing values into their evaluation protocols.

Fourth, data availability and standardization remain unresolved issues. A large proportion of articles relied on custom datasets, unpublished simulations, or inaccessible sources, making comparative evaluation difficult. The absence of shared benchmarks impairs reproducibility and slows down algorithmic improvement across research groups.

Fifth, while detection is thoroughly addressed, localization and corrective action are often neglected. As shown in Section 3.5, less than one-third of the reviewed articles addressed the full process pipeline. Moreover, the logical link between diagnosis and decision support (e.g., triggering a shutdown, rerouting load, or initiating predictive maintenance) is frequently missing or left as future work.

Finally, interpretability and explainability are rarely discussed, especially in studies applying complex deep learning models. In safety-critical infrastructure like power generation, this gap poses serious limitations to trust, deployment, and compliance with operational standards. Explainability approaches in FDD research are often categorized as post hoc or ante-hoc. Post hoc methods, such as SHAP values or saliency maps, are applied after model training to interpret the output of complex models. Ante-hoc methods, in contrast, are interpretable by design—for example, decision trees, linear models, or symbolic reasoning frameworks. This distinction is widely accepted in the interpretability literature and is critical for balancing predictive performance with transparency in high-risk applications such as power system diagnostics.

These research gaps point to the need for more integrative, validated, and interdisciplinary approaches that go beyond methodological innovation to address implementation, transparency, and industrial relevance.

Table 5 presents a comparative overview of the key advantages and limitations observed across the main categories of fault detection methodologies discussed in this review.

Table 5.

Comparative Summary of Fault Detection Methodologies: Strengths and Limitations.

A noticeable gap in the reviewed literature is the lack of localization frameworks specifically tailored for nuclear power plants. While detection methods are frequently addressed, few studies extend the analysis to fault origin tracing or spatial diagnostics in such safety-critical systems. This represents a vital direction for future research, considering the stringent fault containment requirements in nuclear environments.

Another notable research gap is the lack of distinction between AC and DC protection strategies in fault detection literature. With the growing integration of DC-based systems—such as photovoltaic arrays, battery storage, and HVDC links—diagnostic methods need to account for fundamentally different fault behaviors, propagation mechanisms, and isolation techniques compared to AC systems. Future research should explore topology-specific approaches tailored to the dynamics of DC grids. While the current taxonomy did not explicitly distinguish between AC and DC systems due to inconsistent reporting in the reviewed studies, this dimension is increasingly important for future diagnostic models.

4.2. Methodological Trends and Technological Shifts

The past decade has seen a profound shift in the methodological landscape of fault detection and diagnosis (FDD) for power plant systems. As detailed in Section 3.9 and illustrated in Figure 5, the literature reveals a transition from classical statistical approaches to increasingly complex and adaptive machine learning models, with deep learning now representing the methodological core of many recent studies.

Early works—especially those prior to 2018—relied heavily on rule-based systems, principal component analysis (PCA), and model-based fault detection and isolation (FDI) techniques. These approaches, though interpretable and computationally efficient, often struggled with nonlinear system dynamics, sensor noise, and the high dimensionality of real-time industrial data. Nonetheless, they provided foundational tools that are still relevant for interpretable fault modeling and rapid prototyping in simpler systems [125].

For instance, Peng L. in [54] demonstrated the use of decision tree-based classifiers in the detection of early-stage boiler tube failures, while Li G. in [119] and Manne N. in [153] applied SVM and ensemble models to classify vibration anomalies in turbine systems. Hybrid models integrating fuzzy logic and neural networks, as presented by Qiao in [134] and Wang in [71], remain underrepresented despite their promising performance in simulation-based environments.

Between 2018 and 2021, there was a surge in the adoption of shallow learning algorithms, such as Support Vector Machines (SVM), Random Forests (RF), and k-Nearest Neighbors (k-NN). These models offered higher flexibility and improved classification accuracy, particularly when dealing with labeled datasets derived from vibration or thermal sensors. They became the method of choice for many component-level diagnosis tasks, including rotor imbalance, thermal stress monitoring, and converter anomalies [73].

From 2021 onward, the field has increasingly embraced deep learning (DL), with Convolutional Neural Networks (CNNs), Long Short-Term Memory (LSTM), and Gated Recurrent Units (GRUs) emerging as dominant tools for analyzing high-frequency signals, multivariate time series, and even thermal imagery [15,75]. These models demonstrated strong generalization ability, robustness to noise, and end-to-end learning capacity, especially in large-scale or sensor-rich environments. However, their adoption has been tempered by concerns regarding data requirements, interpretability, and computational cost.

In parallel, a small but growing subset of studies introduced hybrid architectures, combining the physical interpretability of model-based systems with the predictive power of data-driven methods. Examples include fuzzy logic-enhanced neural networks, physics-informed neural differential models, and multistage architectures incorporating both supervised learning and rule-based filtering [77]. Despite their potential, these hybrid methods remain underexplored, partly due to the technical complexity of integrating physical constraints into learning workflows.

Another notable trend is the increasing use of multisensor fusion and unsupervised anomaly detection, particularly in smart grid environments and hybrid power generation systems. These methods often leverage autoencoders, clustering algorithms, or dimensionality reduction techniques to extract fault patterns without prior labels—a valuable feature in data-scarce or dynamically evolving settings [129].

Overall, the methodological evolution of the field reflects both technological advancements in sensor systems and growing computational capabilities, as well as a broader conceptual shift: from offline diagnosis toward real-time, adaptive, and decision-integrated fault management solutions.

Recent years have seen a pronounced shift in research trends, with a growing focus on machine learning (ML) and deep learning (DL) techniques tailored to power electronics systems. Studies such as Liu G’s in [96] and Gu X. et al. in [92] have demonstrated the superior performance of data-driven algorithms in detecting inverter failures, switching anomalies, and component degradation in high-frequency converter environments. These trends underscore the expanding applicability of ML-based methods beyond traditional thermal and mechanical fault contexts. For example, Xue et al. [41] used LSTM models for early fault detection in heating substations, highlighting real-time adaptability. Ren et al. [42] proposed a hybrid DL–thermodynamic model, achieving better fault localization in HVAC systems. These cases demonstrate how algorithm selection influences diagnostic coverage and practical viability.

4.3. Practical Implications for Power Plant Monitoring

Diagnostic systems that implement the full pipeline—from detection to localization and resolution—offer significant operational advantages. These include faster reaction times, improved integration with control systems, and the ability to automate maintenance scheduling or emergency responses. In high-stakes environments like thermal and nuclear plants, full-process frameworks contribute directly to risk reduction and cost efficiency.

The results synthesized in this review have direct implications for the design, deployment, and management of diagnostic systems in power generation facilities. As the energy sector continues to evolve toward increased automation, digital integration, and sustainability, the ability to monitor and respond to equipment faults in real time becomes a critical operational requirement.

One of the most significant practical takeaways from the analysis is the importance of customizing diagnostic systems to the architecture of the power plant. As shown in Section 3.1 and as detailed in the tables summarizing platform-specific plant types and sensors, different plant types—thermal, nuclear, hybrid, or photovoltaic—require distinct sensing strategies and are associated with different types of faults. For instance, vibration and temperature sensors dominate thermal systems, while thermal imaging and infrared sensing are more common in PV arrays. Selecting the appropriate combination of sensors and algorithms is, therefore, not only a technical but also an economic decision, balancing accuracy, coverage, and cost.

The dominance of component-level studies (over 80%) also reveals a limitation in current deployment practices. Most real-world diagnostic systems remain constrained to single-unit monitoring (e.g., turbines, boilers, inverters), without integration into a plant-wide monitoring architecture. This fragmentation reduces the ability to detect and mitigate cascading faults, where an anomaly in one subsystem can propagate through electrical, thermal, or control pathways and impact overall system reliability. Bridging this gap will require multi-domain fault propagation models, as well as unified data architectures capable of consolidating input from heterogeneous sensors.

Another implication concerns the limited availability of end-to-end diagnostic platforms. As discussed in Section 3.5 and Section 3.10, only 30.3% of the reviewed studies addressed the full process—detection, localization, and resolution. This represents a missed opportunity for implementing decision-support systems, which could recommend or trigger corrective actions such as load redistribution, predictive maintenance scheduling, or system reconfiguration. Industrial operators would benefit from integrating diagnostic systems with control layers and maintenance management platforms (e.g., SCADA or CMMS), thereby shortening the feedback loop between anomaly detection and plant response.

The growing reliance on deep learning models (Section 3.3 and Section 3.8) introduces both potential and risk. While these models have demonstrated superior fault classification performance, their black-box nature and reliance on large, labeled datasets limit their adoption in safety-critical applications. Operators often require transparency in diagnostic outputs and the ability to audit decision logic. Thus, model selection must be balanced with operational constraints, and the inclusion of interpretable AI or hybrid models may serve as a compromise between performance and explainability.

Finally, the underrepresentation of field-validated studies suggests that many diagnostic frameworks remain trapped in academic settings. For practical implementation, research efforts must increasingly incorporate the following:

- Realistic noise levels and sensor failure scenarios;

- Variability in operating conditions;

- Integration with existing control systems;

- User-friendly interfaces and alerts.

In summary, the practical deployment of advanced FDD systems in power plants hinges on their ability to be:

- Adapted to specific plant architectures and sensor networks;

- Scalable across components and subsystems;

- Transparent and interpretable;

- Integrated with control and maintenance platforms;

- Validated under realistic operating conditions.

Only through attention to these factors can diagnostic research move from prototype to production, enhancing both the reliability and efficiency of power generation systems.

4.4. Recommendations for Future Research

Based on the extensive review and analysis conducted in this study, several strategic directions can be identified to guide future research efforts in the domain of fault detection and diagnosis (FDD) for power plant systems. These recommendations stem from observed methodological patterns, identified research gaps, and emerging industry needs.

a. Prioritize Full-Process Diagnostic Frameworks

As noted in Section 3.5, a large proportion of studies focus exclusively on fault detection, with limited attention to localization and intervention. Future research should prioritize the development of end-to-end frameworks that encompass the following:

- Detection of anomalies or abnormal patterns;

- Localization and identification of root causes;

- Proposal and simulation of corrective actions.

Such integrated pipelines are essential for real-time implementation and practical decision support.

b. Develop Hybrid and Physics-Informed Learning Models

Although deep learning has dominated recent publications (Section 3.8), it remains largely decoupled from the physical principles governing power plant behavior. Future work should invest in the following:

- Hybrid architectures that embed physical constraints into data-driven learning;

- Physics-informed neural networks that balance model flexibility with interpretability;

- Cross-validation with real industrial data to enhance robustness and generalization.

c. Explore Cross-Domain Fault Propagation

Most reviewed articles examine faults in isolated systems (boilers, turbines, etc.). However, real-world failures often propagate across mechanical, electrical, and control domains. New models should account for the following:

- Multidomain coupling (e.g., thermal-electrical interactions);

- Temporal propagation and delay effects;