Mycelium-Based Composites Derived from Lignocellulosic Residual By-Products: An Insight into Their Physico-Mechanical Properties and Biodegradation Profile

Abstract

1. Introduction

2. Materials and Methods

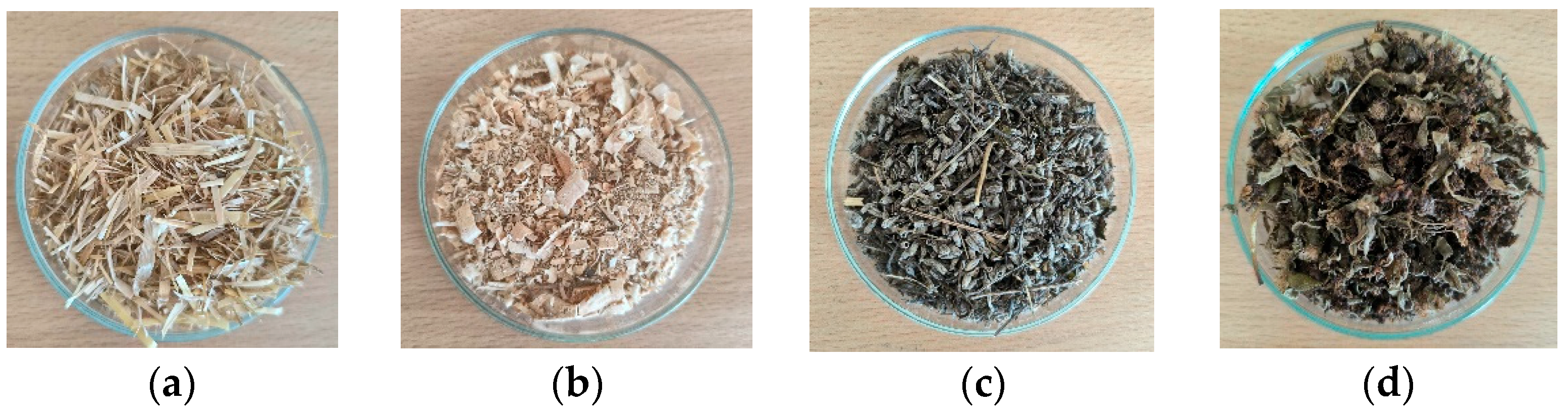

2.1. Substrates and Mushroom

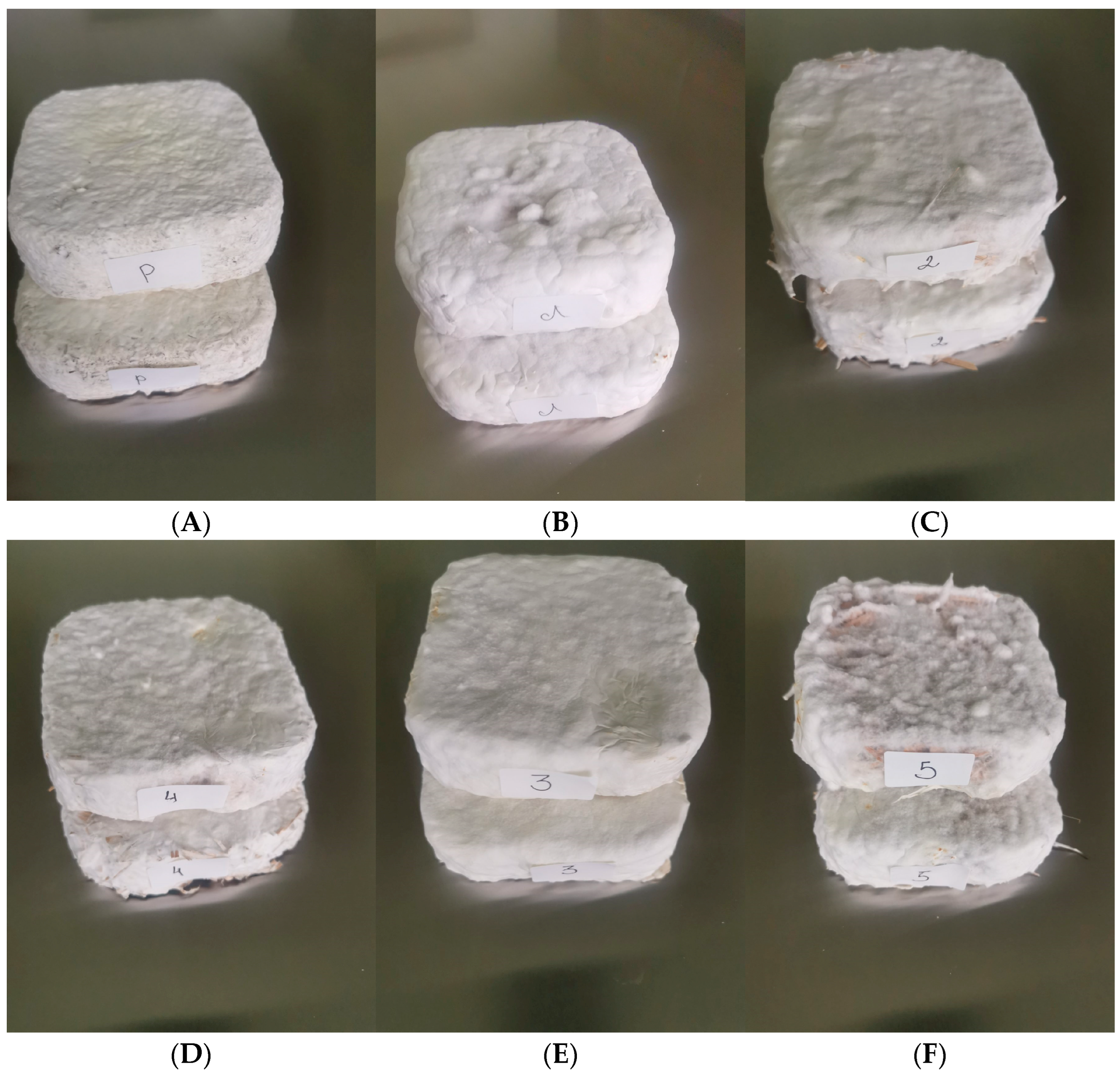

2.2. Solid-State Cultivation of G. resinaceum for MBCs Acquisition

2.3. Physical and Mechanical Characterization of MBCs

2.3.1. Apparent Density

2.3.2. Water Absorption

2.3.3. Compressive Resistance at 10% Deformation

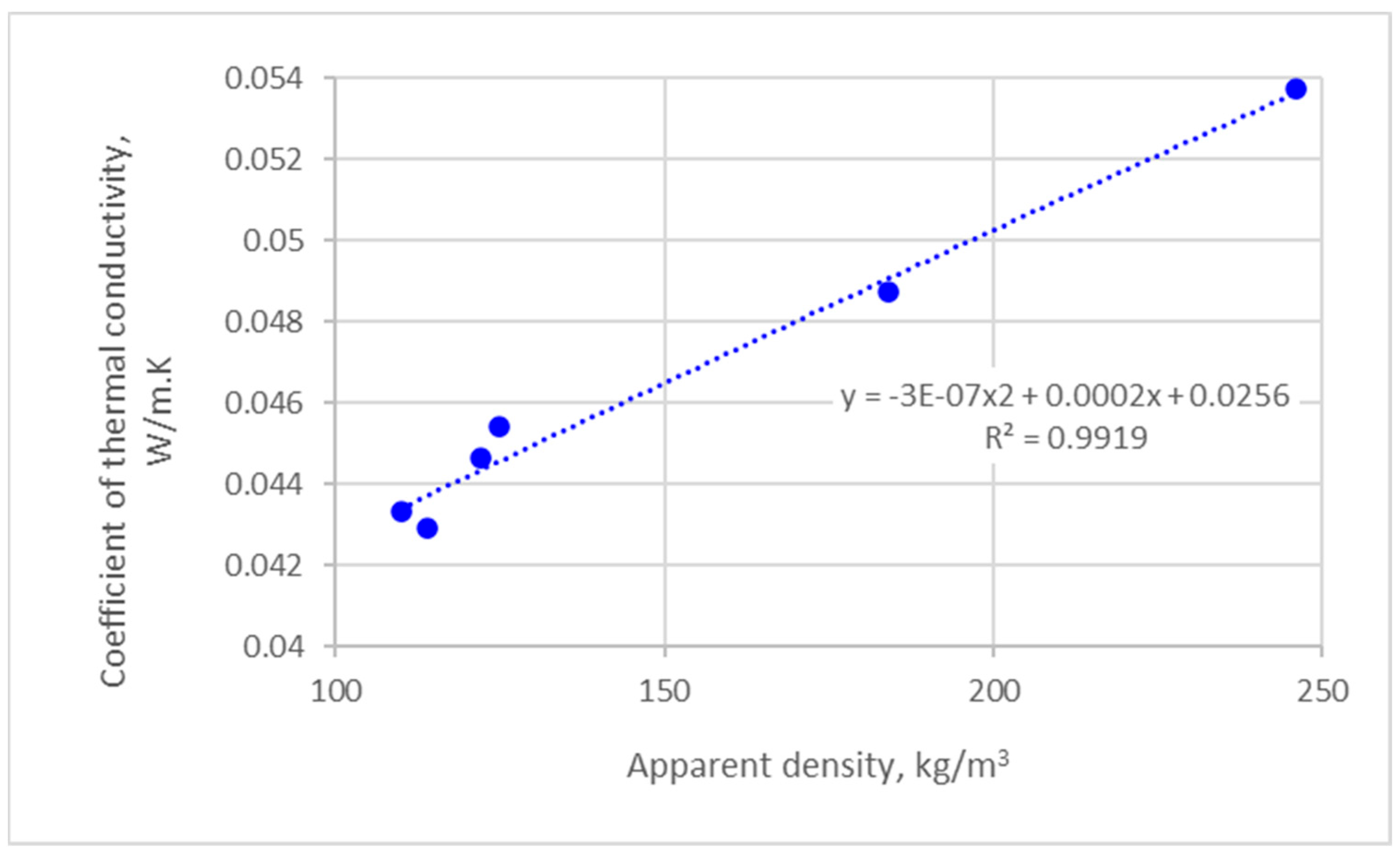

2.3.4. Thermal Conductivity

2.4. Biodegradation of MBCs

2.4.1. COD

2.4.2. Microbial Culture Enrichment and Inoculum Preparation

2.4.3. Biodegradation Tests and Interpretation of the Results

2.5. Statistical Analysis

3. Results and Discussion

3.1. Characterization of the Mycelium-Based Composites

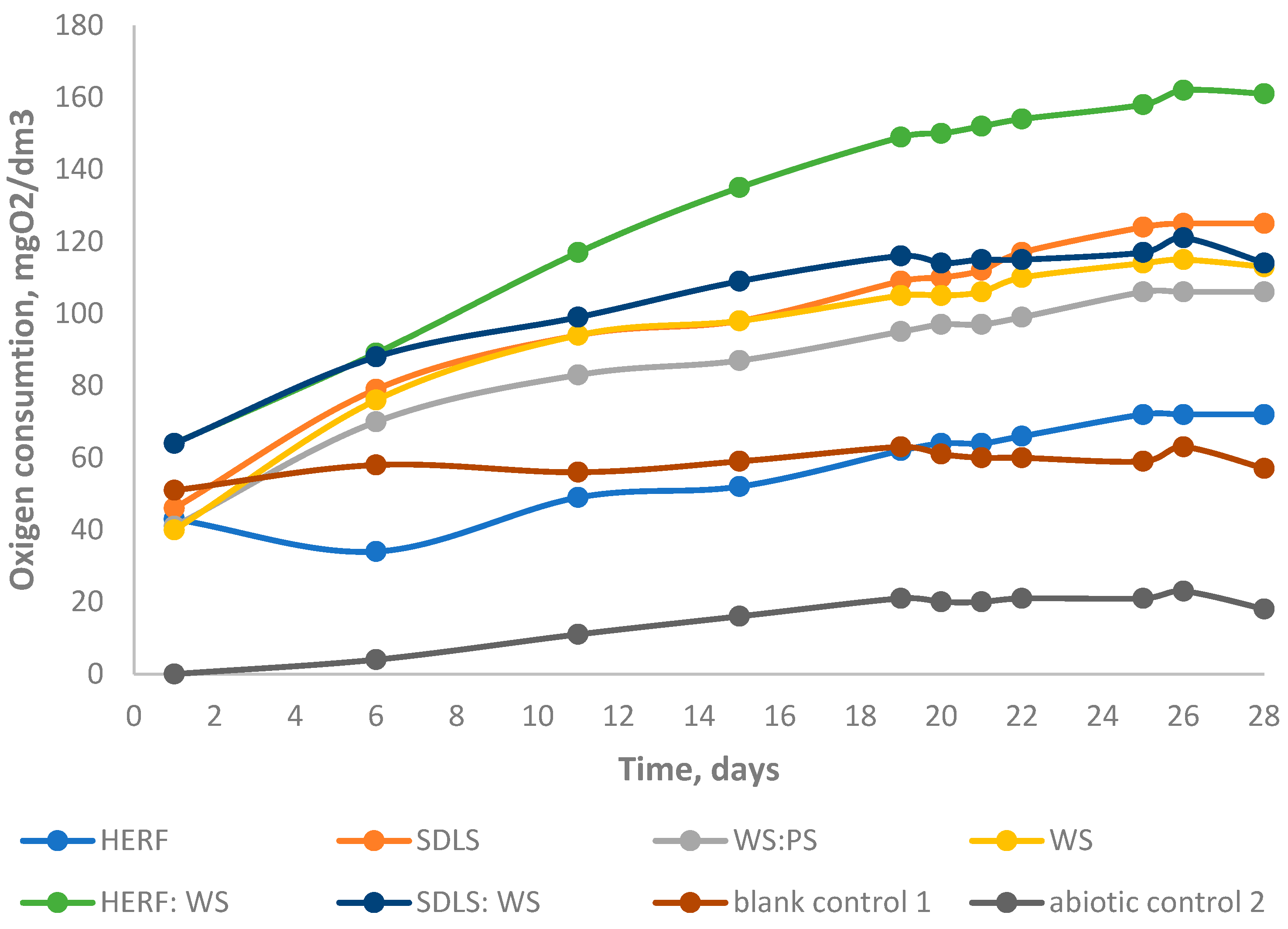

3.2. Biodegradation Profile

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MBCs | Mycelium-based composites |

| HERF | Hexane-extracted rose flower |

| SDLS | Steam-distilled lavender straw |

| WS | Wheat straw |

| PS | Pine sawdust |

| WHO | World Health Organization |

| SDGs | Sustainable development goals |

| FAO | Food and agriculture organization |

| ThOD | Theoretical oxygen demand |

| COD | Chemical oxygen demand |

| BOD | Biological oxygen demand |

| WWTP | Wastewater treatment plant |

References

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Teeraphantuvat, T.; Jatuwong, K.; Jinanukul, P.; Thamjaree, W.; Lumyong, S.; Aiduang, W. Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste. Polymers 2024, 16, 262. [Google Scholar] [CrossRef] [PubMed]

- Amran, M.A.; Palaniveloo, K.; Fauzi, R.; Satar, N.M.; Mohidin, T.B.M.; Mohan, G.; Razak, S.A.; Arunasalam, M.; Nagappan, T.; Sathiya Seelan, J.S. Value-Added Metabolites from Agricultural Waste and Application of Green Extraction Techniques. Sustainability 2021, 13, 11432. [Google Scholar] [CrossRef]

- Falade, A.O. Valorization of agricultural wastes for production of biocatalysts of environmental significance: Towards a sustainable environment. Environ. Sustain. 2021, 4, 317–328. [Google Scholar] [CrossRef]

- Sharma, S.; Basu, S.; Shetti, N.P.; Kamali, M.; Walvekar, P.; Aminabhavi, T.M. Waste-to-energy nexus: A sustainable development. Environ. Pollut. 2020, 267, 115501. [Google Scholar] [CrossRef]

- Fuer, N.; Ou, S.-J.; Lee, Y.-L. Cognitive Research on the Development of Agricultural Waste Resource Treatment Technology for a Sustainable Environment. IOP Conf. Ser. Earth Environ. Sci. 2021, 811, 012002. [Google Scholar] [CrossRef]

- Ambient (Outdoor) Air Pollution. Available online: https://www.who.int/news-room/fact-sheets/detail/ambient-(outdoor)-air-quality-and-health (accessed on 18 March 2025).

- Elsacker, E.; Vandelook, S.; Van Wylick, A.; Ruytinx, J.; De Laet, L.; Peeters, E. A comprehensive framework for the production of mycelium-based lignocellulosic composites. Sci. Total Environ. 2020, 725, 138431. [Google Scholar] [CrossRef]

- Aiduang, W.; Chanthaluck, A.; Kumla, J.; Jatuwong, K.; Srinuanpan, S.; Waroonkun, T.; Oranratmanee, R.; Lumyong, S.; Suwannarach, N. Amazing Fungi for Eco-Friendly Composite Materials: A Comprehensive Review. J. Fungi 2022, 8, 842. [Google Scholar] [CrossRef]

- Yang, L.; Park, D.; Qin, Z. Material Function of Mycelium-Based Bio-Composite: A Review. Front. Mater. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Angelova, G.; Brazkova, M.; Stefanova, P.; Blazheva, D.; Vladev, V.; Petkova, N.; Slavov, A.; Denev, P.; Karashanova, D.; Zaharieva, R.; et al. Waste Rose Flower and Lavender Straw Biomass—An Innovative Lignocellulose Feedstock for Mycelium Bio-Materials Development Using Newly Isolated Ganoderma resinaceum GA1M. J. Fungi 2021, 7, 866. [Google Scholar] [CrossRef]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials from Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, srep41292. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Picu, R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017, 7, 13070. [Google Scholar] [CrossRef] [PubMed]

- Kuribayashi, T.; Lankinen, P.; Hietala, S.; Mikkonen, K.S. Dense and continuous networks of aerial hyphae improve flexibility and shape retention of mycelium composite in the wet state. Compos.—A Appl. Sci. Manuf. 2022, 152, 106688. [Google Scholar] [CrossRef]

- Zolotovsky, K. Guided Growth: Design and Computation of Biologically Active Materials. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2017. [Google Scholar]

- Jones, M.; Bhat, T.; Kandare, E.; Thomas, A.; Joseph, P.; Dekiwadia, C.; Yuen, R.; John, S.; Ma, J.; Wang, C.-H. Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium—Biomass Composite Materials. Sci. Rep. 2018, 8, 17583. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; John, S. Inherent species characteristic influence and growth performance assessment for mycelium composite applications. Adv. Mater. Lett. 2018, 9, 71–80. [Google Scholar] [CrossRef]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and applications of fungal mycelium-based advancedfunctional materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Grimm, D.; Wösten, H.A.B. Mushroom cultivation in the circular economy. Appl. Microbiol. Biotechnol. 2018, 102, 7795–7803. [Google Scholar] [CrossRef]

- Perez, R.; Luccioni, M.; Kamakaka, R.; Clamons, S.; Gaut, N.; Stirling, F.; Adamala, K.P.; Silver, P.A.; Endy, D. Enabling community-based metrology for wood-degrading fungi. Fungal Biol. Biotechnol. 2020, 7, 2. [Google Scholar] [CrossRef]

- Higgins, C.; Margot, H.; Warnquist, S.; Obeysekare, E.; Mehta, K. Mushroom cultivation in the developing world: A comparison of cultivation technologies. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 19–22 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–7. [Google Scholar]

- Bruscato, C.; Malvessi, E.; Brandalise, R.N.; Camassola, M. High performance of macrofungi in the production of mycelium-based biofoams using sawdust—Sustainable technology for waste reduction. J. Clean. Prod. 2019, 234, 225–232. [Google Scholar] [CrossRef]

- Nussbaumer, M.; Opdenbosch, D.V.; Engelhardt, M.; Briesen, H.; Benz, J.P.; Karl, T. Material characterization of pressed and unpressed wood–mycelium composites derived from two Trametes species. Environ. Technol. Innov. 2023, 30, 103063. [Google Scholar] [CrossRef]

- Appels, F.V.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281. [Google Scholar] [CrossRef]

- Gezer, E.D.; Uçar, E.; Gümüşkaya, E. Physical and mechanical properties of mycelium-based fiberboards. BioResources 2024, 19, 3421–3435. [Google Scholar] [CrossRef]

- Camilleri, E.; Narayan, S.; Lingam, D.; Blundell, R. Mycelium-based composites: An updated comprehensive overview. Biotechnol. Adv. 2025, 79, 108517. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; Laet, L.D. Mechanical, physical and chemical characterisation of mycelium–based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 7, e0213954. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Tudryn, G. Manufacturing of biocomposite sandwich structures using mycelium-bound cores and preforms. J. Manuf. Process. 2017, 28, 50–59. [Google Scholar] [CrossRef]

- Toju, H.; Tanabe, A.S.; Yamamoto, S.; Sato, H. High-coverage ITS primers for the DNA-based identification of ascomycetes and basidiomycetes in environmental samples. PLoS ONE 2012, 7, e40863. [Google Scholar] [CrossRef]

- Calvo-Flores, F.G.; Dobado, J.A.; Isac-García, J.; Martín-Martínez, F.J. Lignin and lignans as renewable raw materials. In Chemistry, Technology and Applications; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and mechanical properties of fungal mycelium-based biofoam. J. Mater. Civ. Eng. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Pavol, P.; Schwarzova, I.; Kacik, F.; Geffert, A. Water Absorption behavior of hemp hurds composites. Materials 2015, 8, 2243–2257. [Google Scholar] [CrossRef]

- Amstislavski, P.; Yang, Z.; White, M.D. Thermal Insulation Material from Mycelium and Forestry Byproducts. United States Patent Application Publication WO 2017/132523 Al, 3 August 2017. [Google Scholar]

- Tacer-Caba, Z.; Varis, J.J.; Lankinen, P.; Mikkonen, K.S. Comparison of novel fungal mycelia strains and sustainable growth substrates to produce humidity-resistant biocomposites. Mater. Des. 2020, 192, 108728. [Google Scholar] [CrossRef]

- Chan, X.Y.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Gupta, M. Mechanical properties of dense mycelium-bound composites under accelerated tropical weathering conditions. Sci. Rep. 2021, 11, 22112. [Google Scholar] [CrossRef]

- Mardijanti, D.S.; Megantara, E.N.; Bahtiar, A.; Sunardi, S. Turning the cocopith waste into myceliated biocomposite to make an insulator. Int. J. Biomater. 2021, 2021, 663065. [Google Scholar] [CrossRef]

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel mycelium-based biocomposites (MBB) as building materials. J. Renew. Mater. 2020, 8, 1067–1076. [Google Scholar] [CrossRef]

- ISO 20200:2023; Plastics—Determination of the Degree of Disintegration of Plastic Materials under Composting Conditions in a Laboratory-Scale Test. ISO: Geneva, Switzerland, 2023.

- Van Wylick, A.; Elsacker, E.; Yap, L.L.; Peeters, E.; De Laet, L. Mycelium composites and their biodegradability: An exploration on the disintegration of mycelium-based materials in soil. In Proceedings of the 4th International Conference on Bio-Based Building Materials (ICBBM 2021), Barcelona, Spain, 16–18 June 2021; pp. 652–659. [Google Scholar]

- Enriquez-Medina, I.; Bermudez, A.C.; Ortiz-Montoya, E.Y.; Alvarez-Vasco, C. From purposeless residues to biocomposites: A hyphae made connection. Biotechnol. Rep. 2023, 39, e00807. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Florea, I.; Manea, D.L. Analysis of Thermal Insulation Building Materials Based on Natural Fibers. Procedia Manuf. 2019, 32, 230–235. [Google Scholar] [CrossRef]

- OECD. OECD Guidelines for the Testing of Chemicals: Revised Introduction to the OECD Guidelines for Testing of Chemicals, Section 3; OECD: Paris, France, 2006. [Google Scholar]

- Pelletier, M.G.; Holt, G.A.; Wanjura, J.D.; Lara, A.J.; Tapia-Carillo, A.; Mcintyre, G.; Bayer, E. An evaluation study of pressure–compressed acoustic absorbers grown on agricultural by-products. Ind. Crop. Prod. 2017, 95, 342–347. [Google Scholar] [CrossRef]

- ISO 29470:2020(en); Thermal Insulating Products for Building Applications—Determination of the Apparent Density. ISO: Geneva, Switzerland, 2020. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:29470:ed-2:v1:en (accessed on 20 February 2025).

- ISO 29767:2019; Thermal Insulating Products for Building Applications—Determination of Short-Term Water Absorption by Partial Immersion. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:29767:ed-2:v1:en (accessed on 20 February 2025).

- ISO 16535:2019; Thermal Insulating Products for Building Applications—Determination of Long-Term Water Absorption by Immersion. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:16535:ed-2:v1:en (accessed on 20 February 2025).

- EN 826:2013; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. European Standard: Brussels, Belgium, 2013. Available online: https://standards.iteh.ai/catalog/standards/cen/f54055a6-cacc-4d69-b85a-b190aea8ed7f/en-826-2013?srsltid=AfmBOoqKvqqgQ1WjAStRgrYVFxXOjgWjUksVA1j4fTwZcirs1286Plf3 (accessed on 20 February 2025).

- EN 12667:2004; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. European Standard: Brussels, Belgium, 2004. Available online: https://bds-bg.org/bg/project/show/bds:proj:45613 (accessed on 20 February 2025).

- Al-Qahtani, S.; Koç, M.; Isaifan, R.J. Assessing the Effectiveness of Mycelium-Based Thermal Insulation in Reducing Domestic Cooling Footprint: A Simulation-Based Study. Energies 2025, 18, 980. [Google Scholar] [CrossRef]

- Al-Qahtani, S.; Koç, M.; Isaifan, R.J. Mycelium-Based Thermal Insulation for Domestic Cooling Footprint Reduction: A Review. Sustainability 2023, 15, 13217. [Google Scholar] [CrossRef]

- Zhao, J.; Zheng, R.; Tang, J.; Sun, H.; Wang, J. A mini-review on building insulation materials from perspective of plastic pollution: Current issues and natural fibres as a possible solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef] [PubMed]

- Nava, J.A.L.; González, J.M.; Chacón, X.R.; Luna, J.A.N. Assessment of Edible Fungi and Films Bio-Based Material Simulating Expanded Polystyrene. Mater. Manuf. Process. 2015, 31, 1085–1090. [Google Scholar] [CrossRef]

- Pakkala, T.A.; Lahdensivu, J. Long-term water absorption tests for frost insulation materials taking into account frost attack. Case Stud. Constr. Mater. 2014, 1, 40–45. [Google Scholar] [CrossRef]

- Ziegler, A.R.; Bajwa, S.G.; Holt, G.A.; McIntyre, G.; Bajwa, D.S. Evaluation of physico-mechanical properties of mycelium reinforced green biocomposites made from cellulosic fibers. Appl. Eng. Agric. 2016, 32, 931–938. [Google Scholar] [CrossRef]

- Nedeltcheva-Antonova, D.; Stoicheva, P.; Antonov, L. Chemical profiling of Bulgarian rose absolute (Rosa damascena Mill.) using gas chromatography–mass spectrometry and trimethylsilyl derivatives. Ind. Crops Prod. 2017, 108, 36–43. [Google Scholar] [CrossRef]

- Coppo, E.; Marchese, A. Antibacterial activity of polyphenols. Curr. Pharm. Biotechnol. 2014, 15, 380–390. [Google Scholar] [CrossRef] [PubMed]

| MBCs | Apparent Density, ρa | Compressive Resistance at 10% Deformation, σ10 | Capillary Absorption, Wc | Short-Term Water Absorption, Wma,1d | Long-Term Water Absorption, Wva,28d | Coefficient of Thermal Conductivity, λ |

|---|---|---|---|---|---|---|

| kg/m3 | kPa | [kg/m2] | %wt. | % vol. | W/mK | |

| HERF | 246 ± 23.8 | 176 ± 21.2 | 4.79 ± 0.431 | 123 ± 11.1 | 59.3 ± 5.34 | 0.054 ± 0.0043 |

| SDLS | 184 ± 22.4 | 125 ± 22.3 | 5.63 ± 0.620 | 148 ± 16.3 | 50.4 ± 4.54 | 0.049 ± 0.0049 |

| WS | 110 ± 2.6 | 104 ± 12.1 | 1.83 ± 0.037 | 197 ± 5.9 | 52.8 ± 1.59 | 0.043 ± 0.0017 |

| HERF: WS | 114 ± 4.8 | 49 ± 6.9 | 2.85 ± 0.114 | 242 ± 12.1 | 61.5 ± 3.07 | 0.043 ± 0.0026 |

| SDLS:WS | 122 ± 3.0 | 39 ± 3.2 | 1.44 ± 0.029 | 148 ± 4.4 | 47.3 ± 1.89 | 0.045 ± 0.0018 |

| WS: PS | 125 ± 8.1 | 54 ± 4.4 | 4.17 ± 0.292 | 186 ± 14.9 | 49.2 ± 3.44 | 0.045 ± 0.0036 |

| Sample | COD of 500 mg/L Suspension (mgO2/dm3) | Theoretical Oxygen Demand per Gram Material (g/g) |

|---|---|---|

| HERF | 666 (±43) | 1.332 |

| SDLS | 552(±26) | 1.104 |

| WS | 584(±37) | 1.168 |

| HERF:WS | 414 (±17) | 0.828 |

| SDLS:WS | 440 (±11) | 0.88 |

| WS: PS | 808 (±44) | 1.616 |

| Sample Period for Degradation | HERF | SDLS | WS | HERF: WS | SDLS: WS | WS: PS | BC | AC |

|---|---|---|---|---|---|---|---|---|

| 28 days | 72 | 125 | 113 | 161 | 114 | 106 | 57 | 18 |

| 56 days | 99 | 149 | 141 | 192 | 133 | 122 | 49 | 18 |

| Oxygen consumption as % of the ThOD * | 14.9 | 27.1 | 24.1 | 46.4 | 30.2 | 15.1 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Angelova, G.; Yemendzhiev, H.; Zaharieva, R.; Brazkova, M.; Koleva, R.; Stefanova, P.; Baldzhieva, R.; Vladev, V.; Krastanov, A. Mycelium-Based Composites Derived from Lignocellulosic Residual By-Products: An Insight into Their Physico-Mechanical Properties and Biodegradation Profile. Appl. Sci. 2025, 15, 6333. https://doi.org/10.3390/app15116333

Angelova G, Yemendzhiev H, Zaharieva R, Brazkova M, Koleva R, Stefanova P, Baldzhieva R, Vladev V, Krastanov A. Mycelium-Based Composites Derived from Lignocellulosic Residual By-Products: An Insight into Their Physico-Mechanical Properties and Biodegradation Profile. Applied Sciences. 2025; 15(11):6333. https://doi.org/10.3390/app15116333

Chicago/Turabian StyleAngelova, Galena, Husein Yemendzhiev, Roumiana Zaharieva, Mariya Brazkova, Ralitza Koleva, Petya Stefanova, Radka Baldzhieva, Veselin Vladev, and Albert Krastanov. 2025. "Mycelium-Based Composites Derived from Lignocellulosic Residual By-Products: An Insight into Their Physico-Mechanical Properties and Biodegradation Profile" Applied Sciences 15, no. 11: 6333. https://doi.org/10.3390/app15116333

APA StyleAngelova, G., Yemendzhiev, H., Zaharieva, R., Brazkova, M., Koleva, R., Stefanova, P., Baldzhieva, R., Vladev, V., & Krastanov, A. (2025). Mycelium-Based Composites Derived from Lignocellulosic Residual By-Products: An Insight into Their Physico-Mechanical Properties and Biodegradation Profile. Applied Sciences, 15(11), 6333. https://doi.org/10.3390/app15116333