Thermal Damage Characterization and Modeling in Granite Samples Subjected to Heat Treatment by Leveraging Machine Learning and Experimental Data

Abstract

Featured Application

Abstract

1. Introduction

2. Granite Thermal Damage Dataset Description

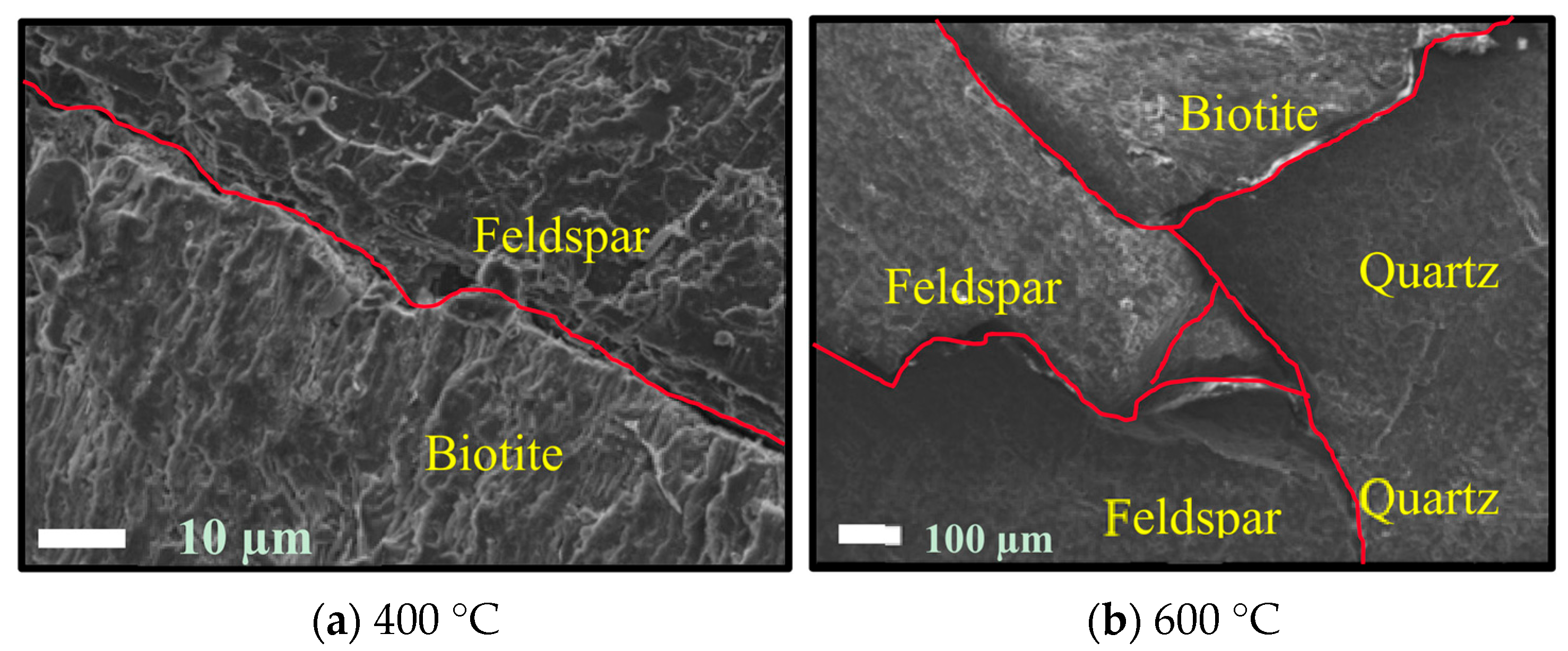

3. Crack Evolution

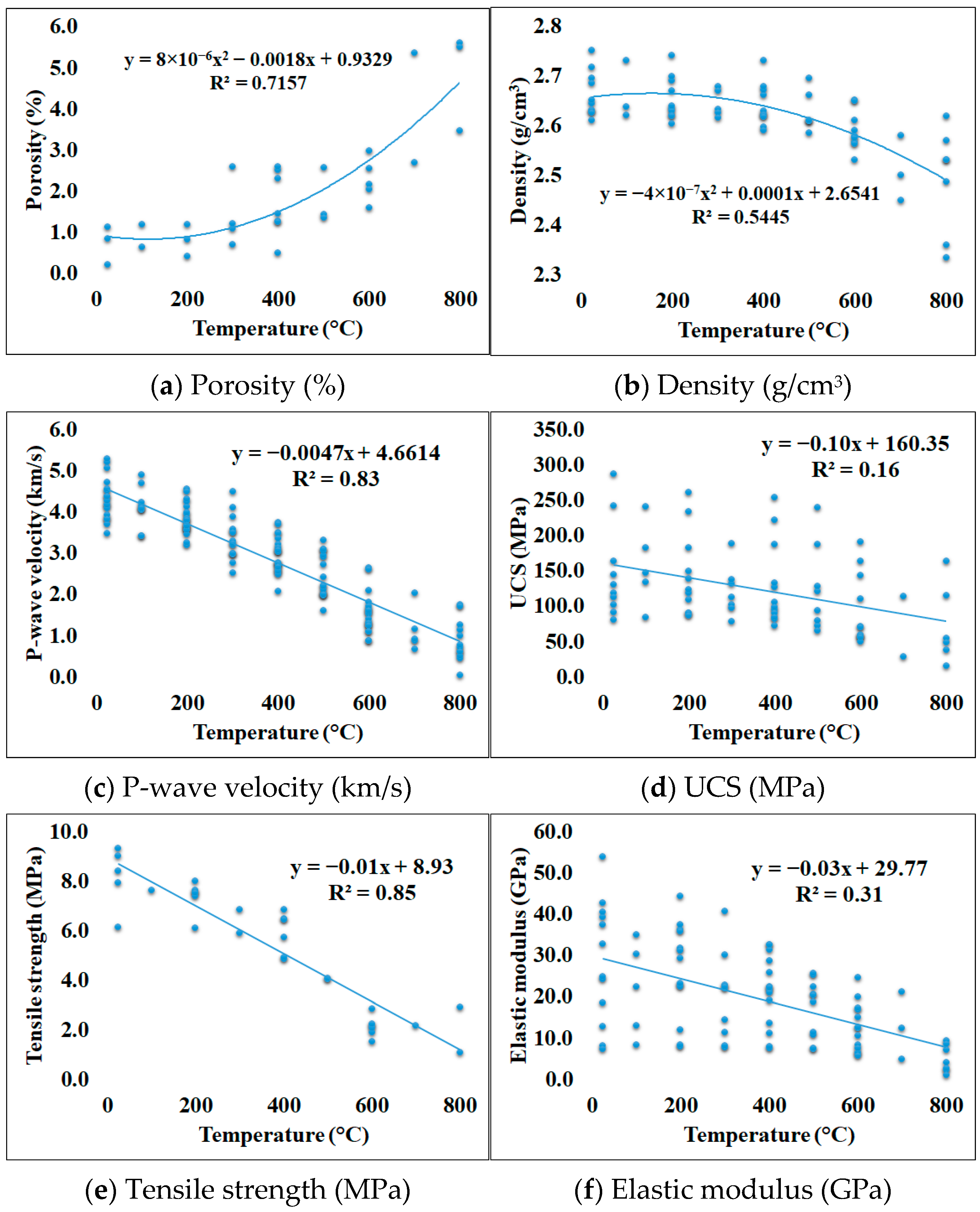

4. Physical and Mechanical Parameters

4.1. Porosity

4.2. Density

4.3. P-Wave Velocity

4.4. UCS and Tensile Strength

4.5. Elastic Modulus

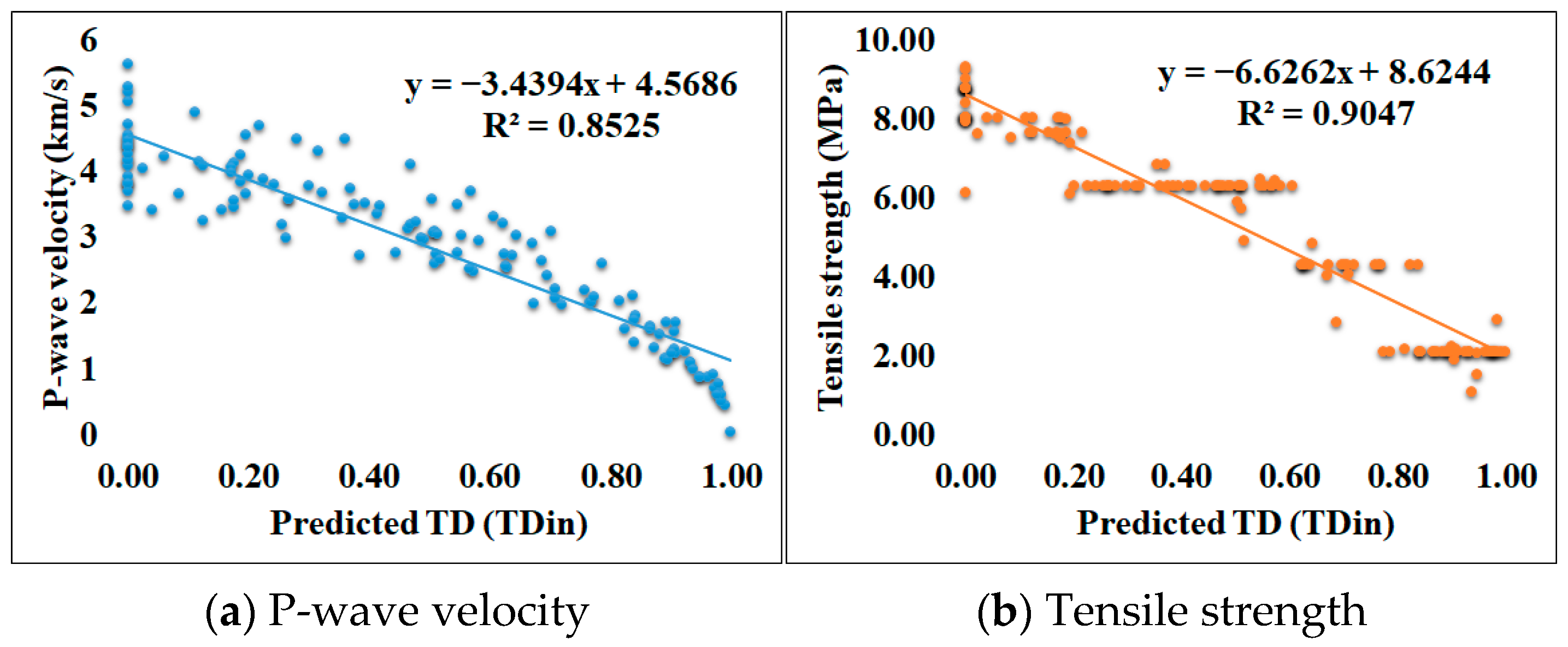

4.6. Physical and Mechanical Parameters Versus Crack Development

5. Thermal Damage

5.1. Definition of TD and Its Influencing Parameters

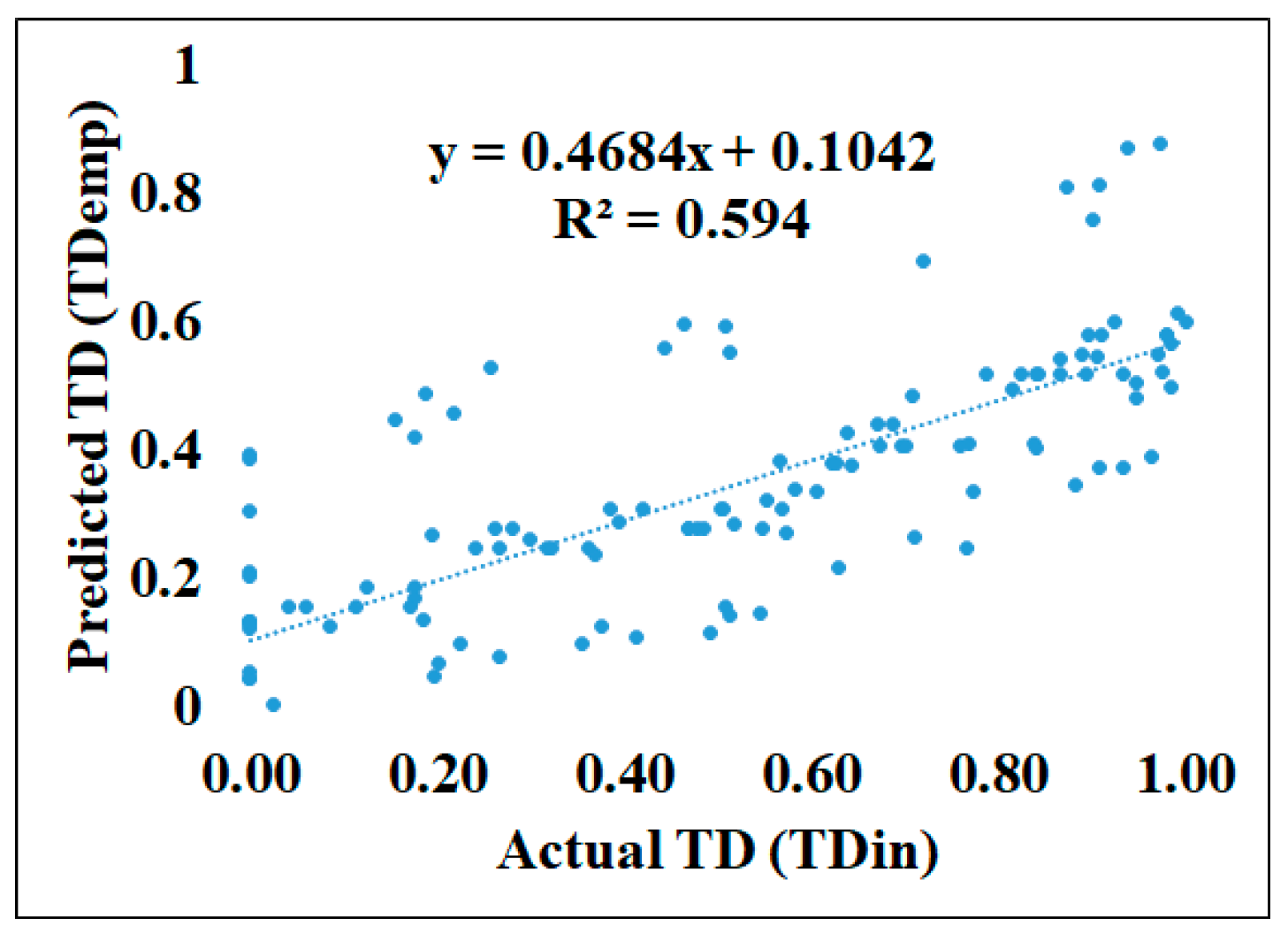

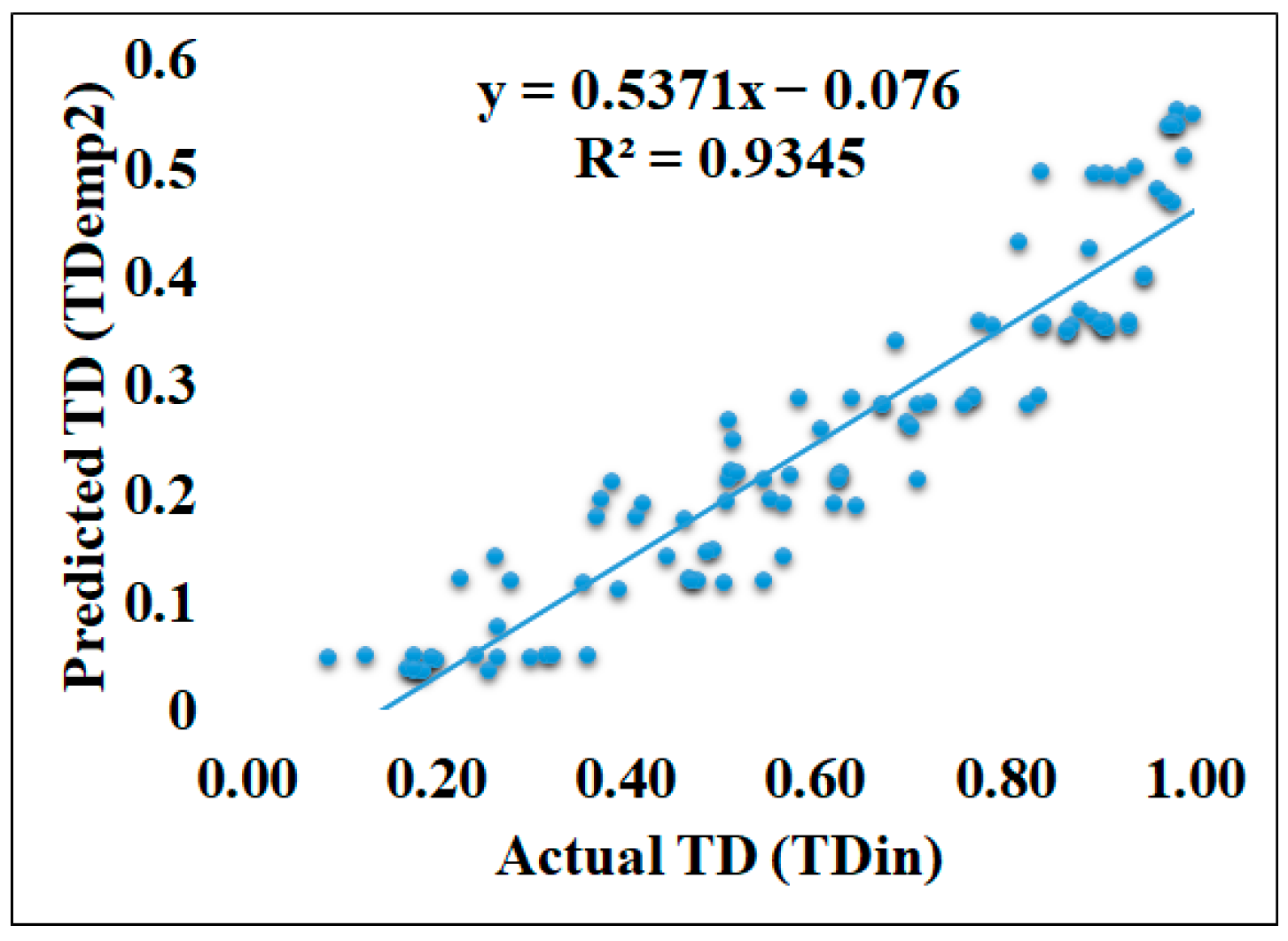

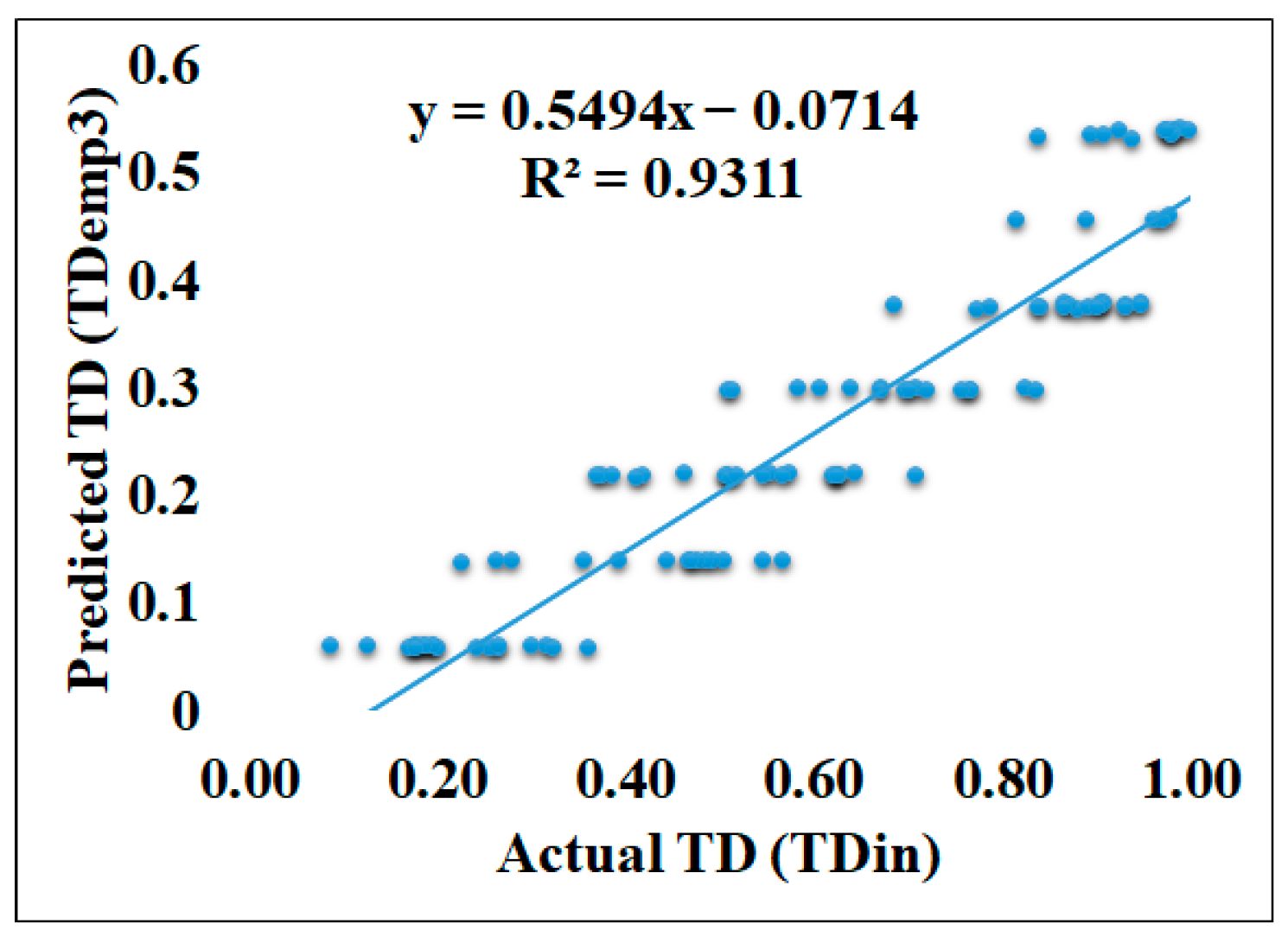

5.2. Multivariate Regression Model

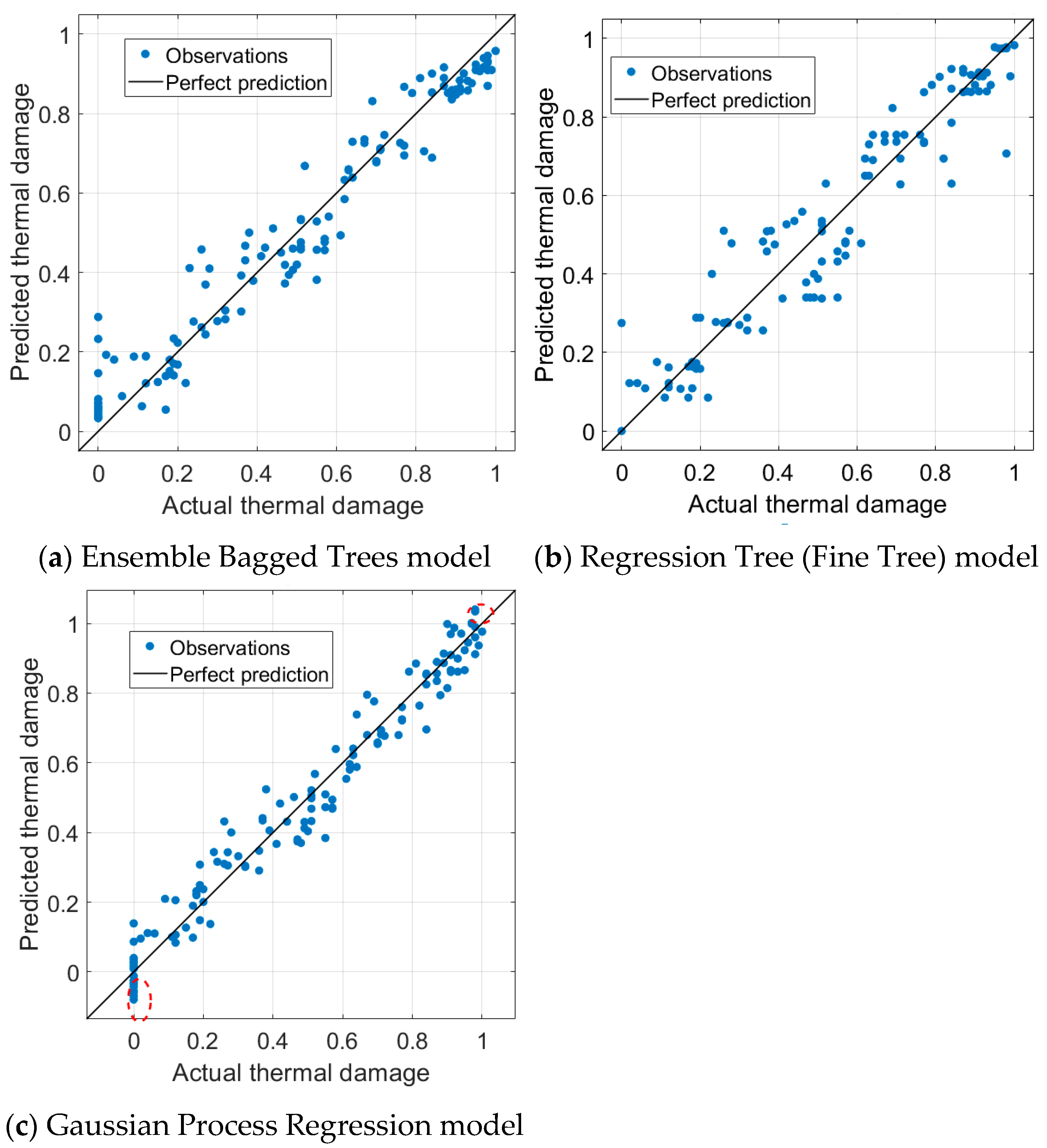

5.3. Machine Learning Techniques

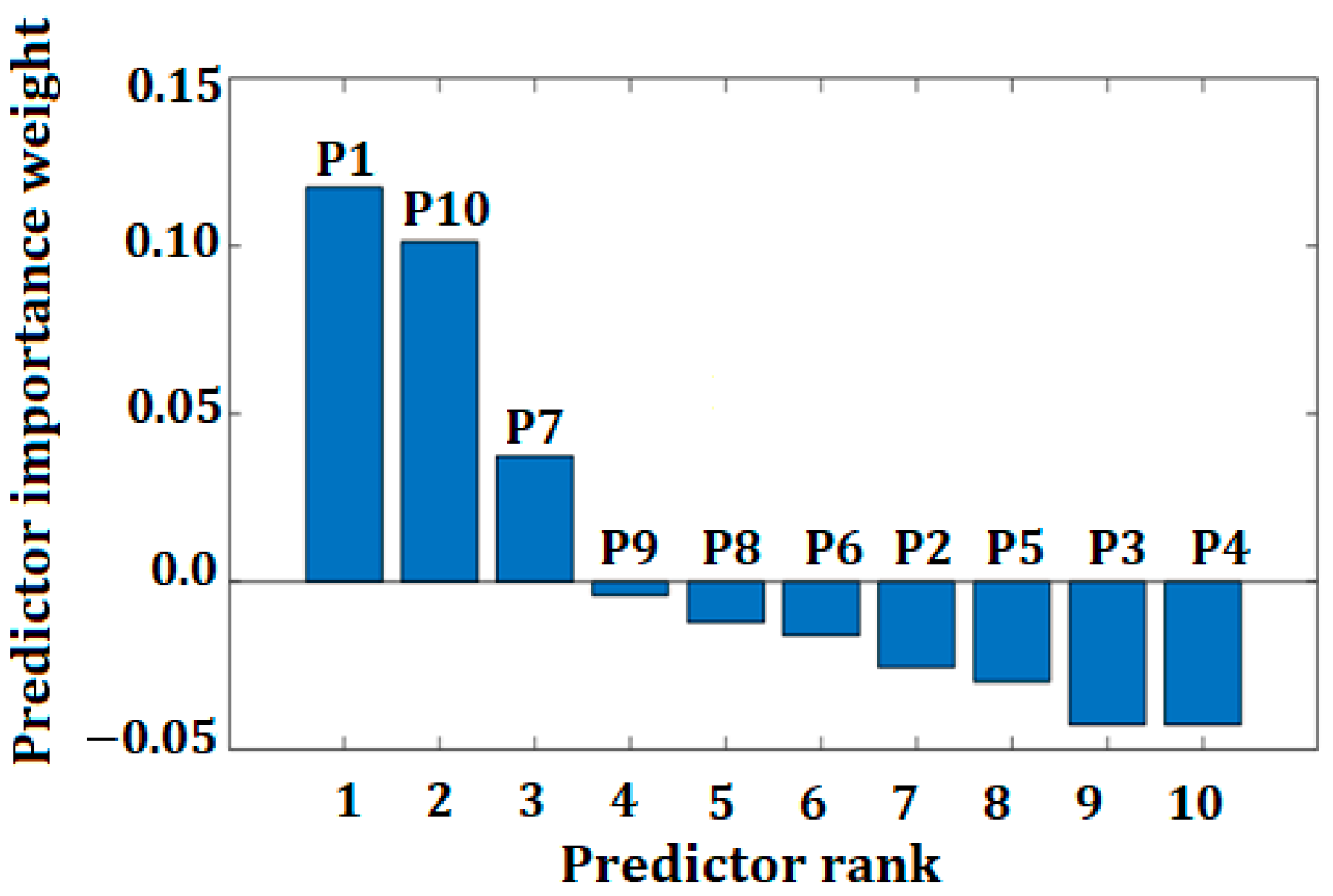

5.4. Sensitivity Analysis (Importance of the Input Parameters)

5.5. Discussions

6. Conclusions

- (1)

- Crack development analysis revealed that no intra- or intergranular cracks occur below 400 °C; however, intergranular cracks appear between quartz–quartz, quartz–feldspar, and biotite–feldspar at 400 °C, and additional intergranular and intragranular cracks involving biotite, quartz, and feldspar emerge at 600 °C.

- (2)

- Based on the observed cracking behavior, three temperature zones have been identified: up to 200 °C, between 200 °C and 600 °C, and above 600 °C.

- (3)

- Physical and mechanical tests indicated a steady decrease in density, P-wave velocity, UCS, tensile strength, and elastic modulus, alongside an increase in porosity as the temperature rose from 25 °C to 800 °C.

- (4)

- Two distinct zones of property change were noted: minimal changes occurred up to 600 °C, while significant changes were observed between 600 °C and 800 °C, supporting the crack development pattern.

- (5)

- Predictive models developed using machine learning and linear regression demonstrated excellent performance in estimating TD based on comprehensive input parameters, including mineralogical, physical, and mechanical variables.

- (6)

- These models can serve as practical tools for planning underground operations in granite-rich environments subjected to thermal effects.

- (7)

- New equations were proposed to determine the TD of rocks at high temperatures.

- (8)

- Finally, the novelty of this research lies in the use of soft computing techniques to model and predict thermal damage in granite specimens heated up to 800 °C, using a globally sourced dataset.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SEM | Scanning electron 57 microscopy |

| CT | X-ray microcomputed tomography |

| PM | Polarizing microscope |

| NMR | Nuclear magnetic resonance imaging |

| AE | Acoustic emission |

| TGA | Thermogravimetric 61 analyses |

| DSC | Differential scanning calorimetry |

| XRD | X-ray diffraction |

| MI | Multiple imputation |

| TD | Thermal damage |

| UCS | Unconfined compressive strength |

References

- Alcock, T.; Bullen, D.; Benson, P.M.; Vinciguerra, S. Temperature-driven micro-fracturing in granite: The interplay between microstructure, mineralogy and tensile strength. Heliyon 2023, 9, e13871. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Yang, S.; Wang, R.; Xie, J.; Tian, N.; Tian, H.; Zheng, J.; Jiang, G.; Dou, B. Experimental investigation on the physical-thermal properties of Nanan granite after air and water cooling for deep geothermal heat extraction. Renew. Energy 2024, 223, 119963. [Google Scholar] [CrossRef]

- Wang, L.; Wu, Y.; Huang, Z.; Lin, J.; Wang, Y.; Zhang, W. Effects of temperature and confining pressure on the permeability of Beishan granite from high-level radioactive waste disposal repository. Case Stud. Therm. Eng. 2024, 55, 104111. [Google Scholar] [CrossRef]

- Shao, S.; Ranjith, P.; Wasantha, P.; Chen, B. Experimental and numerical studies on the mechanical behaviour of Australian Strathbogie granite at high temperatures: An application to geothermal energy. Geothermics 2015, 54, 96–108. [Google Scholar] [CrossRef]

- Shang, X.; Zhang, Z.; Xu, X.; Liu, T.; Xing, Y. Mineral Composition, Pore Structure, and Mechanical Characteristics of Pyroxene Granite Exposed to Heat Treatments. Minerals 2019, 9, 553. [Google Scholar] [CrossRef]

- Jin, Y.; He, C.; Yao, C.; Sun, Z.; Wang, J.; Zhang, X.; Yang, J.; Jiang, Q.; Zhou, C. Experimental and numerical simulation study on the evolution of mechanical properties of granite after thermal treatment. Comput. Geotech. 2024, 172, 106464. [Google Scholar] [CrossRef]

- Shi, Z.; Li, J.; Ranjith, P.G.; Wang, M.; Lin, H.; Han, D.; Li, K. Acoustic emission and fracture morphology characteristics of thermal-damage granite under mixed mode I/III loading. Theor. Appl. Fract. Mech. 2024, 133, 104524. [Google Scholar] [CrossRef]

- Dang, Y.; Yang, Z.; Liu, X. Three-dimensional numerical study on failure mechanism of granite after thermal treatment based on moment tensor inversion. Comput. Geotech. 2023, 155, 105185. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Mei, G.; Jiang, G.; Dou, B. Experimental investigation on physical and mechanical properties of thermal cycling granite by water cooling. Acta Geotech. 2020, 15, 1881–1893. [Google Scholar] [CrossRef]

- Kang, F.; Jia, T.; Li, Y.; Deng, J.; Huang, X. Experimental study on the physical and mechanical variations of hot granite under different cooling treatments. Renew. Energy 2021, 179, 1316–1328. [Google Scholar] [CrossRef]

- Wu, X.; Guo, Q.; Zhu, Y.; Ren, F.; Zhang, J.; Wu, X.; Cai, M. Pore structure and crack characteristics in high-temperature granite under water-cooling. Case Stud. Therm. Eng. 2021, 28, 101646. [Google Scholar] [CrossRef]

- Gao, M.; Li, T.; Zhu, J.; Yin, H.; Yang, Y. An Analysis of Relationship between the Microfracture Features and Mineral Morphology of Granite. Adv. Civ. Eng. 2021, 2021, 4765731. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Zhang, Y.; Wu, Z. Rock strengthening or weakening upon heating in the mild temperature range? Eng. Geol. 2020, 272, 105619. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Q.; Geng, J. Microstructural characterization of limestone exposed to heat with XRD, SEM and TG-DSC. Mater. Charact. 2017, 134, 285–295. [Google Scholar] [CrossRef]

- Shen, Y.-J.; Zhang, Y.-L.; Gao, F.; Yang, G.-S.; Lai, X.-P. Influence of Temperature on the Microstructure Deterioration of Sandstone. Energies 2018, 11, 1753. [Google Scholar] [CrossRef]

- Peng, L.; Li, X.; Peng, X.; Gan, Y.; Wang, J. Analysis of physical and mechanical behaviors and microscopic mineral characteristics of thermally damaged granite. Sci. Rep. 2024, 14, 14776. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Shao, S.; Chen, B.K.; Lashin, A.; Arifi, N.A.; Rathnaweera, T.D. Mechanical behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: An application to geothermal energy extraction. Geothermics 2017, 65, 44–59. [Google Scholar] [CrossRef]

- Xiao, P.; Zheng, J.; Dou, B.; Tian, H.; Cui, G.; Kashif, M. Mechanical Behaviors of Granite after Thermal Shock with Different Cooling Rates. Energies 2021, 14, 3721. [Google Scholar] [CrossRef]

- Zhang, B.; Tian, H.; Dou, B.; Zheng, J.; Chen, J.; Zhu, Z.; Liu, H. Macroscopic and microscopic experimental research on granite properties after high-temperature and water-cooling cycles. Geothermics 2021, 93, 102079. [Google Scholar] [CrossRef]

- Inserra, C.; Biwa, S.; Chen, Y. Influence of thermal damage on linear and nonlinear acoustic properties of granite. Int. J. Rock Mech. Min. Sci. 2013, 62, 96–104. [Google Scholar] [CrossRef]

- Su, G.; Chen, Z.; Ju, J.W.; Jiang, J. Influence of temperature on the strainburst characteristics of granite under true triaxial loading conditions. Eng. Geol. 2017, 222, 38–52. [Google Scholar] [CrossRef]

- Wang, F.; Frühwirt, T.; Konietzky, H. Influence of repeated heating on physical-mechanical properties and damage evolution of granite. Int. J. Rock Mech. Min. Sci. 2020, 136, 104514. [Google Scholar] [CrossRef]

- Jin, P.; Hu, Y.; Shao, J.; Zhao, G.; Zhu, X.; Li, C. Influence of different thermal cycling treatments on the physical, mechanical and transport properties of granite. Geothermics 2019, 78, 118–128. [Google Scholar] [CrossRef]

- Kang, F.; Li, Y.; Tang, C.a. Grain size heterogeneity controls strengthening to weakening of granite over high-temperature treatment. Int. J. Rock Mech. Min. Sci. 2021, 145, 104848. [Google Scholar] [CrossRef]

- Miao, S.; Pan, P.-Z.; Yu, P.; Zhao, S.; Shao, C. Fracture analysis of Beishan granite after high-temperature treatment using digital image correlation. Eng. Fract. Mech. 2020, 225, 106847. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Ni, J.; Shao, W.; Azzam, R. Experimental study on the influence of temperature on the mechanical properties of granite under uni-axial compression and fatigue loading. Int. J. Rock Mech. Min. Sci. 2012, 56, 62–66. [Google Scholar] [CrossRef]

- Xu, Z.; Zhong, X.; Zhang, S.; Wang, Y.; Liu, K.; Liu, X.; Meng, Y.; Hou, X.; Chen, C. Experimental study on mechanical damage and creep characteristics of Gonghe granite under real-time high temperature. Geothermics 2024, 123, 103100. [Google Scholar] [CrossRef]

- Li, C.; Hu, Y.; Meng, T.; Jin, P.; Zhao, Z.; Zhang, C. Experimental study of the influence of temperature and cooling method on mechanical properties of granite: Implication for geothermal mining. Energy Sci. Eng. 2020, 8, 1716–1728. [Google Scholar] [CrossRef]

- Pan, P.-Z.; Shao, C.-Y. Experimental studies on the physical and mechanical properties of heated rock by air, water and high-viscosity fluid cooling. Geomech. Energy Environ. 2022, 31, 100315. [Google Scholar] [CrossRef]

- Austin, P.C.; White, I.R.; Lee, D.S.; van Buuren, S. Missing Data in Clinical Research: A Tutorial on Multiple Imputation. Can. J. Cardiol. 2021, 37, 1322–1331. [Google Scholar] [CrossRef]

- Woods, A.D.; Gerasimova, D.; Van Dusen, B.; Nissen, J.; Bainter, S.; Uzdavines, A.; Davis-Kean, P.E.; Halvorson, M.; King, K.M.; Logan, J.A.R.; et al. Best practices for addressing missing data through multiple imputation. Infant Child Dev. 2024, 33, e2407. [Google Scholar] [CrossRef]

- Isaka, B.L.A.; Gamage, R.P.; Rathnaweera, T.D.; Perera, M.S.A.; Chandrasekharam, D.; Kumari, W.G.P. An Influence of Thermally-Induced Micro-Cracking under Cooling Treatments: Mechanical Characteristics of Australian Granite. Energies 2018, 11, 1338. [Google Scholar] [CrossRef]

- Li, M.; Wang, D.; Shao, Z. Experimental study on changes of pore structure and mechanical properties of sandstone after high-temperature treatment using nuclear magnetic resonance. Eng. Geol. 2020, 275, 105739. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Ranjith, P.G.; Jing, H.-W.; Tian, W.-L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Chen, S.; Yang, C.; Wang, G. Evolution of thermal damage and permeability of Beishan granite. Appl. Therm. Eng. 2017, 110, 1533–1542. [Google Scholar] [CrossRef]

- Gautam, P.K.; Verma, A.K.; Jha, M.K.; Sharma, P.; Singh, T.N. Effect of high temperature on physical and mechanical properties of Jalore granite. J. Appl. Geophys. 2018, 159, 460–474. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K.; Abdulagatov, I.M. Temperature-dependent mechanical behaviour of Australian Strathbogie granite with different cooling treatments. Eng. Geol. 2017, 229, 31–44. [Google Scholar] [CrossRef]

- Fan, L.F.; Gao, J.W.; Wu, Z.J.; Yang, S.Q.; Ma, G.W. An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Appl. Therm. Eng. 2018, 140, 505–519. [Google Scholar] [CrossRef]

- Shao, Z.; Wang, Y.; Tang, X. The influences of heating and uniaxial loading on granite subjected to liquid nitrogen cooling. Eng. Geol. 2020, 271, 105614. [Google Scholar] [CrossRef]

- Griffiths, L.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Quantification of microcrack characteristics and implications for stiffness and strength of granite. Int. J. Rock Mech. Min. Sci. 2017, 100, 138–150. [Google Scholar] [CrossRef]

- Mnzool, M.; Al-Mukhtar, A.; Majeed, A.J.; Arafat, A.; Gomaa, E. Simulation and performance characteristics of rock with borehole using Visual Finite Element Analysis. Min Min. Depos 2024, 18, 33–41. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, C.; Wang, J.; Song, W.; Wang, H. An Improved Statistical Damage Constitutive Model for Rock Considering the Temperature Effect. Int. J. Geomech. 2022, 22, 04022203. [Google Scholar] [CrossRef]

- Liu, W.; Yin, S.; Thanh, H.V.; Soltanian, M.R.; Yu, Q.; Yang, S.; Li, Y.; Dai, Z. Advancements and development trend in statistical damage constitutive models for rock: A comprehensive review. Nat. Hazards 2025, 121, 3703–3744. [Google Scholar] [CrossRef]

- Liu, H.; Cai, J.; Ong, Y.-S.; Wang, Y. Understanding and comparing scalable Gaussian process regression for big data. Knowl. Based Syst. 2019, 164, 324–335. [Google Scholar] [CrossRef]

- Hultquist, C.; Gang, C.; Zhao, K. A comparison of Gaussian process regression, random forests and support vector regression for burn severity assessment in diseased forests. Remote Sens. Lett. 2014, 5, 723–732. [Google Scholar] [CrossRef]

- Zhu, Z.; Kempka, T.; Ranjith, P.G.; Tian, H.; Jiang, G.; Dou, B.; Mei, G. Changes in thermomechanical properties due to air and water cooling of hot dry granite rocks under unconfined compression. Renew. Energy 2021, 170, 562–573. [Google Scholar] [CrossRef]

- Fan, L.F.; Wu, Z.J.; Wan, Z.; Gao, J.W. Experimental investigation of thermal effects on dynamic behavior of granite. Appl. Therm. Eng. 2017, 125, 94–103. [Google Scholar] [CrossRef]

- Wu, Q.; Weng, L.; Zhao, Y.; Guo, B.; Luo, T. On the tensile mechanical characteristics of fine-grained granite after heating/cooling treatments with different cooling rates. Eng. Geol. 2019, 253, 94–110. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, H.; Mei, G.; Jiang, G.; Dou, B.; Xiao, P. Experimental investigation on mechanical behaviors of Nanan granite after thermal treatment under conventional triaxial compression. Environ. Earth Sci. 2021, 80, 46. [Google Scholar] [CrossRef]

- Yin, T.-B.; Shu, R.-H.; Li, X.-B.; Wang, P.; Dong, L.-J. Combined effects of temperature and axial pressure on dynamic mechanical properties of granite. Trans. Nonferrous Met. Soc. China 2016, 26, 2209–2219. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, W.; Sun, Q.; Deng, S.; Geng, J.; Li, C. Thermally induced variation of primary wave velocity in granite from Yantai: Experimental and modeling results. Int. J. Therm. Sci. 2017, 114, 320–326. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, W.; Xue, L.; Zhang, Z.; Su, T. Thermal damage pattern and thresholds of granite. Environ. Earth Sci. 2015, 74, 2341–2349. [Google Scholar] [CrossRef]

- Liu, S.; Xu, J. An experimental study on the physico-mechanical properties of two post-high-temperature rocks. Eng. Geol. 2015, 185, 63–70. [Google Scholar] [CrossRef]

- Shao, S.; Wasantha, P.; Ranjith, P.; Chen, B. Effect of cooling rate on the mechanical behavior of heated Strathbogie granite with different grain sizes. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2014, 70, 381–387. [Google Scholar] [CrossRef]

- Xu, X.L.; Karakus, M. A coupled thermo-mechanical damage model for granite. Int. J. Rock Mech. Min. Sci. 2018, 103, 195–204. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.; Yu, Y.; Hu, D.; Shao, J. Influence of cooling rate on thermal degradation of physical and mechanical properties of granite. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2020, 129, 104285. [Google Scholar] [CrossRef]

- Németh, A.; Antal, Á.; Török, Á. Physical Alteration and Color Change of Granite Subjected to High Temperature. Appl. Sci. 2021, 11, 8792. [Google Scholar] [CrossRef]

- Guo, P.; Zhang, N.; He, M.; Bai, B. Effect of water saturation and temperature in the range of 193 to 373K on the thermal conductivity of sandstone. Tectonophysics 2017, 699, 121–128. [Google Scholar] [CrossRef]

| Temp, °C | Feldspar Content, % | Quartz Content, % | Biotite Content, % | Other Minerals, % | Elastic Modulus, GPa | Porosity, % | Density g/cm3 | UCS, MPa | Tensile Strength, MPa | P-Wave Velocity, km/s |

|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 50 | 40 | 5 | 5 | NA | 0.2 | 2.63 | NA | 9.03 | 4.71 |

| 100 | 75 | 20 | 5 | 0 | 12.96 | NA | 2.64 | 134.1 | 7.62 | 4.04 |

| 200 | 72.21 | 11.89 | 15.9 | 0 | 22.25 | NA | NA | 149 | NA | 3.57 |

| 300 | 59.85 | 11.12 | 21.56 | 7.47 | 11.12 | 0.68 | 2.63 | 102.04 | 59.85 | 3.52 |

| 400 | 83.51 | 9.04 | 0 | 7.45 | 7.36 | NA | NA | 72.51 | 4.85 | 3.03 |

| 500 | 60.59 | 34.09 | 5.32 | 0 | 20.5 | 1.43 | NA | 187 | NA | 3.09 |

| 600 | 63.59 | 27.72 | 4.94 | 3.75 | 5.69 | NA | 2.61 | 54.88 | 1.51 | NA |

| 700 | 29 | 50 | 15 | 6 | 1.82 | NA | NA | 22.43 | 8.69 | NA |

| 800 | 48.34 | 41.78 | 4.29 | 5.39 | 6.96 | NA | 2.49 | 38.07 | NA | 0.49 |

| Temperature (°C) | The Neighboring Minerals | |||

|---|---|---|---|---|

| Quartz and Quartz | Quartz and Biotite | Quartz and Feldspar | Biotite and Feldspar | |

| 25 | No intergranular cracks in the mineral boundaries | |||

| 200 | Crack initiation | No crack initiation | Crack initiation | No crack initiation |

| 400 | The intergranular cracks occur between two quartz minerals | No intergranular cracks in the mineral boundaries | The intergranular cracks occur between quartz and feldspar minerals | The intergranular cracks occur between biotite and feldspar minerals |

| 600 | Widening of the intergranular cracks in quartz minerals | The intergranular cracks occur between quartz and biotite minerals | Widening of the intergranular cracks between quartz and feldspar minerals | Widening of the intergranular cracks between biotite and feldspar minerals |

| 800 | Intergranular cracks fully developed with large apertures. | |||

| Temperature (°C) | Mineral | ||

|---|---|---|---|

| Quartz | Feldspar | Biotite | |

| 200 | No intragranular cracks | ||

| 400 | Intragranular cracks are initiated in large quartz minerals (crystals > 0.5 mm) | Intragranular cracks are initiated in feldspar minerals | Almost intact |

| 600 | Widening of the intragranular cracks in quartz minerals | Widening of intragranular cracks in feldspar grains | Initiation of intragranular cracks in large weak biotite minerals (parallel to the grain boundaries and grain boundary cracks) |

| 800 | Macroscopic intragranular cracks with large apertures | ||

| Model | R2 | RMSE |

|---|---|---|

| Regression Tree (Fine Tree) | 0.94 | 0.0837 |

| Regression Tree (Coarse Tree) | 0.69 | 0.1902 |

| ANN | 0.89 | 0.1110 |

| Gaussian Process Regression | 0.97 | 0.0633 |

| SVM | 0.95 | 0.0790 |

| SVM (Medium Gaussian) | 0.91 | 0.1445 |

| Ensemble Boosted Trees | 0.95 | 0.0741 |

| Ensemble Bagged Trees | 0.95 | 0.0767 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sansyzbekov, G.; Adoko, A.C.; George, P.M. Thermal Damage Characterization and Modeling in Granite Samples Subjected to Heat Treatment by Leveraging Machine Learning and Experimental Data. Appl. Sci. 2025, 15, 6328. https://doi.org/10.3390/app15116328

Sansyzbekov G, Adoko AC, George PM. Thermal Damage Characterization and Modeling in Granite Samples Subjected to Heat Treatment by Leveraging Machine Learning and Experimental Data. Applied Sciences. 2025; 15(11):6328. https://doi.org/10.3390/app15116328

Chicago/Turabian StyleSansyzbekov, Gabit, Amoussou Coffi Adoko, and Paul Mathews George. 2025. "Thermal Damage Characterization and Modeling in Granite Samples Subjected to Heat Treatment by Leveraging Machine Learning and Experimental Data" Applied Sciences 15, no. 11: 6328. https://doi.org/10.3390/app15116328

APA StyleSansyzbekov, G., Adoko, A. C., & George, P. M. (2025). Thermal Damage Characterization and Modeling in Granite Samples Subjected to Heat Treatment by Leveraging Machine Learning and Experimental Data. Applied Sciences, 15(11), 6328. https://doi.org/10.3390/app15116328