Assessing Resilience Practices in the Digital Transformation Era: A Storytelling-Based Cross-Sectional Study in Italy

Abstract

1. Introduction

2. Background and Motivation

- -

- Work-As-Imagined (WAI): What people think others are doing, or expect to do.

- -

- Work-As-Prescribed (WAP): The formal instructions or rules about how work should be conducted (e.g., laws, procedures, checklists, job descriptions).

- -

- Work-As-Disclosed (WADi): How people describe or report their work in documents or conversations.

- -

- Work-As-Done (WAD): The actual work that takes place in practice, i.e., the real actions that people perform. It includes the influences of variability, fluctuating goals, changing demands, and unexpected conditions.

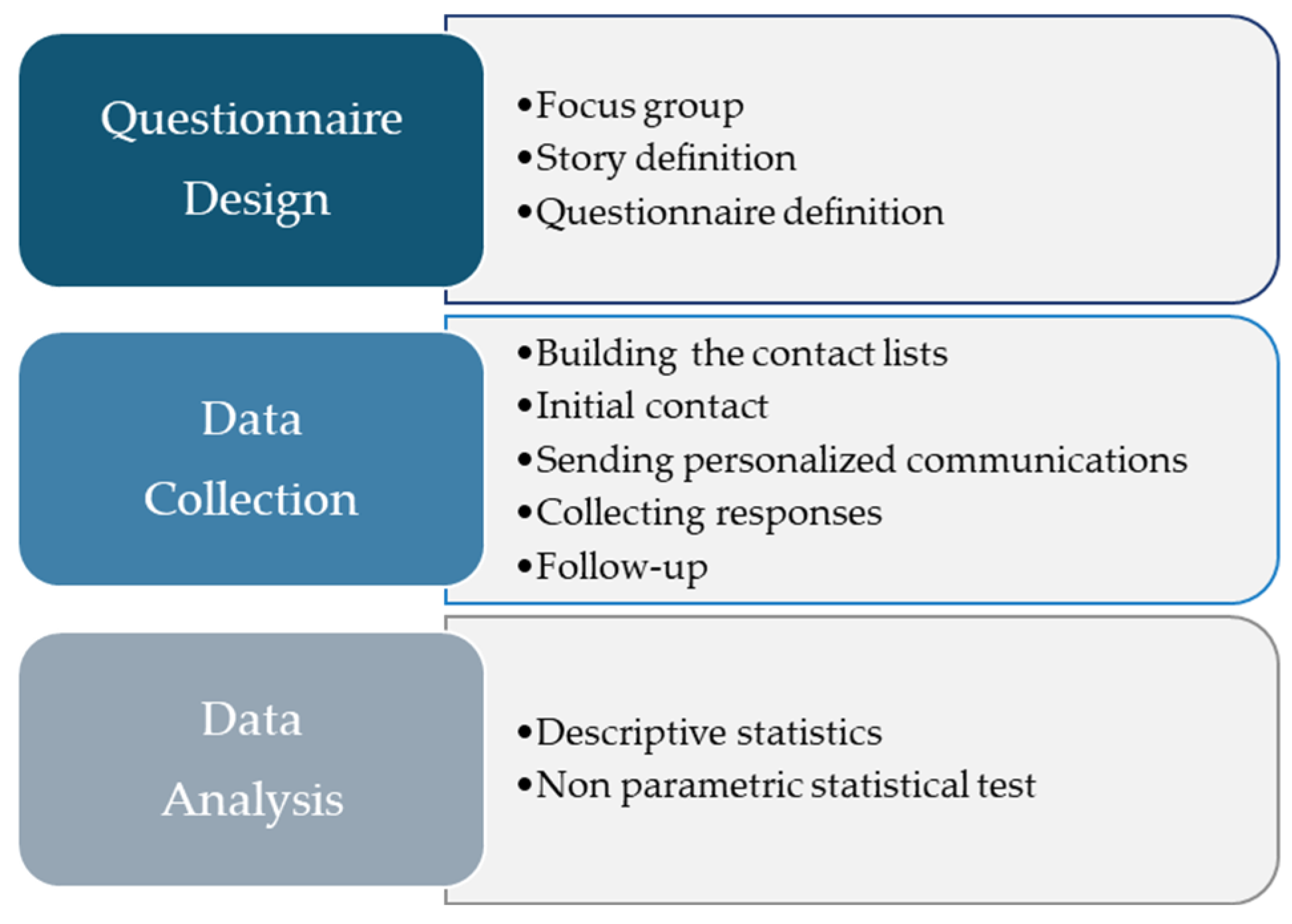

3. Materials and Methods

3.1. Questionnaire Design

3.1.1. Focus Group

3.1.2. Story Definition

- The first story represents an incident in a model company (“Compeso” company), resulting in a work-related injury caused by a violent event;

- The second story represents a near-miss in the same exemplary company, i.e., a work-related event that could have caused injury or harm to the worker’s OSH but, by sheer chance, did not.

- External, i.e., to assess the importance of specific systems or actions that could have prevented the incident or near-miss with respect to the company in question (to explore the perceived importance);

- Internal, i.e., to relate the issues from the two stories to their own organizational context, examining the actual implementation of specific systems or actions (to assess the actual level of implementation).

3.1.3. Questionnaire Definition

- Sub-section 1: external perspective, accident event;

- Sub-section 2: internal perspective, accident event;

- Sub-section 3: external perspective, near-miss event;

- Sub-section 4: internal perspective, near-miss event.

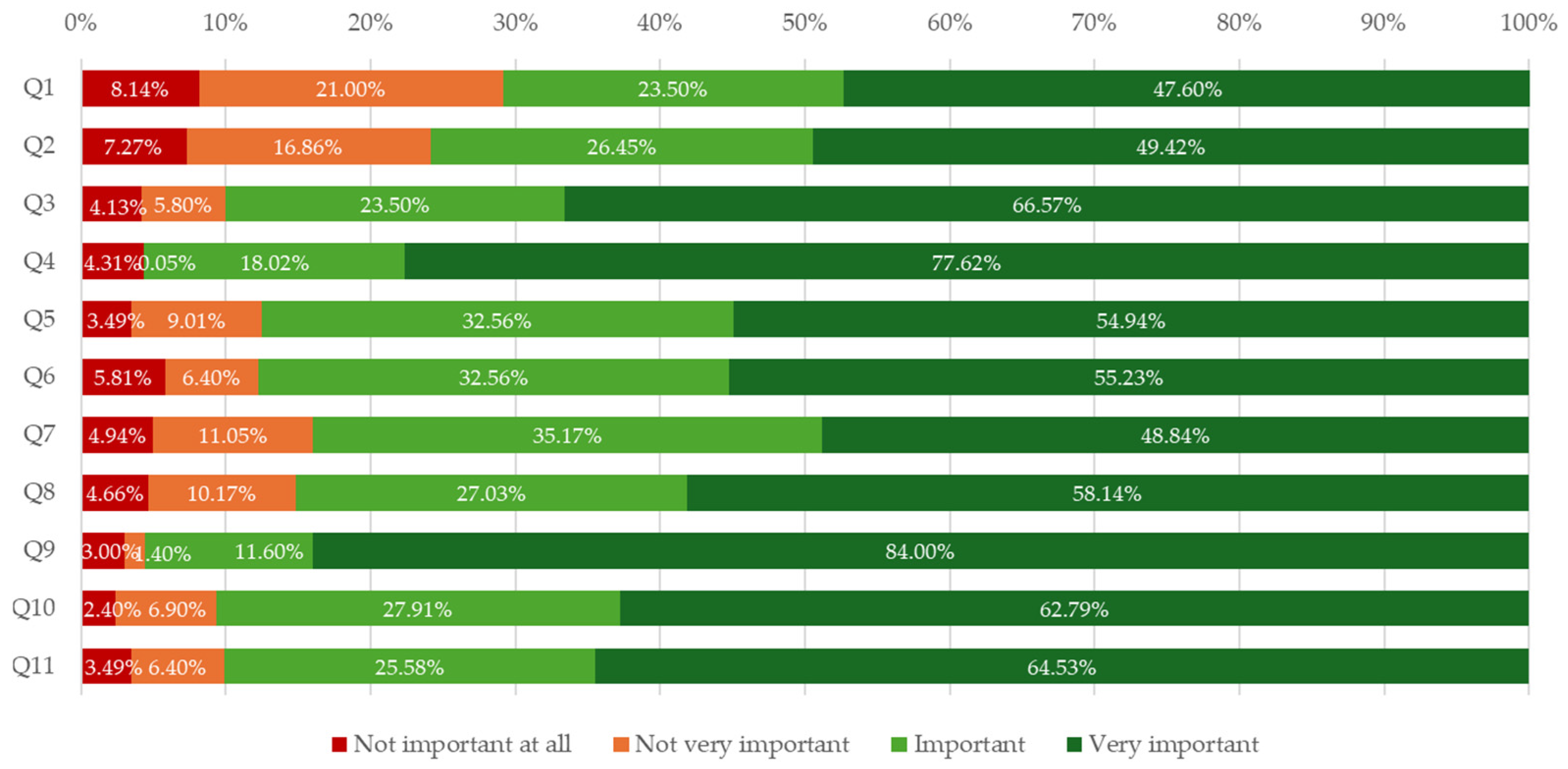

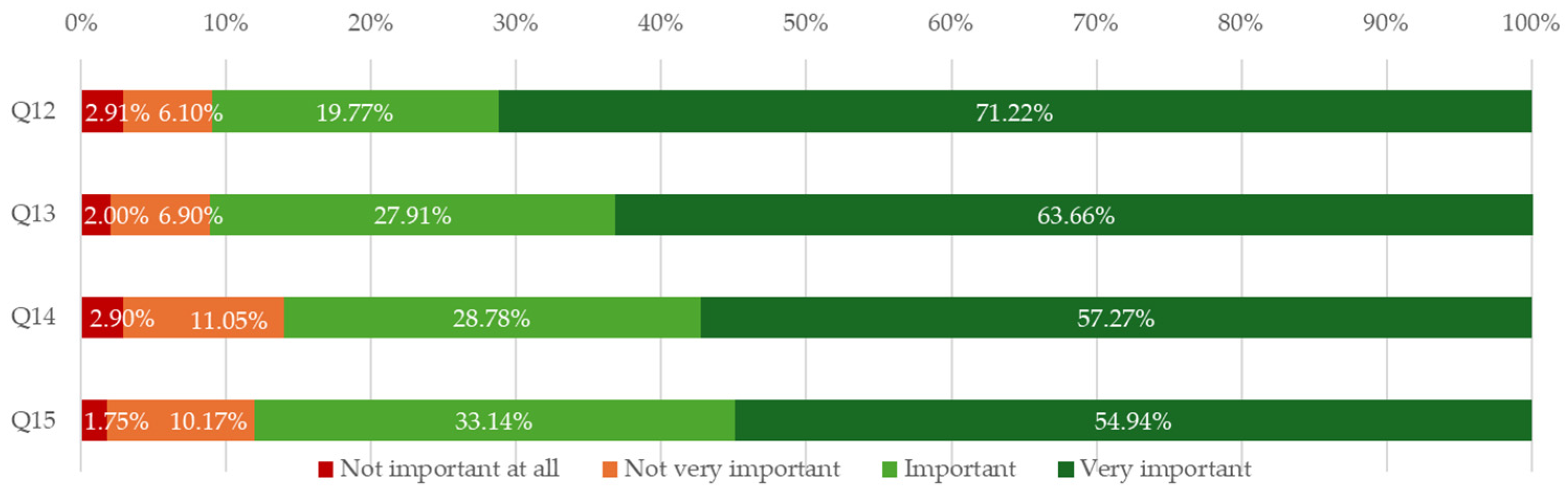

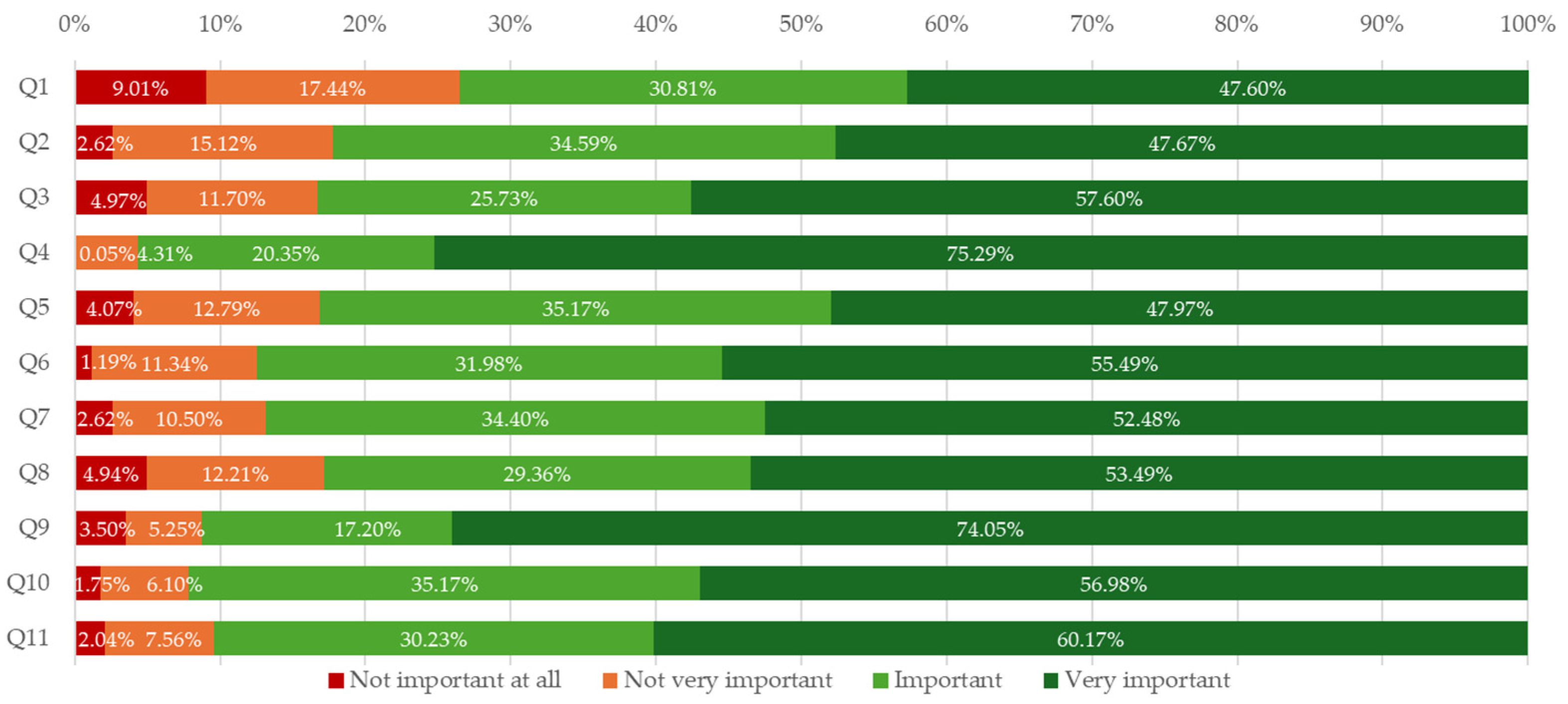

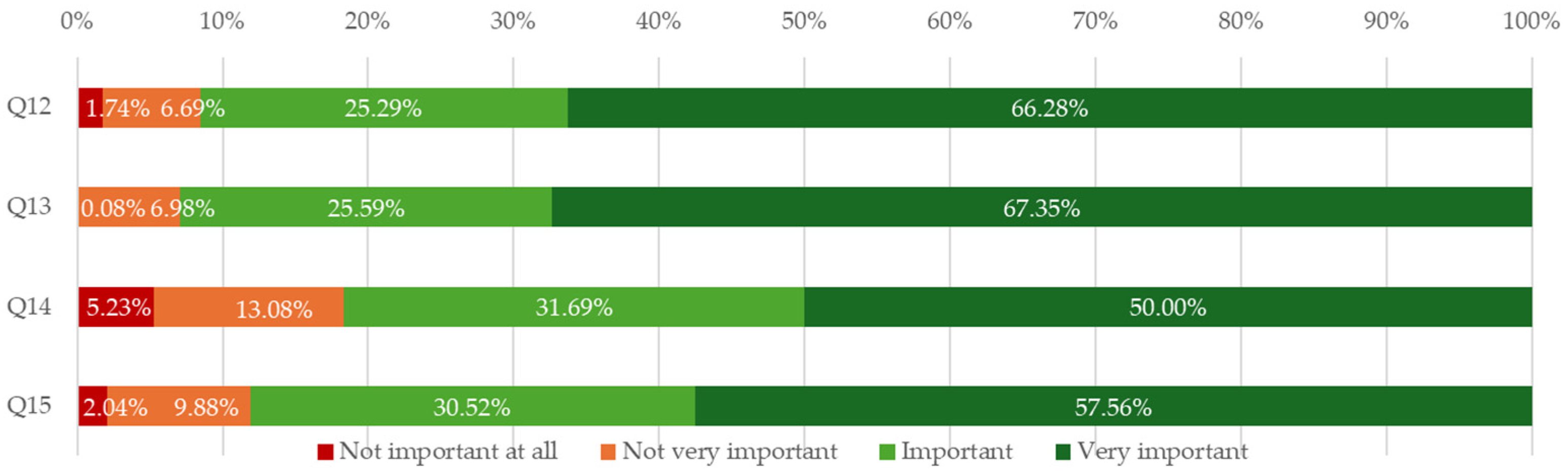

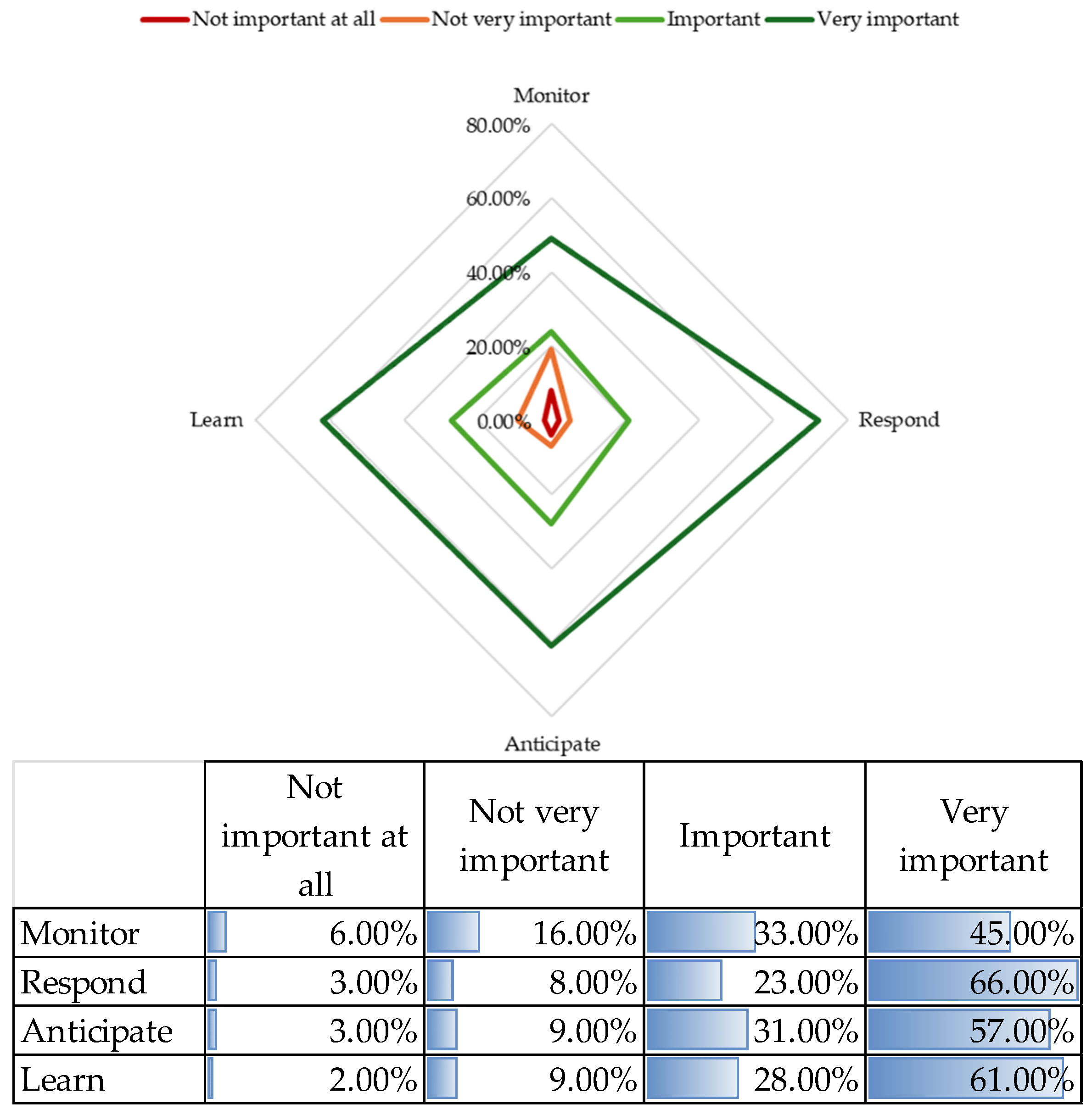

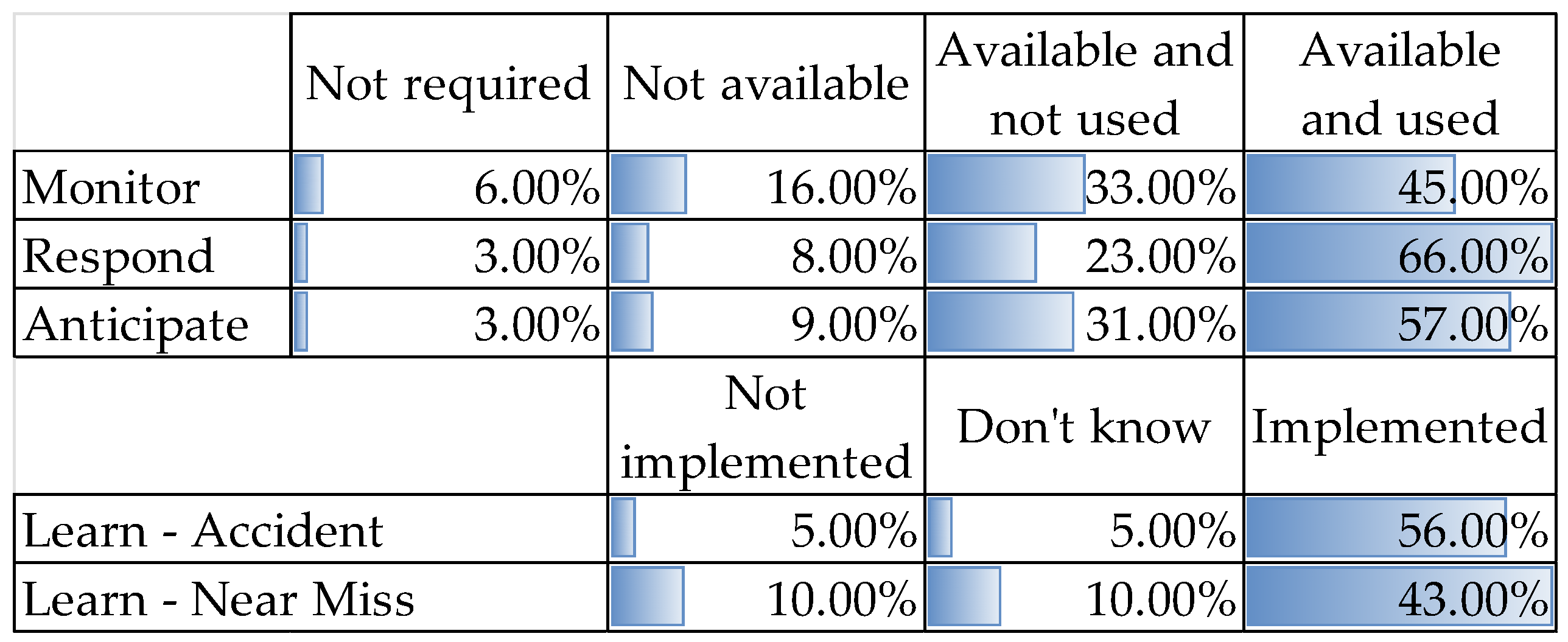

- Monitor: a system to notify when Personal Protective Equipment (PPE) is not being worn (Q1); a system for monitoring and recording real-time environmental conditions (e.g., temperature, humidity) (Q2).

- Respond: a system to prevent entry in industrial/operational areas without PPE (Q3); a system to shut down technology when anomalies are detected (Q4).

- Anticipate: awareness programs on the importance of PPE (Q5); updates to risk assessments related to new technologies (Q6); training on how to handle unforeseen situations (Q7); training on the proper use of PPE (Q8); ensuring PPE is provided for every worker (Q9); risk assessments for changes in the environment where technology is used (e.g., maintenance work, introduction of external personnel) (Q10); communication to staff about significant changes to the environment (e.g., maintenance work, introduction of external personnel) (Q11).

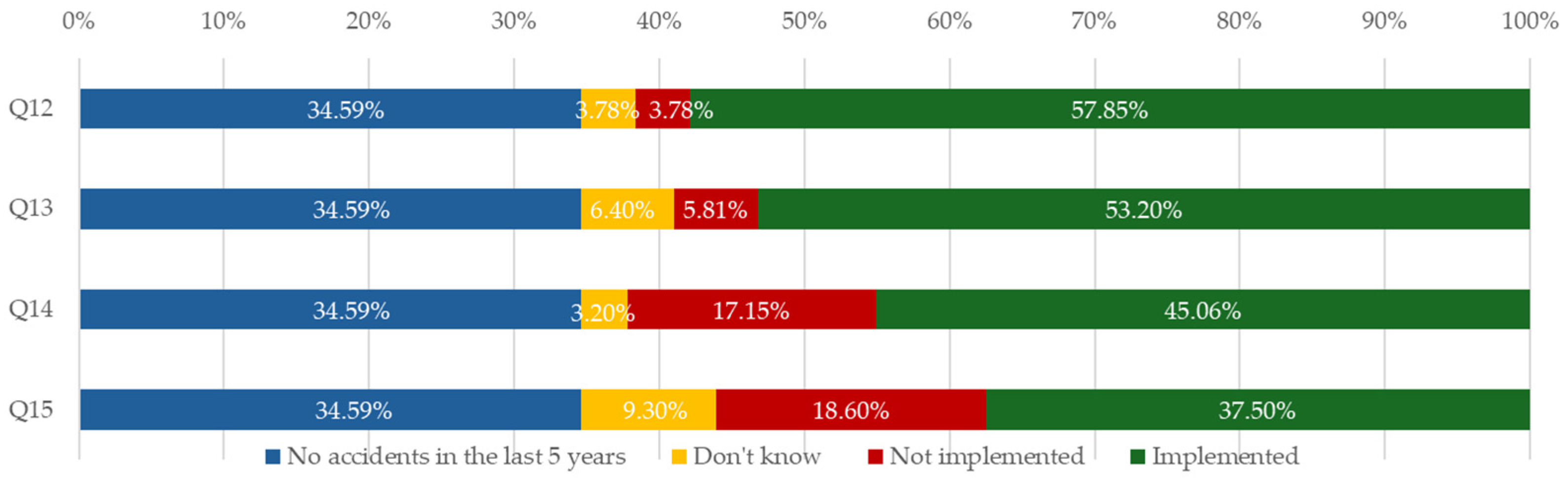

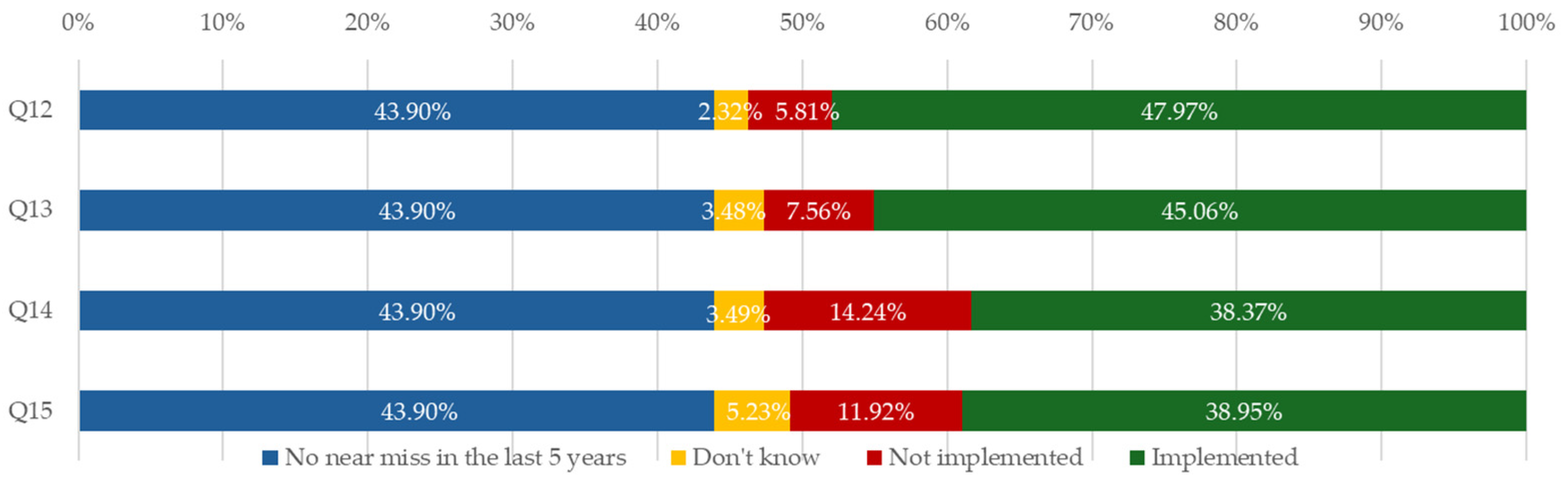

- Learn: investigations into the causes of accidents (Q12); improving knowledge of the technology involved in incidents (Q13); revising procedures for PPE usage (Q14); updating internal communication processes related to changes in environmental conditions (Q15).

3.2. Data Collection

3.2.1. Building the Contact Lists and Directories

3.2.2. Initial Contact with Companies

3.2.3. Sending Personalized Communications

3.2.4. Collecting Responses

3.2.5. Follow-Up with Companies

3.3. Data Analysis Techniques

4. Results

4.1. Perceived Importance of Good Practice in Resilience Engineering Principles

4.1.1. Accident

4.1.2. Near Miss

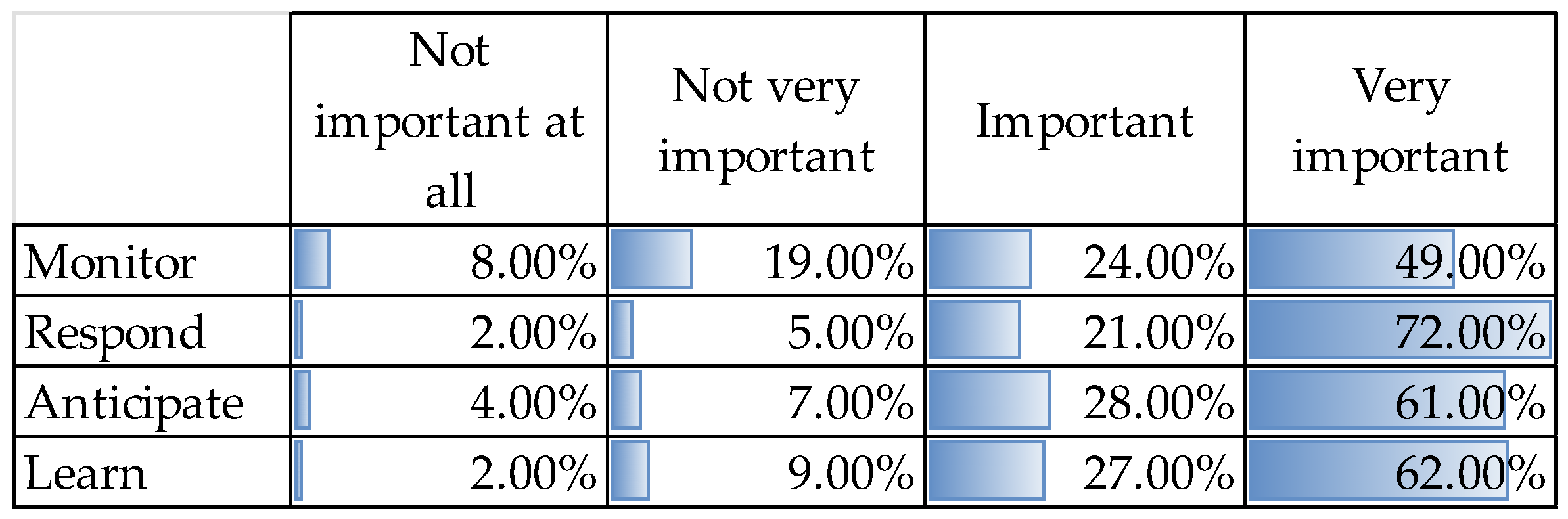

4.2. Implementation in Italian Companies of Good Practice in Resilience Engineering Principles

4.3. Differences by Company Size

4.4. Impact of New Technologies

5. Discussion

5.1. Consideration About Storytelling as a Methodology

5.2. Implications for Occupational Safey and Health

5.3. Study Limitations

6. Conclusions and Future Directions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Questionnaire

| Section 1: Master data |

| Gender Age Company location Number of employees in the company Division of ATECO Section C—Manufacturing Activities where your company operates Role played in OSH Seniority in this role |

| Section 2.1: External perspective—accident |

| Story 1: On September 11, 2023, Compeso scheduled maintenance for the air conditioning system across all its warehouses. However, the operators continued working as usual, not noticing any changes in temperature. One of Compeso’s logistics operators was walking down a corridor in the raw materials warehouse when, suddenly, SHARK collided with him from behind, striking his right foot at high speed. SHARK is a compact, advanced autonomous vehicle that can move in all directions and navigate tight spaces. For optimal performance, SHARK requires specific temperature and humidity levels in its environment. The collision was forceful, and the operator was taken to the hospital, where he was diagnosed with a foot fracture. That day, the operator was not wearing safety shoes because his size was unavailable in the locker room. |

| How important would the presence of the systems and the implementation of the following actions have been to avoid the accident in the Compeso company? |

| Q1. System to notify entry without PPEs Q2. System to monitor and record real-time operating environmental conditions (e.g., temperature, humidity) |

| Q3. System to prevent entry without PPEs |

| Q4. System to stop the technology when anomalies are detected |

| Q5. Organize information and awareness-raising activities on the importance of PPEs |

| Q6. Update risk assessment for new technologies in place |

| Q7. Train on how to handle unforeseen situations |

| Q8. Train in the proper use of PPEs |

| Q9. Make PPE available for each worker |

| Q10. Assess risks resulting from extraordinary changes to the technological environment (e.g., maintenance work, introduction of outside personnel) |

| Q11. Notify staff about extraordinary changes to the environment where technology is present (e.g., maintenance intervention, introduction of outside personnel) |

| To prevent the recurrence of this type of accident, how important would it be for Compeso company to implement the following actions? |

| Q12. Activate an investigation into the causes of the event |

| Q13. Increase the level of knowledge regarding technological equipment associated with the event |

| Q.14 Revise the procedure regarding the use of PPEs |

| Q.15 Review internal communication processes/systems regarding changes in environmental conditions |

| Section 2.2: External perspective—near-miss scenario |

| Story 2: On September 11, 2023, Compeso scheduled maintenance for the air conditioning system across all its warehouses. However, the operators continued working as usual, not noticing any changes in temperature. That morning, the maintenance supervisor had informed Francesco, a warehouse logistics operator, that SHARK was exhibiting unusual behavior compared to previous days. SHARK is a compact, advanced autonomous vehicle designed to move in all directions and navigate tight spaces. For optimal performance, SHARK requires specific temperature and humidity levels in its environment. Later that afternoon, while walking through a corridor in the raw materials warehouse, Francesco noticed that SHARK, traveling at high speed, had lost control. He was able to avoid a collision and prevent an injury. That day, Francesco was not wearing safety shoes because his size was unavailable in the locker room. |

| How important would the presence of the systems and the implementation of the following actions have been to avoid the near miss in the Compeso company? |

| (Q.1–Q.11) |

| To prevent the recurrence of this type of near miss, how important would it be for Compeso company to implement the following actions? |

| (Q.12–Q.15) |

| Section 2.3: Internal perspective |

| Are the following OSH systems and measures in place in your company? (Q.1–Q.11) |

| Following an accident, has your company implemented the following actions? (Q.12–Q.15) Following an near mis, has your company implemented the following actions? (Q.12–Q.15) |

| RAG Dimension | Question | Motivation | |

|---|---|---|---|

| ID | Focus | ||

| Monitor | 1 | System to notify entry without PPE | To detect unsafe behaviors in real time by monitoring unauthorized access |

| 2 | System to monitor and record real-time operating environmental conditions (e.g., temperature, humidity) | To observe and track critical environmental variables for early detection of deviations | |

| Respond | 3 | System to prevent entry without PPE | To react promptly to safety threats by preventing unsafe access |

| 4 | System to stop the technology when anomalies are detected | To respond effectively to abnormal conditions and mitigate associated risks | |

| Anticipate | 5 | Organize information and awareness-raising activities on the importance of PPE | To increase awareness and prepare personnel for potential future risks |

| 6 | Update risk assessment for new technologies in place | To foresee and address risks associated with the implementation of new technologies | |

| 7 | Train on how to handle unforeseen situations | To prepare personnel to act effectively in uncertain or unexpected scenarios | |

| 8 | Train on the proper use of PPE | To ensure correct usage of PPE and prevent future safety issues | |

| 9 | Make PPE available for each worker | To anticipate needs and guarantee the availability of protective equipment | |

| 10 | Assess risks resulting from extraordinary changes to the technological environment (e.g., maintenance work, introduction of outside personnel) | To identify and mitigate potential hazards resulting from atypical operational conditions | |

| 11 | Notify staff about extraordinary changes to the environment where technology is present (e.g., maintenance intervention, introduction of outside personnel) | To inform proactively about changes that may affect safety, enabling anticipatory adjustments | |

| Learn | 12 | Initiate an investigation into the causes of the event | To analyze incidents and promote organizational learning |

| 13 | Increase the level of knowledge regarding technological equipment associated with the event | To enhance understanding of technical aspects and derive lessons from events | |

| 14 | Revise the procedure regarding the use of PPEs | To adapt existing protocols based on past experience and improve future performance | |

| 15 | Revise internal communication processes/systems regarding changes in environmental conditions | To improve information flow and incorporate feedback for better adaptation | |

| ATECO Code | Description | % of Companies |

|---|---|---|

| 10 | Manufacture of food products | 9.30% |

| 11 | Manufacture of beverages | 0.29% |

| 13 | Manufacture of textile items | 2.91% |

| 14 | Manufacture of workwear | 1.74% |

| 16 | Manufacture of wooden containers | 8.72% |

| 17 | Manufacture of paper and paper products | 4.07% |

| 18 | Printing and reproduction of recorded media | 0.87% |

| 19 | Manufacture of coke and refined petroleum products | 1 0.29% |

| 20 | Manufacture of chemicals and chemical products | 5.81% |

| 22 | Manufacture of rubber and plastics products | 6.98% |

| 23 | Manufacture of other non-metallic mineral products | 1.74% |

| 24 | Metallurgy | 2.33% |

| 25 | Manufacture of metal products (excluding machinery and equipment) | 12.21% |

| 26 | Manufacture of computers, electronics, optics, electromedical equipment, measuring equipment | 6.69% |

| 27 | Manufacture of electrical and non-electrical household equipment | 5.81% |

| 28 | Manufacture of machinery and equipment | 6.40% |

| 30 | Manufacture of other vehicles | 1.16% |

| 31 | Manufacture of furniture | 4.94% |

| 32 | Other manufacturing industry | 10.76% |

| 33 | Repair, maintenance, and installation of machinery | 0.87% |

| - | Other (to be specified) | 6.10% |

| Company Size | of Companies (%) |

|---|---|

| employees < 50 | 59.59% |

| 50 ≤ employees ≤ 149 | 26.45% |

| 150 ≤ employees ≤ 249 | 5.23% |

| employees ≥ 250 | 8.72% |

References

- Hollnagel, E.; Wears, R.L.; Braithwaite, J. From Safety-I to Safety-II: A White Paper; University of Southern Denmark: Odense, Denmark; University of Florida: Gainesville, FL, USA; Macquarie University: Sydney, Australia, 2015; p. 43. [Google Scholar] [CrossRef]

- Hollnagel, E. Safety-I and Safety-II: The Past and Future of Safety Management. Cogn. Technol. Work. 2015, 17, 461–464. [Google Scholar] [CrossRef]

- Hollnagel, E. Safety-II in Practice: Developing the Resilience Potentials; Routledge: England, UK, 2017; ISBN 978-1-351-78076-6. [Google Scholar]

- Dekker, S. Foundations of Safety Science: A Century of Understanding Accidents and Disasters; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-1-351-05978-7. [Google Scholar]

- Pillay, M. Resilience Engineering: An Integrative Review of Fundamental Concepts and Directions for Future Research in Safety Management. OJSST 2017, 7, 129–160. [Google Scholar] [CrossRef]

- Dekker, S.; Hollnagel, E.; Woods, D.; Cook, R. Resilience Engineering: New Directions for Measuring and Maintaining Safety in Complex Systems. Lund Univ. Sch. Aviat. 2008, 1, 1–6. [Google Scholar]

- Ranasinghe, U.; Jefferies, M.; Davis, P.; Pillay, M. Resilience Engineering Indicators and Safety Management: A Systematic Review. Saf. Health Work. 2020, 11, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Pellissier, R. The Implementation of Resilience Engineering to Enhance Organizational Innovation in a Complex Environment. IJBM 2010, 6, 145. [Google Scholar] [CrossRef]

- Hollnagel, E. RAG–Resilience Analysis Grid. Resilience Engineering in Practice: A Guidebook; Routledge: England, UK, 2011; pp. 275–295. [Google Scholar]

- Woods, D. Four Concepts for Resilience and the Implications for the Future of Resilience Engineering. Reliab. Eng. Syst. Saf. 2015, 141, 5–9. [Google Scholar] [CrossRef]

- Hollnagel, E.; Woods, D.D.; Leveson, N. Resilience Engineering: Concepts and Precepts. BMJ Qual. Saf. 2006, 15, 447–448. [Google Scholar] [CrossRef]

- Rooney, T.; Lawlor, K.; Rohan, E. Telling Tales: Storytelling as a Methodological Approach in Research; Academic Conferences International Limited: Berkshire, UK, 2016; Volume 14. [Google Scholar]

- Gray, J. The Power of Storytelling: Using Narrative in the Healthcare Context. J. Commun. Healthc. 2009, 2, 258–273. [Google Scholar] [CrossRef]

- Kampmann, A.; Pedell, B. Using Storytelling to Promote Organizational Resilience: An Experimental Study of Different Forms of Risk Communication. Schmalenbach J. Bus. Res. 2022, 74, 695–725. [Google Scholar] [CrossRef]

- Adriaensen, A.; Patriarca, R.; Smoker, A.; Bergström, J. A Socio-Technical Analysis of Functional Properties in a Joint Cognitive System: A Case Study in an Aircraft Cockpit. Ergonomics 2019, 62, 1661527. [Google Scholar] [CrossRef]

- Bentivenga, R.; Bernabei, M.; Carli, M.; Colabianchi, S.; Costantino, F.; Ferrarotti, A.; Neri, M.; Pietrafesa, E.; Sorrentino, E.; Stabile, S. Advancing Occupational Safety and Health Training: A Safety-II Integration of the ADDIE Model for Virtual Reality. In Proceedings of the Methodologies and Intelligent Systems for Technology Enhanced Learning, 14th International Conference, Salamanca, Spain, 26–28 June 2024; Springer: Charm, Switzerlands, 2024; Volume 1171. [Google Scholar]

- Cutchen, S.S. Safety-II—Resilience in the Face of Abnormal Operation. Process Saf. Prog. 2020, 40, e12212. [Google Scholar] [CrossRef]

- Sujan, M.A.; Huang, H.; Braithwaite, J. Learning from Incidents in Health Care: Critique from a Safety-II Perspective. Saf. Sci. 2017, 99, 115–121. [Google Scholar] [CrossRef]

- Patriarca, R.; Falegnami, A.; Costantino, F.; Di Gravio, G.; De Nicola, A.; Villani, M.L. WAx: An Integrated Conceptual Framework for the Analysis of Cyber-Socio-Technical Systems. Saf. Sci. 2021, 136, 105142. [Google Scholar] [CrossRef]

- Shorrock, S. The Varieties and Archetypes of Human Work. 2019. Available online: https://humanisticsystems.com/2016/12/05/the-varieties-of-human-work/ (accessed on 15 September 2024).

- Walker, G. Come Back Sociotechnical Systems Theory, All Is Forgiven …. Civ. Eng. Environ. Syst. 2015, 32, 170–179. [Google Scholar] [CrossRef]

- Woods, D.; Hollnagel, E. Joint Cognitive Systems: Patterns in Cognitive Systems Engineering; CRC Press-Taylor & Francis Group: Boca Raton, FL, USA, 2006; ISBN 978-1-4200-0568-4. [Google Scholar]

- Hollnagel, E. How Resilient Is Your Organisation? An Introduction to the Resilience Analysis Grid (RAG). 2010. Available online: https://minesparis-psl.hal.science/hal-00613986v1 (accessed on 15 September 2024).

- Hollnagel, E.; Leonhardt, J.; Licu, T. The Systemic Potentials Management: Building a Basis for Resilient Performance; EUROCONTROL: Brussels, Belgium, 2021; pp. 1–30. Available online: https://skybrary.aero/sites/default/files/bookshelf/32380.pdf (accessed on 15 September 2024).

- Safi, M.; Thude, B.R.; Brandt, F.; Austin, E.; Williams, R.-C. The Application of the Resilience Assessment Grid in Outpatient Clinics: A Validation Study. Saf. Sci. 2024, 171, 106396. [Google Scholar] [CrossRef]

- Klockner, K.; Meredith, P. Measuring Resilience Potentials: A Pilot Program Using the Resilience Assessment Grid. Safety 2020, 6, 51. [Google Scholar] [CrossRef]

- Ljungberg, D.; Lundh, V. Resilience Engineering within ATM-Development, Adaption, and Application of the Resilience Analysis Grid (RAG). Final. Rep. 2015, 2015, 74. [Google Scholar]

- Adriaensen, A.; Bernabei, M.; Costantino, F.; Falegnami, A.; Stabile, S.; Patriarca, R. Resilience Potentials for Health and Safety Management in Cobot Applications Using the Resilience Analysis Grid. J. Manuf. Sci. Eng. 2023, 145, 1–17. [Google Scholar] [CrossRef]

- Pęciłło, M. Identification of Gaps in Safety Management Systems from the Resilience Engineering Perspective in Upper and Lower-Tier Enterprises. Saf. Sci. 2020, 130, 104851. [Google Scholar] [CrossRef]

- Bauer, D.; Bohm, M.; Bauernhansl, T. Increased Resilience for Manufacturing Systems in Supply Networks through Data-Based Turbulence Mitigation. Prod. Eng. 2021, 15, 385–395. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Anagiannis, I.; Nikolakis, N.; Chryssolouris, G. A Quantitative Approach to Resilience in Manufacturing Systems. Int. J. Prod. Res. 2022, 60, 7178–7193. [Google Scholar] [CrossRef]

- Lebepe, P.; Mathaba, T.N.D. Enhancing Energy Resilience in Manufacturing Enterprises: A Systematic Mapping of Challenges to Strategies. J. Econ. Technol. 2025, 3, 82–94. [Google Scholar] [CrossRef]

- Ngongo, P.K.; Almaktoof, A.M.A.; Kahn, M.T.E. Practical Approach to Enhance Energy Resilience in Manufacturing Facilities. Energy Sci. Eng. 2025, 13, 673–686. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J.; Larsson, L.; Rönnbäck, A.Ö. Building Manufacturing Resilience through Production Innovation. In Proceedings of the 2021 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 21–23 June 2021; pp. 1–9. [Google Scholar]

- Sekeľová, F.; Lališ, A. Application of Resilience Assessment Grid in Production of Aircraft Components. MAD 2020, 7, 6–11. [Google Scholar] [CrossRef]

- Falegnami, A.; Tomassi, A.; Corbelli, G.; Romano, E. Resilience Analysis Grid–Rasch Rating Scale Model for Measuring Organizational Resilience Potential. Appl. Sci. 2025, 15, 1695. [Google Scholar] [CrossRef]

- Isingizwe, J.; Eiris, R.; Jalil Al-Bayati, A. Enhancing Safety Training Engagement through Immersive Storytelling: A Case Study in the Residential Construction. Saf. Sci. 2024, 179, 106631. [Google Scholar] [CrossRef]

- Yazdi, M. Safety Through Stories: Leveraging Literature’s Lessons for Practical Safety Insights. Stud. Syst. Decis. Control 2025, 232, 51–72. [Google Scholar] [CrossRef]

- Bliss, M.M.; Dalto, J. Storytelling In Safety Training. Prof. Saf. 2018, 63, 34–35. [Google Scholar]

- Eiris, R.; Jain, A.; Gheisari, M.; Wehle, A. Safety Immersive Storytelling Using Narrated 360-Degree Panoramas: A Fall Hazard Training within the Electrical Trade Context. Saf. Sci. 2020, 127, 104703. [Google Scholar] [CrossRef]

- Gruen, D.; Rauch, T.; Redpath, S.; Ruettinger, S. The Use of Stories in User Experience Design. Int. J. Hum.-Comput. Interact. 2002, 14, 503–534. [Google Scholar] [CrossRef]

- Quesenbery, W.; Brooks, K. Storytelling for User Experience: Crafting Stories for Better Design; Rosenfeld Media: Brooklyn, NY, USA, 2010. [Google Scholar]

- Benjamin, B. The Case Study: Storytelling in the Industrial Age and Beyond. Horizon 2006, 14, 159–164. [Google Scholar] [CrossRef]

- Asbury, J.-E. Overview of Focus Group Research. Qual. Helth Res. 1995, 5, 414–420. [Google Scholar] [CrossRef]

- McKnight, P.E.; Najab, J. Mann-Whitney U Test. In The Corsini Encyclopedia of Psychology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; p. 1. ISBN 978-0-470-47921-6. [Google Scholar]

- Tapp, L. Case Studies Related to Total Worker Health®. In The Wiley Guide to Strategies, Ideas, and Applications for Implementing a Total Worker Health® Program; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2024; pp. 395–412. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9781394302147.ch16 (accessed on 15 September 2024).

- Ploeckelman, M.; Heiberger, S.; Rautiainen, R.; Johnson, A.; Charlier, D.; Yoder, A.; Duysen, E. The Use of Injury and Fatality Narratives to Convey Agricultural Safety and Health Messages and to Develop Effective Resources Through Collaborative, Multi-Disciplinary Approaches (Tell a Story, Save a Life). J. Agromedicine 2024, 29, 645–652. [Google Scholar] [CrossRef] [PubMed]

- Edwards, T.; Mkwanazi, N.; Mitchell, J.; Bland, R.M.; Rochat, T.J. Empowering Parents for Human Immunodeficiency Virus Prevention: Health and Sex Education at Home. S. Afr. J. HIV Med. 2020, 21, a970. [Google Scholar] [CrossRef]

- Fubini, L.; Pasqualini, O.; Ferro, E.; Marino, M.; Santoro, S.; Tosco, E.; Gilardi, L. Injury Narratives in Occupational Safety and Health Prevention in Italy. Occup. Med. 2019, 69, 500–503. [Google Scholar] [CrossRef]

- Yonge, O.; Jackman, D.; Luhanga, F.; Myrick, F.; Oosterbroek, T.; Foley, V. “We Have to Drive Everywhere”: Rural Nurses and Their Precepted Students. Rural. Remote Health 2019, 19, 5347. [Google Scholar] [CrossRef]

- Ricketts, M.; Shanteau, J.; McSpadden, B.; Fernandez-Medina, K.M. Using Stories to Battle Unintentional Injuries: Narratives in Safety and Health Communication. Soc. Sci. Med. 2010, 70, 1441–1449. [Google Scholar] [CrossRef]

- Rajala, H.-K.; Väyrynen, S. Constructing “Core Stories” for Contributing Practical Safety Actions in Industrial Units. Saf. Sci. 2010, 48, 1393–1401. [Google Scholar] [CrossRef]

- Krieger, S.H.; Krieger, J.D. Storytelling and Relevancy. Or. L. Rev. 2020, 99, 163. [Google Scholar]

- Betsch, C.; Haase, N.; Renkewitz, F.; Schmid, P. The Narrative Bias Revisited: What Drives the Biasing Influence of Narrative Information on Risk Perceptions? Judgm. Decis. Mak. 2015, 10, 241–264. [Google Scholar] [CrossRef]

- Mannay, D.; Pauwels, L. The SAGE Handbook of Visual Research Methods; Sage: Thousand Oaks, CA, USA, 2019; pp. 1–776. [Google Scholar]

- Boyce, M.E. Organizational Story and Storytelling: A Critical Review. In The Aesthetic Turn in Management; Routledge: England, UK, 2007; ISBN 978-1-351-14796-5. [Google Scholar]

- Yazdi, M. Confidence Versus Competence: The Role of the Dunning-Kruger Effect in Workplace Safety. In Safety-Centric Operations Research: Innovations and Integrative Approaches: A Multidisciplinary Approach to Managing Risk in Complex Systems; Yazdi, M., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 73–89. ISBN 978-3-031-82934-5. [Google Scholar]

- A Review of the Literature on Preventive Occupational Health and Safety Activities in Small Enterprises-PubMed. Available online: https://pubmed.ncbi.nlm.nih.gov/16610525/ (accessed on 20 February 2025).

- Eakin, J.M. Leaving It up to the Workers: Sociological Perspective on the Management of Health and Safety in Small Workplaces. Int. J. Health Serv. 1992, 22, 689–704. [Google Scholar] [CrossRef] [PubMed]

- Hasle, P.; Bager, B.; Granerud, L. Small Enterprises–Accountants as Occupational Health and Safety Intermediaries. Saf. Sci. 2010, 48, 404–409. [Google Scholar] [CrossRef]

- Huy, Q.N. Narratives of Enterprise: Crafting Entrepreneurial Self-Identity in a Small Firm. Adm. Sci. Q. 2008, 53, 374–376. [Google Scholar] [CrossRef]

- Zimber, A.; Horchler, J.; Weiser, I.; Gregersen, S.; Prüße, M.; Schumacher, K.; Pietrzyk, U.; Schmitt-Howe, B. Small Enterprises as a Neglected Target Group Regarding Occupational Safety and Health: A Qualitative Study on the Activities of Entrepreneurs and the Contributing Factors. Z. Fur Arb.-Und Organ. 2024, 68, 200–209. [Google Scholar] [CrossRef]

- Micheli, G.J.L.; Cagno, E.; Calabrese, A. The Transition from Occupational Safety and Health (OSH) Interventions to OSH Outcomes: An Empirical Analysis of Mechanisms and Contextual Factors within Small and Medium-Sized Enterprises. Int. J. Environ. Res. Public Health 2018, 15, 1621. [Google Scholar] [CrossRef]

- Bernabei, M.; Colabianchi, S.; Carli, M.; Costantino, F.; Ferrarotti, A.; Neri, M.; Stabile, S. Enhancing Occupational Safety and Health Training: A Guideline for Virtual Reality Integration. IEEE Access 2024, 12, 154349–154364. [Google Scholar] [CrossRef]

- Asadzadeh, A.; Arashpour, M.; Li, H.; Ngo, T.; Bab-Hadiashar, A.; Rashidi, A. Sensor-Based Safety Management. Autom. Constr. 2020, 113, 103128. [Google Scholar] [CrossRef]

- Simone, F.; Ansaldi, S.M.; Agnello, P.; Di Gravio, G.; Patriarca, R. Knowledge in Graphs: Investigating the Completeness of Industrial near Miss Reports. Saf. Sci. 2023, 168, 106305. [Google Scholar] [CrossRef]

- INAIL Prevenzione E Sicurezza | Incentivi Alle Imprese. Available online: https://www.inail.it (accessed on 13 May 2025).

| Background | Area of Expertise | Focus on the Research | Years of Experience |

|---|---|---|---|

| Public research | Training and education | Occupational safety and health | 26 |

| Public research | Communication and digital technologies | Occupational safety and health | 17 |

| Public research | Legal | Occupational safety and health | 18 |

| Public research | Psychology | Occupational safety and health | 29 |

| Academic/Industrial | Operations management | Manufacturing systems | 21 |

| Academic | Smart factories | Manufacturing systems | 6 |

| Academic | Advanced industrial applications | Resilience Engineering | 4 |

| MONITOR | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 18.31% | 30.23% | 48.55% |

| Important | 8.72% | 16.28% | 25.00% |

| Not Very Important | 9.01% | 9.74% | 18.75% |

| Not Important At All | 4.36% | 3.34% | 7.70% |

| Total | 40.41% | 59.59% | 100.00% |

| RESPOND | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 29.36% | 42.73% | 72.09% |

| Important | 8.28% | 12.50% | 20.78% |

| Not Very Important | 1.74% | 3.05% | 4.80% |

| Not Important At All | 1.02% | 1.31% | 2.33% |

| Total | 40.41% | 59.59% | 100.00% |

| ANTICIPATE | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 23.89% | 36.77% | 60.66% |

| Important | 11.72% | 16.09% | 27.81% |

| Not Very Important | 3.15% | 4.41% | 7.56% |

| Not Important At All | 1.65% | 2.33% | 3.97% |

| Total | 40.41% | 59.59% | 100.00% |

| LEARN | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 25.41% | 36.92% | 62.33% |

| Important | 10.99% | 16.05% | 27.03% |

| Not Very Important | 3.08% | 5.00% | 8.08% |

| Not Important At All | 0.93% | 1.63% | 2.56% |

| Total | 40.41% | 59.59% | 100.00% |

| MONITOR | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 13.23% | 19.48% | 32.70% |

| Important | 3.78% | 2.03% | 5.81% |

| Not Very Important | 5.52% | 10.76% | 16.28% |

| Not Important At All | 17.88% | 27.33% | 45.20% |

| Total | 40.41% | 59.59% | 100.00% |

| RESPOND | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 7.32% | 15.63% | 22.95% |

| Important | 1.77% | 1.02% | 2.79% |

| Not Very Important | 2.50% | 5.20% | 7.7% |

| Not Important At All | 28.82% | 37.74% | 66.56% |

| Total | 40.41% | 59.59% | 100.00% |

| ANTICIPATE | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 11.76% | 18.74% | 30.51% |

| Important | 1.50% | 1.62% | 3.12% |

| Not Very Important | 3.20% | 6.23% | 9.43% |

| Not Important At All | 23.95% | 33.00% | 56.95% |

| Total | 40.41% | 59.59% | 100.00% |

| LEARN | |||

| Importance Level | Medium-Large Companies | Small Companies | Total |

| Very Important | 10.39% | 17.81% | 28.20% |

| Important | 1.31% | 1.09% | 2.40% |

| Not Very Important | 3.27% | 5.89% | 9.16% |

| Not Important At All | 25.44% | 34.81% | 60.25% |

| Total | 40.41% | 59.59% | 100.00% |

| Action/System | RAG Dimension | Accident/Near Miss | Average Rank | Significance | Greater Perceived Importance |

|---|---|---|---|---|---|

| System to notify entries without PPEs | Monitor | Accident | gr_1) 150.43 gr_2) 128.57 | 0.016 | Small companies |

| Training on how to handle unforeseen situations | Anticipate | Accident | gr_1) 149.23 gr_2) 129.77 | 0.027 | Small companies |

| Initiate an investigation into the causes of the event | Learn | Accident | gr_1) 121.59 gr_2) 157.41 | <0.001 | Medium–large companies |

| Initiate an investigation into the causes of the event to prevent its recurrence | Learn | Accident | gr_1) 124.47 gr_2) 154.53 | <0.001 | Medium–large companies |

| Action/System | RAG Dimension | Accident/Near Miss | Average Rank | Significance | Greater Level of Implementation |

|---|---|---|---|---|---|

| Update risk assessment for new technologies | Anticipate | - | gr_1) 146.44 gr_2) 132.56 | 0.007 | Medium–large companies |

| Assess risks from extraordinary changes to the environment in which the technology is placed | Anticipate | - | gr_1) 152.00 gr_2) 127.00 | <0.001 | Medium–large companies |

| Notify staff of extraordinary changes to the environment where technology is located | Anticipate | - | gr_1) 149.14 gr_2) 129.86 | 0.007 | Medium–large companies |

| Initiate an investigation into the causes of the event | Learn | Accident | gr_1) 103.44 gr_2) 89.56 | 0.003 | Medium–large companies |

| Initiate an investigation into the causes of the event | Learn | Near miss | gr_1) 85.83 gr_2) 67.17 | Medium–large companies | |

| Increase the level of knowledge of technological equipment associated with the event | Learn | Accident | gr_1) 102.90 gr_2) 90.10 | 0.020 | Medium–large companies |

| Increase the level of knowledge of technological equipment associated with the event | Learn | Near miss | gr_1) 81.91 gr_2) 71.09 | 0.031 | Medium–large companies |

| Action/System | RAG Dimension | Accident/Near Miss | Average Rank | Significance | Greater Perceived Importance |

|---|---|---|---|---|---|

| Initiate an investigation into the causes of the event | Learn | Accident | gr_1) 154.58 gr_2) 178.42 | 0.004 | New technology introduced |

| Action/System | RAG Dimension | Accident/Near Miss | Average Rank | Significance | Greater Level of Implementation |

|---|---|---|---|---|---|

| System to notify entries without PPEs | Monitor | - | gr_1) 176.41 gr_2) 156.59 | 0.045 | New technology introduced |

| System to stop the technology when anomalies are detected | Respond | - | gr_1) 187.45 gr_2) 145.55 | <0.001 | New technology introduced |

| Notify staff of extraordinary changes to the environment where technology is located | Anticipate | - | gr_1) 176.68 gr_2) 156.32 | 0.009 | New technology introduced |

| Initiate an investigation into the causes of the event | Learn | Near miss | gr_1) 157.71 gr_2) 175.29 | 0.046 | New technology introduced |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stabile, S.; Bentivenga, R.; Pietrafesa, E.; Sorrentino, E.; Bernabei, M.; Colabianchi, S.; Costantino, F. Assessing Resilience Practices in the Digital Transformation Era: A Storytelling-Based Cross-Sectional Study in Italy. Appl. Sci. 2025, 15, 6291. https://doi.org/10.3390/app15116291

Stabile S, Bentivenga R, Pietrafesa E, Sorrentino E, Bernabei M, Colabianchi S, Costantino F. Assessing Resilience Practices in the Digital Transformation Era: A Storytelling-Based Cross-Sectional Study in Italy. Applied Sciences. 2025; 15(11):6291. https://doi.org/10.3390/app15116291

Chicago/Turabian StyleStabile, Sara, Rosina Bentivenga, Emma Pietrafesa, Edvige Sorrentino, Margherita Bernabei, Silvia Colabianchi, and Francesco Costantino. 2025. "Assessing Resilience Practices in the Digital Transformation Era: A Storytelling-Based Cross-Sectional Study in Italy" Applied Sciences 15, no. 11: 6291. https://doi.org/10.3390/app15116291

APA StyleStabile, S., Bentivenga, R., Pietrafesa, E., Sorrentino, E., Bernabei, M., Colabianchi, S., & Costantino, F. (2025). Assessing Resilience Practices in the Digital Transformation Era: A Storytelling-Based Cross-Sectional Study in Italy. Applied Sciences, 15(11), 6291. https://doi.org/10.3390/app15116291